tekmar 511 Installation

- Data Brochure

D 510

Programmable Thermostat 510 and 511

02/12

Replaces: 09/09

Table of Contents

Display / Keypad Operation ............ pg 1

Display Symbols ............................. pg 2

General ........................................ pg 2-3

Sequence of Operation................... pg 4

Installation - Slab Sensor 079 ...... pg 5-7

Installation - Thermostats ............pg 8-9

Wiring Examples ........................ pg 9-10

This brochure is for Thermostats 510 and 511 (with sensor). The section on the 079 slab

sensor installation is for the 511 only!

Menus ....................................... pg 11-13

View Menu ...............................pg 11

Adjust Menu ......................pg 11-13

Error Messages ..................... pg 14

Technical Data .............................. pg 15

Warranty ....................................... pg 16

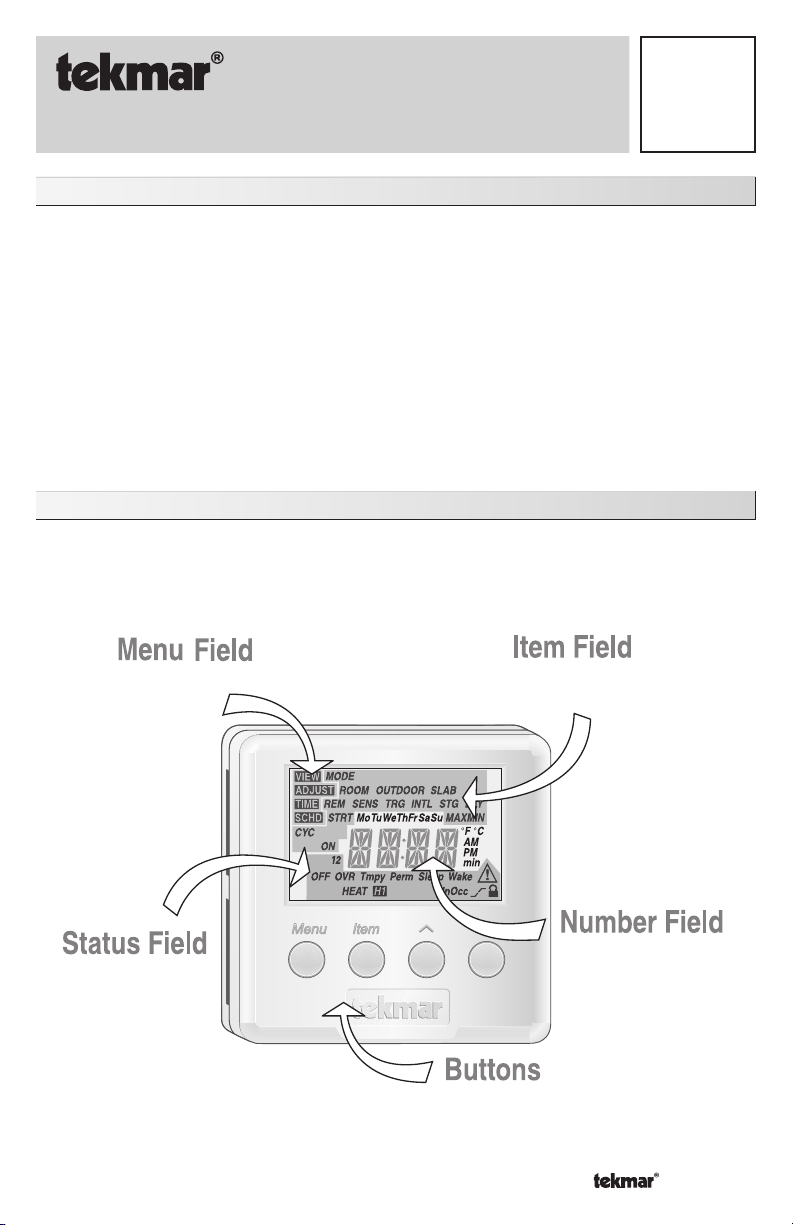

Display / Keypad Operation

The thermostat’s display has four distinct fields. These fields are the Menu field, the Item

field, the Number field and the Status field. The four buttons on the face of the thermostat are

used to navigate through the menus and items to view and / or adjust the desired settings.

Displays the

current

menu

Displays an abbreviated

name of the selected item

Displays the current value

Displays the current

status of the

thermostat's inputs,

outputs and operation

Selects Menus, Items

and adjusts settings

1 of 16 © 2012 D 510 - 02/12

of the selected item

Display Symbols

Warning

Displays when an error exists.

