Page 1

User’s Manual

HEIDENHAIN

Conversational

Programming

TNC 128

NC Software

771841-01

771844-01

English (en)

4/2013

Page 2

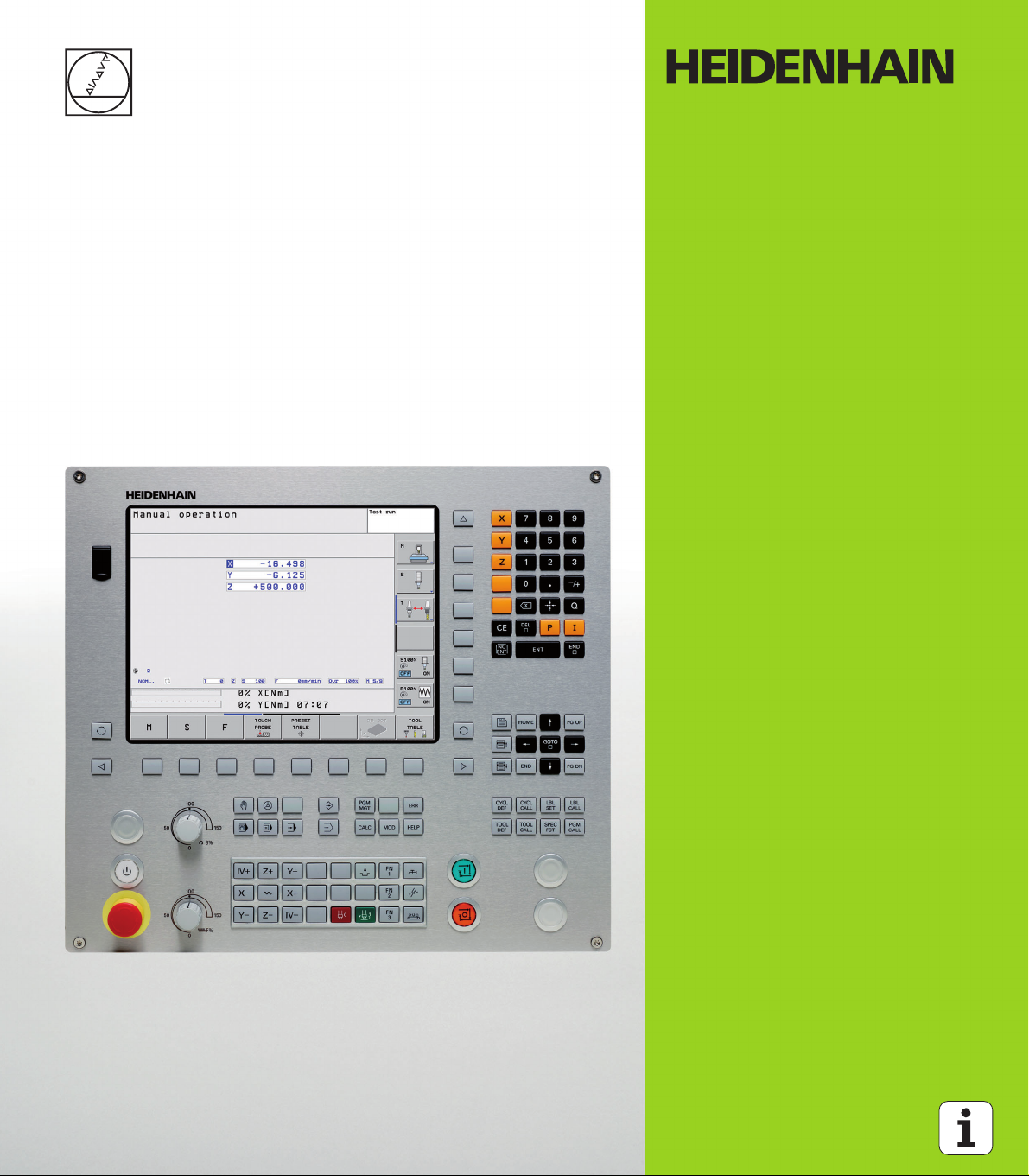

Controls of the TNC

1

50

0

50

100

F %

1

50

0

50

100

S %

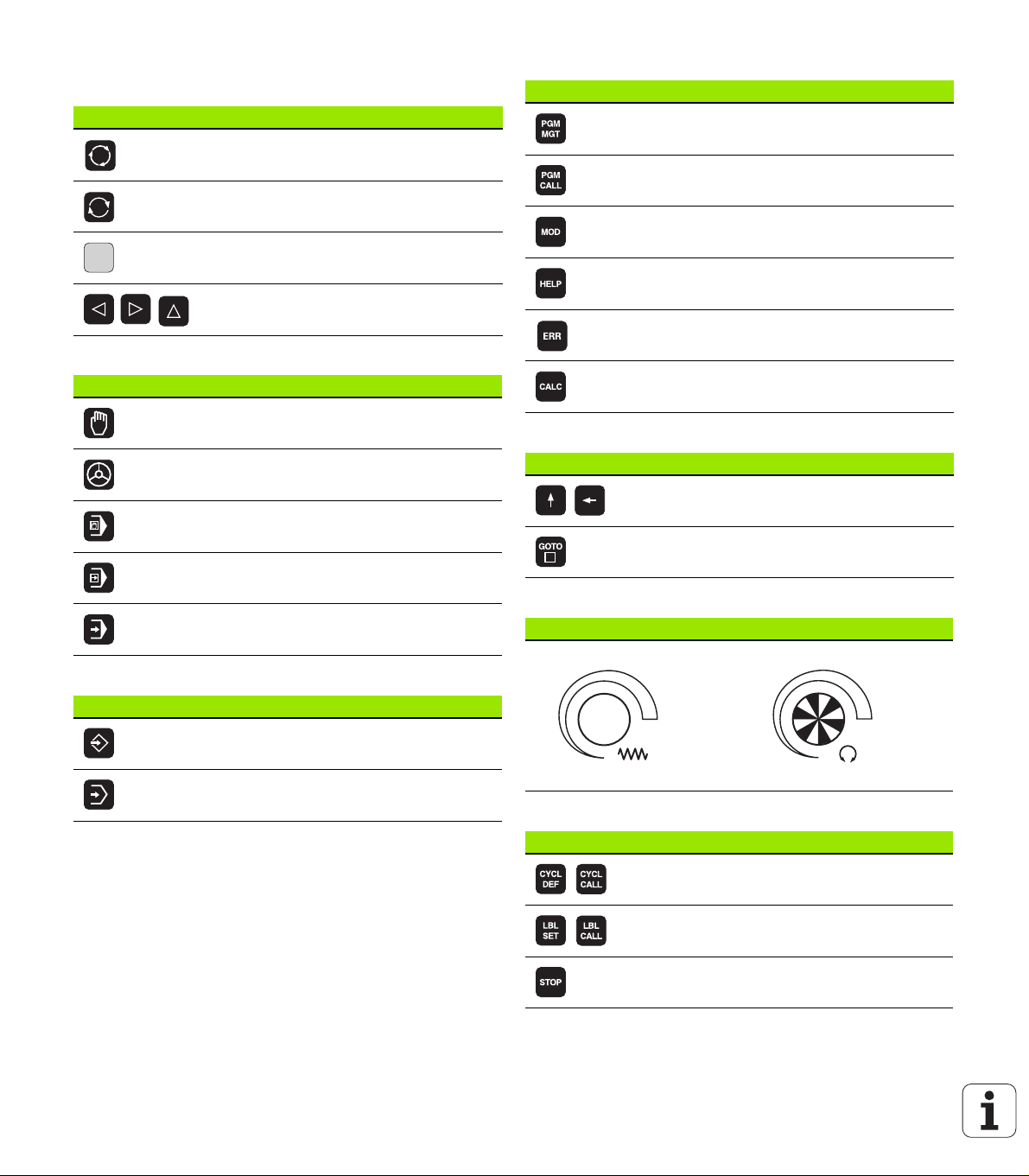

Keys on visual display unit

Key Function

Split screen layout

Toggle the display between machining

and programming modes

Soft keys for selecting functions on

screen

Shift between soft-key rows

Machine operating modes

Key Function

Manual Operation

Electronic Handwheel

Positioning with Manual Data Input

Program Run, Single Block

Program/file management, TNC functions

Key Function

Select or delete programs and files,

external data transfer

Define program call, select datum and

point tables

Select MOD functions

Display help text for NC error messages,

call TNCguide

Display all current error messages

Show calculator

Navigation keys

Key Function

Move highlight

Go directly to blocks, cycles and

parameter functions

Programming modes

Key Function

Program Run, Full Sequence

Programming and Editing

Test Run

Potentiometer for feed rate and spindle speed

Feed rate Spindle speed

Cycles, subprograms and program section repeats

Key Function

Define and call cycles

Enter and call labels for subprogramming

and program section repeats

Enter program stop in a program

Page 3

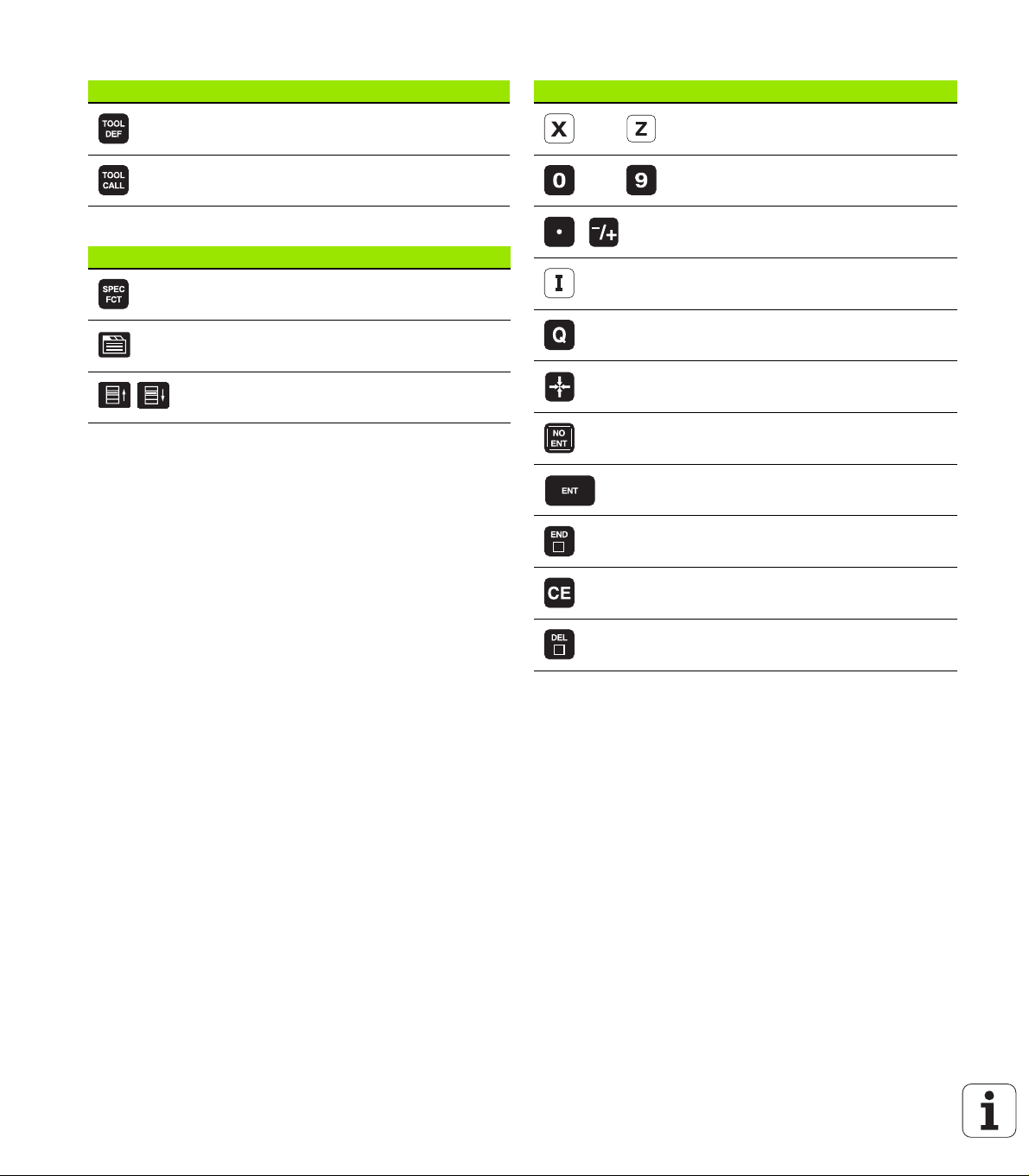

Tool functions

Key Function

Define tool data in the program

Coordinate axes and numbers: Entering and editing

Key Function

Select coordinate axes or

enter them into the program

Call tool data

Special functions

Key Function

Show special functions

Select the next tab in forms

Up/down one dialog box or button

Numbers

Decimal point / Reverse algebraic sign

Enter incremental dimensions

Q parameter programming /

Q parameter status

Save actual position or values from

calculator

Skip dialog questions, delete words

Confirm entry and resume dialog

Conclude block and exit entry

Clear numerical entry or TNC error

message

Abort dialog, delete program section

Page 4

Page 5

About this manual

The symbols used in this manual are described below.

This symbol indicates that important notes about the

function described must be regarded.

This symbol indicates that there is one or more of the

following risks when using the described function:

Danger to workpiece

Danger to fixtures

Danger to tool

Danger to machine

Danger to operator

This symbol indicates that the described function must be

adapted by the machine tool builder. The function

described may therefore vary depending on the machine.

This symbol indicates that you can find detailed

information about a function in another manual.

