Panasonic CS-E15DKDW, CU-E15DKD, CS-E18DKDW, CU-E18DKD, CS-E21DKDS Service Manual

...

Order No. MAC0501021C2

Air Conditioner

CS-E15DKDW CU-E15DKD CS-E18DKDW CU-E18DKD CS-E21DKDS CU-E21DKD

CONTENTS

1Features

2Functions

2.1.Remote Control

2.2.Indoor Unit

2.3.Outdoor Unit

3Product Specifications

3.1.CS-E15DKDW CU-E15DKD

3.2.CS-E18DKDW CU-E18DKD

3.3.CS-E21DKDS CU-E21DKD

4Dimensions

4.1.Indoor Unit & Remote Control

4.2.Outdoor Unit

Page |

|

|

|

Page |

2 |

5 |

Refrigeration Cycle Diagram |

15 |

|

3 |

6 |

Block Diagram |

16 |

|

3 |

7 |

Wiring Diagram |

17 |

|

4 |

8 |

Operation Details |

18 |

|

5 |

|

8.1. Basic Function |

18 |

|

6 |

|

8.2. Protection Control Features |

35 |

|

6 |

9 |

Operating Instructions |

47 |

|

8 |

|

9.1. CS-E15DKDW |

47 |

|

10 |

|

9.2. CS-E18DKDW CS-E21DKDS |

53 |

|

12 |

10 |

Installation And Servicing Air Conditioner Using R410A |

59 |

|

12 |

|

10.1. Outline |

59 |

|

14 |

|

10.2. Tools For Installing/Servicing Refrigerant Piping |

60 |

|

|

|

|

|

|

|

|

|

© 2005 Panasonic HA Air-Conditioning (M) Sdn Bhd |

|

|

|

|

(11969-T). All rights reserved. Unauthorized copying |

|

|

|

|

and distribution is a violation of law. |

|

|

|

|

|

|

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

|

10.3. Refrigerant Piping Work |

64 |

|

14.2. Sensible Capacity Chart |

103 |

|

10.4. Installation, Transferring, Servicing |

66 |

15 |

Exploded View (Indoor Unit) |

104 |

11 |

Installation Instructions |

70 |

|

15.1. CS-E15DKDW |

104 |

|

11.1. Safety Precautions |

70 |

|

15.2. CS-E18DKDW CS-E21DKDS |

105 |

|

11.2. Indoor Unit |

73 |

16 |

Replacement Parts List (Indoor Unit) |

106 |

|

11.3. Outdoor Unit |

77 |

|

16.1. CS-E15DKDW |

106 |

12 |

Installation Instructions |

81 |

|

16.2. CS-E18DKDW CS-E21DKDS |

107 |

|

12.1. Safety Precautions |

81 |

17 |

Exploded View (Outdoor Unit) |

108 |

|

12.2. Indoor Unit |

84 |

|

17.1. CU-E15DKD CU-E18DKD CU-E21DKD |

108 |

|

12.3. Outdoor Unit |

88 |

18 |

Replacement Parts List (Outdoor Unit) |

109 |

13 |

Servicing Information |

92 |

|

18.1. CU-E15DKD CU-E18DKD CU-E21DKD |

109 |

|

13.1. Troubleshooting |

92 |

19 |

Electronic Circuit Diagram |

110 |

|

13.2. Breakdown Self Diagnosis Function |

94 |

|

19.1. Indoor Unit |

110 |

|

13.3. Remote Control |

96 |

|

19.2. Outdoor Unit |

114 |

|

13.4. Disassembly of Parts |

97 |

|

19.3. Remote Control |

120 |

14 |

Technical Data |

100 |

|

19.4. Print PatternIndoor Unit Printed Circuit Board |

121 |

|

14.1. Operation Characteristics |

100 |

|

19.5. Print PatternOutdoor Unit Printed Circuit Board View |

122 |

1Features

•Product

−Four modes of operation selection

−Powerful Mode operation

−Delay ON Timer and OFF Timer

−Ionizer Mode Operation

−Quiet Mode Operation

−Automatic air swing and manual adjusted by Remote Control for horizontal and vertical airflow

−Supersonic Air Purifying System with Super AlleruBuster.

Inactive various harmful airbone elements including allergens, viruses and bacteria. Generated supersonic waves enhance the ability to collect dust and dirt in the air.

•Serviceability Improvement

−Removable washable Front Panel

−Breakdown Self Diagnosis function

•Environmental Protection

−Non-ozone depletion substances refrigerant (R410A)

•Quality Improvement

−Gas leakage detection

−Deice operation

−Auto restart control

2

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

2 Functions

2.1.Remote Control

OFF/ON

I

Operation OFF / ON

MODE

Operation Mode Selection

•a Automatic Operation

•HEAT Heating Operation

•COOL Cooling Operation

•DRY Soft Dry Operation

POWERFUL

Powerful Mode Operation

QUIET

Quiet Mode Operation

Ion Mode Operation

Ion Mode Operation

AIR SWING

Airflow Direction Control

Airflow Direction Control

• |

Vertical Automatic Airflow |

|

Direction Control and Manual |

|

Airflow Direction Control (5 |

|

stages of adjustment). |

• |

Horizontal Automatic Airflow |

|

Direction Control and Manual |

|

Airflow Direction Control (5 |

|

stages of adjustment). |

FAN SPEED

Indoor Fan Speed Selection

• |

|

|

|

|

|

|

|

|

|

|

|

Low |

|

||||||||||||

|

||||||||||||

• |

|

|

|

|

|

|

|

|

|

|

|

Medium- |

|

|

|

||||||||||

• |

|

|

|

|

|

|

|

|

|

|

|

Medium |

|

|

|

|

|

||||||||

• |

|

|

|

|

|

|

|

|

|

|

|

Medium+ |

|

|

|

|

|

|

|

|

|||||

• |

|

|

|

|

|

|

|

|

|

|

|

High |

|

|

|

|

|

|

|

|

|

|

•AUTO Automatic Fan Speed

FAN

TEMP

Room Temperature Setting

• Increase or decrease set temperature. TIMER (16°C to 30°C)

ON

OFF

Timer Setting

• 24-hour, OFF / ON Real Timer Setting.

Time / Timer Setting

• Hours and minutes setting.

SET

CANCEL

Timer Operation Set / Cancel

•ON Timer and OFF Timer setting and cancellation.

CLOCK

Clock Setting

• Current time setting.

CHECK

Check Point

• Breakdown self diagnosis function.

RESET

Reset Point

• Clear memory data.

3

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

2.2.Indoor Unit

Automatic Operation Switch

Automatic Operation Switch

•Press for < 5s to run Automatic Operation. (Used when the remote control cannot be used.)

•Press continuously for 5s and < 8s to run Forced Cooling Operation.

•Press continuously for 8s and < 11s to run Forced Heating Operation.

•Press continuously for 11s and < 16s to change different remote controlling setting (4 type of transmission code).

•Press continuously for 16s or < 21s to switch OFF / ON Remote Control Receiving Sound or H14 Abnormality Detection Mode.

Operation Indication Lamps (LED)

Operation Indication Lamps (LED)

• |

POWER (Green) ...... Lights up in operation, |

|

|

|

blinks in Automatic |

|

|

Operation Mode |

|

|

judging, deice, On |

|

|

Timer sampling and |

|

|

Hot Start operation. |

• |

TIMER (Orange) .... Lights up in Timer |

|

|

|

Setting. |

|

|

Blinks in Self |

|

|

Diagnosis Control. |

• |

QUIET |

(Orange) .... Lights up in Quiet |

|

|

Mode Operation. |

• |

POWERFUL (Orange) ... Lights up when |

|

|

|

Powerful Mode is |

|

|

selected. |

• |

(Green) ............ Lights up in Ionizer |

|

|

|

Mode Operation. |

|

|

Blinks in Ionizer |

|

|

error. |

• SUPER ALLERU-BUSTER .... Lights up in |

||

|

(Blue) |

operation. |

Four Operation Modes

Four Operation Modes

•Automatic, Heating, Cooling and Soft Dry Operation.

Automatic and 5 Manual Indoor

Fan Speeds

Automatic and 5 Manual Vertical

Airflow Directions

Automatic and 5 Manual Horizontal

Airflow Directions

Powerful Mode

Powerful Mode

• For quick cooling or heating.

Quiet Mode

Quiet Mode

• To provide quiet operation.

Ionizer Control

Ionizer Control

•Ionizer control for generate negative ion in discharge air.

Delay ON Timer and OFF Timer

Delay ON Timer and OFF Timer

Automatic Restart Control

Automatic Restart Control

•Operation is restarted after power failure at previous setting mode.