Heat One

Displays when the heat contac t

is on.

Access Level

Displays when in the user

access level.

Early Start

Displays when the thermostat

is in early start.

General

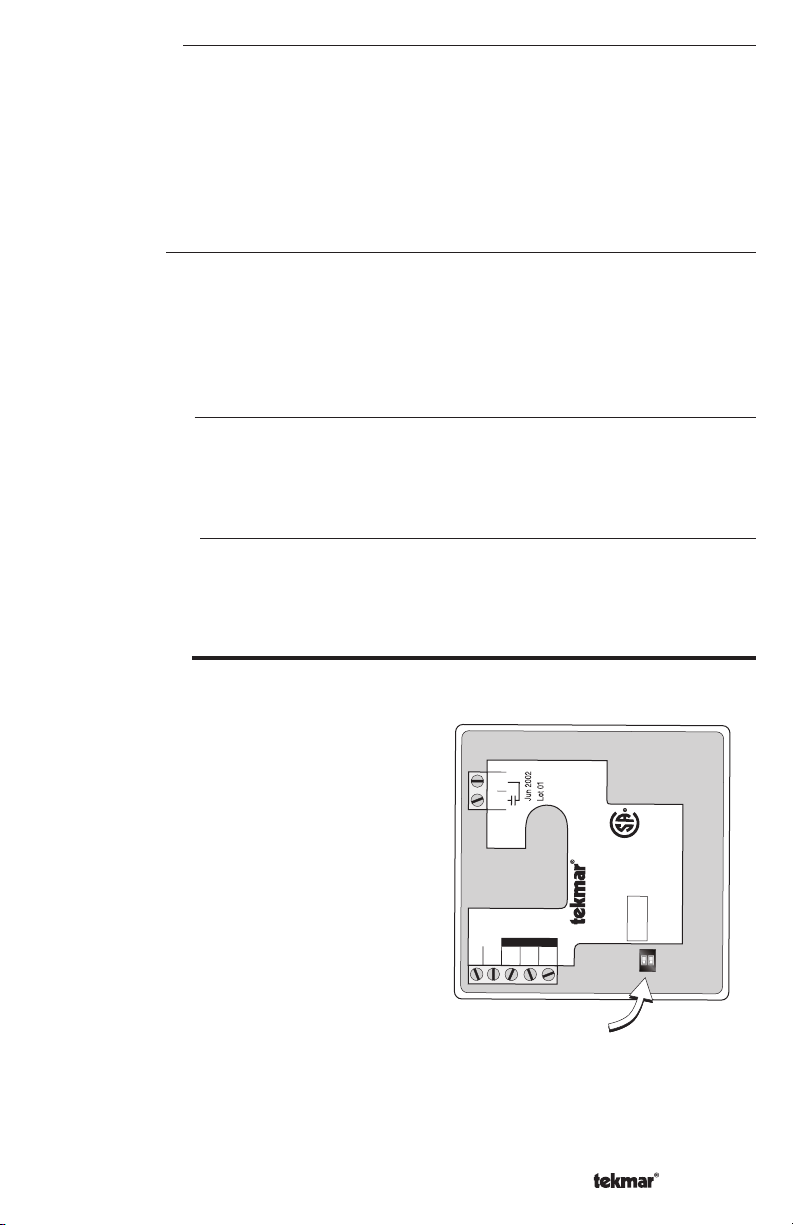

CYCLES PER HOUR (HEAT CYCLE)

The thermostat operation is based on cycles per hour. The number of cycles per hour is

adjustable through the HEAT CYCLE settings in the Adjust menu. During each cycle that

heating is required, the thermostat turns on the Heat relay for a calculated amount of time.

This amount of time is the “on time”. The on time is calculated based on the requirements of

the zone. If the zone requires more heating, the ON time is increased. If the zone requires

less heat, the ON time is reduced.

In order to prevent short cycling of the heating relay(s), the thermostat ensures that the

relay(s) remains on or off for a minimum amount of time.

An Auto Cycle setting is available for the

heating cycle. This setting allows the

thermostat to determine the best number of

cycles per hour that balances both temperature

swings and equipment cycles.

Cycles Per Hour

on onon

offoff

⇐ Cycle Length ⇒

Time

off

EARLY START ( )

The early start function ensures that the

zone is up to the proper temperature at the

beginning of each period. The thermostat

learns the recovery rate over multiple setback

events in order to determine the proper lead

time for the zone. If both an air sensor and

70°F (21°C)

62°F (17°C)

70°F (21°C)

Early Start OFF

Early Start ON

a slab sensor are used, the lead time is the

greater of the air sensor’s or the slab sensor’s

requirements.

