Page 1

•

•

•

- Data Brochure

D 481

tekmarNet®4 User Switch 481

1

Information

Brochure

Choose controls

to match

application

2

Application

Brochure

Design your

mechanical

applications

3

Rough In

Wiring

Rough-in

wiring

instructions

4

Wiring

Brochure

Wiring and

installation of

specific control

5

Data

Brochure

Control settings

and sequence of

operation

Introduction

The User Switch 481 has 3 programmable buttons that allow

users to easily change the operating scene or allow users

to enable / disable tN4 setpoint controls on a tN4 system.

Multiple User Switches are required if more than 3 scenes

or setpoint enable / disables are desired.

The 481 has 3 output relay contacts that allow for connection

to alarm systems or paging systems to alert service personnel.

The output relay contacts can also be used to indicate the

scene of the tN4 system to an automation system.

Features

• tN4 Compatible

• 3 User buttons

• 3 Programmable Output

Relay Contacts

- Output for Critical Alert

- Output for Non Critical

Alert

- Output for Scenes

- Output for Enable /

Disable Signal

User

Button

1

User

Button

2

User

Button

3

07/09

6

Job

Decora cover plate not included

Record

Record settings &

wiring details for

future reference

1 of 12 © 2009 D 481 - 07/09

Page 2

Table of Contents

Table of Contents .............................. 2

User Interface ................................... 2

Sequence of Operation ..................... 2

Three User Buttons ..................... 2

Programming the User Buttons .... 4

Output Relay Contacts and

Applications Using Multiple

480 & 481 Together ..........................9

Cleaning the User Switch .............. 10

User Button Label Template ........... 10

Error Messages .............................. 11

Warranty ......................................... 12

DIP Switches .................................... 7

User Interface

The User Switch has a total of 5 buttons.

User Buttons 1, 2, and 3 allow for users to select the operation of the tN4 system.

Buttons A and B allow the installer to program the operation of User Buttons 1, 2,

and 3.

BUTTON

A

User

Button

1

User

Button

2

User

Button

3

BUTTON

B

Factory Defaults:

User Button 1

Scene = 1

Label = Normal

User Button 2

Scene = 3

Label = Unoccupied

User Button 3

Scene = 2

Label = Away

Sequence of Operation

Three User Buttons

The User Switch provides users with a simple interface to change the operating

scene of the tN4 system or provide an enable / disable to tN4 setpoint controls. The

481 has 3 User Buttons and 3 output relay contacts.

© 2009 D 481 - 07/09 2 of 12

Page 3

The 3 User Buttons provide the ability to:

1) Select a scene for the tN4 system

The User Buttons allow users to select the scene of the tN4 system. Each of the 3

User Buttons is programmed by the installer to select a particular scene on the tN4

system. The temperature of each tN4 thermostat in the system is pre-programmed

by the installer for each of the scenes. This allows users to change the temperature

of all the thermostats using a single button.

tN4 thermostats and tN4 setpoint controls must have Scenes turned to “On” in order

to respond to scene changes on the User Switch.

When a User Button is pressed, the green LED under that button turns on and

remains on until a new scene is selected, or the time for the selected temporary

scene expires.

When the current selected scene on the tN4 network is the same as the scene that

the User Button is programmed for, the button turns green.

When a selected scene is “On” and that User button is pressed again, the scene is

changed based on the following table:

Current Scene

Press the

Same Button

New Scene

Perm Scene 1 No Change

Perm Scene 2 - Away Selects Scene 1

Perm Scene 3 - Unoccupied Selects Scene 1

Perm Scene 4 Selects Scene 1

Perm Scene 5 Selects Scene 1

Tmpy Scene 6 - Occupied Selects previous perm scene

Tmpy S c ene 7 Selects previous perm scene

Tmpy S c ene 8 Selects previous perm scene

Application Examples:

Allows residential users to change the scene to 2 (Away) while going on vacation,

or select an occupied scene while entertaining guests.

Allows commercial users a simple way to allow staff to override the night setback

/ setup schedule on the tN4 system.

3 of 12 © 2009 D 481 - 07/09

Page 4

2) Provide a setpoint device enable

Each of the 3 User Buttons can be programmed to enable or disable one or more

tN4 setpoint controls on the tN4 bus. The installer programs a setpoint device enable

number for one of the User Buttons. In turn, the installer programs a tN4 setpoint

control with the same setpoint device enable number. This allows users to enable

or disable a tN4 setpoint control by pressing a single button. Multiple tN4 setpoint

controls can be enabled or disabled from the same User Switch button.

