SHARP KB3425L, KB-3425JK, KB-3425JW, KB-4425JS, KB-442 Service Manual

...

KB-3425LS/K/W

KB-4425LS/K/W

SERVICE MANUAL

S66R264KB442L

FREE STANDING/SLIDE-IN RANGE

WITH MICROWAVE DRAWER

MODELS

KB-3425LS KB-3425LK KB-3425LW

KB-4425LS KB-4425LK KB-4425LW

KB-4425LW pictured

WARNING TO SERVICE PERSONNEL:

This service manual is intended for use by persons having electrical and mechanical training and a level of knowledge of these subjects generally considered acceptable in the appliance repair trade. Sharp Electronics Corporation cannot be responsible, nor assume any liability, for injury or damage of any kind arising from the use of this manual.

Microwave ovens contain circuitry capable of producing very high voltage and current. Contact with the following parts may result in a severe, possibly fatal, electrical shock. (High Voltage Capacitor, High Voltage Power Transformer, High Voltage Rectifier and Heat sink etc., and Magnetron, High Voltage Harness etc..)

TABLE OF CONTENTS |

|

|

Page |

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO |

|

AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY..................... |

INSIDE FRONT COVER |

BEFORE SERVICING........................................................................................................ |

INSIDE FRONT COVER |

WARNING TO SERVICE PERSONNEL................................................................................................................. |

3 |

MICROWAVE MEASUREMENT PROCEDURE..................................................................................................... |

5 |

FOREWORD AND WARNING................................................................................................................................ |

7 |

PRODUCT SPECIFICATIONS................................................................................................................................ |

8 |

POWER CONNECTION....................................................................................................................................... |

10 |

ANTI-TIP DEVICE................................................................................................................................................. |

12 |

CONTROL LAYOUT.............................................................................................................................................. |

13 |

SCHEMATICS....................................................................................................................................................... |

14 |

TEST PROCEDURES........................................................................................................................................... |

18 |

TOUCH CONTROL PANEL ASSEMBLY............................................................................................................... |

29 |

OVEN/MICROWAVE DRAWER DISASSEMBLY.................................................................................................. |

40 |

WIRING DIAGRAMS............................................................................................................................................. |

52 |

PRINTED WIRING BOARDS................................................................................................................................ |

58 |

PARTS LIST.......................................................................................................................................................... |

63 |

PACKING AND ACCESSORIES........................................................................................................................... |

74 |

SHARP ELECTRONICS CORPORATION

This document has been published to be used for after sales service only. The contents are subject to change without notice.

KB-3425LS/K/W

KB-4425LS/K/W

PRECAUTIONSTO BE OBSERVED BEFORE AND DURING SERVICING TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

(a)Do not operate or allow the oven to be operated with the door open.

(b)Make the following safety checks on all ovens to be serviced before activating the magnetron or other microwave source, and make repairs as necessary: (1) interlock operation, (2) proper door closing, (3) seal and sealing surfaces (arcing, wear, and other damage), (4) damage to or loosening of hinges and latches, (5) evidence of dropping or abuse.

(c)Before turning on microwave power for any service test or inspection within the microwave generating compartments, check the magnetron, wave guide or transmission line, and cavity for proper alignment, integrity, and connections.

(d)Any defective or misadjusted components in the interlock, monitor, door seal, and microwave generation and transmission systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is released to the owner.

(e)A microwave leakage check to verify compliance with the Federal Performance Standard should be performed on each oven prior to release to the owner.

BEFORE SERVICING

Before servicing an operative unit, perform a microwave emission check as per the Microwave Measurement Procedure outlined in this service manual.

If microwave emissions level is in excess of the specified limit, contact SHARP ELECTRONICS CORPORATION immediately @1-800-237-4277.

If the unit operates with the door open, service person should 1) tell the user not to operate the oven and 2) contact SHARP ELECTRONICS CORPORATION and Food and Drug Administration's Center for Devices and Radiological Health immediately.

Service personnel should inform SHARP ELECTRONICS CORPORATION of any certified unit found with emissions in excess of 4mW/cm2. The owner of the unit should be instructed not to use the unit until the oven has been brought into compliance.

KB-3425LS/K/W

KB-4425LS/K/W

WARNING TO SERVICE PERSONNEL

Range units contain circuitry capable of producing very high voltage and current, contact with following parts may result in a severe, possibly fatal, electrical shock.

(Example)

High Voltage Capacitor, High Voltage Power Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness, Heating Elements, etc..

Read the Service Manual carefully and follow all instructions.

Before Servicing

1.Disconnect the power supply cord

, and then remove cabinet.

, and then remove cabinet.

2.Open the drawer and keep it open.

3.Discharge high voltage capacitor.

WARNING: RISK OF ELECTRIC SHOCK. DISCHARGE THE HIGH-VOLTAGE CAPACITOR BEFORESERVICING.

The high-voltage capacitor remains charged about 60 seconds after the oven has been switched off. Wait for 60 seconds and then short-circuit the connection of the high-voltage capacitor (that is the connecting lead of the high-voltage rectifier) against the chassis with the use of an insulated screwdriver.

When the testing is completed,

1.Disconnect the power supply cord, and then remove covers.

2.Open the drawer and keep it open.

3.Discharge high voltage capacitor.

4.Reconnect the leads to the primary of the power transformer.

5.Reinstall the covers.

6.Reconnect the power supply cord.

7.Run the unit and check all functions.

After repairing

1.Reconnect all leads removed from components during testing.

2.Reinstall the covers.

3.Reconnect the power supply cord.

4.Run the oven and check all functions.

Whenever troubleshooting is performed the power supply must be disconnected. It may, in some cases, be necessary to connect the power supply after the outer case has been removed, in this event:

1.Disconnect the power supply cord, and then remove neccessary covers.

2.Open the drawer and keep it open.

3.Discharge high voltage capacitor.

4.Disconnect the leads to the primary of the power transformer.

5.Ensure that the leads remain isolated from other components and oven chassis by using insulation tape.

6.After that procedure, reconnect the power supply cord.

Microwave ovens should not be operated empty. To test for the presence of microwave energy within a cavity, place a cup of cold water on the oven tray, close the drawer and set the power to HIGH and set the microwave timer for two (2) minutes. When the two minutes has elapsed (timer at zero) carefully check that the water is now hot.If the water remains cold carry out Before Servicing procedure and re-examine the connections to the component being tested.

When all service work is completed and the oven is fully assembled, the microwave power output should be checked and a microwave leakage test should be carried out.

