Nokia 3310 Repairhints 1

nokia

Service & Competence Center Europe

Customer Care Training Group

CONFIDENTIAL |

1 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

Repairhints

3310

NHM-5 HDa 12

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

nokia

Service & Competence Center Europe

Customer Care Training Group

CONFIDENTIAL |

2 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

GENERAL

-How to use this document

Put the QUICK REPAIR layouts behind this manual.

Now you are able to follow these specifications with graphical layouts and it is easier for you to find the components and measuring points.

-Component characteristics:

Some components contain important data.

Several described steps are only practicable if you are able to reflash/ realign the phone and/or rewrite IMEI/SIMlock in certain cases. Please pay attention to separate notes.

-Underfills, broken balls, µBGA

It is not possible to change underfilled components. The trial will damage PCB surely. All replaceable µBGA-components must be renewed after removing. Reflow is not allowed.

Check soldering points, remove oxidated solderings (broken balls) carefully by enclosing few new solder before placing new components.

µBGA must be soldered only with NMP approved µBGA-rework machines (e.g. Zevac/OK International). Use only recommended Fluxtype and an appropriate amount of it.

-PCB handling & cleaning

Only use appropriate cleaning materials, don`t use scratching or rubbing tools. Clean PCB carefully after every rework and take great pains over the keyboard area. Don´t make any loose wiring connections anywhere.

If it is necessary to clean the PCB, please pay attention to the following: Because of organic surface protection (OSP), cleaning must only be done with a lint-free cloth which may be moisten with DI-water. IPA or other solvent like ethanol should only be used to clean gold pads for spring contacts without affecting the surrounding copper layers.

If it is necessary to change any item located under the metal shields, remove the shield first, don´t cut partially or bend it.

-Realign after repair

Characteristics of replacement parts are different.

To prevent additional faults after repair (eg. low standby time, loosing network etc.) it is necessary to retune phone values after repair.

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

nokia

Service & Competence Center Europe

Customer Care Training Group

IMPORTANT:

CONFIDENTIAL |

3 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

This document is intended for use by authorized NOKIA service centers only.

The purpose of this document is to provide some further service information for NOKIA 3310 phones. It contains a lot of collected tips and hints to find failures and repair solutions easily.

It also will give support to the inexperienced technicians.

Saving process time and improving the repair quality is the aim of using this document.

We have build it up based on fault symptoms (listed in "Contents") followed by detailed description for further analysis.

It is to be used additionally to the service manual and other service information like Service Bulletins, for that reason it doesn't contain any circuit descriptions or schematics.

All measurements are made using following equipment:

Nokia repair SW |

: WinTesla Version 6.43 |

DLL version |

: 311.03.00 |

Nokia Module Jig |

: MJS-19 |

Digital multimeter |

: Fluke 73 |

Oscilloscope |

: Hitachi V-1565; Fluke PM 3380A/B |

Spectrum Analyzer |

: Advantest R3131 with an analogue probe |

RF-Generator / |

: Rohde & Schwarz CMU 200 |

GSM Tester |

|

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If any errors are found by the reader, NOKIA should be notified in writing, using following procedure :

Please state:

Title of the Document + Issue Number/Date of publication.

Page(s) and/or Figure(s) in error.

Please send to: |

Nokia GmbH |

|

Service & Competence Center Europe |

|

Meesmannstr.103 |

|

D-44807 Bochum / Germany |

|

Email: training.sace@nokia.com |

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

nokia

Service & Competence Center Europe

Customer Care Training Group

Contents

CONFIDENTIAL |

4 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

GENERAL |

2 |

|

INTRODUCTION |

3 |

|

HARDWARE CHANGES |

5 |

|

PHONE DOESN´T SWITCH ON |

6 |

|

FLASH UPDATE NOT POSSIBLE |

8 |

|

PHONE SWITCHES OFF |

9 |

|

LOW STANDBY TIME |

10 |

|

NOT CHARGING |

12 |

|

CONTACT SERVICE |

14 |

|

SIMCARD FAULTS |

15 |

|

AUDIO FAULTS |

18 |

|

USER INTERFACE FAULTS |

19 |

|

NO SERVICE |

21 |

|

FREQUENCY LIST |

29 |

|

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

nokia

Service & Competence Center Europe

Customer Care Training Group

HW-CHANGES IN 3310/NHM-5/HDa 12

Intermittent switches off problem ( SB 12 )

CONFIDENTIAL |

5 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

In case of HW-ID 0600, 0601,0602, 0603, 0604, 0607, 0608, 0612 and 0614 change following parts:

R559 from 2.2kΩ to 1kΩ |

(1430754) |

|

C559 from 100pF to 47pF |

(2320552) |

|

C560 from 1nF |

to 47pF |

(2320552) |

C303 from 1nF |

to 47pF |

(2320552) |

Since HW-ID 0615 these changes are implemented in production.

