INSTRUCTION MANUAL

IMVICR01

MODEL VIC

VERTICAL INDUSTRIAL TURBINE CAN PUMPS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Foreword

Foreword

This manual provides instructions for the Installation, Operation, and Maintenance of the Goulds Water

Technology Vertical Industrial Turbine Type Can Pumps. This manual covers a standard product. For special

options, supplemental instructions are available. This manual must be read and understood before

installation and start-up.

This instruction manual covers several different pump models. Most assembly, disassembly, and inspection

procedures are the same for all the pumps. However, where there are differences, these differences will be noted

within the manual. The design, materials, and workmanship incorporated in the construction of the Goulds

Water Technology VIC pumps makes them capable of giving long, trouble-free service. The life and satisfactory

service of any mechanical unit, however, is enhanced and extended by correct application, proper installation,

periodic inspection, condition monitoring and careful maintenance. This instruction manual was prepared

to assist operators in understanding the construction and the correct methods of installing, operating, and

maintaining these pumps.

The information contained in this book is intended to assist operating personnel by providing information on the

characteristics of the purchased equipment. It does not relieve the user of their responsibility of using accepted

engineering practices in the installation, operation, and maintenance of this equipment.

Goulds Water Technology pumps shall not be liable for physical injury, damage, or delays caused by failure

to observe the instructions for installation, operation, and maintenance contained in this manual.

Warranty is valid only when genuine Goulds Water Technology pumps parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty, unless written approval

is obtained in advance from Goulds Pumps.

For information or questions not covered in this manual, contact Goulds Water Technology at (806) 743-5700.

THIS MANUAL EXPLAINS :

• Proper Installation • Pump Overhaul

• Start-up Procedures • Trouble Shooting

• Operation Procedures • Ordering Spare or Repair Parts

• Routine Maintenance

Owner’s Information

Pump Model Number:

Pump Serial Number:

Motor Model Number:

Motor Serial Number:

Dealer:

Dealer Telephone:

Purchase Date:

Installation Date:

2

Table of Contents

SUBJECT PAGE

SECTION 1 – Safety ................................................................................................................................................... 4

SECTION 2 – General Information ............................................................................................................................. 4

Introduction .............................................................................................................................................................. 4

Receiving and Checking ............................................................................................................................................4

Materials and Equipment Required ...........................................................................................................................5

Storage ...................................................................................................................................................................... 5

General Description .................................................................................................................................................. 6

SECTION 3 – Installation ........................................................................................................................................... 9

Foundation / Piping ................................................................................................................................................... 9

Pump Installation .................................................................................................................................................... 10

Installing the Bowl Assembly ................................................................................................................................... 10

Installing the Column .............................................................................................................................................. 11

Installing the Discharge Head .................................................................................................................................. 12

Installing the Stuffing Box .......................................................................................................................................12

Installing the Mechanical Seal .................................................................................................................................. 13

Mechanical Seal Alignment ...................................................................................................................................... 14

Installing the Driver ................................................................................................................................................ 14

Installing the Thrust Pot ..........................................................................................................................................19

SECTION 4 – Pump Start Up and Operation ............................................................................................................ 21

SECTION 5 – Maintenance ...................................................................................................................................... 22

Preventive Maintenance Schedule ............................................................................................................................ 22

Packing Adjustment and Replacement ...................................................................................................................... 22

Thrust Pot Lubrication and Maintenance ................................................................................................................. 23

Seasonal Shutdown .................................................................................................................................................. 23

Recommended Lubricants .......................................................................................................................................24

Troubleshooting ...................................................................................................................................................... 25

SECTION 6 – Disassembly and Reassembly ..............................................................................................................27

Disassembly ............................................................................................................................................................. 27

Inspection and Reassembly ...................................................................................................................................... 28

SECTION 7 – Repair Parts ........................................................................................................................................ 30

Limited Warranty ...................................................................................................................................................... 32

3

DANGER

WARNING

CAUTION

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

CAUTION

WARNING

CAUTION

Safety Instructions – SECTION 1

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN THE

MANUAL AND ON THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump or

in the manual, look for one of the following signal words and be alert to the potential for personal injury or property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause personal

injury or property damage.

If equipment is to be installed in a potentially explosive atmosphere and these procedures are not

followed, personal injury or equipment damage

from an explosion may result.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND MUST BE

FOLLOWED.

THIS MANUAL IS INTENDED TO ASSIST IN

THE INSTALLATION AND OPERATION OF

THIS UNIT. THOROUGHLY REVIEW ALL

INSTRUCTIONS AND WARNINGS PRIOR TO

PERFORMING ANY WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

Install, ground and wire according

to local and National Electrical Code

Requirements.

Install an all leg disconnect switch

near the pump.

Disconnect and lockout electrical

power before installing or servicing

the pump.

Electrical supply must match motor’s

nameplate specifications. Incorrect

voltage can cause fire, damage motor

and void the warranty.

Single phase pump motors are equipped with an

automatic thermal protector, which opens the motor’s

electrical circuit when an overload condition exists.

This can cause the pump to start unexpectedly.

General Precautions

Personal injuries will result if procedures

outlined in this manual are not followed

Electric supply MUST match pump’s

nameplate specifications. Incorrect voltage

can cause fire, damage to motor and voids warranty.

Safety Apparel:

• Insulated work gloves when handling hot sand collar.

• Heavy work gloves when handling parts with sharp

4

edges, especially impellers.

• Safety glasses (with side shields) for eye protection.

• Steel-toed shoes for foot protection when handling

parts, heavy tools, etc.

• Other personal protective equipment to protect against

hazardous/toxic fluid.

Maintenance Safety:

• Always lock out power prior to any procedure.

• Ensure pump is isolated from system and the pressure

is relieved before disassembling the pump, removing

plugs, or disconnecting the piping.

• Use proper lifting and supporting equipment to prevent

serious injury or death.

• Observe all decontamination procedures.

General Information – SECTION 2

INTRODUCTION

NOTE: The information in this manual intends to be

used as a guide only. If you are in doubt, consult

your Goulds Water Technology representative

for specific information about your pump.

The design, material, and workmanship incorporated

in the construction of Goulds Water Technology VIC

pumps makes them capable of giving long, trouble

free service. The life and satisfactory service of any

mechanical unit, however, is enhanced and extended

by correct application, proper installation, periodic

inspection and careful maintenance. This instruction

manual was prepared to assist operators in understanding

the construction and the correct methods of installing,

operating and maintaining these pumps.

Rotating components of the pump

assembly must be covered with a suitable

rigid guard to prevent injury to personnel.

Improper impeller adjustment could cause

contact between the rotating and stationary

parts, resulting in a spark and heat generation.

Study thoroughly Sections 1 through 6 and carefully

follow the instructions for installing and operating.

Section 5 contains answers to troubleshooting and

maintenance questions. Keep this instruction manual

handy for reference.

Goulds Water Technology will not be

liable for any damages or delay caused by

failure to comply with the provisions of this instruction

manual.

RECEIVING AND CHECKING

The pump should be carefully supported prior to

unloading from the carrier. Handle all components

carefully. Inspection for damage of the shipping crate

should be made prior to unpacking the pump. After

unpacking, visually inspect the pump and check the

following:

1. Contents of the pump assembly against the

packing list.

2. All components against damage.

3. All shafting for damage, should the crate be

broken or show careless handling. All shafting

must be checked for straightness.

Any shortages or damages should be immediately called

to the attention of the local freight agent of the carrier by

which the shipment arrived and proper notation made on

the bill. This will prevent any controversy when a claim is

made and facilitate prompt and satisfactory adjustment.

MATERIALS AND EQUIPMENT REQUIRED

The material and equipment necessary for installation

of the pump will vary with the size of the pump and the

type of installation.

The following list of standard tools and supplies is

offered only as a guide.

BULK MATERIAL

• Anti-Galling lubricant

(such as Dow Corning “MOLYKOTE”)

• Thread Compound

• Lubrication Oil

• Turbine Oil

• Grease

RIGGING EQUIPMENT

• Mobile power hoist, traveling crane or derrick.

• Drag line and blocks.

• Lifting Bail for Threaded Column.

• Elevator clamps, if unit is unassembled.

• Clevises – for use with eyebolts.

• Timbers – size, length and quantity to support long

pump parts on the floor.

• I-Beams or timbers to support pump over

installation.

HAND TOOLS

• Pipe wrenches

• Feeler gauges

• Machinist Level

• Set of mechanics tools including: files, wire brush,

pliers, wire cutters and pocket knife.

• Clean rags

• Dial indicator to assist in motor and pump

alignment.

OPTIONAL TOOLS TO FACILITATE PUMP

ASSEMBLY AND DISASSEMBLY

• Taperlock driver to assist in bowl assembly and

disassembly for pumps with taper lock impellers

only.

STORAGE

Goulds Water Technology carefully preserves and

protects its products for shipment. However, the

effective life of the preservatives applied at the factory

can vary from 3 to 18 months depending on the severity

of the environment in which the equipment is stored.

This section provides procedures for preparation prior to

storage and maintenance during storage of Goulds Water

Technology pumps. These procedures are necessary

to protect the precision parts of the pumps. Specific

procedures for storing motors, gear-drivers, and engines,

should be obtained from the equipment manufacturer.

This section is intended to be of general assistance to

users of Goulds Water Technology VIC pumps. It shall

not modify, amend and/or otherwise alter the scope

of Goulds Water Technology VIC pumps warranty

responsibilities to the purchaser in any way whatsoever.

Storage Preparation

Goulds Water Technology VIC pumps require proper

preparation for storage and, regular maintenance during

storage. The pump shall be considered in storage when

it has been delivered to the job site and is awaiting

installation.

Preferably, the storage area shall be paved, well drained

and free from flooding, and be indoors whenever

possible.

Weatherproof coverings used for outdoor storage shall be

flame resistant type sheeting or tarpaulins. They shall be

placed so as to provide good drainage and air circulation

and shall be tied down to protect from wind damage.

Storage area shall be maintained in a clean condition at

all times.

Pumps and/or component parts shall be placed on skids,

pallets, or shoring to permit good air circulation.

Pumps and/or component parts shall be sorted so as to

permit ready access for inspection and/or maintenance

without excessive handling.

Pumps and/or component parts stacked during storage

shall be arranged so that the racks, containers, or crates

bear full weight without distortion of pumps or parts.

Identification markings must be readily visible. Any

cover removed for internal access shall be replaced

immediately.

Pump and bowl assembly shafting shall be rotated

counter clockwise, as a minimum, once a month. Shaft

shall not be left in the same previous position, nor in the

extreme raised or lowered lateral position. Shaft should

rotate freely.

NOTE: For further information on these procedures

contact your Goulds Water Technology

representative.

Recommended Storage Procedures

Controlled storage facilities should be maintained at an

even temperature 10º F (6º C) or more above the dew

point with relative humidity less than 50% and little or

no dust. (If these requirements can not be met the pump

is to be considered in uncontrolled storage.)

For uncontrolled storage periods of 6 months or less,

the pump is to be inspected periodically to insure that all

preservatives are intact.

All pipe threads and flanged pipe covers are to be sealed

with tape.

The pump must not be stored closer than six inches (15

cm) from the ground.

5

Uncontrolled Long Term Storage Preparations

When applicable to the pump, storage periods over six

months require the preceding storage procedure and

storage preparation plus the following:

Inspect the lube oil and seal flush piping and either

fill the piping with rust preventative oil, or re-coat the

piping periodically to prevent corrosion.

Place 10 pounds (4.5 kg) of moisture absorbing desiccant

or 5 pounds (2.3 kg) of vapor phase inhibitor crystals

near the center of the pump. If the pump is assembled,

place an additional one pound (0.5 kg) in the discharge

nozzle securely fastened to the discharge elbow.