The tN4 setpoint control operates for the “Occupied Time” or until the User Button

is pressed once again to cancel the operation. The User Button is green when the

tN4 setpoint device is in operation. Should the tN4 setpoint control be unable to

operate, the button turns red for 5 seconds and then the button light is turned off.

See the tN4 Setpoint Control Data Brochure for more information on the setpoint

control operation.

Application Examples:

A user can remotely enable a tN4 setpoint control to heat a hot tub or sauna.

A user can remotely enable a tN4 setpoint control to heat a garage or

workshop.

3) Disabled Button

The User Button can be disabled so that it does not function when pressed.

In certain cases, the disabled button can be used to close the corresponding relay

contact. See the “Button Operation” section for more information.

Programming the User Buttons

STEP 1

Remove the plastic trim bezel.

© 2009 D 481 - 07/09 4 of 12

Button

Button

Button

User

1

User

2

User

3

Page 5

STEP 2

•

•

•

User

Press button “A” once using a blunt object to begin

programming mode.

Each of the 3 User Buttons will begin to flash to indicate

the current program setting:

• Red flashes indicate the User Button is programmed

PRESS

BUTTON

A

Button

Button

Button

1

User

2

User

3

to select a scene. The number of flashes in a row

indicate the scene number.

• Green flashes indicate the User Button is programmed to enable or disable a

tN4 setpoint control. The number of flashes in a row indicate the setpoint device

enable number.

• Orange indicates the User Button has been disabled.

STEP 3

Press and hold down the User Button until the button changes to the color of

operation that is desired and then release the button.

Red = Scene

Green = tN4 Setpoint Control Enable / Disable

Orange = Disabled Button

STEP 4

(Scene Operation, Red Flashes)

Press the User Button the number of times equal to the desired scene.

Press “User”

Button

Scene Red Light Flash

Sequence

1 Time 1 1 Red, Off, Repeat

2 Times 2 (Away) 2 Red, Off, Repeat

3 Times 3 (Unoccupied) 3 Red, Off, Repeat

4 Times 4 4 Red, Off, Repeat

5 Times 5 5 Red, Off, Repeat

6 Times 6 (3 hr. Temporary Occupied) 6 Red, Off, Repeat

7 Times 7 (4 hr. Temporary) 7 Red, Off, Repeat

8 Times 8 (8 hr. Temporary) 8 Red, Off, Repeat

5 of 12 © 2009 D 481 - 07/09

Page 6

STEP 4 (Continued)

(Setpoint Device Enable, Green Flashes)

Press the User Button the number of times equal to the desired setpoint device

enable number.

Press “User” Button Setpoint Enable Green Light Flash Sequence

1 Time 1 1 Green, Off, Repeat

2 Times 2 2 Green, Off, Repeat

3 Times 3 3 Green, Off, Repeat

4 Times 4 4 Green, Off, Repeat

5 Times 5 5 Green, Off, Repeat

6 Times 6 6 Green, Off, Repeat

7 Times 7 7 Green, Off, Repeat

8 Times 8 8 Green, Off, Repeat

9 Times 9 9 Green, Off, Repeat

10 Times 10 10 Green, Off, Repeat

11 Times 11 11 Green, Off, Repeat

12 Times 12 12 Green, Off, Repeat

STEP 5

Press button “B” to finalize the User Button setting and

exit the programming mode.

Note: To return to Step 2 without saving the setting,

press button “A”.

STEP 6

Repeat steps 2 through 5 to program each User

Button.

STEP 7

Included with the User Switch are labels to identify

the operation of each User Button. Each label has a

description on it. Choose the label with the appropriate

description for each button.

A template has been included on Page 10 to create

your own labels.

Insert the label into the slot located under the right

hand side of each User Button.

Repeat for each User Button.

© 2009 D 481 - 07/09 6 of 12

Button

Button

Button

User

1

User

2

User

3

PRESS

BUTTON

B

User

Button

1

User

Button

2

User

Button

3

Page 7

STEP 8

1

ON

OFF

123

Replace the trim bezel.

Output Relay Contacts and DIP Switches

The functionality of the 3 dry relay contacts

on the User Switch 481 are determined by

the settings of DIP switches 1, 2 and 3. Dip

switches 1 and 2 select the mode of operation

for relay outputs.