62°F (17°C)

UnOccupied

Occupied

NOTE: The Early Start feature occurs when the schedule changes from a low temperature

to a higher temperature.

AUXILIARY SENSORS

The thermostat has a single built-in sensor to measure air temperature at the thermostat. In

addition to the built-in sensor, the thermostat has terminals to connect up to two separate

sensors. These sensors can be either indoor sensors, slab sensors, a remote sensor, or

an outdoor sensor.

© 2012 D 510 - 02/12 2 of 16

Indoor Sensor

An indoor sensor is used to measure the air temperature in the zone that the thermostat is

controlling. The temperature being read by the indoor sensor is used in the calculations of

the on times for the relay in the thermostat. Either one or both of the auxiliary sensor inputs

can be configured for indoor sensors. This setting is made through the Adjust menu of the

thermostat. If more than one sensor, either the built-in sensor or an auxiliary sensor set as

an indoor sensor, is being used to measure the zone temperature, the temperature of the

active sensors is averaged and used to calculate the on time of the relay.

Slab Sensor

A slab sensor is used to measure the slab temperature in the zone that the thermostat

is controlling. The temperature being read by the slab sensor is used in the calculations

of the on time for the Heat relay and allows the thermostat to operate the slab between

the slab minimum and slab maximum settings. If more than one slab sensor is used, the

slab temperatures are averaged by the thermostat.

Remote Sensor

A single remote sensor can be connected to the thermostat. The temperature measured

by a remote sensor does not affect the on time of the relay and is only used for display

purposes.

Outdoor Sensor

A single outdoor sensor can be connected to the thermostat. The temperature measured

by an outdoor sensor does not affect the on time of the relay and is only used for display

purposes.

