Page 1

ITT

Goulds Pumps

G&L SERIES

MODEL SVI

Installation, Operation and

Maintainence Instructions

General Industry

Goulds Pumps is a brand of ITT Water Technology, Inc.

- a subsidiary of ITT Industries, Inc.

www.goulds.com

Engineered for life

Page 2

SUBJECT PAGE

SVI Product Line Numbering System .............................................................................................................................3

Safety Instructions .........................................................................................................................................................5

Installation ....................................................................................................................................................................5

Piping ............................................................................................................................................................................5

Shaft Alignment – Motor to Pump .................................................................................................................................5

Wiring and Grounding ..................................................................................................................................................6

Operation ......................................................................................................................................................................6

Maintenance..................................................................................................................................................................6

Disassembly/Assembly

Mechanical Seal Replacement ......................................................................................................................................7

Motor Replacement .....................................................................................................................................................7

Troubleshooting ............................................................................................................................................................8

Engineering Data ...........................................................................................................................................................8

Motor Data ...................................................................................................................................................................8

SVI Sectional Assembly ................................................................................................................................................10

Limited Warranty ........................................................................................................................................................13

Declaration of Conformity ..........................................................................................................................................33

Pump Model Number:

Pump Serial Number:

Control Model Number:

Dealer:

Dealer Phone No.:

Date of Purchase: Installation:

Current Readings at Startup:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Volts: Volts:

SERIES — SÉRIE — SERIES

1SV 3SV

2SV 4SV

2

Page 3

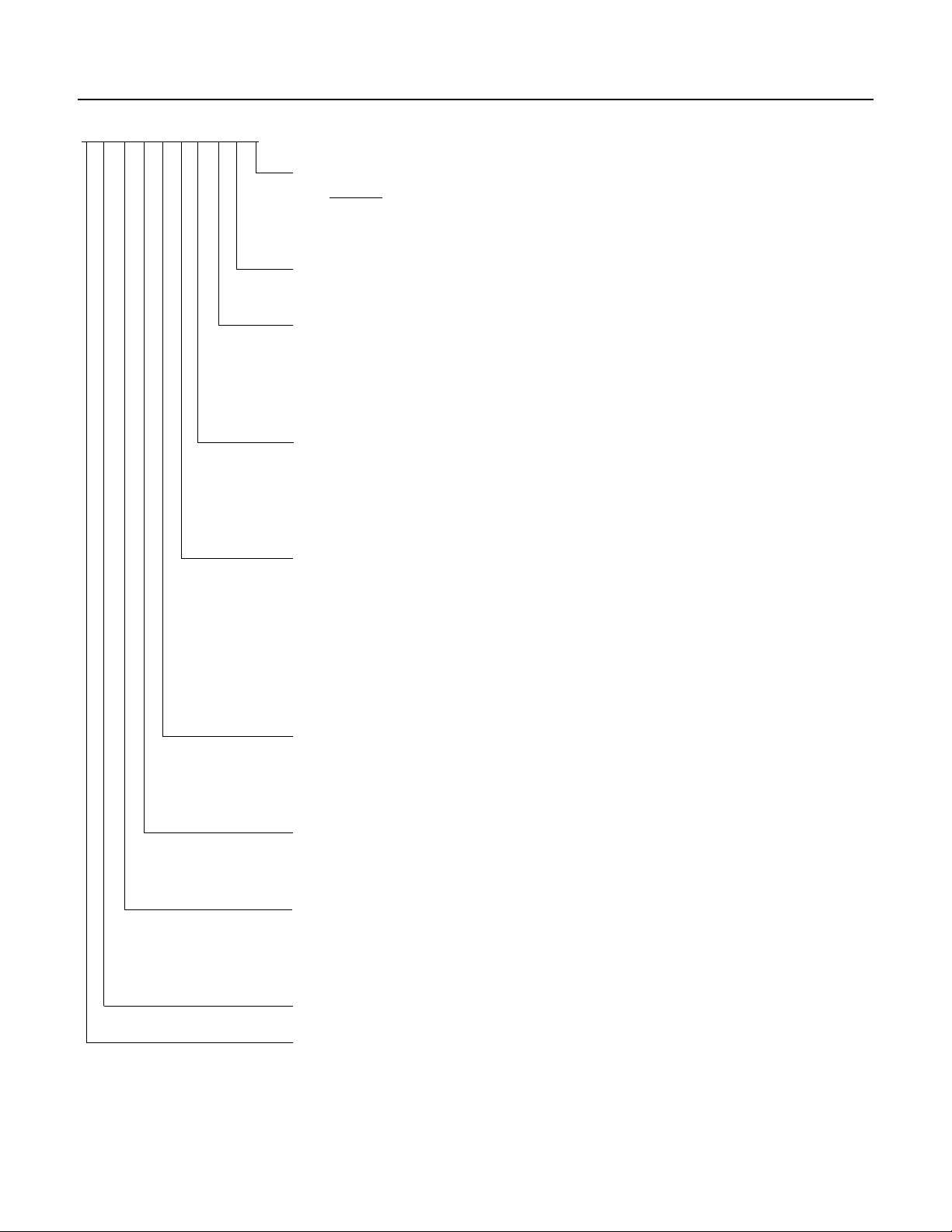

SVI PRODUCT LINE NUMBERING SYSTEM

COMPLETE PUMPS

2 SV N 1 G 11 F H E 5 EXAMPLE PRODUCT CODE*

➤

Seal Options:

0 = Standard Silicon Carbide/Carbon/Viton

4 = Silicon Carbide/Silicon Carbide/Viton

5 = Tungsten Carbide/Tungsten Carbide/Viton

Discharge Connection:

E = NPT M = BSP A = Flanged ANSI Drilling D = Flanged DIN Drilling

Bowls:

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Impellers:

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Driver:

01 = 1PH, ODP, NEMA 07 = 3PH, XP, NEMA 13 = 3PH, 575V, TEFC, NEMA, MF**

02 = 3PH, ODP, NEMA 08 = 575V, XP, NEMA 14 = 1PH, 230V, TEFC, NEMA, MF**

03 = 575V, ODP, NEMA 09 = 3PH, TEFC, PE, NEMA 15 = 3PH, 220-255/380-440, IEC

04 = 1PH, TEFC, NEMA 10 = 1PH, XP, NEMA 16 = 3PH, 265-277/460-480, IEC

05 = 3PH, TEFC, NEMA 11 = 3PH, 200V, TE, NEMA, MF**

06 = 575V, TEFC, NEMA 12 = 3PH, 208-230/460V, TE, NEMA, MF**

**MF = Metric Flange

* Not all combinations are available.

HP Rating:

C = ½ F = 1½ J = 5 M = 15 Q = 30

D = ¾ G = 2 K = 7½ N = 20

E = 1 H = 3 L = 10 P = 25

Hertz/RPM:

1 = 60 Hz/3500 RPM

2 = 50 Hz/2900 RPM

Version:

S = CI/NEMA Motor Adapter

X = CI/IEC Motor Adapter

N = Stainless Steel/IEC Motor Adapter

Product Line: Stainless Vertical Immersed

Nominal Flow:

1 = 15 GPM 3 = 55 GPM

2 = 28 GPM 4 = 86 GPM

3

Page 4

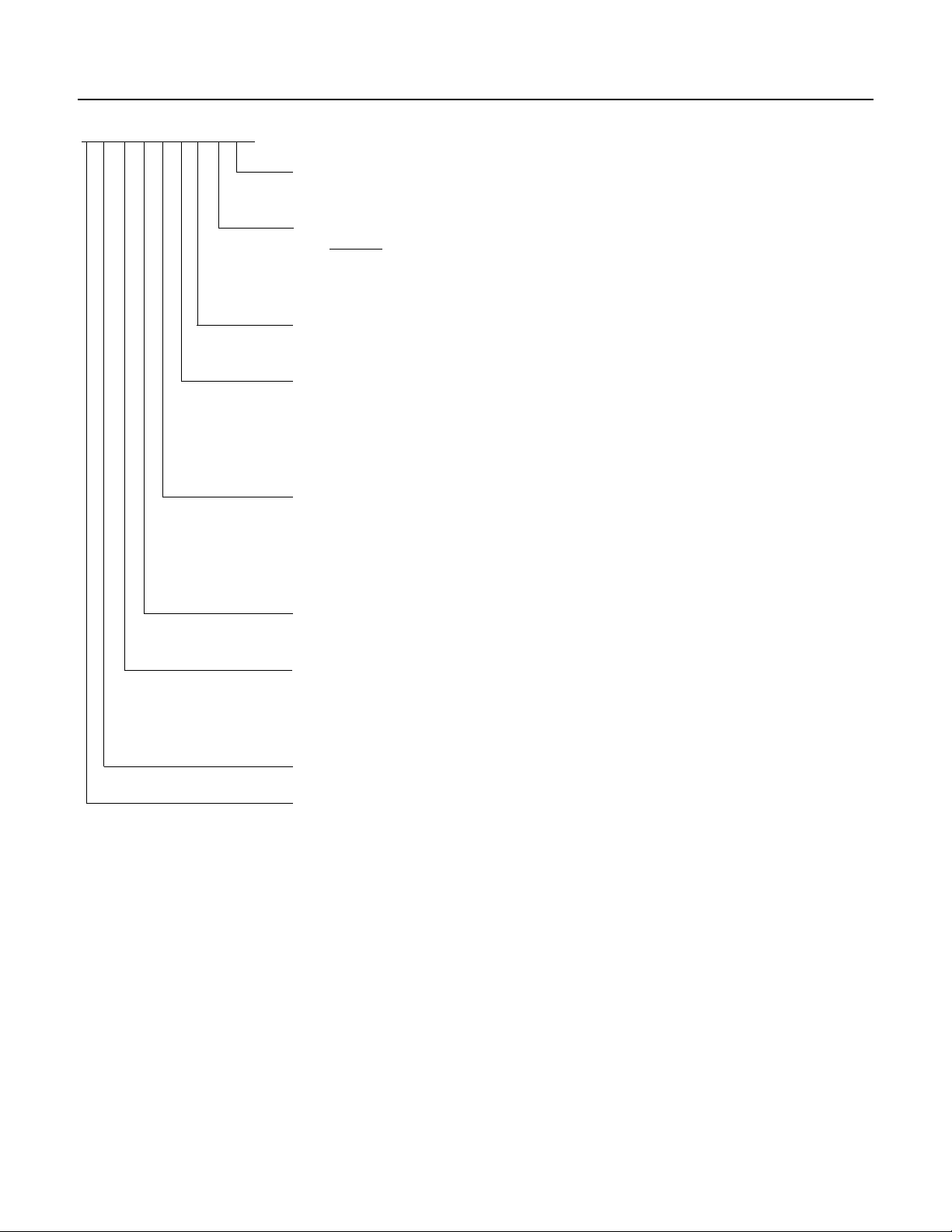

SVI PRODUCT LINE NUMBERING SYSTEM

LIQUID ENDS

2 SV N K F H E 5 T EXAMPLE PRODUCT CODE

➤

Optional Suffix:

T = Next Size Larger Motor Frame

Seal Options:

0 = Standard Silicon Carbide/Carbon/Viton

4 = Silicon Carbide/Silicon Carbide/Viton

5 = Tungsten Carbide/Tungsten Carbide/Viton

Discharge Connection:

E = NPT M = BSP

Bowls:

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Impellers:

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Liquid End:

Version:

S = CI/NEMA Motor Adapter

X = CI/IEC Motor Adapter

N = Stainless Steel/IEC Motor Adapter

Product Line: Stainless Vertical Immersed

Nominal Flow:

1 = 15 GPM 3 = 55 GPM

2 = 28 GPM 4 = 86 GPM

4

Page 5

DANGER

WARNING

CAUTION

WARNING

Hazardous fluids

can cause fire,

burns or death.

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert

to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES. THESE

FLUIDS MAY BE PRESENT IN

CONTAINMENT AREAS.

Provide adequate space and ventilation around unit for

•

service and for motor cooling.

Protect the pump and piping from freezing tempera-

•

tures.