About this manual

Would you like any changes, or have you found any errors?

We are continuously striving to improve our documentation for you.

Please help us by sending your requests to the following e-mail

address: tnc-userdoc@heidenhain.de.

HEIDENHAIN TNC 128 5

Page 6

TNC model, software and features

This manual describes functions and features provided by TNCs as of

the following NC software numbers.

TNC model NC software number

TNC 128 771841-01

TNC 128 Programming Station 771844-01

The machine tool builder adapts the usable features of the TNC to his

machine by setting machine parameters. Some of the functions

described in this manual may therefore not be among the features

provided by the TNC on your machine tool.

TNC functions that may not be available on your machine include:

Probing functions for the 3-D touch probe

Please contact your machine tool builder to become familiar with the

features of your machine.

Many machine manufacturers, as well as HEIDENHAIN, offer

programming courses for the TNCs. We recommend these courses as

an effective way of improving your programming skill and sharing

information and ideas with other TNC users.

TNC model, software and features

6

Page 7

Software options

The TNC 128 features various software options that can be enabled by

your machine tool builder. Each option is to be enabled separately and

contains the following respective functions:

Touch probe function (option number 17)

Touch probe cycles

Datum setting

Workpiece measurement

HEIDENHAIN DNC (option number 18)

Communication with external PC applications over COM

component

Additional conversational language (option number 41)

Function for enabling the conversational languages Slovenian,

Slovak, Norwegian, Latvian, Estonian, Korean, Turkish, Romanian,

Lithuanian.

TNC model, software and features

HEIDENHAIN TNC 128 7

Page 8

Feature content level (upgrade functions)

Along with software options, significant further improvements of the

TNC software are managed via the Feature Content Level (FCL)

upgrade functions. Functions subject to the FCL are not available

simply by updating the software on your TNC.

All upgrade functions are available to you without

surcharge when you receive a new machine.

Upgrade functions are identified in the manual with FCL n, where n

indicates the sequential number of the feature content level.

You can purchase a code number in order to permanently enable the

FCL functions. For more information, contact your machine tool

builder or HEIDENHAIN.

Intended place of operation

The TNC complies with the limits for a Class A device in accordance with the specifications in EN 55022, and is intended for use primarily in industrially-zoned areas.