Microcomputer-controlled Room

Temperature Control

4

2.3.Outdoor Unit

Breakdown Self Diagnosis

Function

Low Pressure Control

(Gas Leakeage Detection)

Indoor Power Relay Control

Indoor Power Relay Control

Anti-Dew Formation Control

Anti-Dew Formation Control

Anti Freezing Control

Anti Freezing Control

Anti-Cold Draft Control

Anti-Cold Draft Control

Hot Start

Hot Start

Intake Air Temperature Control

Intake Air Temperature Control

High Pressure Control

High Pressure Control

Deodorizing Control

Deodorizing Control

Deice Operation

Deice Operation

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

Time Delay Safety Control

Time Delay Safety Control

30 seconds Forced Operation

30 seconds Forced Operation

Overload Protection Control

Overload Protection Control

Total Running Current Control

Total Running Current Control

Compressor Overheating

Prevention Control

IPM (Power Transistor)

Overheating Protection Control

Low Operation Frequency

Protection Control

Mininum Operation Frequency

Protection Control

Outdoor Air Temperature

Control

Standby Control

Standby Control

Deice Operation

Deice Operation

5

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

3 Product Specifications

3.1.CS-E15DKDW CU-E15DKD

|

|

Unit |

CS-E15DKDW |

|

CU-E15DKD |

Cooling Capacity |

|

kW |

4.40 (0.90 - 5.00) |

||

|

|

kcal/h |

3,780 (770 - 4,300) |

||

|

|

BTU/h |

15,000 (3,070 - 17,100) |

||

|

|

|

|

|

|

Heating Capacity |

|

kW |

5.50 (0.90 - 7.10) |

||

|

|

kcal/h |

4,730 (770 - 6,110) |

||

|

|

BTU/h |

18,800 (3,070 - 24,200) |

||

|

|

|

|

|

|

Moisture Removal |

|

l/h |

2.4 |

|

|

|

|

Pint/h |

(5.1) |

|

|

|

|

|

|

|

|

Power Source (Phase, Voltage, Cycle) |

ø |

Single |

|

||

|

|

V |

220 - 230 |

|

|

|

|

Hz |

50 |

|

|

|

|

|

|

|

|

Airflow Method |

|

OUTLET |

SIDE VIEW |

|

TOP VIEW |

|

|

INTAKE |

|

|

|

|

|

|

|

|

|

Air Volume |

Lo |

m3/min (cfm) |

Cooling; 7.4 (260) |

|

— |

|

|

|

Heating; 8.8 (310) |

|

|

|

|

|

|

|

|

|

Me |

m3/min (cfm) |

Cooling; 9.2 (320) |

|

— |

|

|

|

Heating; 10.3 (360) |

|

|

|

|

|

|

|

|

|

Hi |

m3/min (cfm) |

Cooling; 11.0 (390) |

|

Cooling; 48.5 (1,710) |

|

|

|

Heating; 11.8 (420) |

|

Heating; 46.8 (1,650) |

|

|

|

|

|

|

|

|

dB (A) |

Cooling; High 43, Low 32 |

|

Cooling; 46 |

|

|

|

Heating; High 43, Low 35 |

|

Heating; 46 |

Noise Level |

|

|

|

|

|

|

|

Power level dB |

Cooling; High 54 |

|

Cooling; High 59 |

|

|

|

Heating; High 54 |

|

Heating; High 59 |

|

|

|

|

|

|

Electrical Data |

Input Power |

W |

Cooling; 1,370 (215 - 1,600) |

||

|

|

|

Heating; 1,570 (245 - 2,250) |

||

|

|

|

|

|

|

|

Running Current |

A |

Cooling; 6.5 - 6.3 |

||

|

|

|

Heating; 7.3 - 7.1 |

||

|

|

|

|

|

|

|

EER |

W/W |

Cooling; 3.21 (4.19 - 3.13) |

||

|

|

BTU/hW |

Cooling; 10.9 (14.3 - 10.7) |

||

|

|

|

|

|

|

|

COP |

W/W |

Heating; 3.50 (3.67 - 3.16) |

||

|

|

BTU/hW |

Heating; 12.0 (12.5 - 10.8) |

||

|

Starting Current |

A |

7.3 |

|

|

|

|

|

|

|

|

6

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

|

|

|

Unit |

CS-E15DKDW |

CU-E15DKD |

Piping Connection Port |

|

|

inch |

G ; Half Union 1/2” |

G ; 3-way valve 1/2” |

(Flare piping) |

|

|

inch |

L ; Half Union 1/4” |

L ; 2-way valve 1/4” |

Pipe Size |

|

|

inch |

G (gas side) ; 1/2” |

G (gas side) ; 1/2” |

(Flare piping) |

|

|

inch |

L (liquid side) ; 1/4” |

L (liquid side) ; 1/4” |

Drain |

Inner diameter |

|

mm |

12 |

— |

Hose |

|

|

|

|

|

Length |

|

m |

0.65 |

— |

|

Power Cord Length |

|

|

|

—— |

— |

Number of core-wire |

|

|

|

|

— |

Dimensions |

Height |

|

inch (mm) |

11 - 1/32 (280) |

29 - 17/32 (750) |

|

|

|

|

|

|

|

Width |

|

inch (mm) |

31 - 15/32 (799) |

34 - 7/16 (875) |

|

Depth |

|

inch (mm) |

7 - 7/32 (183) |

13 - 19/32 (345) |

|

|

|

|

|

|

Net Weight |

|

|

lb (kg) |

20 (9) |

106 (48) |

Compressor |

|

Type |

|

— |

Involute scroll |

|

Motor |

Type |

|

— |

Brushless (4-pole) |

|

|

|

|

|

|

|

Rated |

Output |

W |

— |

700 |

Air Circulation |

|

Type |

|

Cross-flow Fan |

Propeller Fan |

|

|

|

|

|

|

|

|

Material |

|

ASHT-18 |

P.P |

|

Motor |

Type |

|

Transistor (8-poles) |

Transistor (8-poles) |

|

|

Rate Output |

W |

30 |

40 |

|

Fan Speed |

Lo (Cool/Heat) |

rpm |

980 / 1,160 |

— |

|

|

Me (Cool/Heat) |

rpm |

1,220 / 1,360 |

— |

|

|

|

|

|

|

|

|

Hi (Cool/Heat) |

rpm |

1,460 / 1,560 |

660 / 640 |

Heat Exchanger |

Description |

|

|

Evaporator |

Condenser |

|

Tube material |

|

|

Copper |

Copper |

|

|

|

|

|

|

|

Fin material |

|

|

Aluminium (Pre Coat) |

Aluminium (Blue Coated) |

|

Fin Type |

|

|

Slit Fin |

Corrugated Fin |

|

|

|

|

|

|

|

Row / Stage |

|

|

(Plate fin configuration, forced draft) |

|

|

|

|

|

2 / 15 |

1 / 28 |

|

FPI |

|

|

21 |

18 |

|

|

|

|

|

|

|

Size (W × H × L) |

mm |

610 × 315 × 25.4 |

871.7 × 711.2 × 22 |

|

Refrigerant Control Device |

|

|

— |

Expansion Valve |

|

Refrigeration Oil |

|

|

(c.c) |

— |

RB68A (360) |

Refrigerant (R410A) |

|

|

kg (oz) |

— |

1.06 (37.4) |

Thermostat |

|

|

|

Electronic Control |

— |

Protection Device |

|

|

|

Electronic Control |

Electronic Control |

|

Length |

|

mm |

— |

— |

Capillary Tube |

Flow Rate |

|

l/min |

— |

— |

|

Inner Diameter |

|

mm |

— |

— |

Air Filter |

Material |

|

|

P.P. |

— |

|

Style |

|

|

Honeycomb |

|

• Specifications are subjected to change without notice for further improvement.