The unit MUST be securely affixed to a level metal

•

base foundation, adequate to absorb vibration and provide permanent, rigid support for the pump and motor

assembly. See the “ENGINEERING DATA” section of

this manual for specific model weights and pump base

dimensions.

NOTICE: DO NOT DRAW PIPING INTO PLACE BY

FORCING THE PUMP DISCHARGE

CONNECTIONS.

Discharge piping should be no smaller than the

•

respective pump opening and should be kept as short

as possible, avoiding unnecessary fittings to minimize

friction losses.

NOTICE: PIPING MUST BE INDEPENDENTLY SUP-

PORTED AND NOT PLACE ANY PIPING

LOADS ON THE PUMP.

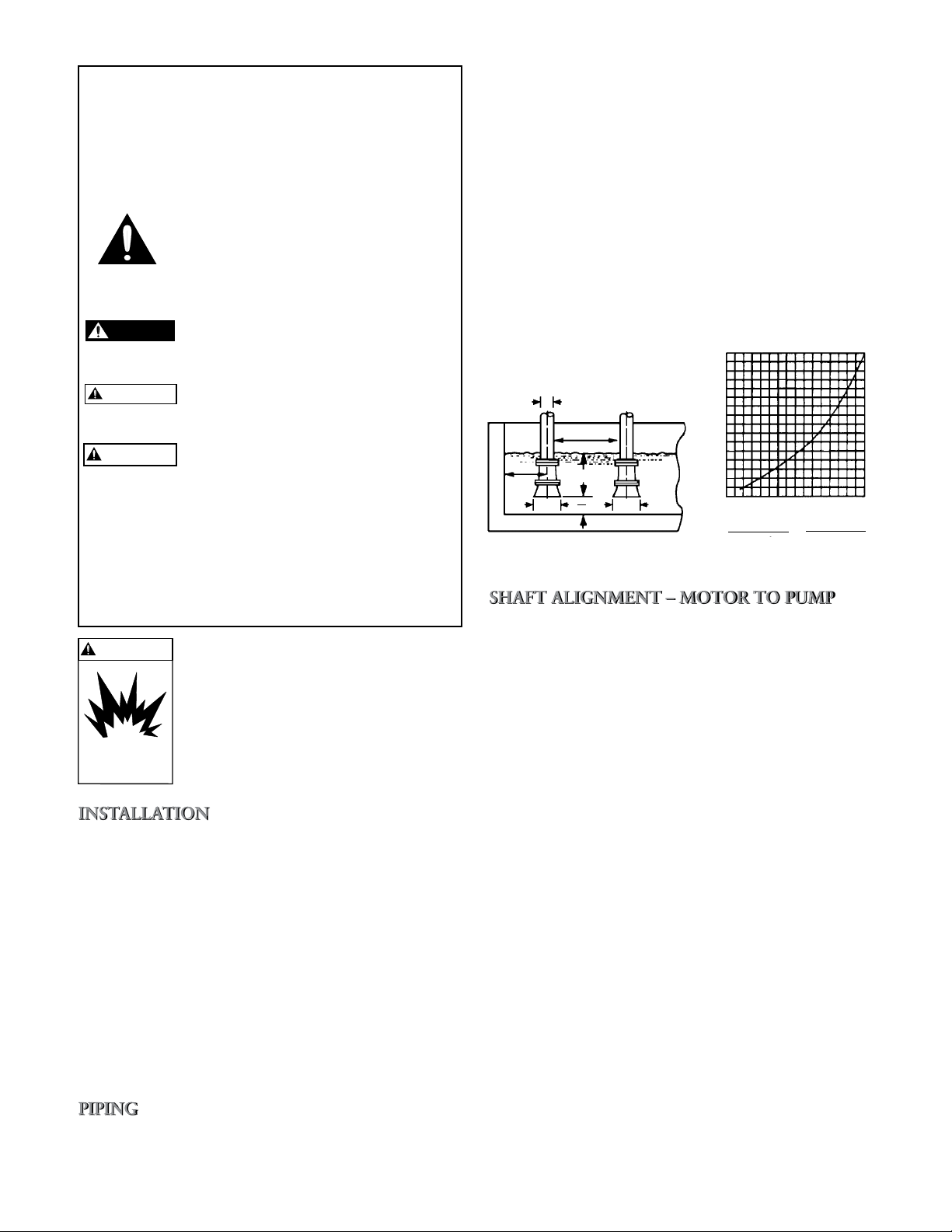

Insure that the size and minimum liquid submergence,

•

over the suction inlet, is sufficient to prevent air from

entering through a suction vortex. See typical suction

piping Figures 1 and 2.

Install a discharge check valve, suitable to handle the

•

flow and liquids, to prevent backflow.

Install an appropriately sized gate valve, AFTER the

•

discharge valve, to regulate the pump capacity, for

pump inspection and for maintenance.

When a pipe increaser is required, install between the

•

check valve and the pump discharge.

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

H = Min. Submergence in feet

1

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 V

V = Velocity in feet per second

=GPM x 0.321

Area

GPM x 0.4085

2

D

4D

min.

D

8D

min.

H min.

min.

3D

3D

3D

2

Figure 1 Figure 2

When the pump is purchased less motor, the pump will

•

be supplied with a motor assembly shim positioned

between the motor adapter and the coupling.

To assemble the motor to the pump remove the plastic

•

shipping straps, the 2 stainless steel coupling guard

halves, and the expanded polyurethane.

Insure that the motor assembly shim is properly posi-

•

tioned between the coupling and the motor adapter. If

the motor assembly shim is not available, a 0.203"

(5 mm) shim may be used to locate the pump shaft

assembly and to set the correct height.

For motor frame sizes 213TC and larger, attach the

•

motor adapter flange to the motor using 4 hex cap

screws. Torque to values shown in the

“ENGINEERING DATA” section of this manual.

Loosen the 4 coupling socket head screws enough to

•

provide an adequate opening in the coupling to receive

the motor shaft.

With an adequately sized crane, carefully lower the

•

motor assembly onto the pump motor adapter and

into the coupling. Secure the 4 motor hex cap screws,

torquing to the value provided in the

“ENGINEERING DATA” section of this manual.

Torque the 4 coupling socket head screws to the value

•

provided in “ENGINEERING DATA” section of this

manual.

Remove the motor assembly shim and retain for future

•

use.

Install the 2 coupling guard halves.

•

5

Page 6

Install, ground and wire

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous

voltage

208-230V 3/60 460V 3/60

4

5

6

1

7

2

8

3

9

L

1

L

2

L

3

4

7

5

8

6

9

1

2

3

L

1

L

2

L

3

G

G

MOTOR LEADS

MOTOR LEADS

POWER CABLE LEADS

POWER CABLE LEADS

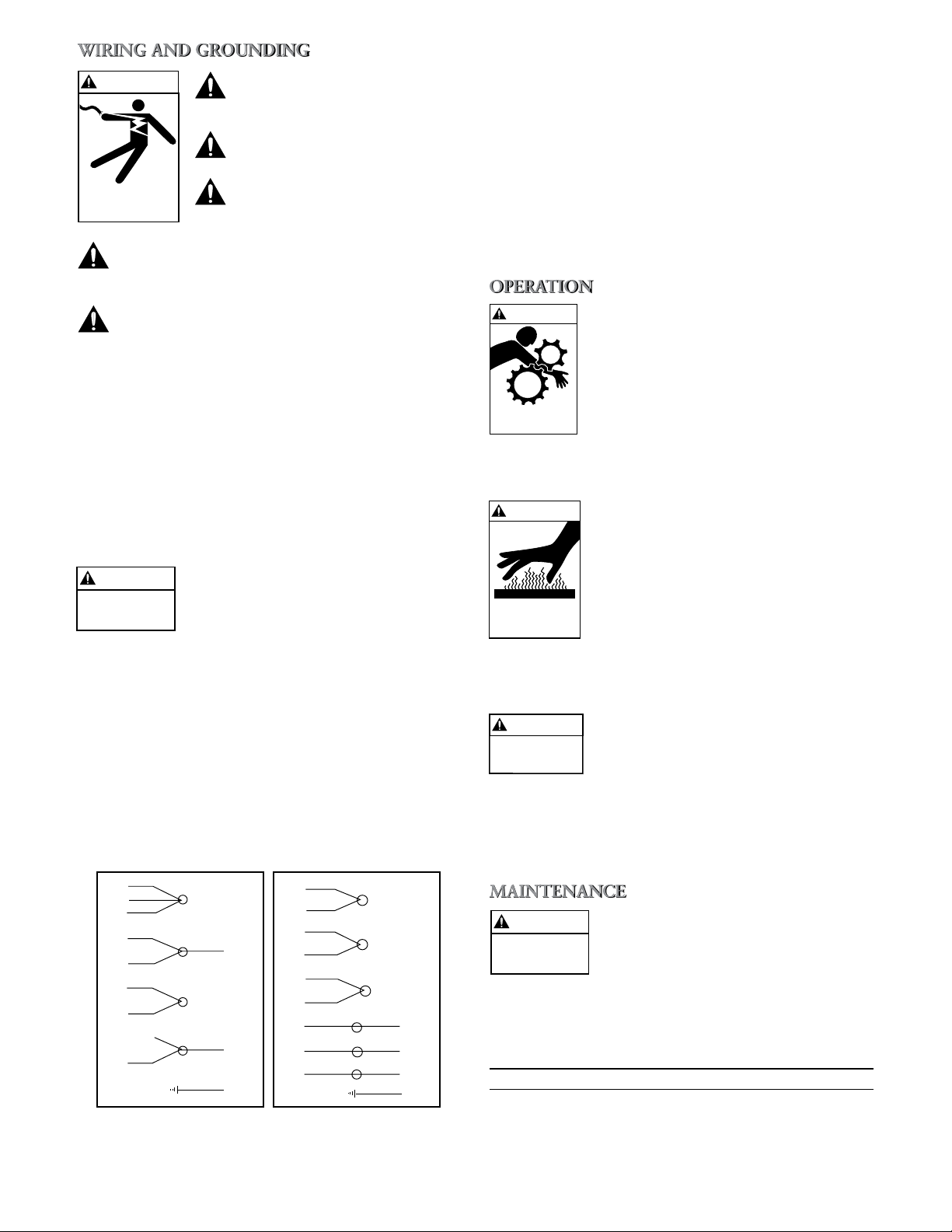

THREE PHASE MOTOR WIRING DIAGRAM

WARNING

Hazardous machinery

can cause personal

injury or death.

WARNING

Extreme heat can

cause personal injury

or property damage

WARNING

Hazardous

machinery

WARNING

Hazardous

voltage

according to local and National

Electrical Code requirements.

Install an all leg disconnect

switch near pump.

Disconnect and lockout electrical power before installing or

servicing pump.

Electrical supply MUST match pump’s nameplate

specifications. Incorrect voltage can cause fire,

damage motor and voids warranty.

NOTICE: UNIT ROTATION IS CLOCKWISE WHEN

VIEWED FROM MOTOR END.

INCORRECT ROTATION MAY CAUSE

DAMAGE TO THE PUMP AND VOIDS

WARRANTY.

Check pump rotation by observing the motor fan or

•

the coupling THROUGH the coupling guard. DO

NOT confuse the flow arrows, stamped on the pump

body, with the rotation arrows on the coupling and

motor adapter. Three phase motors only – If rotation is

incorrect, have a qualified electrician interchange any

two of the three power cable leads.

Motors equipped with automatic thermal protectors open the motor’s electrical circuit when an

overload exists. This can cause the pump to start

unexpectedly and without warning.

Use only stranded copper wire to motor and ground.

•

Wire size MUST limit the maximum voltage drop to

10% of the motor nameplate voltage, at the motor terminals. Excessive voltage drop will affect performance

and void motor warranty. The ground wire must be at

least as large as the wires to the motor. Wires should be

color coded for ease of maintenance.

Three phase motors require all leg protection with

•

properly sized magnetic starters and thermal overloads.

PERMANENTLY GROUND THE

PUMP, MOTOR AND CONTROLS

PER NEC OR LOCAL CODES BEFORE CONNECTING TO ELECTRICAL POWER. FAILURE TO DO SO

CAN CAUSE SHOCK, BURNS OR

DEATH.