Install a moisture indicator near the perimeter of the

pump. Cover the pump with 6 mil (0.15 mm) minimum

thickness black polyethylene or equal and seal it with

tape. Provide a small ventilation hole approximately ½

inch (12 mm) diameter.

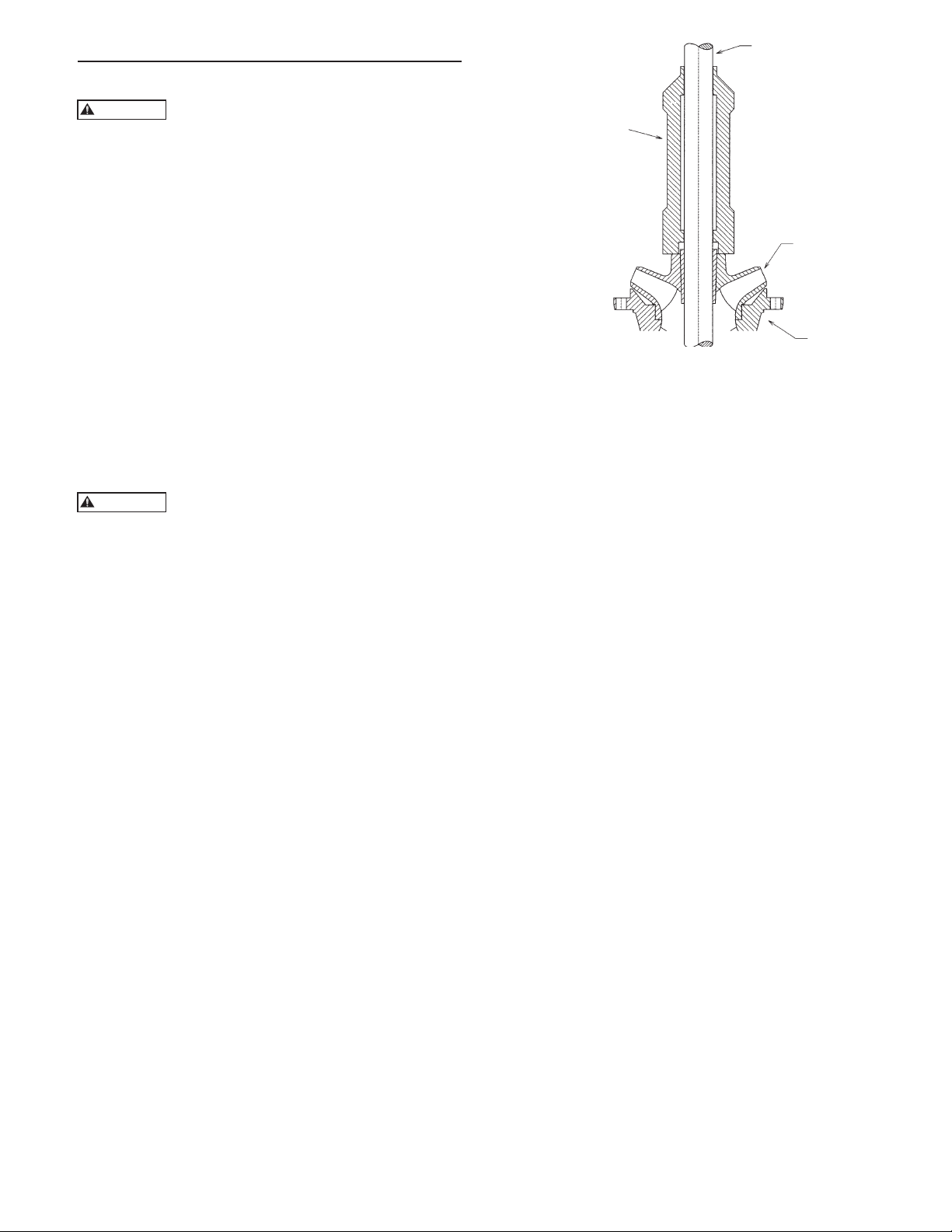

Discharge Head

The discharge head is either a cast iron head or a

fabricated head. Ports are provided for connecting

the pressure gauge, stuffing box or mechanical seal

bypass return and lubricator connections. The driver

support portion of the discharge head is designed with

large windows for easy stuffing box or mechanical seal

adjustment. The windows are covered with coupling

guards for safe operation.

Column

Threaded or flanged column construction provides

positive shaft and bearing alignment and ease of assembly

and disassembly. The line-shaft is supported within

the column by using bearing retainers in the column

assembly. The retainers are usually integrally fabricated

in the column pipes. Bearings are spaced to provide

vibration free operation below the shaft first critical

speed in order to insure long bearing life and reduced

shaft wear.

Provide a roof or shed shelter to protect from direct

exposure to the elements.

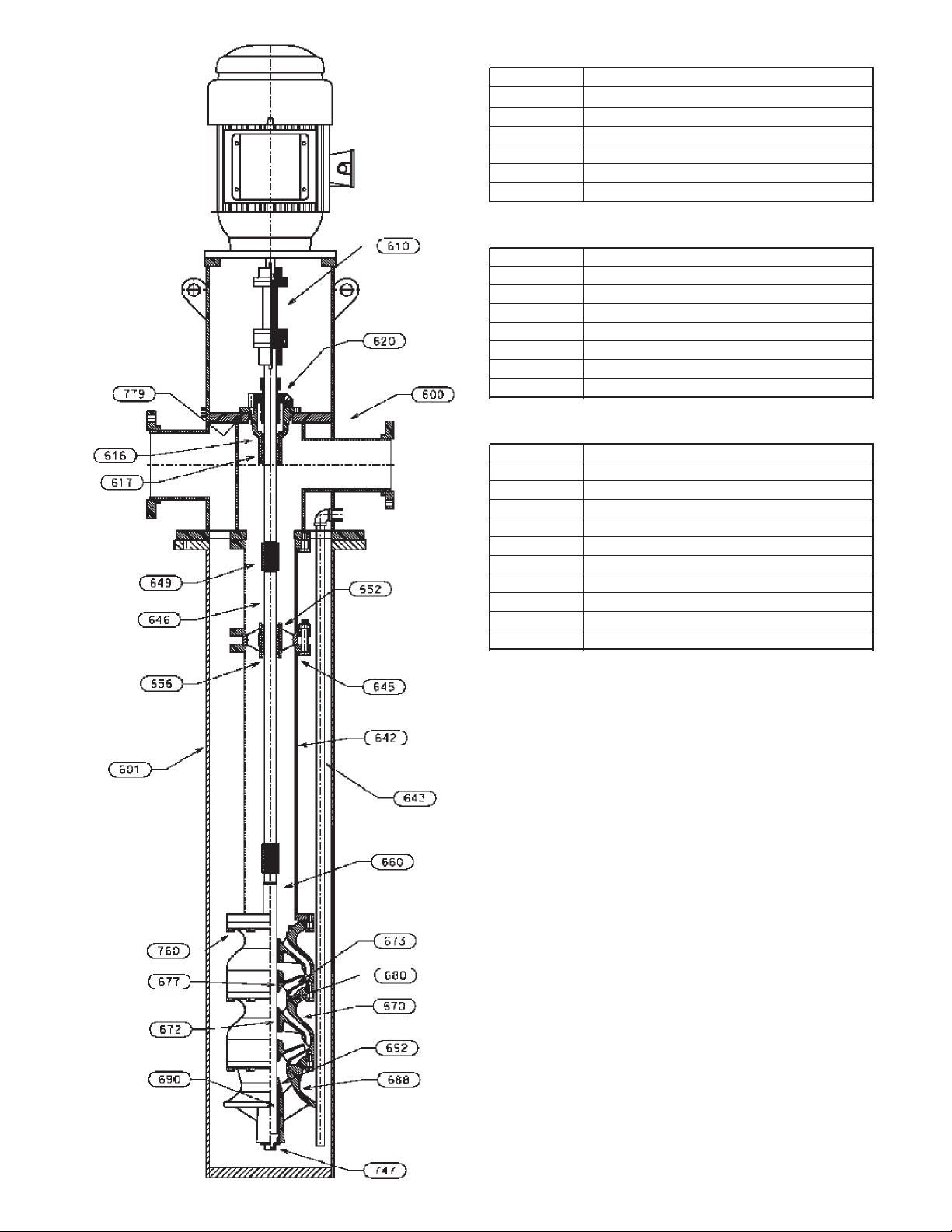

GENERAL DESCRIPTION

The model VIC pump is a vertical industrial turbine type

pump installed in a can (barrel), and is designed to meet

wide ranges of service with maximum dependability. See

Figure 1 or Figure 2 for some typical VIC pump.

Drivers

When mechanical seals are required, the most common

type of drivers supplied are solid vertical shaft motors

with adjustable spacer type couplings. When packed

stuffing boxes are used with open line shaft pumps,

hollow shaft motors or right angle gear drives, are often

used with a separate head shaft through the driver and

connected to the pump by a threaded coupling.

Bowl Assembly

The bowls are generally of flanged construction for

accurate alignment and ease of assembly and disassembly.

Impellers may be either open or enclosed depending

on the design requirements. They are fastened to the

pump shaft by taperlocks. For temperatures over 140°F

(60°C) and in the larger size bowls (over 18”), impellers

are keyed to the shaft. A special first stage low NPSH

impeller may be provided in certain application.

Thrust Pot

A thrust pot is utilized when the driver is not designed to

carry the pump thrust.