7

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

3.2.CS-E18DKDW CU-E18DKD

|

|

Unit |

CS-E18DKDW |

|

CU-E18DKD |

Cooling Capacity |

|

kW |

5.30 (0.90 - 6.00) |

||

|

|

kcal/h |

4,560 (770 - 5,160) |

||

|

|

BTU/h |

18,100 (3,070 - 20,500) |

||

|

|

|

|

|

|

Heating Capacity |

|

kW |

6.60 (0.90 - 8.00) |

||

|

|

kcal/h |

5,680 (770 - 6,880) |

||

|

|

BTU/h |

22,500 (3,070 - 27,300) |

||

|

|

|

|

|

|

Moisture Removal |

|

l/h |

2.9 |

|

|

|

|

Pint/h |

(6.1) |

|

|

|

|

|

|

|

|

Power Source (Phase, Voltage, Cycle) |

ø |

Single |

|

||

|

|

V |

220 - 230 |

|

|

|

|

Hz |

50 |

|

|

|

|

|

|

|

|

Airflow Method |

|

OUTLET |

SIDE VIEW |

|

TOP VIEW |

|

|

INTAKE |

|

|

|

|

|

|

|

|

|

Air Volume |

Lo |

m3/min (cfm) |

Cooling; 12.3 (430) |

|

— |

|

|

|

Heating; 13.0 (460) |

|

|

|

|

|

|

|

|

|

Me |

m3/min (cfm) |

Cooling; 13.9 (490) |

|

— |

|

|

|

Heating; 14.6 (520) |

|

|

|

|

|

|

|

|

|

Hi |

m3/min (cfm) |

Cooling; 15.2 (540) |

|

40.0 (1,410) |

|

|

|

Heating; 16.7 (590) |

|

|

|

|

|

|

|

|

|

|

dB (A) |

Cooling; High 44, Low 37 |

|

Cooling; 47 |

|

|

|

Heating; High 44, Low 37 |

|

Heating; 47 |

Noise Level |

|

|

|

|

|

|

|

|

|

|

|

|

|

Power level dB |

Cooling; High 57 |

|

Cooling; High 60 |

|

|

|

Heating; High 57 |

|

Heating; High 60 |

|

|

|

|

|

|

Electrical Data |

Input Power |

W |

Cooling; 1,650 (215 - 2,050) |

||

|

|

|

Heating; 1,790 (245 - 2,650) |

||

|

|

|

|

|

|

|

Running Current |

A |

Cooling; 7.7 - 7.5 |

||

|

|

|

Heating; 8.3 - 8.1 |

||

|

|

|

|

|

|

|

EER |

W/W |

Cooling; 3.21 (4.19 - 2.93) |

||

|

|

BTU/hW |

Cooling; 11.0 (14.3 - 10.0) |

||

|

COP |

W/W |

Heating; 3.69 (3.67 - 3.02) |

||

|

|

|

|

|

|

|

|

BTU/hW |

Heating; 12.6 (12.5 - 10.3) |

||

|

Starting Current |

A |

8.3 |

|

|

Piping Connection Port |

|

inch |

G ; Half Union 1/2” |

|

G ; 3-way valve 1/2” |

(Flare piping) |

|

inch |

L ; Half Union 1/4” |

|

L ; 2-way valve 1/4” |

8

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

|

|

|

Unit |

CS-E18DKDW |

|

CU-E18DKD |

Pipe Size |

|

|

inch |

G (gas side) ; 1/2” |

|

G (gas side) ; 1/2” |

(Flare piping) |

|

|

inch |

L (liquid side) ; 1/4” |

|

L (liquid side) ; 1/4” |

Drain |

Inner diameter |

|

mm |

12 |

|

— |

Hose |

Length |

|

m |

0.65 |

|

— |

|

|

|

|

|

|

|

Power Cord Length |

|

|

|

—— |

|

— |

Number of core-wire |

|

|

|

|

|

— |

Dimensions |

Height |

|

inch (mm) |

10 - 13/16 (275) |

|

29 - 17/32 (750) |

|

Width |

|

inch (mm) |

39 - 9/32 (998) |

|

34 - 7/16 (875) |

|

|

|

|

|

|

|

|

Depth |

|

inch (mm) |

9 - 1/16 (230) |

|

13 - 19/32 (345) |

Net Weight |

|

|

lb (kg) |

24 (11) |

|

108 (49) |

|

|

|

|

|

|

|

Compressor |

|

Type |

|

— |

|

Involute scroll |

|

Motor |

Type |

|

— |

|

Brushless (4-pole) |

|

Rated |

Output |

W |

— |

|

900 |

|

|

|

|

|

|

|

Air Circulation |

|

Type |

|

Cross-flow Fan |

|

Propeller Fan |

|

|

Material |

|

ASHT-18 |

|

P.P |

|

|

|

|

|

|

|

|

Motor |

Type |

|

Transistor (8-poles) |

|

Transistor (8-poles) |

|

|

Rate Output |

W |

30 |

|

40 |

|

Fan Speed |

Lo (Cool/Heat) |

rpm |

1,170 / 1,240 |

|

— |

|

|

|

|

|

|

|

|

|

Me (Cool/Heat) |

rpm |

1,330 / 1,395 |

|

— |

|

|

Hi (Cool/Heat) |

rpm |

1,450 / 1,580 |

|

660 / 640 |

|

|

|

|

|

|

|

Heat Exchanger |

Description |

|

|

Evaporator |

|

Condenser |

|

Tube material |

|

|

Copper |

|

Copper |

|

Fin material |

|

|

Aluminium (Pre Coat) |

|

Aluminium (Blue Coated) |

|

|

|

|

|

|

|

|

Fin Type |

|

|

Slit Fin |

|

Corrugated Fin |

|

Row / Stage |

|

|

(Plate fin configuration, forced draft) |

||

|

|

|

|

2 / 15 |

|

2 / 34 |

|

|

|

|

|

||

|

FPI |

|

|

21 |

|

16 |

|

Size (W × H × L) |

mm |

810 × 315 × 25.4 |

|

849.3 × 714 × 36.4 |

|

|

|

|

|

|

|

878 |

|

|

|

|

|

|

|

Refrigerant Control Device |

|

|

— |

|

Expansion Valve |

|

Refrigeration Oil |

|

|

(c.c) |

— |

|

RB68A (360) |

Refrigerant (R410A) |

|

|

kg (oz) |

— |

|

1.18 (41.7) |

Thermostat |

|

|

|

Electronic Control |

|

— |

Protection Device |

|

|

|

Electronic Control |

|

Electronic Control |

|

Length |

|

mm |

— |

|

— |

Capillary Tube |

Flow Rate |

|

l/min |

— |

|

— |

|

Inner Diameter |

|

mm |

— |

|

— |

Air Filter |

Material |

|

|

P.P. |

|

— |

|

Style |

|

|

Honeycomb |

|

|

• Specifications are subjected to change without notice for further improvement.