KB-3425LS/K/W

KB-4425LS/K/W

SAFE SERVICING PRACTICES

To avoid personal injury and/or property damage, it is important that SafeServicing

Practices be observed. The following are some limited examples of safe practices:

1.DO NOT attempt a product repair if you have any doubts as to your ability to complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

•Removethepowercordfromtheelectricaloutlet,tripthecircuitbreakertothe OFF position, or remove the fuse.

3. Never interfere with the proper operation of any safety device.

4.USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE. SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY STANDARDS SET FOR HOME APPLIANCES.

5.GROUNDING : The standard color coding for safety ground wires is GREEN, or GREEN with YELLOW STRIPES . Ground leads are not to be used as current carrying conductors. It is EXTREMELY important that the service technician reestablish all safety grounds prior to completion of service. Failure to do so will create a hazard.

6. Prior to returning the product to service, ensure that:

•All electrical connections are correct and secure

•Allelectricalleadsareproperlydressedandsecuredawayfromsharpedges, high-temperaturecomponents,andmovingparts

•Allnon-insulatedelectricalterminals,connectors,heaters,etc.areadequately spaced away from all metal parts and panels

•All safety grounds (both internal and external) are correctly and securely connected

•All panels are properly and securely reassembled

ATTENTION!!!

Thisservicemanualisintendedforusebypersonshavingelectricalandmechanicaltraining andalevelofknowledgeofthesesubjectsgenerallyconsideredacceptableintheappliance repairtrade. SharpElectronicsCorporationcannotberesponsible,norassumeanyliability, for injury or damage of any kind arising from the use of this manual.

KB-3425LS/K/W

KB-4425LS/K/W

MICROWAVE MEASUREMENT PROCEDURE

A. Requirements:

1)Microwave leakage limit (Power density limit): The power density of microwave radiation emitted by a microwave oven should not exceed 1mW/cm2 at any point 5cm or more from the external surface of the oven, measured prior to acquisition by a purchaser, and thereafter (through the useful life of the oven), 5 mW/cm2 at any point 5cm or more from the external surface of the oven.

2)Safety interlock switches:

Primary interlock relay switch shall prevent microwave radiation emission in excess of the requirement as above mentioned. Secondary interlock relay and door sensing switch shall prevent microwave radiation emission in excess of

5 mW/cm2 at any point 5cm or more from the external surface of the oven.

B. Preparation for testing:

Before beginning the actual measurement of leakage, proceed as follows:

1) Make sure that the actual instrument is operating normally as specified in its instruction booklet.

Important:

Survey instruments that comply with the requirement for instrumentation as prescribed by the performance standard for microwave ovens, 21 CFR 1030.10(c)(3)(i), must be used for testing.

2)Place the load of 275±15 ml (9.8 oz) of tap water initially at 20±5O C (68OF) in the center of the oven cavity.

The water container shall be a low form of 600 ml (20 oz) beaker with an inside diameter of approx. 8.5 cm (3-1/2 in.) and made of an electrically nonconductive material such as glass or plastic.

The placing of this standard load in the oven is important not only to protect the oven, but also to insure that any leakage is measured accurately.

3)Set the cooking control on Full Power Cooking Mode.

4)Close the drawer and select a cook cycle of several minutes. If the water begins to boil before the survey is completed, replace it with 275 ml of cool water.

C. Leakage test:

Closed-drawer leakage test (microwave measurement):

1)Grasp the probe of the survey instrument and hold it perpendicular to the gap between the drawer and the body of the oven.

2)Move the probe slowly, not faster than 1 in./sec. (2.5 cm/sec.) along the gap, watching for the maximum indication on the meter.

3)Check for leakage at the drawer screen, sheet metal seams and other accessible positions where the continuity of the metal has been breached (eg., around the switches, indicator, and vents).

While testing for leakage around the drawer, pull the drawer away from the front of the oven as far as is permitted by the closed latch assembly.

4)Measure carefully at the point of highest leakage and make sure that the highest leakage is no greater than 4mW/cm2, and that the primary interlock switch/secondary interlock relay does turn the oven OFF before any door movement.

KB-3425LS/K/W

KB-4425LS/K/W

NOTES

SERVICE MANUAL

FREE STANDING /SLIDE-IN RANGE

WITH MICROWAVE DRAWER

KB-3425LS / KB-3425LK / KB-3425LW

KB-4425LS / KB-4425LK / KB-4425LW

FOREWORD

This Manual has been prepared to provide Sharp Electronics Corp. Service Personnel with Operation and Service Information for the SHARP FREE STANDING and SLIDE-IN RANGEWITH MICROWAVE DRAWER, KB-3425LS/JK/JW and KB-4425LS/JK/JW

It is recommended that service personnel carefully study the entire text of this manual so that they will be qualified to render satisfactory customer service.

Check the interlock switches and the door seal carefully. Special attention should be given to avoid electrical shock and microwave radiation hazard.

WARNING

Never operate the oven until the following points are ensured.

(A)The door is tightly closed.

(B)The door brackets and hinges are not defective.

(C)The door packing is not damaged.

(D)The door is not deformed or warped.

(E)There is not any other visible damage with the oven.

Servicing and repair work must be carried out only by trained service

personnel.

DANGER

Certaininitialpartsareintentionallynotgroundedandpresent a risk of electrical shock only during servicing. Service personnel - Do not contact the following parts while the appliance is energized;

High Voltage Capacitor, PowerTransformer, Magnetron, High Voltage Rectifier Assembly, High Voltage Harness;

If provided, Vent Hood, Fan assembly, Cooling Fan Motor.

All the parts marked “*” on parts list are used at voltages more than 250V.

Removal of the outer wrap gives access to voltage above 250V.

All the parts marked “∆” on parts list may cause undue microwave exposure, by themselves, or when they are damaged, loosened or removed.