Software update to PhoneSW 4.06 or higher makes above mentioned HW update unnecessary (SB16)

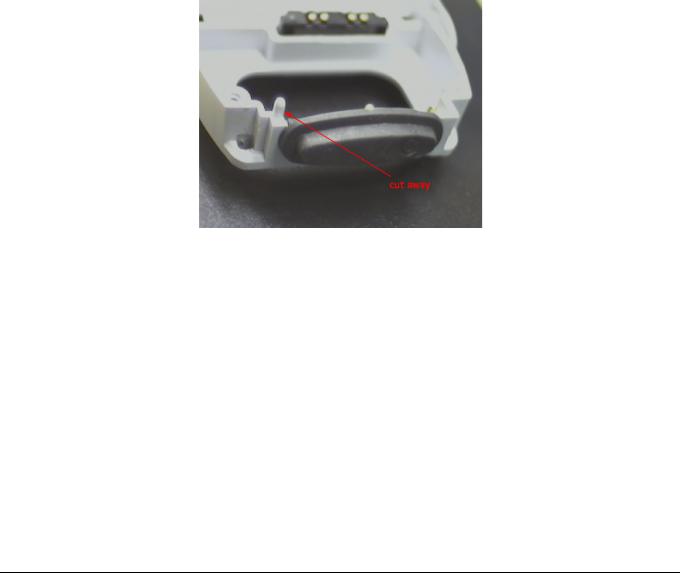

Difficulties when removing B-Cover ( SB 13 )

If customers critisize bad removal of B-Cover cut away the guiding pin of the D-Cover ( see picture below ) After this procedure it is necessary to assemble the phone with a torque screwdriver prepared for 30Ncm!

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

nokia

Service & Competence Center Europe

Customer Care Training Group

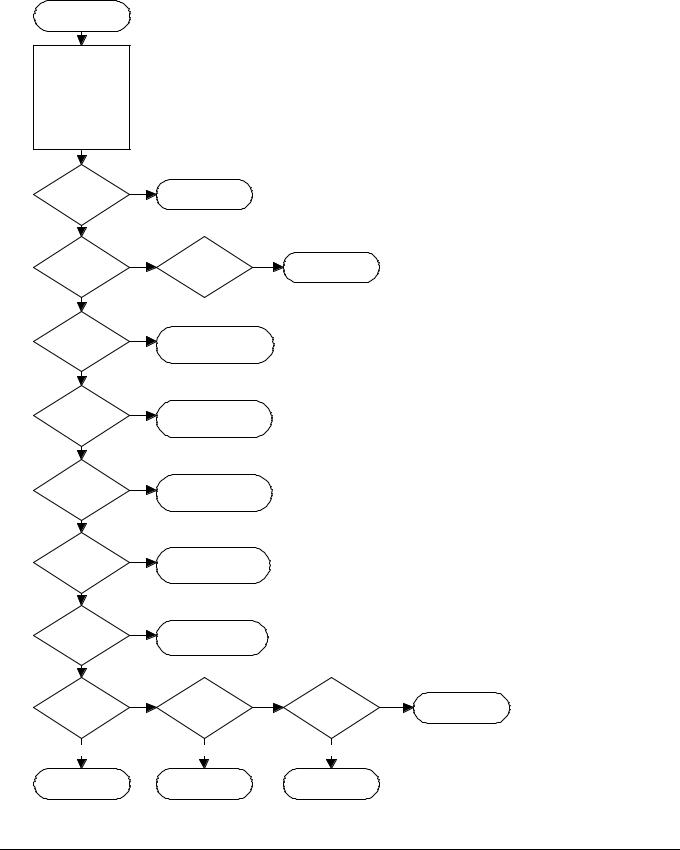

PHONE DOESN`T SWITCH ON

Phone doesn`t switch on

Check current consumption Off state: 0.1-0.6 mA Sleepmode: 0.6-4 mA

Call mode: 100-550 mA, if too high, continue with section "LOW STANDBY/OPERATION MODE TIME"