Connect the electrical leads to the motor, as follows:

•

Single Phase Motors – Connect the BLACK wire to the

•

BLACK motor wire. Connect the WHITE wire to the

WHITE motor wire. Connect the GREEN wire to the

GREEN motor wire.

Three Phase Motors – See Figure 3.

•

DO NOT OPERATE UNIT WITHOUT SAFETY GUARD IN PLACE.

TO DO SO CAN CAUSE SEVERE

PERSONAL INJURY.

NOTICE: PUMP MUST BE COMPLETELY PRIMED

BEFORE OPERATION.

DO NOT OPERATE PUMP AT OR

NEAR ZERO FLOW. TO DO SO CAN

CAUSE EXTREME HEAT, DAMAGE

TO THE PUMP, INJURY OR PROPERTY DAMAGE.

After stabilizing the system at normal operating condi-

•

tions, check piping for correct alignments. If necessary,

adjust pipe supports.

MOTOR THERMAL PROTECTORS

CAN RESTART MOTOR UNEXPECTEDLY AND WITHOUT WARNING, CAUSING SEVERE PERSONAL

INJURY.

See the “ENGINEERING DATA” section in this

•

manual for the recommended maximum pump starts

per hour.

6

Figure 3

DISCONNECT AND LOCKOUT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE. FAILURE TO DO SO CAN

CAUSE SHOCK, BURNS OR DEATH.

Unit motor requires regular lubrication maintenance.

•

MOTOR LUBRICATION

Recommended Motor Bearing Lubrication Intervals

Interval Service Environment

1 – 2 Years Light Duty in Clean Atmosphere

1 Year 8 – 16 hours/day – Clean, Dry Atmosphere

6 Months 12 – 24 hours/day – Moisture Present

3 Months 12 – 24 hours/day – Dirty, High Moisture

Page 7

When lubricants are operated at elevated temperatures,

•

the lubrication frequency should be increased.

DO NOT intermix grease bases (lithium, sodium, etc.).

•

Completely purge old grease if changing grease base.

Over greasing can cause excessive bearing tempera-

•

tures, lubricant and bearing failure.

1. Close all necessary suction and discharge valves.

2. Remove the coupling guards, the 4 coupling hex cap

screws, the coupling and coupling drive pin.

3. Remove pump and drain.

4. Remove the 4 motor hex cap screws. On units with

motor frames 213TC and larger, remove the 4 motor

adapter flange hex cap screws. With an adequately

sized crane, carefully remove the motor. DO NOT

rest the motor on the motor shaft.

5. Remove the 4 tie rod nuts and lock washers.

6. Carefully remove the suction bottom and strainer.

Larger units may require an adequately sized crane to

lift the motor adapter. DO NOT damage the shaft.

NOTICE: EDGES OF THE STAINLESS STEEL PARTS

ARE SHARP. WEAR APPROPRIATE PROTECTIVE CLOTHING.

7. Remove the stack and casing.

8. Slide the mechanical seal rotary element, spring and

washer from the pump shaft.

9. Remove the seal stationary element from the pump

discharge head. Discard the entire seal assembly.

10. Lubricate the inside of the new mechanical seal as-

sembly with a quality grade of glycerin.

11. Lubricate the outside of the new mechanical seal sta-

tionary element with a quality grade of glycerin.

12. Insert the stationary seat into the discharge head

with the seal face out. DO NOT scratch or otherwise

damage the seal face. Insure that the stationary seat

is fully seated into the seal housing. With a clean, lint

free cloth, wipe the seal face clean of all lubricant or

debris.

13. To install a new mechanical seal rotary assembly, slide

the assembly onto the pump shaft, spring end first.

Be sure the top spring tip is in the hole of the rotary

portion of the seal. DO NOT scratch or otherwise

damage the seal face. With a clean, lint free cloth,

wipe the seal face clean of all lubricant or debris.

14. Carefully replace the impellers, spacers, bowls and

casing in the reverse order.

15. Install the base and strainer. Tighten the tie rod nuts

and torque to the value provided in the

“ENGINEERING DATA” section of this manual.

16. With an adequately sized crane, carefully lower the

motor onto the motor adapter, lining up the electrical conduit connection and the 4 motor adapter bolt

holes, as required.

17. Install the 4 motor hex cap screws, torquing to the

value provided in the “ENGINEERING DATA”

section of this manual.

18. Place the coupling drive pin into the pump shaft and

install the coupling halves onto the motor and pump

shafts. Install the 4 coupling socket head screws, lock

washers and nuts, DO NOT tighten.

19. Position the motor assembly shim between the coupling and the motor adapter. If the motor assembly

shim is not available, a 0.203" (5 mm) shim may be

used to locate the pump shaft assembly and to set the

correct height.

20. Tighten the 4 coupling socket head screws, torquing

screws to values provided in the “ENGINEERING

DATA” section of this manual. Tighten evenly so that

the gap between the halves is equal side to side and

top to bottom.

21. Install the 2 coupling guard halves.

To remove the motor follow steps 1 through 4, as

•

provided in the “MECHANICAL SEAL REPLACE-

MENT” section of this manual.

For motor frames 213TC and larger, remove the 4 mo-

•

tor hex cap screws and the motor adapter.

Install the motor adapter flange onto the new motor,

•

torquing the 4 hex cap screws to the values provided in

the “ENGINEERING DATA” section of this manual.

Complete the reassembly following steps 16 through

•

21 in the “MECHANICAL SEAL REPLACEMENT”

section of this manual.

• All additional unit service or maintenance, not

addressed in this manual, should be performed at a

qualified service location. Contact your local dealer or

G&L Pumps distributor for assistance.

7

Page 8

DISCONNECT AND LOCKOUT

WARNING

Hazardous

voltage

ELECTRICAL POWER BEFORE ATTEMPTING ANY MAINTENANCE.

FAILURE TO DO SO CAN CAUSE

SHOCK, BURNS OR DEATH.

SYMPTOM

MOTOR NOT RUNNING

See Probable Cause – 1 through 5

LITTLE OR NO LIQUID DELIVERED BY PUMP

See Probable Cause – 6 through 12

POWER CONSUMPTION TOO HIGH

See Probable Cause – 3, 12, 13, 15

EXCESSIVE NOISE AND VIBRATION

See Probable Cause – 3, 6 - 8, 10, 12, 13, 16

PROBABLE CAUSE

1. Motor thermal protector tripped.

2. Open circuit breaker or blown fuse.

3. Impellers binding.

4. Motor improperly wired.

5. Defective motor.

6. Pump is not primed, air or gases in liquid.

7. Discharge, suction plugged or valve closed.

8. Incorrect rotation (three phase only).

9. Low voltage or phase loss.

10. Impellers worn or plugged.

11. System head too high.

12. NPSHA too low – excessive suction lift or losses.

13. Discharge head too low – excessive flow rate.

14. Fluid viscosity, specific gravity too high.

15. Worn bearing.

16. Pump, motor or piping loose.

Maximum Working Pressure =

(1SV, 2SV, 3SV, 4SV)

230 psi (16 bar) with the oval suction and

discharge flanges

360 psi (25 bar) with ANSI suction and

discharge flanges

Maximum Liquid Temperature =

230º F (110º C)

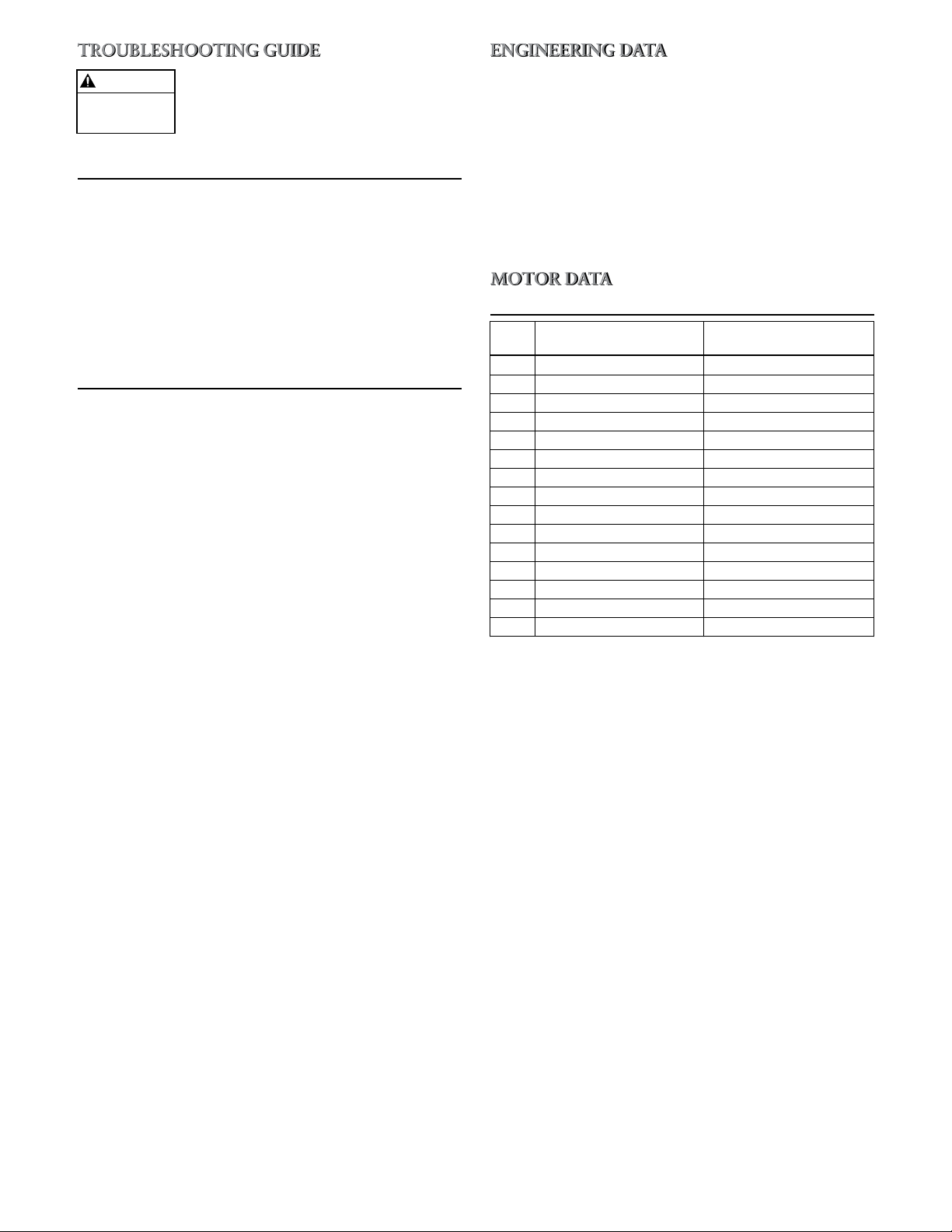

STARTS PER HOUR / MINIMUM RUN TIME – 3 Phase Only

HP Maximum Starts Per Hour Minimum Run Time Between

(evenly distributed) Starts (seconds)

1 15 75

1.5 13 76

2 12 77

3 9 80

5 8 83

7.5 7 88

10 6 92

15 5 100

20 5 110

25 5 115

30 4 120

40 4 130

50 3 145

60 3 170

75 3 180

NOTE(S)

1) Recommended motor starts per hour and minimum run time calculated based on

NEMA standards MG1-12.44 in accordance to manufacturers allowable tolerance

for heat rise and insulation breakdown.

2) Applied voltage and frequency in accordance with NEMA MG1-12.44

3) Starts based on NEMA three phase design A and design B AC induction motors.

4) External load WK2 is equal to or less than the values listed in NEMA MG1-12.54

5) Applicable to all NEMA JM, JP, T and TC frame motors used for Goulds Pumps

products.

6) SINGLE PHASE starts and run time depend on many factors (e.g. capacitor size/

type, wire size and length, switch type) and will not be the same as three phase

motors.