6

DISCHARGE HEAD ASSEMBLY

ITEM DESCRIPTION

600 DISCHARGE HEAD

610 COUPLING ASSEMBLY

617 SEAL HOUSING BEARING

616 SEAL HOUSING

779 SEAL HOUSING GASKET

620 MECHANICAL SEAL

COLUMN ASSEMBLY

642 COLUMN PIPE

645 COLUMN BOLTING

646 LINESHAFT

649 LINESHAFT COUPLING

652 BEARING RETAINER

656 LINESHAFT BEARING

643 CLEAN-OUT PIPE (OPTIONAL)

601 BARREL

BOWL ASSEMBLY

660 PUMP SHAFT

670 INTERMEDIATE BOWL

672 INTER. BOWL BEARING

673 IMPELLER

677 TAPERLOCK

680 WEAR RING (OPTIONAL)

760 HEX BOLT

692 SAND COLLAR

688 SUCTION BOWL/BELL

690 SUCTION BEARING

747 PLUG

Figure 1 VIC Pump with Solid Shaft Motor, Fabricated

T-Head, Mechanical Seal and Flanged Column

7

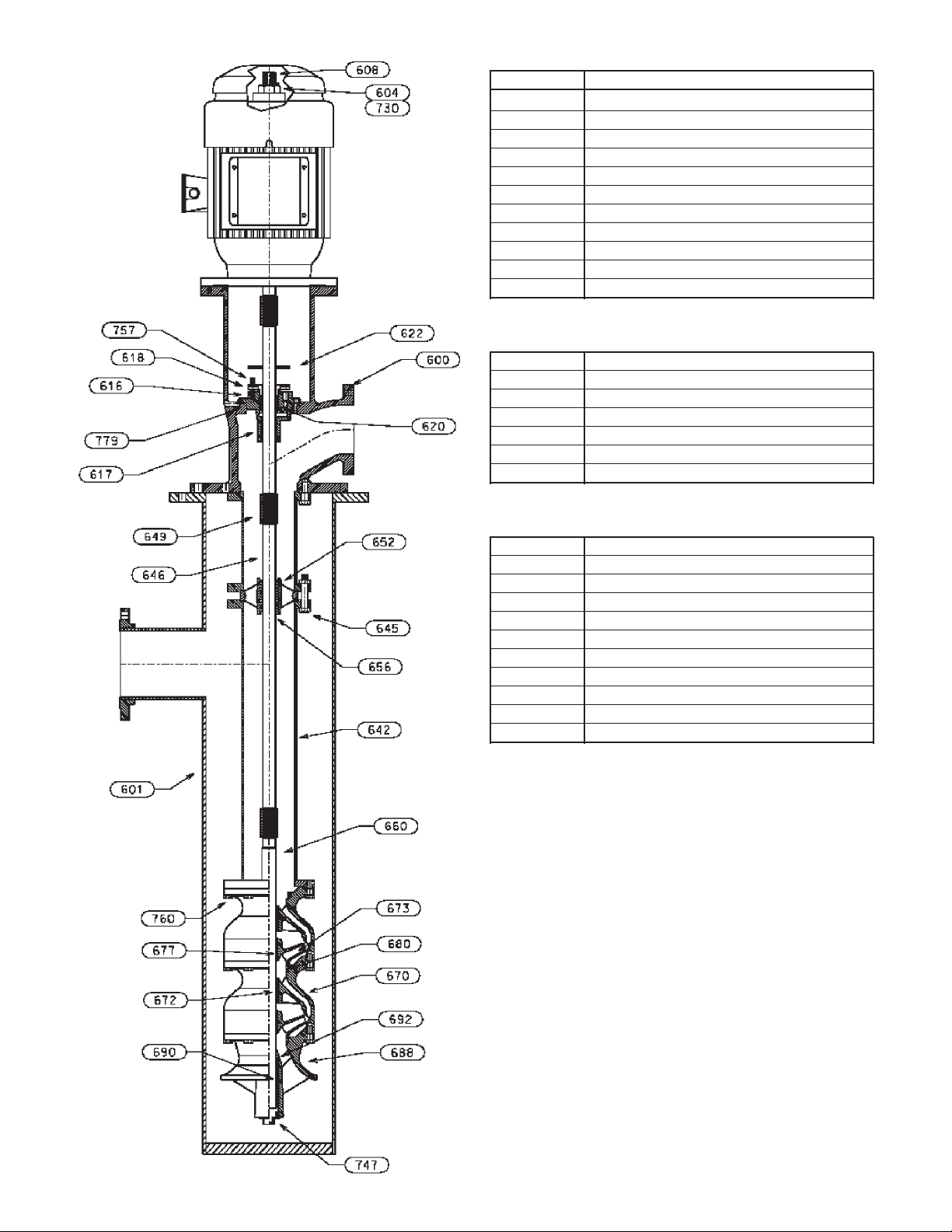

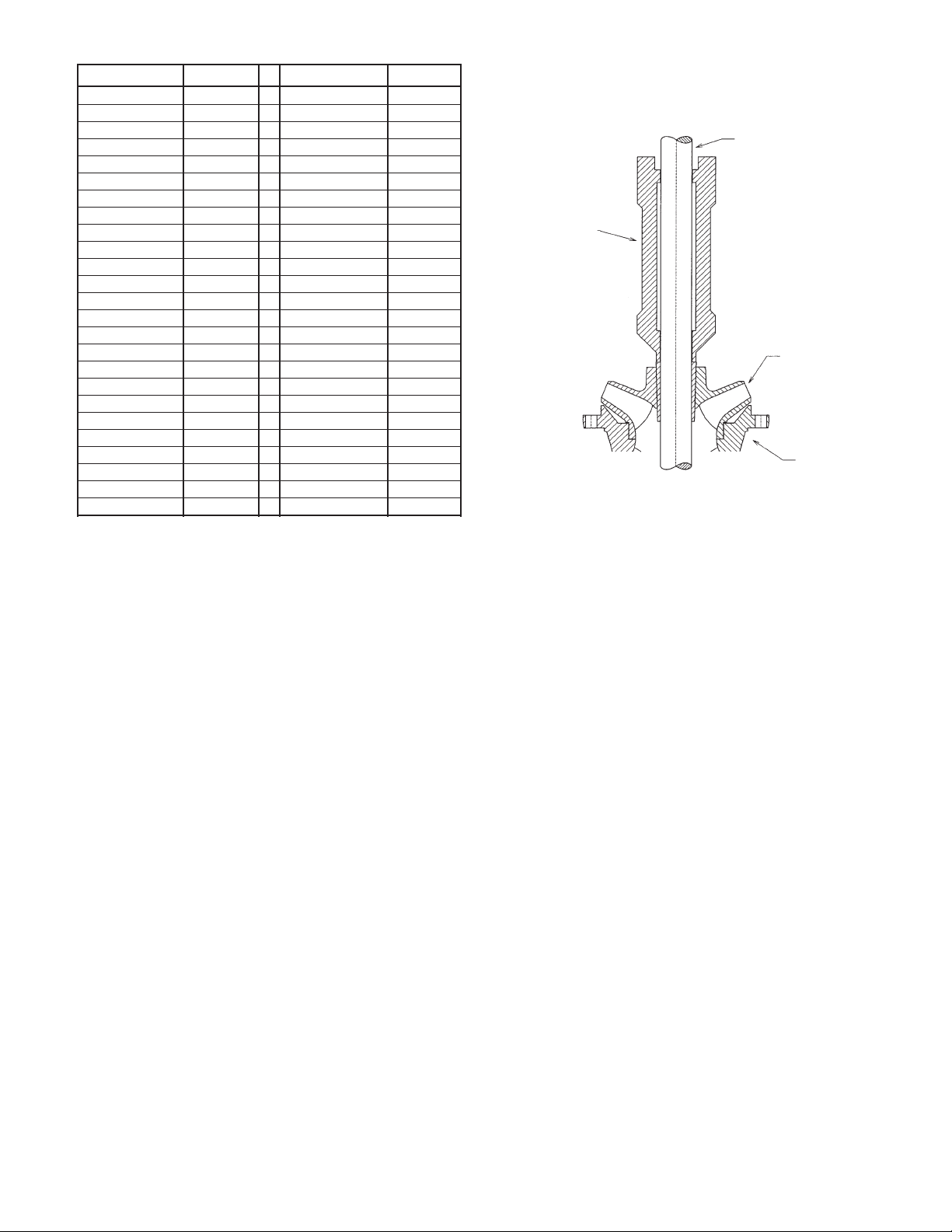

DISCHARGE HEAD ASSEMBLY

ITEM DESCRIPTION

600 DISCHARGE HEAD

604 ADJUSTING NUT

730 GIB KEY

608 HEAD SHAFT

616 STUFFING BOX

617 STUFFING BOX BEARING

618 SPLIT GLAND

620 PACKING

622 SLINGER

757 GLAND ADJUSTING SCREW

779 STUFFING BOX GASKET

COLUMN ASSEMBLY

642 COLUMN PIPE (FLG)

645 COLUMN BOLTING

646 LINESHAFT

652 BEARING RETAINER

656 LINESHAFT BEARING

649 LINESHAFT COUPLING

601 BARREL

BOWL ASSEMBLY

660 BOWL SHAFT

670 INTERMEDIATE BOWL

672 INTER. BOWL BEARING

673 IMPELLER

677 TAPERLOCK

680 WEAR RING (OPTIONAL)

760 HEX BOLT

692 SAND COLLAR

688 SUCTION BOWL/BELL

690 SUCTION BEARING

747 PLUG

Figure 2 VIC Pump with Cast L-Head, VHS Motor,

8

Packed stuffing Box and flanged column

Installation – SECTION 3

When pumping unit is installed in a potentially

explosive environment, the instruction after

the symbol must be followed. Personal

injury and/or equipment damage may occur if these

instructions are not followed. If there is any question

regarding these requirements or equipment is to be

modified, please contact a Goulds Water Technology

representative before proceeding.

FOUNDATION AND PIPING

SUB BASE (SOLE PLATE) OR BARREL FLANGE

INSPECTION

Sub base and sole plate are terms in common use to

describe a general class of solid steel plates mounted

in grout (or bolted to steel structures) at the pumpfoundation interface.

1. Remove the sub base from the pump discharge head

or barrel flange, when shipped assembled.

2. Completely clean the underside of the sub base. It is

sometimes necessary to coat the underside of the sub

base with an epoxy primer. (This is available as an

option.)

3. Remove the rust preventative solution from the

machined topside with an appropriate solution.

SITE WITH CONCRETE FOUNDATION

1. A pump should have adequate space for operation,

maintenance, and inspection.

2. Sub base mounted pumps are normally grouted

on a concrete foundation, which has been poured

on a solid footing. The foundation must be able to

absorb any vibration and to form a permanent, rigid

support for the pumping unit.

3. The foundation must be of adequate strength to

support the complete weight of the pump, plus the

weight of the liquid passing through it. A typical

installation will have bolts with a pipe sleeve 2 ½

times the bolt diameter embedded in the concrete.

Bolts should be sized and located in accordance

with the dimensions given on the Certified Pump

Outline Drawing, if provided. The pipe sleeve

allows movement for the final positioning of the

foundation bolts to conform to the holes in the sub

base flange. See Figure 3.

All equipment being installed must be properly

grounded to prevent unexpected static electrical

discharge. If not, a static electric discharge may

occur when the pump is drained and disassembled for

maintenance purpose.

4. Remove water and/or debris from anchor bolt holes/

sleeves prior to grouting. If the sleeve type bolts are

being used, fill the sleeves with packing or rags to

prevent grout from entering.

5. Carefully lower the sub base onto the foundation

bolts. Hand tighten the nuts.

6. Leveling the sub base may be done by several

methods. Two common methods are:

A. Using leveling wedges. This is shown in Figure 4.

B. Leveling nuts on the anchor bolts.

Regardless of the method, a machinist level must be

used for leveling.

NOTE: When using a machinist level, it is important

that the surface being leveled is free of all

contaminants, such as dust, to ensure an

accurate reading.

7. Level the sub base in two directions at 90º on the

machined surface. The levelness tolerance is 0.005

inches per foot for commercial, and 0.001 inches

per foot for API.