Disable watchdog if phone switches off after 2-3 seconds

nOK

Check Vb 3.6V at

C227/228

Check X203 if bent or soiled, check L513,L201

OK |

|

|

|

nOK |

nOK |

Check |

|

Check/change |

32.768kHz at C220, |

|

B200,R211/212/214, |

3Vpp squarewave |

|

C229/230 |

OK |

|

|

Check if |

nOK |

|

|

Check/change |

|

PWRONX at R402 drops |

|

|

to 0V during |

|

S419,R402,R224, |

powerswitch-use |

|

Change N201 if necessary |

OK |

|

|

Check |

nOK |

|

|

Check resistance of line |

|

Vbb 2.8V at |

|

|

|

to GND (~90k). If line OK, |

|

C209/211 |

|

|

|

change N201 |

|

|

|

|

OK |

|

|

|

nOK |

|

Check Vxo 2.8VDC at |

|

Check resistance of line |

C243 |

|

to GND (~45k). If line OK, |

|

|

change N201 |

OK |

|

|

Check |

nOK |

|

|

Check resistance of line |

|

Vcore 1.7VDC at both |

|

|

pads of L200, change if |

|

to GND (~180k). If line |

necessary. |

|

OK, change N201 |

OK |

|

|

|

nOK |

|

Check SLEEPX |

|

MAD is faulty in all |

2.8VDC at J308 |

|

probability. Swap phone, |

|

MAD is not changeable |

|

|

|

|

OK |

|

|

Check |

OK |

OK |

|

Check 13MHz |

|

PURX 2.8V DC at |

|

|

|

REFCLK at C303 |

|

R308 after |

|

|

|

(500mVpp) |

|

Powerkey-press |

|

|

|

|

|

nOK |

|

nOK |

Change N201

Check values around

G502,N500,V502

CONFIDENTIAL |

6 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

Change N201

OK

Try to flash the

Phone is OK

phone

nOK

Continue with section "FLASH UPDATE NOT POSSIBLE"

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

nokia

Service & Competence Center Europe

Customer Care Training Group

CONFIDENTIAL |

7 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

X203 Battery connector

Check if bent or soiled.

Check that pads of connector on PCB are clean.

S419 Power on/off switch faulty

Check that voltage at R402 is 3.6V when powerswitch is not pressed. If voltage is not ok, check R402 and R224, change N201 if necessary.

If voltage at R402 is ok, it must decrease to 0V if S419 is pressed, else change S419. Disable watchdog by connecting R224 to GND if phone switches off after 2 or 3 seconds.

B200 Sleep Clock Oscillator faulty

Check 32.768kHz, 3Vpp squarewave at pad of C220 located towards B200.

If oscillator does not work, check voltage at the two pads of B200 which are located towards N201, normally 1.6V DC. If not ok, check periphery of B200 or change CCONT N201. If frequency is not ok, check parts around B200 (R211, R212, R214, C229/230).

G502 Reference oscillator faulty

Check Vcc 2.7V DC at G502 pin 2 and Vcont (varies between 0.03V and 2.3V, typically 1.3VDC) at C552. Check 26MHz Clk-frequency at pin 3 of G502, 1Vpp

Check 13MHz Clk-frequency at C559, 300mVpp

If not ok, check voltages for HAGAR N500. (Detailed information in chapter “No Service”). Check 13MHz Clk-frequency at C303, 500mVpp at pad located towards V103.

If not ok, check values around V502

N201 CCONT faulty

Check Vb 3.6V DC at C227/228.

Check 32.768kHz, 3Vpp squarewave at pad of C220 located towards B200. Check that PWRONX decreases from 3.6V DC to 0V at R402 if powerswitch is pressed.

If these conditions are fulfilled output voltage lines should rise to their intended values and PURX is released after some milliseconds by CCONT.

If CCONT does not work, check output voltage lines for shorts to ground ( check current consumption! ), if ok, change CCONT with µBGA soldering machine and run energy management calibration.

D300 MAD faulty

Check 32.768kHz squarewave at C220.

Check 13MHz Clk-frequency at C303.

Check Vbb 2.8V DC at C209/211 and Vcore 1.7V DC at L200.

Check SLEEPX 2.8V DC at J308.

Check PURX 2.8V DC at R308.

Try to flash the phone.

MAD is probably faulty, swap the phone because MAD is not changeable.