9

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

3.3.CS-E21DKDS CU-E21DKD

|

|

Unit |

CS-E21DKDS |

|

CU-E21DKD |

Cooling Capacity |

|

kW |

6.30 (0.90 - 7.10) |

||

|

|

kcal/h |

5,420 (770 - 6,110) |

||

|

|

BTU/h |

21,500 (3,070 - 24,200) |

||

|

|

|

|

|

|

Heating Capacity |

|

kW |

7.20 (0.90 - 8.50) |

||

|

|

kcal/h |

6,190 (770 - 7,310) |

||

|

|

BTU/h |

24,600 (3,070 - 29,000) |

||

|

|

|

|

|

|

Moisture Removal |

|

l/h |

3.5 |

|

|

|

|

Pint/h |

(7.4) |

|

|

|

|

|

|

|

|

Power Source (Phase, Voltage, Cycle) |

ø |

Single |

|

||

|

|

V |

220 - 230 |

|

|

|

|

Hz |

50 |

|

|

|

|

|

|

|

|

Airflow Method |

|

OUTLET |

SIDE VIEW |

|

TOP VIEW |

|

|

INTAKE |

|

|

|

|

|

|

|

|

|

Air Volume |

Lo |

m3/min (cfm) |

Cooling; 12.5 (440) |

|

— |

|

|

|

Heating; 13.5 (480) |

|

|

|

|

|

|

|

|

|

Me |

m3/min (cfm) |

Cooling; 14.4 (510) |

|

— |

|

|

|

Heating; 14.9 (530) |

|

|

|

|

|

|

|

|

|

Hi |

m3/min (cfm) |

Cooling; 16.2 (570) |

|

Cooling; 42.8 (1,510) |

|

|

|

Heating; 17.3 (610) |

|

Heating; 41.5 (1,460) |

|

|

|

|

|

|

|

|

dB (A) |

Cooling; High 45, Low 37 |

|

Cooling; 48 |

|

|

|

Heating; High 45, Low 37 |

|

Heating; 49 |

Noise Level |

|

|

|

|

|

|

|

|

|

|

|

|

|

Power level dB |

Cooling; High 58 |

|

Cooling; High 61 |

|

|

|

Heating; High 58 |

|

Heating; High 62 |

|

|

|

|

|

|

Electrical Data |

Input Power |

W |

Cooling; 2,210 (215 - 2,540) |

||

|

|

|

Heating; 2,100 (245 - 2,750) |

||

|

|

|

|

|

|

|

Running Current |

A |

Cooling; 10.4 - 9.9 |

||

|

|

|

Heating; 9.7 - 9.3 |

||

|

|

|

|

|

|

|

EER |

W/W |

Cooling; 2.85 (4.19 - 2.80) |

||

|

|

BTU/hW |

Cooling; 9.7 (14.3 - 9.5) |

||

|

COP |

W/W |

Heating; 3.43 (3.67 - 3.09) |

||

|

|

|

|

|

|

|

|

BTU/hW |

Heating; 11.7 (12.5 - 10.5) |

||

|

Starting Current |

A |

9.7 |

|

|

Piping Connection Port |

|

inch |

G ; Half Union 1/2” |

|

G ; 3-way valve 1/2” |

(Flare piping) |

|

inch |

L ; Half Union 1/4” |

|

L ; 2-way valve 1/4” |

10

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

|

|

|

Unit |

CS-E21DKDS |

CU-E21DKD |

Pipe Size |

|

|

inch |

G (gas side) ; 1/2” |

G (gas side) ; 1/2” |

(Flare piping) |

|

|

inch |

L (liquid side) ; 1/4” |

L (liquid side) ; 1/4” |

Drain |

Inner diameter |

|

mm |

12 |

— |

Hose |

Length |

|

m |

0.65 |

— |

|

|

|

|

|

|

Power Cord Length |

|

|

|

—— |

— |

Number of core-wire |

|

|

|

|

— |

Dimensions |

Height |

|

inch (mm) |

10 - 13/16 (275) |

29 - 17/32 (750) |

|

Width |

|

inch (mm) |

39 - 9/32 (998) |

34 - 7/16 (875) |

|

|

|

|

|

|

|

Depth |

|

inch (mm) |

9 - 1/16 (230) |

13 - 19/32 (345) |

Net Weight |

|

|

lb (kg) |

24 (11) |

112 (51) |

|

|

|

|

|

|

Compressor |

|

Type |

|

— |

Involute scroll |

|

Motor |

Type |

|

— |

Brushless (4-pole) |

|

Rated |

Output |

W |

— |

900 |

|

|

|

|

|

|

Air Circulation |

|

Type |

|

Cross-flow Fan |

Propeller Fan |

|

|

Material |

|

ASHT-18 |

P.P |

|

|

|

|

|

|

|

Motor |

Type |

|

Transistor (8-poles) |

Transistor (8-poles) |

|

|

Rate Output |

W |

30 |

40 |

|

Fan Speed |

Lo (Cool/Heat) |

rpm |

1,170 / 1,270 |

— |

|

|

|

|

|

|

|

|

Me (Cool/Heat) |

rpm |

1,355 / 1,400 |

— |

|

|

Hi (Cool/Heat) |

rpm |

1,520 / 1,610 |

700 / 680 |

|

|

|

|

|

|

Heat Exchanger |

Description |

|

|

Evaporator |

Condenser |

|

Tube material |

|

|

Copper |

Copper |

|

Fin material |

|

|

Aluminium (Pre Coat) |

Aluminium (Blue Coated) |

|

|

|

|

|

|

|

Fin Type |

|

|

Slit Fin |

Corrugated Fin |

|

Row / Stage |

|

|

(Plate fin configuration, forced draft) |

|

|

|

|

|

2 / 15 |

|

|

|

|

|

2 / 34 |

|

|

FPI |

|

|

19 |

18 |

|

Size (W × H × L) |

mm |

810 × 315 × 25.4 |

839.5 × 714 × 36.4 |

|

|

|

|

|

|

868 |

|

|

|

|

|

|

Refrigerant Control Device |

|

|

— |

Expansion Valve |

|

Refrigeration Oil |

|

|

(c.c) |

— |

RB68A (360) |

Refrigerant (R410A) |

|

|

kg (oz) |

— |

1.29 (45.5) |

Thermostat |

|

|

|

Electronic Control |

— |

Protection Device |

|

|

|

Electronic Control |

Electronic Control |

|

Length |

|

mm |

— |

— |

Capillary Tube |

Flow Rate |

|

l/min |

— |

— |

|

Inner Diameter |

|

mm |

— |

— |

Air Filter |

Material |

|

|

P.P. |

— |

|

Style |

|

|

Honeycomb |

|

• Specifications are subjected to change without notice for further improvement.

11

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

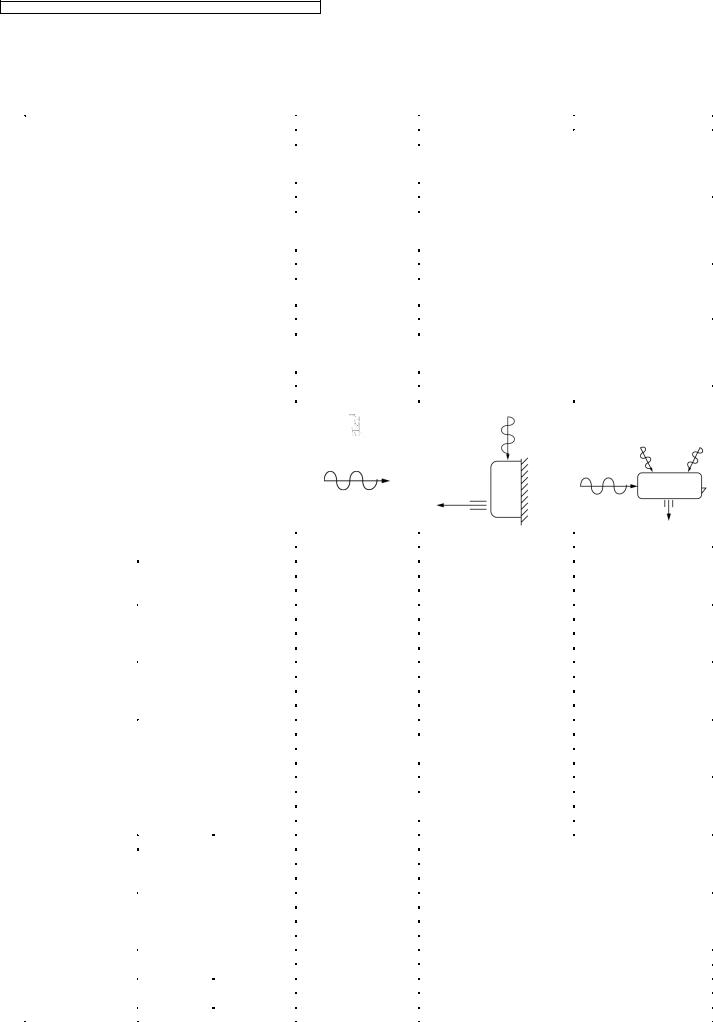

4 Dimensions

4.1.Indoor Unit & Remote Control

4.1.1.CS-E15DKDW

12

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

4.1.2.CS-E18DKDW CS-E21DKDS

13

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

4.2.Outdoor Unit

4.2.1.CU-E15DKD CU-E18DKD CU-E21DKD

14

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

5 Refrigeration Cycle Diagram

15

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

6 Block Diagram

16

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

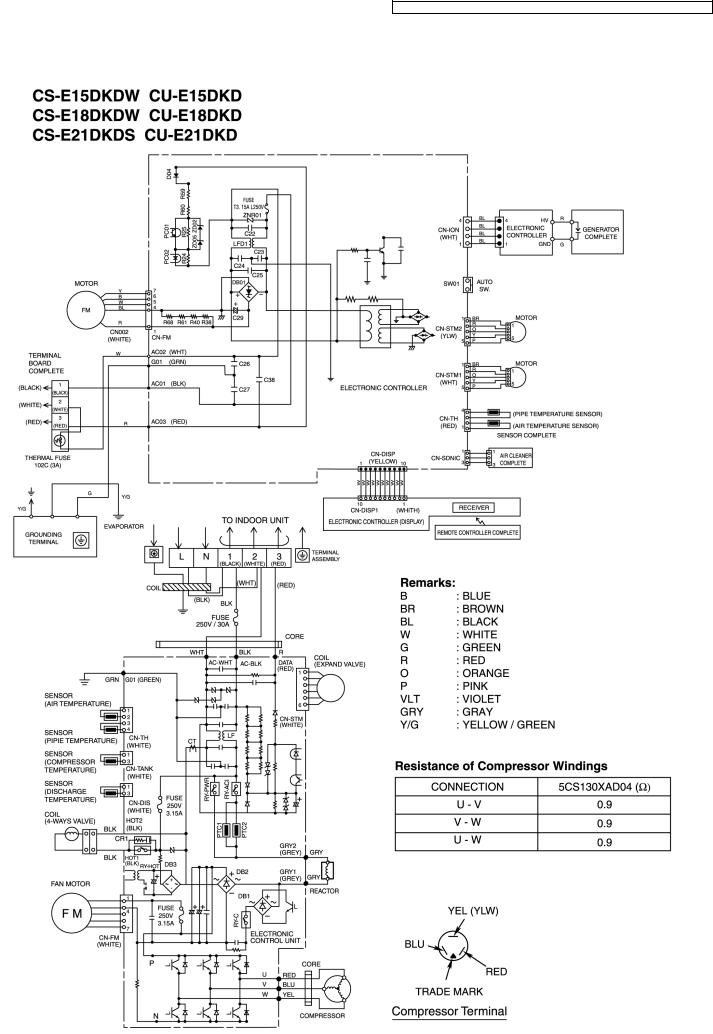

7 Wiring Diagram

17

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

8 Operation Details

8.1.Basic Function

Inverter control, which equipped with a microcomputer in determining the most suitable operating mode as time passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operating mode, the microcomputer maintains the set temperature by measuring the temperature of the environment and performing temperature shifting. The compressor at outdoor unit is operating following the frequency instructed by the microcomputer at indoor unit that judging the condition according to internal setting temperature and intake air temperature.