SHARP ELECTRONICS CORPORATION

SHARP PLAZA, MAHWAH,

NEW JERSEY 07430-2135

KB-3425LS/K/W

KB-4425LS/K/W

PRODUCT DESCRIPTION

POWER CONNECTION

ANTI-TIP DEVICE

SCHEMATICS

TEST PROCEDURE

TOUCH CONTROL PANEL

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

WIRING DIAGRAM

PARTS LIST

KB-3425LS/K/W

KB-4425LS/K/W

|

OVEN SPECIFICATION |

|

|

|

|

ITEM |

|

DESCRIPTION |

Power Requirements |

20 /208 - 120/240Volts / 46/50 Amperes |

|

|

60 Hertz |

|

|

Single phase, 3 wire grounded |

|

|

|

|

Thermal Oven Heating Elemants |

Top - 3000W Bottom - 3000W Rear - 2500W |

|

|

|

|

Case Dimensions |

Width |

29-7/8" |

|

Height |

36" |

|

Depth |

27-7/8 |

|

|

|

Cooking Cavity Dimensions |

Width |

22-5/8" |

|

Height |

15-13/16" |

3.6 Cubic Feet |

Depth |

18" |

|

|

|

Cook Top Heating Elements |

Two 6" - 1200W |

|

|

One 8" - 2000W |

|

|

One 6"/9" - 1200/2400W One 6" - 100W |

|

|

|

|

Control Complement |

Touch Navigation System |

|

|

Clock ( 1:00 - 12:59 ) |

|

|

Timer (0 - 99 min. 99 seconds) |

|

|

Kitchen Timer, Cooktop Warm, Stop/Clear, Oven Light, Start, LOWER OVEN |

|

Oven Cavity Light |

40W x 1 |

|

|

|

|

Safety Standard |

UL Listed |

|

|

|

|

Weight |

Approx. 260 lbs. |

|

|

|

|

KB-3425LS/K/W

KB-4425LS/K/W

MICROWAVE DRAWER SPECIFICATION

ITEM |

|

|

DESCRIPTION |

|

|

|

Power Output |

000 watts (IEC TEST PROCEDURE) |

|

|

|

||

|

Operating frequency of 2450MHz |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooking Cavity Dimensions |

Width |

17-11/32 |

|

|

|

|

|

Height |

5-7/8" |

|

|

|

|

1.0 Cubic Feet |

Depth |

17-1/8" |

|

|

|

|

|

|

|

|

|

||

Control Complement |

Touch Navigation System |

|

|

|

||

|

Clock ( 1:00 - 12:59 ) |

|

|

|

||

|

Timer (0 - 99 min. 99 seconds) |

|

|

|

||

|

Microwave Power for Variable Cooking |

|

|

|

||

|

Repetition Rate; |

|

|

|

|

|

|

P-HI................................................... |

|

Full power throughout the cooking time |

|

|

|

|

P-90..................................................................... |

|

approx. |

90% of Full Power |

|

|

|

P-80..................................................................... |

|

approx. |

80% of Full Power |

|

|

|

P-70..................................................................... |

|

approx. |

70% of Full Power |

|

|

|

P-60..................................................................... |

|

approx. |

60% of Full Power |

|

|

|

P-50..................................................................... |

|

approx. |

50% of Full Power |

|

|

|

P-40..................................................................... |

|

approx. |

40% of Full Power |

|

|

|

P-30 .................................................................... |

|

approx. |

30% of Full Power |

|

|

|

P-20..................................................................... |

|

approx. |

20% of Full Power |

|

|

|

P-10..................................................................... |

|

approx. |

10% of Full Power |

|

|

|

P-0..................................................... |

|

No power throughout the cooking time |

|

|

|

|

Kitchen Timer, Cooktop Warm, Stop/Clear, Oven Light, Start, LOWER OVEN, Start/ |

|

|

|||

|

Minute Plus, UPPER MICROWAVE OVEN, OPEN, CLOSE. |

|

|

|||

Oven Cavity Light |

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

Safety Standard |

UL Listed |

FCC Authorized |

|

|

|

|

|

DHHS Rules, CFR, Title 21, Chapter 1, Subchapter J |

|

|

|

||

|

|

|

|

|

|

|

KB-3425LS/K/W

KB-4425LS/K/W

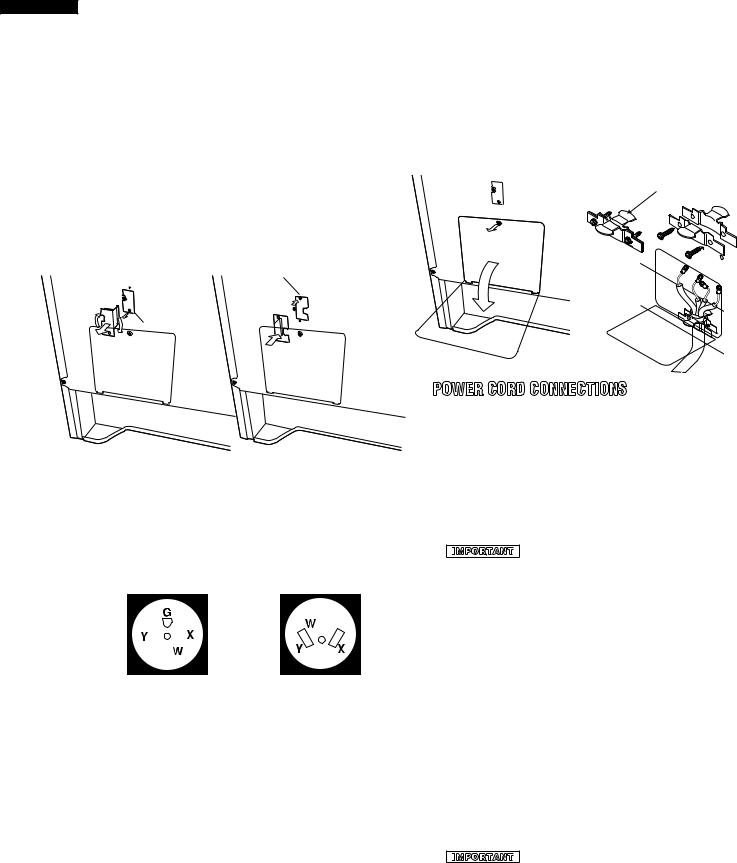

POWER CONNECTION

208/240 VOLT CONNECTION INSTRUCTIONS

The range can be set for 208V or 240V. The voltage setting for your range is pre-set at 240V from the factory. Follow these steps to change the voltage setting.

1Locate the voltage switch on the lower back side of the range.

2Remove the screw and rotate the switch plate 180 as indicated in the Figure 3.

3Reinsert the switch plate and replace screw as indicated in Figure 4. The voltage setting is indicated by the visible

marking. |

screw |

240V |

208V |

180 |

|

screw |

|

Figure 3 |

Figure 4 |

3 & 4-WIRE ELECTRICAL WALL RECEPTACLE TYPES & RECOMMENDED MOUNTING ORIENTATION ON WALL

Figure 5A illustrates 4-wire receptacle required for new and remodeled installations.

Figure 5B illustrates 3-wire receptacle that is allowed for existing installations.