1014-01

Relays

Rly

Pwr

123

tN4 User Switch 481

Three Outputs

Power: 24 V ± 10% 50/60 Hz 4 VA

Relays: 30 V (ac) 1A

Use at least 194°F

(90°C) conductors

For product

instructions

see brochure

CRtN4

OFF

1

tN4

Meets Class B:

Canada

• Canadian ICES

• FCC Part 15

ON

123

User

Button

1

User

Button

2

User

Button

3

DIP Switches

Permanent or Momentary Contact Closure

DIP switch 3 = OFF (Permanent)

DIP switch 3 = ON (Momentary)

The output relay contacts can close momentarily for 5 seconds and then re-open or

the relay contacts can close permanently. Use DIP switch 3 to select either Momentary

or Permanent. Momentary closure is often used in alarm systems. Permanent is

the factory default setting.

Alert and Scene Status

DIP switch 1 = OFF

DIP switch 2 = OFF

DIP switch 3 = Permanent or Momentary

Relay contact 1 closes to provide an alert when there is an error message present

on the tN4 system.

Relay contact 2 closes while the scene is set to Away (Scene 2).

Relay contact 3 closes while the scene is set to Scene 3.

Application Examples:

The relay contacts can connect to a third party alarm system or automation system

to provide the status of the tN4 system.

Relay contact 2 can connect to a non-tN4 snow melt control (664, 665, 667) to

provide an Idle Demand. The snow melt control Idle temperature is set to OFF.

While the tN4 system is in Away (scene 2), the snow melt control is prevented

from entering the melting operation.

7 of 12 © 2009 D 481 - 07/09

OFF

OFF

ON

ON

Page 8

OFF

Critical and Non-Critical Alert Levels

ON

DIP switch 1 = ON

DIP switch 2 = OFF

DIP switch 3 = Permanent or Momentary

Relay contact 1 closes while a non-critical error message is present on the tN4

system. A non-critical error allows the heating system to continue to operate.

Relay contact 2 closes while a critical error message is present on the tN4 system.

The critical errors are:

1) Adjust EEPROM error on any device.

2 Boiler supply sensor open or short circuit.

3) Mix supply sensor open or short circuit.

4) A thermostat has no air or floor temperature sensor reading.

Relay contact 3 is not used.

Application Example:

The relay contacts can connect to a third party paging device that, when activated,

pages a service technician when a critical error message is present.

Button Operation

OFF

ON

DIP switch 1 = OFF

DIP switch 2 = ON

DIP switch 3 = Permanent or Momentary

Each relay contact is synchronized with the corresponding User Button. When a

button is pressed or the scene is changed to the User Button’s programmed scene,

the relay contact closes.

Application Examples:

The relay contacts can connect to a third party automation system to indicate that

one of the User Buttons has been activated.

The User Button can be programmed to the “disabled” button operation. When the

User Button is pressed, the light turns green and the corresponding output relay

contact can activate lighting, security cameras, alarms or power a melt demand

on a non-tN4 snow melt control (664, 665, 667) to manually start snow melting.

OFF

Scene Signal

ON

DIP switch 1 = ON

DIP switch 2 = ON

DIP switch 3 = Permanent or Momentary

The relay contacts operate in combinations in order to communicate the current tN4

scene to third party devices. The contacts operate according to the following table:

© 2009 D 481 - 07/09 8 of 12

Page 9

Scene 1 2 3 4 5 6 7 8

Contact 1

Contact 2

Contact 3

Application Example:

The relay contact can connect to a third party automation system to indicate the

current tN4 scene.

Off On Off On Off On Off On

Off Off On On Off Off On On

Off Off Off Off On On On On

Scene

Signals

Applications Using Multiple 480 and 481 Together

Multiple User Switches 480 and 481 can be used together when:

1) Applications require more than 3 User Buttons.

2) Applications require both input demands and output relay contacts.

3) User Switches with the same functionality are required at different locations.

Each tN4 bus cannot exceed 24 devices. Devices include Thermostats, Setpoint

Controls, Mixing Expansion Modules, and User Switches.

When using multiple User Switches at the same location, they can be installed

adjacent to each other in the same switch box.

Applications requiring more than 3 User Buttons

When more than 3 User Buttons are required, two or more User Switches can be

located next to each other in a double switch box. Each button can be programmed

to either select a scene or provide a setpoint enable.

Application Example:

Applications that select more than three scenes or setpoint device enables will

require two or more User Switches.

Applications with both input demands and output relay contacts

Applications that require input demands and output relay contacts require a 480

and a 481. The 480 provides the input demands and the 481 provides the output

contacts.

