Jaguar 444, 745 User manual

JAGUAR

JAGUAR

INSTRUCTION MANUAL

745 / 444

FREEARM, LIGHTWEIGHT, SUPER-AUTOMATIC WITH BUILT-IN PRACTICAL STITCHES AND STRETCH STITCHES

“IMPORTANT SAFETY INSTRUCTIONS”

“When using an electrical appliance, basic safety precautions should always be followed, including the following.”

“Read all instructions before using this sewing machine.”

“DANGER-To reduce the risk of electric shock:”

1.“ This sewing machine should never be left unattended when plugged in. Always unplug this sewing machine from the electric outlet immediately after using and before cleaning.”

2.“ Always unplug before replacing light bulb. Replace bulb with same type rated 15 watts.”

This appliance complies with EEC Directive 89/336/EEC covering the electromagnetic compatibility.

“WARNING-To reduce the risk of burns, fire, electric shock, or injury to persons: ”

1.“Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near children.”

2.“Use this sewing machine only for its intended use as described in this manual. Use only attachments recommended by the manufacturer as contained in this manual.”

3.“Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.”

4.“Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing machine and foot control free from the accumulation of lint, dust, and loose cloth.”

5.“Never drop or insert any object into any opening.”

6.“Do not use outdoors.”

7.“Do not operate where aerosol (spray) products are being used or where oxygen is being administered.”

8.“To disconnect, turn switch to the off (“0”) position, then remove plug from outlet.”

9.“Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.”

10.“Keep fingers away from all moving parts. Special care is required around the sewing machine needle.”

11.“Never sew with a damaged needle plate as this can cause needle to break.”

12.“Do not use bent needles.”

13.“Do not pull or push fabric while stitching. It may deflect the needle causing it to break.”

14.“Switch the sewing machine off (“0”) when making any adjustments in the needle area, such as threading needle, changing needle, threading bobbin, or changing presser foot, etc.”

15.“Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when making any other user servicing adjustments mentioned in the instruction manual.”

“CAUTION-Moving parts-To reduce risk of injury, switch off before servicing. Close cover before operating machine.”

“SAVE THESE INSTRUCTIONS”

“This product is for household use, or equivalent.”

1

Этот бытовой прибор соответствует требованиям подавления радиопомех, установленным директивой

Европейского Экономического Сообщества 89/336/EEC.

*Данное изделие сертифицировано Госстандартом России на соответствие требованиям нормативных документов ГОСТ 27570.0-87, ГОСТ 27570.22-89,

ГОСТ 23511-79, ГОСТ Р 50033-92.

**Предприятием-изготовителем установлены:

•срок гарантии - 1 год

•срок службы швейной машины - 7 лет со дня покупки.

Уважаемый покупатель!

Вы приобрели бытовую швейную машину старейшей японской фирмы «Ягуар Ко., ЛТД.».

Надеемся, что работа на этой машине доставит Вам радость и удовольствие.

Напоминаем Вам, что при пользовании швейной машиной необходимо соблюдать следующие меры предосторожности:

• при проведении ремонта, снятии крышек, замене лампы накаливания (макс. мошность-15 Вт), смене иголки, челнока, игольчатой пластины, лапок следует отключить питание отсоединением штепсельной вилки из сетевой розетки.

• пластиковые упаковочные пакеты могут быть опасны, во избежание опасности задохнуться

|

убирайте эти пакеты от младенцев и детей. |

|

Перечисленные меры предосторожности |

|

представлены в инструкции по эксплуатации, |

|

а также могут быть указаны на педали- |

|

регуляторе и её упаковочном пакете на |

2 |

иностранном языке. |

|

TABLE OF CONTENTS |

|

Machine identification ------------------------------------------------------ |

4 |

Accessories ------------------------------------------------------------------- |

