GE CVW93613M1DS, CVW93612M1SS, CVW93014M1WM, CVW93013M1DS, CVW93012M1SS Owner’s Manual

...

TM

TM

Owner’s Manual & Installation Instructions

Vented Range Hoods

Models: CVW9301 and CVW9361

Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.3 |

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . |

. .8 |

Using the Hood |

|

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . |

.20 |

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.5 |

Limited Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.22 |

Care And Cleaning |

|

Accessories |

23 |

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.6 |

||

Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

Consumer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

Write the model and serial numbers here:

Model # _______________________________

Serial # _______________________________

You can find them on a label on the inside of the hood.

Español

Para consultar una version en español de este manual de instrucciones, visite nuestro sitio de internet cafeappliances.com.

49-2000061 Rev. 2 01-19 GEA

THANK YOU FOR MAKING CAFÉ A PART OF YOUR HOME.

We take pride in the craftsmanship, innovation and design that goes into every Café product, and we think you will too. Among other things, registration of your appliance ensures that we can deliver important product information and warranty details when you need them.

Register your Café appliance now online. Helpful websites are available in the Consumer Support section of this Owner’s Manual. You may also mail in the pre-printed registration card included in the packing material.

TM

TM

2 |

49-2000061 Rev. 2 |

IMPORTANT SAFETY INFORMATION READ ALL INSTRUCTIONS BEFORE USING

WARNING TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

WARNING TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A.Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

B.Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent power from being switched

on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

C.Do not use this unit with any solid-state speed control device.

D.This unit must be grounded.

CAUTION |

FOR GENERAL VENTILATING USE |

|

|

ONLY. DO NOT USE TO EXHAUST HAZARDOUS |

|

OR EXPLOSIVE MATERIALS AND VAPORS. |

|

|

|

CAUTION |

To reduce risk of fire and to properly |

|

|

exhaust air, be sure to duct air outside. Do not vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

WARNING TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

WARNING TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

A.SMOTHER FLAMES with a close-fitting lid, cookie sheet or metal tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

B.NEVER PICK UP A FLAMING PAN—You may be burned.

C.DO NOT USE WATER, including wet dishcloths or towels—a violent steam explosion will result.

D.Use an extinguisher ONLY if:

1.You know you have a Class ABC extinguisher, and you already know how to operate it.

2.The fire is small and contained in the area where it started.

3.The fire department is being called.

4.You can fight the fire with your back to an exit.

*Based on “Kitchen Fire Safety Tips” published by NFPA.

WARNING TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

WARNING TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A.Never leave surface units unattended at high settings. Boil overs cause smoking and greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

B.Always turn hood ON when cooking on high heat or when flambéing food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

C.Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

D.Use proper pan size. Always use cookware appropriate for the size of the surface element.

INFORMATION SAFETY

READ AND SAVE THESE INSTRUCTIONS

49-2000061 Rev. 2 |

3 |

SAFETY INFORMATION

IMPORTANT SAFETY INFORMATION READ ALL INSTRUCTIONS BEFORE USING

WARNING TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

WARNING TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A.Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction.

B.Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent back drafting.

Follow the heating equipment manufacturer’s guidelines and safety standards such as those published by the National Fire Protection Association (NFPA), the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) and the local code authorities. When applicable, install any makeup (replacement) air system in accordance with local building code requirements. Visit cafeappliances.com for available makeup air solutions.

C.When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

D.Ducted fans must always be vented to the outdoors.

E.Turn off breaker to adjacent rooms while working.

WARNING TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

WARNING TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

Do not attempt to repair or replace any part of your hood unless it is specifically recommended in this manual. All other servicing should be referred to a qualified technician.

How to Remove Protective Shipping Film and Packaging Tape

Carefully grasp a corner of the protective shipping film |

To assure no damage is done to the finish of the |

with your fingers and slowly peel it from the appliance |

product, the safest way to remove the adhesive from |

surface. Do not use any sharp items to remove the film. |

packaging tape on new appliances is an application of |

Remove all of the film before using the appliance for the |

a household liquid dishwashing detergent. Apply with a |

first time. |

soft cloth and allow to soak. |

|

NOTE: The adhesive must be removed from all parts. |

READ AND SAVE THESE INSTRUCTIONS

4 |

49-2000061 Rev. 2 |

Controls

Throughout this manual, features and appearance may vary from your model.

