Siemens 7MF4333, 7MF4033, 7MF4233, 7MF4433, 7MF4533 User Manual

...

Siemens Industry, Inc.

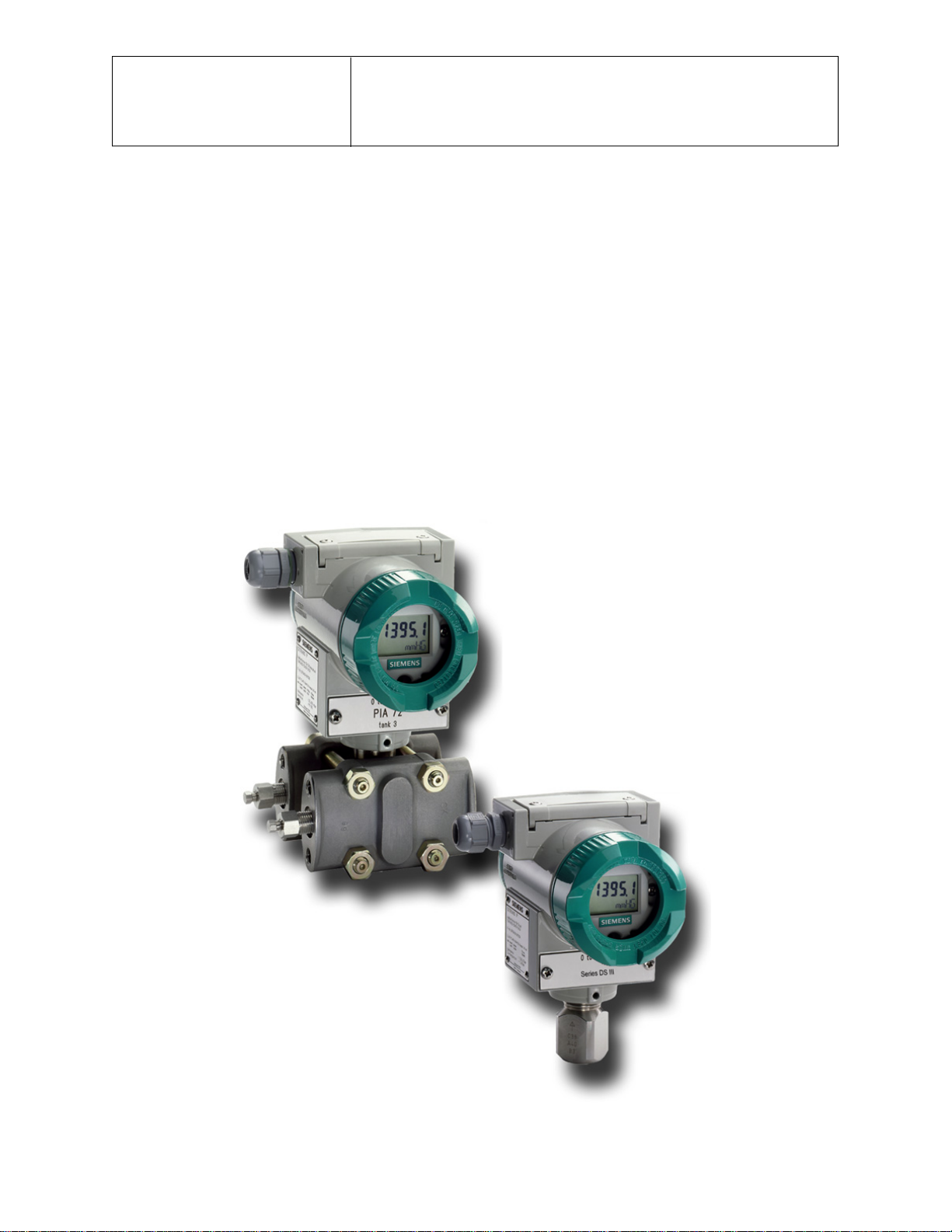

SITRANS P, Series DSIII Transmitters

Pressure, Differential Pressure,

Flanged Level, and Absolute Pressure

USER'S MANUAL

for

Model 7MF4*33-

UMSITRPDS3-1

Rev 10

November 2010

Supersedes Rev 9

IMPORTANT

MODEL 275 HART COMMUNICATOR AND

MODEL 375 FIELD COMMUNICATOR

Many procedures, screens, and wiring diagrams shown in this manual feature the Model 275 HART

Communicator.

The Model 375 Field Communicator is also available. Procedures and screens are similar to those for the

Model 275, however, there are significant differences and an online Configuration Map for use with the

Model 375 is provided at the back of this manual.

Transmitter model and firmware version can affect the displays, display options, and Configuration Maps.

Whether using the Model 275 or the Model 375, be sure to read the manual supplied by the manufacturer

before installing or using the device. Refer to the communicator nameplate for hazardous area

certifications and approvals and other important information.

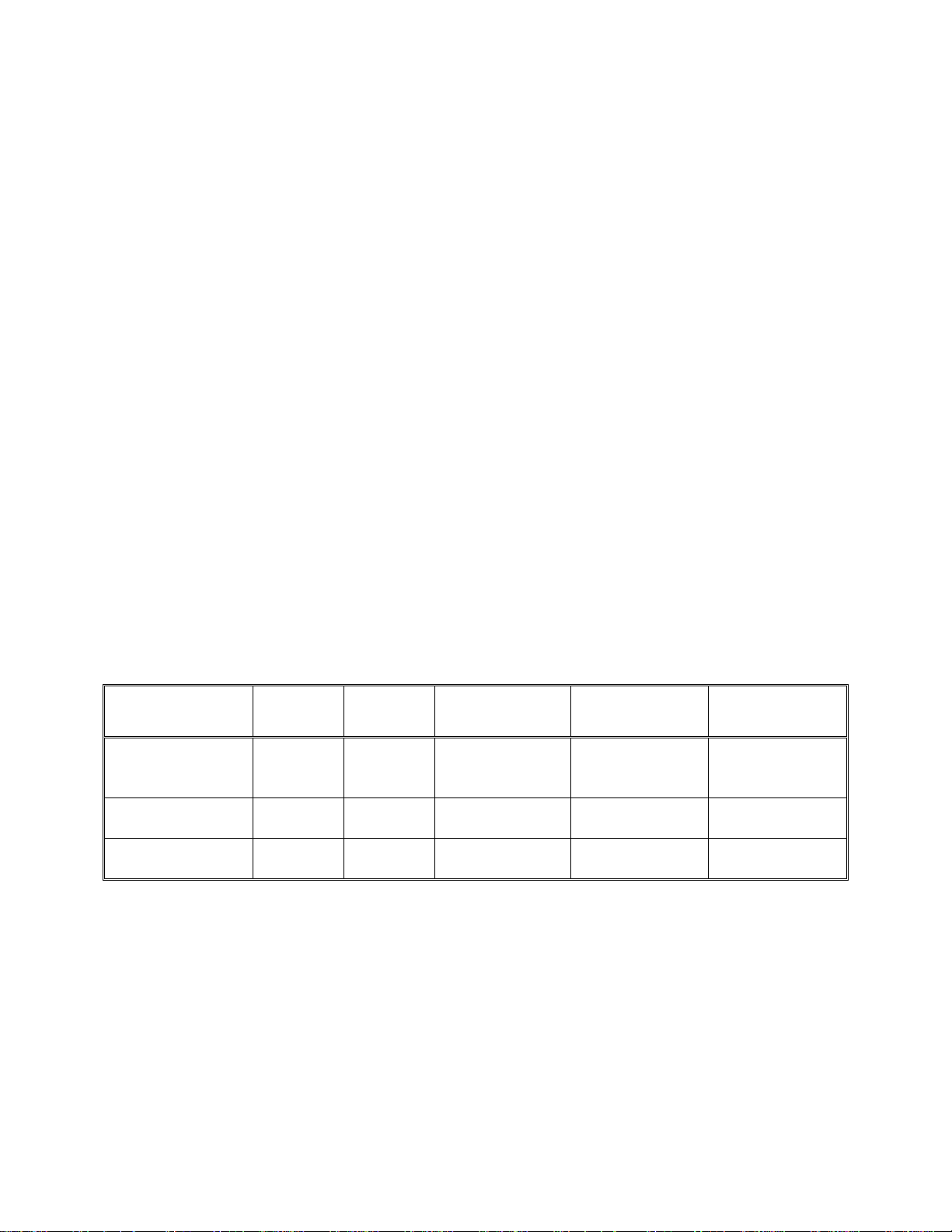

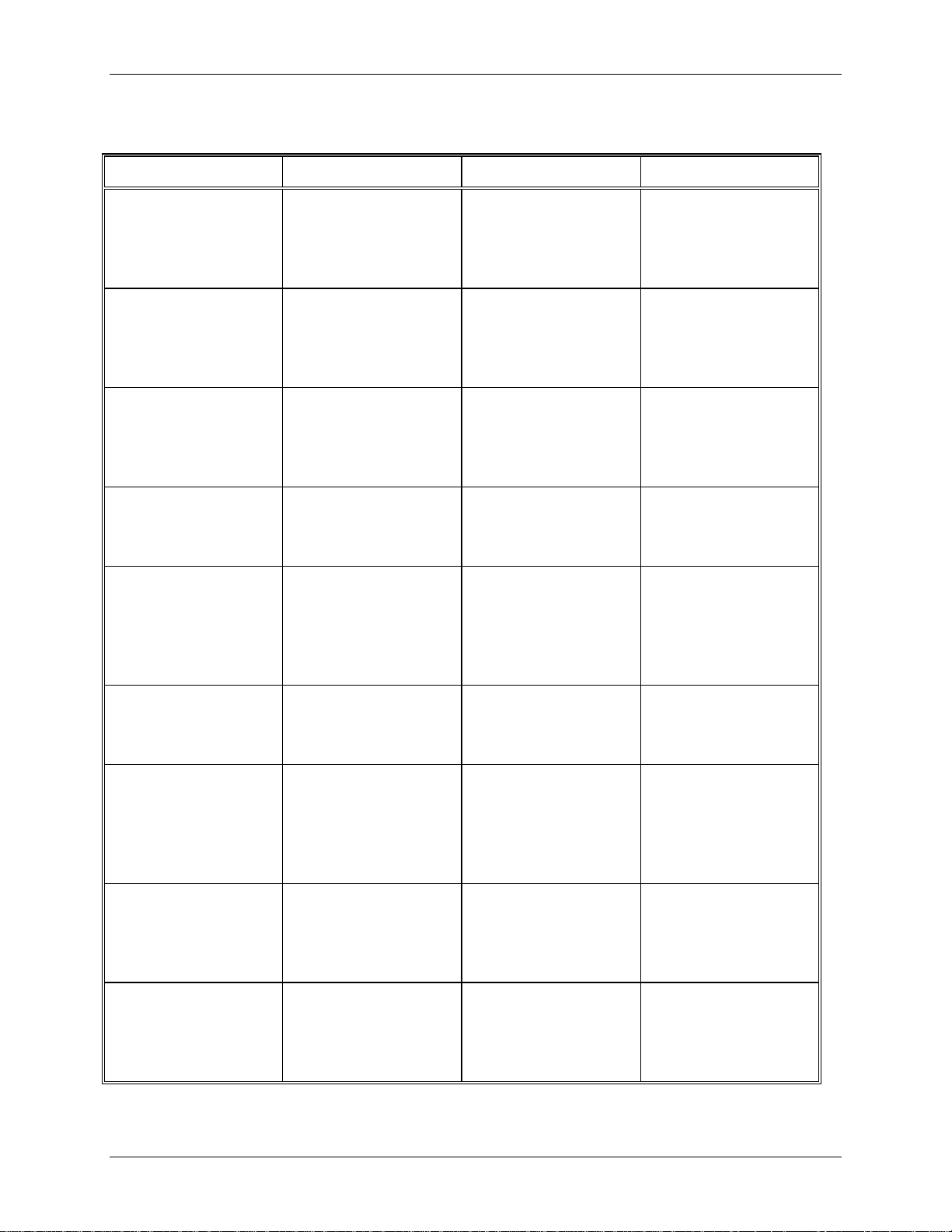

APPLICATION AND MODEL QUICK LOCATOR

The following table provides an overview of measurement categories and available models. For details

pertaining to a particular model, see the appropriate section for a dimension drawing, the model

designation table and specifications in Section 9 Model Designations and Specifications. To quickly

locate other information, refer to the Table of Contents.