8

Page 9

3500 RPM

HP Phase Enclosure Nameplate Voltage Frame Goulds PN

TEFC 115/230 56C V04722

½ ODP 230/460 56C V04741

3 TEFC 230/460 56C V04742

X-PROOF 230/460 56C V04743

TEFC 115/230 56C V05722

¾

X-PROOF 230/460 56C V05743

PREMIUM EFFICIENCY TEFC 230/460 56C V05742PE

TEFC 115/230 56C V06722

1

X-PROOF 230/460 56C V06743

PREMIUM EFFICIENCY TEFC 230/460 56C V06742PE

TEFC 115/230 56C V07722

ODP 230/460 56C V07741

1½

3 X-PROOF 230/460 56C V07743

PREMIUM EFFICIENCY ODP 230/460 56C V07741PE

PREMIUM EFFICIENCY TEFC 230/460 56C V07742PE

TEFC 115/230 56C V08722

ODP 208-230/460 56C V08741

2 TEFC 208-230/460 56C V08742

3 X-PROOF 208-230/460 56C V08743

PREMIUM EFFICIENCY ODP 208-230/460 56C V08741PE

PREMIUM EFFICIENCY TEFC 208-230/460 56C V08742PE

TEFC 115/230 56C V09722

ODP 208-230/460 56C V09741

3 TEFC 208-230/460 56C V09742

3 X-PROOF 208-230/460 56C V09743

PREMIUM EFFICIENCY ODP 208-230/460 56C V09741PE

PREMIUM EFFICIENCY TEFC 208-230/460 184TCH V09742PE

TEFC 208-230 184TCH V10722

ODP 208-230/460 184TCH V10741

5 TEFC 208-230/460 184TCH V10742

3 X-PROOF 230/460 184TCH V10743

PREMIUM EFFICIENCY ODP 208-230/460 184TCH V10741PE

PREMIUM EFFICIENCY TEFC 208-230/460 184TCH V10742PE

TEFC 230 213TC V11722

ODP 208-230/460 184TCH V11741

7½ TEFC 208-230/460 184TCH V11742

3 X-PROOF 230/460 184TCH V11743

PREMIUM EFFICIENCY ODP 208-230/460 184TCH V11741PE

PREMIUM EFFICIENCY TEFC 230/460 213TC V11742APE

TEFC 230 213TC V12722

ODP 208-230/460 213TC V12741

10 TEFC 208-230/460 215TC V12742

3 X-PROOF 230/460 215TC V12743

PREMIUM EFFICIENCY ODP 208-230/460 213TC V12741PE

PREMIUM EFFICIENCY TEFC 230/460 215TC V12742PE

ODP 208-230/460 215TC V13741

TEFC 208-230/460 254TC V13742

15 3 X-PROOF 230/460 254TC V13743

PREMIUM EFFICIENCY ODP 208-230/460 215TC V13741PE

PREMIUM EFFICIENCY TEFC 208-230/460 254TC V13742PE

ODP 230/460 254TC V14741

TEFC 208-230/460 256TC V14742

20 3 X-PROOF 230/460 256TC V14743

PREMIUM EFFICIENCY ODP 208-230/460 254TC V14741PE

PREMIUM EFFICIENCY TEFC 208-230/460 256TC V14742PE

ODP 115/230 56C V04721

1

1

3

1

3

1

1

1

1

1

1

ODP 115/230 56C V05721

ODP 230/460 56C V05741

TEFC 230/460 56C V05742

ODP 115/230 56C V06721

ODP 230/460 56C V06741

TEFC 230/460 56C V06742

ODP 115/230 56C V07721

TEFC 230/460 56C V07742

ODP 115/230 56C V08721

ODP 230 56C V09721

ODP 208-230 184TCH V10721

ODP 230 213TC V11721

ODP 230 213TC V12721

9

Page 10

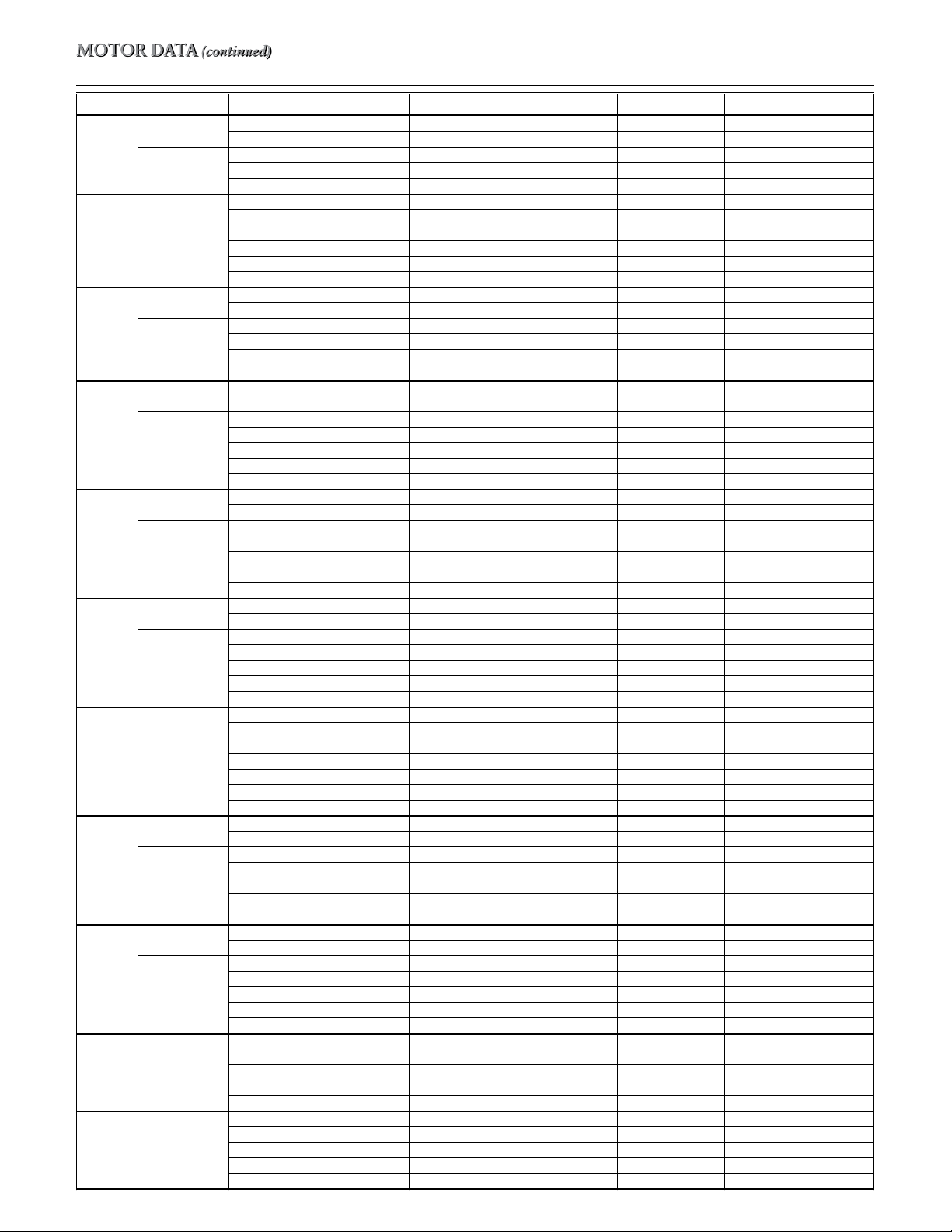

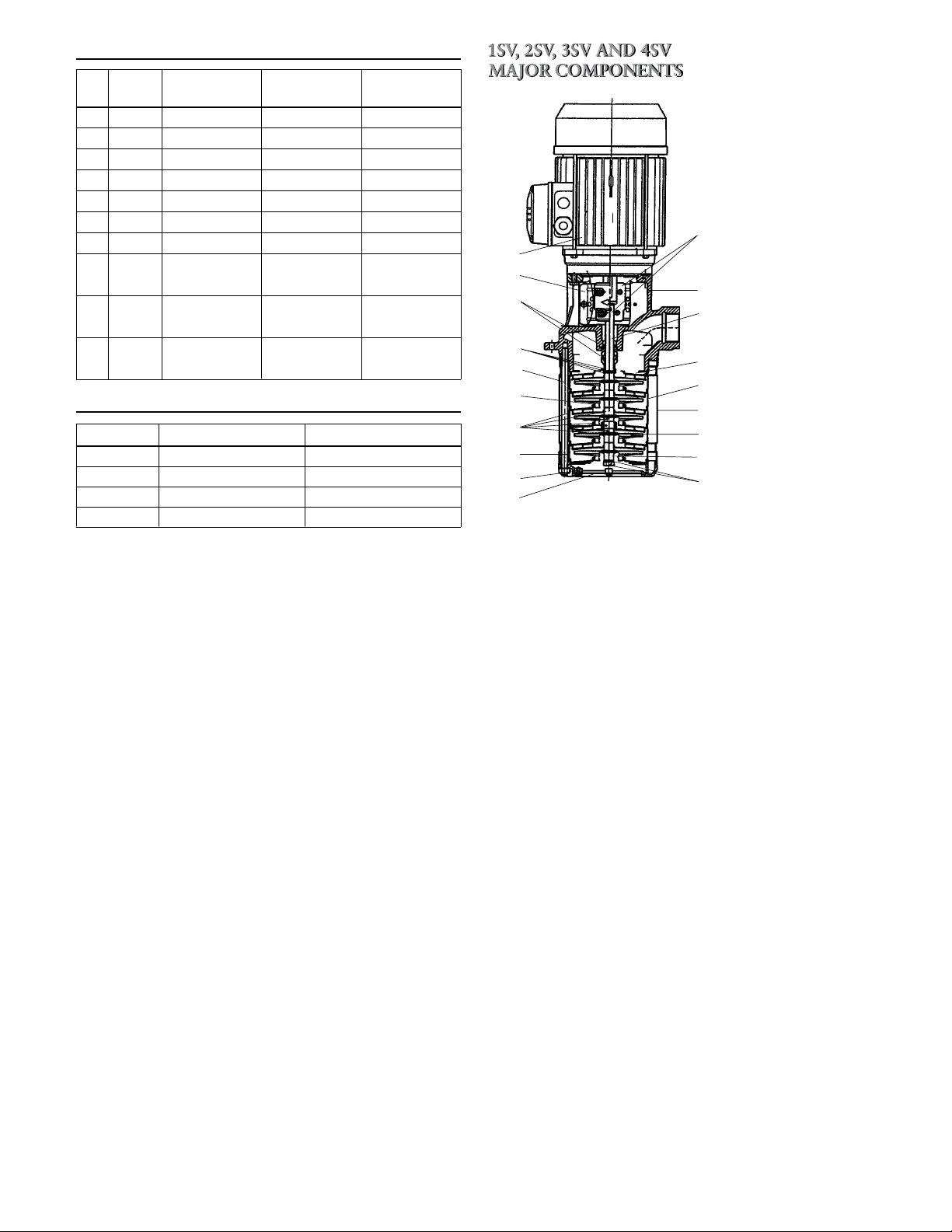

TORQUE VALUES

1

4

2

7

10

11

8

16

17

3

13

18

5

15

12

14

6

9

15

Motor

HP

¾ 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

1 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

1½ 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

2 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

3 56C 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

5 184TCH 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

7½ 184TCH 20 lbs ft (27 N .m) – 15 lbs ft (20 N .m)

10 213TC

215TC

15 215TC

254 TC 48 lbs ft (65 N .m) 48 lbs ft (65 N .m)

20 254TC

256TC

Frame

Motor Bolt Adapter Flange Coupling

45 lbs ft (61 N .m) 30 lbs ft (40 N .m) 30 lbs ft (40 N .m)

45 lbs ft (61 N .m)

45 lbs ft (61 N .m) 48 lbs ft (65 N .m) 48 lbs ft (65 N .m

30 lbs ft (40 N .m) 30 lbs ft (40 N .m)

TORQUE VALUES

Pump Size Tie Rod Nuts Vent and Drain

1SV 22 lbs ft (30 N .m) 15 lbs ft (20 N .m)

2SV 22 lbs ft (30 N .m) 15 lbs ft (20 N .m)

3SV 37 lbs ft (50 N .m) 15 lbs ft (20 N .m)

4SV 37 lbs ft (50 N .m) 15 lbs ft (20 N .m)

1 Motor adapter/discharge

2 Suction bottom cover

3 Sleeve

4 Strainer

5 Diffuser

6 First stage box

7 Diffuser with bush kit

8 Last stage diffuser

9 Impeller

10 Shaft

11 Coupling guard

12 Coupling

)

13 Mechanical seal

14 Tie rod and nut

15 Impeller bolt

16 O-ring

17 Impeller spacer

18 Motor

10

Page 11

ITT

General Industry

GOULDS PUMPS LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Pumps.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The

warranty period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, which

ever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Pumps distributor from whom the pump was purchased

and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Pumps Customer

Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Pumps and

the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or

leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership,

corporation, limited liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

-

Goulds Pumps, G&L and the ITT Engineered Blocks Symbol

are registered trademarks and tradenames of ITT Industries Inc.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

IM170R02 March, 2006

© 2006 ITT Water Technology, Inc.