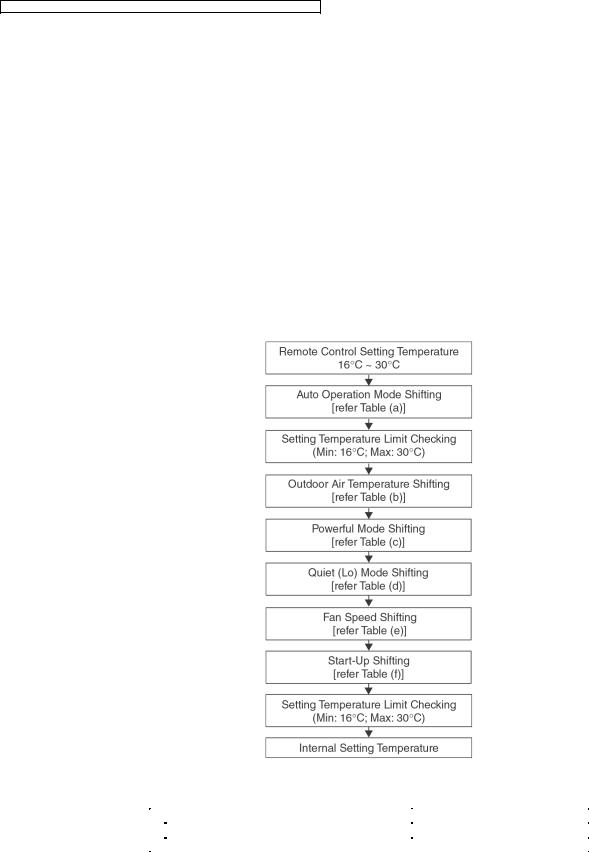

8.1.1.Internal Setting Temperature

Once the operation starts, remote control setting temperature will be taken as base value for temperature shifting processes. These shifting processes are depending on the air conditioner settings and the operation environment. The final shifted value will be used as internal setting temperature and it is updated continuously whenever the electrical power is supplied to the unit.

Table (a): Auto Operation Mode Setting

Mode Shift: |

Temperature Shift (°C) |

Cooling/Soft Dry → Heating |

-2.0 |

Heating → Cooling/Soft Dry |

+2.0 |

18

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

Table (b): Outdoor Air Temperature Shifting

Mode: |

Outdoor Temperature, X (°C): |

Temperature Shift (°C) |

|||

|

|

|

|

Manual Operation |

Auto Operation |

Cooling/Soft Dry |

|

38 |

X |

1.50 |

2.00 |

|

|

|

|

|

|

|

30 |

X |

38 |

1.25 |

1.25 |

|

23 |

X |

30 |

1.25 |

1.25 |

|

|

|

|

|

|

|

|

X |

23 |

1.75 |

1.75 |

Heating |

|

21 |

X |

-2.25 |

-1.50 |

|

17 |

X |

21 |

-1.75 |

-1.00 |

|

|

|

|

|

|

|

13 |

X |

17 |

-0.75 |

0.00 |

|

9 |

X |

13 |

0.25 |

0.25 |

|

|

|

|

|

|

|

5 |

X |

9 |

1.25 |

1.00 |

|

1 |

X |

5 |

0.75 |

1.00 |

|

-3 X 1 |

1.50 |

1.00 |

||

|

|

|

|

|

|

|

|

X |

-3 |

1.50 |

1.00 |

Table (c): Powerful Mode Shifting

Mode: |

Period, X (min): |

Temperature Shift (°C) |

|

Cooling |

X |

20 |

-2.0 |

|

X |

20 |

0.0 |

|

|

|

|

Soft Dry |

X |

20 |

-1.0 |

|

X |

20 |

0.0 |

|

|

|

|

Heating |

X |

20 |

+3.5 |

|

X |

20 |

+3.25 |

Table (d): Quiet (Lo) Mode Shifting

Mode: |

Period, X (min): |

Temperature Shift (°C) |

||

Cooling, Soft Dry |

20 min |

X |

50 min |

-3.0 |

|

50 min |

X |

110 min |

-4.0 |

|

110 min |

X |

440 min |

-5.0 |

Table (e): Fan Speed Shifting

Mode: |

Fan Speed: |

Temperature Shift (°C) |

Cooling |

Lo |

-0.25 |

|

Me-, Me, Me+, Auto |

0.00 |

|

|

|

|

Hi |

+0.25 |

Soft Dry |

All |

+0.25 |

|

|

|

Heating |

Lo |

+1.50 |

|

Me-, Me, Me+, Auto |

+0.75 |

|

Hi |

+0.75 |

|

|

|

Table (f): Start-Up Shifting

Mode within 60 Minutes from Start-up: |

Temperature Shift (°C) |

Cooling/Soft Dry |

-1.0 |

Heating |

+2.0 |

19

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

8.1.2.Compressor Operation Frequency

|

Intake Air Temperature - Internal Setting Temperature (°C) |

|

Freq. H |

|

||

Zone |

Cooling & Soft Dry |

Heating |

Cooling |

Soft Dry |

Heating |

Remark |

1 |

-2.0 |

1.5 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

2 |

-1.5 |

1.0 |

1 |

1 |

1 |

|

|

|

|

|

|

|

|

3 |

-1.0 |

0.5 |

14 |

8 |

11 |

|

4 |

-0.5 |

0.0 |

20 |

8 |

15 |

|

|

|

|

|

|

|

|

5 |

0.0 |

-0.5 |

27 |

8 |

22 |

|

6 |

0.5 |

-1.0 |

35 |

11 |

27 |

|

|

|

|

|

|

|

|

7 |

1.0 |

-1.5 |

43 |

11 |

36 |

|

|

|

|

|

|

|

|

8 |

1.5 |

-2.0 |

46 |

11 |

39 |

Fc, Fh |

9 |

2.0 |

-2.5 |

46 |

11 |

39 |

Fc, Fh |

|

|

|

|

|

|

|

10 |

2.5 |

-3.0 |

46 |

11 |

39 |

Fc, Fh |

11 |

Nil |

-3.5 |

Nil |

Nil |

39 |

Fh |

|

|

|

|

|

|

|

12 |

Nil |

-4.0 |

Nil |

Nil |

39 |

Fh |

|

|

|

|

|

|

|

Operating Frequency Calculation Formula:

CompHz = Freq. A × Freq. H + Freq. C

Example Calculation:

Model No.: E18DK

Operation Mode: Cooling

When Intake Air Temperature - Internal setting Temperature: 1.5°C

CompHz = Freq. A × Freq. H + Freq. C

=1.53 × 46 + 2.5

=72 Hz (It cuts down less than a decimal point)

Remarks:

Cooling & Soft Dry |

|

|

|

E18DK |

|

E21DK |

||||||

|

|

|

|

|

Freq. A |

|

|

Freq. C |

|

Freq. A |

|

Freq. C |

|

|

|

|

|

|

|

|

|

|

|

|

|

Low Load (Freq. H |

9) |

1.2 |

|

5.0 |

1.7 |

|

7.0 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

High Load (Freq. H > 10) |

1.53 |

|

2.5 |

2.0 |

|

4.0 |

||||||

|

|

|

|

|

|

|

|

|

|

|||

|

Heating |

|

|

|

E18DK |

|

E21DK |

|||||

|

|

|

|

|

Freq. A |

|

|

Freq. C |

|

Freq. A |

|

Freq. C |

|

|

|

|

|

|

|

|

|

|

|

|

|

Low Load (Freq. H |

11) |

|

1.6 |

|

|

8.0 |

1.9 |

|

7.0 |

|||

|

|

|

|

|

|

|

|

|

|

|

||

High Load (Freq. H > 12) |

|

2.2 |

|

|

1.0 |

2.35 |

|

1.0 |

||||

|

|

|

|

|

|

|

|

|||||

Freq. Range |

|

|

|

E18DK |

|

E21DK |

||||||

Cooling |

Fc |

|

|

|

|

72 |

|

|

96 |

|||

|

|

|

|

|

|

|||||||

|

Operation Range |

|

12 ~ 86 |

|

12 ~ 102 |

|||||||

|

|

|

|

|

|

|

|

|

|

|||

Heating |

Fh |

|

|

|

|

86 |

|

|

92 |

|||

|

Operation Range |

|

14 ~ 128 |

|

14 ~ 128 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

When Freq. H is equal to 46 (Cooling), 39 (Heating) or above, the Comp. may run at the freq. higher than Fc or Fh up to max. freq. operation.