TNC model, software and features

Legal information

This product uses open source software. Further information is

available on the control under

Programming and Editing operating mode

MOD function

LICENSE INFO soft key

8

Page 9

Contents

First steps with the TNC 128

1

Introduction

2

Programming: Fundamentals,

file management

3

Programming: Programming aids

4

Programming: Tools

5

Programming: Tool movements

6

Programming: Subprograms and program

section repeats

7

Programming: Q parameters

8

Programming: Miscellaneous functions

9

Programming: Special functions

10

Manual operation and setup

11

Positioning with manual data input

12

Test run and program run

13

MOD functions

14

Fundamentals of cycles

15

Drilling, boring and thread cycles

16

Fixed cycles: Pocket milling / stud milling

/ slot milling

17

Cycles: Coordinate transformations

18

Cycles: Special functions

19

Touch probe cycles

20

Tables and overviews

21

HEIDENHAIN TNC 128 9

Page 10

Page 11

1 First steps with the TNC 128 ..... 35

1.1 Overview ..... 36

1.2 Machine switch-on ..... 37

Acknowledging the power interruption and moving to the reference points ..... 37

1.3 Programming the first part ..... 38

Selecting the correct operating mode ..... 38

The most important TNC keys ..... 38

Creating a new program/file management ..... 39

Defining a workpiece blank ..... 40

Program layout ..... 41

Programming a simple contour ..... 42

Creating a cycle program ..... 45

1.4 Graphically testing the first part ..... 48

Selecting the correct operating mode ..... 48

Selecting the tool table for the test run ..... 48

Choosing the program you want to test ..... 49

Selecting the screen layout and the view ..... 49

Starting the test run ..... 50

1.5 Tool setup ..... 51

Selecting the correct operating mode ..... 51

Preparing and measuring tools ..... 51

The tool table TOOL.T ..... 51

1.6 Workpiece setup ..... 52

Selecting the correct operating mode ..... 52

Clamp the workpiece ..... 52

Datum setting with a 3-D touch probe ..... 53

1.7 Running the first program ..... 54

Selecting the correct operating mode ..... 54

Choosing the program you want to run ..... 54

Starting the program ..... 54

HEIDENHAIN TNC 128 11

Page 12

2 Introduction ..... 55

2.1 The TNC 128 ..... 56

Programming: HEIDENHAIN conversational format ..... 56

Compatibility ..... 56

2.2 Visual display unit and keyboard ..... 57

Visual display unit ..... 57

Setting the screen layout ..... 58

Operating panel ..... 59

2.3 Operating modes ..... 60

Manual Operation and El. Handwheel ..... 60

Positioning with Manual Data Input ..... 60

Programming and Editing ..... 61

Test Run ..... 61

Program Run, Full Sequence and Program Run, Single Block ..... 62

2.4 Status displays ..... 63

"General" status display ..... 63

Additional status displays ..... 64

2.5 Window manager ..... 71

Task bar ..... 72

2.6 Accessories: HEIDENHAIN 3-D touch probes and electronic handwheels ..... 73

3-D touch probes ..... 73

HR electronic handwheels ..... 73

12

Page 13

3 Programming: Fundamentals, file management ..... 75

3.1 Fundamentals ..... 76

Position encoders and reference marks ..... 76

Reference system ..... 76

Reference system on milling machines ..... 77

Designation of the axes on milling machines ..... 77

Absolute and incremental workpiece positions ..... 78

Setting the datum ..... 79

3.2 Creating and writing programs ..... 80

Organization of an NC program in HEIDENHAIN conversational format ..... 80

Defining the workpiece blank: BLK FORM ..... 80

Creating a new part program ..... 81

Programming tool movements in conversational format ..... 83

Actual position capture ..... 85

Editing a program ..... 86

The TNC search function ..... 90

3.3 File management: Fundamentals ..... 92

Files ..... 92

Showing externally created files on the TNC ..... 94

Data backup ..... 94

3.4 Working with the file manager ..... 95

Directories ..... 95

Paths ..... 95

Overview: Functions of the file manager ..... 96

Calling the file manager ..... 97

Selecting drives, directories and files ..... 98

Creating a new directory ..... 100

Creating a new file ..... 100

Copying a single file ..... 101

Copying files into another directory ..... 102

Copying a table ..... 103

Copying a directory ..... 103

Choosing one of the last files selected ..... 104

Deleting a file ..... 104

Deleting a directory ..... 105

Tagging files ..... 106

Renaming a file ..... 107

File sorting ..... 107

Additional functions ..... 108

Additional tools for management of external file types ..... 109

Data transfer to or from an external data medium ..... 114

The TNC in a network ..... 116

USB devices on the TNC ..... 117

HEIDENHAIN TNC 128 13

Page 14

4 Programming: Programming aids ..... 119

4.1 Screen keyboard ..... 120

Entering text with the screen keyboard ..... 120

4.2 Adding comments ..... 121

Application ..... 121

Adding comments ..... 121

Functions for editing of the comment ..... 121

4.3 Structuring programs ..... 122

Definition and applications ..... 122

Displaying the program structure window / Changing the active window ..... 122

Inserting a structuring block in the (left) program window ..... 122

Selecting blocks in the program structure window ..... 122

4.4 Integrated calculator ..... 123

Operation ..... 123

4.5 Programming graphics ..... 125

Generating / not generating graphics during programming ..... 125

Generating a graphic for an existing program ..... 125

Block number display ON/OFF ..... 126

Erasing the graphic ..... 126

Showing grid lines ..... 126

Magnifying or reducing a detail ..... 126

4.6 Error messages ..... 127

Display of errors ..... 127

Opening the error window ..... 127

Closing the error window ..... 127

Detailed error messages ..... 128

INTERNAL INFO soft key ..... 128

Clearing errors ..... 129

Error log ..... 129

Keystroke log ..... 130

Informational texts ..... 131

Saving service files ..... 131

Calling the TNCguide help system ..... 131

4.7 Context-sensitive help system ..... 132

Application ..... 132

Working with the TNCguide ..... 133

Downloading current help files ..... 137

14

Page 15

5 Programming: Tools ..... 139

5.1 Entering tool-related data ..... 140

Feed rate F ..... 140

Spindle speed S ..... 141

5.2 Tool data ..... 142

Requirements for tool compensation ..... 142

Tool numbers and tool names ..... 142

Tool length L ..... 142

Tool radius R ..... 142

Delta values for lengths and radii ..... 143

Entering tool data into the program ..... 143

Entering tool data in the table ..... 144

Calling tool data ..... 151

Tool change ..... 152

5.3 Tool compensation ..... 155

Introduction ..... 155

Tool length compensation ..... 155

Tool radius compensation for paraxial positioning blocks ..... 156

HEIDENHAIN TNC 128 15

Page 16

6 Programming: Tool movements ..... 159

6.1 Fundamentals ..... 160

Tool movements in the program ..... 160

Radius compensation ..... 160

Miscellaneous functions M ..... 160

Subprograms and program section repeats ..... 161

Programming with Q parameters ..... 161

6.2 Programming tool movements ..... 162

Programming tool movements for workpiece machining ..... 162

16

Page 17

7 Programming: Subprograms and program section repeats ..... 165

7.1 Labeling subprograms and program section repeats ..... 166

Labels ..... 166

7.2 Subprograms ..... 167

Operating sequence ..... 167

Programming notes ..... 167

Programming a subprogram ..... 167

Calling a subprogram ..... 167

7.3 Program section repeats ..... 168

Label LBL ..... 168

Operating sequence ..... 168

Programming notes ..... 168

Programming a program section repeat ..... 168

Calling a program section repeat ..... 168

7.4 Separate program as subprogram ..... 169

Operating sequence ..... 169

Programming notes ..... 169

Calling any program as a subprogram ..... 170

7.5 Nesting ..... 171

Types of nesting ..... 171

Nesting depth ..... 171

Subprogram within a subprogram ..... 172

Repeating program section repeats ..... 173

Repeating a subprogram ..... 174

7.6 Programming examples ..... 175

HEIDENHAIN TNC 128 17

Page 18

8 Programming: Q parameters ..... 179

8.1 Principle and overview ..... 180

Programming notes ..... 181

Calling Q-parameter functions ..... 182

8.2 Part families—Q parameters in place of numerical values ..... 183

Application ..... 183

8.3 Describing contours through mathematical operations ..... 184

Application ..... 184

Overview ..... 184

Programming fundamental operations ..... 185

8.4 Trigonometric functions ..... 186

Definitions ..... 186

Programming trigonometric functions ..... 187

8.5 Circle calculations ..... 188

Application ..... 188

8.6 If-then decisions with Q parameters ..... 189

Application ..... 189

Unconditional jumps ..... 189

Programming if-then decisions ..... 190

Abbreviations used: ..... 190

8.7 Checking and changing Q parameters ..... 191

Procedure ..... 191

8.8 Additional functions ..... 192

Overview ..... 192

FN 14: ERROR: Display error messages ..... 193

FN 16: F-PRINT: Formatted output of text and Q-parameter values ..... 198

FN 18: SYS-DATUM READ ..... 202

FN 19: PLC: Transfer values to the PLC ..... 211

FN 20: WAIT FOR: NC and PLC synchronization ..... 211

FN 29: PLC: Transfer values to the PLC ..... 213

FN 37: EXPORT ..... 214

8.9 Accessing tables with SQL commands ..... 215

Introduction ..... 215

A transaction ..... 216

Programming SQL commands ..... 218

Overview of the soft keys ..... 218

SQL BIND ..... 219

SQL SELECT ..... 220

SQL FETCH ..... 223

SQL UPDATE ..... 224

SQL INSERT ..... 224

SQL COMMIT ..... 225

SQL ROLLBACK ..... 225

18

Page 19

8.10 Entering formulas directly ..... 226

Entering formulas ..... 226

Rules for formulas ..... 228

Programming example ..... 229

8.11 String parameters ..... 230

String processing functions ..... 230

Assigning string parameters ..... 231

Chain-linking string parameters ..... 232

Converting a numerical value to a string parameter ..... 233

Copying a substring from a string parameter ..... 234

Converting a string parameter to a numerical value ..... 235

Checking a string parameter ..... 236

Finding the length of a string parameter ..... 237

Comparing alphabetic priority ..... 238

Reading machine parameters ..... 239

8.12 Preassigned Q parameters ..... 242

Values from the PLC: Q100 to Q107 ..... 242

Active tool radius: Q108 ..... 242

Tool axis: Q109 ..... 243

Spindle status: Q110 ..... 243

Coolant on/off: Q111 ..... 243

Overlap factor: Q112 ..... 243

Unit of measurement for dimensions in the program: Q113 ..... 244

Tool length: Q114 ..... 244

Coordinates after probing during program run ..... 244

Deviation between actual value and nominal value during automatic tool measurement with the TT 130 ..... 245