5 |

Setting up your machine --------------------------------------------------- |

6 |

Foot control, Power/light switch, Spool pin, |

|

Presser foot lever |

|

Winding bobbin -------------------------------------------------------------- |

7 |

Removing bobbin case from shuttle ------------------------------------ |

8 |

Inserting bobbin into bobbin case --------------------------------------- |

9 |

Inserting bobbin case into shuttle --------------------------------------- |

9 |

Needle, thread and fabric chart ----------------------------------------- |

10 |

Threading top thread ------------------------------------------------------ |

11 |

Picking up bobbin thread ------------------------------------------------- |

12 |

Adjusting top thread tension --------------------------------------------- |

13 |

Adjusting bobbin thread tension ---------------------------------------- |

14 |

Changing presser feet ---------------------------------------------------- |

15 |

Stitch selector and indicator --------------------------------------------- |

15 |

Stitch length/super (stretch) stitch control --------------------------- |

16 |

Reverse stitch lever -------------------------------------------------------- |

16 |

Converting to free-arm sewing ------------------------------------------ |

16 |

Machine setting chart ----------------------------------------------- |

17 - 18 |

Straight stitch ---------------------------------------------------------- |

19 - 21 |

Starting to sew, Removing fabric, Turning a square corner, |

|

Inserting zips and piping |

|

Zigzag stitch ----------------------------------------------------------------- |

22 |

Overcasting, Satin stitch |

|

Blind stitch -------------------------------------------------------------------- |

23 |

Three-step zigzag ---------------------------------------------------------- |

24 |

Double-action stitch -------------------------------------------------------- |

24 |

Lingerie stitch --------------------------------------------------------------- |

25 |

Faggoting --------------------------------------------------------------------- |