FOUNDATION

DAM

GROUT

CENTERLINE

ANCHOR BOLT

SUB BASE

LEVELING

WEDGES

DAM

BOLT

SHIMS

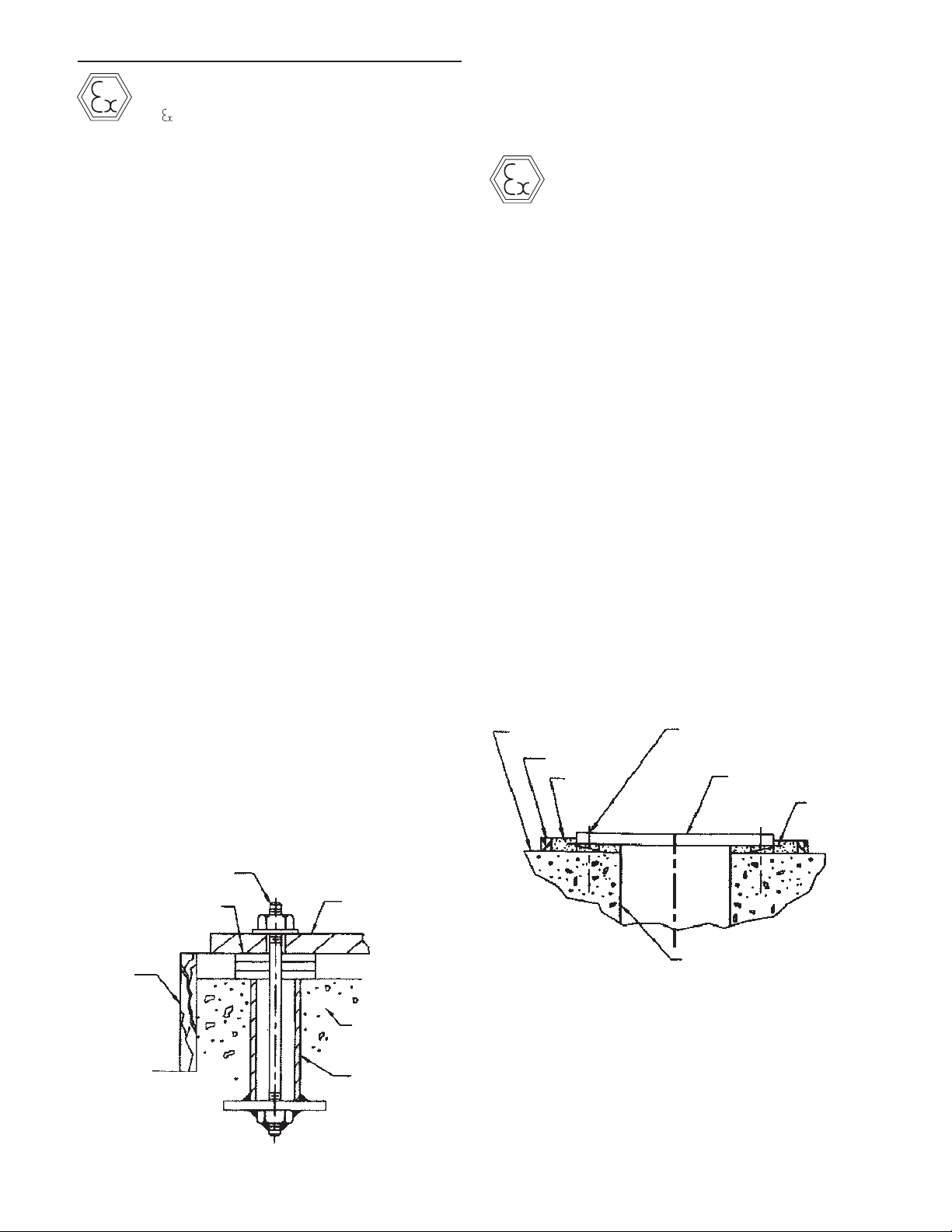

Figure 3

SUB BASE

FOUNDATION

SLEEVE

FLOOR SLEEVE

(OPTIONAL)

Figure 4

SUB BASE OR BARREL FLANGE GROUTING

1. Inspect foundation for dust, dirt, oil, chips, water,

etc. and remove any contaminants. Do not use oilbased cleaners as grout will not bond to it. Refer to

grout manufacturer’s instructions.

2. Build dam around foundation (See Figure 4).

Thoroughly wet foundation.

9

3. Pour grout between sub base or barrel flange and

WARNING

WARNING

CAUTION

concrete foundation, up to level of dam. Remove

air bubbles from grout as it is poured by puddling,

using a vibrator, or pumping the grout into place.

Non-shrink grout is recommended.

4. Allow grout to set at least 48 hours.

5. Tighten foundation bolts.

SITE WITH STRUCTURAL STEEL FOUNDATION

When the pump is mounted directly on a structural steel

frame, pumps shall be located directly over, or as near as

possible to, the main building members, beams or walls.

The barrel, discharge head mounting flange or sub base,

shall be bolted to the support to avoid distortion, prevent

vibration and retain proper alignment.

PUMP INSTALLATION

When pumping unit is installed in a potentially

explosive environment, the instruction after the

symbol must be followed. Personal injury and/

or equipment damage may occur if these instructions

are not followed. If there is any question regarding these

requirements or equipment is to be modified, please

contact a Goulds Water Technology representative before

proceeding.

Pumps of 20 feet (6 m) or less in length are usually

shipped assembled, with the exception of the driver,

mechanical seal with tubing and coupling assembly,

spacer or non spacer type. When provided, refer to the

Certified Pump Outline for the applicable base plate plan

for the location of anchor bolt holes.

INSTALLING A PARTIALLY ASSEMBLED PUMP

PIPING

Guidelines for piping are given in the “Hydraulic

Institute Standards”, available from: Hydraulic Institute,

9 Sylvan Way, Parsippany, NJ 07054-3802 and must be

reviewed prior to pump installation.

Never draw piping into place by forcing

the flange connections of the pump. Pipe

strain will adversely effect the operation of the pump

resulting in damage to the equipment and possible

physical injury.

1. All piping must be supported independently, and

line up naturally with the pump flange so that undue

pipe strain is not imposed on the pump.

2. DO NOT connect piping to pump until grout has

hardened and pump hold-down bolts have been

tightened.

3. It is suggested that expansion loops or joints, if used,

be properly installed in the discharge line. When

handling liquids at elevated temperatures expansion

joints are used, so linear expansion of piping will

not draw pumps out of alignment.

4. Carefully clean all pipe parts, valves and fittings,

and piping branches prior to assembly.

5. Isolation and check valves should be installed in

discharge line. Locate the check valve between

isolation valve and pump, this will permit inspection

of the check valve. The isolation valve is required

for regulation of flow, and for inspection and

maintenance of pump. The check valve prevents

pump or seal damage due to reverse flow through

the pump when the driver is turned off.

6. Increasers, if used, should be placed between pump

and check valves.

1. If a base plate was supplied, install as described in

Foundation/Piping Section (page 9).

2. Clean the mounting surface of the plate and clean

bottom surface of discharge head mounting flange.

3. Check that all fasteners on the pump are tight, as it

is recognized that transportation and handling may

result in bolt relaxation.

4. Install the barrel (can) to discharge head O-ring

(743).

5. Sling through discharge head holes or thread two

eyebolts through bolt holes in mounting flange and

hoist unit into position over foundation.

NOTE: Eyebolts or sling should be rated to handle

in excess of the pump weight (see Outline

Drawing).

6. Lower the unit and carefully guide it so that unit

does not strike the side of the base plate. Continue

to lower unit until the discharge head flange engages

and rests firmly on the plate, then secure with

capscrews provided.

7. When a lineshaft is shipped separately check shaft

for straightness; average total run out should not

exceed 0.005” T.I.R. (0.127mm) for 10 feet (3 m).

Shaft must be within tolerance prior to installation.

8. Refer to remainder of this manual for complete

assembly, startup, maintenance, disassembly and

recommended lubricants for the pump.

INSTALLING THE BOWL ASSEMBLY

Do not work under a heavy suspended

object unless there is positive support and

safe guards, which will protect personnel, should a hoist

or sling fail.

7. Cushioning devices should be used to protect the

pump from surges and water hammer if quickclosing valves are installed in the system.

10

Do not attempt to lift bowl assembly

by the pump shaft. This can result in

damaging the pump shaft.

1. Prior to installing the bowl assembly, check that

CAUTION

CAUTION

CAUTION

all capscrews are tight. Turn the pump shaft by

hand and make sure it turns freely. Remove all

accumulated dust, oil, or other foreign material

from the external surfaces.

2. If a suction strainer is provided, assemble it to the

suction bell (or suction bowl).

1. Coat a thin film of oil to the threads on the lineshaft

(646) and the coupling (649) (for non-galling

material, or Molykote if galling material).

2. Install threaded coupling onto pumpshaft by

threading it on for one-half its length. A fine

wire inserted in the drill hole at the center of the

coupling can be used as a gauge to determine

when the coupling is correctly positioned on the

pumpshaft. Remove the wire after installed the

coupling.

Use “MOLYKOTE” Dow Corning or

equal for all galling material such as 316

stainless steel.

INSTALLING THE COLUMN

OPEN LINESHAFT

Pump lineshafts are coupled with either threaded

or keyed couplings. Follow only those procedures

appropriate for the type of lineshaft coupling supplied.

When provided, see the Certified Pump Outline Drawing

for the number of column and shaft sections required.

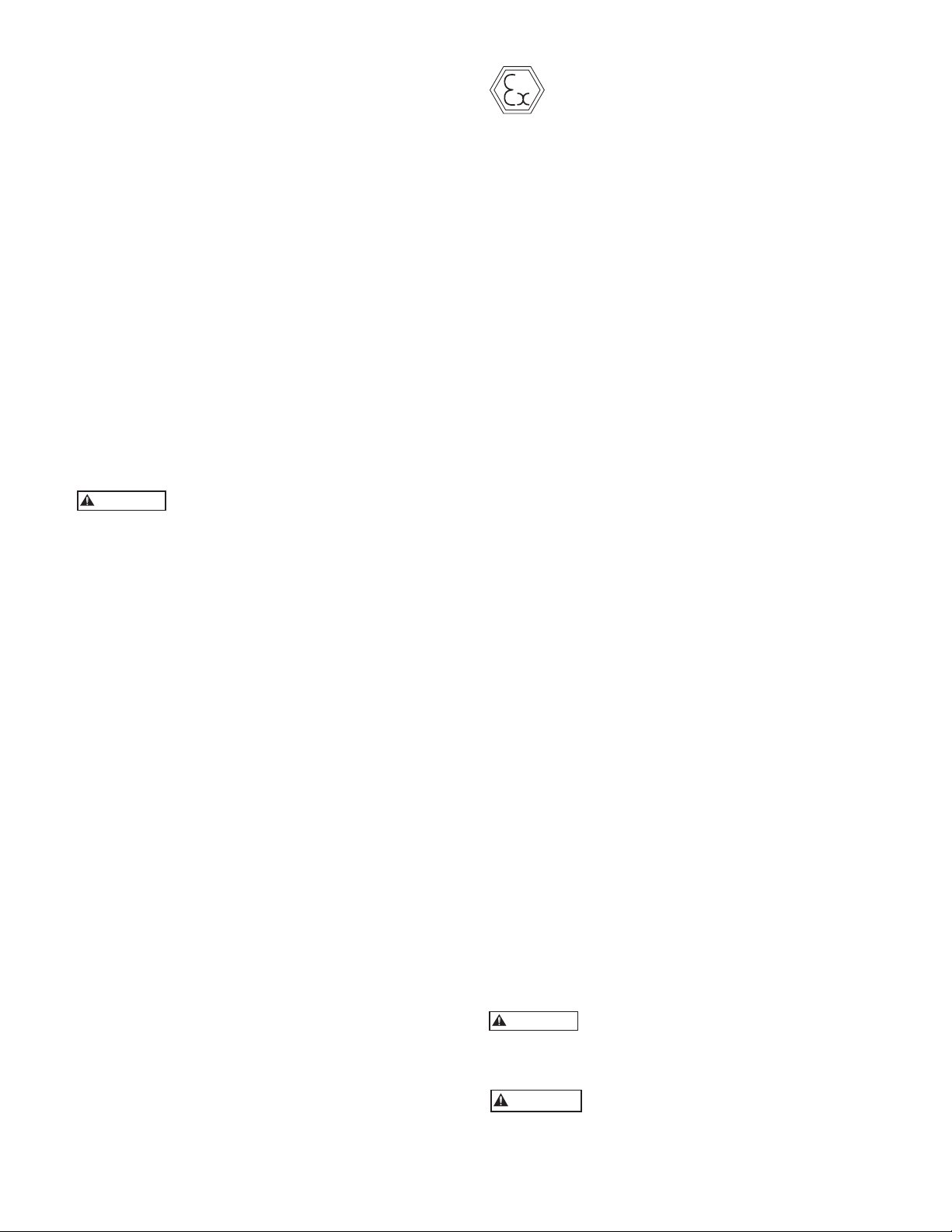

Figure 5

3. Place two I-beam supports across the base plate

opening, strong enough to safely support the weight

of the entire pump assembly. These I-beams should

be connected by threaded rods and nuts so as to

clamp them firmly together for the portion to be

supported. (See Figure 5).

4. Place a suitable hoist or derrick over base plate

opening with the hook in the center. Place the

elevator clamps just below the discharge bowl. Place

the elevator clamps just below the discharge bowl.

For flanged column install two threaded eyebolts

through the discharge bowl bolt holes 180º apart

for flanged column. For threaded discharge utilize

a lifting bail sized to handle the weight of the bowl

assembly and suction apparatus. Attach a sling to the

elevator clamps, eyebolts, or lifting bail and hoist it

into position.