HEIDENHAIN TNC 128 19

Page 20

9 Programming: Miscellaneous functions ..... 247

9.1 Entering miscellaneous functions M and STOP ..... 248

Fundamentals ..... 248

9.2 Miscellaneous functions for program run control, spindle and coolant ..... 249

Overview ..... 249

9.3 Miscellaneous functions for coordinate data ..... 250

Programming machine-referenced coordinates: M91/M92 ..... 250

Reducing display of a rotary axis to a value less than 360°: M94 ..... 252

9.4 Miscellaneous functions for contouring behavior ..... 253

Feed rate factor for plunging movements: M103 ..... 253

Feed rate in millimeters per spindle revolution: M136 ..... 254

Retraction from the contour in the tool-axis direction: M140 ..... 255

Suppressing touch probe monitoring: M141 ..... 256

20

Page 21

10 Programming: Special functions ..... 257

10.1 Overview of special functions ..... 258

Main menu for SPEC FCT special functions ..... 258

Program defaults menu ..... 259

Functions for contour and point machining menu ..... 259

Menu for defining various plain-language functions ..... 260

10.2 Freely definable tables ..... 261

Fundamentals ..... 261

Creating a freely definable table ..... 261

Editing the table format ..... 262

Switching between table and form view ..... 264

FN26: TABOPEN: Opening a freely definable table ..... 265

FN 27: TABWRITE: Writing to a freely definable table ..... 266

FN28: TABREAD: Reading a freely definable table ..... 267

10.3 File functions ..... 268

Application ..... 268

Defining file functions ..... 268

10.4 Defining coordinate transformations ..... 269

Overview ..... 269

TRANS DATUM AXIS ..... 269

TRANS DATUM TABLE ..... 270

TRANS DATUM RESET ..... 270

10.5 Creating text files ..... 271

Application ..... 271

Opening and exiting text files ..... 271

Editing texts ..... 272

Deleting and re-inserting characters, words and lines ..... 272

Editing text blocks ..... 273

Finding text sections ..... 274

HEIDENHAIN TNC 128 21

Page 22

11 Manual operation and setup ..... 275

11.1 Switch-on, switch-off ..... 276

Switch-on ..... 276

Switch-off ..... 277

11.2 Moving the machine axes ..... 278

Note ..... 278

Moving the axis using the machine axis direction buttons ..... 278

Incremental jog positioning ..... 279

Traversing with the HR 410 electronic handwheel ..... 280

11.3 Spindle speed S, feed rate F and miscellaneous functions M ..... 281

Function ..... 281

Entering values ..... 281

Changing the spindle speed and feed rate ..... 282

Activating feed-rate limitation ..... 283

11.4 Datum setting without a 3-D touch probe ..... 284

Note ..... 284

Preparation ..... 284

Workpiece presetting with axis keys ..... 285

Datum management with the preset table ..... 286

11.5 Using the 3-D touch probe ..... 291

Overview ..... 291

Functions in touch probe cycles ..... 292

Selecting touch probe cycles ..... 293

Recording measured values from the touch-probe cycles ..... 294

Writing the measured values from touch probe cycles to datum tables ..... 295

Writing the measured values from touch probe cycles to the preset table ..... 296

11.6 Calibrating a 3-D touch probe ..... 297

Introduction ..... 297

Calibrating the effective length ..... 298

Calibrating the effective radius and compensating center offset ..... 299

Displaying calibration values ..... 302

11.7 Datum setting with a 3-D touch probe ..... 303

Overview ..... 303

Datum setting in any axis ..... 303

Circle center as datum ..... 304

Center line as datum ..... 307

Measuring workpieces with a 3-D touch probe ..... 308

Using touch probe functions with mechanical probes or dial gauges ..... 310

22

Page 23

12 Positioning with manual data input ..... 311

12.1 Programming and executing simple machining operations ..... 312

Positioning with manual data input (MDI) ..... 312

Protecting and erasing programs in $MDI ..... 314

HEIDENHAIN TNC 128 23

Page 24

13 Test run and program run ..... 315

13.1 Graphics ..... 316

Application ..... 316

Setting the speed of the test run ..... 317

Overview of display modes ..... 318

Plan view ..... 318

Projection in 3 planes ..... 319

3-D view ..... 320

Magnifying details ..... 322

Repeating graphic simulation ..... 323

Displaying the tool ..... 323

Measuring the machining time ..... 324

13.2 Showing the workpiece blank in the working space ..... 325

Application ..... 325

13.3 Functions for program display ..... 326

Overview ..... 326

13.4 Test Run ..... 327

Application ..... 327

13.5 Program run ..... 330

Application ..... 330

Running a part program ..... 331

Interrupting machining ..... 332

Moving the machine axes during an interruption ..... 333

Resuming program run after an interruption ..... 334

Mid-program startup (block scan) ..... 335

Returning to the contour ..... 337

13.6 Optional block skip ..... 338

Application ..... 338

Inserting the "/" character ..... 338

Erasing the "/" character ..... 338

13.7 Optional program-run interruption ..... 339

Application ..... 339

24

Page 25

14 MOD functions ..... 341

14.1 Selecting MOD functions ..... 342

Selecting the MOD functions ..... 342

Changing the settings ..... 342

Exiting the MOD functions ..... 342

Overview of MOD functions ..... 343

14.2 Software numbers ..... 344

Application ..... 344

14.3 Entering code numbers ..... 345

Application ..... 345

14.4 Setting the data interfaces ..... 346

Serial interfaces on the TNC 128 ..... 346

Application ..... 346

Setting the RS-232 interface ..... 346

Setting the baud rate (baudRate) ..... 346

Setting the protocol (protocol) ..... 346

Setting the data bits (dataBits) ..... 347

Parity check (parity) ..... 347

Setting the stop bits (stopBits) ..... 347

Setting the handshake (flowControl) ..... 347

Settings for data transfer with the TNCserver PC software ..... 348

Setting the operating mode of the external device (fileSystem) ..... 348

Software for data transfer ..... 349

14.5 Ethernet interface ..... 351

Introduction ..... 351

Connection possibilities ..... 351

Connecting the control to the network ..... 352

14.6 Position display types ..... 357

Application ..... 357

14.7 Unit of measurement ..... 358

Application ..... 358

14.8 Displaying operating times ..... 359

Application ..... 359

HEIDENHAIN TNC 128 25

Page 26

15 Fundamentals of cycles ..... 361

15.1 Introduction ..... 362

15.2 Available cycle groups ..... 363

Overview of fixed cycles ..... 363

15.3 Working with fixed cycles ..... 364

Machine-specific cycles ..... 364

Defining a cycle using soft keys ..... 365

Defining a cycle using the GOTO function ..... 365

Calling cycles ..... 366

15.4 PATTERN DEF pattern definition ..... 368

Application ..... 368

Entering PATTERN DEF ..... 369

Using PATTERN DEF ..... 369

Defining individual machining positions ..... 370

Defining a single row ..... 371

Defining a single pattern ..... 372

Defining individual frames ..... 373

Defining a full circle ..... 374

Defining a pitch circle ..... 375

15.5 POLAR PATTERN (Cycle 220) ..... 376

Cycle run ..... 376

Please note while programming: ..... 376

Cycle parameters ..... 377

15.6 CARTESIAN PATTERN (Cycle 221) ..... 379

Cycle run ..... 379

Please note while programming: ..... 379

Cycle parameters ..... 380

15.7 Point tables ..... 381

Application ..... 381

Creating a point table ..... 381

Hiding single points from the machining process ..... 382

Selecting a point table in the program ..... 382

Calling a cycle in connection with point tables ..... 383

26

Page 27

16 Drilling, boring and thread cycles ..... 385

16.1 Fundamentals ..... 386

Overview ..... 386

16.2 CENTERING (Cycle 240) ..... 387

Cycle run ..... 387

Please note while programming: ..... 387

Cycle parameters ..... 388

16.3 DRILLING (Cycle 200) ..... 389

Cycle run ..... 389

Please note while programming: ..... 389

Cycle parameters ..... 390

16.4 REAMING (Cycle 201) ..... 391

Cycle run ..... 391

Please note while programming: ..... 391

Cycle parameters ..... 392

16.5 BORING (Cycle 202) ..... 393

Cycle run ..... 393

Please note while programming: ..... 394

Cycle parameters ..... 395

16.6 UNIVERSAL DRILLING (Cycle 203) ..... 397

Cycle run ..... 397

Please note while programming: ..... 398

Cycle parameters ..... 399

16.7 BACK BORING (Cycle 204) ..... 401

Cycle run ..... 401

Please note while programming: ..... 402

Cycle parameters ..... 403

16.8 UNIVERSAL PECKING (Cycle 205) ..... 405

Cycle run ..... 405

Please note while programming: ..... 406

Cycle parameters ..... 407

16.9 SINGLE-LIP DEEP-HOLE DRILLING (Cycle 241) ..... 409

Cycle run ..... 409

Please note while programming: ..... 409

Cycle parameters ..... 410

HEIDENHAIN TNC 128 27

Page 28

16.10 Programming examples ..... 412

16.11 TAPPING NEW with floating tap holder (Cycle 206) ..... 416

Cycle run ..... 416

Please note while programming: ..... 416

Cycle parameters ..... 417

16.12 RIGID TAPPING without a floating tap holder NEW (Cycle 207) ..... 418

Cycle run ..... 418

Please note while programming: ..... 419

Cycle parameters ..... 420

16.13 Programming example ..... 421

28

Page 29

17 Fixed cycles: Pocket milling / stud milling / slot milling ..... 425

17.1 Fundamentals ..... 426

Overview ..... 426

17.2 RECTANGULAR POCKET (Cycle 251) ..... 427

Cycle run ..... 427

Please note while programming: ..... 428

Cycle parameters ..... 429

17.3 RECTANGULAR STUD (Cycle 256) ..... 432

Cycle run ..... 432

Please note while programming: ..... 433

Cycle parameters ..... 434

17.4 Programming examples ..... 437

HEIDENHAIN TNC 128 29

Page 30

18 Cycles: Coordinate transformations ..... 441

18.1 Fundamentals ..... 442

Overview ..... 442

Effect of coordinate transformations ..... 442

18.2 DATUM SHIFT (Cycle 7, DIN/ISO: G54) ..... 443

Effect ..... 443

Cycle parameters ..... 443

18.3 DATUM SHIFT with datum tables (Cycle 7) ..... 444

Effect ..... 444

Please note while programming: ..... 445

Cycle parameters ..... 446

Selecting a datum table in the part program ..... 446

Editing the datum table in the Programming and Editing mode of operation ..... 447