Engineered for life

11

Page 12

ITT

Goulds Pumps

MODÈLE SVI,

SÉRIE G&L

Directives d’installation,

d’utilisation et d’entretien

Industrie

12

Goulds Pumps est une marque d’ITT Water Technology, Inc., une filiale d’ITT Industries, Inc.

www.goulds.com

Engineered for life

Page 13

SUJET PAGE

Codification des SVI ....................................................................................................................................................14

Consignes de sécurité ..................................................................................................................................................16

Installation ..................................................................................................................................................................16

Tuyauterie ...................................................................................................................................................................16

Réglage de la position de l'arbre de pompe ..................................................................................................................16

Câblage et mise à la terre .............................................................................................................................................17

Utilisation ....................................................................................................................................................................17

Entretien .....................................................................................................................................................................18

Remplacement de la garniture mécanique ....................................................................................................................18

Remplacement du moteur ............................................................................................................................................19

Diagnostic des anomalies .............................................................................................................................................19

Données techniques .....................................................................................................................................................19

Données sur les moteurs ..............................................................................................................................................19

Dessin et principaux composants des SVI (1SV à 4SV) .................................................................................................21

Garantie limitée ...........................................................................................................................................................22

Déclaration de Conformité ..........................................................................................................................................33

Informations pour le propriétaire

Numéro de modèle de la pompe :

Numéro de série de la pompe :

No de modèle de la commande :

Détaillant :

No de téléphone du détaillant :

Date d’achat : d’installation :

Courant mesuré au démarrage :

1 Ø 3 Ø L1-2 L2-3 L3-1

A : A :

V : V :

13

Page 14

CODIFICATION DES SVI

NOMENCLATURE DU NUMÉRO DE GROUPE DE POMPAGE

2 SV N 1 G 11 F H E 5 EXEMPLE DE CODE DE PRODUIT

➤

Code et choix de garnitures mécaniques

0 = garniture standard en carbure de silicium, carbone, Viton

4 = carbure de silicium, carbure de silicium, Viton

5 = carbure de tungstène, carbure de tungstène, Viton

Raccord de refoulement

A = bride ANSI D = bride DIN E = filetage NPT M = filetage BSP (gaz)

Nombre de corps d’étages

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Nombre de roues

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Nombre de phases ou tension et carcasse de moteur

01 = 1 Ø, ODP*, NEMA 07 = 3 Ø, XP*, NEMA 13 = 3 Ø, 575 V, TEFC, NEMA, BM

02 = 3 Ø, ODP, NEMA 08 = 575 V, XP, NEMA 14 = 1 Ø, 230 V, TEFC, NEMA, BM

03 = 575 V, ODP, NEMA 09 = 3 Ø, TEFC, RS*, NEMA 15 = 3 Ø, 220-255 V ou 380-440 V, CEI*

04 = 1 Ø, TEFC*, NEMA 10 = 1 Ø, XP, NEMA 16 = 3 Ø, 265-277 V ou 460-480 V, CEI

05 = 3 Ø, TEFC, NEMA 11 = 3 Ø, 200 V, TE*, NEMA, BM*

06 = 575 V, TEFC, NEMA 12 = 3 Ø, 208-230 V ou 460 V, TE, NEMA, BM

* BM = bride métrique, CEI = Commission électrotechnique internationale, ODP = abritée,

RS = rendement supérieur, TE = fermée non ventilée, TEFC = fermée autoventilée,

XP = antidéflagrante.

1

Puissance nominale (hp)

C = ½ F = 1½ J = 5 M = 15 Q = 30

D = ¾ G = 2 K = 7½ N = 20

E = 1 H = 3 L = 10 P = 25

Fréquence de courant et vitesse de rotation

1 = 60 Hz, 3 500 r/min

2 = 50 Hz, 2 900 r/min

Version

N = adaptateur de moteur CEI en inox

S = adaptateur de moteur NEMA en fonte

X = adaptateur de moteur CEI en fonte

Gamme de produits

Pompes verticales immergées en inox

Débit nominal

1 = 15 gal US/min 3 = 55 gal US/min

2 = 28 gal US/min 4 = 86 gal US/min

1

Certaines combinaisons de caractères de code sont impossibles.

14

Page 15

CODIFICATION DES SVI

NOMENCLATURE DU NUMÉRO DE TÊTE DE POMPAGE

2 SV N K F H E 5 T EXEMPLE DE CODE DE PRODUIT

➤

Suffixe facultatif

T = Carcasse de moteur suivante (plus grosse)

Code et choix de garnitures mécaniques

0 = garniture standard en carbure de silicium, carbone, Viton

4 = carbure de silicium, carbure de silicium, Viton

5 = carbure de tungstène, carbure de tungstène, Viton

Raccord de refoulement

E = filetage NPT M = filetage BSP (gaz)

Nombre de corps d’étages

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Nombre de roues

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Tête de pompage

Version

N = adaptateur de moteur CEI en inox

S = adaptateur de moteur NEMA en fonte

X = adaptateur de moteur CEI en fonte

Gamme de produits

Pompes verticales immergées en inox

Débit nominal

1 = 15 gal US/min 3 = 55 gal US/min

2 = 28 gal US/min 4 = 86 gal US/min

15

Page 16

CONSIGNES DE SÉCURITÉ

DANGER

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

Les fluides dangereux

peuvent causer un

incendie, des brûlures

ou la mort.

AVIS : SERT À ÉNONCER LES DIRECTIVES

•

•

•

AVIS : POSER LA TUYAUTERIE DE FAÇON À CE

•

AVIS : LA TUYAUTERIE DOIT POSSÉDER SES

16

AFIN DE PRÉVENIR LES BLESSURES GRAVES OU

MORTELLES ET LES DOMMAGES MATÉRIELS

IMPORTANTS, LIRE ET SUIVRE TOUTES LES

CONSIGNES DE SÉCURITÉ FIGURANT DANS LE

MANUEL ET SUR LA POMPE.

LE PRÉSENT MANUEL A POUR BUT DE FACILITER

L’INSTALLATION ET L’UTILISATION DE LA POMPE

ET DOIT RESTER PRÈS DE CELLE-CI.

Le symbole ci-contre est un SYMBOLE

DE SÉCURITÉ employé pour signaler

les mots-indicateurs dont on trouvera la

description ci-dessous. Sa présence sert à

attirer l’attention afin d’éviter les blessures

et les dommages matériels.

Prévient des risques qui VONT causer

des blessures graves, la mort ou des

dommages matériels importants.

Prévient des risques qui PEUVENT

causer des blessures graves, la mort ou

des dommages matériels importants.

Prévient des risques qui PEUVENT causer

des blessures ou des dommages matériels.

SPÉCIALES DE GRANDE IMPORTANCE

QUE L’ON DOIT SUIVRE.

LIRE SOIGNEUSEMENT CHAQUE DIRECTIVE ET

AVERTISSEMENT AVANT D’EFFECTUER TOUT

TRAVAIL SUR LA POMPE.

N’ENLEVER AUCUN AUTOCOLLANT DE SÉCURITÉ.

APPAREIL NON CONÇU POUR LES

LIQUIDES DANGEREUX NI POUR

LES GAZ INFLAMMABLES. CES

FLUIDES POURRAIENT ÊTRE PRÉSENTS DANS LES INSTALLATIONS

DE CONFINEMENT (PUITS COLLECTEURS).

Laisser suffisamment d'espace pour le refroidissement

du moteur et l'entretien.

Protéger l'appareil contre le gel.

L'appareil DOIT être fixé solidement à une assise en

béton ou en métal de niveau, qui peut absorber les

vibrations et constitue un support rigide permanent.

QU’ELLE N’APPLIQUE AUCUNE CONTRAINTE SUR LA POMPE.

Afin de réduire la perte de charge (par frottement) au

minimum, le tuyau de refoulement devrait être aussi

court que possible et ne comporter aucun raccord ni

accessoire superflus. Son calibre ne devrait pas être inférieur à celui de l’orifice de refoulement de la pompe.

PROPRES SUPPORTS ET N'APPLIQUER

AUCUNE CONTRAINTE SUR LA POMPE.

S'assurer que le diamètre (d) et la hauteur d'immersion

•

minimale (h min.) de l'orifice d'aspiration sont

suffisants pour empêcher l'aspiration d'air par vortex

(v. fig. 1 et 2).

Poser sur le tuyau de refoulement un clapet de non-

•

retour convenant au débit et aux liquides pompés et

empêchant tout retour de liquide.

Installer, APRÈS le clapet précité, un robinete-vanne de

•

calibre approprié permettant la régularisation du débit,

l'inspection et l'entretien de la pompe.

Lorsqu'un raccord agrandisseur est nécessaire, le poser

•

entre le clapet de non-retour et l'orifice de refoulement

de la pompe.

h

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

h = hauteur d’immers. min. (pi)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 v

v = vitesse d’écoulement (pi/s)

gal US/min x 0,321

=

section de passage

gal US/min x 0,408 5

2

d

4d

(min.)

d

8d

(min.)

h min.

3d

(min.)

3d

2

3d

Figure 1 Figure 2

Lorsque la pompe est achetée sans moteur, elle est

•

livrée avec une cale de réglage de position placée entre

l'accouplement et l'adaptateur de moteur.

Avant d'assujettir le moteur à la pompe, enlever les

•

bandes de fixation en plastique servant au transport,

les deux carters d'accouplement en inox et les éléments

d'emballage en polyuréthane expansé.

S'assurer que la cale de réglage de position est placée

•

correctement entre l'adaptateur et l'accouplement.

S'il n'y a pas de cale, on peut en utiliser une de 5 mm

(0,203 po) d'épaisseur pour que l'arbre de pompe soit à

la bonne hauteur.

S'il s'agit d'un moteur à carcasse 213TC ou plus grosse,

•

fixer au moteur la bride pour adaptateur de moteur

avec 4 vis à tête hexagonale serrées au couple indiqué

(v. DONNÉES TECHNIQUES).

Desserrer l’accouplement (4 vis d'assemblage) assez

•

pour pouvoir y insérer l’arbre de moteur.

À l’aide d’un palan ou d'un autre appareil de levage

•

approprié suffisamment solide, abaisser le moteur

avec précaution jusqu’à ce que son arbre soit en place

dans l’accouplement et que le moteur repose sur

l'adaptateur. Fixer ce dernier au moteur avec 4 vis à

tête hexagonale serrées au couple indiqué (v. DON-

NÉES TECHNIQUES).

Serrer les 4 vis d'assemblage de l’accouplement au

•

couple stipulé dans les DONNÉES TECHNIQUES.

Enlever et conserver la cale.

•

Poser les 2 carters d'accouplement.

•

Page 17

Installer la pompe, la mettre à la

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

ou la mort.

AVERTISSEMENT

Tension

dangereuse

208 à 230 V, 3 Ø, 60 Hz 460 V, 3 Ø, 60 Hz

4

5

6

1

7

2

8

3

9

L

1

L

2

L

3

4

7

5

8

6

9

1

2

3

L

1

L

2

L

3

G

G

FILS DE MOTEUR

FILS DE CÂBLE D’ALIMENTATION

SCHÉMAS DE CÂBLAGE DES MOTEURS TRIPHASÉS

FILS DE MOTEUR

FILS DE CÂBLE D’ALIMENTATION

La machinerie dangereuse peut causer des

blessures ou la mort.