5. Carefully lower bowl assembly, guiding the unit so it

does not strike the sides of the opening. Continue

to lower bowl assembly until the elevator clamps

or discharge bowl flange rests firmly on the I-beam

supports.

6. Place a cover over the discharge bowl opening to

prevent entrance of dirt or other foreign matter

until ready for installation of the column assembly.

Do not drop any foreign object into the

bowl assembly. Such an object can cause

serious damage to the pump and any downstream

components. Any foreign object dropped into the bowl

assembly must be retrieved prior to continuing assembly.

THREADED COUPLING INSTALLATION

NOTE: Shaft threads are left-handed.

When the threaded coupling is not installed on the

pumpshaft, install as follows:

1. Check the headshaft (608) and lineshaft (646) for

straightness. Average total runout should be less

than 0.0005” T.I.R. per foot, not to exceed 0.005”

T.I.R. for every 10 feet of shafting.

2. Hoist the first piece of lineshaft over the bowl

assembly. Lower the lineshaft until the bottom end

is properly aligned with the coupling of the pump

shaft. Apply a thin film of oil to the threads on the

lineshaft (646) and the coupling (649) (for nongalling material, or Molykote if galling material).

Use “MOLYKOTE” Dow Corning or

equal for all galling material such as

316 stainless steel.

3a. With lineshaft in the proper position on the

coupling, screw lineshaft into the coupling manually

until resistance is felt. A fine wire inserted in the

hole at the center of the coupling can be used as a

gage to determine when the coupling is correctly

positioned on the shaft. Remove the wire after

installing the shaft. Completely tighten the joint

by using a pair of pipe wrenches. Use care not to

damage any bearing journal areas on the shaft.

NOTE: Shaft threads are left-handed.

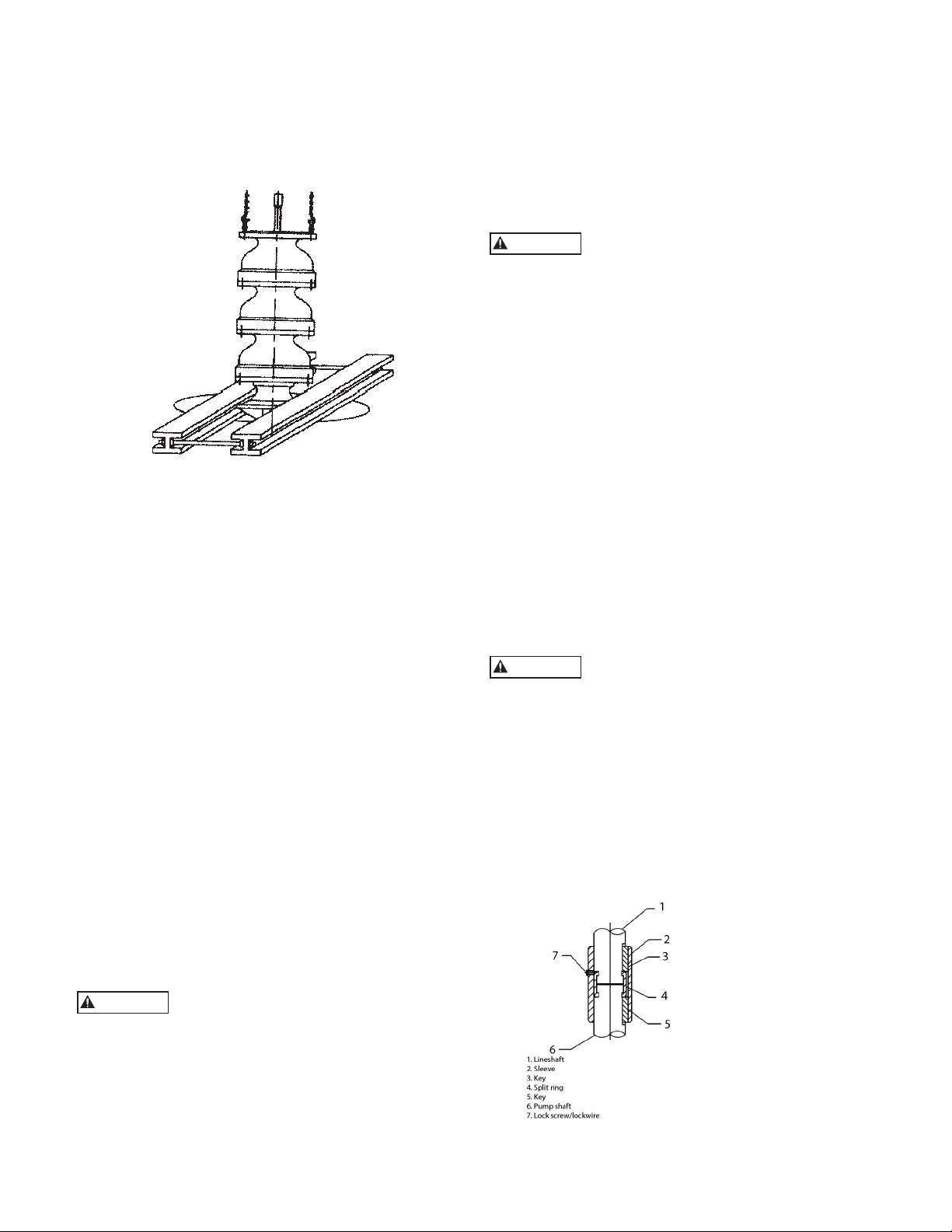

3b. With a keyed coupling

insert the key into the

pump shaft. Lower the

sleeve over the pump shaft,

to approximately 1.0 in

(25.4 mm) below the top

of the shaft. Then lower

the lineshaft until it touches

the pump shaft. Insert the

split ring into the grooves

of the pump shaft and

lineshaft. Raise the sleeve

until it covers the split ring,

then insert the key into the

lineshaft. Raise the sleeve to the top of the key and

secure the sleeve to the split ring with a lock screw

and lock wire.

11

CAUTION

WARNING

CAUTION

4. Install two eyebolts diametrically opposite the upper

flange of the bottom column (644). Attach a sling to

the eyebolts and to the hoist hook. Lower column

section until the flange engages the flanged top bowl

register. Insert as many bolts through both flanges

as possible. Lift column assembly high enough to

allow rotation of the supports. Install and tighten

remaining capscrews gradually in diametrically

opposite pairs until all are uniformly tightened.

5. Lift the assembly and remove the elevator clamp or

supports and slowly lower the bowl and the column

assembly. Place supports on the base plate and

continue to lower the assembly until the column

elevator clamps or column flange comes to rest on

the supports.

NOTE: Normally, the bearing retainer will be integral

with column. The top flange of the column will

have male register and the bottom flange of the

column will have a female register. If you have

separate bearing retainers, there will be a female

register in the flange at both ends of the column.

Follow step 6 below.

6. Place the bearing retainer (652) with bearing (656)

over the shaft and fit the retainer in the female

register of the flange. Make sure the contact faces in

the flanges are clean. Use a file to remove nicks or

dings.

7. Install threaded coupling (649) on the protruding

end of the lineshaft (646), if required.

8. Assemble next column (642) section, or top column

(641) as required, and make sure bottom column

register (or bearing retainer (652)) engages the top

column register, and secure with capscrews (760B)

and hex nuts (735A) provided. Tighten capscrews

into hex nuts gradually and uniformly.

9. Repeat the preceding procedures until all column

sections required have been installed.

Do not drop any foreign object into the

column assembly. Such an object can

cause serious damage to the pump and any downstream

components. Any foreign object dropped into the column

assembly must be retrieved prior to continuing assembly.

INSTALLING THE DISCHARGE HEAD

VIC Pumps are provided with either “T” type or “L” type

head. Install the discharge head as follows:

1. If the stuffing box (See Fig. 6) is assembled to the

head, remove it and all the attached piping.

2. When a mechanical seal is provided it is shipped

separately.

3. Remove coupling guard if provided. Attach a sling

to the lifting lugs on the side of the discharge head

or through windows and hoist discharge head over

the protruding top shaft.

Eyebolts or sling should be rated to handle

in excess of the pump weight (see Outline

Drawing).

Do not bump or scrape the shaft protruding above the column. This could result in

bending or damaging the shaft.

12

4. Orient the discharge head in the required position

and lower the head. Centering the vertical hole with

the top shaft protruding above the column until the

discharge head engages the column flange. Install

capscrews and secure discharge head to the column

flange. Tighten capscrews gradually in diametrically

opposite pairs.

5. Lift the pump assembly high enough to allow rotation of the supports. Realign and lower assembly.

Install and tighten remaining capscrews. Repeat

the rotating and the tightening procedure until all

capscrews are uniformly tight.

6. Hoist the discharge head by lifting lug and remove

the elevator clamp attached to column.

7. Remove the support timbers or I-beams and clean

the top of barrel flange. Orient the discharge head

in the required position.

NOTE: Sling should be rated to handle in excess of the

pump weight.

8. Lower bowl, column and head assembly, until

discharge head mounting flange engages with the

barrel flange. Secure discharge head to barrel.

Check the levelness of the discharge head in all

directions, utilizing a machinist level across the

driver’s mounting surface of the discharge head.

9. Check whether the top shaft (or stub shaft) is in

the center of the stuffing box bore. If not, the shaft

must be centered by shimming the head base and the

sub base (or the foundation).

10. Rotate the shaft approximately 90º. Check again

whether the shaft is at the center of the stuffing box

bore or not. If not, either the top shaft is bent or the

first shaft below it did not butt properly. Correction

must be made before the installation procedures can

proceed.

INSTALLING THE STUFFING BOX

Assemble stuffing box as shown in Figure 6.

1. Clean the surface of the discharge head where

the stuffing box will be mounted and remove any

nicks or burrs with a fine flat file. Position gasket

on surface. Slide stuffing box (616) down over

headshaft and into position on the gasket. Secure

stuffing box with capscrews.

2. Grease the packing ring (620) for easier installation.

3. Twist the packing ring sideways to get it around the

shaft easily. Start the first ring into the stuffing box.

When the entire ring is worked in using the fingers,

tamp it down using a split wood bushing (or equal)

and push the packing ring down firmly. It must seal

on the shaft and bore of the stuffing box. Install

three (3) rings in this manner. Stagger ring joints

90 degrees apart. The split gland may be used as a

tamper for the top ring.

4. Insert lantern ring (622) into stuffing box. Be sure

it is properly positioned so that it aligns with the

lubrication passage in the stuffing box.

5. Insert three (3) additional rings of packing. Stagger

ring joints 90º apart.

6. Install the split gland and screw nuts on the split

gland studs. Tighten nuts then relieve the nuts and

tighten finger tight.

Check that the split gland is square in the

CAUTION

CAUTION

CAUTION

CAUTION

stuffing box. Cocking can cause uneven

compression of packing and damage to the shaft or sleeve

and heat up the shaft and stuffing box.

7. The stuffing box is shipped with both ports plugged.

If the discharge pressure is over 100 psi, remove the

plug on Port “A” and attach a bypass (relief) line. If

the discharge pressure is over 200 psi, remove the

plug on Port “B” and attach another bypass line.

8. Final adjustment of the stuffing box must be made at

pump start up.

9. A properly packed stuffing box should be loose

enough to allow the shaft to be turned manually

and must have leakage (see page 22 – Packing

Adjustment).

Do not over tighten packing or excessive

wear can occur on the shaft or sleeve.

(619) STUD (2)

(735) HEX NUT

(2)

PORT "A"

(624) BYPASS LINE

(618) GLAND

PORT "B"

shaft packing. When further clean up is required,

protect by covering the inside of the pump seal

housing. Remove burrs, nicks and sharp corners by

using a strip of emery cloth over the shaft threads.

File threads around the keyway with a smooth mill

file or emery cloth. Sharp edges must be rounded.