Measurement Models

Section

See

Dimensions

Model

Designation

Specifications

Absolute or Gauge

Pressure

Differential

Pressure

Level (Flange)

7MF4033

7MF4233

7MF4333

7MF4433

7MF4533

7MF4633

7MF4812

9.1

9.2

9.3

9.4 Figure 9-3 or 9-4

9.5 Figure 9-5 Table 9-10 Table 9-11

Figure 9-1

Figure 9-2

Figure 9-3

Table 9-1

Table 9-3

Table 9-5

Table 9-7

Table 9-8

Table 9-2

Table 9-4

Table 9-6

Table 9-9

UMSITRPDS3-1 Contents

TABLE OF CONTENTS

Section and Title Page

Conventions, Symbols, and General Information.................................................................viii

Conventions and Symbols ...................................................................................................viii

Scope ..................................................................................................................................viii

Warranty ............................................................................................................................... ix

Qualified Persons ................................................................................................................. ix

General Warnings and Cautions........................................................................................... ix

1.0 INTRODUCTION....................................................................................................1-1

1.1 CONTENTS......................................................................................................................1-1

1.2 PRODUCT DESCRIPTION ..............................................................................................1-2

1.3 RATING, APPROVAL, AND TAG PLATES......................................................................1-9

1.4 CONFIGURATION ...........................................................................................................1-9

1.5 CUSTOMER/PRODUCT SUPPORT..............................................................................1-10

2.0 MODEL 275 UNIVERSAL HART COMMUNICATOR............................................2-1

2.1 INTRODUCTION..............................................................................................................2-1

2.2 COMMUNICATOR CONNECTIONS................................................................................2-1

2.3 CONTROLS OVERVIEW .................................................................................................2-4

2.3.1 Liquid Crystal Display ................................................................................................2-4

2.3.2 Software-Defined Function Keys ...............................................................................2-4

2.3.3 Action Keys................................................................................................................2-6

2.3.4 Alphanumeric and Shift Keys.....................................................................................2-7

2.4 GETTING TO KNOW THE COMMUNICATOR ................................................................2-8

2.4.1 Display Icons .............................................................................................................2-8

2.4.2 Menu Structure ..........................................................................................................2-9

2.4.3 Reviewing Installed Devices......................................................................................2-9

2.5 MAIN MENU...................................................................................................................2-11

2.5.1 Offline Menu ............................................................................................................2-12

2.5.2 Online Menu ............................................................................................................2-18

2.5.3 Frequency Device Menu..........................................................................................2-21

2.5.4 Utility Menu..............................................................................................................2-21

2.6 USING THE QUICK ACCESS KEY................................................................................2-23

2.6.1 Adding Quick Access Key Options ..........................................................................2-24

2.6.2 Deleting Quick Access Key Options ........................................................................2-25

3.0 PRE-INSTALLATION TEST ..................................................................................3-1

3.1 PROCEDURE ..................................................................................................................3-1

3.1.1 Test Equipment..........................................................................................................3-2

3.2 ESTABLISHING COMMUNICATION ...............................................................................3-3

3.3 TESTING THE TRANSMITTER .......................................................................................3-3

3.4 REVIEWING CONFIGURATION DATA ...........................................................................3-4

3.5 CHECKING TRANSMITTER OUTPUT ............................................................................3-4

4.0 INSTALLATION.....................................................................................................4-1

4.1 EQUIPMENT DELIVERY AND HANDLING .....................................................................4-1

4.1.1 Receipt of Shipment ..................................................................................................4-1

4.1.2 Storage ......................................................................................................................4-1

4.2 ENVIRONMENTAL CONSIDERATIONS .........................................................................4-2

4.3 PRE-INSTALLATION CONSIDERATIONS AND CALCULATIONS .................................4-2

November 2010

i

Contents UMSITRPDS3-1

4.3.1 Mechanical ................................................................................................................4-2

4.3.2 Electrical ....................................................................................................................4-3

4.3.3 Impulse Piping for Absolute and Differential Models .................................................4-4

4.3.4 Transmitter Operating Mode and Network Type......................................................4-10

4.3.5 Power Supply Requirements ...................................................................................4-14

4.3.6 Determining Network (Loop) Length........................................................................4-17

4.3.7 Network Junctions ...................................................................................................4-19

4.3.8 Safety Barriers.........................................................................................................4-19

4.3.9 Connection of Miscellaneous Hardware ..................................................................4-20

4.3.10 Shielding and Grounding .......................................................................................4-21

4.4 MECHANICAL INSTALLATION .....................................................................................4-22

4.4.1 Pipe Mounting, Differential and Gauge Construction...............................................4-22

4.4.2 Direct Mounting to Process, Model 7MF4433 or 7MF4533 .....................................4-24

4.4.3 Flange Mounting, Model 7MF4633/7MF4812..........................................................4-25

4.5 MECHANICAL INSTALLATION, All Models...................................................................4-27

4.5.1 Enclosure Rotation ..................................................................................................4-27

4.5.2 Display Orientation ..................................................................................................4-28

4.5.3 Electrical Conduit and Cable Installation .................................................................4-29

4.6 ELECTRICAL INSTALLATION.......................................................................................4-31

4.7 HAZARDOUS AREA INSTALLATION............................................................................4-33

5.0 POST-INSTALLATION TEST................................................................................5-1

5.1 TEST EQUIPMENT..........................................................................................................5-1

5.2 INSTALLATION REVIEW.................................................................................................5-1

5.3 EQUIPMENT CONNECTION ...........................................................................................5-2

5.4 VERIFICATION ................................................................................................................5-3

5.4.1 Communication Test..................................................................................................5-3

5.4.2 Transmitter Selftest....................................................................................................5-3

5.4.3 Loop Test...................................................................................................................5-4

5.5 TRANSMITTER ZERO AND SHUTOFF VALVE MANIPULATION ..................................5-5

5.5.1 Absolute Pressure .....................................................................................................5-5

5.5.2 Differential Pressure and Flow...................................................................................5-8

5.5.3 Measuring Vapor .....................................................................................................5-11

6.0 ON-LINE CONFIGURATION AND OPERATION ..................................................6-1

6.1 LOCAL OPERATION AND DISPLAY...............................................................................6-1

6.1.1 Digital Display............................................................................................................6-1

6.1.2 Numeric Display.........................................................................................................6-2

6.1.3 Unit/Bargraph Display................................................................................................6-3

6.1.4 Error Message ...........................................................................................................6-3

6.1.5 Output Signal Range .................................................................................................6-3

6.1.6 Mode Display...........................................................................................................6-4

6.2 LOCAL OPERATION WITH THE MAGNETIC PUSHBUTTONS .....................................6-5

6.2.1 Cancel Pushbutton Disable and Write Protection......................................................6-7

6.2.2 Set/Adjust Zero and Full Scale ..................................................................................6-7

6.2.3 Electric Damping......................................................................................................6-10

6.2.4 Blind Setting of Zero and Full Scale ........................................................................6-10

6.2.5 Zero Adjustment (Position Correction).....................................................................6-12

6.2.6 Fixed Current Output ...............................................................................................6-13

6.2.7 Failure Current.........................................................................................................6-13

6.2.8 Pushbutton and Function Disable............................................................................6-14

6.2.9 Flow Measurement (Differential Pressure only).......................................................6-14

6.2.10 Select Measured Value to Display.........................................................................6-16

November 2010

ii

UMSITRPDS3-1 Contents

6.2.11 Select the Displayed Input Pressure Engineering Unit..........................................6-16

6.3 LOCAL OPERATION WITHOUT A DISPLAY OR WITH ACTIVATED KEYLOCK.........6-18

6.3.1 Set Zero and Full Scale ...........................................................................................6-18

6.4 REMOTE CONFIGURATION AND OPERATION BY HART..........................................6-20

6.4.1 Process Data ...........................................................................................................6-20

6.4.2 Setting Zero and Full Scale .....................................................................................6-21

6.4.3 Blind Setting of Zero and Full Scale ........................................................................6-21

6.4.4 Zero Adjustment for Position Correction..................................................................6-21

6.4.5 Electric Damping......................................................................................................6-22

6.4.6 Fast Measured Value Acquisition (fast response mode) .........................................6-22

6.4.7 Fixed Current Output ...............................................................................................6-23

6.4.8 Fault Current............................................................................................................6-23

6.4.9 Disabling the Transmitter Magnetic Pushbuttons and Write Protection...................6-24

6.4.10 Measured Value Display........................................................................................6-25

6.4.11 Select Pressure Engineering Units........................................................................6-25

6.4.12 Display/Bargraph ...................................................................................................6-25

6.4.13 Sensor Trim ...........................................................................................................6-26

6.4.14 D/A Trim.................................................................................................................6-28

6.4.15 Transmitter Current Adjustment.............................................................................6-28

6.4.16 Factory Calibration (Manufacturer Trims) ..............................................................6-29

6.4.17 Device Information.................................................................................................6-30

6.4.18 Flow Measurement (Differential Pressure) ............................................................6-30

6.4.19 Diagnostic Functions .............................................................................................6-30

6.4.20 Simulation..............................................................................................................6-33

6.4.21 Self Test and Master Reset ...................................................................................6-34

7.0 CALIBRATION AND MAINTENANCE ..................................................................7-1

7.1 CALIBRATION .................................................................................................................7-2

7.2 PREVENTIVE MAINTENANCE........................................................................................7-3

7.2.1 Transmitter Exterior Inspection..................................................................................7-3

7.2.2 Transmitter Exterior Cleaning ....................................................................................7-3

7.2.3 Transmitter Enclosure Interior Inspection..................................................................7-4

7.2.4 Transmitter Calibration ..............................................................................................7-4

7.2.5 Impulse Piping ...........................................................................................................7-4

7.3 TROUBLESHOOTING .....................................................................................................7-5

7.3.1 Analog Output............................................................................................................7-5

7.3.2 Digital Output (Communication).................................................................................7-8

7.4 ASSEMBLY REMOVAL AND REPLACEMENT ...............................................................7-9

7.4.1 Display Assembly ....................................................................................................7-11

7.4.2 Replacing the Electronics Module ...........................................................................7-12

7.4.3 Measuring Cell Assembly Removal and Replacement............................................7-13

7.4.4 Terminal Board Assembly Removal and Replacement ...........................................7-16

7.5 NON-FIELD-REPLACEABLE ITEMS .............................................................................7-16

7.6 TRANSMITTER REPLACEMENT ..................................................................................7-17

7.7 MAINTENANCE RECORDS ..........................................................................................7-18

7.8 RECOMMENDED SPARE AND REPLACEMENT PARTS ............................................7-18

7.9 COMPATIBILITY, Revision Numbers.............................................................................7-19

8.0 CIRCUIT DESCRIPTION .......................................................................................8-1

8.1 OVERALL OPERATION...................................................................................................8-2

8.2 PRESSURE......................................................................................................................8-2

8.3 DIFFERENTIAL PRESSURE AND FLOW .......................................................................8-3

8.4 FLANGED LEVEL ............................................................................................................8-3

November 2010

iii

Contents UMSITRPDS3-1

8.5 ABSOLUTE PRESSURE (DIFFERENTIAL CONSTRUCTION).......................................8-4

8.6 ABSOLUTE PRESSURE (GAUGE CONSTRUCTION) ...................................................8-4

8.7 COMMUNICATION FORMAT ..........................................................................................8-5

9.0 MODEL DESIGNATIONS AND SPECIFICATIONS ..............................................9-1

9.1 MODEL 7MF4033, GAGE PRESSURE ...........................................................................9-2

9.2 MODEL 7MF4233, ABSOLUTE PRESSURE...................................................................9-7

9.3 MODEL 7MF4333, ABSOLUTE PRESSURE.................................................................9-12

9.4 MODELS 7MF4433 AND 7MF4533, DIFFERENTIAL PRESSURE AND FLOW ...........9-17

9.5 MODELS 7MF4633 AND 7MF4812, LEVEL ..................................................................9-24

9.6 SERVICE PARTS, ALL MODELS ..................................................................................9-30

9.7 ACCESSORIES .............................................................................................................9-35

9.8 NETWORK TOPOLOGY ................................................................................................9-35

9.8.1 Two-Wire Cable.......................................................................................................9-35

9.9 HAZARDOUS AREA CLASSIFICATION........................................................................9-36

9.9.1 CSA Hazardous Locations Precautions...................................................................9-38

10.0 GLOSSARY.......................................................................................................10-1

11.0 APPENDIX A - ONLINE CONFIGURATION MAP.............................................11-1

12.0 APPENDIX B - HAZARDOUS AREA INSTALLATION.....................................12-1

13.0 APPENDIX C - ELEVATION AND SUPPRESSION CORRECTIONS...............13-1

13.1 HOW ADJUSTMENT IS MADE....................................................................................13-1

13.2 ELEVATION CALCULATION EXAMPLE .....................................................................13-2

13.3 SUPPRESSION CALCULATION EXAMPLE ...............................................................13-2

13.4 RECOMMENDED METHOD ........................................................................................13-3

Online Configuration Map (with Model 275 Communicator)

Online Configuration Map (with Model 375 Communicator)