AVERTISSEMENT

AVERTISSEMENT

Les hautes températures

peuvent causer des

blessures et des

dommages matériels.

AVERTISSEMENT

Machinerie

dangereuse

terre et la brancher suivant les

prescriptions du code provincial

ou national de l’électricité pertinent et les réglements locaux.

Poser un sectionneur tout conducteur près de la pompe.

Verrouiller la source de courant en position hors

circuit avant de procéder à l’installation ou à

l’entretien de la pompe.

L’alimentation électrique DOIT être conforme

aux spécifications de la plaque signalétique de la

pompe. Une tension inappropriée peut causer un

incendie ou des dommages au moteur et annule la

garantie.

Le protecteur thermique de certains moteurs

coupe le courant lorsqu’il y a surcharge et le

rétablit automatiquement, redémarrant ainsi la

pompe inopinément.

N’utiliser que du fil de cuivre torsadé pour la mise à

•

la terre et l’alimentation du moteur. Le calibre du fil

DOIT limiter la chute de tension maximale, aux bornes

du moteur, à 10 % de la valeur de tension indiquée sur

la plaque signalétique du moteur. Les chutes de tension excessives altèrent les performances et annulent

la garantie du moteur. Le calibre du fil de terre doit

être au moins égal à celui des fils d’alimentation. Les

fils devraient tous être chromocodés pour faciliter

l’entretien.

Les moteurs triphasés requièrent une protection tout

•

conducteur contre les surcharges thermiques et un démarreur magnétique, appropriés à la charge électrique.

Figure 3

AVIS : LA POMPE TOURNE EN SENS HORAIRE, VUE

DE L'EXTRÉMITÉ DU MOTEUR. LA ROTATION ANTIHORAIRE PEUT ENDOMMAGER

LA POMPE ET ANNULE LA GARANTIE.

Vérifier le sens de rotation de la pompe en observant

•

le ventilateur de moteur ou l’accouplement (PAR les

orifices des carters). NE PAS confondre les flèches

indiquant le sens d’écoulement, estampées sur la tubulure de pompe, avec les flèches montrant le sens de

rotation, sur l’accouplement et l’adaptateur de moteur.

Dans le cas des moteurs triphasés, faire intervertir

deux des trois fils d’alimentation par un électricien si la

pompe ne tourne pas dans le bon sens.

NE PAS FAIRE FONCTIONNER

LA POMPE SANS SES CARTERS

D'ACCOUPLEMENT, SINON CELA

POURRAIT ENTRAÎNER DES BLESSURES GRAVES.

AVANT DE LES BRANCHER À LA

SOURCE DE COURANT, METTRE

LA POMPE, LE MOTEUR ET LES

COMMANDES À LA TERRE DE

FAÇON PERMANENTE SUIVANT

LES PRESCRIPTIONS DU CODE PROVINCIAL OU

NATIONAL DE L’ÉLECTRICITÉ PERTINENT ET

LES RÈGLEMENTS LOCAUX. OMETTRE CETTE

PRÉCAUTION PEUT CAUSER UN CHOC ÉLECTRIQUE, DES BRÛLURES OU LA MORT.

Brancher les fils d'alimentation au moteur comme suit :

•

Moteurs monophasés — connecter le fil d'alimentation

•

NOIR au fil NOIR du moteur, le BLANC au BLANC et

le VERT au VERT.

Moteurs triphasés — voir la figure 3.

•

AVIS : ON DOIT AMORCER LA POMPE CORRECTE-

MENT AVANT SA MISE EN SERVICE.

NE PAS FAIRE FONCTIONNER LA

POMPE SI SON DÉBIT EST PRESQUE

NUL, CAR CELA POURRAIT CAUSER UN ÉCHAUFFEMENT EXCESSIF, L’ENDOMMAGEMENT DE LA

POMPE, DES BLESSURES ET DES

DOMMAGES MATÉRIELS.

Une fois que le système a fonctionné dans des condi-

•

tions de service normales et s'est stabilisé, vérifier

l’alignement de la tuyauterie. Au besoin, régler la position des supports de tuyauterie.

LE PROTECTEUR THERMIQUE DU

MOTEUR PEUT REDÉMARRER CE

DERNIER INOPINÉMENT ET CAUSER AINSI DE GRAVES BLESSURES.

Voir les DONNÉES TECHNIQUES du présent manuel

•

pour le nombre de démarrages par heure maximal

recommandé.

17

Page 18

AVERTISSEMENT

Tension

dangereuse

VERROUILLER LA SOURCE DE

COURANT EN POSITION HORS

CIRCUIT AVANT DE PROCÉDER À

L’ENTRETIEN DE LA POMPE.

OMETTRE CETTE PRÉCAUTION

PEUT ENTRAÎNER UN CHOC

ÉLECTRIQUE, DES BRÛLURES OU

LA MORT.

Il faut lubrifier le moteur régulièrement.

•

LUBRIFICATION DU MOTEUR

Fréquence de lubrifi cation recommandée pour les paliers et roulements

Intervalle Service

1 à 2 ans Service léger dans un lieu propre

1 an 8 à 16 h/jour dans un lieu propre et sec

6 mois 12 à 24 h/jour dans un lieu humide

3 mois 12 à 24 h/jour dans un lieu sale et très humide

On devrait augmenter la fréquence de lubrification

•

lorsque la température de service des lubrifiants est

plus élevée.

NE PAS mélanger les graisses de types différents (à base

•

de lithium, de sodium, etc.). Enlever complètement

l’ancienne graisse quand on utilise un autre type de

graisse.

Un graissage excessif peut entraîner un échauffement

•

trop élevé des paliers et roulements, l'inefficacité du

lubrifiant et la défaillance des paliers et roulements.

1. Fermer les robinets de refoulement.

2. Enlever les carters d'accouplement, les 4 vis

d'assemblage des demi-accouplements, ces derniers et

la goupille de liaison.

3. Retirer le groupe de pompage et vidanger la pompe.

4. Enlever les 4 vis de fixation (à tête hexagonale) du

moteur. S'il s'agit d'un moteur à carcasse 213TC ou

suivante, déposer les 4 vis de fixation du moteur à

la bride pour adaptateur de moteur. Avec un palan

ou autre appareil de levage par le haut de résistance

adéquate, enlever le moteur avec précaution. NE PAS

le déposer sur son arbre.

5. Ôter les écrous et les rondelles-freins des 4 tirants

d’assemblage de la pompe.

6. Retirer le carter d'aspiration, la crépine et

l’adaptateur de moteur avec précaution. On doit

parfois employer un appareil de levage par le haut

robuste pour enlever les adaptateurs très lourds. NE

PAS endommager l’arbre de pompe.

AVIS : LES PIÈCES EN INOX ONT DES ARÊTES

VIVES. PORTER LES VÊTEMENTS DE PROTECTION APPROPRIÉS.

7. Ôter les éléments des corps d’étage, ces derniers et le

corps de pompe.

8. Retirer de l’arbre de pompe l’élément mobile de la

garniture mécanique, le ressort et la rondelle.

18

9. Retirer l’élément fixe de la garniture mécanique hors

de son logement, dans la tubulure de refoulement.

Jeter toutes les pièces de la garniture.

10. Appliquer sur la surface intérieure de la garniture

mécanique neuve du glycérol (« glycérine ») de qualité

supérieure.

11. Enduire de glycérol de qualité supérieure la surface

extérieure de l’élément fixe de la garniture mécanique

neuve.

12. Insérer l’élément fixe dans son logement (tubulure),

la surface d’étanchéité vers l’extérieur. NE PAS éra-

fler ni endommager la surface d’étanchéité. S’assurer

que l’élément fixe est poussé à fond dans son logement. Enlever le lubrifiant et les corps étrangers avec

un linge propre non pelucheux.

13. Enfiler l’élément mobile de la garniture mécanique

sur l’arbre de pompe, le côté ressort en premier.

S’assurer que le bout du ressort côté logement est

dans l’orifice de l’élément mobile. NE PAS érafler

ni endommager les surfaces de la garniture. À l’aide

d’un linge propre non pelucheux, ôter le lubrifiant et

les corps étrangers de la garniture.

14. Reposer avec soin et dans l’ordre approprié le corps

de pompe, les corps d’étage et leurs éléments.

15. Mettre le carter d’aspiration et la crépine en place.

Poser les 4 rondelles-freins et écrous sur les tirants

d’assemblage et serrer les écrous au couple stipulé (v.

DONNÉES TECHNIQUES).

16. À l’aide d’un palan ou d’un autre appareil de levage

approprié, placer le moteur avec soin sur l’adaptateur

de moteur en tenant compte de l’alignement du conduit électrique et des 4 trous de vis de l’adaptateur.

17. Poser et serrer les 4 vis de fixation du moteur au

couple indiqué (v. DONNÉES TECHNIQUES).

18. Mettre la goupille de liaison en place sur l’arbre de

pompe, puis poser les demi-accouplements, leurs

4 vis d’assemblage, leurs rondelles-freins et leurs

écrous, mais NE PAS les serrer.

19. Placer la cale de réglage de position entre l’adaptateur de moteur et l’accouplement. S’il n’y a pas de

cale, on peut en employer une de 5 mm (0,203 po)

d’épaisseur pour que l’arbre de pompe soit à la bonne

hauteur.

20. Serrer les 4 vis d’assemblage des demi-accouplements

uniformément et au couple stipulé (v. DONNÉES

TECHNIQUES) afin que l’écart entre les demiaccouplements soit égal partout.

21. Poser les 2 carters d'accouplement.

Page 19

Pour déposer le moteur, exécuter d’abord les tâches 1

AVERTISSEMENT

Tension

dangereuse

•

à 4 de REMPLACEMENT DE LA GARNITURE MÉ-

CANIQUE.

Dans le cas des moteurs à carcasse 213TC et plus

•

grosse, enlever les 4 vis de fixation à tête hexagonale

du moteur, puis la bride pour adaptateur de moteur.

Fixer la bride au moteur neuf avec 4 vis à tête hexago-

•

nale serrées au couple indiqué (v. DONNÉES TECH-

NIQUES).

Achever le remontage en exécutant les tâches 16 à 21

•

de la section REMPLACEMENT DE LA GARNI-

TURE MÉCANIQUE.

• Les travaux d’entretien non décrits dans le présent

manuel devraient être réalisés par un centre de service

agréé. Pour toute assistance, communiquer avec le

détaillant local ou le distributeur G&L Pumps.

VERROUILLER LA SOURCE DE

COURANT EN POSITION HORS

CIRCUIT AVANT DE PROCÉDER

À L’ENTRETIEN DE LA POMPE.

OMETTRE CETTE PRÉCAUTION

PEUT ENTRAÎNER UN CHOC ÉLECTRIQUE, DES BRÛLURES OU LA

MORT.

ANOMALIE

NON-FONCTIONNEMENT DU MOTEUR

(V. causes probables 1 à 5)

DÉBIT DE REFOULEMENT FAIBLE OU NUL

(V. causes probables 6 à 12)

CONSOMMATION D’ÉNERGIE EXCESSIVE

(V. causes probables 3, 12, 13 et 15)

VIBRATION ET BRUIT EXCESSIFS

(V. causes probables 3, 6 à 8, 10, 12, 13 et 16)

CAUSE PROBABLE

1. Protecteur thermique du moteur déclenché

2. Disjoncteur ouvert ou fusible sauté

3. Roue(s) bloquée(s)

4. Moteur mal connecté

5. Moteur défectueux

6. Pompe non amorcée, air ou gaz présent dans le

liquide pompé

7. Orifice d’aspiration ou tubulure ou tuyau de

refoulement obstrués, ou bien robinet(s) fermé(s)

8. Mauvais sens de rotation (moteurs triphasés

seulement)

9. Basse tension électrique ou perte de phase

10. Roue(s) usée(s) ou engorgée(s)

11. Hauteur de charge du système trop élevée

12. Hauteur nette d’aspiration disponible (NPSHA) trop

faible — hauteur ou perte d’aspiration excessives

13. Hauteur de refoulement trop faible — débit excessif

14. Viscosité ou densité trop élevées

15. Palier(s), coussinet(s) ou roulement(s) usé(s)

16. Pompe, moteur ou tuyauterie mal assujettis

Pression de service maximale (1SV à 4SV) :

1,6 MPa (16 bars, 230 lbf/po²), avec raccord de

refoulement ovale ;

2,5 MPa (25 bars, 360 lbf/po²), avec raccord de

refoulement à bride ANSI.