Configuring the datum table ..... 448

Exiting a datum table ..... 448

Status displays ..... 448

18.4 DATUM SETTING (Cycle 247) ..... 449

Effect ..... 449

Please note before programming: ..... 449

Cycle parameters ..... 449

Status displays ..... 449

18.5 MIRROR IMAGE (Cycle 8) ..... 450

Effect ..... 450

Please note while programming: ..... 450

Cycle parameters ..... 451

18.6 SCALING FACTOR (Cycle 11) ..... 452

Effect ..... 452

Cycle parameters ..... 452

18.7 AXIS-SPECIFIC SCALING (Cycle 26) ..... 453

Effect ..... 453

Please note while programming: ..... 453

Cycle parameters ..... 454

18.8 Programming examples ..... 455

30

Page 31

19 Cycles: Special functions ..... 457

19.1 Fundamentals ..... 458

Overview ..... 458

19.2 DWELL TIME (Cycle 9) ..... 459

Function ..... 459

Cycle parameters ..... 459

19.3 PROGRAM CALL (Cycle 12) ..... 460

Cycle function ..... 460

Please note while programming: ..... 460

Cycle parameters ..... 461

19.4 ORIENTED SPINDLE STOP (Cycle 13) ..... 462

Cycle function ..... 462

Please note while programming: ..... 462

Cycle parameters ..... 462

HEIDENHAIN TNC 128 31

Page 32

20 Touch probe cycles ..... 463

20.1 General information about touch probe cycles ..... 464

Method of function ..... 464

Touch probe cycles in the Manual Operation and El. Handwheel modes ..... 464

20.2 Before you start working with touch probe cycles ..... 465

Maximum traverse to touch point: DIST in touch probe table ..... 465

Set-up clearance to touch point: SET_UP in touch probe table ..... 465

Orient the infrared touch probe to the programmed probe direction: TRACK in touch probe table ..... 465

Touch trigger probe, probing feed rate: F in touch probe table ..... 466

Touch trigger probe, rapid traverse for positioning: FMAX ..... 466

Touch trigger probe, rapid traverse for positioning: F_PREPOS in touch probe table ..... 466

Executing touch probe cycles ..... 466

20.3 Touch probe table ..... 467

General information ..... 467

Editing touch probe tables ..... 467

Touch probe data ..... 468

20.4 Fundamentals of tool measurement ..... 469

Overview ..... 469

Setting the machine parameters ..... 471

Entries in the tool table TOOL.T ..... 472

20.5 Calibrating the TT (Cycle 480) ..... 474

Cycle run ..... 474

Please note while programming: ..... 474

Cycle parameters ..... 474

20.6 Calibrating the wireless TT 449 (Cycle 484) ..... 475

Fundamentals ..... 475

Cycle run ..... 475

Please note while programming: ..... 475

Cycle parameters ..... 475

20.7 Measuring the tool length (Cycle 481) ..... 476

Cycle run ..... 476

Please note while programming: ..... 476

Cycle parameters ..... 477

20.8 Measuring the tool radius (Cycle 482) ..... 478

Cycle run ..... 478

Please note while programming: ..... 478

Cycle parameters ..... 479

20.9 Measuring the tool length and radius (Cycle 483) ..... 480

Cycle run ..... 480

Please note while programming: ..... 480

Cycle parameters ..... 481

32

Page 33

21 Tables and overviews ..... 483

21.1 Machine-specific user parameters ..... 484

Application ..... 484

21.2 Pin layouts and connecting cables for the data interfaces ..... 492

RS-232-C/V.24 interface for HEIDENHAIN devices ..... 492

Non-HEIDENHAIN devices ..... 493

Ethernet interface RJ45 socket ..... 493

21.3 Technical information ..... 494

HEIDENHAIN TNC 128 33

Page 34

34

Page 35

First steps with the

TNC 128

Page 36

1.1 Overview

This chapter is intended to help TNC beginners quickly learn to handle

the most important procedures. For more information on a respective

topic, see the section referred to in the text.

The following topics are included in this chapter:

Machine switch-on

1.1 Overview

Programming the first part

Graphically testing the first part

Tool setup

Workpiece setup

Running the first program

36 First steps with the TNC 128

Page 37

1.2 Machine switch-on

Acknowledging the power interruption and moving to the reference points

Switch-on and crossing the reference points can vary

depending on the machine tool. Your machine manual

provides more detailed information.

Switch on the power supply for control and machine. The TNC

starts the operating system. This process may take several

minutes. Then the TNC will display the message "Power

interrupted" in the screen header

Press the CE key: The TNC compiles the PLC

program

Switch on the control voltage: The TNC checks

operation of the emergency stop circuit and goes into

the reference run mode

Cross the reference points manually in the displayed

sequence: For each axis press the machine START

button. If you have absolute linear and angle encoders

on your machine there is no need for a reference run

The TNC is now ready for operation in the Manual Operation mode.

Further information on this topic

Traversing the reference marks: See "Switch-on" on page 276

Operating modes: See "Programming and Editing" on page 61

1.2 Machine switch-on

HEIDENHAIN TNC 128 37

Page 38

1.3 Programming the first part

Selecting the correct operating mode

You can write programs only in the Programming and Editing mode:

Press the operating modes key: The TNC goes into

the Programming and Editing mode

Further information on this topic

Operating modes: See "Programming and Editing" on page 61

The most important TNC keys

Functions for conversational guidance Key

Confirm entry and activate the next dialog

prompt

Ignore the dialog question

1.3 Programming the first part

End the dialog immediately

Abort dialog, discard entries

Soft keys on the screen with which you select

functions appropriate to the active state

Further information on this topic

Writing and editing programs: See "Editing a program" on page 86

Overview of keys: See "Controls of the TNC" on page 2

38 First steps with the TNC 128

Page 39

Creating a new program/file management

Press the PGM MGT key: The TNC opens the file

manager. The file management of the TNC is

arranged much like the file management on a PC with

the Windows Explorer. The file management enables

you to manipulate data on the TNC hard disk

Use the arrow keys to select the folder in which you

want to open the new file

Enter a file name with the extension .H: The TNC then

automatically opens a program and asks for the unit

of measure for the new program

To select the unit of measure, press the MM or INCH

soft key: The TNC automatically starts the workpiece

blank definition (see "Defining a workpiece blank" on

page 40)

The TNC automatically generates the first and last blocks of the

program. Afterwards you can no longer change these blocks.

Further information on this topic

File management: See "Working with the file manager" on page 95

Creating a new program: See "Creating and writing programs" on

page 80

1.3 Programming the first part

HEIDENHAIN TNC 128 39

Page 40

Defining a workpiece blank

Y

X

Z

MAX

MIN

-40

100

100

0

0

Immediately after you have created a new program, the TNC starts the

dialog for entering the workpiece blank definition. Always define the

workpiece blank as a cuboid by entering the MIN and MAX points,

each with reference to the selected reference point.

After you have created a new program, the TNC automatically initiates

the workpiece blank definition and asks for the required data:

Working plane in graphic: XY?: Enter the active spindle axis. Z is

saved as default setting. Accept with the ENT key

Workpiece blank def.: minimum X: Enter the smallest X coordinate

of the workpiece blank with respect to the reference point, e.g. 0.

Confirm with the ENT key

Workpiece blank def.: minimum Y: Smallest Y coordinate of the

workpiece blank with respect to the reference point, e.g. 0. Confirm

with the ENT key

Workpiece blank def.: minimum Z: Smallest Z coordinate of the

workpiece blank with respect to the reference point, e.g. –40.

Confirm with the ENT key

Workpiece blank def.: maximum X: Largest X coordinate of the

1.3 Programming the first part

workpiece blank with respect to the reference point, e.g. 100.

Confirm with the ENT key

Workpiece blank def.: maximum Y: Largest Y coordinate of the

workpiece blank with respect to the reference point, e.g. 100.

Confirm with the ENT key

Workpiece blank def.: maximum Z: Largest Z coordinate of the

workpiece blank with respect to the reference point, e.g. 0. Confirm

with the ENT key. The TNC concludes the dialog

Example NC blocks

0 BEGIN PGM NEW MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 END PGM NEW MM

Further information on this topic

Defining the workpiece blank: (see page 81)

40 First steps with the TNC 128

Page 41

Program layout

NC programs should be arranged consistently in a similar manner. This

makes it easier to find your place, accelerates programming and

reduces errors.

Recommended program layout for simple, conventional contour

machining

1 Call tool, define tool axis

2 Retract the tool

3 Pre-position the first axis in the working plane in front of the

contour starting point

4 Pre-position the second axis in the working plane next to the

contour starting point

5 In the tool axis, position the tool above the workpiece, or

preposition immediately to workpiece depth. If required, switch on

the spindle/coolant

6 Approach the contour

7 Machine the contour

8 Depart the contour

9 Retract the tool, end the program

Further information on this topic:

Contour programming: See "Fundamentals" on page 160

Recommended program layout for simple cycle programs

1 Call the tool, define the tool axis

2 Retract the tool

3 Define the machining positions

4 Define the fixed cycle

5 Call the cycle, switch on the spindle/coolant

6 Retract the tool, end the program

Further information on this topic:

Cycle programming: See "Working with fixed cycles" on page 364.

Example: Layout of contour machining programs

0 BEGIN PGM BSPCONT MM

1 BLK FORM 0.1 Z X... Y... Z...

2 BLK FORM 0.2 X... Y... Z...

3 TOOL CALL 5 Z S5000

4 Z+250 R0 FMAX

5 X... R0 FMAX

6 Y... R0 FMAX

7 Z+10 R0 F3000 M13

...