1 |

2 |

1. FAN Control: Turn the FAN speed control to LO, MED LO, MED HI or HI, as needed. Continuous use of the fan system while cooking helps keep the kitchen comfortable and less humid. It also reduces cooking odors and soiling moisture that create a frequent need for cleaning. NOTE: When the fan

is operating on the LO setting, it will be very quiet. Always make sure that the fan is turned OFF when you are finished in the kitchen.

2. LIGHT Control: Turn the LIGHT control to HI for bright light while cooking. Turn to NITE for use as a night light.

Controls HOOD: THE USING

49-2000061 Rev. 2 |

5 |

CARE AND CLEANING: Filter / Surfaces

Filter

Be sure the circuit breaker is off and all surfaces are cool before cleaning or servicing any part of the vent hood.

Reusable Metal Grease Filters

The hood has 2 metal reusable grease filters.

The metal filters trap grease released by foods on the cooktop. They also help prevent flaming foods on the cooktop from damaging the inside of the hood.

For this reason, the filters must ALWAYS be in place when the hood is used. The grease filters should be cleaned once a month, or as needed.

To clean the grease filters, soak them and then swish them around in hot water and detergent. Don’t use ammonia or ammonia products because they will darken the metal. Do not use abrasives or oven cleaners. Light brushing can be used to remove embedded dirt. Rinse, shake and let them dry before replacing.

To remove:

Grasp the filter handle and pull it up, forward and out.

To replace:

1.Hold the filter at the bottom with the handle.

2.Place the top end of the filter against the inside front of the hood.

3. Slide it up until it stops and push the bottom end back until it snaps into place.

Surfaces

Stainless Steel Surfaces (on some models)

Do not use a steel wool pad; it will scratch the surface.

To clean the stainless steel surface, use warm sudsy water or a stainless steel cleaner or polish. Always wipe the surface in the direction of the brush line. Follow the cleaner instructions for cleaning the stainless steel surface. Cleaners with oxalic acid such as Bar Keepers Friend Soft Cleanser™ will

remove surface rust, tarnish, and small blemishes. To receive a $2.00 coupon for a trial sample of Bar Keepers Friend Soft Cleanser™ follow the link below or scan the QR Code.

www.barkeepersfriend.com/ge

Use only a liquid cleanser free of grit and rub in the direction of the brush lines with a damp soft sponge.

To inquire about purchasing stainless steel appliance cleaner or polish, or to find the location of a dealer nearest you, visit cafeappliances.com/parts.

Painted Surfaces (on some models)

Do not use a steel wool pads or other abrasive cleaners; they will scratch the surface.

Clean grease-laden surfaces of the hood frequently. To clean the hood surface, use a hot, damp cloth with a mild detergent suitable for painted surfaces. About one tablespoon of ammonia may be added to the water. Use a clean, hot, damp cloth to remove soap. Dry with a dry, clean cloth.

NOTE: When cleaning, take care not to come in contact with filters and other surfaces.

CAUTION When cleaning the hood surfaces, be certain that you do not touch the light with moist hands or cloth. A warm or hot light may break if touched with a moist surface. Always let the light cool completely before cleaning around it.

CAUTION When cleaning the hood surfaces, be certain that you do not touch the light with moist hands or cloth. A warm or hot light may break if touched with a moist surface. Always let the light cool completely before cleaning around it.

6 |

49-2000061 Rev. 2 |

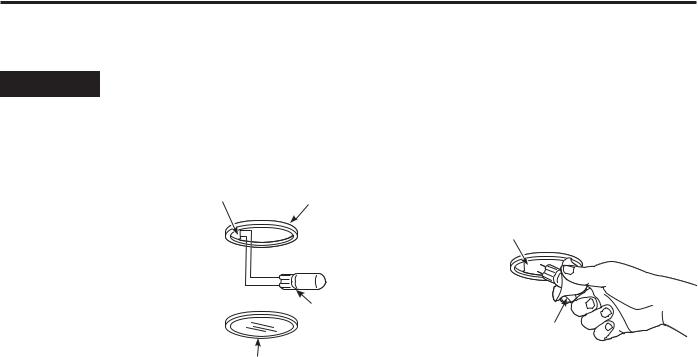

Lights

Be sure electrical power is off and all surfaces are cool before cleaning or servicing any part of the vent hood.

NOTE: The glass cover should be removed only when cold. Wearing latex gloves may offer a better grip.