Température maximale du liquide :

110 °C (230 °F)

DÉMARRAGES PAR HEURE ET DURÉE DE MARCHE

MINIMALE — 3 Ø seulement

hp Nombre maximal de Durée de marche minimale

démarrages par heure (en secondes)

(répartis uniformément) entre les démarrages

1 15 75

1,5 13 76

2 12 77

3 9 80

5 8 83

7,5 7 88

10 6 92

15 5 100

20 5 110

25 5 115

30 4 120

40 4 130

50 3 145

60 3 170

75 3 180

NOTA

:

1) Le nombre maximal de démarrages par heure du moteur et sa durée de marche

minimale recommandés sont calculés d’après les normes NEMA MG1-12.44, conformément aux tolérances admissibles des fabricants en matières d’échauffement

et de rupture d’isolation.

2) La tension et la fréquence de courant sont appliquées selon les normes NEMA

MG1-12.44.

3) Les démarrages sont calculés pour des moteurs triphasés asynchrones (à induction)

NEMA à courant alternatif de types A et B.

4) La charge extérieure WK2 est égale ou inférieure aux valeurs données dans les

normes NEMA MG1-12.54.

5) Les données ci-dessus sont applicables à tous les moteurs à carcasses NEMA JM,

JP, T et TC utilisés pour les produits Goulds Pumps.

6) Le nombre de démarrages des MOTEURS MONOPHASÉS et leur durée de marche

sont fonction de quelques facteurs (la puissance du condensateur et son type, le

calibre et la longueur des fils ainsi que le type d’interrupteur) et ne seront pas les

mêmes que pour les moteurs triphasés.

19

Page 20

hp Ø Carcasse de moteur V (sur plaque signalétique) N

TEFC* 115 ou 230 56C V04722

½ ODP 230 ou 460 56C V04741

3 TEFC 230 ou 460 56C V04742

X-PROOF* 230 ou 460 56C V04743

TEFC 115 ou 230 56C V05722

¾ ODP 230 ou 460 56C V05741

X-PROOF 230 ou 460 56C V05743

TEFC à RS* 230 ou 460 56C V05742PE

TEFC 115 ou 230 56C V06722

1 ODP 230 ou 460 56C V06741

X-PROOF 230 ou 460 56C V06743

TEFC à RS 230 ou 460 56C V06742PE

TEFC 115 ou 230 56C V07722

ODP 230 ou 460 56C V07741

1½ TEFC 230 ou 460 56C V07742

3 X-PROOF 230 ou 460 56C V07743

ODP à RS 230 ou 460 56C V07741PE

TEFC à RS 230 ou 460 56C V07742PE

TEFC 115 ou 230 56C V08722

ODP 208 à 230 ou 460 56C V08741

2 TEFC 208 à 230 ou 460 56C V08742

3 X-PROOF 208 à 230 ou 460 56C V08743

ODP à RS 208 à 230 ou 460 56C V08741PE

TEFC à RS 208 à 230 ou 460 56C V08742PE

TEFC 115 ou 230 56C V09722

ODP 208 à 230 ou 460 56C V09741

3 TEFC 208 à 230 ou 460 56C V09742

3 X-PROOF 208 à 230 ou 460 56C V09743

ODP à RS 208 à 230 ou 460 56C V09741PE

TEFC à RS 208 à 230 ou 460 184TCH V09742PE

TEFC 208 à 230 184TCH V10722

ODP 208 à 230 ou 460 184TCH V10741

5 TEFC 208 à 230 ou 460 184TCH V10742

3 X-PROOF 230 ou 460 184TCH V10743

ODP à RS 208 à 230 ou 460 184TCH V10741PE

TEFC à RS 208 à 230 ou 460 184TCH V10742PE

TEFC 230 213TC V11722

ODP 208 à 230 ou 460 184TCH V11741

7½ TEFC 208 à 230 ou 460 184TCH V11742

3 X-PROOF 230 ou 460 184TCH V11743

ODP à RS 208 à 230 ou 460 184TCH V11741PE

TEFC à RS 230 ou 460 213TC V11742APE

TEFC 230 213TC V12722

ODP 208 à 230 ou 460 213TC V12741

10 TEFC 208 à 230 ou 460 215TC V12742

3 X-PROOF 230 ou 460 215TC V12743

ODP à RS 208 à 230 ou 460 213TC V12741PE

TEFC à RS 230 ou 460 215TC V12742PE

ODP 208 à 230 ou 460 215TC V13741

TEFC 208 à 230 ou 460 254TC V13742

15 3 X-PROOF 230 ou 460 254TC V13743

ODP à RS 208 à 230 ou 460 215TC V13741PE

TEFC à RS 208 à 230 ou 460 254TC V13742PE

ODP 230 ou 460 254TC V14741

TEFC 208 à 230 ou 460 256TC V14742

20 3 X-PROOF 230 ou 460 256TC V14743

ODP à RS 208 à 230 ou 460 254TC V14741PE

TEFC à RS 208 à 230 ou 460 256TC V14742PE

* ODP = abritée, RS = rendement supérieur, TEFC = fermée autoventilée, X-PROOF = antidéflagrante.

20

ODP* 115 ou 230 56C V04721

1

ODP 115 ou 230 56C V05721

1

TEFC 230 ou 460 56C V05742

3

ODP 115 ou 230 56C V06721

1

TEFC 230 ou 460 56C V06742

3

ODP 115 ou 230 56C V07721

1

ODP 115 ou 230 56C V08721

1

ODP 230 56C V09721

1

ODP 208 à 230 184TCH V10721

1

ODP 230 213TC V11721

1

ODP 230 213TC V12721

1

o

de carcasse No d’article Goulds

Page 21

COUPLE DE SERRAGE

1

4

2

7

10

11

8

16

17

3

13

18

5

15

12

14

6

9

15

Carcasse

hp

de moteur

¾ 56C 27 N·m (20 lbf·pi) 20 N·m (15 lbf·pi)

1 56C 27 N·m (20 lbf·pi) 20 N·m (15 lbf·pi)

1½ 56C 27 N·m (20 lbf·pi) 20 N·m (15 lbf·pi)

2 56C 27 N·m (20 lbf·pi) 20 N·m (15 lbf·pi)

3 56C 27 N·m (20 lbf·pi) 20 N·m (15 lbf·pi)

5 184TCH 27 N·m (20 lbf·pi) 20 N·m (15 lbf·pi)

7½ 184TCH 27 N·m (20 lbf·pi) 20 N·m (15 lbf·pi)

10 213TC

215TC

15 215TC

254 TC 65 N·m (48 lbf·pi) 65 N·m (48 lbf·pi)

20 254TC

256TC

Moteur-

adaptateur

61 N·m (45 lbf·pi) 40 N·m (30 lbf·pi) 40 N·m (30 lbf·pi)

61 N·m (45 lbf·pi)

61 N·m (45 lbf·pi) 65 N·m (48 lbf·pi) 65 N·m (48 lbf·pi)

Moteur-bride Accouplement

40 N·m (30 lbf·pi) 40 N·m (30 lbf·pi)

COUPLE DE SERRAGE

Pompe Tirants d’assemblage

1SV 30 N·m (22 lbf·pi) 20 N·m (15 lbf·pi)

2SV 30 N·m (22 lbf·pi) 20 N·m (15 lbf·pi)

3SV 50 N·m (37 lbf·pi) 20 N·m (15 lbf·pi)

4SV 50 N·m (37 lbf·pi) 20 N·m (15 lbf·pi)

Bouchons

(vidange et mise à l’air libre)

DESSIN ET PRINCIPAUX COMPOSANTS DES

SVI (1SV À 4SV)

1 Adaptateur de moteur et

tubulure de refoulement

2 Carter d’aspiration

3 Enveloppe extérieure

4 Crépine

5 Diffuseur

6 Premier corps d’étage

7 Jeu de diffuseurs et de

coussinets

8 Diffuseur du dernier étage

9 Roue

10 Arbre

11 Carter d’accouplement

12 Accouplement

13 Garniture mécanique

14 Tirant d’assemblage,

rondelle-frein et écrou

15 Vis de roue

16 Joint torique

17 Entretoise de roue

18 Moteur

21

Page 22

ITT

Industrie

GARANTIE LIMITÉE DE GOULDS PUMPS

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Goulds Pumps.

Toute pièce se révélant défectueuse durant la période de garantie sera remplacée sans frais pour le détaillant durant ladite période, qui dure

douze (12) mois à compter de la date d’installation ou dix-huit (18) mois à partir de la date de fabrication, soit la période qui expirera la

première.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Goulds Pumps agréé

chez lequel la pompe a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le

biais du service à la clientèle de Goulds Pumps.

La garantie ne couvre pas :

a) les frais de main-d’oeuvre ou de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

«

Distributeur» signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant

1)

d’intermédiaire entre Goulds Pumps et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

«

Détaillant» veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les

2)

activités commerciales sont la vente ou la location de pompes à des clients.

«

Client» signifie une entité qui achète ou loue les pompes en question chez un détaillant. Un «client» peut être une personne, une société de

3)

personnes, une société de capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque

activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

22

Goulds Pumps, G&L et le logo à blocs siglés ITT sont des

marques déposées et de commerce d’ITT Industries.

LES CARACTÉRISTIQUES PEUVENT CHANGER SANS PRÉAVIS.

IM170R02 Mars, 2006

© 2006, ITT Water Technology, Inc.

Engineered for life

Page 23

ITT

Goulds Pumps

SERIE G&L

MODELO SVI

Instrucciones de instalación,

funcionamiento y mantenimiento

Industria General

Goulds Pumps son una marca de fábrica de ITT Water

Technology, Inc. - un subsidiario de ITT Industries, inc.

www.goulds.com

Engineered for life

23

Page 24

TEMA PÁGINA

Sistema de numeración de la línea de productos SVI ................................................................................................... 25

Instrucciones de seguridad .......................................................................................................................................... 27

Instalación .................................................................................................................................................................. 27

Tubería ....................................................................................................................................................................... 27

Alineación del eje - Motor a la bomba ........................................................................................................................ 27

Cableado y conexión a tierra ...................................................................................................................................... 28

Operación .................................................................................................................................................................. 28

Mantenimiento ........................................................................................................................................................... 29

Desmontaje/Montaje

Recambio de la junta hermética mecánica ................................................................................................................ 29

Recambio del motor ................................................................................................................................................ 29

Localización de falla ................................................................................................................................................... 30

Datos de ingeniería ..................................................................................................................................................... 30

Datos sobre el motor .................................................................................................................................................. 31

Montaje por secciones del SVI .................................................................................................................................... 32

Declaración de Conformidad ...................................................................................................................................... 33

Garantía Limitada ...................................................................................................................................................... 36

Número de modelo de la bomba:

Número de serie de la bomba:

Número de modelo de control:

Vendedor:

Número telefónico del vendedor:

Fecha de compra: Instalación:

Lecturas actuales de la puesta en servicio:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Voltios: Voltios:

24

Page 25

SISTEMA DE NUMERACIÓN DE LA LÍNEA DE PRODUCTOS SVI

BOMBAS COMPLETAS

2 SV N 1 G 11 F H E 5 EJEMPLO DE CÓDIGO DE PRODUCTO*

➤

Opciones de juntas herméticas:

0 = Carburo de silicio estándar/Carbono/Viton

4 = Carburo de silicio/Carburo de silicio/Viton

5 = Carburo de tungsteno/Carburo de tungsteno/Viton

Conexión de descarga:

A = Perforación de brida ANSI D = Perforación de brida DIN E = NPT M = BSP

Tasas

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Impulsores

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Impulsor de arrastre

01 = 1PH, ODP, NEMA 07 = 3PH, XP, NEMA 13 = 3PH, 575V, TEFC, NEMA, MF**

02 = 3PH, ODP, NEMA 08 = 575V, XP, NEMA 14 = 1PH, 230V, TEFC, NEMA, MF**

03 = 575V, ODP, NEMA 09 = 3PH, TEFC, PE, NEMA 15 = 3PH, 220-255/380-440, IEC

04 = 1PH, TEFC, NEMA 10 = 1PH, XP, NEMA 16 = 3PH, 265-277/460-480, IEC

05 = 3PH, TEFC, NEMA 11 = 3PH, 200V, TE, NEMA, MF**

06 = 575V, TEFC, NEMA 12 = 3PH, 208-230/460V, TE, NEMA, MF**

**MF = Brida métrica

Régimen HP

C = ½ F = 1½ J = 5 M = 15 Q = 30

D = ¾ G = 2 K = 7½ N = 20

E = 1 H = 3 L = 10 P = 25

Hertz/RPM

1 = 60 Hz/3500 RPM

2 = 50 Hz/2900 RPM

Versión

S = Adaptador de motor CI/NEMA

X = Adaptador de motor CI/IEC

N = Adaptador de motor I/IEC de acero inoxidable

Línea de producto

Sumergido, vertical, inoxidable

Flujo nominal

1 = 15 GPM 3 = 55 GPM

2 = 28 GPM 4 = 86 GPM

* Todas las combinaciones no están disponibles.