4-wire wall receptacle (14-50R) |

3-wire wall receptacle (10-50R) |

Figure 5A |

Figure 5B |

ACCESS TO TERMINAL BLOCK

Loosen screw on rear access cover and pull down as illustrated in Figure 6 to access terminal block wiring connection. To close, return to original location and secure screw.

strain-relief clamp

Figure 6 |

Figure 7 |

POWER CORD CONNECTIONS

4-WIRE CONNECTION INSTRUCTIONS-FIGURE 8

Before wiring the range, review the suggested power source location. If connecting to a 4-wire electrical system for a new branch-

circuit or mobile home use a 4-wire connection.

1Follow the power supply kit manufacturer s Installation Instructions supplied with the strain relief clamp and install. See Figure 7.

2Insert the end connectors for line 1, line 2 and neutral and tighten securely to the terminal block.

IMPORTANT

DO NOT LOOSEN the factory installed nut connections which secure the range wiring to the terminal block. Electrical failure or loss of electrical connection may occur if these 3 nuts are loosened or removed.

DO NOT LOOSEN the factory installed nut connections which secure the range wiring to the terminal block. Electrical failure or loss of electrical connection may occur if these 3 nuts are loosened or removed.

3You must disconnect the ground strap. Remove the factory installed ground screw and plate to release the copper ground strap from the frame of the range. Cut and discard the copper ground strap and plate. KEEP the ground screw.

4Connect the green ground wire lead with the eyelet to the frame of the range with the ground screw using the same hole in the frame where the ground screw was originally installed. See Figure 8.

5Make sure all screws are tightened securely and replace the rear access cover. See Figure 6.

3-WIRE CONNECTION INSTRUCTIONS

For existing installations ONLY, refer to Figure 9.

1Follow the power supply kit manufacturer s Installation Instructions supplied with the strain relief clamp and install. See Figure 7.

2Insert the end connectors for line 1, line 2 and neutral and tighten securely to the terminal block. See Figure 7.

IMPORTANT

DO NOT LOOSEN the factory installed nut connections which secure the range wiring to the terminal block. Electrical failure or loss of electrical connection may occur if these 3 nuts are loosened or removed.

DO NOT LOOSEN the factory installed nut connections which secure the range wiring to the terminal block. Electrical failure or loss of electrical connection may occur if these 3 nuts are loosened or removed.

10

3Make sure all connections are tightened securely and replace the rear access cover. See Figure 7.

GROUNDING INSTRUCTIONSONLY 3-WIRE CONNECTIONS:

A ground strap is installed on this range which connects the center terminal of the neutral terminal block to the range chassis. The ground strap is connected to the range by the center, lowest screw See Figure 9. The ground strap must not be removed unless National State or Local Codes do not permit use of a ground strap.

Note: If the ground strap is removed for any reason, a separate ground wire must be connected to the separate ground screw attached to the range chassis and to an adequate ground source

3 & 4-WIRE PERMANENT WIRE CONNECTIONS

3–wire permanent connection – follow steps 1, 2 and 5 below. 4–wire permanent connection – follow all steps below.

Before wiring the range, review the suggested power source location drawings in Figure 2. If connecting to a 4-wire electrical system:

1Follow the manufacturer s Installation Instructions supplied with the strain relief clamp and install.

2Strip insulation away from the ends of the permanent wiring for line 1, line 2 and neutral; also strip ground wire on 4-wire

4-WIRE CONNECTION

Connect line 1 here.

Cut ground strap. Discard ground strap & ground plate.

Connect green insulated copper ground wire with ground screw here.

Figure 8

b l a c k

i t e

r e d

terminal block

Connect line 2 here.

Note: Install strain-relief clamp. Center or white wire must always be attached to the center terminal on block.

Connect neutral (white or center) here.

A user supplied strainrelief clamp must be installed at this location. It requires 1 3/8-inches (3.5 cm) diameter cord kit hole.

3-WIRE CONNECTION

|

terminal block |

|

Connect |

|

line 2 |

Connect line |

here. |

1 here. |

|

Ground strap |

|

Note: Install strain-relief clamp. Center or white wire must always be attached to the center terminal on block.

Connect neutral (white or center) here.

A user supplied strain-relief clamp must be installed at this location. It requires

1 3/8-inches (3.5 cm) diameter cord kit hole.

Figure 9

KB-3425LS/K/W

KB-4425LS/K/W

connections. Tighten all 3 or 4-wire leads to the terminal block. Follow wire locations shown in Figure 10.

IMPORTANT DO NOT LOOSEN the factory installed nut connections which secure the range wiring to the terminal block. Electrical failure or loss of electrical connection may occur if these 3 nuts are loosened or removed.

Note: For 3-wire permanent connection skip steps 3 and 4 and continue with step 5.

3Disconnect the ground strap. Remove the factory installed ground screw and plate to release the factory installed copper ground strap from frame of the range. Cut and discard the copper strap from the terminal block. KEEP the ground screw, ground plate and go to step 4.

4Connect the green ground wire lead to the frame of the range using the ground screw and plate as shown in Figure 11. Be sure to install using the same hole in the frame where the ground screw was originally installed.

5Make sure all connections are tightened securely and replace the rear access cover. See Figure 7.

Note: Non-terminated field wire compression connections must be set at approximately 90 in./lbs.