Application Example:

A third party telephone switch device allows a user to change the scene from 1

to 2 (Away) through the demand input on the 480. Should a critical or non-critical

error occur on the tN4 system, a 481 can close an alert contact to allow a third

party telephone switch to page a service technician.

9 of 12 © 2009 D 481 - 07/09

Page 10

User Switches with the same functionality at different locations

There may be applications where there are two or more User Switches installed

in a building. Each of the User Switch User Buttons can be programmed with the

same functionality. When an User Button is pressed, User Buttons with the same

functionality will all light green at the same time.

Application Example:

A User Switch is installed in the garage and another User Switch is installed in

the master bedroom.

Cleaning the User Switch

The User Switch’s exterior can be cleaned using a damp cloth. Moisten the cloth

with water and wring out prior to wiping the device. Do not use solvents or cleaning

solutions.

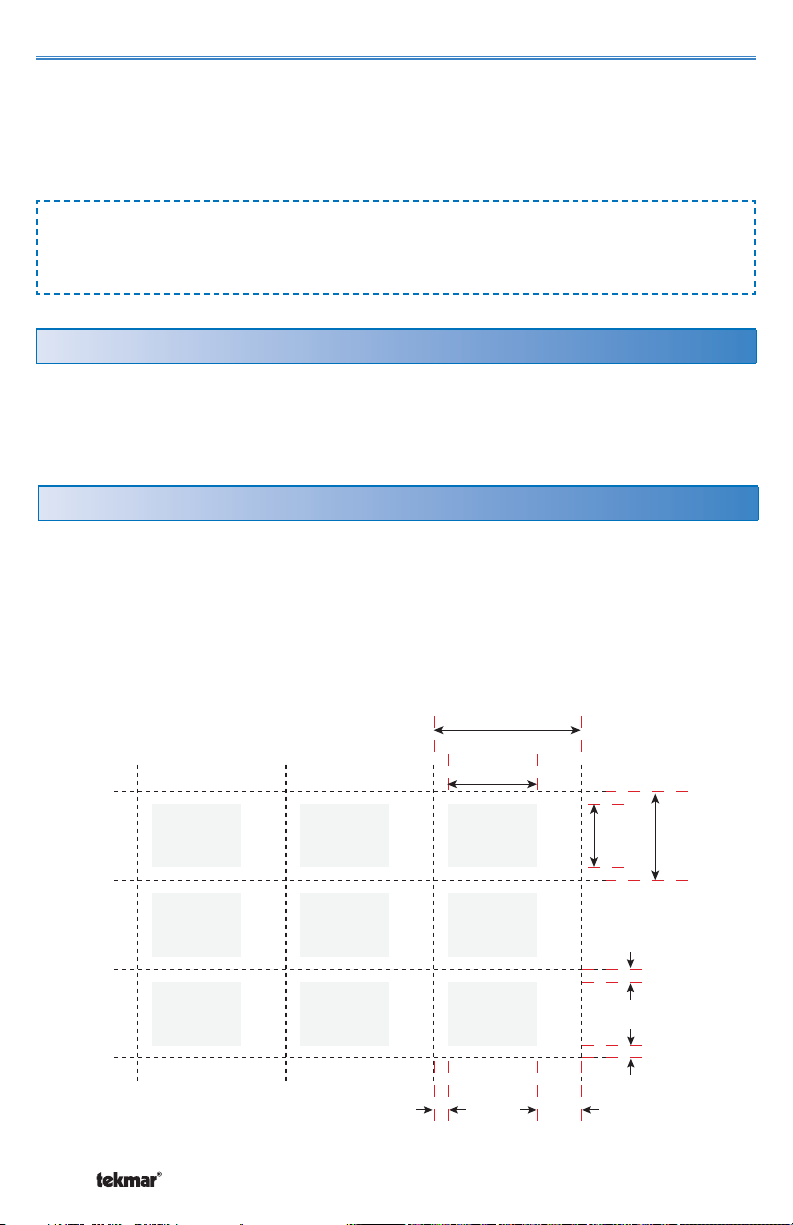

User Button Label Template

1) Download the User Switch Data Brochure PDF file D481.pdf from the

Downloadable Literature Section on our tekmar website:

http://www.tekmarcontrols.com to your computer.

2) Click on the grey area (text field) and type the label description.

3) Print this page onto transparency film. Ensure the correct transparency film type

is used for either laser printers or bubble-jet printers.