LIST OF FIGURES

Figure and Title Page

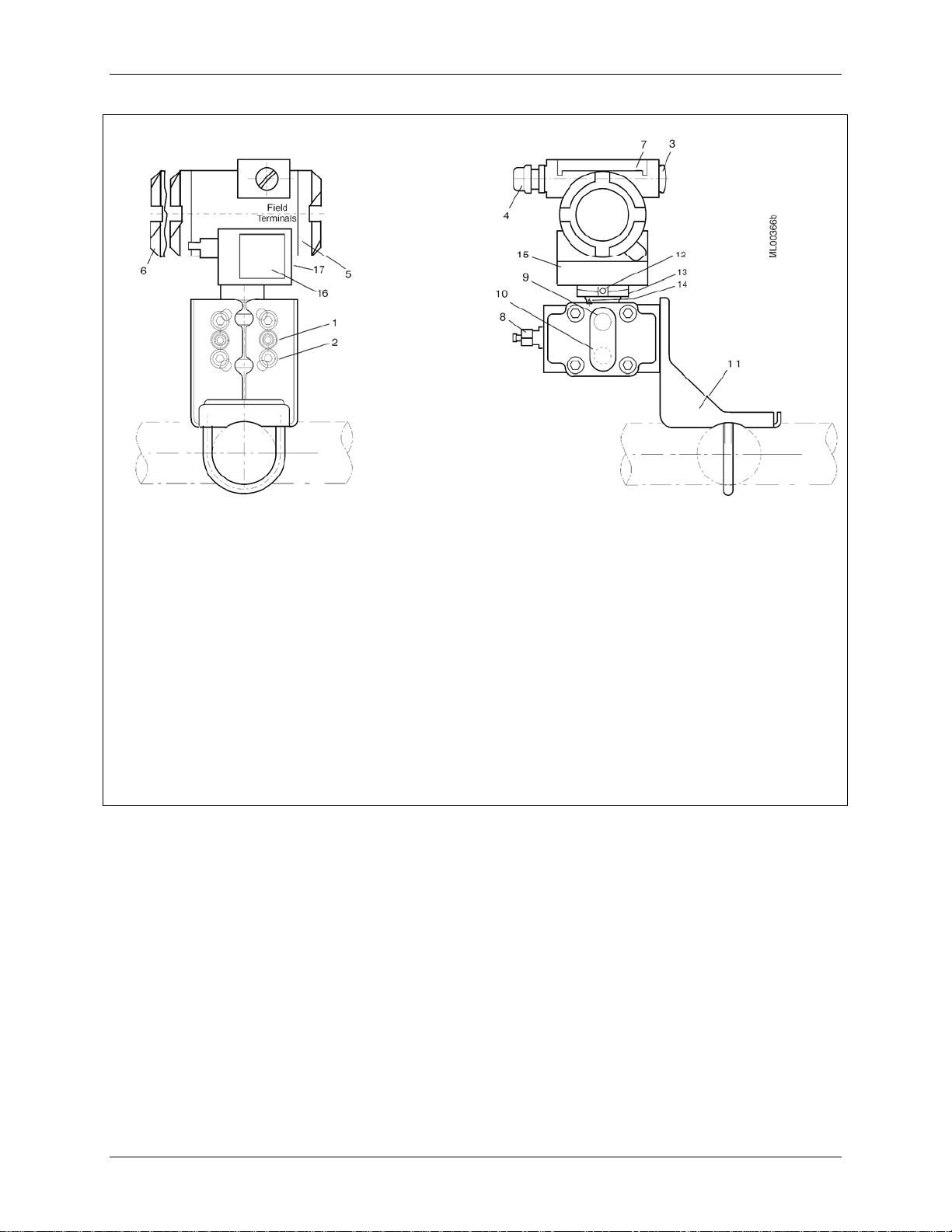

1-1 Gauge Construction, Pressure and Absolute Pressure Models .........................................1-3

1-2 Differential Construction; Differential, Flow, and Absolute Models .....................................1-4

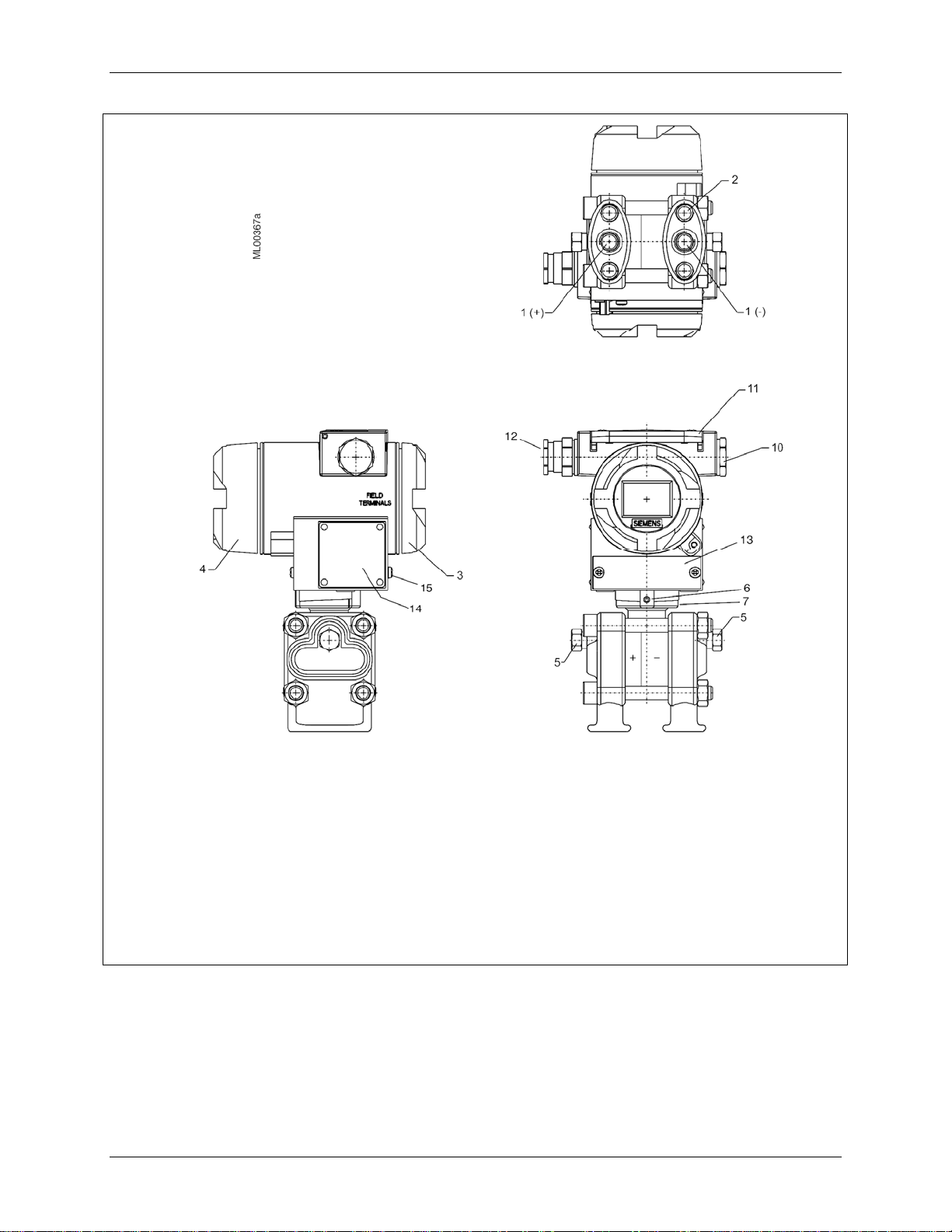

1-3 Differential Pressure and Flow Models with H03 Option ....................................................1-5

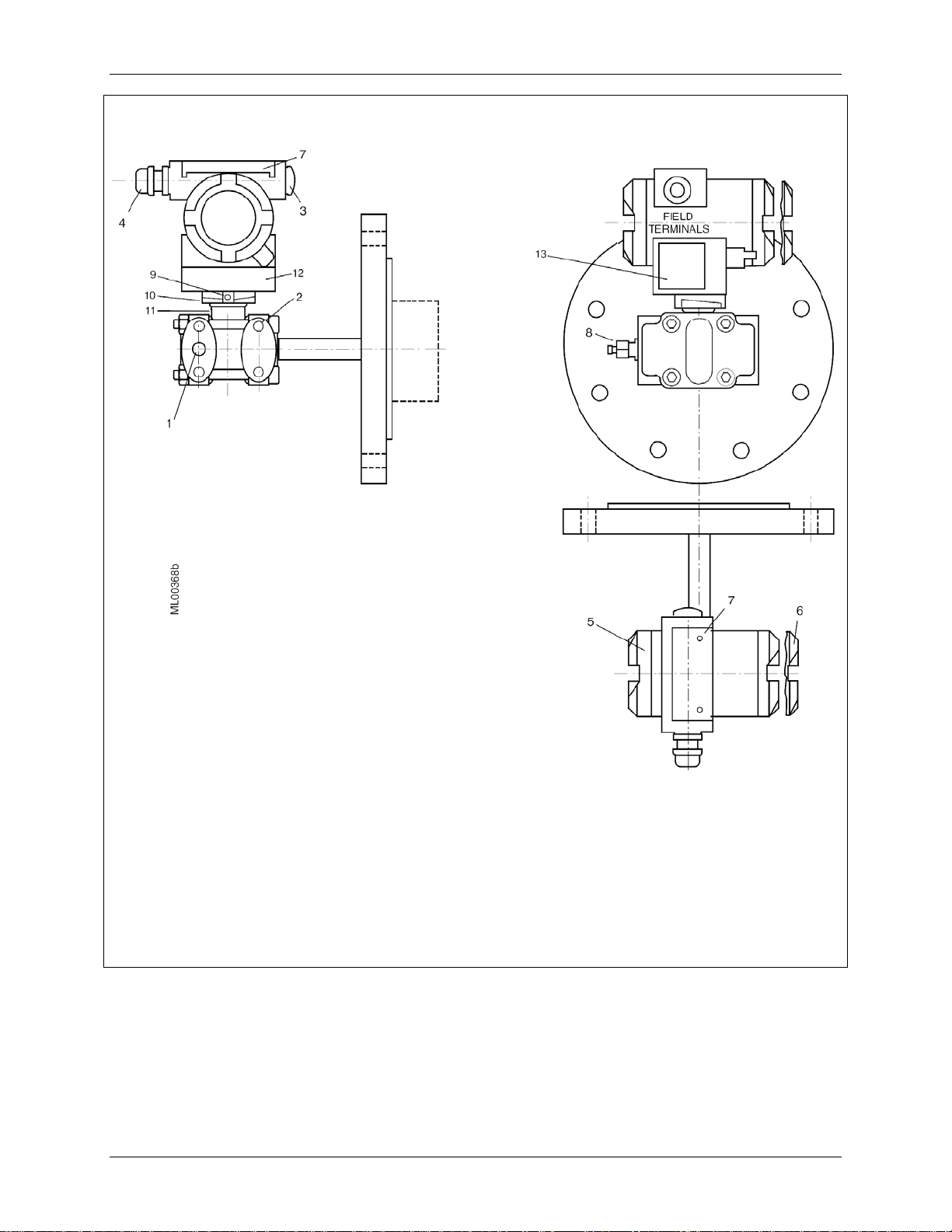

1-4 Flanged Liquid Level Models ..............................................................................................1-6

1-5 Traditional Application ........................................................................................................1-7

1-6 Digital Display and Field Terminals ....................................................................................1-8

2-1 Model 275 Universal HART Communicator........................................................................2-2

2-2 HART Communicator Connections to a Transmitter Loop .................................................2-3

2-3 HART Communicator Display Icons ...................................................................................2-8

2-4 Offline Menu Map .............................................................................................................2-12

2-5 SITRANS P Online Menu Map .........................................................................................2-19

2-6 Generic Online Menu Map................................................................................................2-20

3-1 Bench Test Connections.....................................................................................................3-1

3-2 Field Test Connections .......................................................................................................3-2

4-1 Differential Flow Measurement Piping for Gas and Liquid..................................................4-5

4-2 Differential Liquid Measurement Piping ..............................................................................4-6

4-3 Absolute or Gauge Pressure Measurement Piping ............................................................4-7

4-4 Steam Service, Below the Line Mounting ...........................................................................4-8

November 2010

iv

UMSITRPDS3-1 Contents

4-5 Open and Closed Tank Level Measurement, Flange Mounted Transmitters .....................4-9

4-6 Point-To-Point Network (Analog Mode) ............................................................................4-11

4-7 Procidia to Transmitter Connections (Analog Mode) ........................................................4-12

4-8 Model 353/354 to Transmitter Connections (Analog Mode) .............................................4-13

4-9 Multi-Drop Network (Digital Mode)....................................................................................4-15

4-10 Power Supply vs. Loop Resistance ................................................................................4-16

4-11 Pipe Mounting, Gauge Construction...............................................................................4-23

4-12 Pipe Mounting, Differential Construction ........................................................................4-23

4-13 Differential Construction, Position Options .....................................................................4-24

4-14 Enclosure Rotation Considerations ................................................................................4-27

4-15 Display Removal and Repositioning ...............................................................................4-28

4-16 Conduit Drain and Explosion Proof Installations.............................................................4-29

4-17 Network Conductor Terminations ...................................................................................4-32

5-1 Equipment Connection for System Checkout .....................................................................5-2

5-2 Measuring Gases................................................................................................................5-6

5-3 Measuring Vapor and Liquid...............................................................................................5-7

5-4 Measuring Gases................................................................................................................5-9

5-5 Measuring Liquids.............................................................................................................5-10

5-6 Measuring Vapor ..............................................................................................................5-11

6-1 Digital Display .....................................................................................................................6-1

6-2 Switch Point of the Square Root Characteristic................................................................6-15

6-3 Displayable Engineering Units..........................................................................................6-17

6-4 Sensor Trim ......................................................................................................................6-27

6-5 Pressure Min/Max Pointer Example .................................................................................6-32

6-6 Saturation Monitoring Examples.......................................................................................6-33

6-7 Simulation Circuit Diagram ...............................................................................................6-34

7-1 Transmitter Exploded View.................................................................................................7-9

7-2 Display Assembly Installed and Partially Removed..........................................................7-11

7-3 Electronics Module Removal and Installation ...................................................................7-12

7-4 Measuring Cell Alignment and Insertion Depth ................................................................7-15

8-1 Transmitter Block Diagram .................................................................................................8-1

8-2 Pressure Measuring Cell ....................................................................................................8-2