16 X... R0 FMAX

17 Z+250 R0 FMAX M2

18 END PGM BSPCONT MM

Example: Cycle program layout

0 BEGIN PGM BSBCYC MM

1 BLK FORM 0.1 Z X... Y... Z...

2 BLK FORM 0.2 X... Y... Z...

3 TOOL CALL 5 Z S5000

4 Z+250 R0 FMAX

5 PATTERN DEF POS1( X... Y... Z... ) ...

6 CYCL DEF...

7 CYCL CALL PAT FMAX M13

8 Z+250 R0 FMAX M2

9 END PGM BSBCYC MM

1.3 Programming the first part

HEIDENHAIN TNC 128 41

Page 42

Programming a simple contour

X

Y

95

5

95

5

1

4

2

3

The contour shown to the right is to be milled once to a depth of 5 mm.

You have already defined the workpiece blank. After you have initiated

a dialog through a function key, enter all the data requested by the

TNC in the screen header.

Call the tool: Enter the tool data. Confirm each of your

entries with the ENT key. Do not forget the tool axis

Retract the tool: Press the orange Z axis key in order

to retract in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

Confirm Radius comp.: R+/R–/no comp? by pressing

the ENT key: Do not activate the radius compensation

Confirm Feed rate F=? with the ENT key: Move at

rapid traverse (FMAX)

Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

1.3 Programming the first part

block

Preposition the tool in the working plane: Press the

orange X axis key and enter the value for the position

to be approached, e.g. –20

Confirm Radius comp.: R+/R–/no comp? by pressing

the ENT key: Do not activate the radius compensation

Confirm Feed rate F=? with the ENT key: Move at

rapid traverse (FMAX)

Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

block

Press the orange Y axis key and enter the value for the

position to be approached, e.g. –20. Confirm with the

ENT key

Confirm Radius comp.: R+/R–/no comp? by pressing

the ENT key: Do not activate the radius compensation

Confirm Feed rate F=? with the ENT key: Move at

rapid traverse (FMAX)

Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

block

42 First steps with the TNC 128

Page 43

Move the tool to workpiece depth: Press the orange Z

axis key and enter the value for the position to be

approached, e.g. –5. Confirm with the ENT key

Confirm Radius comp.: R+/R–/no comp? by pressing

the ENT key: Do not activate the radius compensation

Feed rate F=? Enter the positioning feed rate, e.g.

3000 mm/min and confirm with the ENT key

Miscellaneous function M? Switch on the spindle and

coolant, e.g. M13. Confirm with the END key: The TNC

saves the entered positioning block

Approach contour point 1: Press the orange X axis key

and enter the value 5 for the position to be

approached

Tool radius comp: R+/R–/no comp? Select the R– soft

key: The traverse path is decreased by the tool radius

Feed rate F=? Enter the machining feed rate, e.g. 700

mm/min, and confirm your entry with the END key

Approach contour point 2: Press the orange Y axis key

and enter the value 95 for the position to be

approached

Tool radius comp: R+/R–/no comp? Select the R+ soft

key: The traverse path is increased by the tool radius.

Confirm your entry with the END soft key

Approach contour point 3: Press the orange X axis key

and enter the value 95 for the position to be

approached

Tool radius comp: R+/R-/no comp? Select the R+ soft

key: The traverse path is increased by the tool radius.

Confirm your entry with the END soft key

Approach contour point 4: Press the orange Y axis key

and enter the value 5 for the position to be

approached

Tool radius comp: R+/R-/no comp? Select the R+ soft

key: The traverse path is increased by the tool radius.

Confirm your entry with the END soft key

1.3 Programming the first part

HEIDENHAIN TNC 128 43

Page 44

Approach contour point 1 and retract the tool: Press

the orange X axis key and enter the value 0 for the

position to be approached

Tool radius comp: R+/R-/no comp? Select the R+ soft

key: The traverse path is increased by the tool radius.

Confirm your entry with the END soft key

Retract the tool: Press the orange Z axis key in order

to retract in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

Confirm Radius comp.: R+/R–/no comp? by pressing

the ENT key: Do not activate the radius compensation

Confirm Feed rate F=? with the ENT key: Move at

rapid traverse (FMAX)

Miscellaneous function M? Enter M2 to end the

program and confirm with the END key: The TNC

saves the entered positioning block

Further information on this topic

Creating a new program: See "Creating and writing programs" on

1.3 Programming the first part

page 80

Programmable feed rates: See "Possible feed rate input" on page 84

Tool radius compensation: See "Tool radius compensation for

paraxial positioning blocks" on page 156

Miscellaneous functions (M): See "Miscellaneous functions for

program run control, spindle and coolant" on page 249

44 First steps with the TNC 128

Page 45

Creating a cycle program

X

Y

20

10

100

100

10

90

9080

The holes (depth of 20 mm) shown in the figure at right are to be drilled

with a standard drilling cycle. You have already defined the workpiece

blank.

Call the tool: Enter the tool data. Confirm each of your

entries with the ENT key. Do not forget the tool axis

Retract the tool: Press the orange Z axis key in order

to retract in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

Confirm Radius comp.: R+/R–/no comp? by pressing

the ENT key: Do not activate the radius compensation

Confirm Feed rate F=? with the ENT key: Move at

rapid traverse (FMAX)

Confirm the Miscellaneous function M? with the

END key: The TNC saves the entered positioning

block

Call the cycle menu

Display the drilling cycles

Select the standard drilling cycle 200: The TNC starts

the dialog for cycle definition. Enter all parameters

requested by the TNC step by step and conclude each

entry with the ENT key. In the screen to the right, the

TNC also displays a graphic showing the respective

cycle parameter

1.3 Programming the first part

HEIDENHAIN TNC 128 45

Page 46

Call the menu for special functions

Display the functions for point machining

Select the pattern definition

Select point entry: Enter the coordinates of the 4

points and confirm each with the ENT key. After

entering the fourth point, save the block with the END

key

Display the menu for defining the cycle call

Run the drilling cycle on the defined pattern:

Confirm Feed rate F=? with the ENT key: Move at

rapid traverse (FMAX)

Miscellaneous function M? Switch on the spindle and

coolant, e.g. M13. Confirm with the END key: The TNC

saves the entered positioning block

Retract the tool: Press the orange Z axis key in order

1.3 Programming the first part

to retract in the tool axis, and enter the value for the

position to be approached, e.g. 250. Confirm with the

ENT key

Confirm Radius comp.: RL/RR/no comp? by pressing

the ENT key: Do not activate the radius compensation

Confirm Feed rate F=? with the ENT key: Move at

rapid traverse (FMAX)

Miscellaneous function M? Enter M2 to end the

program and confirm with the END key: The TNC

saves the entered positioning block

46 First steps with the TNC 128

Page 47

Example NC blocks

0 BEGIN PGM C200 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 TOOL CALL 5 Z S4500

4 Z+250 R0 FMAX

5 PATTERN DEF

POS1 (X+10 Y+10 Z+0)

POS2 (X+10 Y+90 Z+0)

POS3 (X+90 Y+90 Z+0)

POS4 (X+90 Y+10 Z+0)

6 CYCL DEF 200 DRILLING

Q200=2 ;SET-UP CLEARANCE

Q201=–20 ;DEPTH

Q206=250 ;FEED RATE FOR PLNGNG

Q202=5 ;PLUNGING DEPTH

Q210=0 ;DWELL TIME AT TOP

Q203=–10 ;SURFACE COORDINATE

Q204=20 ;2ND SET-UP CLEARANCE

Q211=0.2 ;DWELL TIME AT DEPTH

7 CYCL CALL PAT FMAX M13

8 Z+250 R0 FMAX M2

9 END PGM C200 MM

Definition of workpiece blank

Tool call

Retract the tool

Define the machining positions

Define the cycle

1.3 Programming the first part

Spindle and coolant on, call the cycle

Retract the tool, end program

Further information on this topic

Creating a new program: See "Creating and writing programs" on

page 80

Cycle programming: See User’s Manual for Cycles

HEIDENHAIN TNC 128 47

Page 48

1.4 Graphically testing the first part

Selecting the correct operating mode

You can test programs only in the Test Run mode:

Press the Test Run operating mode key: the TNC

switches to that mode

Further information on this topic

Operating modes of the TNC: See "Operating modes" on page 60

Testing programs: See "Test Run" on page 327

Selecting the tool table for the test run

You only need to execute this step if you have not activated a tool

table in the Test Run mode.