© 2009 D 481 - 07/09 10 of 12

0.10”

(2.6 mm)

0.62” (15.7 mm)

1.03” (26.2 mm)

0.31”

(7.9 mm)

0.44”

(11.0 mm)

0.62”

(15.8 mm)

0.10”

(2.4 mm)

0.10”

(2.4 mm)

Page 11

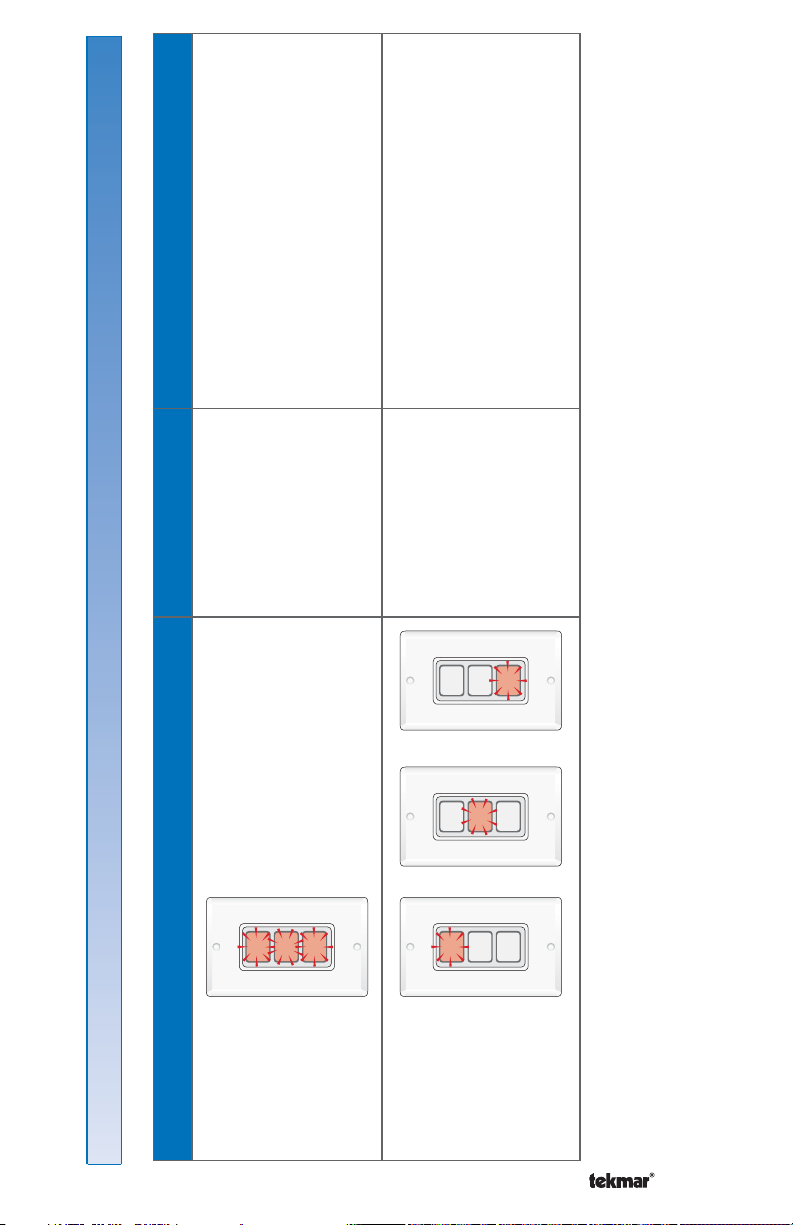

•

loose wire connections.

•

•

•

• Check tN4 and common wires for

• Ensure the tN4 controls have power.• • Check R and C wires for correct

User Switch

disconnected from

tN4 bus.

1

2

User

Button

3

User

User

Button

Button

polarity.

power and is connected to the tN4

• Ensure the setpoint device has

The User Button

is configured for

1

User

Button

1

User

Button

bus.

• Ensure the setpoint device enable

setpoint device

enable operation

and there is no

2

3

User

User

Button

Button

2

3

User

User

Button

Button

number of the User Button and of

the tN4 setpoint control match.

response from the

tN4 setpoint control.

or or

1

2

User

Button

3

User

User

Button

Button

Error Messages

Error Messages

Symptom Cause Corrective Action

3 Buttons

Flashing Red

1 Button

Flashing Red

11 of 12 © 2009 D 481 - 07/09

Page 12

Limited Warranty and Product Return Procedure

Limited Warranty The li ability of tekmar u nder this warranty is li mit ed. The Purchas er, by taking r eceipt of

any tekmar product (“Product”), acknowledges the terms of the Limited Warranty in effect at the time of

such Product sale and acknowledges that it has read and understands same.