Best Amenity Control

Every 90s (Cooling), 120s (Heating) maintain same zone Freq. H + 1 until Fc (46), Fh (39).

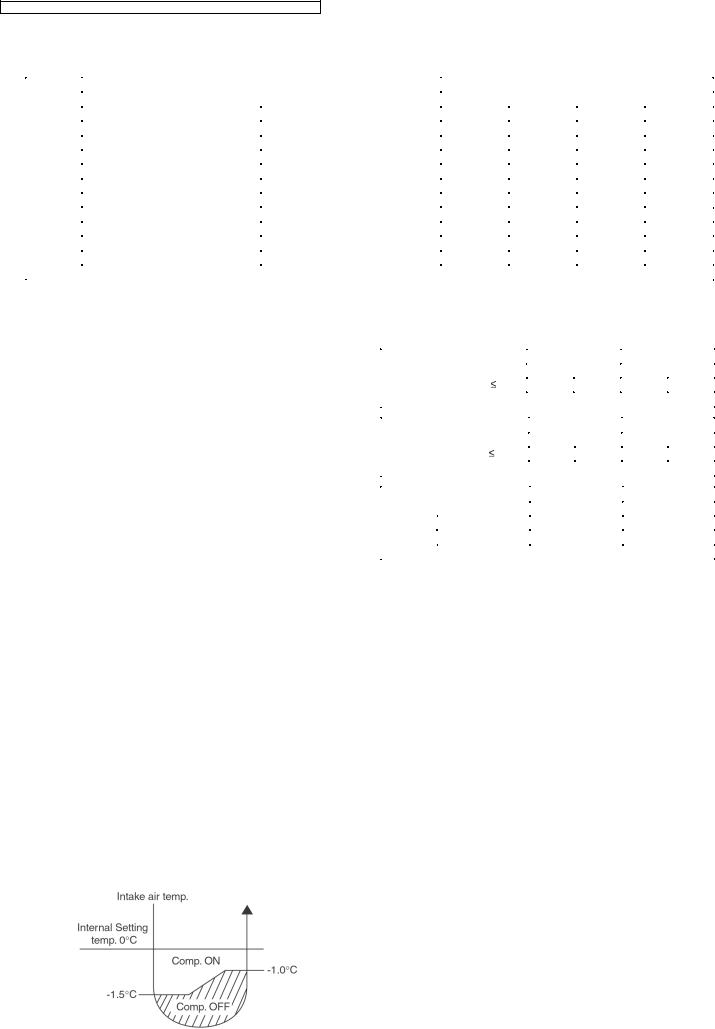

8.1.3.Cooling Operation

8.1.3.1.Thermostat control

•Compressor is OFF when Intake Air Temperature - Internal Setting Temperature < -1.5°C.

•Compressor is ON after waiting for 3 minutes, if the Intake Air Temperature - Internal Setting Temperature > Compressor OFF point +0.5°C.

20

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

8.1.4.Soft Dry Operation

8.1.4.1.Thermostat control

•Compressor is OFF when Intake Air Temperature - Internal Setting Temperature < -2.5°C.

•Compressor is ON after waiting for 3 minutes, if the Intake Air Temperature - Internal Setting Temperature > Compressor OFF point.

8.1.5.Heating Operation

8.1.5.1.Thermostat control

•Compressor is OFF when Intake Air Temperature - Internal Setting > +1.5°C.

•Compressor is ON after waiting for 3 minutes, if the Intake Air Temperature - Internal Setting Temperature < Compressor OFF point -0.5°C.

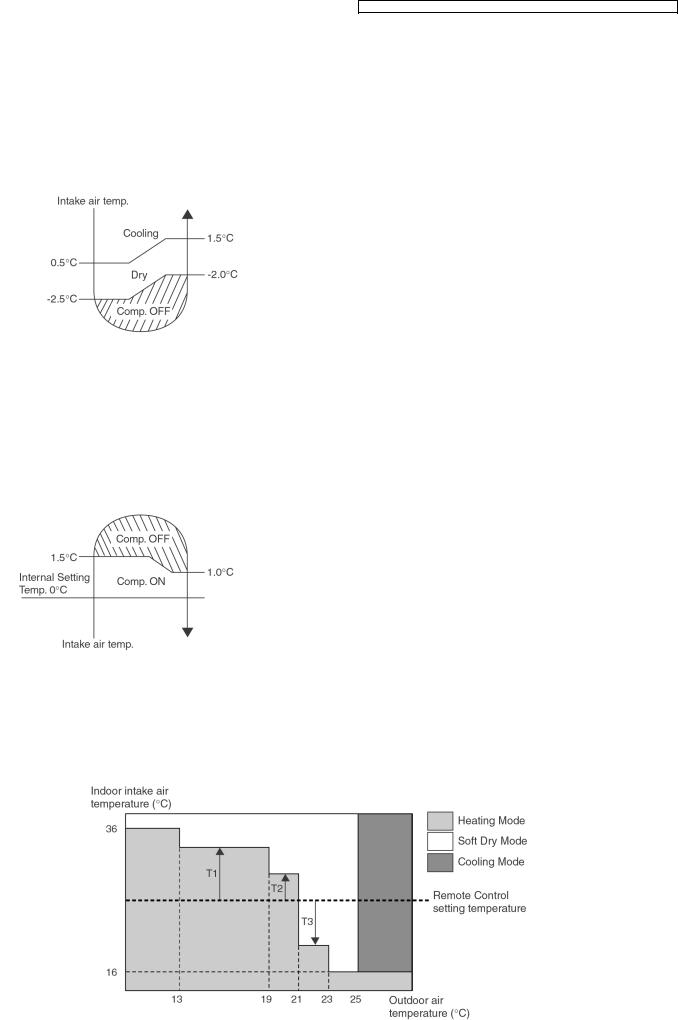

8.1.6.Automatic Operation

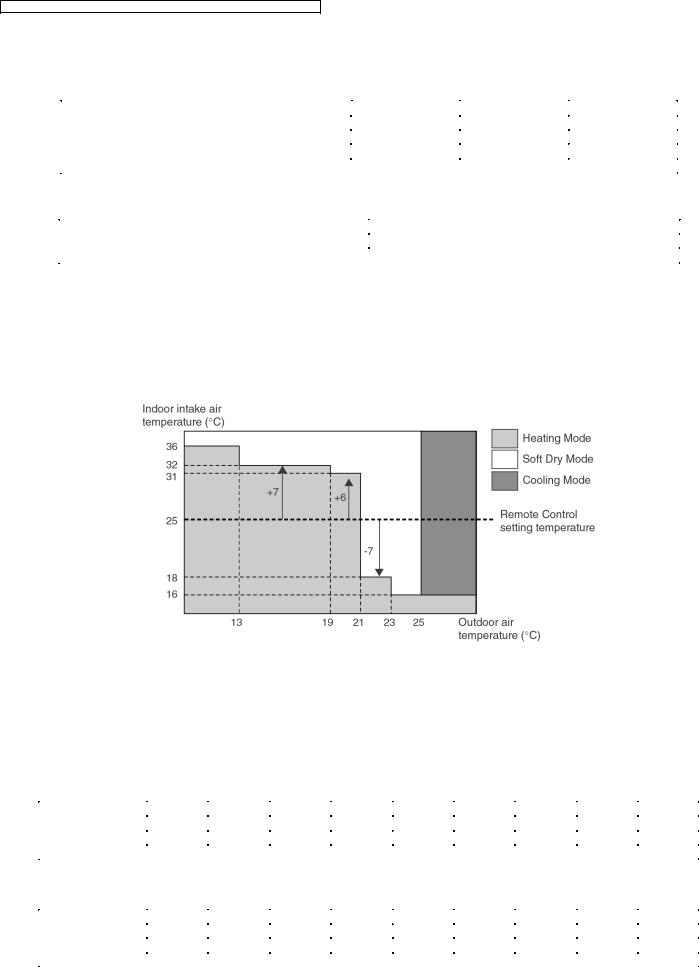

This mode can be set using remote control and the operation is decided by remote control setting temperature, indoor intake air temperature and outdoor air temperature.

During operation mode judgment, indoor fan motor (with speed of Lo-) and outdoor fan motor are running for 30 seconds to detect the indoor intake and outdoor air temperature. The operation mode is decided based on below chart.

21

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

Values of T1, T2, and T3 depend on remote control setting temperature, as shown in below table. After the adjustment of T1, T2 and T3 values, the operation mode for that particular environment and remote control setting is judged and performed, based on the above operation mode chart, every 30 minutes.

Remote Control Setting Temperature (°C) |

T1 |

T2 |

T3 |

16 ~ 18 |

+10 |

+8 |

-5 |

|

|

|

|

19 ~ 22 |

+8 |

+7 |

-7 |

23 ~ 26 |

+7 |

+6 |

-7 |

|

|

|

|

27 ~ 30 |

+6 |

+5 |

-8 |

There is a temperature shifting on T1, T2, and T3 if the operation mode judged is changed from Cooling/Soft Dry to Heating or vice verse.