CAUTION Before replacing your light bulb, disconnect the electrical power to the hood at the main fuse or circuit breaker panel.

CAUTION Before replacing your light bulb, disconnect the electrical power to the hood at the main fuse or circuit breaker panel.

Be sure to let the light cover and bulb cool completely.

For your safety, do not touch a hot bulb with bare hands |

||

or a damp cloth. |

Receptacle |

Socket |

|

||

To remove: |

|

|

|

|

|

1. Turn the glass cover |

|

|

counterclockwise until |

|

|

the glass cover clears the |

|

|

socket. |

|

|

2. Using gloves or a dry cloth, |

|

Bulb |

remove the bulb by pulling it |

|

|

straight out. |

|

|

Glass cover

To replace:

1.Use a new 12-volt, 20-watt (maximum) Halogen bulb for a G-4 base.

2.Using gloves or a dry cloth, remove the new bulb from its packaging. NOTE: Do not touch the new halogen bulb with bare fingers. Touching the bulb with bare fingers will significantly reduce the life of the bulb.

3.Push the bulb straight into the receptacle all the way.

4.Place the glass cover onto the socket and turn clockwise until secure. For improved lighting, clean

the glass cover |

Receptacle |

frequently using a |

|

damp cloth. This |

|

should be done |

|

when the hood is |

|

completely cool. |

|

5. Reconnect electrical |

Use |

power to the hood. |

gloves |

or cloth |

Lights CLEANING: AND CARE

49-2000061 Rev. 2 |

7 |

INSTALLATION INSTRUCTIONS

Installation |

Range Hoods |

|

Instructions |

||

|

||

|

|

|

If you have questions, visit our website at: cafeappliances.com |

||

|

|

|

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT— Save these

instructions for local inspector’s use.

• IMPORTANT— Observe all governing codes and ordinances.

•Note to Installer – Be sure to leave these instructions with the Consumer.

•Note to Consumer – Keep these instructions for future reference.

•Skill level – Installation of this vent hood requires basic mechanical and electrical skills.

•Completion time – Approximately 1 to 3 hours

•Proper installation is the responsibility of the installer.

•Product failure due to improper installation is not covered under the Warranty.

CAUTION Due to the weight and size of these vent hoods and to reduce the risk of personal injury or damage to the product, TWO PEOPLE

CAUTION Due to the weight and size of these vent hoods and to reduce the risk of personal injury or damage to the product, TWO PEOPLE

ARE REQUIRED FOR PROPER INSTALLATION.

WARNING TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

WARNING TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A.Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction.

B.Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent back drafting. Follow the heating equipment manufacturer’s guidelines and safety standards such as those published by the National Fire Protection Association (NFPA), the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE) and the local code authorities.

C.When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

D.Ducted fans must always be vented to the outdoors.

E.Turn off breaker to adjacent rooms while working.

WARNING TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCT WORK.

WARNING TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCT WORK.

FOR YOUR SAFETY

WARNING Before beginning the installation, switch power off at service panel and lock the service disconnecting means to prevent power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

WARNING Before beginning the installation, switch power off at service panel and lock the service disconnecting means to prevent power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

WARNING Disconnect all electrical power at the main circuit breaker or fuse box before installing.

WARNING Disconnect all electrical power at the main circuit breaker or fuse box before installing.