FOR 3 & 4-WIRE PERMANENT CONNECTIONS

terminal |

|

block |

|

line 1 |

line 2 |

neutral |

ground strap |

|

ground plate |

|

ground |

|

screw |

Figure 10

4-WIRE PERMANENT CONNECTION ONLY

ground

plate

proper ground for 4-wire permanent

proper ground for 4-wire permanent

connection

ground

screw

ground wire lead

Figure 11

11

KB-3425LS/K/W

KB-4425LS/K/W

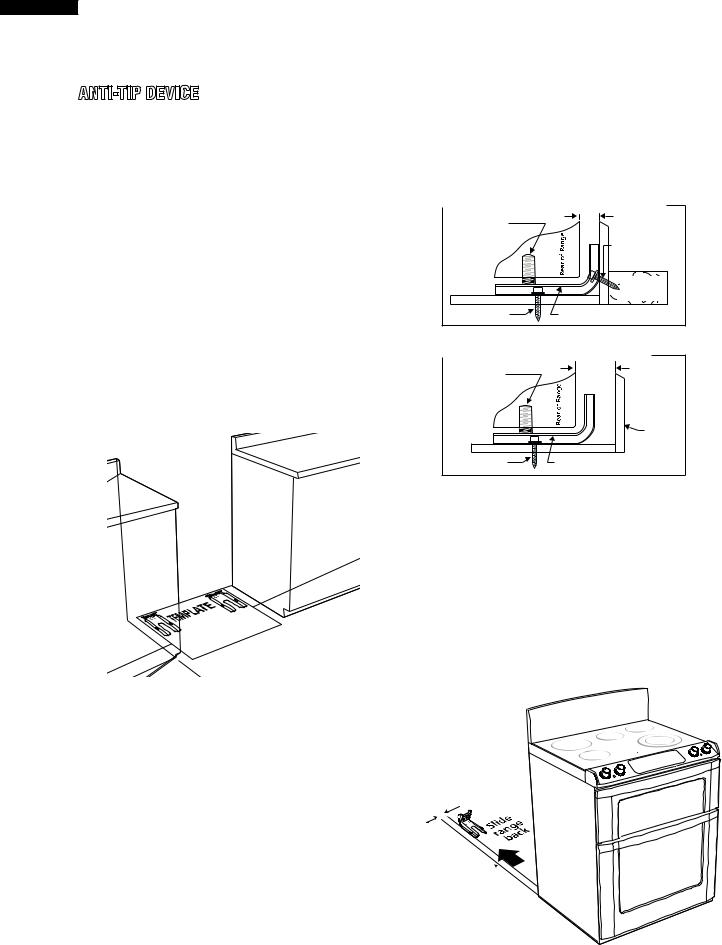

ANTI-TIP DEVICE |

2 DRILL PILOT HOLES AND FASTEN BRACKET |

||

Drill a 1/8-inch pilot hole where screws are to be located. If bracket |

|||

|

|||

NORMAL INSTALLATION STEPS |

is to be mounted to the wall, drill pilot hole at an approximate 20 |

||

degree downward angle. If bracket is to be mounted to masonry or |

|||

|

|||

ANTI-TIP BRACKET INSTALLATION INSTRUCTIONS |

ceramic floors, drill a 5/32-inch pilot hole 1 3/4-inches deep. The |

||

IMPORTANT SAFETY WARNING |

screws provided may be used in wood or concrete material. Use a |

||

To reduce the risk of tipping of the range, the range must be secured |

5/16-inch nut-driver or flat head screwdriver to secure the bracket |

||

to the floor by properly installed Anti-Tip bracket and screws packed |

in place. |

|

|

with the range. Failure to install the Anti-Tip bracket will allow the |

FASTEN BRACKET (WALL OR FLOOR MOUNTING) |

||

range to tip over if excessive weight is placed on an open door or if |

Leveling Leg |

Max 1 1/4" |

|

a child climbs upon it. Serious injury might result from spilled hot |

|

||

|

|

||

liquids or from the range itself. |

|

Wall Mount |

|

If range is ever moved to a different location, the Anti-Tip bracket |

|

|

|

must also be moved and installed with the range. Instructions are |

|

|

|

provided for installation in wood or cement fastened to either the floor |

|

Wall Plate |

|

or wall. When installed to the wall, make sure that screws completely |

|

|

|

penetrate dry wall and are secured in wood or metal. When fastening |

Floor Mount |

Anti-Tip Bracket |

|

to the floor or wall, be sure that screws do not penetrate electrical |

Figure 16 |

|

|

wiring or plumbing. |

|

||

|

FASTEN BRACKET (FLOOR MOUNTING ONLY) |

||

1 LOCATE THE BRACKET - USING THE TEMPLATE |

Leveling Leg |

More Than |

|

The bracket may be located on either the left or right side of the |

1 1/4" |

||

|

|||

range. Use the information below to locate the bracket if template |

|

|

|

is not available. |

|

|

|

|

|

Wall |

|

|

Floor Mount |

Anti-Tip Bracket |

|

Figure 15

Mark the floor or wall where left or right side of the range will be located. If rear of range is against the wall or no further than 1 1/4- inches from wall when installed, you may use the wall or floor mount method. If molding is installed and does not allow the bracket to fit push against the wall, remove molding or mount bracket to the floor. For wall mount, locate the bracket by placing the back edge of the template against the rear wall and the side edge of template on the mark made referencing the side of the range. Place bracket on top of template and mark location of the screw holes in wall. If rear of range is further than 1 1/4-inches from the wall when installed, attach bracket to the floor. For floor mount, locate the bracket by placing back edge of the template where the rear of the range will be located. Mark the location of the screw holes, shown in template.

Figure 17

3 LEVEL AND POSITION RANGE

Level range by adjusting the (4) leveling legs with a wrench. Note: A minimum clearance of 1/8-inch is required between the bottom of the range and the leveling leg to allow room for the bracket. Use a level to check your adjustments. Plug range into properly prepared electrical receptacle or if hard wired, check that it was completed properly. Check door condition for evenness and stability. Slide range back into position.

Visually check that rear leveling leg is inserted into and fully secured by the Anti-Tip bracket by looking underneath the range with a flashlight and carefully attempt to tilt it forward.