8-3 Differential Pressure and Flow Measuring Cell...................................................................8-3

8-4 Flanged Level Measuring Cell ............................................................................................8-4

8-5 Absolute Pressure Measuring Cell, Differential Construction .............................................8-4

8-6 Absolute Pressure Measuring Cell, Gauge Construction ...................................................8-5

9-1 Model 7MF4033, Dimensions .............................................................................................9-2

9-2 Model 7MF4233, Dimensions .............................................................................................9-7

9-3 Models 7MF4333, 7MF4433 and 7MF4533, Dimensions.................................................9-12

9-4 Models 7MF4433 and 7MF4533, Dimensions, With H03 Option......................................9-17

9-5 Models 7MF4633 and 7MF4812, Dimensions ..................................................................9-24

11-1 Online Configuration Map, Part 1 of 2 ............................................................................11-2

11-2 Online Configuration Map, Part 2 of 2 ............................................................................11-3

12-1 Control Drawing ..............................................................................................................12-2

12-2 Control Drawing ..............................................................................................................12-3

12-3 Control Drawing ..............................................................................................................12-4

13-1 Elevation and Suppression Examples ............................................................................13-1

November 2010

v

Contents UMSITRPDS3-1

LIST OF TABLES

Table and Title Page

1-1 Measurements, Models and Figure References.................................................................1-2

2-1 Function Keys with Their Labels and Actions Performed ...................................................2-5

2-2 Communicator Firmware Device Descriptions, Rev. F2.2 ................................................2-10

2-3 Offline Menu Map Continued, “Edit individually” Options1................................................2-12

4-1 Operating Mode and Network...........................................................................................4-10

4-2 Flange And Extension Dimensions...................................................................................4-26

6-1 Operating Mode and Status Arrows....................................................................................6-2

6-2 Parameters Accessible Using the Magnetic Pushbuttons ..................................................6-6

6-3 Pushbutton and Function Disable Options .......................................................................6-14

6-4 Pushbutton and Function Disable Options .......................................................................6-24

9-1 Model 7MF4033, Model Designation ..................................................................................9-3

9-2 Model 7MF4033, Specifications..........................................................................................9-5

9-3 Model 7MF4233, Model Designation ..................................................................................9-8

9-4 Model 7MF4233, Specifications........................................................................................9-10

9-5 Model 7MF4333, Model Designation ................................................................................9-13

9-6 Model 7MF4333, Specifications........................................................................................9-15

9-7 Model 7MF4433, Model Designation ................................................................................9-18

9-8 Model 7MF4533, Model Designation ................................................................................9-20

9-9 Models 7MF4433 and 7MF4533, Specifications...............................................................9-22

9-10 Models 7MF4633 and 7MF4812, Model Designation .....................................................9-25

9-11 Models 7MF4633 and 7MF4812, Specifications.............................................................9-28

9-12 Measuring Cells for Pressure, Service Parts ..................................................................9-30

9-13 Measuring Cells for Absolute Pressure, Gauge Construction, Service Parts .................9-31

9-14 Measuring Cells for Absolute Pressure, Differential Const., Service Parts ....................9-31

9-15 Measuring Cells for Pressure and Flow, Differential Const., Service Parts....................9-32

9-16 Measuring Cells for Differential Pressure and Flow, Service Parts ................................9-33

9-17 Measuring Cells for Filling Level, Service Parts .............................................................9-34

9-18 Electronics and Connecting Boards, Service Parts ........................................................9-34

9-19 Accessories ....................................................................................................................9-35

9-20 Certificate and Approvals, All Models .............................................................................9-37

November 2010

vi

UMSITRPDS3-1 Contents

Changes for Revision 10, November 2010

Significant changes for Rev. 10 are listed below.

Section Revision

Cover Change publication revision number and date.

Conventions, Symbols and General

Information

Update section text; include Warranty subsection and add

“operating time” warranty details.

1.5 Customer/Product Support Update section text and contact information table.

6.2 On-Line Operation Update Table 6-2, Mode 11.

Throughout publication Change Siemens Energy & Automation, Inc. to Siemens

Industry, Inc.

Warranty Remove from publication; see Conventions, Symbols and

General Information above.

SITRANS P, Series DS III, and Procidia are trademarks of Siemens Industry, Inc. Viton and Kalrez

DuPont Performance Elastomers. Teflon

registered trademark of Haynes International. Monel is a registered trademark of Special Metals Corporation. HART is a

registered trademark of the HART Communication Foundation. All product designations may be trademarks or product names of

Siemens Industry, Inc. or other supplier companies whose use by third parties for their own purposes could violate the rights of

the owners.

Siemens Industry, Inc. assumes no liability for errors or omissions in this document or for the application and use of information

included in this document. The information herein is subject to change without notice.

Procedures in this document have been reviewed for compliance with applicable approval agency requirements and are

considered sound practice. Neither Siemens Industry, Inc. nor these agencies are responsible for product uses not included in the

approval certification(s) or for repairs or modifications made by the user.

is a registered trademark of E. I. du Pont de Nemours and Company. Hastelloy is a

are registered trademarks of

!

November 2010

vii

Contents UMSITRPDS3-1

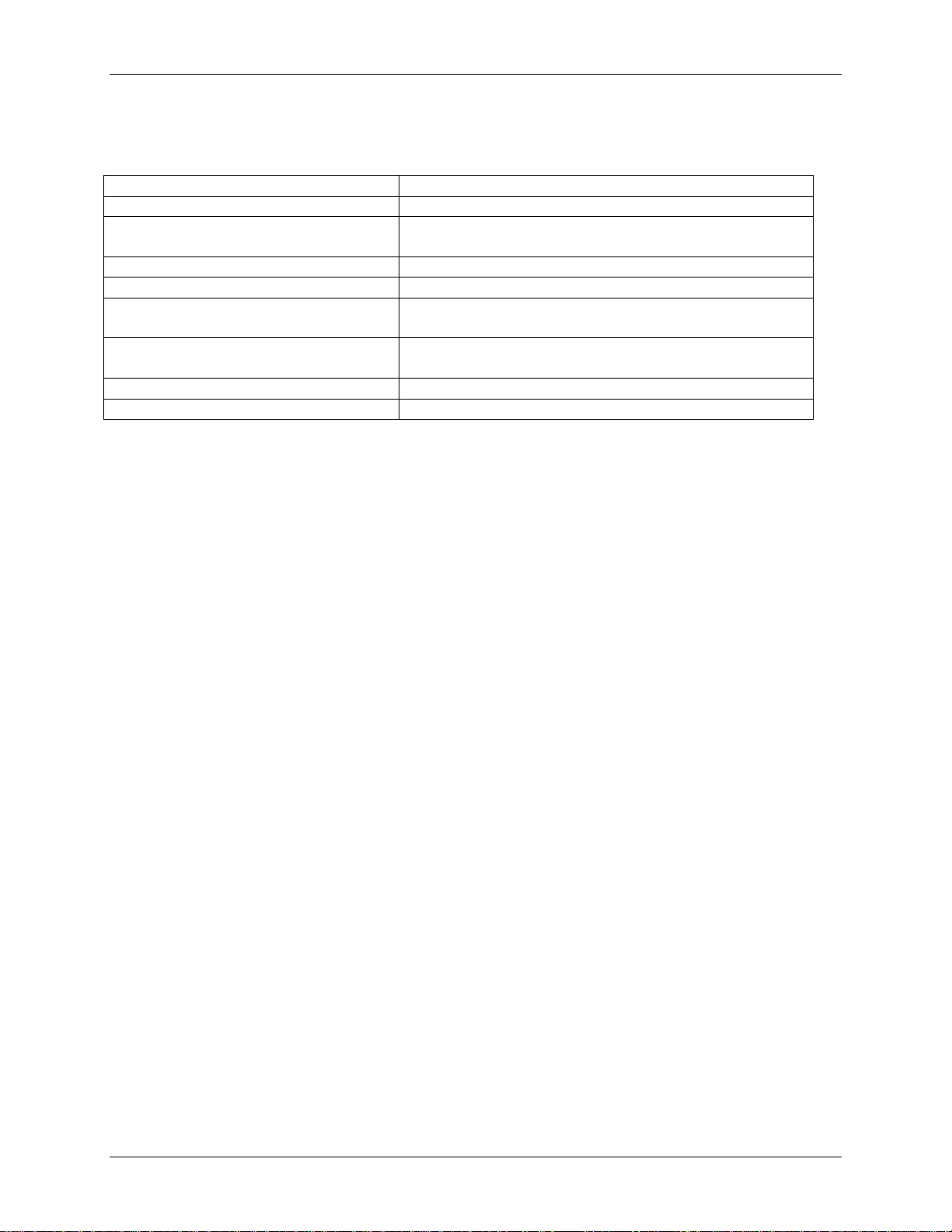

Conventions, Symbols, and General Information

Conventions and Symbols

The following symbols may be used in this manual and may appear on the equipment. The reader should

be familiar with the symbols and their meanings. Symbols are provided to quickly alert the reader to

safety related text.

Symbol Meaning

Indicates an immediate hazardous situation which, if not avoided, will result in

DANGER

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

WARNING

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

CAUTION

minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

CAUTION

property damage.

Indicates a potential situation which, if not avoided, may result in an undesirable

NOTICE

result or state.

IMPORTANT

Note

Identifies an action that should be taken to avoid an undesirable result or state.

Identifies supplemental information that should be read before proceeding.

Electrical shock hazard – Either symbol indicates the presence of an electrical

shock hazard. The associated text states the nature of the hazard, what can happen

as a result of the hazard, and how to avoid the hazard..

Explosion hazard – Symbol indicates that the danger of an explosion hazard

exists. The associated text states the nature of the hazard, what can happen as a

result of the hazard, and how to avoid the hazard.

Electrostatic discharge – The presence of this symbol indicates that electrostatic

discharge can damage the electronic assembly.

Pinch hazard – Symbol indicates that a pinch hazard exists if correct procedures

are not followed.

Part numbers are for items ordered from the Process Instrumentation & Analytics Business Unit of

Siemens Industry, Inc., except as noted.

Scope

This manual does not purport to cover all details or variations in equipment or to provide for every

possible contingency to be met in connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise which are not covered sufficiently for the

purchaser’s purposes, the matter should be referred to a support group listed in the Customer/Product

November 2010

viii

UMSITRPDS3-1 Contents

Support section of this manual or to the local Siemens sales office. The contents of this manual shall not

become part of or modify any prior or existing agreement, commitment or relationship.

Warranty

The SITRANS P DSIII transmitter warranty is based on actual operating hours, as shown in the Operating

Hours Register. The transmitter is warranted for 60 months of operation in two successive steps:

1. A 36-month 100% warranty from date of initial operation.

2. A 24-month pro-rated warranty which decreases linearly from 100% at 36 months to 0% at 60 months

of powered operation.

If Siemens cannot determine transmitter operating hours, the warranty shall commence on the date of

shipment from Siemens. All other provisions of the Siemens standard warranty remain as stated in the

sales contract.

Should the transmitter require repair during the pro-rated warranty period, the charge will be pro-rated

based on prevailing repair rates for parts and labor.

Qualified Persons

The described equipment should be installed, configured, operated, and serviced only by qualified

persons thoroughly familiar with this manual. A copy of this manual accompanies the equipment. The

current version of the manual, in Portable Document Format (PDF), can be downloaded from the Siemens

Internet site; see the Customer/Product Support section of this manual for the address.

For the purpose of this manual and product labels, a qualified person is one who is familiar with the

installation, assembly, commissioning, and operation of the product, and who has the appropriate

qualifications for their activities such as:

• Training, instruction, or authorization to operate and maintain devices/systems according to the safety

standards for electrical circuits, high pressures, and corrosive, as well as, critical media.

• For devices with explosion protection: training, instruction or authorization to work on electrical

circuits for systems that could cause explosions.

• Training or instruction according to the safety standards in the care and use of suitable safety

equipment.

General Warnings and Cautions

WARNING

An explosion-proof device may be opened only after power is removed from the device.

An intrinsically safe device loses its license as soon as it is operated in a circuit that does not meet the

requirements of the examination certificate valid in your country.

The device may be operated with high pressure and corrosive media. Therefore, serious injury and/or

considerable material damage cannot be ruled out in the event of handling of the device.

The perfect and safe operation of the equipment is conditional upon proper transport, proper storage,

installation and assembly, as well as, on careful operation and commissioning.

November 2010

ix

Contents UMSITRPDS3-1

x

The equipment may be used only for the purposes specified in this manual.

CAUTION

Electrostatic discharge can damage or cause the failure of semiconductor devices such as

integrated circuits and transistors. The symbol at right appears on a circuit board or other

electronic assembly to indicate that special handling precautions are needed.

• A properly grounded conductive wrist or heel strap must be worn whenever an electronics module or

circuit board is handled or touched. Static control kits are available from most electrical and

electronic supply companies.

• Electronic assemblies must be stored in static protective bags when not installed in equipment.

!

November 2010

UMSITRPDS3-1 Introduction

1.0 INTRODUCTION

This user’s manual is for the Siemens SITRANS P Series DSIII Pressure Transmitters.

All information needed to bench test, install, configure, calibrate, and service a transmitter is included in

this user’s manual.

IMPORTANT

Save this user’s manual. It should be available to those installing, configuring,

operating, and servicing the described pressure transmitters.