3. Remove all chips and dust from the shaft area.

4. Check that all rotary unit parts of the seal fit over

the shaft. A pre-check may be made by removing the

O-ring(s) from the cartridge sleeve Inside Diameter

(ID) and then installing the seal on the shaft. Further

shaft clean up will be necessary when the seal will

not pass all the way into the seal housing.

5. Remove the seal after the pre-check, and re-install

the sleeve O-ring(s).

6. Sparingly lubricate the shaft and sleeve ID with

the lubricant included with the mechanical seal or

recommended by the mechanical seal manufacturer.

The following lubricants may be used, for water service, when no lubricant is supplied or recommended

by the mechanical seal manufacturer.

• Light oil (SAE #10 or 20)

• Dow Corning #4 Grease

• Silicone lubricant

• Wax or clay

• Soapy water

(621) O-RING

(622) LANTERN

RING

(620) PACKING

(6 RING)

(616)

STUFFING BOX

(617) BEARING

Figure 6

INSTALLING THE MECHANICAL SEAL

The vertical turbine pumps are usually supplied with

cartridge type mechanical seals, shipped assembled

- ready for installation, when mechanical seals are

supplied. Instructions for installing mechanical seals

are provided by the seal manufacturer. Consult the seal

manufacturer’s instructions (furnished with the seal) for

information on the type of seal used. Additionally, refer

to factory furnished outline drawing and seal piping

schematic on complex seal piping arrangements.

GENERAL REQUIREMENTS FOR ALL SEALS

1. Check surfaces at the face of the seal housing and

at the bottom of the seal housing to insure that they

are clean, flat and free of burrs. The face surface

must be smooth to form a good sealing surface for a

gasket or O-ring.

2. Check that shaft is smooth, and free of burrs, nicks

and sharp corners that could ruin the O-ring or

Oil based lubricants will damage EPR / EPDM

elastomer O-rings. Silicone lube and soapy water are

safe for EPR / EPDM elastomer O-rings.

7. Install the O-ring or gasket, between the seal

housing and seal. Install the seal over the shaft and

ease it into position against the face of the seal box.

Take care when passing the sleeve and O-ring over

keyways or threads to avoid damaging the O-ring.

Do not bump carbon members against the

shaft as they may chip, crack or break.

8. Position seal gland on discharge head seal housing

and secure with capscrews (or nuts for studs)

provided. Tighten capscrews gradually and

uniformly in a criss-cross pattern, taking 2 or 3

passes.

Do not over tighten capscrews on gland.

This can distort seal seat and cause seal

failure.

9. Install all seal piping as required. Prior to making

final connections of sealing liquid pressurizing

lines, make sure the seal housing and all sealing

liquid lines are flushed free of dirt, scale and other

particles that would be abrasive to the sealing faces.

10. The Driver and Coupling must now be installed

before the driver installation can proceed. See page

14 - INSTALLATION OF A HOLLOW SHAFT

DRIVER or page 16 - INSTALLATION OF A

SOLID SHAFT DRIVER as appropriate.

13

WARNING

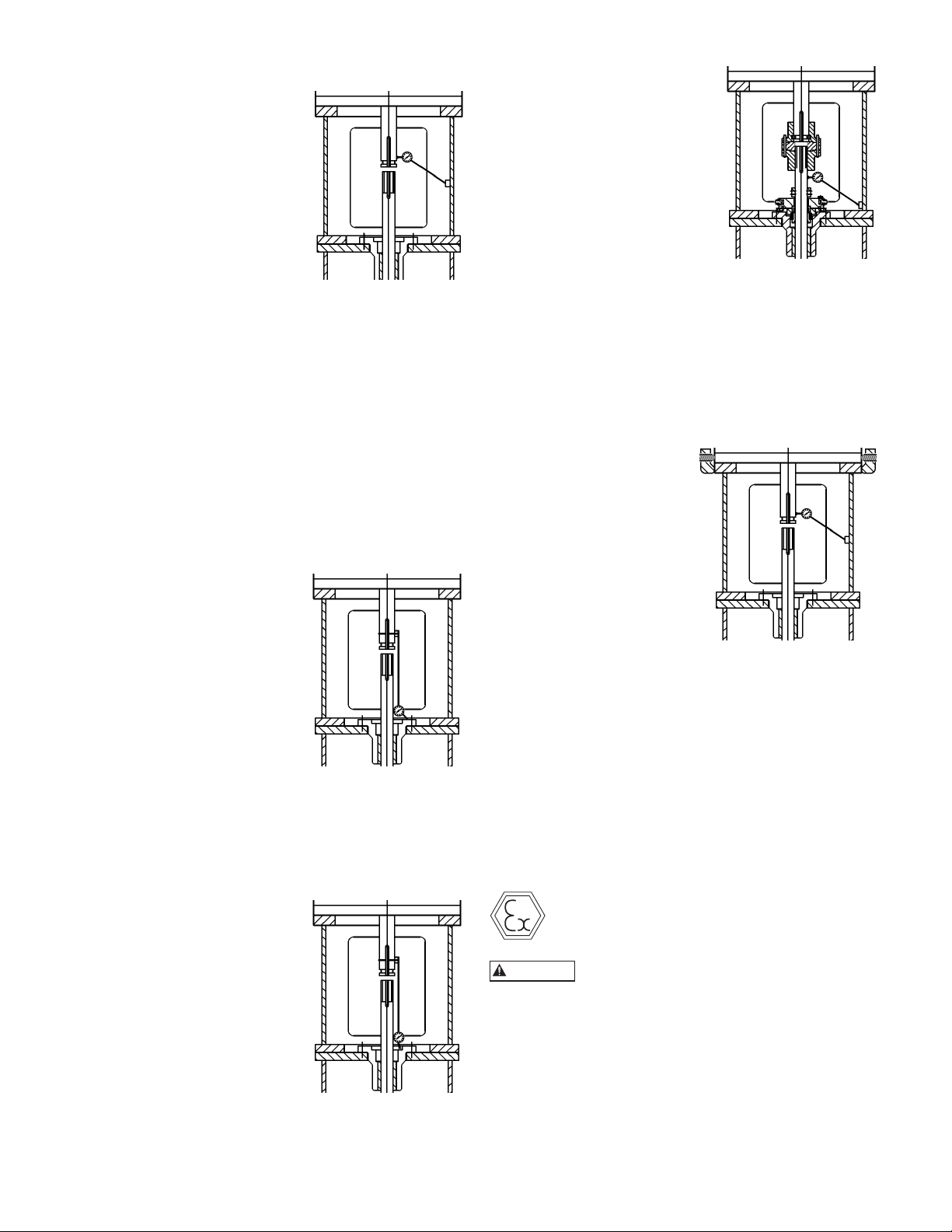

MECHANICAL SEAL ALIGNMENT

CONCENTRICITY OF MOTOR SHAFT

1. Install the dial indicator as

shown, with the base attached

to the motor support.

2. Rotate the motor shaft by

hand while you read the dial.

3. Make sure that the runout

does not exceed NEMA

standards, 0.002 in (0.05

mm) maximum TIR.

4. If the indicator reads higher

than 0.002 in

(0.05 mm)TIR, loosen the four motor hold-down

bolts and relocate the motor on the motor base

register.

5. Obtain the desired position.

6. Tighten the hold-down bolts and repeat the

indicator reading.

Note: Adding or removing shims between the motor

and the discharge head helps alignment in the

vertical direction. The motor may also have to be

adjusted in the horizontal direction for alignment.

FLATNESS OF THE SEAL HOUSING

For this measurement, remove the mechanical seal if the

dial indicator stylus cannot rotate 360° on the top surface

of the seal gland.

1. Install the dial indicator as

shown, with the base 1)

Remove the lower coupling

components and attach the

base of the dial indicator to

the motor shaft.

2. Place the stylus at the top

surface of the seal gland, or

at the top surface of the seal

housing.

3. Slowly rotate the motor

shaft 360°.

4. Check that the face of the seal housing is square with

the shaft to within 0.002 in (0.05 mm) TIR.

CONCENTRICITY OF THE SEAL HOUSING

This measurement requires that you remove the

mechanical seal.

1. Install the dial indicator as

shown.

2. Rotate the motor shaft

by hand and run the

indicator in the insidemachined surface of the

seal housing in order to

determine the concentricity.

3. If the indicator reads

higher than 0.004 in (0.10

mm) TIR, loosen the four

motor hold-down bolts and

relocate the motor on the motor base register.

4. Obtain the desired position.

5. Tighten the hold-down bolts and repeat the

indicator reading.

14

CONCENTRICITY OF THE HEADSHAFT

1. Reinstall the mechanical

seal if it was removed for

the flatness or concentricity

measurement.

2. Install the coupling assembly

and adjust the impeller.

3. Attach the base of the dial

indicator on the discharge

head or motor support.

4. Place the stylus on the shaft

between the top of the seal

and the bottom of the pump coupling.

5. Slowly rotate the motor shaft 360°.

6. Check that the shaft runout is within 0.004 in

(0.10 mm) TIR, or as required by specification.

7. Drill and dowel the pin in three places in order to

secure the motor to the motor base after you obtain

the required runouts.

CONCENTRICITY OF MOTOR SHAFT USING

JACKSCREWS

1. Install the dial indicator

as shown, with the base

attached to the motor

support.

2. Rotate the motor shaft by

hand while you read the

dial.

3. Make sure that the runout

does not exceed NEMA

standards, 0.002 in (0.05

mm) maximum TIR.

4. If the indicator reads higher than 0.002 in

(0.05 mm) TIR, using the jackscrews relocate the

motor on the motor base (sometimes no register).

5. Obtain the desired position.

6. Tighten the hold-down bolts (not the jackscrews)

and repeat the indicator reading.

Note: Adding or removing shims between the

motor and the discharge head helps alignment in

the vertical direction. The jackscrews are provided

to adjust the motor in the horizontal direction for

alignment.

INSTALLING THE DRIVER

When installed in a potentially explosive

environment, please ensure the motor is

properly certified.

Serious damage may result if pump is run

in the wrong direction.

NOTE: When pump is supplied with a thrust pot, do not

secure the driver to discharge head until after the

thrust pot and flexible coupling are installed.

INSTALLATION OF A HOLLOW SHAFT DRIVER

This refers to either VHS type electric motors or hollow

shaft type gear drives. A small paragraph will be devoted

to combination electric motor and right angle gear

drives.

Do not work under a heavy suspended

CAUTION

WARNING

object unless there is a positive support

and safe guards which will protect personnel should a

hoist or sling fail.

1. The driving mechanism of all hollow shaft driver is

shown on Figure 7. The head shaft (608) extends up

through the quill or hollow shaft of the driver and

is held in place by an adjusting nut (604), which not

only carries all the static and hydraulic thrust of the

impellers and shaft, but also provides the adjustment

for the impeller clearances. The head shaft is

connected to top shaft (or stub shaft) by a threaded

coupling or a rigid flange coupling.

2. Attach a sling to the lifting lugs of driver and hoist

the driver up. Inspect the mounting surface, register

and clean these surfaces thoroughly. If any burrs

are found, remove burrs with a smooth mill file,

cleaning thoroughly afterward.

3. For motor, orient the motor conduit box in the

required position. For the right angle gear, orient

the input shaft to the desired position. Align the

driver mounting holes with the mating tapped holes

on the discharge head. Lower the driver until the

registers engage and the driver rests on the discharge

head. Secure driver with capscrews provided.

4. Lubricate the driver bearings in accordance with

instructions given on lubrication plate attached to

the driver case. (Or refer to IOM of the driver)

5. After lowering and orienting the driver as explained

above, remove the drive coupling and the hold

down bolts (See Figure 16). Be sure to mark the

location of the coupling before removing it.