8 |

49-2000061 Rev. 2 |

Installation Preparation

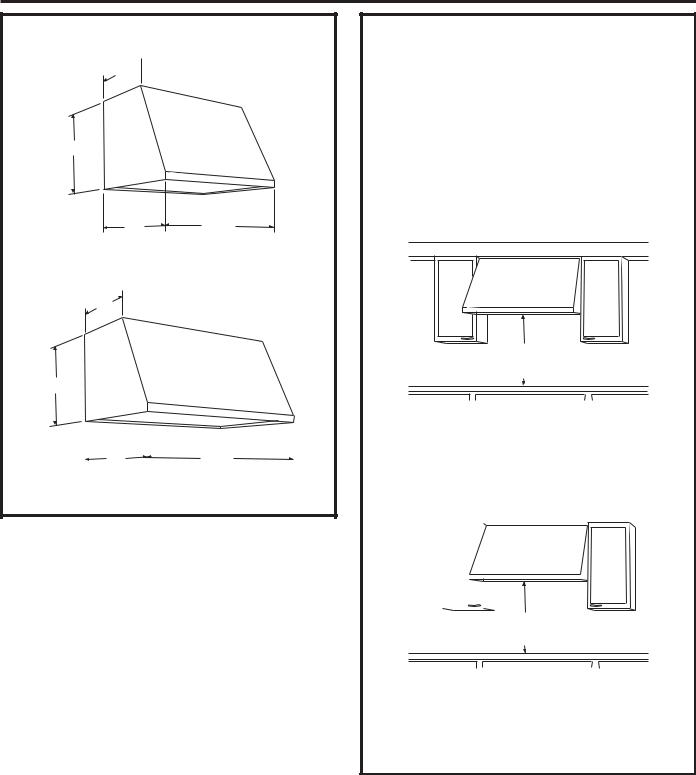

PRODUCT DIMENSIONS |

INSTALLATION CLEARANCES |

These vent hoods are designed to be installed onto 12” a wall. They may be installed beneath a soffit or

a wall. They may be installed beneath a soffit or

cabinet.

• The hoods are designed to fit 12” deep cabinets. When installed onto 15” deep cabinets, a filler

18” panel accessory is available: Order JXS50SS for 30” wide hoods or JXS56SS for 36” wide hoods.

• Install these hoods 24” required minimum and 36” recommended maximum above the cooking space.

21” |

|

SOFFIT INSTALLATION |

29-7/8” |

30” Models |

SOFFIT |

Requires a 30” opening. |

|

12” |

|

|

24” Required Minimum and |

|

36” Recommended Maximum |

18” |

|

|

|

|

|

|

In this installation, the ductwork running from the top |

|||||||||||||

|

|

|

|

|

||||||||||||||

|

|

|

|

|

||||||||||||||

|

21” |

|

|

|

of the hood will be concealed in the soffit or upper |

|||||||||||||

|

|

35-7/8” |

|

cabinetry. |

||||||||||||||

36” Models |

|

|

|

|

|

WALL MOUNT INSTALLATION |

||||||||||||

Requires a 36” opening. |

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24” Required Minimum and

36” Recommended Maximum

For this installation, a decorative duct cover is available to conceal the ductwork running from the top of the hood. Use of the duct cover requires

special consideration to the installation height above the countertop. See page 12 for details.

PREPARATION INSTALLATION

49-2000061 Rev. 2 |

9 |

INSTALLATION PREPARATION

Installation Preparation

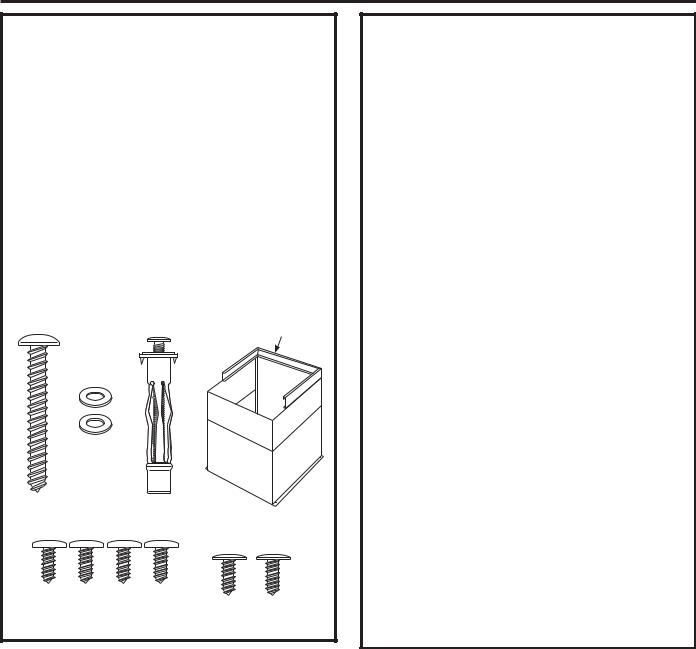

OPTIONAL ACCESSORIES

Duct Cover

A decorative duct cover is available to accommodate 8 to 10 ft. ceiling heights. The duct cover will expand from 12” minimum or 24” to 36” maximum height.

•The duct cover conceals the ductwork running from the top of the hood to the ceiling.

•The duct cover accessory fits both 30” and 36” wide models. Order the duct cover accessory at the same time as the vent hood. All accessories should be on site at the time of hood installation.