1.1 CONTENTS

The user’s manual consists of a table of contents, ten sections, and three appendices. Following the table

of contents is a subsection that contains important information about the symbols that can appear in this

user’s manual and on the transmitter. The subsection also has statements about installing and servicing the

transmitter. A brief description of each major section and appendices follows.

Section 1, Introduction, describes each section in the manual and provides a brief description of the

SITRANS P Series DSIII Pressure Transmitter line. A product support section has telephone, fax, E-mail,

and Internet contact information.

Section 2, Model 275 Universal HART Communicator, describes use of the HART Communicator to test,

configure, and calibrate a transmitter.

Section 3, Pre-Installation Test, provides procedures to perform a bench test of the transmitter to ensure

proper operation of all transmitter functions. Start-up configuration is described here.

Section 4, Installation, furnishes specific information for mechanical and electrical installation of the

transmitter.

Section 5, Post-Installation Test, describes how to confirm that the transmitter has been installed correctly

- sometimes referred to as commissioning.

Section 6, On-Line Configuration and Operation, details local configuration using the magnetic

pushbuttons and remote configuration using the HART Communicator. Local operation and remote

operation of the transmitter are described.

Section 7, Calibration and Maintenance, provides references to calibration procedures for analog and

digital modes and to a zeroing procedure for mounting position. It also furnishes preventive maintenance,

troubleshooting, and assembly replacement procedures.

Section 8, Circuit Description, contains an assembly-level circuit description to support transmitter

servicing.

Section 9, Model Designations and Specifications, has tables that correlate rating plate model numbers to

transmitter physical configurations. This section also contains an accessory list and several service parts

lists. Detailed mechanical, functional, performance, and environmental specifications are provided, as are

dimension drawings of the transmitter. Hazardous area certifications are listed.

Section 10, Glossary, contains definitions of various transmitter-related terms.

November 2010

1-1

Introduction UMSITRPDS3-1

Appendix A, Online Configuration Map, is used to help navigate HART/transmitter menus during remote

configuration and operation of the transmitter.

Appendix B, Hazardous Area Installations, contains control drawings and other information needed for

installation in a hazardous area.

Appendix C, Elevation and Suppression Corrections, explains how to perform elevation and suppression

calculations necessary for certain liquid level gauging applications.

Warranty contains the product warranty statements and information concerning servicing of the product

during the warranty period.

1.2 PRODUCT DESCRIPTION

SITRANS P Series DSIII transmitters provide reliable, accurate, stable, and cost-effective measurement

of differential, absolute, and gauge pressure and liquid level.

The transmitter is a microcontroller-based, self-contained pressure-to-current transducer. A measuring

cell senses the applied process pressure and provides an analog output signal that is proportional to

applied pressure. An analog-to-digital converter produces a digital signal for the microcontroller. The

microcontroller modifies and corrects the signal for linearity and temperature, and a digital-to-analog

converter produces a 4-20 milliampere output signal for the loop.

The transmitter can be installed quickly and easily using one of the optional mounting brackets.

Illustrations showing mounting hardware and dimensions are provided in this manual. Measuring cell

construction determines a transmitter’s physical dimensions and mechanical installation. Note that a given

sensor construction can involve one or more measurement methods, as shown in Table 1-1.

TABLE 1-1 Measurements, Models and Figure References

Measurement Model And Measuring Cell Construction Refer To

Absolute or Gauge Pressure 7MF4033, Gauge Construction

7MF4233, Gauge Construction

Figures 1-1, 4-3, 4-4, 411, 4-13, 9-1, 9-2 and 93

7MF4333, Differential Construction

Differential Pressure 7MF4433, Differential Construction

7MF4533, Differential Construction

Liquid Level (Flange) 7MF4633, Flange Construction

7MF4812, Flange

Figures 1-2, 1-3, 4-1, 42, 4-12, 4-13, 9-3, and 94

Figures 1-4, 4-5, and 9-5

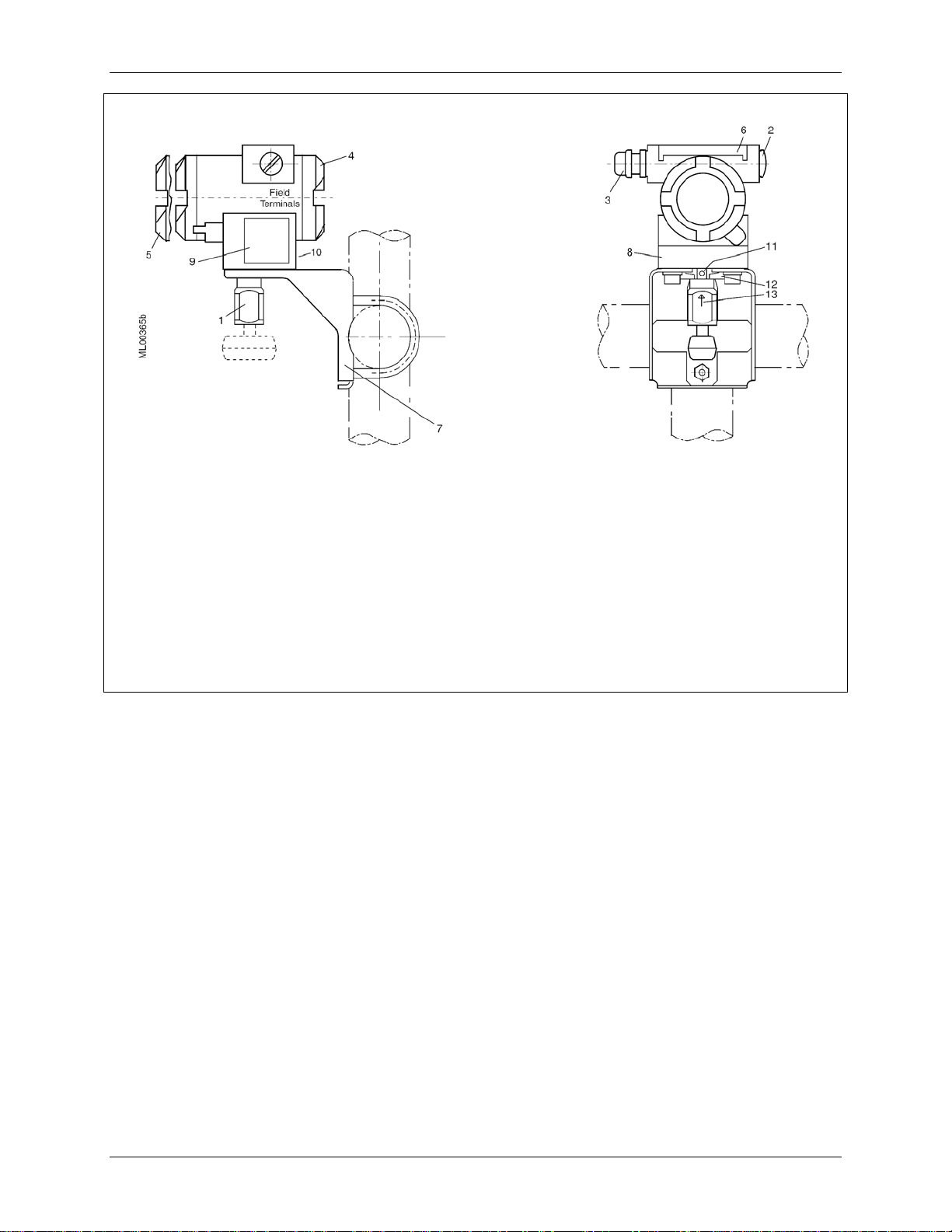

Figures 1-1 through 1-4 show the various transmitter models and constructions. They also show common

transmitter mounting methods. The mounting brackets shown are optional.

November 2010

1-2

UMSITRPDS3-1 Introduction

1

Process connection:

1/2-NPT, connection shank G1/2A

Oval flange

2

Blanking plug

3

Electrical connection:

Screwed gland M20 x 1.5

Screwed gland 1/2-14NPT

4

Field terminals; remove enclosure cap for

access

5

Electronics module and display; remove

enclosure cap for access

FIGURE 1-1 Gauge Construction, Pressure and Absolute Pressure Models

6

Hinged access cover over magnetic

pushbuttons

7

Mounting bracket, optional

8

Tag plate

9

Approval plate; Rating plate on other side

10

Enclosure ground screw

11

Enclosure setscrew

12

Enclosure rotation limits

13

Enclosure rotation reference arrow; see

Section 4 for details

This Figure is for Models 7MF4033 and

7MF4233

November 2010

1-3

Introduction UMSITRPDS3-1

1

Process Connection 1/4-18NPT for absolute

pressure + side

2

Mounting thread M10, M12 or 7/16-20UNF

3

Blanking plug

4

Electrical connection:

Screwed gland M20 x 1.5

Screwed gland 1/2-14NPT

5

Field terminals; remove enclosure cap for

access

6

Electronics module and display; remove

enclosure cap for access

7

Hinged access cover over magnetic

pushbuttons

8

Sealing screw with vent shown (optional)

9

Side vent for measuring liquid

FIGURE 1-2 Differential Construction; Differential, Flow, and Absolute Models

10

Side vent for measuring gas (supplement H02)

11

Mounting bracket, optional

12

Enclosure setscrew

13

Enclosure rotation limits (see 14 reference

arrow)

14

Enclosure rotation reference arrow; see

Section 4 for details

15

Tag plate

16

Approval plate; Rating plate on other side

17

Enclosure ground screw

This Figure is for Models 7MF4333, 7MF4433,

and 7MF4533.

November 2010

1-4

UMSITRPDS3-1 Introduction

1

Process connection 1/4-18NPT

2

Mounting thread M10 or 7/16-20UMF

3

Field terminals; remove enclosure cap for

access

4

Electronics module and display; remove

enclosure cap for access

5

Sealing screw

6

Enclosure setscrew

7

Enclosure rotation limits; enclosure

rotation reference arrow on neck (see

Section 4 for details)

10

11

12

13

14

15

FIGURE 1-3 Differential Pressure and Flow Models with H03 Option

November 2010

Blanking plug

Access cover over magnetic pushbuttons

Electrical connection:

M20 x 1.5

1/2-14NPT

Tag plate

Approval plate; Rating plate on other side

Enclosure ground screw

This Figure is for Models 7MF4433 and

7MF4533 with H03 option.

1-5

Introduction UMSITRPDS3-1

1

Process connection at low side 1/4-18NPT

2

Mounting thread M10, M12, or 7/16-20UNF

3

Blanking plug

4

Electrical connection:

M20 x1.5

1/2-14NPT

5

Field terminals; remove enclosure cap for

access

6

Electronics module and display; remove

enclosure cap for access

7

Access cover to magnetic pushbuttons

8

Sealing screw with vent shown (optional)

9

Enclosure setscrew

10

Enclosure rotation limits

11

Enclosure rotation reference arrow (not

shown; see Section 4 for details)

12

Tag plate

13

Rating plate; approval plate on other side

This Figure is for Models 7MF4633 and

7MF4812

FIGURE 1-4 Flanged Liquid Level Models

November 2010

1-6

UMSITRPDS3-1 Introduction

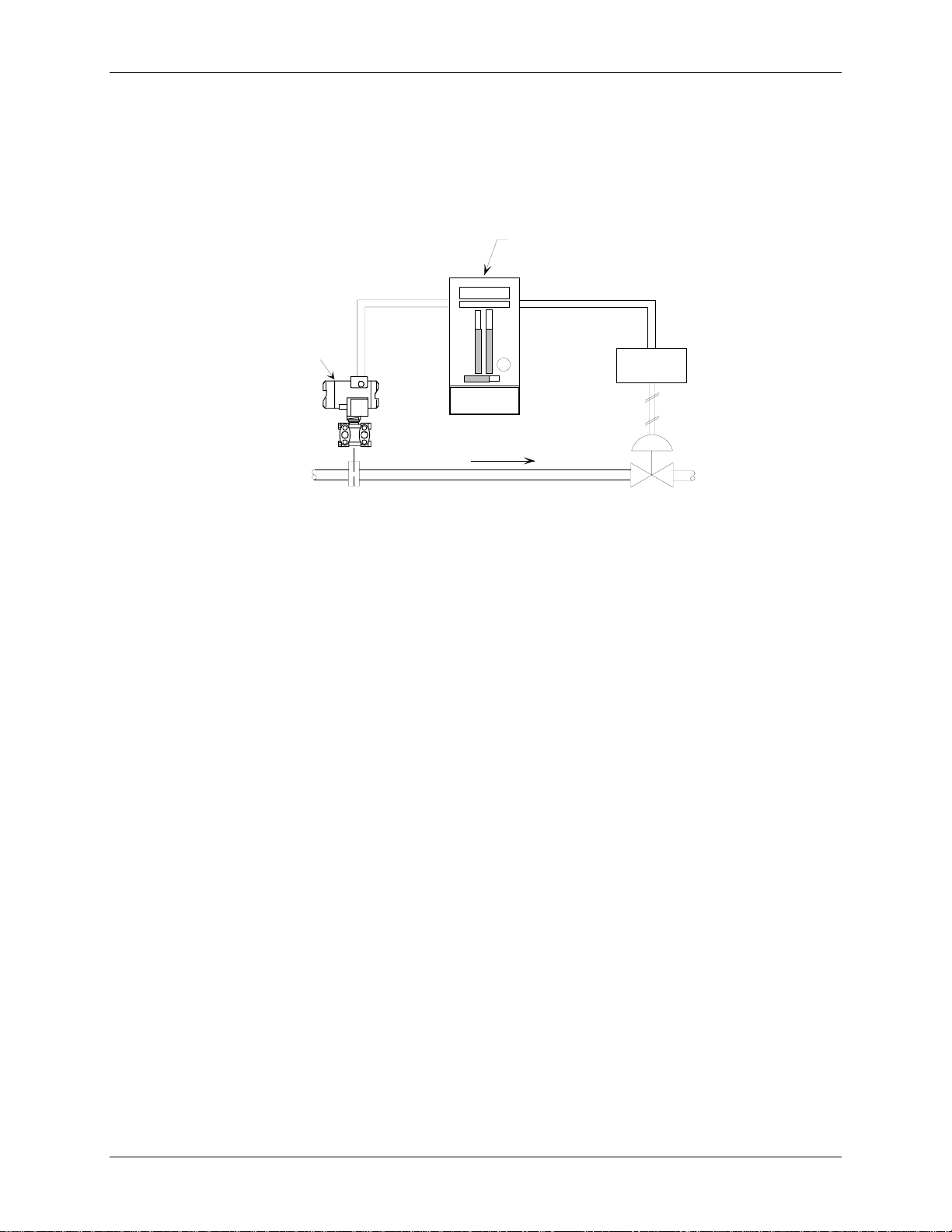

A transmitter can operate in either analog mode or digital mode, as discussed in the following paragraphs.