Operation Mode change from |

Temperature shifts (°C) |

Cooling/Soft Dry → Heating |

-2 |

Heating → Cooling/Soft Dry |

+2 |

Example of operation mode chart adjustment:

From the above table, if remote control setting temperature = 25,

T1 = 25 + 7 = 32; T2 = 25 + 6 = 31; T3 = 25 - 7 = 18

The operation mode chart for this example is as shown in below figure and the operation mode to be performed will depend on indoor intake air temperature and outdoor air temperature at the time when the judgment is made.

8.1.7.Indoor Fan Motor Operation

A.Basic Rotation Speed (rpm)

•Required rotation speed for fan is set to respond to the remote control setting (10 rpm unit)

[Cooling, Dry, Fan]

Remote Control |

— |

O |

O |

O |

O |

O |

— |

— |

— |

Tab (rpm) |

SHI |

Hi |

Me+ |

Me |

Me- |

Lo |

Lo- |

SLo |

SSLo |

|

|

|

|

|

|

|

|

|

|

E18DK |

1530 |

1440 |

1360 |

1290 |

1220 |

1150 |

850 |

760 |

630 |

|

|

|

|

|

|

|

|

|

|

E21DK |

1610 |

1520 |

1420 |

1330 |

1240 |

1150 |

890 |

800 |

630 |

[Heating]

Remote Control |

— |

O |

O |

O |

O |

O |

— |

— |

— |

Tab (rpm) |

SSHI |

SHi |

Me+ |

Me |

Me- |

Lo |

Lo- |

SLo |

SSLo |

E18DK |

1590 |

1560 |

1480 |

1410 |

1340 |

1270 |

850 |

400 |

300 |

|

|

|

|

|

|

|

|

|

|

E21DK |

1640 |

1610 |

1520 |

1440 |

1350 |

1270 |

890 |

400 |

300 |

22

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

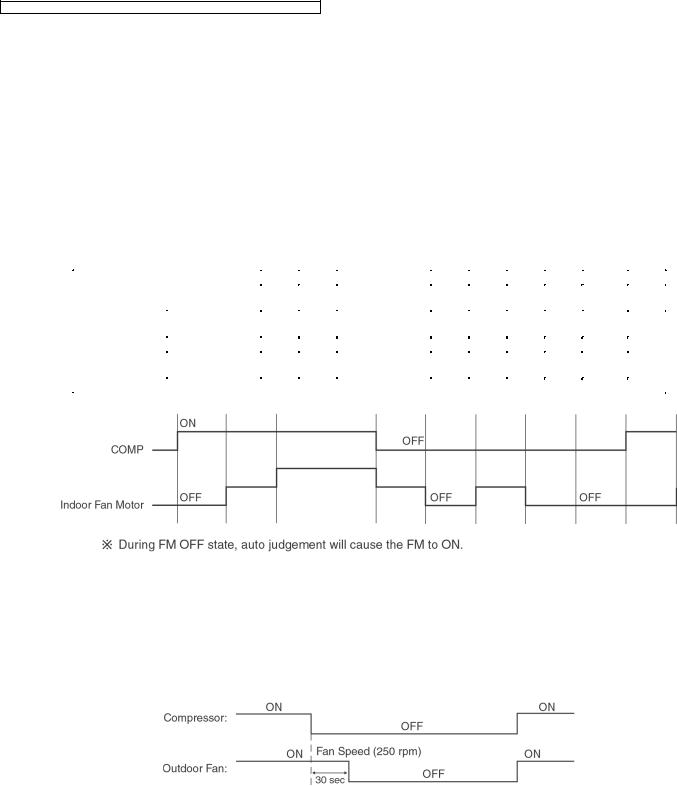

B.Indoor Fan Control

i.Indoor fan control operation outline

1.Cooling / Dry

2. Heating

23

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

ii.Auto Fan Speed

1.Cooling

2. Heating

Note:

a.UP:

•If move from Lo, the fan speed will be shifted to Maximum 1520 rpm (E21DK), 1480 rpm (E18DK).

•If move from Maximum, the fan speed no change.

•In up zone, 10 rpm is added for every 10s until Maximum 1520 rpm (E21DK), 1480 rpm (E18DK).

b.DOWN:

•The fan speed will be decreased one step every 10 sec. until Minimum 1270 rpm.

c.Current Output Fixed:

•Maintain at present fan speed.

d.Instantaneous Maximum:

•Fan speed will be increased to maximum auto fan speed.

e.Temperature in ( ) is for Powerful Mode operation.

24

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

iii. Max Capacity Condition

a)During Cooling operation, if all to the following condition is fulfilled, the indoor fan speed is set to Shi.

1.Indoor intake temperature  24°C.

24°C.

2.Operation frequency 72 Hz (E18DK), 95 Hz (E21DK) & above.

3.Remote Control setting temperature 16°C.

4.Remote Control setting fan speed Hi.

5.Outdoor temperature  30°C.

30°C.

6.Operation start  within 30 minutes.

within 30 minutes.

* If any of above conditions is not valid, the condition is ended.

b)During Heating operation, if all to the following condition is fulfilled, the indoor fan speed is set to SSHi.

1.Indoor intake temperature is 17°C or above and less than 23°C.

2.Operation frequency 86 Hz (E18DK), 93 Hz (E21DK) & above.

3.Remote Control setting temperature 30°C.

4.Remote Control setting fan speed Hi.

5.Outdoor temperature < 4°C.

6.Operation start  2 hours.

2 hours.

* If any of above conditions is not valid, the condition is ended.

C.Fan Motor Control

i.Motor specification High voltage PWM Motor

ii.Feedback Control

1.Rotation speed feedback

Immediately after the fan started, rpm is checked and duty is added, and feedback control is performed.

iii.Abnormal Detection

1. Condition |

* |

Step out signal input |

|

* |

Feedback rotation speed is more than 2550 rpm or below 50 rpm. |

|

|

However, 10s after fan start, rotation abnormality is not detected. |

2. |

Control |

* |

Fan stop |

3. |

Return |

* |

Restart after 5s |

|

|

|

However, in case the fan is stopped by the above conditions within 25s after fan has started, and happened |

|

|

|

continuously for 7 times, restart will not be performed. |

→Indoor fan motor lock abnormal (H19)

iv.Restart Prohibition Control

Prohibit to restart within 5s after fan stop. (except when power is ON)

25

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

D. Deodorizing Control

i. Control condition

Control at cooling/dry operation and auto fan speed.

No Deodorizing Control is performed during ON timer standby operation and during Anti-freezing control prevention.

ii. Operation

The odor status is arranged as below and it is shifted as follow.

* When COMP is ON

(Shift to 4 when COMP is OFF) * When COMP is OFF

(Shift to 1 when COMP is ON)

* Start from 4 if the Thermostat is OFF during the start operation.

Odor Status |

1 |

2 |

3 |

4 |

5 |

4 |

5 |

4.5.4... |

1 |

|||

Status Shift |

|

|

|

ON |

|

|

OFF |

|

|

|

ON |

|

according to COMP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Status Shift |