Order:

UXCHSS for Stainless Models UXCHDS for Matte Black Models UXCH4NWM for Matte White Models

Ceiling Bracket

|

2 Washers |

|

2 Wood |

2 Wall Fasteners |

|

Screws |

||

2-Piece Duct Cover |

||

|

with Ceiling Bracket |

4 Phillips Head Screws

2 Phillips Head

Decorative Screws

ADVANCE PLANNING

Duct Install Planning

•This hood may be vented vertically through upper cabinets, soffit or ceiling. A duct transition piece is supplied for vertical exhaust. Use locally supplied elbows to vent horizontally through the rear wall.

•Use metal ductwork only.

•Determine the exact location of the vent hood.

•Plan the route for venting exhaust to the outdoors. To maximize the ventilation performance of the vent system:

1.Minimize the duct run length and number of transitions and elbows.

2.Maintain a constant duct size.

3.Seal all joints with duct tape to prevent any leaks.

4.Do not use any type of flexible ducting.

•Use the shortest and straightest duct route possible.

•Install a wall cap or roof cap with damper at the exterior opening. Order the wall or roof cap and any transition needed in advance.

•When applicable, install any makeup (replacement) air system in accordance with local building code requirements. Visit cafeappliances.com for available makeup air solutions.

Wall Framing for Adequate Support

•This vent hood is heavy. Adequate structural support must be provided. The hood must be secured to vertical studs in the wall. See page 15.

•We strongly recommend that the vent hood with duct cover be on site before final framing and wall finishing. This will also help to accurately locate the ductwork and electrical service.

10 |

49-2000061 Rev. 2 |

Installation Preparation

DECORATIVE DUCT COVERS

A decorative duct cover is available to fit both model widths. The duct cover conceals the ductwork running from the top of the hood to the ceiling or soffit. The duct cover will fit 8 ft. to 10 ft. ceiling heights. See page 13 for details.

POWER SUPPLY

IMPORTANT – (Please read carefully)

WARNING

WARNING

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE PROPERLY GROUNDED.

Remove house fuse or open circuit breaker before beginning installation.

Do not use an extension cord or adapter plug with this appliance. Follow National Electrical Codes or prevailing local codes and ordinances.

Electrical supply

These vent hoods must be supplied with 120V, 60Hz, and connected to an individual, properly grounded branch circuit, and protected by a 15 or 20 amp circuit breaker or time delay fuse.

•Wiring must be 2 wire with ground.

•If the electrical supply does not meet the above requirements, call a licensed electrician before proceeding.

•Route house wiring as close to the installation location as possible in the ceiling or wall.

•Connect the wiring to the house wiring in accordance with local codes.

Grounding instructions

The grounding conductor must be connected to a ground metal, permanent wiring system, or an

equipment-grounding terminal or lead on the hood.

WARNING The improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or service representative if you are in doubt whether the appliance is properly grounded.

WARNING The improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or service representative if you are in doubt whether the appliance is properly grounded.

This Hood Must Use 7” Round Duct. It Can Transition To 3-1/4” x 12” Duct.

Do NOT use flexible plastic ducting.

NOTE: Any home ventilation system, such as a ventilation hood, may interrupt the proper flow of combustion air and exhaust required by fireplaces, gas furnaces, gas water heaters and other naturally vented systems. To minimize the chance of interruption of such naturally vented systems, follow the heating equipment manufacturer’s guidelines and safety standards

such as those published by NFPA and ASHRAE. When applicable, install any makeup (replacement) air system in accordance with local building code requirements. Visit cafeappliances.com for available makeup air solutions.

Using a smaller diameter duct size will reduce performance.