Press the PGM MGT key: The TNC opens the file

manager

Press the SELECT TYPE soft key: The TNC shows a

soft-key menu for selection of the file type to be

displayed

1.4 Graphically testing the first part

Press the SHOW ALL soft key: The TNC shows all

saved files in the right window

Move the highlight to the left onto the directories

Move the highlight to the TNC:\table directory

Move the highlight to the right onto the files

Move the highlight to the file TOOL.T (active tool

table) and load with the ENT key: TOOL.T receives

the status S and is therefore active for the test run

Press the END key: Exit the file manager

Further information on this topic

Tool management: See "Entering tool data in the table" on page 144

Testing programs: See "Test Run" on page 327

48 First steps with the TNC 128

Page 49

Choosing the program you want to test

Press the PGM MGT key: The TNC opens the file

manager

Press the LAST FILES soft key: The TNC opens a

pop-up window with the most recently selected files

Use the arrow keys to select the program that you

want to test. Load with the ENT key

Further information on this topic

Selecting a program: See "Working with the file manager" on page

95

Selecting the screen layout and the view

Press the key for selecting the screen layout. The TNC

shows all available alternatives in the soft-key row

Press the PROGRAM + GRAPHICS soft key: In the

left half of the screen the TNC shows the program; in

the right half it shows the workpiece blank

Select the desired view via soft key

Plan view

Projection in three planes

1.4 Graphically testing the first part

3-D view

Further information on this topic

Graphic functions: See "Graphics" on page 316

Running a test run: See "Test Run" on page 327

HEIDENHAIN TNC 128 49

Page 50

Starting the test run

Press the RESET + START soft key: The TNC

simulates the active program up to a programmed

break or to the program end

While the simulation is running, you can use the soft

keys to change views

Press the STOP soft key: The TNC interrupts the test

run

Press the START soft key: The TNC resumes the test

run after a break

Further information on this topic

Running a test run: See "Test Run" on page 327

Graphic functions: See "Graphics" on page 316

Adjusting the test speed: See "Setting the speed of the test run" on

page 317

1.4 Graphically testing the first part

50 First steps with the TNC 128

Page 51

1.5 Tool setup

Selecting the correct operating mode

Tools are set up in the Manual Operation mode:

Press the Manual Operation operating mode key: the

TNC switches to that mode

Further information on this topic

Operating modes of the TNC: See "Operating modes" on page 60

Preparing and measuring tools

Clamp the required tools in their chucks

When measuring with an external tool presetter: Measure the tools,

note down the length and radius, or transfer them directly to the

machine through a transfer program

When measuring on the machine: Insert the tool

The tool table TOOL.T

In the tool table TOOL.T (permanently saved under TNC:\TABLE\), save

the tool data such as length and radius, but also further tool-specific

information that the TNC needs to perform its functions.

To enter tool data in the tool table TOOL.T, proceed as follows:

Display the tool table

1.5 Tool setup

Edit the tool table: Set the EDITING soft key to ON

With the upward or downward arrow keys you can

select the tool number that you want to edit

With the rightward or leftward arrow keys you can

select the tool data that you want to edit

To exit the tool table, press the END key

Further information on this topic

Operating modes of the TNC: See "Operating modes" on page 60

Working with the tool table: See "Entering tool data in the table" on

page 144

HEIDENHAIN TNC 128 51

Page 52

1.6 Workpiece setup

Selecting the correct operating mode

Workpieces are set up in the Manual Operation or El. Handwheel

mode

Press the Manual Operation operating mode key: the

TNC switches to that mode

Further information on this topic

Manual Operation mode: See "Moving the machine axes" on page

278

1.6 Workpiece setup

Clamp the workpiece

Mount the workpiece with a fixture on the machine table so that it is

fixed with its edges parallel to the machine axes.

52 First steps with the TNC 128

Page 53

Datum setting with a 3-D touch probe

Insert the 3-D touch probe: In the MDI mode, run a TOOL CALL block

containing the tool axis and then return to the Manual Operation

mode

Select the probing functions: The TNC displays the

available functions in the soft-key row

Select the function for setting the datum, e.g. Probe

Position

Position the touch probe near the first touch point on

the first workpiece edge

Select the probing direction via soft key, e.g. +X

Press NC start: The touch probe moves in the defined

direction until it contacts the workpiece and then

automatically returns to its starting point

Then the TNC displays the coordinates of the

measured position

Set to 0: Press the SET DATUM soft key

Press the END soft key to close the menu

Repeat this procedure for all axes, in which you want to set the

datum

Further information on this topic

Datum setting: See "Datum setting with a 3-D touch probe" on page

303

1.6 Workpiece setup

HEIDENHAIN TNC 128 53

Page 54

1.7 Running the first program

Selecting the correct operating mode

You can run programs either in the Single Block or the Full Sequence

mode:

Press the operating mode key: The TNC goes into the

Program Run, Single Block mode and the TNC

executes the program block by block. You have to

confirm each block with the NC start key

Press the Program Run, Full Sequence operating

mode key: The TNC switches to that mode and runs

the program after NC start up to a program

interruption or to the end of the program

Further information on this topic

Operating modes of the TNC: See "Operating modes" on page 60

Running programs: See "Program run" on page 330

1.7 Running the first program

Choosing the program you want to run

Press the PGM MGT key: The TNC opens the file

manager

Press the LAST FILES soft key: The TNC opens a

pop-up window with the most recently selected files

If desired, use the arrow keys to select the program

that you want to run. Load with the ENT key

Further information on this topic

File management: See "Working with the file manager" on page 95

Starting the program

Press the NC start key: The TNC runs the active

program

Further information on this topic

Running programs: See "Program run" on page 330

54 First steps with the TNC 128

Page 55

Introduction

Page 56

2.1 The TNC 128

The TNC 128 is a workshop-oriented straight cut control that enables

you to program conventional machining operations right at the

machine in an easy-to-use conversational programming language.

They are designed for milling, drilling and boring machines with up to

3 axes. You can also change the angular position of the spindle under

program control.

Keyboard and screen layout are clearly arranged in such a way that the

functions are fast and easy to use.

2.1 The TNC 128

Programming: HEIDENHAIN conversational format

The HEIDENHAIN conversational programming format is an especially

easy method of writing programs. Interactive graphics illustrate the

individual machining steps for programming the contour. Workpiece

machining can be graphically simulated either during or before actual

machining.

You can also enter and test one program while the control is running

another.

Compatibility

Machining programs created on the HEIDENHAIN TNC 124 straight

cut control may not always run on the TNC 128. If NC blocks contain

invalid elements, the TNC will mark them as ERROR blocks when the

file is opened.

56 Introduction

Page 57

2.2 Visual display unit and

1

3

4

4

5

77

8

2

1

6

9

keyboard

Visual display unit

The TNC is shipped with a 12.1-inch TFT flat-panel display.

1 Header

When the TNC is on, the selected operating modes are shown in

the screen header: the machining mode at the left and the

programming mode at right. The currently active operating mode

is displayed in the larger box, where the dialog prompts and TNC

messages also appear (unless the TNC is showing only graphics).

2 Soft keys

In the footer the TNC indicates additional functions in a soft-key

row. You can select these functions by pressing the keys

immediately below them. The thin bars immediately above the

soft-key row indicate the number of soft-key rows that can be

called with the arrow keys to the right and left. The bar

representing the active soft-key row is highlighted.

3 Soft-key selection keys

4 Shifting between soft-key rows

5 Setting the screen layout

6 Shift key for switchover between machining and programming

modes

7 Soft-key selection keys for machine tool builders

8 Switching the soft-key rows for machine tool builders

9 USB connection

2.2 Visual display unit and keyboard

HEIDENHAIN TNC 128 57

Page 58

Setting the screen layout

You select the screen layout yourself: In the PROGRAMMING AND

EDITING mode of operation, for example, you can have the TNC show

program blocks in the left window while the right window displays

programming graphics. As an alternative, the program can be

displayed in a large window. The available screen windows depend on

the selected operating mode.

To change the screen layout:

Press the screen layout key: The soft-key row shows

the available layout options (see "Operating modes",

page 60)

Select the desired screen layout

2.2 Visual display unit and keyboard

58 Introduction

Page 59

Operating panel

1

7

5

1

3

2

4

6

8

The TNC 128 is delivered with an integrated keyboard. The figure at

right shows the controls and displays of the keyboard:

1 File management

Calculator

MOD function

HELP function

2 Programming modes

3 Machine operating modes

4 Initiation of programming dialog

5 Arrow keys and GOTO jump command

6 Numerical input and axis selection

7 Navigation keys

8 Machine operating panel

The functions of the individual keys are described on the inside front

cover.

The keys on the operating panel are assigned to machinedependent functions. Refer to your machine manual.

Machine panel buttons, e.g. NC START or NC STOP, are

described in the manual for your machine tool.

2.2 Visual display unit and keyboard

HEIDENHAIN TNC 128 59

Page 60

2.3 Operating modes

Manual Operation and El. Handwheel

The Manual Operation mode is required for setting up the machine

tool. In this operating mode, you can position the machine axes

manually or by increments and set the datums.

The El. Handwheel mode of operation allows you to move the

machine axes manually with the HR electronic handwheel.

Soft keys for selecting the screen layout (select as described

previously)

Window Soft key

2.3 Operating modes

Positions

Left: positions, right: status display

Positioning with Manual Data Input

This mode of operation is used for programming simple traversing

movements, such as for face milling or prepositioning.

Soft keys for selecting the screen layout

Window Soft key

Program

Left: program blocks, right: status display

60 Introduction

Page 61

Programming and Editing

In this mode of operation you can write your part programs. The

various cycles and Q-parameter functions help you with programming

and adding necessary information. If desired, you can have the

programming graphics show the programmed paths of traverse.

Soft keys for selecting the screen layout

Window Soft key

Program

Left: program, right: program structure

Left: program blocks, right: graphics

Test Run

In the Test Run mode of operation, the TNC checks programs and

program sections for errors, such as geometrical incompatibilities,

missing or incorrect data within the program or violations of the

working space. This simulation is supported graphically in different

display modes.

Soft keys for selecting the screen layout: see "Program Run, Full

Sequence and Program Run, Single Block", page 62.

2.3 Operating modes

HEIDENHAIN TNC 128 61

Page 62

Program Run, Full Sequence and Program Run, Single Block

In the Program Run, Full Sequence mode of operation the TNC

executes a part program continuously to its end or to a manual or

programmed stop. You can resume program run after an interruption.

In the Program Run, Single Block mode of operation you execute each

block separately by pressing the machine START button.

Soft keys for selecting the screen layout

Window Soft key

Program

2.3 Operating modes

Left: program, right: program structure

Left: program, right: status

Left: program, right: graphics

Graphics

62 Introduction

Page 63

2.4 Status displays

ACTL.