Cooling |

|

|

|

|

|

|

|

|

|

|

|

according |

zone |

40 |

50 |

— |

20 |

90 |

20 |

90 |

....... |

|

|

|

to time (s) |

Dry zone |

|

|

|

|

|

|

|

|

|

|

ON |

|

Cooling |

OFF |

|

|

Auto Fan Speed |

|

OFF |

|

|

|

|

|

Fan Speed |

zone |

|

|

SLo |

|

SLo |

|

SLo |

OFF |

....... |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dry zone |

OFF |

|

|

SLo |

|

OFF |

|

|

|

|

|

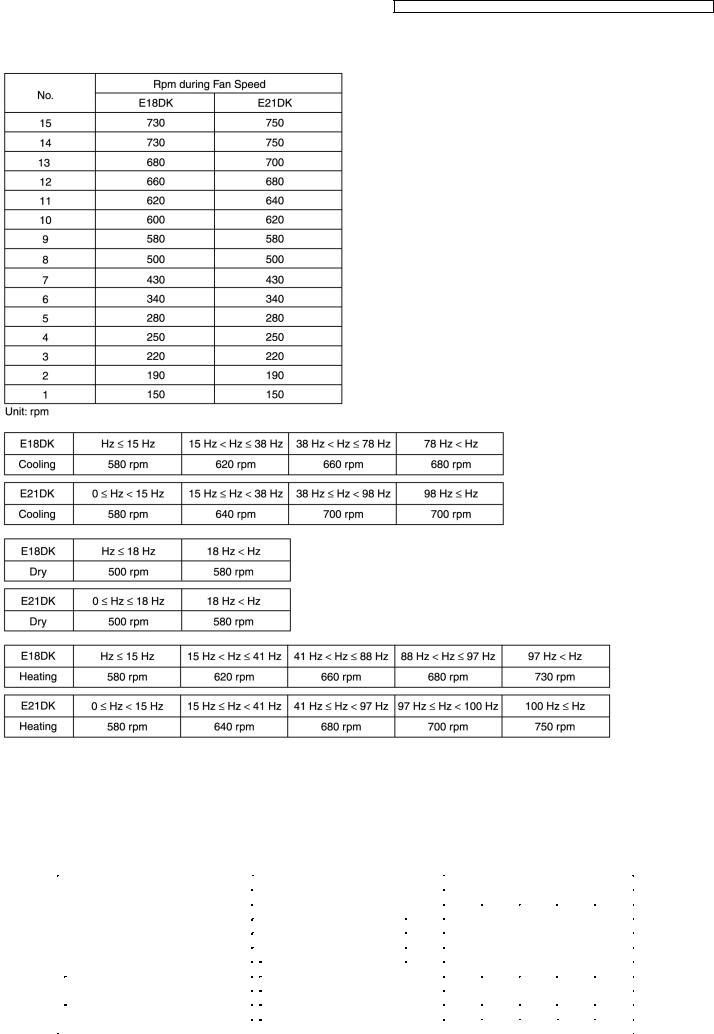

8.1.8.Outdoor Fan Motor Operation

Outdoor fan motor is operated with 15 fan speed. It starts when compressor starts operation and it stops 30 seconds after compressor stops operation.

26

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

Basic Rotation Speed

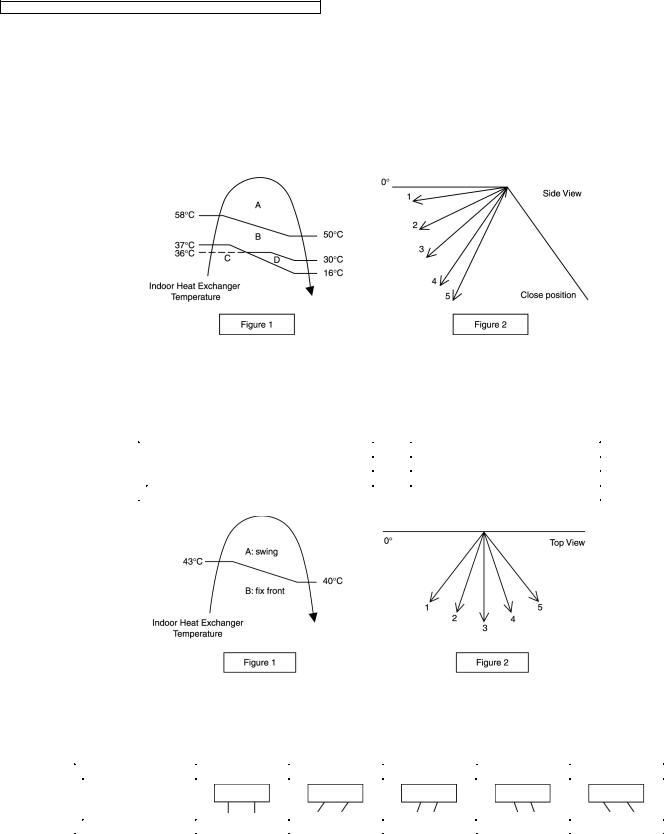

8.1.9.Airflow Direction

1.There are two types of airflow, vertical airflow (directed by horizontal vane) and horizontal airflow (directed by vertical vanes).

2.Control of airflow direction can be automatic (angles of direction is determined by operation mode, heat exchanger temperature and intake air temperature) and manual (angles of direction can be adjusted using remote control).

Vertical Airflow

Operation Mode |

Airflow Direction |

|

|

Vane Angle (°) |

|

||

|

|

|

1 |

2 |

3 |

4 |

5 |

|

|

|

|

|

|

|

|

Heating |

Auto with Heat Exchanger |

A |

|

|

16 |

|

|

|

|

B |

|

|

50 |

|

|

|

|

|

|

|

|

|

|

|

Temperature |

C |

|

|

8 |

|

|

|

|

D |

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

Manual |

|

8 |

17 |

33 |

49 |

60 |

|

|

|

|

|

|

|

|

Cooling, Soft Dry and Ion |

Auto |

|

|

|

8 ~ 38 |

|

|

|

Manual |

|

8 |

17 |

25 |

33 |

38 |

|

|

|

|

|

|

|

|

Mode Judgment in Auto |

Auto |

|

|

|

8 |

|

|

|

Manual |

|

8 |

17 |

25 |

33 |

38 |

|

|

|

|

|

|

|

|

27

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

1.Automatic vertical airflow direction can be set using remote control; the vane swings up and down within the angles as stated above. For heating mode operation, the angle of the vane depends on the indoor heat exchanger temperature as Figure 1 below. When the air conditioner is stopped using remote control, the vane will shift to close position.

2.Manual vertical airflow direction can be set using remote control; the angles of the vane are as stated above and the positions of the vane are as Figure 2 below. When the air conditioner is stopped using remote control, the vane will shift to close position.

Horizontal Airflow

1.Automatic horizontal airflow direction can be set using remote control; the vane swings left and right within the angles as stated below. For heating mode operation, the angle of the vane depends on the indoor heat exchanger temperature as Figure 1 below.

Operation Mode |

|

Vane Angle (°) |

Heating, with heat exchanger temperature |

A |

68 ~ 112 |

|

|

|

|

B |

90 |

Cooling, Soft Dry and Ion |

|

68 ~ 112 |

|

|

|

2.Manual horizontal airflow direction can be set using remote control; the angles of the vane are as stated below and the positions of the vane are as Figure 2 above.

Pattern |

1 |

2 |

3 |

4 |

5 |

Airflow Direction |

|

|

|

|

|

Patterns at Remote |

|

|

|

|

|

Control |

|

|

|

|

|

|

|

|

|

|

|

Vane Angle (°) |

90 |

68 |

79 |

101 |

112 |

|

|

|

|

|

|

28

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

8.1.10. Quiet operation (Cooling Mode/Cooling area of Dry Mode)

A. Purpose

To provide quiet cooling operation compare to normal operation.

B.Control condition

a. Quiet operation start condition

•When “quiet” button at remote control is pressed. Quiet LED illuminates.

b.Quiet operation stop condition

1.When one of the following conditions is satisfied, quiet operation stops:

a.Powerful button is pressed.

b.Stop by OFF/ON switch.

c.Timer “off” activates.

d.Quiet button is pressed again.

2.When quiet operation is stopped, operation is shifted to normal operation with previous setting.

3.When fan speed is changed, quiet operation is shifted to quiet operation of the new fan speed.

4.When operation mode is changed, quiet operation is shifted to quiet operation of the new mode.

5.During quiet operation, if timer “on” activates, quiet operation maintains.

6.After off, when on back, quiet operation is not memorised.

D. Control contents

1.Fan speed is changed from normal setting to quiet setting of respective fan speed. This is to reduce sound of Hi, Me, Lo for 3dB.

2.Fan speed for quiet operation is -100 rpm from setting fan speed.

8.1.10.1. Quiet operation under Soft Dry operation (Dry area at Dry Mode)

Automatic Fan Speed (Dry operation)

Manual Fan Speed (Dry operation)

29

CS-E15DKDW CU-E15DKD / CS-E18DKDW CU-E18DKD / CS-E21DKDS CU-E21DKD

8.1.10.2. Quiet operation (Heating)

A. Purpose

To provide quiet heating operation compare to normal operation.

B.Control condition

a. Quiet operation start condition

•When “quiet” button at remote control is pressed. Quiet LED illuminates.

b.Quiet operation stop condition

1.When one of the following conditions is satisfied, quiet operation stops:

a.Powerful button is pressed.

b.Stop by OFF/ON switch.

c.Timer “off” activates.

d.Quiet button is pressed again.

2.When quiet operation is stopped, operation is shifted to normal operation with previous setting.

3.When fan speed is changed, quiet operation is shifted to quiet operation of the new fan speed.

4.When operation mode is changed, quiet operation is shifted to quiet operation of the new mode, except fan only mode.

5.During quiet operation, if timer “on” activates, quiet operation maintains.

6.After off, when on back, quiet operation is not memorised.

C.Control contents

a. Fan Speed manual

1.Fan speed is changed from normal setting to quiet setting of respective fan speed. This is to reduce sound of Hi, Me, Lo for 3dB.

2.Fan speed for quiet operation is -100 rpm from setting fan speed.

3.Fan Speed Auto

•If FM  Lo

Lo

-100 rpm reduce from normal Heating Auto Fan Speed

•If FM  Lo

Lo

maintain RPM

Indoor FM RPM depends on pipe temp sensor of indoor heat exchanger.

30

Loading...

Loading...