PREPARATION INSTALLATION

49-2000061 Rev. 2 |

11 |

INSTALLATION PREPARATION

Installation Preparation |

|

|

||

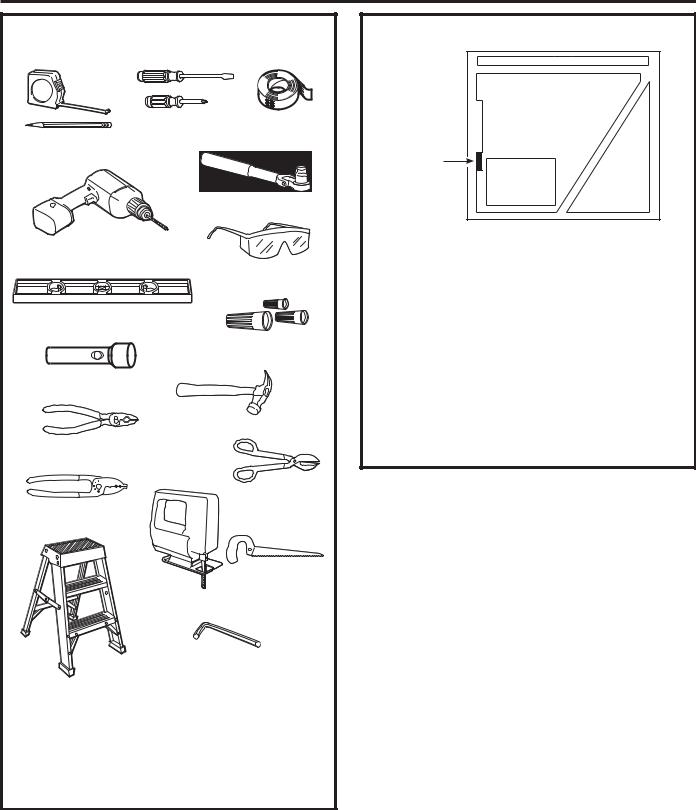

TOOLS AND MATERIALS REQUIRED |

REMOVE THE PACKAGING |

|||

(NOT SUPPLIED) |

|

|

|

|

Phillips and Flat blade |

Duct tape |

|

|

Hood |

screwdrivers |

|

|

|

|

Pencil and tape |

|

|

|

|

measure |

|

Wood |

|

|

|

|

|

|

|

|

|

Mounting |

Motor |

Parts |

|

|

Support |

||

1/4” pivoting hex socket |

|

|

Package |

|

|

|

|

||

|

|

|

Shipping Carton |

|

Electric drill with 1/8” and 3/8” bits |

• Remove the small box housing the motor. |

|

Safety glasses |

||

• Lift the hood out of the box. |

||

|

||

|

• Remove shipping screws holding the wood |

|

Spirit level |

mounting piece to the back side of the hood. Set |

|

aside wood mounting piece and screws for later |

||

|

||

UL Listed Wire nuts |

installation. Do not discard. |

|

|

• Remove the “V” shaped carton insert. |

|

Flashlight |

• Remove parts package from the “V” shaped |

|

cardboard insert. |

||

|

||

|

• Remove junction box cover and knockout. |

|

Hammer |

• Install strain relief onto back or top of hood. |

|

Pliers |

• Remove all tape and packing material from the |

|

hood, duct transition and motor. |

||

|

||

Tin Snips |

|

|

Wire Cutter/Stripper |

|

|

Saber saw or Key Hole Saw |

|

|

Allen Wrench |

|

Ladder

Additional Materials:

•120V 60Hz, 15 or 20 Amp, 2 wire with ground. Properly grounded branch circuit.

•Strain relief for junction box.

•7” round metal duct or 3-1/4” x 12” rectangular duct length to suit installation.