1 5/8" to edge of bracket

Range Slide

Figure 18

KB-3425L Shown

12

KB-3425LS/K/W

KB-4425LS/K/W

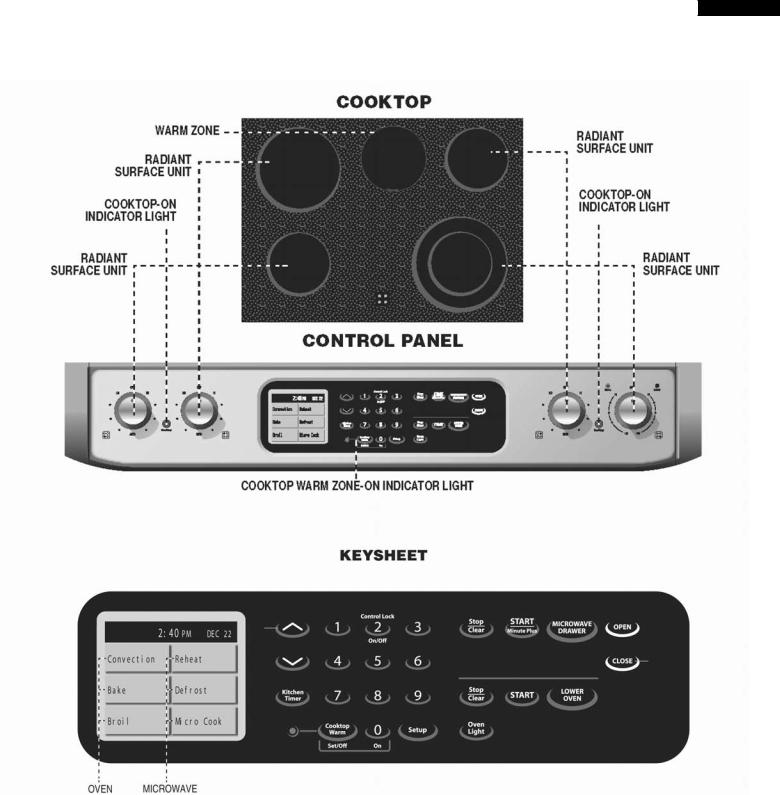

KB-3425LS

13

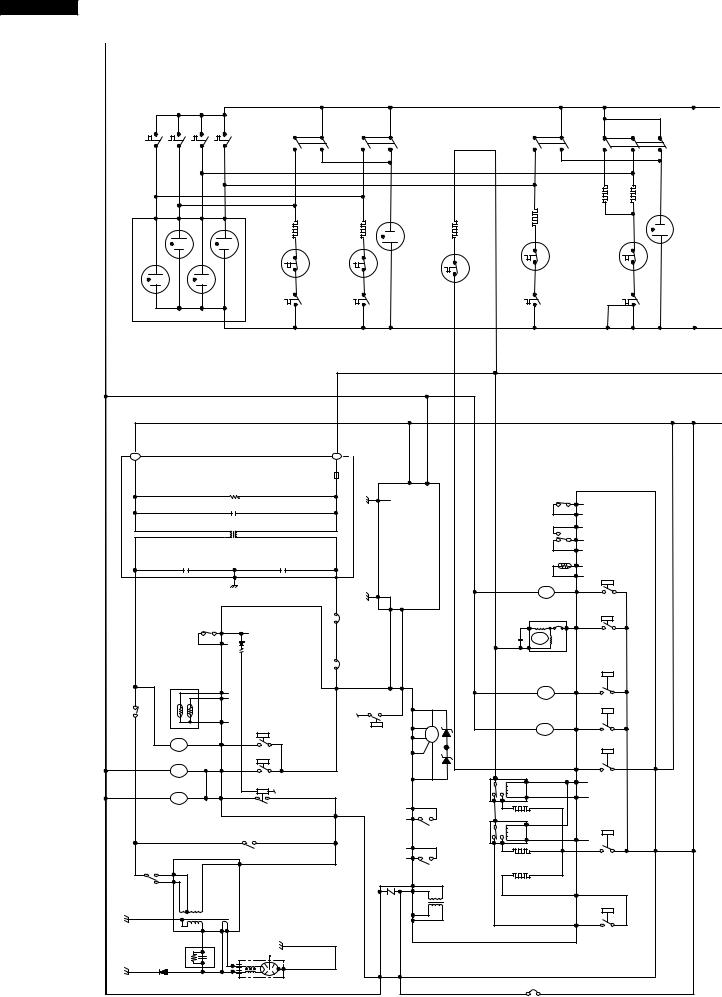

KB-3425LS/K/W KB-4425LS/K/W

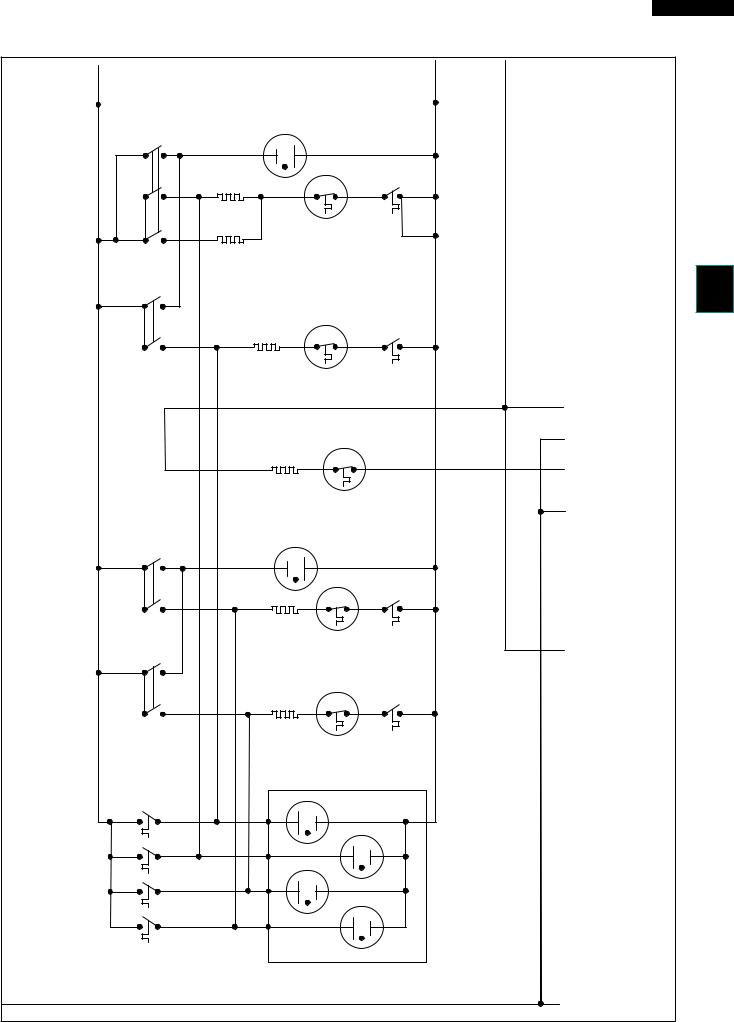

Schematic-Off Condition

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COOK TOP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

viewback sockets lamp on side right the on located is that Terminal 2. .wire neutral to connected be must |