25 |

Stretch stitch ----------------------------------------------------------- |

26 - 27 |

Triple straight stitch, Ric-rac stitch, Overlock stitch, |

|

Smocking stitch |

|

Decorative embroidery designs ---------------------------------------- |

28 |

Tips on design stitching |

|

Buttonhole making --------------------------------------------------- |

29 - 30 |

Adjusting stitch length, Procedure, Corded buttonhole |

|

Caring for your machine -------------------------------------------------- |

31 |

Cleaning the feed dogs and shuttle area, |

|

Changing light bulb |

|

Check chart for performance problems ------------------------------- |

32 |

3

1

2

3

4

5

6

21

22

23

24

25

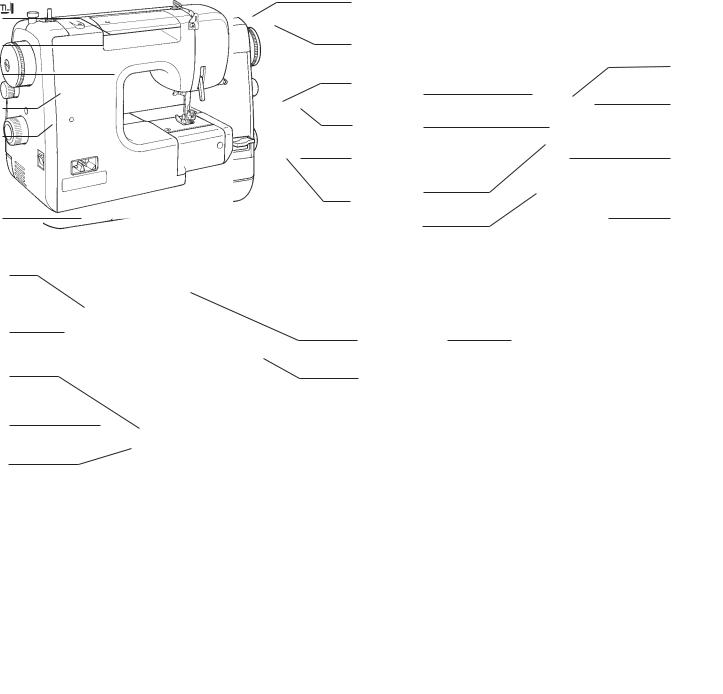

MACHINE IDENTIFICATION

1. |

Bobbin winder tension disc |

15. |

Needle |

2. |

Thread take-up |

16. |

Feed dogs |

3. |

Thread tension control |

17. |

Needle clamp screw |

4. |

Face cover |

18. |

Foot release lever |

5. |

Thread cutter |

19. |

Presser foot |

6. |

Extension table |

20. |

Needle plate |

7. |

Bobbin winder shaft |

21. |

Hand wheel |

8. |

Bobbin winder stop |

22. |

Clutch knob |

9. |

Stitch indicator |

23. |

Foot control socket |

10. |

Stitch length control |

24. |

Power/light switch |

11. |

Stitch selector |

25. |

Identification plate |

12. |

Reverse stitch lever |

26. |

Carrying handle |

13. |

Thread guide |

27. |

Presser foot lever |

14. |

Presser foot screw |

28. |

Foot control |

7

8

9

10

11

12

26

27

13

14

15

16

28

17

18

19

20

4

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

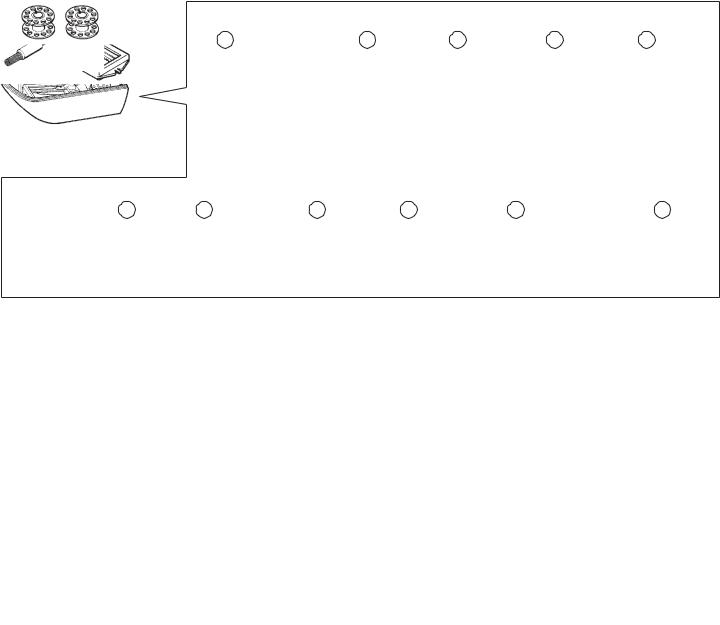

ACCESSORIES

In accessory box

1. |

Needles |

6. |

Screwdriver (large) |

11. Buttonhole foot |

2. |

Bobbins |

7. |

Screwdriver (small) |

|

3. |

Spool pin |