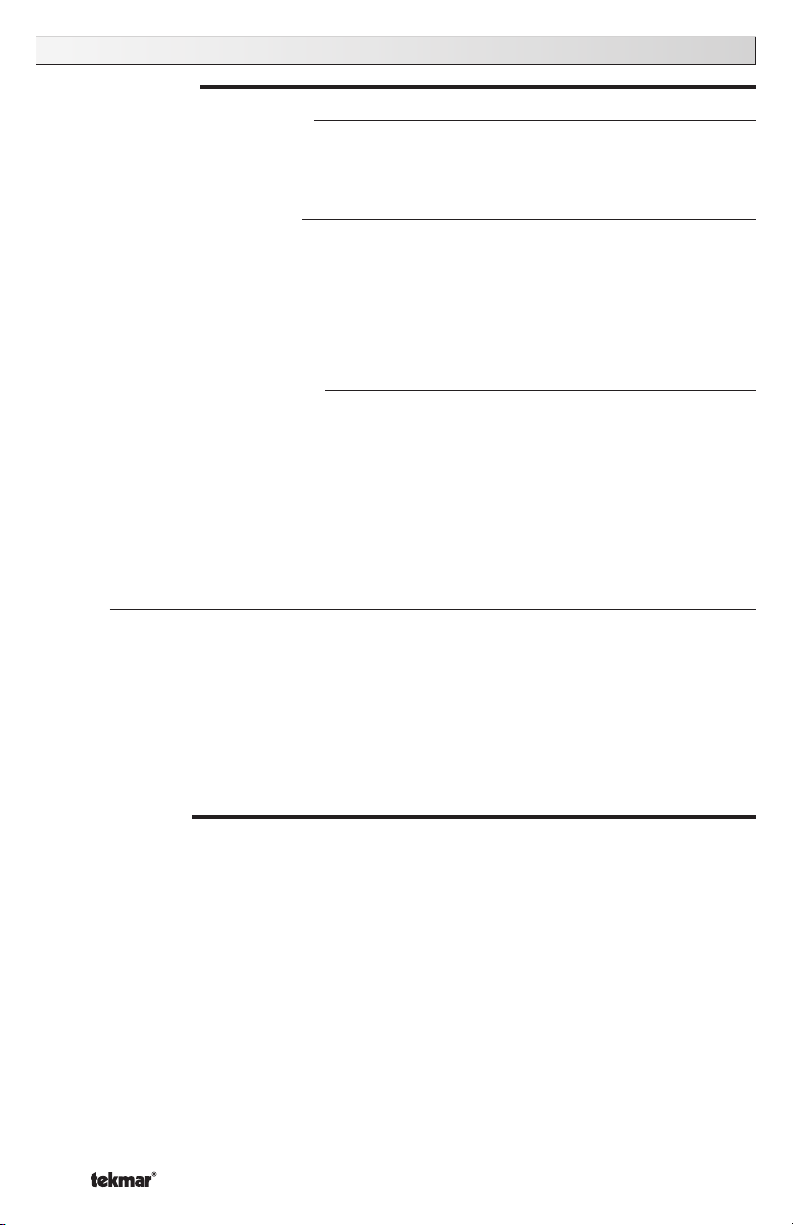

ACCESS LEVELS

The tekmar Programmable Thermostat has two

access levels. These access levels restrict the

number of items available in the menus of the

thermostat. The two access levels are User and

Installer. This selection is made using the DIP

switch located on the circuit board inside the

thermostat.

The Installer access level allows the installer to

adjust all of the settings in the thermostat including

those required to match the thermostat to the

mechanical system and the devices used.

The User access level allows the end user to

adjust the time, temperatures and schedules

6

Heat

7

1

2

R

C

Com

3

No Pow

Made in Canada

Meets Class B:

Canadian ICES

FCC Part 15

er

4

5

S1

S2

Programmable Thermostat 510

One Stage Heat

Switch Settings:

US

C

Installer/User

938-01

510

60 Hz 3 VA

V (ac) 2 A

Power: 24 V ± 10%

Relay: 24

Class 2

used by the thermostat.

Dip Switch

3 of 16 © 2012 D 510 - 02/12

Sequence of Operation

ONE STAGE HEAT

Air Sensor(s) Only Operation

When operating with only an air sensor, the on time for the Heat relay is calculated to

satisfy the requirements of the air sensor.

Slab Sensor Only Operation

When operating with only a slab sensor, the on time for the Heat relay is calculated to

satisfy the requirements of the slab sensor. The thermostat operates to maintain the slab

at the minimum slab temperature setting.

NOTE: Operating with only a slab sensor can lead to either overheating or underheating

of the space.

Air and Slab Sensor Operation

When operating with both air and slab sensors, the thermostat calculates an on time for

the Heat relay to satisfy the slab sensor’s requirements and an on time to satisfy the air

sensor’s requirements. The Heat relay operates for the longer of these two on times.

During light heating loads, overheating can occur due to the minimum slab temperature

requirements.

During heavy heating loads, the maximum slab temperature setting limits the on time of

the Heat relay. In this situation, underheating can occur.

Mode

Heat In the heat mode, the Heat relay is operated to satisfy the temperature requirement

of the zone.

Off In the Off mode, the Heat relay is not operated.

NOTE: If an air or slab sensor is active in the Off mode, a freeze protection is enabled

that allows the Heat relay to be operated to keep the zone above 35°F (2°C).

GETTING READY

Check the contents of this package. If any of the contents are missing or damaged, please

contact your wholesaler or tekmar sales representative for assistance.

Type 510 Includes: •• One Programmable Thermostat 510 •• Data Brochure D 510 •• User

Brochure U 510

Type 511 Includes: •• One Programmable Thermostat 510 •• One Slab Sensor 079 •• Data

Brochure D 510 •• User Brochure U 510

© 2012 D 510 - 02/12 4 of 16

Slab Sensor 079

The tekmar Slab Sensor 079 has a stainless steel sleeve which is designed for use in

concrete, thin-set or grout. The 079 is supplied with 10’ (3 m) of 2 conductor zipcord.