(604) ADJUSTING

NUT

(730) GIB KEY

DRIVE

COUPLING

HEAD SHAFT (608)

CAPSCREW (760)

ADJUSTING NUT

HOLD

DOWN BOLT

top flange, discharge head base flange to base plate

or the base plate itself could be out of level. If the

latter, shimming between it and discharge head base,

will correct it. Also, check concentricity of motor to

motor-stand (if provided) to discharge head.

9. With the motor in place and the head shaft

projecting through the motor quill shaft, make

temporary electrical connection to check the motor

rotation. (Be sure to remove the ratchet pins or balls

before checking motor rotation.) Motor must rotate

counter-clockwise when viewed from the top. See

arrow on pump name plate. If motor does not rotate

counter-clockwise, you can change the rotation by

interchanging any two leads.

Never check motor rotation with the drive

coupling in place. The bore clearance

between the drive coupling and the pump shaft O. D.

is so close that should the motor spin with this shaft

stationary, galling and locking together is very likely to

take place.

10. Install motor drive coupling. (Be sure to line up the

match mark made at step 5.) Insert the ratchet pins

if a non-reverse ratchet is used. Match the coupling

lugs with corresponding holes in motor. Tighten

hold down bolts evenly, making sure driver coupling

is properly seated in the register fit.

11. Fit gib key (730) into keyway, by filing if necessary,

to where there is a snug but sliding fit. This key

must be able to be removed by gentle leverage with

a screwdriver under it.

12. Be careful that the gib key (730) is not too high so

as to hold up the adjusting nut (604) from seating

on the drive coupling. If it is, cut off some length of

the key.

13. Install adjusting nut (604) to hand tight.

COMBINATION ENGINE AND MOTOR DRIVES

1. On combination drivers, the motor is invariably on

top with a projecting head shaft extension.

Figure 7

6. Lower the head shaft through the motor quill shaft

to meet the shaft coupling. Apply a thin film of oil

to head shaft threads (if non-galling material) and

screw into the shaft coupling (located above the

stuffing box). Make sure the shaft is not damaged in

any way. Tighten the joint.

7. Check that the head shaft centers inside the driver

quill shaft within 0.06” (1.5mm). If it does not,

misalignment is indicated.

8. Any head shaft misalignment with driver quill

shaft could be caused by a bent head shaft, burrs,

or foreign matter between shaft ends or any of the

mounting flanges: motor flange to discharge head

2. Follow all procedures outlined in the previous

paragraph, except that the motor must be lowered

over this extended head shaft and great care must be

taken to center it exactly so as not to bump or misalign the shaft while the motor is being lowered into

place.

3. There are several methods of running engines

without electric motors and vice versa, requiring

simple adjustment to the combination drive, but

they are too numerous to mention here and can be

obtained from the gear manufacturers instructions

included with the shipment.

15

IMPELLER ADJUSTMENT FOR ALL HOLLOW

WARNING

WARNING

SHAFT DRIVES

NOTE: Shaft adjustment up or down is accomplished by

turning the adjusting nut (604) Figure 8.

INSTALLATION OF A SOLID SHAFT DRIVER

NOTE: When pump is supplied with a thrust pot, do

not secure driver to discharge head until after

the thrust pot and flexible coupling are installed.

NOTE: There are five holes in the adjusting nut and

only four in the motor coupling. See Figure 8.

1. With shafting all the

way down and the

impellers resting on

their seats, turn the

(604) ADJUSTING NUT

LOWER IMPELLER

adjusting nut (604)

in counter-clockwise

RAISE IMPELLER

direction, thus lifting

the shaft, until the

impellers just clear their

A

seats and the shaft/

motor turns free by

hand. This removes

all deflection from the

B

E

shaft.

2. For enclosed impellers,

make another two turns

MOTOR COUPLING

ROTATION

on the adjusting nut.

(3 turns for 12 thread/

inch shaft) Line-up

one of the holes in

C

the adjusting nut

with the nearest

hole in the driver

coupling. Insert

the capscrew

in the hole and

tighten it.

D

Do not work under a heavy suspended

object unless there is a positive support

and safe guard which will protect personnel should a

hoist or sling fail.

The coupling between the driveshaft and the head shaft

may be a non-spacer type (see Figure 9), or a spacer type

(see Figure 10). The latter is used on pumps furnished

with a mechanical seal to permit servicing of the seal

without removal of the driver.

F

1. Attach a sling to the lifting lugs of driver, hoist

motor, inspect the mounting surface, register, and

shaft extension, and clean these surfaces thoroughly.

If any burrs are found, remove burrs with a smooth

mill file, cleaning thoroughly afterward.

2. Orient the motor conduit box in the required

position. Align the motor mounting holes with the

mating tapped holes on the discharge head. Lower

the motor until the registers engage and the motor

rests on the discharge head. Secure motor with

capscrews provided.

H

3. On drivers having a nonreverse ratchet or pins,

manually turn the driver shaft clockwise viewed

from the top until the nonreverse ratchet or pins

fully engage.

G

4. Lubricate motor bearings in accordance with

instructions given on lubrication plate attached to

the motor case.

Figure 8

NOTE: 1.00” and 1.18” diameter shafts are 12 thread

per inch (tpi), 1.50" through 2.44" are 10 tpi, all

larger sizes are 8 tpi.

3. For Open Impellers, Align hole “A” in the adjusting

nut (604) and hole “C” in the driver coupling

(See Figure 8) or whatever similar holes are in like

position. If care is exercised, this will give an initial

impeller clearance of 0.001” to 0.003” depending

on shaft size or the pitch of the thread.

4. Insert capscrew into hole “B” provided these are

the nearest matching holes for counter-clockwise

rotation of adjusting nut, turn adjusting nut counterclockwise until holes “B” and “D” line up. This

gives 1/20 of a turn which is 0.004” on 12 tpi shaft

or 0.005” on 10 tpi shaft.

5. Normal impeller clearance for the open impeller is

considered to be 0.015” for the first 10 feet of the

column length and 0.010” additional clearance for

each 10 ft of length thereafter. This can be reduced

in some instances where is necessary, but should

not be attempted without consulting the factory or

factory serviceman is present.

NOTE: Please read and follow the motor manufacturer’s

instructions before lubricating the motor

bearings. Too much lubricant can cause the

bearings to overheat prematurely.

The motor must not be tested for direction

of rotation when coupled to the pump.

If pump should rotate in the wrong direction, serious

damage to the pump and motor would result. Also

serious injury to personnel could result.

5. Make temporary electrical connections according

to tagged leads or diagram attached to the motor.

Motor must rotate counterclockwise when viewed

from the top. See arrow on pump name plate. If

motor does not rotate counterclockwise, you can

change the rotation by interchanging any two leads.

6. Motor shaft end play adjustment: if required,

motor shaft end play shall be checked with a dial

indicator prior to connecting the pump coupling to

the solid shaft motor. Consult the applicable motor

manufacturers instruction manual for detailed

information on motor shaft end play.

16

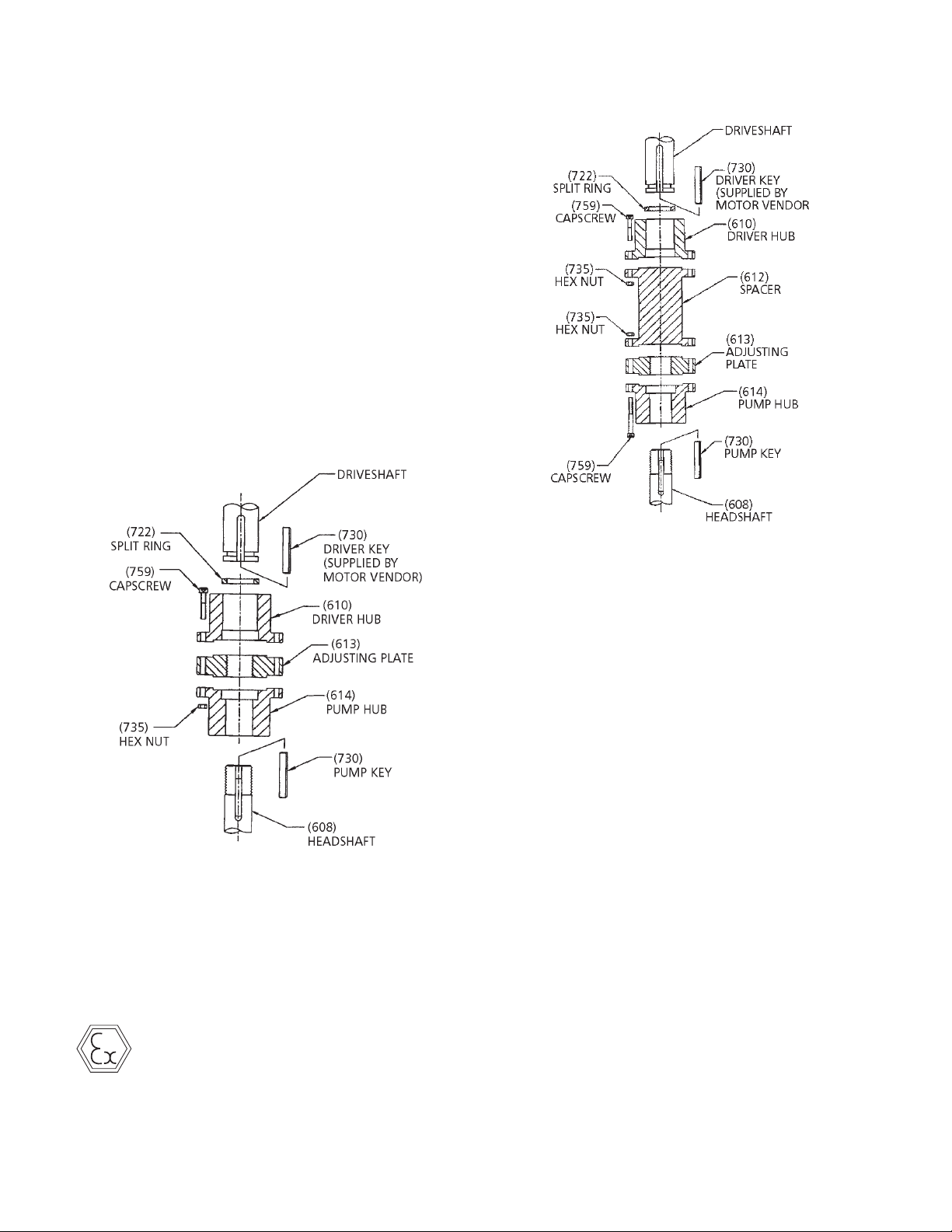

COUPLING INSTALLATION: (SEE FIGURES 9 and 10)

1. Check all mating faces with a fine flat file before

installation. Remove all burrs from face.

2. Apply a thin film of oil on the pump key (730) and

insert key into headshaft keyway seat.

3. Gently lower pump hub of coupling (614) onto

headshaft.

4. Thread on the adjusting plate (613) onto the

headshaft until flush with top of the headshaft.

5. Clean driver shaft by removing all grease and burrs.

Try to fit the key on the driver hub (610) before

installing it to the driver shaft.

6. Apply a thin film of oil to the driver key (730) and

insert key into drive shaft keyway seat. Place the

driver hub (610) onto the drive shaft and with key

slide it up the drive shaft until the annular groove

is exposed. Install split ring (722) in the groove and

slide driver hub down over the split ring to capture

it.

for the specific unit. If the pump has thrust pot, do not

adjust the impeller position until the thrust has been

installed and adjust the impeller position by using the

adjust nut on the thrust pot.

Figure 9

7. If the pump is supplied with an adjustable spacer

coupling (see figure 10), install spacer (612) between head shaft and driveshaft hubs. Secure with

capscrews (759) and hex nuts (735).

IMPELLER ADJUSTMENT

Improper impeller adjustment could cause

contact between the rotating and stationary

parts, resulting in a spark and heat generation.