The tekmar Limited Warranty to the Purchaser on the Products sold hereunder is a manufacturer’s pass-through

warranty which the Purchaser is authorized to pass through to its customers. Under the Limited Warranty, each

tekmar Product is warranted against defects in workmanship and materials if the Product is installed and used

in compliance with tekmar’s instructions, ordinary wear and tear excepted. The pass-through warranty period is

for a period of twenty-four (24) months from the production date if the Product is not installed during that period,

or twelve (12) months from the documented date of installation if installed within twenty-four (24) months from

the production date.

The liability of tekmar under the Limited Warranty shall be limited to, at tekmar’s sole discretion: the cost of parts

and labor provided by tekmar to repair defects in materials and / or workmanship of the defective product; or to the

exchange of the defective product for a warranty replac ement product; or to the granting of credit limited to the

original cost of the defective product, and such repair, exchange or credit shall be the sole remedy available from

tekmar, and, without limiting the foregoing in any way, tekmar is not responsible, in contract, tort or strict product

liability, for any other losses, costs, expenses, inconveniences, or damages, whether direct, indirect, special, secondar y, incidental or c onsequential, arising from ownership or use of the product, or from defects in workmanship

or materials, inc luding any liability for fundamental breach of contract.

The pass-through Limited Warranty applies only to those defective Products returned to tekmar during the warranty period. This Limited Warranty does not cover the cost of the par ts or labor to remove or transport the defective Product, or to reinstall the repaired or replacement Product, all such costs and expenses being subject to

Purchaser’s agreement and warrant y with its customers.

Any representations or warranties about the Products made by Purchaser to its customers which are different from

or in excess of the tekmar Limited Warranty are the Purchaser’s sole responsibility and obligation. Purchaser shall

indemnify and hold tekmar harmless from and against any and all claims, liabilities and damages of any kind or

nature which arise out of or are related to any such representations or warranties by Purchaser to its customers.

The pass-through Limited Warranty does not apply if the returned Produc t has been damaged by negligence by

persons other than tekmar, accident, fire, Act of God, abuse or misuse; or has been damaged by modifications,

alterations or attachments made subsequent to purchase which have not been authorized by tekmar; or if the

Product was not installed in compliance with tekmar’s instruc tions and / or the local codes and ordinances; or if due

to defective installation of the Product; or if the Product was not used in compliance with tek mar’s instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, WHICH THE GOVERNING

LAW ALLOWS PARTIES TO CONTRACTUALLY EXCLUDE, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, DURABILITY OR DESCRIPTION OF THE PRODUCT, ITS NON-INFRINGEMENT OF ANY RELEVANT PATENTS OR TRADEMARKS, AND

ITS COMPLIANCE WITH OR NON-VIOLATION OF ANY APPLICABLE ENVIRONMENTAL, HEALTH OR SAFETY

LEGISLATION; THE TERM OF ANY OTHER WARRANT Y NOT HEREBY CONTRACTUALLY EXCLUDED IS LIMITED SUCH THAT IT SHALL NOT EXTEND BEYOND TWENTY-FOUR (24) MONTHS FROM THE PRODUCTION

DATE, TO THE EXTENT THAT SUCH LIMITATION IS ALLOWED BY THE GOVERNING LAW.

Product Warranty Return Procedure All Products that are believed to have defec ts in workmanship or materials must be returned, together with a written description of the defect, to the tekmar Representative assigned to

the territory in which such Product is located. If tekmar receives an inquiry from someone other than a tekmar

Representative, including an inquiry from Purchaser (if not a tekmar Representative) or Purchaser’s customers,

regarding a potential warrant y claim, tekmar’s sole obligation shall be to provide the address and other contact

information regarding the appropriate Representative.

tekmar Control Systems Ltd., Canada

tekmar Control Systems, Inc., U.S .A.

Head O ffic e: 5100 Sil ver Sta r Road

Vernon, B.C. Can ada V1B 3K4

(250) 54 5-7749 Fax. (2 50) 54 5- 065 0

Web Site: w ww.te kmar contr ols.c om

All specifications are subject

to change without notice

Product design, soft ware and literature

are Copyright © 2009 by:

tekmar Control Systems Ltd. and tekmar

Control Systems, Inc.

12 of 12 D 481 - 07/09.

Loading...

Loading...