Analog Mode

A single transmitter is connected to a controller, recorder, or other field device. A loop known as a Pointto-Point network interconnects the instruments. Figure 1-5 shows a traditional application.

Process Automation Controller

2-Wire

4-20 mA

MG00369c

I/P

Model 771

Differential

Transmitter

2-Wire

4-20 mA

Model 353

Flow

FIGURE 1-5 Traditional Application

The HART

®

(Highway Addressable Remote Transducer) protocol is used for communication between the

transmitter and a HART Communicator, a personal computer running configuration software, or another

remote device. This is done by superimposing the HART digital signal on the analog current. HART

communications can be used to transfer a new or edited configuration, remotely monitor the process

variable, or service a transmitter.

Digital Mode

Up to 15 transmitters can be parallel connected to a Multi-Drop network using only shielded, twisted-pair

cable. The HART protocol provides communication between the transmitters and a HART-compatible

controller, recorder, or other device. Each transmitter is identified by a unique network address that is

selected during configuration.

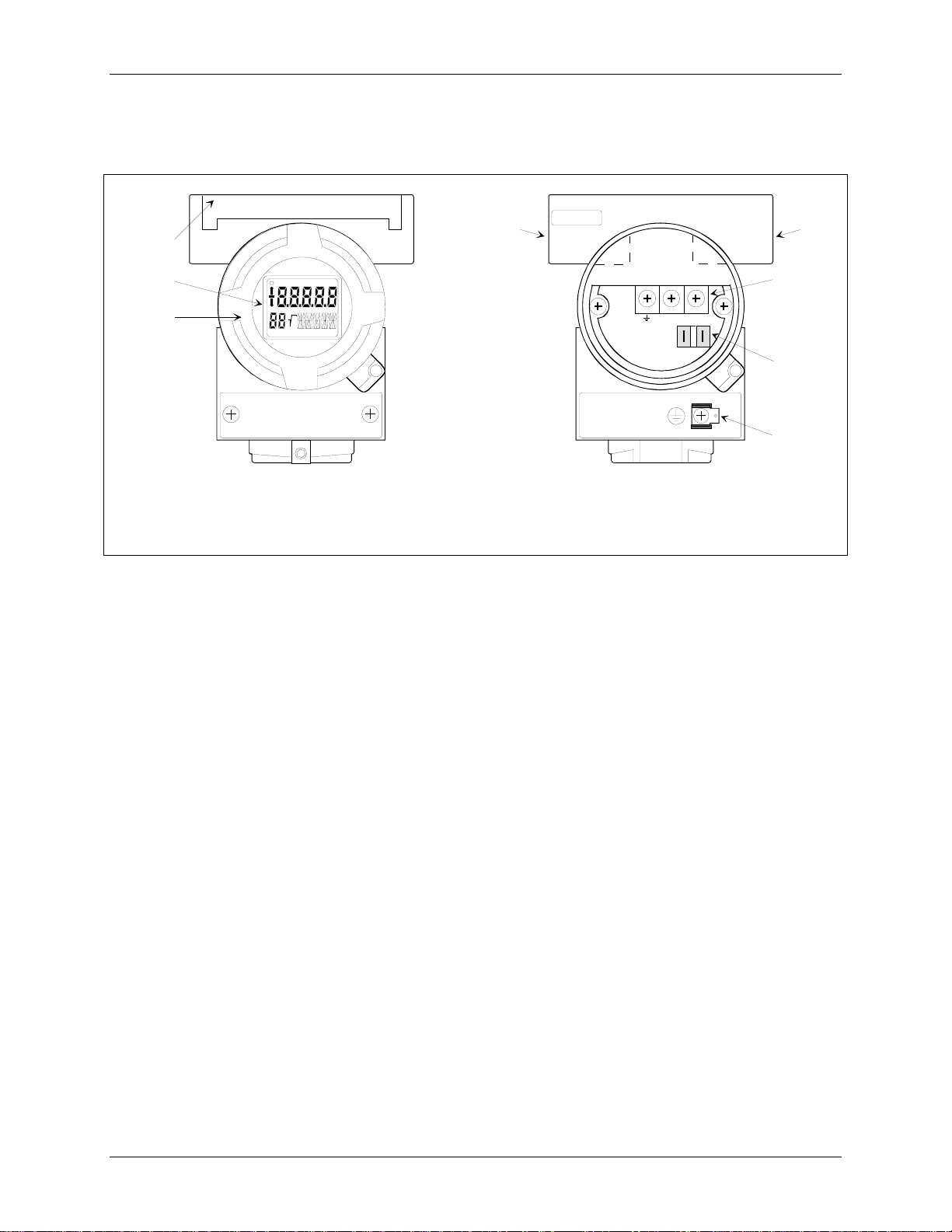

Display, Magnetic Pushbuttons, and Loop Connections

The optional display (Figure 1-6A) permits local viewing of input and output variables and status

messages, and it simplifies local configuration. Local configuration is performed using three magnetic

pushbuttons that are found beneath an access cover in the transmitter housing. Section 6 On-Line

Configuration and Operation describes use of the display and magnetic pushbuttons.

Loop connections are made to a terminal assembly with three screw terminals (Figure 1-6B). The

assembly is located within the transmitter enclosure and is accessed by removing the enclosure cap

adjacent to FIELD TERMINALS on the enclosure. The terminal assembly also has Analog Output Test

Terminals to connect an external digital milliammeter for loop troubleshooting and transmitter

calibration. Loop wiring is shown in Section 4 Installation.

November 2010

1-7

Introduction UMSITRPDS3-1

An enclosure ground connection is located on the housing beneath the field terminal enclosure cap. The

enclosure should always be grounded by a wire connected from this terminal to an earth ground, even

when a ground may be provided by metal conduit protecting the loop wiring.

2

44

1

3

+

+

MG00364b

MG00364b

+

_

-4-20mA+

1

2

3

1

Digital display, optional

2

Magnetic pushbutton access cover

3

Enclosure cap

1

Field terminals for analog output

2

Analog output test terminals

3

Enclosure ground

4

Electrical entrances; plug unused entrance

A. Digital Display B. Field Terminals

FIGURE 1-6 Digital Display and Field Terminals

Transmitters have an intrinsically safe, explosion proof, NEMA 4x (IP67/68), field mountable, hardened

enclosure. Electrical conduit connections are 1/2-14 NPT or M20 x 1.5. All process wetted materials are

316 stainless steel or better. The flush-mount process connection of the liquid level model is compatible

with standard ANSI and metric flange sizes for tanks and pipes.

November 2010

1-8

UMSITRPDS3-1 Introduction

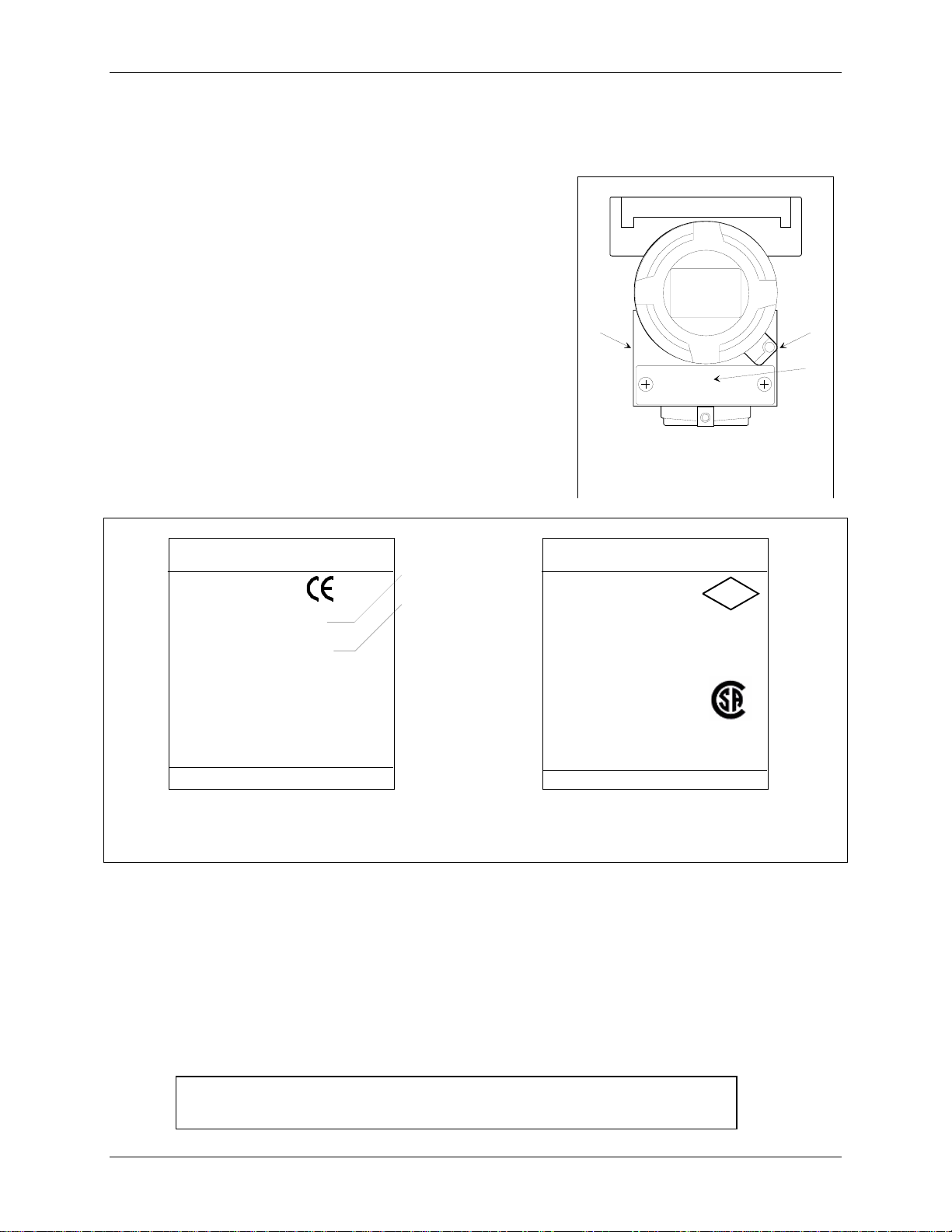

1.3 RATING, APPROVAL, AND TAG PLATES

These plates are fastened to the outside of the transmitter

enclosure, as shown at right. The rating plate shows that

transmitter’s model number, serial number, and performance

data. The approval plate shows that transmitter’s approval and

certification data. Always refer to these plates to confirm the

model number, performance data and approval and certification

data before installing or servicing a transmitter. Representative

plates are shown below.

The tag plate is fastened with two screws so it can be

removed for engraving.

SIEMENS

Springhouse, PA USA

SITRANS P

Transmitter for diff. pressure

7MF4433-1EA22-1NC6-Z

B21

Fab. Nr. IX-T411-9014869

VH :DC 10.5-45V (not intr. safe) outp.: 4-20 mA

Mat.: Connec. Diaphr. O-ring Filling

1.4404 FPM Silicon oil

Measuring span : 2.4 - 240 inH2O

Rated pressure : MWP 2300 psi

Assembled in USA / Components of France

PED:SEP

Type of protection IP 65

Rating Plate

1 Model number

2 Serial number

1

2

MG00384b

+

12

MG00353a

+

3

1 Rating plate

2 Approval plate

3 Tag plate

SIEMENS

Springhouse, PA USA

SITRANS P

(XP/DIP) or (IS)

CL I ZN 0/1 AEx ia IIC T4..T6 (FM)

Ex ia IIC T4. .T6 (CSA cert.2000.1153651)

CL I DIV 1, GP ABCD T4..T6; CL II, DIV 1, GP EFG; CL III

Vi < 30V : Ii < 100 mA : Pi < 0.75 W

Ci < 6 nF : Li < 0.4 mH

Per Control Dwg. A5E00072 770A

CL 1 Div 2 GP ABCD T4..T6

CL II DIV 2 GP FG; CL III

Vmax = 30 V

Ta = T4: -40..85ºC ; T6: -40..60ºC

ENCL Type 4X, seal not required

FW: 0011.03.06 HW: 02.05.01

Assembled in USA / Components of France

Approval Plate

FM

APPROVED

MG00384b

1.4 CONFIGURATION

A transmitter must be configured before use. Each transmitter is shipped with either a default

configuration or, if specified at time of order, a custom configuration defined by the user. The default

configuration may need to be edited before the transmitter is used in a loop. The configuration is stored

within the transmitter in a non-volatile memory.