NOTES: .notice without change to subject are colors wire / Circuits 1. |

WHT |

|

HOT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

LIGHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

BLK |

|

||||

SWITCHES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ORG |

|

|

|

|

|

|

|

BLK |

|

|

||||

|

BLK |

BLK |

BLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YLW |

|

|

|

||||||||

S |

S |

S |

S |

|

|

|

|

|

|

L1 |

|

|

|

|

|

L1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

L1 |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

P2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

/2b |

|

/2b |

/2b |

/2b |

|

|

CONTROL |

|

|

|

P2 |

|

CONTROL |

|

|

|

/ |

|

|

|

|

|

|

|

|

|

|

|

|

|

P2 |

|

|

|

|

|

|

|

|

|

|||||

H |

H |

H |

H |

|

|

4 |

|

/ |

|

4 |

|

P |

|

|

|

|

|

|

|

|

|

|

|

4 |

/ |

|

|

|

|

|

|

|

|

|

|||||||||||

1b/ YLW BLU |

1b/ BLK |

1b/ BLU |

1b/ BRN |

|

|

WHT |

|

BLK /H1 |

YLW |

BLK |

/H1 |

|

YLW |

|

|

|

|

|

|

|

|

CONTROL |

|

WHT |

/H1 |

|

YLW |

WHTYLW |

BLKP24a |

|

RED 4 |

|

CONTROL S2S1 |

|

|

||||||||||

|

|

|

YLW |

|

|

|

|

|

|

|

|

YLW |

|

|

YLW |

|

|

|

|

||||||||||||||||||||||||||

|

|

|

P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

LF YLW YLW SURFACE |

BLK YLWBLU |

BLU YLWBLU LR |

RR BRN YLWBLU RF |

|

|

|

|

|

|

|

|

|

|

ORG |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

|

P1A 4A |

|

P1B 4 |

YLW RED |

YLW |

|

|

|

L1 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YLW |

|

|

|

|

|

|

|

/ |

OUTSIDE |

/ |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

YLW |

|

|

|

|

|

|

|

|

|

4 WHT |

|

|

|

WHT |

|

ELEMENT |

RIGHT |

INSIDE |

|

YLW |

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

WHT |

|

|

|

|

|

|

YLW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||

YLW |

|

|

|

|

|

LEFT |

4 BLK |

|

|

|

|

|

|

ELEMENT |

RIGHT |

|

4 |

|

|

|

|||||||||||||||||||||||||

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

|

|

/P1 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

YLW |

|

ELEMENT |

SURFACE ELEMENT LEFT |

|

P1/ |

|

|

ELEMENT |

WARMER |

|

SURFACE |

|

|

|

P1/ |

|

|

|

|||||||||||||||||||||||||

|

|

2 |

|

SURFACE |

YLW FRONT |

2 |

|

|

|

P1/ |

|

REAR |

|

2 |

|

SURFACE |

|

|

|

||||||||||||||||||||||||||

LIGHTSURFACEHOT |

PROTECTOR |

1a |

|

|

|

REAR |

PROTECTOR |

1a |

|

|

|

|

PROTECTORSURFACE |

2a 1a |

2 |

PROTECTOR |

2a YLW1a |

|

|

|

|

FRONT |

PROTECTOR |

2a 1a |

|

|

|

|

|||||||||||||||||

2a |

|

|

|

2a |

|

LIGHT INDICATOR |

|

YLW |

|

|

BRN |

LIGHT INDICATOR |

|

||||||||||||||||||||||||||||||||

BRN |

2 |

|

WHT |

2 |

|

|

2 |

|

|

|

|||||||||||||||||||||||||||||||||||

|

H2/ |

|

/ H2 |

|

|

|

H2/ |

|

2 |

|

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

L2 |

|

|

|

|

L2 |

|

|

|

|

|

|

|

|

YLW |

|

|

|

|

|

|

L2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P1 |

|

|

|

|

P1 |

|

RED |

|

|

|

|

|

|

|

|

|

|

|

P1 |

|

|

RED WHT |

|

P1 |

|

|

RED |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

RED |

|

/ |

|

|

|

/ RED RED |

|

|

|

|

|

|

|

|

|

RED |

|

|

|

/ |

|

|

RED |

RED RED |

RED |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

L2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

L2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

L1 |

|

BLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

L1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

FUSE |

|

|

|

|

|

BLK |

WHT |

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

20A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

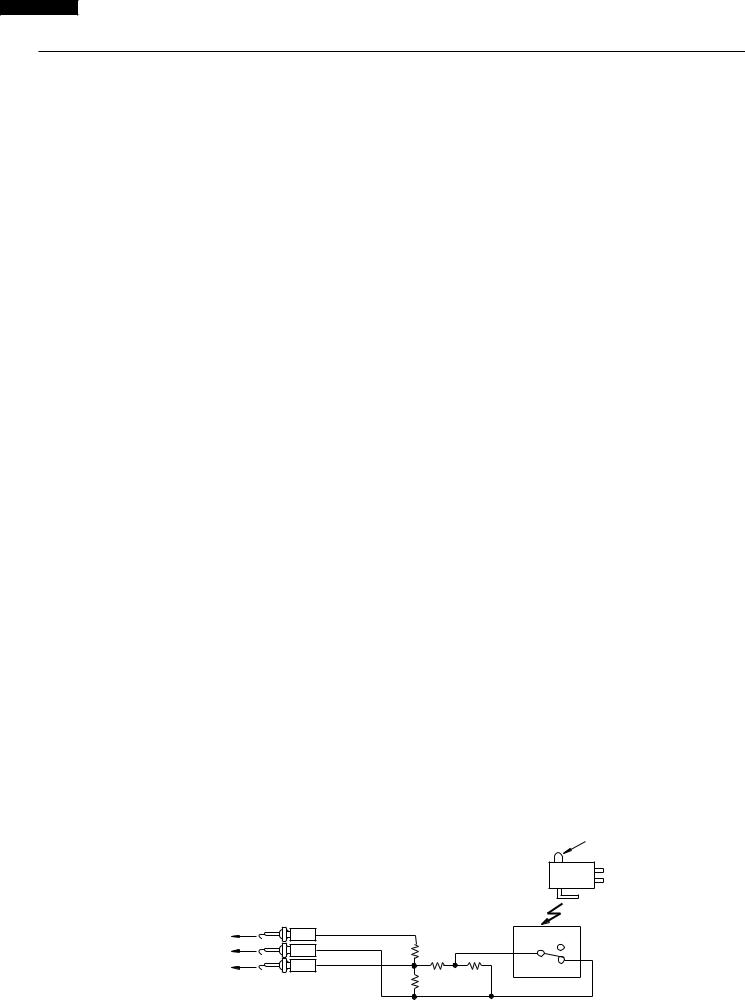

RESISTOR 470 kohm 1/2W |

|

|

|

|

|

|

|

|

|

|

|

3 |

1 |

|

|

|

WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

LINE CROSS CAPACITOR 1.0uF 250V |

|

|

|

|

|

|

|

|

|

|

|

SUPPLY POWER SWITCHING |

|

|

|

|

|

DOOR |

|

|

|

|

M4 |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SWITCH |

|

|

|

RED |

M5 |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

NOISE SUPRESSION COIL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

M9 |

|

|

|

UNIT CONTROL |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DOOR LOCK |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YLW |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

|

|

|

|

M10 |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SWITCH |

|

|

|

BRN |

M8 |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

LINE BYPASS CAPACITOR |

|

LINE BYPASS CAPACITOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ORG |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