8. |

Brush |

|

4. |

Spool pin disc |

9. |

Blind stitch foot |

|

5. |

Buttonhole opener |

10. |

Zipper foot |

|

1 |

6 |

11 |

2 |

|

|

3 |

9 |

|

4 |

|

|

5 |

10 |

|

5

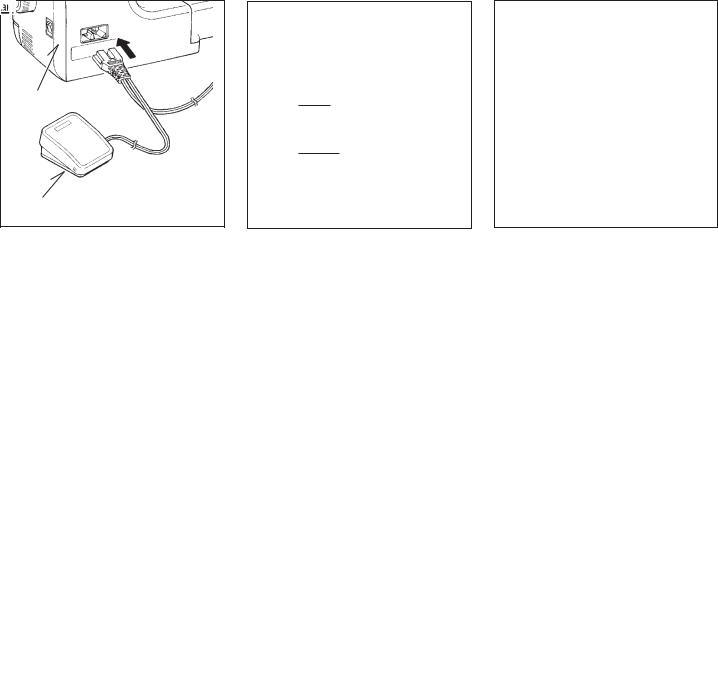

Power/light switch

B

A

Foot control

SETTING UP YOUR MACHINE

Be sure to wipe off any surplus oil from needle plate area before using your machine the first time.

FOOT CONTROL

Push foot control plug into the connector socket on the back of the machine.

POWER/LIGHT SWITCH

Your machine will not operate until the power/light switch is turned on. The same switch controls both the power and the light. When servicing the machine, or changing needles or Iamps, etc., machine must be disconnected from the mains supply.

SPOOL PIN

Attach the spool pin (A) and place a felt disc (B) over it. Place a spool of thread on the spool pin.

PRESSER FOOT LEVER

There are three positions for your presser foot.

1.Lower the presser foot to sew.

2.Raise the lifter to the middle position to insert or remove fabric.

3.Lift it to its highest position to change the presser foot or to remove thick fabric.

: 1

: 1

-

-

2

3

6

1 |

2 |

3 |

4 |

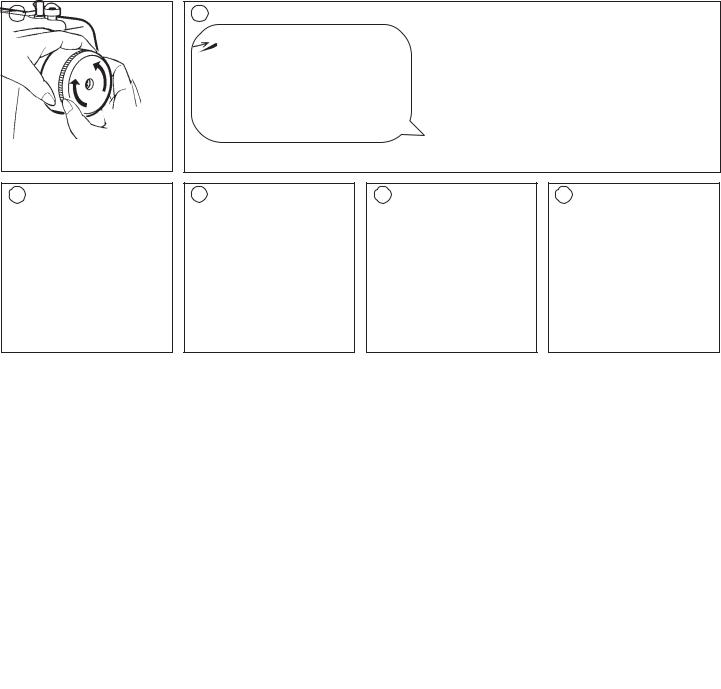

WINDING BOBBIN

1.Release clutch holding hand wheel and turning clutch knob towards you.

2.Pass thread from spool through thread guides as shown.

3.Pull end of thread through hole in bobbin as shown.

4.Push bobbin winder shaft to far left position, if it is not already there. Place bobbin onto shaft with end of thread coming from

5 |

6 |

top of bobbin. Push bobbin winder shaft to right until it clicks. Hold onto end of thread.

5.Start machine. The thread that is held will snap. Bobbin will cease turning when completely filled. Push shaft to left to remove bobbin.

6.Tighten clutch knob and remove bobbin.