A configuration can be created or edited locally at the transmitter’s magnetic pushbuttons or remotely

using the Model 275 HART Communicator.

Note: If using a Model 375 Field Communicator, see the inside of the front

cover of this manual.

November 2010

1-9

Introduction UMSITRPDS3-1

1.5 CUSTOMER/PRODUCT SUPPORT

Support is available through an online Support Request service; a link is provided in

the table at the end of this section.

When contacting Siemens for support:

• Please provide complete product information:

• For hardware, this information is provided on the product nameplate

(part number or model number, serial number, and/or version).

• For most software, this information is given in the Help > About screen.

• If there is a problem with product operation:

• Is the problem intermittent or repeatable? What symptoms have been observed?

• What steps, configuration changes, loop modifications, etc. were performed before the

problem occurred?

• What status messages, error messages, or LED indications are displayed?

• What troubleshooting steps have been performed?

• Is the installation environment (e.g. temperature, humidity) within the product’s specified

operating parameters? For software, does the PC meet or exceed the minimum requirements

(e.g. processor, memory, operating system)?

• A copy of the product Service Instruction, User’s Manual, or other technical publication should be at

hand. The Siemens public Internet site (see the table) has current revisions of technical literature, in

Portable Document Format, for downloading.

• To send an instrument to Siemens for warranty or non-warranty service, call Customer Service and

Return to request a Return Material Authorization (RMA); see the table below.

IMPORTANT

An instrument must be thoroughly cleaned (decontaminated) to remove any process

materials, hazardous materials, or blood-borne pathogens prior to return for repair. Read

and complete the Siemens RMA form(s).

For support and the location of your local Siemens representative, refer to the table below for the URL of

the Process Instrumentation (PI) portion of the Siemens public Internet site. Once at the site, click

Support in the right column and then Product Support. Next select the type of support desired: sales,

technical (see the table below), documentation, or software.

Online Support Request http://www.siemens.com/automation/support-request

Technical Support 1-800-333-7421; 8 a.m. to 4:45 p.m. eastern time, Monday through Friday (except

holidays)

Customer Service & Returns 1-800-365-8766 (warranty and non-warranty)

Public Internet Site http://www.usa.siemens.com/pi

Technical Publications

in PDF

Click the above link to go to the PI home page. Click Support and then Manuals

and then, under “Additional Manuals,” select the product line (e.g. Control

Solutions)

November 2010

1-10

UMSITRPDS3-1 Model 275 Universal Hart Communicator

2.0 MODEL 275 UNIVERSAL HART COMMUNICATOR

The Model 275 Universal HART Communicator is a handheld interface that provides a common

communication link to SITRANS P transmitters and other HART-compatible instruments.

This section describes HART Communicator connections, liquid crystal display, keypad, and on-line and

off-line menus. It also provides overviews of many Communicator functions. The Communicator is

shown in Figure 2-1. For information about the Communicator’s battery pack, Memory Module, Data

Pack, and maintenance procedures, refer to the manual supplied with the Communicator.

2.1 INTRODUCTION

The HART Communicator connects to and communicates with a transmitter or other HART device using

a 4-20 mA loop, provided a minimum load resistance of 250Ω is present between the Communicator and

the power supply. The Communicator uses Bell 202 frequency-shift keying (FSK) to impose highfrequency digital signals on a standard 4-20 mA current loop. Because no net energy is added to the loop,

HART communication does not disturb the 4-20 mA signal.

The Communicator can be used in hazardous and non-hazardous locations.

WARNING

Explosion can cause death or serious injury.

Before connecting the HART Communicator in an

explosive atmosphere, be sure that the instruments in

the loop are installed in accordance with intrinsically

safe or non-incendive field wiring practices.

Refer to the Communicator nameplate and the supplied

manual for certifications and approvals before

connecting, or making a connection to the serial port or

NiCad charger port on the Communicator.

2.2 COMMUNICATOR CONNECTIONS

The Communicator can interface with a transmitter from the control room, the instrument site, or any

wiring termination point in the loop. Connections are made through a supplied 40" (1m) cable (dual

banana plug to mini-hook test clips). The connection panel also may have a jack for the optional NiCad

charger, and it has a serial port for a future connection to a personal computer (PC).

To interface with a transmitter or other HART device, connect the HART Communicator in parallel with

the instrument or load resistor. The connections are non-polar. For intrinsically safe FM and CSA wiring

connections, see the manual supplied with the Communicator.

Figure 2-2 illustrates typical wiring connections between the HART Communicator and a loop with a

transmitter or other HART-compatible device in a loop. The Communicator is quickly connected into a

transmitter loop.

November 2010

2-1

Model 275 Universal Hart Communicator UMSITRPDS3-1

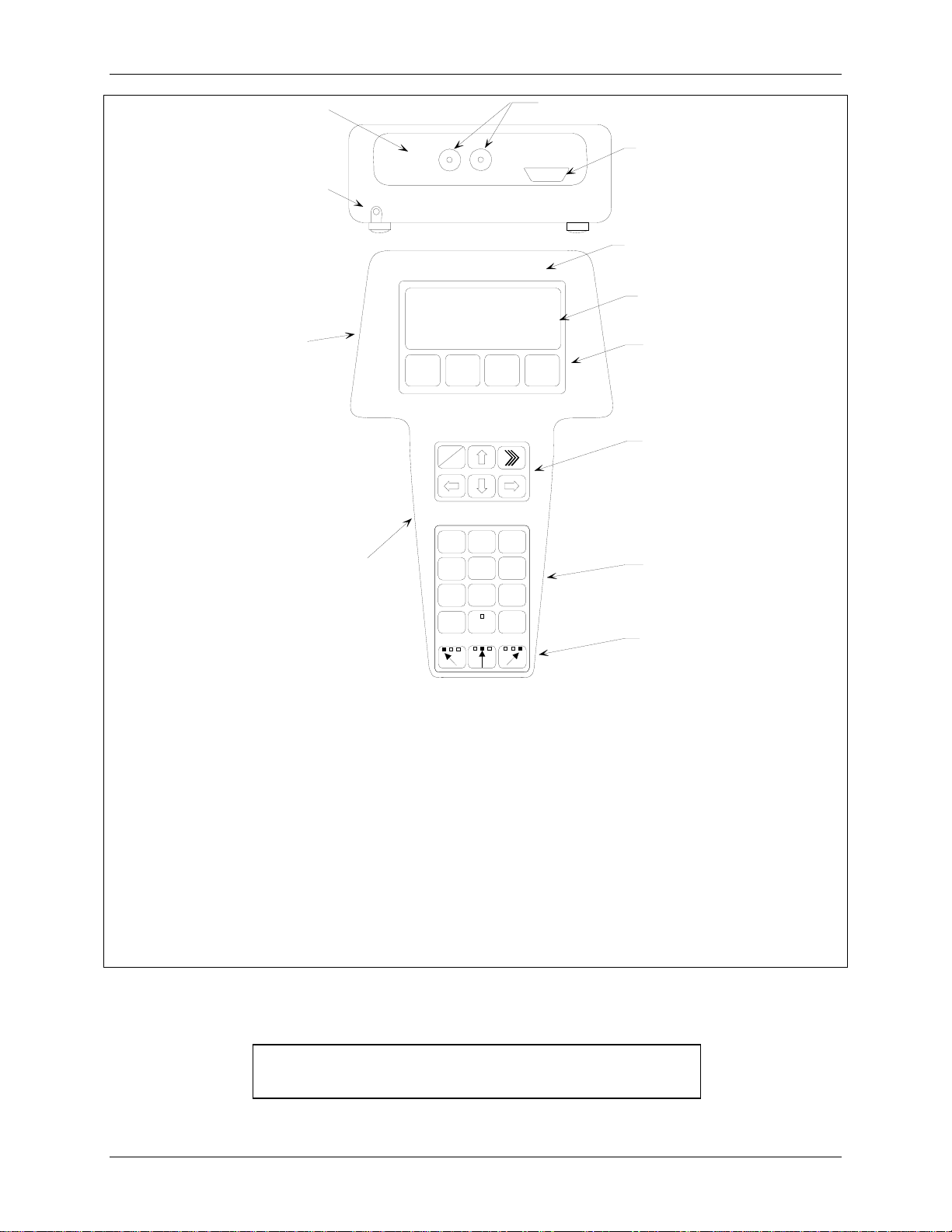

9

10

11

12

1

2

7

F1 F2 F3 F4

3

HART Communicator

4

5

6

MG00360a

I

O

A B C D E F G H I

13

2

J K L

8

M N O P Q R

4

5

V W X Y Z /

S T U

78

# % &

< >

.

0

6

9

+

:

*

_

Model 275 Universal HART Communicator

1

Liquid Crystal Display (LCD), 8 lines, 21 characters per line

2

Function Keys (softkeys), software defined

3

Action Keys – ON/OFF (I/O), Up Arrow, Quick Access Key (>>>), Previous Menu (Back, left arrow),

4

Down Arrow, Select (Forward, right arrow)

Alphanumeric Keys (keypad number sequence may be different from that shown)

5

Shift Keys – Use to select alphabetic and other characters above a number, period, or dash.

6

Communicator Nameplate – On back of device. See nameplate for certifications and approvals

7

before connecting in a hazardous location.

Communicator model number and serial number on back

8

Connection panel.

9

Non-polar loop connection; dual banana plug

10

Serial port for PC connection; DB9

11

NiCad Charger Jack, optional

12

FIGURE 2-1 Model 275 Universal HART Communicator

Note: If using a Model 375 Field Communicator, see the

inside of the front cover of this manual.

November 2010

2-2

UMSITRPDS3-1 Model 275 Universal Hart Communicator

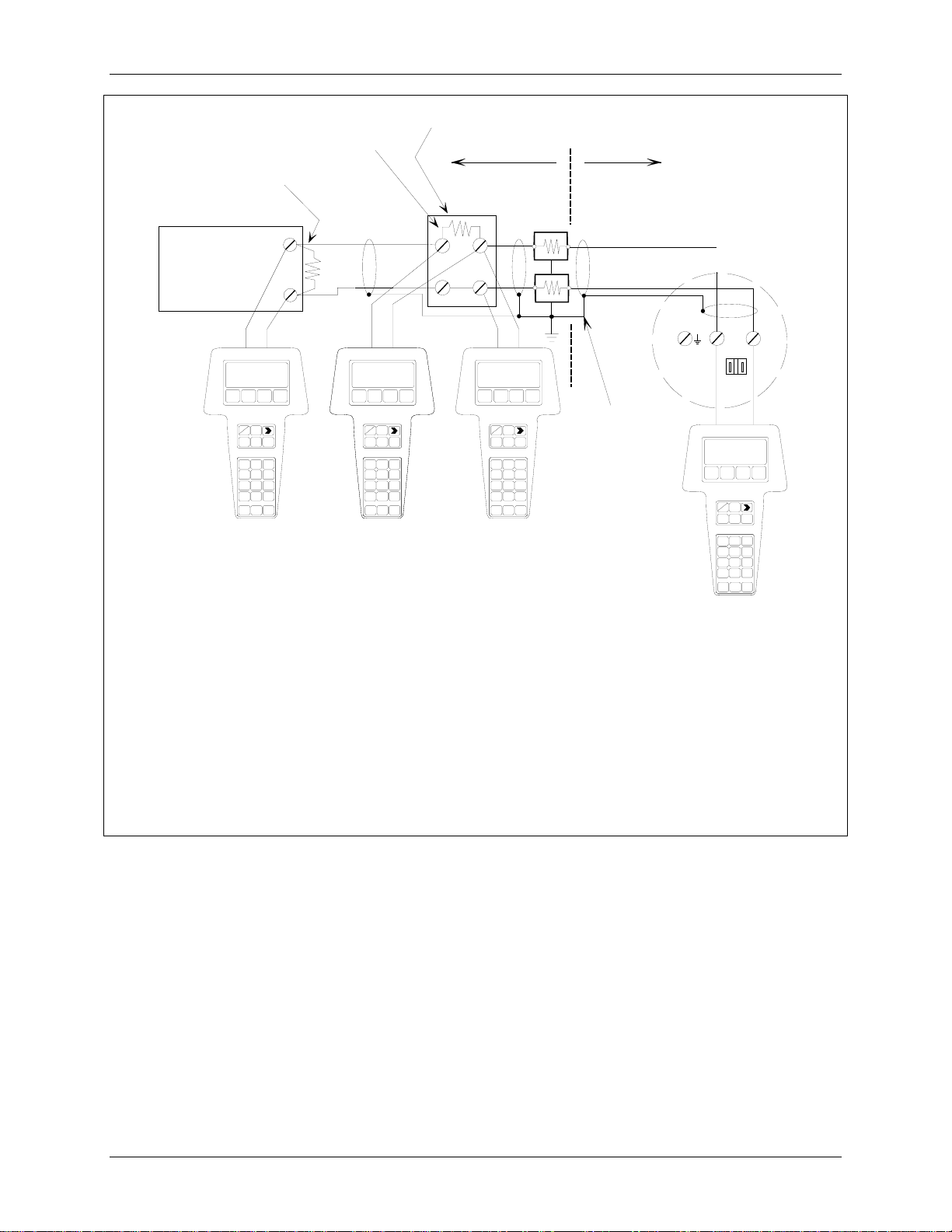

Range Resistor

250, typical

Controller,

Recorder, or

Other 1-5 Vdc

Device; See

Note 2

I

Current Sense

Resistor 250 to

1100; See Note 3

+

_

O

See

Note 1

Circuit

Junction

MG00359a

Non-Hazardous

Location

Hazardous

Location

Transmitter

Terminals

_

+

- +

4-20 mA

See Note 4

IOI

O

I

O

I

See

O

Note 1

Notes:

1 HART Communicator Connections:

Non-hazardous location – Connect as shown above.