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

nokia

Service & Competence Center Europe

Customer Care Training Group

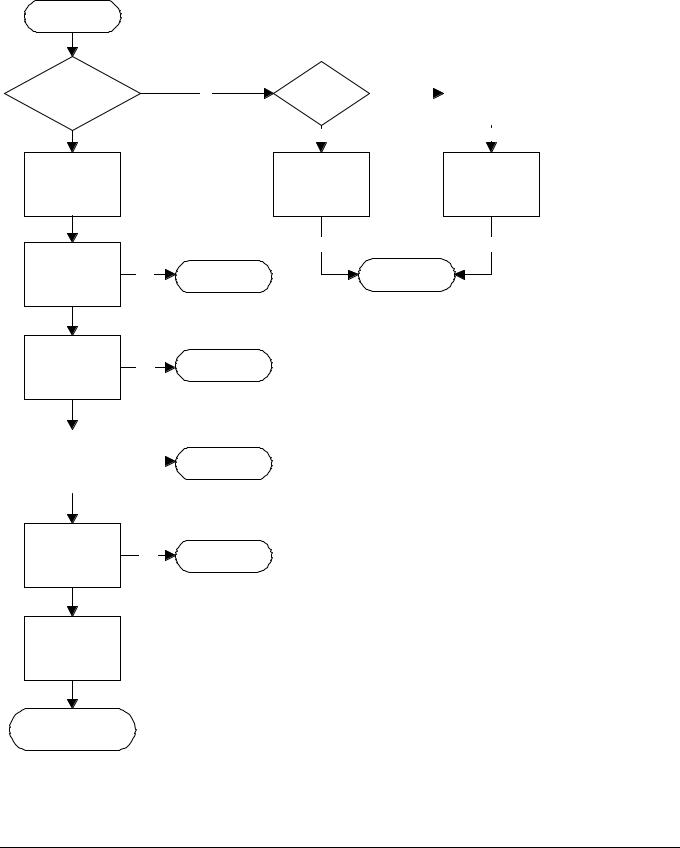

FLASH UPDATE NOT POSSIBLE

Flash update not possible

Prommer fault code 1. MCU boot failure

2. Serial clock line failure no

3. Serial data line failure

yes

Connect "watchdog disable" R224 to GND if phone does not stay on

CONFIDENTIAL |

8 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

Algorithm code fail, |

|

|

|

|

|

|

|

|

|

||||

|

no |

|

|

External RAM failure |

|||||||||

|

|

|

|||||||||||

alias ID missing |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

yes |

|

|

|

|

|

|

yes |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Update FP box with latest flash device list, try to

Change SRAM D302, try to

update again

update again

OK |

|

|

|

|

|

nOK |

nOK |

Check Vbb 2.8V at C209/211 |

nOK |

Continue with section |

Change Flash D301, try |

Vxo 2.8V at C243 |

"Phone doesn`t switch |

to update again. If not |

|

Vcore 1.7V at L200 |

|

on" |

ok, MAD or PCB faulty |

OK

Check SLEEPX 2.8V

at J308

MAD is faulty in all nOK  probability, swap the

probability, swap the

phone.

OK

|

|

|

|

|

Check PURX 2.8V at R308 |

|

nOK |

|

Change CCONT N201 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

OK

Check 13MHz RFCLK at C303 500mVpp

nOK |

Check values around |

|

G502, N500, V502 |

||

|

OK

Check M/F-bus lines (X201, pad 1,2,4) for shorts to GND, also check R217, R302/304/307, C232 and V204

OK

If update is still not possible, swap the phone, because MAD or PCB should be the reason

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

nokia

Service & Competence Center Europe

Customer Care Training Group

CONFIDENTIAL |

9 (29) |

Product NHM-5 |

Repairhints |

Introduction |

Version 1.0 Approved |

Date 2001-03-27 |

|

PHONE INTERMITTENT SWITCHES OFF/DOESN`T SWITCH ON

Check first of all phone´s software version.

If version is < 4.06, make SW update and check if fault persists.

If phone switches off intermittent although phone SW is 4.06 or higher and battery is fully charged, check phone´s HW-ID.

In case of HW-ID 0600, 0601,0602, 0603, 0604, 0607, 0608, 0612 and 0614 it is necessary to change the following parts:

R559 from 2.2kΩ to 1kΩ |

(1430754) |

|

C559 from 100pF to 47pF |

(2320552) |

|

C560 from |

1nF to 47pF |

(2320552) |

C303 from |

1nF to 47pF |

(2320552) |

If HW-ID is 0615 or higher, the above mentioned changes are already done.

Other possibilities if SWand/or HW-update do not solve the problem:

Check mechanical appearance of connector X203. Check that pads of X203 on PCB are clean.

Check amplitude of 32.768kHz at C220, 3Vpp squarewave,

probably broken solderings under CCONT N201. Remove CCONT and replace it with µBGA soldering machine, run energy management calibration after changing CCONT.

The same problem may be caused by N500, because the reference oscillator G502 ( 26MHz ) is divided to 13MHz system clock by HAGAR N500.

© NMP 2001

Checked by: |

Approved by: |

CC Training Group |

SCCE |

Loading...

Loading...