25

Page 26

SISTEMA DE NUMERACIÓN DE LA LÍNEA DE PRODUCTOS SVI

EXTREMOS DE LÍQUIDO

2 SV N K F H E 5 T EJEMPLO DE CÓDIGO DE PRODUCTO

➤

Sufijo opcional:

T = Armazón del motor, tamaño mayor siguiente

Opciones de junta hermética:

0 = Carburo de silicio estándar/Carbono/Viton

4 = Carburo de silicio/Carburo de silicio/Viton

5 = Carburo de tungsteno/Carburo de tungsteno/Viton

Conexión de descarga

E = NPT M = BSP

Tasas

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Impulsores

A = 1 E = 5 J = 9 N = 13

B = 2 F = 6 K = 10 P = 14

C = 3 G = 7 L = 11 Q = 15

D = 4 H = 8 M = 12 R = 16

Extremo de líquido

Versión

S = Adaptador de motor CI/NEMA

X = Adaptador de motor CI/IEC

N = Adaptador de motor I/IEC de acero inoxidable

Línea de producto

Sumergido, vertical, inoxidable

Flujo Nominal

1 = 15 GPM 3 = 55 GPM

2 = 28 GPM 4 = 86 GPM

26

Page 27

INSTRUCCIONES DE SEGURIDAD

PELIGRO

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

Los fluidos peligrosos

pueden causar

incendios, quemaduras

o la muerte.

PARA EVITAR LESIONES PERSONALES GRAVES O

FATALES, Y DAÑOS SIGNIFICATIVOS A LA PROPIEDAD, LEA Y SIGA TODAS LAS INSTRUCCIONES

DE SEGURIDAD QUE SE ENCUENTRAN EN ESTE

MANUAL O EN LA BOMBA.

ESTE MANUAL TIENE LA FUNCIÓN DE ASISTIRLO

EN LA INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y DEBE CONSERVARSE CON LA BOMBA.

Éste es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

sobre la bomba o en el manual, localice

una de las siguientes palabras de señalización y esté alerta ante posibles lesiones personales o daños a la propiedad.

Advierte sobre los peligros que PROVO-

CARÁN lesiones graves, muerte o daños

significativos a la propiedad.

Advierte sobre los peligros que

PUEDEN PROVOCAR lesiones graves,

muerte o daños significativos a la

propiedad.

Advierte sobre los peligros que PRO-

VOCARÁN o PUEDEN PROVOCAR

lesiones o daños a la propiedad.

AVISO: INDICA QUE EXISTEN INSTRUCCIONES

ESPECIALES MUY IMPORTANTES QUE

DEBEN RESPETARSE.

EXAMINE COMPLETAMENTE TODAS LAS INSTRUCCIONES Y ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN ESTA BOMBA.

CONSERVE TODAS LAS CALCOMANÍAS.

ESTA UNIDAD NO SE ENCUENTRA

DISEÑADA PARA SER USADA CON

LÍQUIDOS O GASES INFLAMABLES.

ESTOS FLUIDOS PUEDEN ESTAR

PRESENTES EN ÁREAS CONTAMINADAS.

Los tubos de descarga no deben ser más pequeños

•

que la abertura correspondiente de la bomba y deben

mantenerse tan cortos como sea posible, evitando

adaptadores innecesarios para minimizar las pérdidas

por fricción.

AVISO: LA TUBERÍA DEBE TENER SOPORTES IN-

DEPENDIENTES. NO DEBEN COLOCARSE

TUBOS SOBRE LA BOMBA.

Asegúrese de que el tamaño y la mínima inmersión del

•

líquido, sobre la entrada de succión, sea sufi ciente para

impedir que el aire entre a través del vórtice de succión. Vea la tubería de succión típica, Figuras 1 y 2.

Instale una válvula de retención en la descarga, adec-

•

uada para manejar el caudal y líquidos, para impedir el

contrafl ujo.

Instale una válvula de compuerta bien dimensionada,

•

DESPUÉS de la válvula de descarga, para regular la

capacidad de la bomba, para la inspección y mantenimiento de la bomba.

Cuando se necesite una prolongación de tubería,

•

colóquela entre la válvula de contención y la descarga

de la bomba.

D

8D

mín.

4D

mín.

H mín.

3D

3D

2

mín.

3D

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

H = Mín. inmersión en pies

1

0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 V

V = Velocidad en pies/segundo

=GPM x 0.321

Área

GPM x 0.4085

2

D

Figura 1 Figura 2

•

•

•

AVISO: NO ESTIRE LA TUBERÍA EN EL LUGAR

Proporcione espacio y ventilación adecuados alrededor

de la unidad para darle servicio y enfriamiento al motor.

Proteja la bomba y la tubería de las temperaturas de

congelación.

La unidad DEBE estar sujeta fi jamente a una cimen-

tación a nivel de concreto o base metálica, adecuada

para absorber las vibraciones y proporcionar un apoyo

rígido y permanente del conjunto de la bomba y el motor. Vea la sección de “DATOS TÉCNICOS” de este

manual para los pesos de modelos específi cos y dimensiones de la base de la bomba.

FORZANDO LAS CONEXIONES DE LA

SUCCIÓN O DESCARGA DE LA BOMBA.

Cuando se compra la bomba sin el motor, la bomba

•

será provista con conjunto de compensación del motor,

puesta entre el adaptador del motor y el acoplamiento.

Para montar el motor a la bomba, quite las correas de

•

embarque de plástico, las dos mitades del resguardo

del acoplamiento de acero inoxidable, y el poliuretano

expandido.

Asegúrese que el conjunto de compensación del motor

•

esté ubicado correctamente entre el acoplamiento y el

adaptador de motor. Si no se cuenta con un conjunto

de compensación de motor, se puede utilizar una cuña

de 0,203” (5 mm) para ubicar el montaje del eje de la

bomba y colocarla a la altura correcta.

Para los tamaños de armazón de motor 213TC y más

•

grandes, fije la brida del adaptador de motor utilizando

4 tornillos de cabeza hexagonal. Ajuste hasta alcanzar

los valores de torque detallados en la sección “DATOS

DE INGENIERÍA” en este manual.

Afloje los 4 tornillos de cabeza hueca del acoplamiento,

•

lo suficiente para proporcionar una abertura adecuada

en el acoplamiento para recibir el eje del motor.

27

Page 28

Con una grúa del tamaño adecuado, baje el montaje del

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

Tensión

p

eligrosa

ADVERTENCIA

208-230V 3/60 460V 3/60

4

5

6

1

7

2

8

3

9

L

1

L

2

L

3

4

7

5

8

6

9

1

2

3

L

1

L

2

L

3

G

G

CONDUCTORES DEL MOTOR

CABLES CONDUCTORES DE CORRIENTE

DIAGRAMA DEL CABLEADO DEL MOTOR TRIFÁSICO

CONDUCTORES DEL MOTOR

CABLES CONDUCTORES DE CORRIENTE

Las maquinarias

peligrosas pueden

causar lesiones

personales o la muerte.

ADVERTENCIA

ADVERTENCIA

El calor extremo puede

causar lesiones

personales o daños

materiales.

Máquina

Peligrosa

ADVERTENCIA

•

motor con cuidado sobre el adaptador de motor de la

bomba y dentro del acoplamiento. Ajuste los 4 tornillos de cabeza hexagonal hasta alcanzar los valores de

torque detallados en la sección “DATOS DE INGENI-

ERÍA” en este manual.

Apriete con los valores de torsión dados en la sección

•

“DATOS DE INGENIERÍA” de este manual, los 4

tornillos de cabeza hueca.

Quite el conjunto de compensación de motor y con-

•

sérvelo para usos futuros.

Instale las 2 mitades de protección del acoplamiento.

•

La alimentación eléctrica DEBE estar de acuerdo

con las especifi caciones de la placa del fabricante.

La tensión incorrecta puede causar incendio, dañar el motor y anular la garantía.

Los motores trifásicos requieren protección de

circuito derivado con arrancadores magnéticos

y sobrecargas térmicas adecuados. Esto puede

causar que la bomba arranque inesperadamente y

sin advertencia.

Use sólo alambre de cobre trenzado al motor y a tierra.

•

El tamaño del alambre DEBE limitar la máxima caída

de tensión a 10% de la tensión de la placa del fabricante del motor, a los terminales del motor. La caída

de tensión excesiva afectará el rendimiento y anulará la

garantía del motor. El alambre a tierra DEBE ser por

lo menos tan grande como los alambres al motor. Los

alambres deben ser de color codifi cado para facilitar el

mantenimiento.

Los motores trifásicos requieren protección en todos

•

los alambres exteriores con arrancadores magnéticos y

sobrecargas térmicas dimensionados apropiadamente.

CONECTE A TIERRA PERMANENTEMENTE LA BOMBA, EL

MOTOR Y LOS CONTROLES DE

•

•

28

Conecte los conductores eléctricos al motor, como

sigue:

Motores monofásicos - Conecte el alambre NEGRO

al alambre NEGRO del motor. Conecte el alambre

BLANCO al alambre BLANCO del motor. Conecte el

alambre VERDE al alambre VERDE del motor.

ACUERDO CON LOS CÓDIGOS

NACIONAL Y LOCAL DE ELECTRICIDAD, ANTES DE CONECTAR A LA

ALIMENTACIÓN ELÉCTRICA. LA

OMISIÓN DE ESTO PUEDE CAUSAR

CHOQUES, QUEMADURAS O LA

MUERTE.

Instale la conexión a tierra y

el cableado de acuerdo con

los requerimientos del Código

Nacional de Electricidad.

Instale un interruptor de

desconexión de todos los circuitos derivados cerca de la bomba.

Desconecte y bloquee la alimentación eléctrica antes de instalar

o dar servicio a la bomba.

Motores trifásicos - Vea la Figura 3.

•

Figura 3

AVISO: LA ROTACIÓN DE LA UNIDAD ES EN

SENTIDO DEXTRORSO CUANDO SE MIRA

DESDE EL EXTREMO DEL MOTOR. LA

ROTACIÓN INCORRECTA PUEDE CAUSAR

DAÑOS A LA BOMBA Y ANULAR LA GARANTÍA.

Verifi que la rotación de la bomba observando el

•

ventilador del motor o el acoplamiento A TRAVÉS del

resguardo del acoplamiento. NO confunda las flechasdel caudal, estampadas en el cuerpo de la bomba, con

las flechas de rotación en el acoplamiento y el adaptador del motor. Sólo en los motores trifásicos - si la

rotación es incorrecta, con un electricista calificado

mande intercambiar dos cualesquiera de los tres cables

conductores de corriente.

NO HAGA FUNCIONAR SIN LA

UNIDAD EL RESGUARDO DE SEGURIDAD INSTA-LADO. HACERLO

PUEDE CAUSAR SEVERAS LESIONES

CORPORALES.

AVISO: LA BOMBA DEBE ESTAR COMPLETAMENTE

CEBADA ANTES DEL FUNCIONAMIENTO.

NO HAGA FUNCIONAR LA BOMBA