X Y Z

F S M

"General" status display

The status display in the lower part of the screen informs you of the

current state of the machine tool. It is displayed automatically in the

following modes of operation:

Program Run, Single Block and Program Run, Full Sequence, except

if the screen layout is set to display graphics only, and

Positioning with Manual Data Input (MDI).

In the Manual Operation and El. Handwheel modes the status display

appears in the large window.

Information in the status display

Symbol Meaning

Actual or nominal coordinates of the current position

Machine axes; the TNC displays auxiliary axes in

lower-case letters. The sequence and quantity of

displayed axes is determined by the machine tool

builder. Refer to your machine manual for more

information

The displayed feed rate in inches corresponds to one

tenth of the effective value. Spindle speed S, feed

rate F and active M functions

2.4 Status displays

Axis is clamped

Axis can be moved with the handwheel

No active program

Program run has started

Program run is stopped

Program run is being aborted

HEIDENHAIN TNC 128 63

Page 64

Additional status displays

The additional status displays contain detailed information on the

program run. They can be called in all operating modes except for the

Programming and Editing mode of operation.

To switch on the additional status display:

Call the soft-key row for screen layout

2.4 Status displays

To select an additional status display:

The available status displays described below can be selected either

directly by soft key or with the switch-over soft keys.

Select the screen layout with additional status

display: In the right half of the screen, the TNC shows

the Overview status form

Switch the soft-key rows until the STATUS soft keys

appear

Either select the additional status display directly by

soft key, e.g. positions and coordinates, or

use the switch-over soft keys to select the desired

view

Please note that some of the status information described

below is not available unless the associated software

option is enabled on your TNC.

64 Introduction

Page 65

Overview

After switch-on, the TNC displays the Overview status form, provided

that you have selected the PROGRAM+STATUS screen layout (or

POSITION + STATUS). The overview form contains a summary of the

most important status information, which you can also find on the

various detail forms.

Soft key Meaning

Position display

Tool information

Active M functions

Active coordinate transformations

Active subprogram

Active program section repeat

Program called with PGM CALL

Current machining time

Name of the active main program

General program information (PGM tab)

Soft key Meaning

No direct

selection

possible

Name of the active main program

Dwell time counter

Machining time when the program was

completely simulated in the Test Run operating

mode

Current time

2.4 Status displays

Active programs

HEIDENHAIN TNC 128 65

Page 66

Program section repeat/Subprograms (LBL tab)

Soft key Meaning

No direct

selection

possible

Information on standard cycles (CYC tab)

2.4 Status displays

Soft key Meaning

No direct

selection

possible

Active program section repeats with block

number, label number, and number of

programmed repeats/repeats yet to be run

Active subprogram numbers with block number in

which the subprogram was called and the label

number that was called

Active machining cycle

66 Introduction

Page 67

Active miscellaneous functions M (M tab)

Soft key Meaning

No direct

selection

possible

List of the active M functions with fixed meaning

List of the active M functions that are adapted by

your machine manufacturer

2.4 Status displays

HEIDENHAIN TNC 128 67

Page 68

Positions and coordinates (POS tab)

Soft key Meaning

Type of position display, e.g. actual position

Information on tools (TOOL tab)

Soft key Meaning

T: Tool number and name

RT: Number and name of a replacement tool

2.4 Status displays

Tool axis

Tool length and radii

Oversizes (delta values) from the tool table (TAB) and

the TOOL CALL (PGM)

Tool life, maximum tool life (TIME 1) and maximum

tool life for TOOL CALL (TIME 2)

Display of the active tool and the (next) replacement

tool

68 Introduction

Page 69

Tool measurement (TT tab)

The TNC displays the TT tab only if the function is active

on your machine.

Soft key Meaning

No direct

selection

possible

Number of the tool to be measured

Display whether the tool radius or the tool length

is being measured

MIN and MAX values of the individual cutting

edges and the result of measuring the rotating

tool (DYN = dynamic measurement)

Cutting edge number with the corresponding

measured value. If the measured value is

followed by an asterisk, the permissible tolerance

in the tool table was exceeded

Coordinate transformations (TRANS tab)

Soft key Meaning

Name of the active datum table

Active datum number (#), comment from the

active line of the active datum number (DOC) from

Cycle 7

Active datum shift (Cycle 7); The TNC displays an

active datum shift in up to 8 axes

Mirrored axes (Cycle 8)

Active scaling factor/factors (Cycles 11 / 26); The

TNC displays an active scaling factor in up to 6

axes

2.4 Status displays

Scaling datum

For further information, refer to the User's Manual for Cycles,

"Coordinate Transformation Cycles."

HEIDENHAIN TNC 128 69

Page 70

Displaying Q parameters (QPARA tab)

Soft key Meaning

Display the current values of the defined Q

parameters

Display the character strings of the defined string

parameters

Press the Q PARAMETER LIST soft key. The TNC opens a

2.4 Status displays

pop-up window in which you can enter the desired range

for display of the Q parameters or string parameters.

Multiple Q parameters are entered separated by commas

(e.g. Q 1,2,3,4). To define display ranges, enter a hyphen

(e.g. Q 10-14).

70 Introduction

Page 71

2.5 Window manager

The machine tool builder determines the scope of function

and behavior of the window manager. The machine

manual provides further information.

The TNC features the Xfce window manager. Xfce is a standard

application for UNIX-based operating systems, and is used to manage

graphical user interfaces. The following functions are possible with the

window manager:

Display a task bar for switching between various applications (user

interfaces).

Manage an additional desktop, on which special applications from

your machine tool builder can run.

Control the focus between NC-software applications and those of

the machine tool builder.

The size and position of pop-up windows can be changed. It is also

possible to close, minimize and restore the pop-up windows.

The TNC shows a star in the upper left of the screen if an

application of the window manager or the window

manager itself has caused an error. In this case, switch to

the window manager and correct the problem. If required,

refer to your machine manual.

2.5 Window manager

HEIDENHAIN TNC 128 71

Page 72

Task bar

In the task bar you can choose different workspaces by mouse click.

The TNC provides the following workspaces:

Workspace 1: Active mode of operation

Workspace 2: Active programming mode

Workspace 3: Manufacturer's applications (optionally available)

In the task bar you can also select other applications that you have

started together with the TNC (switch for example to the PDF viewer

or TNCguide).

Click the green HEIDENHAIN symbol to open a menu in which you can

get information, make settings or start applications. The following

functions are available:

2.5 Window manager

About Xfce: Information on the Windows manager Xfce

About HEROS: Information about the operating system of the TNC

NC Control: Start and stop the TNC software. Only permitted for

diagnostic purposes

Web Browser: Start Mozilla Firefox

Diagnostics: Available only to authorized specialists to start

diagnostic functions

Settings: Configuration of miscellaneous settings

Date/Time: Set the date and time

Language: Language setting for the system dialogs. During startup

the TNC overwrites this setting with the language setting of MP

7230

Network: Network setting

Reset WM-Conf: Restore basic settings of the Windows Manager.

May also reset settings implemented by your machine

manufacturer

Screensaver: Settings for the screen saver; several are available

Shares: Configure network connections

Tools: Only for authorized users. The applications available under

tools can be started directly by selecting the pertaining file type in

the file management of the TNC (see "File management:

Fundamentals" on page 92)

72 Introduction

Page 73

2.6 Accessories: HEIDENHAIN 3-D

touch probes and electronic

handwheels

3-D touch probes

The various HEIDENHAIN 3-D touch probes enable you to:

Quickly and precisely set datums

Measure the workpiece

TS 220 and KT 130 touch trigger probes

These touch probes are particularly effective for datum setting and

workpiece measurement. The TS 220 and KT 130 touch probes

transmit the triggering signals to the TNC via cable.

Principle of operation: HEIDENHAIN triggering touch probes feature a

wear resisting optical switch that generates an electrical signal as

soon as the stylus is deflected. This signal is transmitted to the

control, which stores the current position of the stylus as the actual

value.

HR electronic handwheels

Electronic handwheels facilitate moving the axis slides precisely by

hand. A wide range of traverses per handwheel revolution is available.

Apart from the HR 130 and HR 150 panel-mounted handwheels,

HEIDENHAIN also offers the HR 410 portable handwheel.

HEIDENHAIN TNC 128 73

2.6 Accessories: HEIDENHAIN 3-D touch probes and electronic handwheels

Page 74

2.6 Accessories: HEIDENHAIN 3-D touch probes and electronic handwheels

74 Introduction

Page 75

Programming:

Fundamentals,

file management

Page 76

3.1 Fundamentals

Y

X

Z

X (Z,Y)

X

MP

Y

X

Z

Position encoders and reference marks

The machine axes are equipped with position encoders that register

the positions of the machine table or tool. Linear axes are usually

equipped with linear encoders, rotary tables and tilting axes with angle

encoders.

When a machine axis moves, the corresponding position encoder

generates an electrical signal. The TNC evaluates this signal and

calculates the precise actual position of the machine axis.

3.1 Fundamentals

If there is a power interruption, the calculated position will no longer

correspond to the actual position of the machine slide. To recover this

association, incremental position encoders are provided with

reference marks. The scales of the position encoders contain one or

more reference marks that transmit a signal to the TNC when they are

crossed over. From that signal the TNC can re-establish the

assignment of displayed positions to machine positions. For linear

encoders with distance-coded reference marks, the machine axes

need to move by no more than 20 mm, for angle encoders by no more

than 20°.