Hazardous location – Refer to Communicator nameplate and the manual supplied with the

Communicator for certifications and approvals before connecting.

The HART Communicator is a non-polar device.

2 The System Power Supply may be part of the host input device or a separate device.

3 Network resistance equals the sum of the barrier resistances and the current sense resistor.

Minimum value is 250!; maximum value is 1100!.

4 Supply and return barriers are shown. Interconnect all cable shields and ground only at the barriers.

FIGURE 2-2 HART Communicator Connections to a Transmitter Loop

November 2010

2-3

Model 275 Universal Hart Communicator UMSITRPDS3-1

2.3 CONTROLS OVERVIEW

As shown in Figure 2-1, the front of the HART Communicator has five major functional areas: liquid

crystal display (LCD), function keys, action keys, alphanumeric keys, and shift keys. The next five

sections describe how each of these functional areas is used to enter commands and display data.

2.3.1 Liquid Crystal Display

The liquid crystal display (LCD) is an 8-line by 21-character display that provides communication

between the user and a connected device. When the HART Communicator is connected to a SITRANS P

transmitter or other HART-compatible device, the top line of the Online menu displays the model name

of the device and its tag. A typical display is shown below. The actual display content can vary with the

device type and manufacturer.

SITRANS P

Online "

1->Pres

2 Type

3 Device setup

HELP |SAVE

Note: If using a Model 375 Field

Communicator, see the inside of

the front cover of this manual.

The bottom line of each menu is reserved for dynamic labels for the software-defined function keys, F1F4, which are found directly below the display. More information on software-defined function keys is

given in the next section.

2.3.2 Software-Defined Function Keys

The four software-defined function keys (softkeys), located below the LCD and marked F1 through F4,

are used to perform software functions as indicated by the dynamic labels. Pressing the function key

immediately beneath a label activates the displayed function.

The label appearing above a function key indicates the function of that key for the current menu

. For

example, in menus providing access to on-line help, the HELP label appears above the F1 key. In menus

providing access to the Online menu, the HOME label appears above the F3 key. Table 2-1 lists these

labels and describes what happens when each function key is pressed.

November 2010

2-4

UMSITRPDS3-1 Model 275 Universal Hart Communicator

TABLE 2-1 Function Keys with Their Labels and Actions Performed

F1 F2 F3 F4

HELP

Access on-line help

RETRY

Try to reestablish

communication

EXIT

Leave the current menu

YES

Answer to yes/no

question

ALL

Include current Quick

Access Key item on

Quick Access Key

menu for all devices

ON/OFF

Activate or deactivate a

bit-enumerated binary

variable

DEL

Delete current

character or Quick

Access Key menu item

SEND

Send configuration

data to device

PGUP

Move up one help

screen

PREV

Go to previous

message in a list of

messages

ABORT

Terminate current task

ESC

Leave a value

unchanged

QUIT

Terminate session

because of a

communication error

PGDN

Move down one help

screen

NEXT

Go to next message in

a list of messages

OK

Acknowledge

information on the

LCD

ENTER

Accept user-entered

data

EXIT

Leave the current menu

NO

Answer to yes/no

question

ONE

Include Quick Access

Key item for one

device

NEXT

Go to the next variable

in off-line edit

FILTR

Open customization

menu to sort

configurations

XPAND

CMPRS

SAVE

Save information to

Communicator

MARK

Toggle marked

variable in

configuration to be sent

to a field device

Opens detailed

configuration

information

Closes detailed

configuration

information

HOME

Go the top menu in the

device description

BACK

Go back to the menu

from which HOME

was pressed

EDIT

Edit a variable value

ADD

Add current item to

Quick Access Key

menu

November 2010

2-5

Model 275 Universal Hart Communicator UMSITRPDS3-1

2.3.3 Action Keys

Directly beneath the LCD and software-defined function keys are six blue, white, and black action keys.

Each has a specific function as described below:

I

ON/OFF KEY – Use to power-up the Communicator. When the Communicator is turned on,

it automatically searches for a HART-compatible device on the 4-20 mA loop. If no device is

O

found, the Communicator displays the Main menu:

If a SITRANS P transmitter is found, the Communicator displays the Online menu:

UP ARROW KEY – Use to move the cursor up through a menu or list of options or to scroll

through lists of available characters when editing fields that accept both alpha and numeric

data.

DOWN ARROW KEY – Use to move the cursor through a menu or a list of options or to

scroll through lists of available characters when editing fields that accept alpha and numeric

data.

LEFT ARROW/PREVIOUS MENU KEY – Use to move the cursor to the left or back to the

previous menu.

HART Communicator

1#Offline

2 Online

3 Frequency device

4 Utility

SITRANS P

Online "

1#Pres

2 Type

3 Device setup

HELP |SAVE

RIGHT ARROW/SELECT KEY – Use to move the cursor to the right or to select a menu

option.

QUICK ACCESS KEY (HOT KEY) – When the Communicator is on and connected to a

HART-compatible device, pressing the Quick Access Key instantly displays the Quick Access

Key menu of user-defined options. When the Communicator is off and the Quick Access Key

is pressed, the Communicator automatically powers-up and displays the Quick Access Key

menu.

See Section 2.6 for more information on using the Quick Access Key.

November 2010

2-6

UMSITRPDS3-1 Model 275 Universal Hart Communicator

IMPORTANT

When performing certain operations, the message “OFF KEY DISABLED”

indicates that the Communicator cannot be turned off. This feature helps prevent

accidental shutoff of the Communicator while the output of a device is fixed or a

device variable is being edited.

2.3.4 Alphanumeric and Shift Keys

The alphanumeric keys perform two functions: (1) rapid selection of menu options and (2) data entry. The

shift keys located below the alphanumeric keys on the keypad are used during data entry to select from

among the characters available above each number.

2.3.4.1 Rapid Selection of Menu Options

From any menu, use the keypad to select available options in two ways. First, use the UP or DOWN

arrow keys, followed by the RIGHT ARROW/SELECT key, to access available options displayed on the

LCD.

As an alternative, use the rapid select feature. Simply press the number on the alphanumeric keypad that

corresponds to the desired menu option. For example, to quickly access the Utility menu from the Main

menu, simply press “4” on the keypad.

2.3.4.2 Data Entry

Some menus require data entry. Use the alphanumeric and shift keys to enter all alphanumeric

information into the HART Communicator. Pressing an alphanumeric key alone while editing causes the

large character in the center of the key (number 0-9, decimal point, or dash) to be entered.

Pressing and releasing a shift key activates shift and causes the appropriate arrow icon ($, %, or &) to

appear in the upper right-hand corner of the LCD. When shift is activated, the indicated alpha characters

or symbols are entered when the keypad is used.

Example

To enter a number, such as “7,” simply press the number key.

To enter one of the small characters appearing above the large numeral (i.e., a letter, space, or

mathematical symbol), first press and release

the corresponding shift key at the bottom of the keypad,

then press the desired alphanumeric key. To enter the letter “E,” press and release the middle shift key,

then press the number “2” key.

To deactivate a shift key without entering a letter, space, or mathematical symbol, simply press that shift

key again.

November 2010

2-7

Model 275 Universal Hart Communicator UMSITRPDS3-1

A

2.4 GETTING TO KNOW THE COMMUNICATOR

The HART Communicator operates either on-line or off-line. Off-line operation is used to create or edit a

configuration that can then be downloaded to a HART device, such as a transmitter. On-line operation is

used to download a configuration to a HART device, upload a configuration, edit HART device operating

parameters, and monitor process values.

For off-line operation, the Communicator need not be connected to a HART device. On-line operation

requires a connection to a powered HART device.

The menu that appears first when the Communicator is turned on depends on whether the Communicator

is connected to a powered HART device.

• Communicator not connected - Main menu (off-line operation)

• Communicator connected - Online menu (on-line operation)

To work off-line when connected to a powered loop, access the Main menu from the Online menu by

pressing the LEFT ARROW/PREVIOUS MENU key.

Note

Communicator internal operation is controlled by firmware. Consequently,

operation will depend upon the firmware version and the installed device drivers,

as discussed in this section.

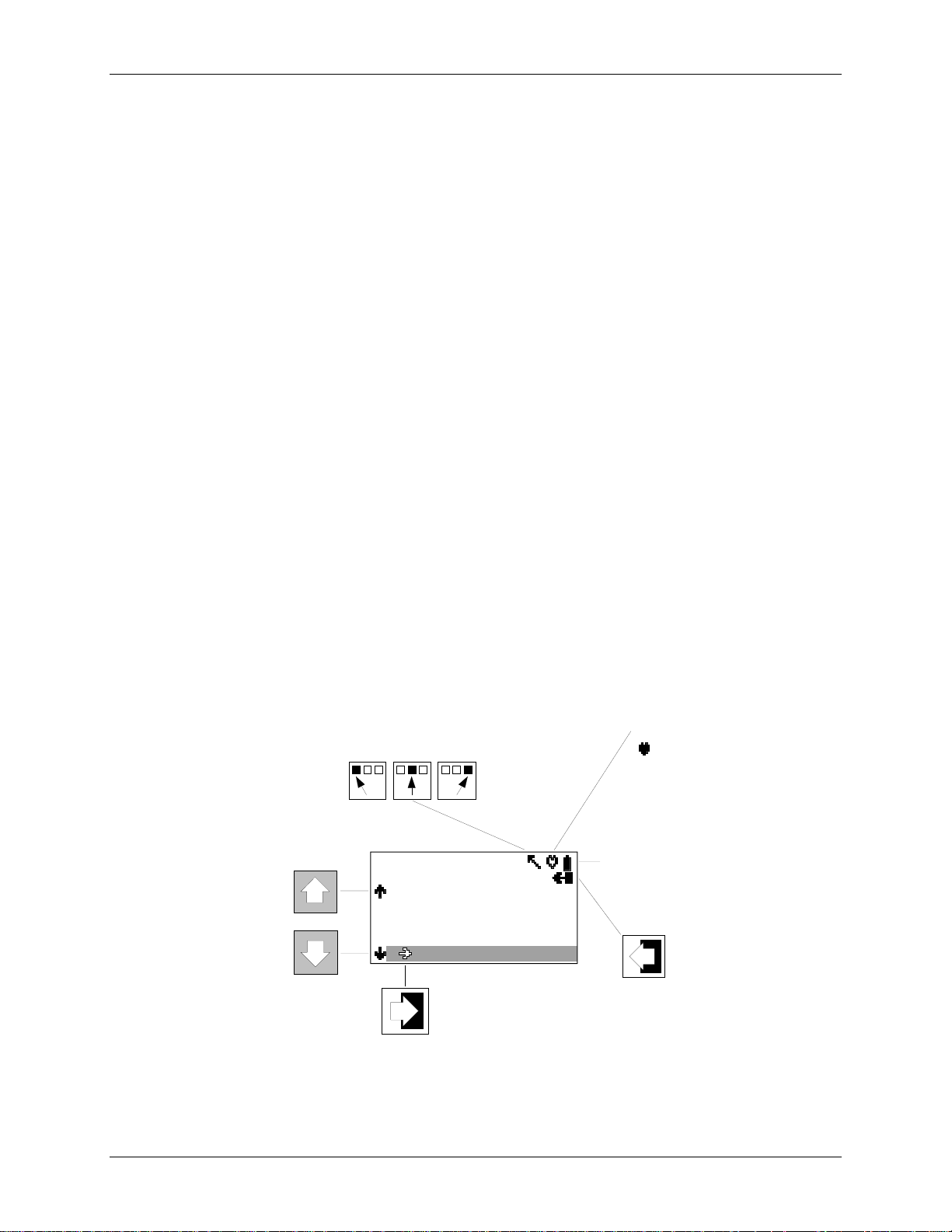

2.4.1 Display Icons

Several different symbols (icons) appear on the LCD to show the state of the Communicator and provide

visible response to actions of the user. Figure 2-3 shows the display icons and how they relate to keypad

functions.

HART Communication

( indicates connected

device is configured in

the burst mode)

ccess Additional

Menu Items

HART Communicator

Device Info

2 Dev Type

3 Dev ID 0

4 Tag

5 MM/DD/YY 10/10/10

6 Write Protect Yes

Low Battery

Access

Previous

Menu

X03034S1

FIGURE 2-3 HART Communicator Display Icons

November 2010

2-8

Loading...

Loading...