7

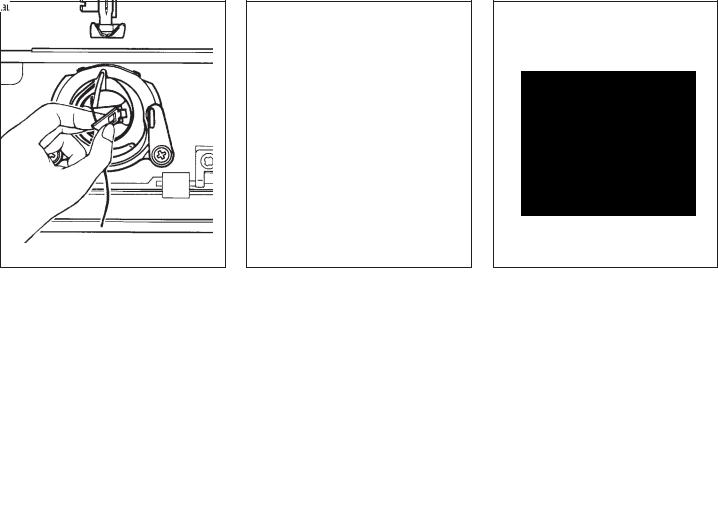

REMOVING BOBBIN CASE FROM SHUTTLE

1.Remove the extension table from the machine.

Raise the needle to its highest position by turning hand wheel manually towards you.

2.Open the bobbin access cover by pulling it down.

With your fingers, pull open the bobbin case latch as shown, and take out the bobbin case from the shuttle.

3.Release the latch, and bobbin will drop out of the case.

1 |

2 |

3 |

8

Locating pin

Locating groove

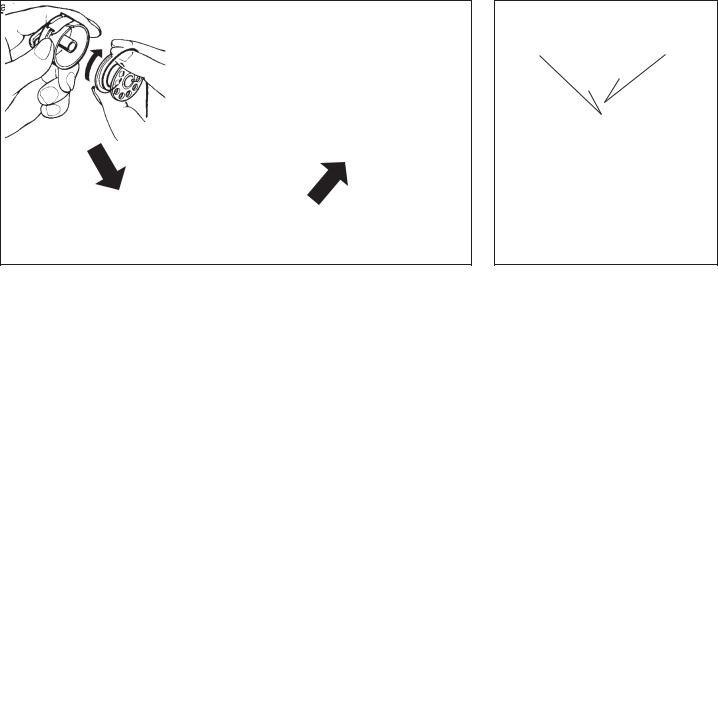

INSERTING BOBBIN INTO BOBBIN CASE

1.Hold the bobbin in your right hand with the thread running clockwise.

2.Insert the bobbin into the case with about 4” (10 cm) of thread showing outside the case.

3.Pull the thread through the slit in the case and then underneath the flat tension spring. It will click when it is in place.

1 |

3 |

2

INSERTING BOOBBIN CASE INTO SHUTTLE

1.Hold the latch open, with locating pin straight up.

2.Slide the bobbin case onto the center spindle of the shuttle, keeping the thread toward you.

NOTE: Be sure the locating pin fits into the locating groove at the top

of the shuttle.

3.Release the latch to lock the bobbin case in place.