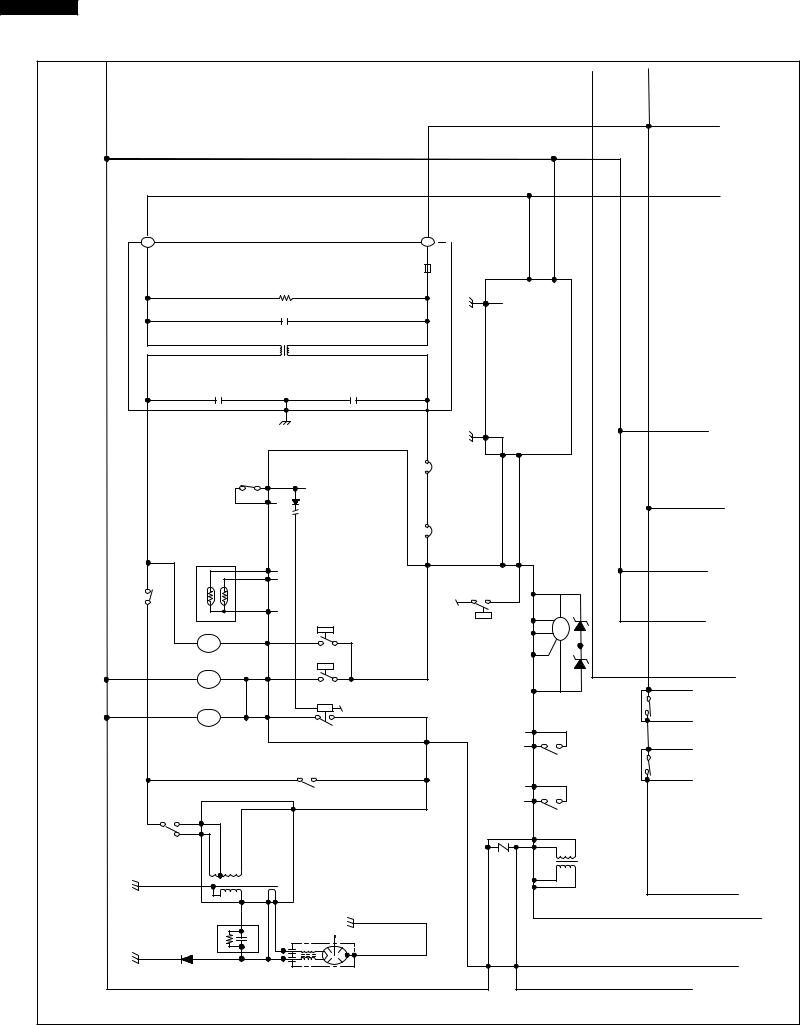

MICROWAVE |

|

|

0.0033uF 250V |

|

|

|

0.0033uF 250V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M11 |

|

|

|

|

|

OVEN |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNIT |

|

|

|

|

|

THERMISTOR |

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M12 RY6 |

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ORG |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

|

|

|

FM |

YLW |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

|

|

|

D1 C3 |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OVEN THERMAL -CUT OUT-CUT |

|

1 |

3 |

|

|

|

|

|

|

|

CLOSS FLOW |

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

DOOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAN MOTOR |

|

RY9 |

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

SENSING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

SWITCH |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

M1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

M3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

CM |

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

GRN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DOOR |

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

|

|

|

|

BLU |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ORG |

BLK |

RED |

|

|

MICROWAVE OPEN |

|

|

|

|

CONV. MOTOR |

RY8 |

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DOOR LOCK |

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

HUMIDITY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

DRAWER |

|

|

|

|

|

|

|

|

|

|

|

|

OUT |

|

|

E1 |

|

E2 |

|

|

CLOSE- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

SENSOR |

|

F3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

MOTOR |

|

BRN |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LM |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

F2 |

|

|

|

|

|

|

|

COM. |

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N1 |

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RY7 |

|

|

|

|

|

|

|

|||

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

|

|

OVEN LAMP |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

F1 |

|

RY5 |

|

|

|

|

|

|

|

|

RY11 |

|

N2 |

|

|

|

|

|

WHT |

|

|

|

|

OL |

ORG |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

WHT |

BRNBLK SWITCHINTELOCKSECONDARY |

|

FM |

|

BLK |

C1 |

|

CONTROLUNIT |

|

|

|

ORG |

|

MG THERMAL |

|

|

N3 |

ORG |

DM |

|

DRAWER |

|

|

|

|

|

|

|

|

|

|

D3 C7C5 |

RY10 |

|

|

|

|

RED |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

FAN MOTOR |

|

RY1 |

|

|

|

|

|

|

N4 |

YLW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

BRNREDBLK |

|

ORG |

ORG |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YLW |

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

WHT |

SM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D5 |

|

|

|

|||||||

|

|

|

|

WHT |

ORG |

RED |

.O.N |

|

|

|

|

|

|

|

|

|

|

|

|

N5 |

BLU |

|

|

|

|

|

|

|

WHT |

|

WHT |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C-RY |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

STIRRER MOTOR |

|

RY2 |

PRIMARY INTERLOCK |

|

|

|

|

|

|

|

|

|

|

|

|

|

E6 |

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHT |

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

WHT |

OL |

ORG |

RED |

|

|

|

|

RELAY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GRY |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

.COM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FRONT |

|

DOOR |

|

|

|

|

|

|

|

E5 E3 |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

WHT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M6 |

|

GRY |

|

BLK |

|

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

OVEN LAMP |

|

|

|

|

|

|

|

N.O. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M7 |

|

|

|

CONV. HEATER |

BLK |

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SWITCH |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RED RED |

|

|

|

|

|

BRN |

|

|

POSITION |

ORG B-RY |

|

|

|

|

|

|

WHT |

|

RY3 |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

BRN |

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M14 |

|

BLK |

REAR |

|

|

|

|

|

|

BLU |

|

|

|

|

|

|

|

COM. |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

MONITOR SWITCH |

|

|

|

|

|

|

|

|

|

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

RED |

|

|

|

|

|

M13 |

|

|

SWITCH |

DOOR |

BOTTOM HEATER |

|

BLK |

BLK |

N.O. |

|

|

|

|

|

|

BLK |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

POSITION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

RED |

|

|

|

|

POWER TRANSFORMER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLK |

|

|

|

|

TOP HEATER |

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

BLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

VOLTAGESWITCH |

BRN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A1 A4A6 |

WHT |

|

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VOLTAGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COM. |

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RY4 |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|