Figure 10

NOTE: Mechanical seal, when provided, must not be

secured to the shaft prior to impeller adjustment.

(open or enclosed type impellers). Shaft must

move up or down within the seal Assembly.

For pumps handling liquids between –50º to

200º F, impeller adjustment can be made under

ambient conditions. For liquids in excess of

this range, it is recommended that impeller

adjustment be made after the pump surface

temperature has reached an equilibrium when

charged with the pumpage. In those cases, where

this is not feasible due to safety consideration

or impossible due to external ice build up in

cryogenic applications, refer to factory for

specific instructions.

OPEN IMPELLERS

1. With the impellers touching the bottom of the

bowls, turn the adjusting plate (613) towards the

driver hub (610) or spacer (612) obtain 0.015 inch

clearance between the adjusting plate and driver

hub or spacer for the first 10 feet of column. Add

0.010” for each additional 10 feet of column. See

figure 10 or 11. Note: The determination of driver

shaft end play can be critical and should be added

to this setting. For larger pumps over 8”, this

amount may be too little; please refer to Outline

Drawing.

Impeller adjustment is identical for all motors and

right angle gear drives. Adjustment is accomplished by

turning the adjusting plate (613). (See figure 11 or 12).

The correct adjustment is listed on the Outline Drawing

17

2. After impeller adjustment, align adjusting plate (613)

WARNING

with the pump hub (614), and tightly draw coupling

flanges together with capscrews (759) and nuts

(735). (See figure 9 and 10).

3. Check shaft run out with dial indicator. For

mechanical seal installation, the run out should be

0.005 or less.

4. Set seal after impeller adjustment. Securely tighten

all set screws in the collar. Remove the spacer

between the gland plate and collar. Retain spacer for

future resetting of seal.

ENCLOSED IMPELLERS

For enclosed impellers obtain the clearance between the

adjusting plate and driver hub or spacer as specified on

the outline drawing. See Figure 11 or 12.

INSTALLING THE GREASE LUBRICATED THRUST POT

This type of thrust pot and the motor stand are

assembled on the discharge head by the factory. This

thrust pot is designed to be used with NEMA Vertical

C-face motors. The motor shaft and the pump shaft have

to be coupled with flexible coupling.

NOTE: When impellers are reset, the seal must also be

reset.

Figure 11

INSTALLATION:

1. Install both coupling halves prior to mounting

the motor. Refer to the coupling manufacturer’s

instructions.

2. Using the lifting lugs on the motor, carefully lower

the motor onto the motor stand of the thrust pot

(See Figure 13) and align the bolt holes.

3. Install the bolts finger tight.

4. Make temporary electrical connections according

to tagged leads or diagram attached to the motor.

Motor must rotate counterclockwise when viewed

from the top. See arrow on pump name plate. If

motor does not rotate counterclockwise, you can

change the rotation by interchanging any two leads.

Before beginning any alignment procedure,

make sure driver power is locked out.

Failure to lock out driver power will result in serious

physical injury.

ALIGNMENT OF FLEXIBLE COUPLING:

Alignment of the pump and motor is extreme importance

for trouble-free mechanical operation. Straight edge

alignment by an experienced installer proves adequate for

most installations.

1. Check for coupling alignment by laying a straight

edge across both coupling rims at four points 90º

apart.

2. Move motor until straight edge rests evenly at each

position. Repeat procedure until correct alignment is

achieved.

3. Install flexible sleeve between the hubs per the

manufacture’s instructions.

4. Tighten all motor bolts.

NOTE: Be sure the relief fitting (#11 in Figure 13) is

clear of paint or any other obstructive material.

Otherwise it will cause premature failure of the

thrust pot and is not covered under warranty.

Figure 12

18

ITEM DESCRIPTION

1 Motor stand

2 Headshaft

3 Bearing housing

4 Bearing

5 Top seal

6 Snap ring

7 Lock nut

8 Lock washer

9 Lower seal

10 Grease lube fitting

11 Grease relief fitting

12 Hex tap bolt

13 Hex nut

14 Hex capscrew

Figure 13 – Grease Lubricated Thrust Pot

3. Lower the drive shaft through the quill of the thrust

pot assembly to meet the shaft coupling. Apply a

thin film of oil to the head shaft thread and screw

into the shaft coupling.

4. For unit with mechanical seal and flanged coupling,

install the spacer flange coupling as instructed on

page 16.

5. Install the gib key (#16) into the drive shaft and the

hollow shaft clutch.

6. Install the adjusting nut (#17) to hand tight.

7. With shafting all the way down and the impellers

resting on their seats, turn the adjusting nut (#17)

in counter-clockwise direction, thus lifting the shaft,

until the impellers just clear their seats and the

shaft/motor turns free by hand. This removes all

deflection from the shaft.

8. Line-up one of the holes in the adjusting nut with

the nearest hole in the driver coupling. Insert the

capscrew in the hole and tighten it.

NOTE: 1.00” and 1.18” diameter shafts are 12 tpi, 1.50"

through 2.44" are 10 tpi, all larger sizes are 8 tpi.

9. Install the bottom of the flexible coupling to the top

of the drive shaft.

10. Attach a sling to the lifting lugs of driver and hoist

the driver up. Inspect the mounting surface, register

and clean these surfaces thoroughly. If any burrs

are found, remove burrs with a smooth mill file,

cleaning thoroughly afterward. Temporarily attach

the top half of the flexible coupling to the motor

shaft.

11. Orient the motor conduit box in the required

position. Align the driver mounting holes with the

mating tapped holes on the discharge head. Lower

the driver until the registers engage and the driver

rests on the thrust pot assembly. Secure driver with

capscrews provided.

12. Secure the flexible coupling assembly.

INSTALLING THE OIL LUBRICATED THRUST POT

If the unit is supplied with a thrust pot (see Figure 14),

the thrust pot should be installed on top of the discharge

head or motor stand before installing the driver. The

driving mechanism of the thrust pot assembly is similar to

the hollow shaft motor. (See Figure 7)

1. Attach a sling to the thrust pot assembly through

the windows on the motor adapter and hoist the

assembly over the top of the discharge head.

2. Clean the mounting face with a flat file to remove

any burr of the discharge head and the thrust pot.

Lower the thrust pot assembly and orient it so that

the bolt hole on the base of the thrust pot and the

top flange of the discharge head are lined up. Install

all the bolts to secure the assembly to the discharge

head.

13. Install the coupling guard.

14. Fill the oil reservoir with recommended oil.

19

ITEM DESCRIPTION

1 Thrust Pot Body

2 Tube - Oil Retaining

3 Thrust Bearing

4 Capscrew - Head to Thrust Pot

5 Washer - Head to Thrust Pot

6 Hex Nut - Head to Thrust Pot

7 Roller Bearing

8 Bearing Seat

9 Allen Head Screw

10 Capscrew - Motor Adapter to Motor or Thrust Pot

11 Washer - Motor Adapter to Motor or Thrust Pot

12 Gasket

13 Capscrew

14 Non-reverse Pin

15 Socket Head Screw

16 Gib Key

17 Adjusting Nut

18 Coupling Guard

19 Setscrew

ITEM DESCRIPTION

20 Flexible Shaft Coupling

21 Gib Key

22 Key (Motor Shaft)

23 Setscrew

24 Round Head Screw for Coupling Guard

25 Washer Coupling Guard

26 Motor Adapter

27 Capscrew - Adjusting Nut

28 Washer - Adjusting Nut

29 Retaining Ring

30 Hollow Shaft Clutch

31 Non-reverse Plate

32 Pipe Plug - Oil Filling

33 Retaining Ring

34 Hollow Shaft

35 Shaft Sleeve

36 Sight Gauge

37 Pipe Plug - Oil Drain

20

Figure 14 – Oil Lubricated Thrust Pot

Pump Startup And Operation – SECTION 4

WARNING

WARNING

WARNING

CAUTION

PRE-START PROCEDURE

Consult the applicable manufacturer’s instructions for

detailed information for the prime mover (electric motor,

engine or steam turbine), coupling, driveshaft, gear

driver. Prior to startup, check the following:

1. Confirm that the following procedures described

in the “Installing the Drivers” sections have been

performed:

STARTUP PRECAUTIONS

1. All equipment and personal safety related devices

and controls must be installed and operating

properly.

2. To prevent premature pump failure at initial start-up

due to debris in the pipe system, ensure the system

has been adequately cleaned and flushed.

3. Variable speed drivers should be brought to rated

speed as quickly as possible.

A. Wiring of Driver.

B. Driver must rotate counterclockwise (CCW)

when viewed from above.

Serious damage may result if pump is run

in the wrong direction.

Do not check motor rotation unless motor

is bolted to pump and drive coupling is

match marked and removed.

Be sure to install the coupling guards

around all exposed shafts and couplings

before start up of the pump. Failure to comply may result

in severe personnel injury or death.

C. Check alignment of pump and driver.

D. Impeller adjustment has been made.

E. Mechanical seal lock collar is attached to shaft.

2. For open lineshaft pump, make sure the stuffing box

relief (bleed) line is connected (if applicable).

3. For pump with mechanical seal, make sure mechani-

cal seal is properly lubricated and all piping to seal is

connected. Also, check that all cooling, heating and

flushing lines are operating and regulated.

4. Open the air release system isolation valve. Adjust

the air release system throttling device so that it is

partially open. It should not be closed or fully open.

NOTE: Not exhausting the air or exhausting it too fast

can damage the pump.

5. All connections to driver and starting device match

wiring diagram. Voltage, phase, and frequency on

motor nameplate agree with line current.

6. Rotate shaft manually to ensure impellers are not

binding.

4. Variable speed drivers should not be adjusted or

checked for speed governor or over-speed trip

settings while coupled to pump at initial startup. If

settings have not been verified, uncouple the unit

and refer to driver manufacturer’s instructions for

assistance.

5. Running a new or rebuilt pump at slow speeds

may not provide enough flow to adequately flush

and cool the stuffing box bushing’s close running

surfaces.

6. Pumpage temperatures in excess of 200º F (93º C)

will require warm-up of pump prior to operation.

Circulate a small amount of pumpage through the

pump until the casing temperature is within 100º

F (38º C) of the pumpage temperature and evenly

heated.

PRIMING

The pump must be properly vented

through the discharge head/barrel vent

connections. This is especially important for fluids with

suction pressure close to their vapor pressures. Vent

piping must be continuously rising back to source so that

fluid cannot collect in the vent line.

The first stage impeller must always be completely

submerged. Pump must not run dry as the rotating parts

within the pump may gall and seize to the stationary

parts. The parts must be lubricated by the liquid being

pumped.

NOTE: NPSHa must always exceed NPSHr as shown on

Goulds Water Technology performance curves.

NOTE: Pump must never be throttled on the suction

side by allowing suction strainer to become

clogged.

PUMP STARTUP

7. Verify that driver bearings are properly lubricated

and check oil level in housing.

8. Check that auxiliary seal components are properly

vented.

9. Inspect discharge piping connection, valves and

pressure gauges for proper operation.

1. Partially close the valve in the discharge line.

2. Crack open suction side valves on pressurized

systems slowly. Open suction valves fully.

3. Vent system when the pump surface temperature has

reached an equilibrium.

4. Start the pump. If any abnormal noises, jerking

or vibration is noted, stop the pump immediately,

determine the cause of the abnormalities and correct

them.

21

5. After the pump is operating at full speed, slowly

WARNING

WARNING

CAUTION

open discharge valve. If driver overheats or there is

excessive vibration, stop the pump, determine the

causes and correct them.

Improper impeller adjustment could cause

contact between the rotating and stationary

parts, resulting in a spark and heat generation.

6. If the air release valve is manually operated, close it.

7. For open lineshaft pumps, with the pump in

operation, there should be some leakage at the

stuffing box packing. The correct leakage rate is

approximately one drop per second. Check the