Installation - Slab Sensor 079

STEP ONE

INSTALLING THE SENSOR

New Installations

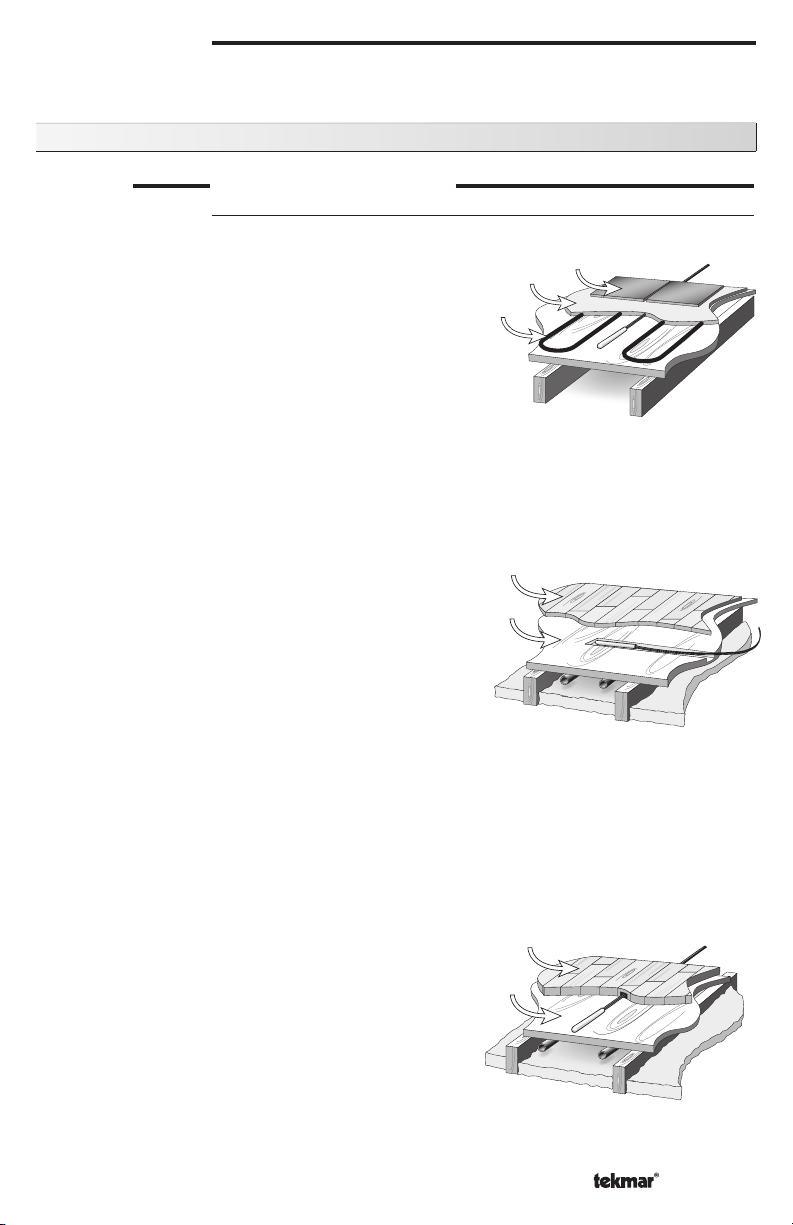

Thin-Set or Thin-Pour Applications

If the floor covering is to be installed over either

a thin-set or thin-pour material of sufficient

depth, the 079 slab sensor can be placed

Electric

Cables

Thin-set

Tiles

directly into either the thin-set material or the

thin-pour material and covered over. Ensure

that the sensor is located in such a position that

the attached wire is able to reach to a suitable

junction location. Splices within the thin-set or

thin-pour should be avoided to ensure trouble free operation. The sensor should be located

mid way between the heating elements to ensure a proper temperature reading.

Thin Floor Coverings (less than 3/8” (10 mm))

If a thin floor covering is to be installed directly

to the subfloor, a groove 1/8” (4 mm) wide by

Hardwood

1/16” (2 mm) deep can be cut into the surface of

the subfloor to accommodate the wire for the

Subfloor

sensor. Ensure that the sensor is located in

such a position that the attached wire is able

to reach to a suitable junction location. Splices

under the floor covering should be avoided to

ensure trouble free operation. A groove 3/16”

(5 mm) wide by 3/16” (5 mm) deep by 1-3/4”

(45 mm) long should be cut to accommodate the sensor. The sensor should be located

mid way between the heating elements to ensure a proper temperature reading.

Thick Floor Coverings (greater than 3/8” (10 mm))

If a thick floor covering is to be installed directly to the subfloor, a groove 1/8” (4 mm) wide

by 1/16” (2 mm) deep can be cut into the back of the flooring material to accommodate

the wire for the sensor. Ensure that the sensor is located in such a position that the

attached wire is able to reach to a suitable junction location.

Splices under the floor covering should be

avoided to ensure trouble free operation. A

groove 3/16” (5 mm) wide by 3/16” (5 mm)

Hardwood

Subfloor

deep by 1-3/4” (45 mm) long should be cut to

accommodate the sensor. The sensor should be

located mid way between the heating elements

to ensure a proper temperature reading.

NOTE: If it is not practical to cut a groove in the surface covering, follow the installation

method used for thin floor coverings.

5 of 16 © 2012 D 510 - 02/12

Loading...

Loading...