12 |

49-2000061 Rev. 2 |

Installation Preparation

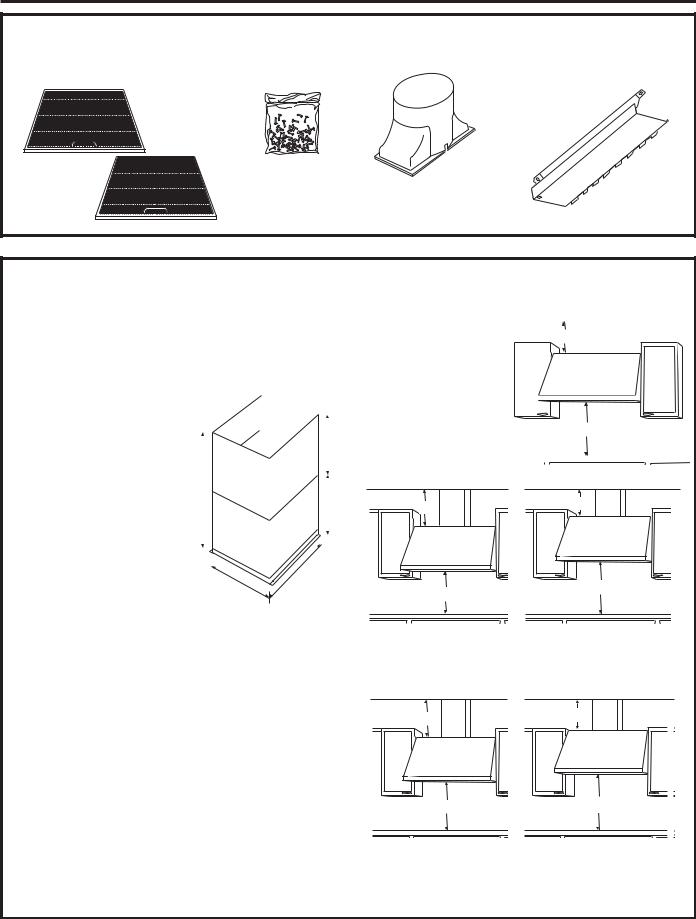

PARTS PROVIDED

Locate the hardware accessory box packed with the hood and check contents.

2 Aluminum |

Screws, wall |

|

|

fasteners, washers |

|

||

Grease Filters |

Filter |

||

Duct Transition |

|||

|

Support |

||

|

with Damper |

|

DUCT COVER REQUIREMENTS

We recommend that the vent hood and decorative duct cover (if used) be on site before final framing and wall finishing. This will help to accurately locate studs, ductwork, and electrical service. Read these instructions to determine if the duct cover accessory can be used for your installation situation.

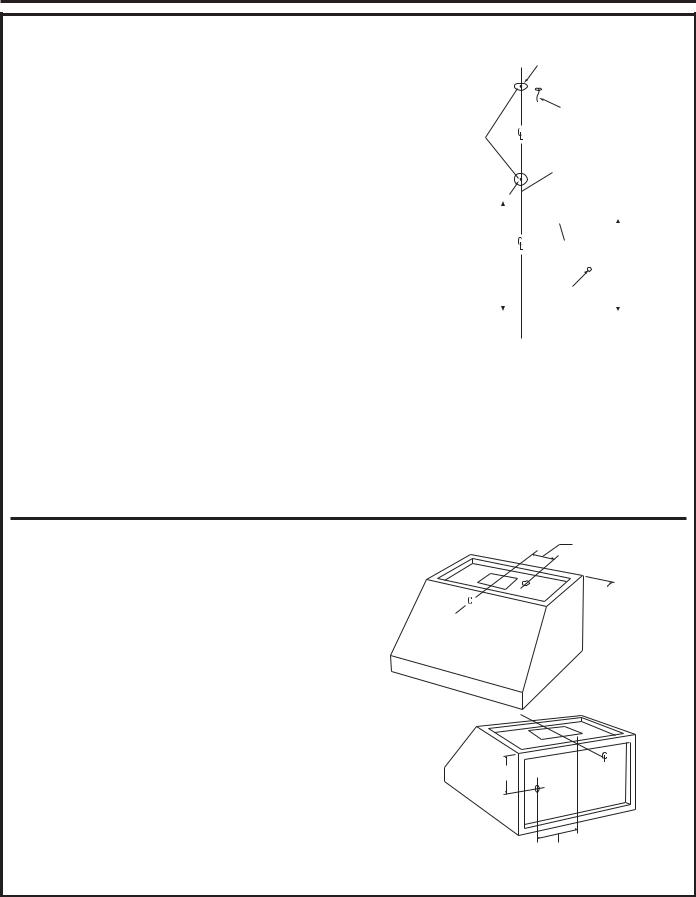

Duct Cover Accessory: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Use the decorative duct |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cover to conceal ductwork |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12” |

|||

|

|

|

|

|

|

|

|

|

|

|

||||

running from the top of the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

hood to the ceiling. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• The duct cover accessory |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22” |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

12” |

|||||||

consists of 2 pieces. The |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

outside piece is 12” high, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the inside piece is 22”. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nested together they are |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24” minimum expanding to a |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

12” |

|||||

|

|

|

|

|

|

|

|

|||||||

total maximum height of 34”. |

|

|

|

|

|

11” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

•The outside piece can be used alone to fill a 12” height.

•For heights over 12”, the ceiling bracket must be installed to secure the cover at the top.

To avoid unsightly gaps, plan the hood installation height for duct cover use.

•The cover will fit a 12” minimum height from the top of the hood to the ceiling or 24” minimum and expanding up to 34” from the top of the hood to the ceiling.

THE DUCT COVER CANNOT BE USED WHEN THE DISTANCE ABOVE THE TOP OF THE HOOD IS BETWEEN 12” AND 24”.