1

2

9

NEEDLE, THREAD AND FABRIC CHART

Use the standard needles. The size of your |

on the upper part of the machine. |

||||

needle should match the size of the thread |

Never use a bent or dull needle. |

||||

and both should match the fabric. |

|

For successful sewing of stretch fabrics |

|||

For normal sewing, the same size and type |

use stretch stitch needles. |

||||

of thread should be used in the bobbin as |

|

|

|

||

|

|

|

|

|

|

|

Thread Size |

Needle Size |

Fabric |

|

|

|

Cotton 60 - 100 |

Stretch stitch |

All stretch fabrics. |

|

|

|

Synthetic |

needle |

|

|

|

|

Machine embroidery |

|

|

|

|

|

Cotton |

70 |

|

Sheer cottons, silk |

|

|

Synthetic |

|

synthetics, fine laces, |

|

|

|

or |

|

|

||

|

Silk A |

|

batiste, dimity. |

|

|

|

80 |

|

|

||

|

Machine embroidery |

|

|

|

|

|

|

|

|

|

|

|

Cotton 60 - 80 |

80 |

|

Medium weight cottons, |

|

|

Mercerized 50 - 60 |

|

medium weight synthetics, |

|

|

|

or |

|

|

||

|

Synthetic |

|

poplin, seersucker, |

|

|

|

90 |

|

|

||

|

|

|

gingham, velvet, light |

|

|

|

|

|

|

|

|

|

|

|

|

weight woolens, linen. |

|

|

|

|

|

|

|

|

Cotton 30 - 60 |

|

|

Heavy weight cottons, |

|

|

Mercerized heavy |

100 |

|

medium to heavy |

|

|

duty |

|

|

weight woollens, denim. |

|

60 - 1

70

-

-

5

1

3

”

Flat side

Needle

Needle

Pin

Flat side away from you.

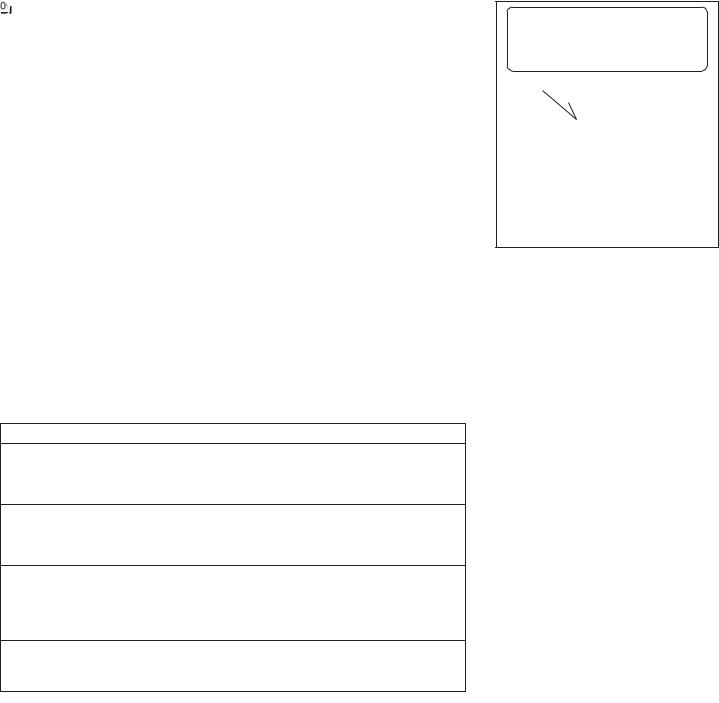

Changing the needle

1.Raise the needle bar to its highest position by turning the hand wheel toward you.

2.Loosen the needle clamp screw by turning it toward you.

3.Remove the needle by pulling it downward.

4.Insert the new needle into the needle clamp with the flat side away from you.

5.Push the needle up as far as it can go.

6.Tighten the needle clamp screw firmly with the screw driver.

1.

2.

3

4.

5.

10

Loading...

Loading...