Review the following examples to ensure a trouble free installation using the duct cover accessory.

8ft. Ceilings: The hood |

|

|

|

|

|

|

|

8 ft. Ceiling |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

must be installed at |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12” |

|

|

|

|

|

|

|

||

30” above the cooking |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

surface (or 66” above |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

the floor). the duct cover |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

will not fit if the hood |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

is installed at a lower |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

or higher height. Use |

|

|

|

|

|

|

|

|

30” |

|

|||||||

the outside 12” section, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

discard the inside section. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 ft. Ceiling |

|

|

|

|

|

|

|

|

|

|||||||

30” |

24”

24” |

30”

9 ft Ceiling: Install the hood 24” min. and up to a maximum of 30” above the cooking surface. The duct cover will expand to reach ceiling height.

|

10 ft. Ceiling |

34” |

30” |

32” |

36” Max |

10 ft. Ceiling: Install the hood 32” min to 36” max. above the cooking surface. The duct cover will expand to a maximum of 34” above the top of the hood to meet the ceiling.

PREPARATION INSTALLATION

49-2000061 Rev. 2 |

13 |

INSTALLATION PREPARATION

Installation Preparation

DETERMINE HOOD, DUCTWORK AND WIRING LOCATIONS

•Keep the wood support piece and its screws for later installation. Do not discard.

•Measure desired distance from the bottom of the hood to the cooking surface, 24” required minimum and 36” recommended maximum. Refer to the previous page if the accessory duct cover will be used.

•Use a level to draw a horizontal line indicating the bottom of the hood.

•Use a level to draw the cooktop centerline location.

•Measure 15-3/8” up from the horizontal line for the bottom of the hood. Draw another horizontal line.

•Measure 18” up from the line for the bottom of the hood, draw another horizontal line to indicate the top of the hood.

For Vertical (Straight Up) Ducting:

•If venting out the ceiling, extend the centerline forward on the ceiling.

-Measure 6-7/8” from drywall to mark centerline for a 7-1/2” diameter duct hole on the ceiling.

-If drywall is not present, add drywall thickness to the 6-7/8” dimension.

Venting Through a Soffit or Upper Cabinet:

•Follow the same procedure for ceiling ducting to cut the 7-1/2” dia. hole through the top of the cabinet or soffit.

•See Step 4, page 16 for details to cut opening for duct transition.

|

|

|

|

|

|

|

FOR CEILING VENT |

||||||

6-7/8” Centerline to Wall |

|

|

|

DUCTING |

|||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrical |

||||||

7-1/2” Dia. Hole |

|

|

|

|

|

|

|

|

|

|

|||

FOR WALL VENT |

|

|

|

Centerline 8” Min. |

|||||||||

|

|

|

above Top of Hood |

||||||||||

|

DUCTING |

|

|

|

|

|

|

|

|

|

|

||

|

Top of Hood |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wood |

|

|

||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

18” |

|

|

|

|

|||||

|

|

|

|

|

Support |

15-3/8” |

|

||||||

|

|

|

|

|

|

|

|

||||||

Bottom of Hood |

|

|

|

Electrical |

|

|

|

||||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For Ducting Through Rear Wall:

•Measure the supplied duct transition with any straight run length of duct used, plus 90” elbow height. Draw a horizontal line on the wall intersecting the centerline.

House Wiring Location:

•The junction box is fastened to the back of the hood on the right side. See illustrations for hood knockout locations.

NOTE: The junction box can be relocated to the inside top of the hood.

House wiring may enter the junction box from the rear or the top of the hood at the right side.

To route house wiring through the ceiling or soffit:

•Cut a hole approximately 1” dia., 5-7/8” forward on the ceiling; 11-1/8” to the right of the centerline for 30” models or 14-1/8” to the right of the centerline for 36” models.

To route house wiring through the wall:

•Cut a hole approximately 1” dia. 10-1/16” down from the top of the hood, 11-1/8” to the right of the centerline for 30” models or 14-1/8” to the right of the centerline for 36” models.

•Remove top or rear knockout depending on your installation.

•Install strain relief onto back or top of hood.

14-1/8” for 36” Models

11-1/8” for 30” Models

5-7/8”

5-7/8”

Knockout

Locations

10-1/16”

14-1/8” for 36” Models

11-1/8” for 30” Models

14 |

49-2000061 Rev. 2 |

Installation Instructions

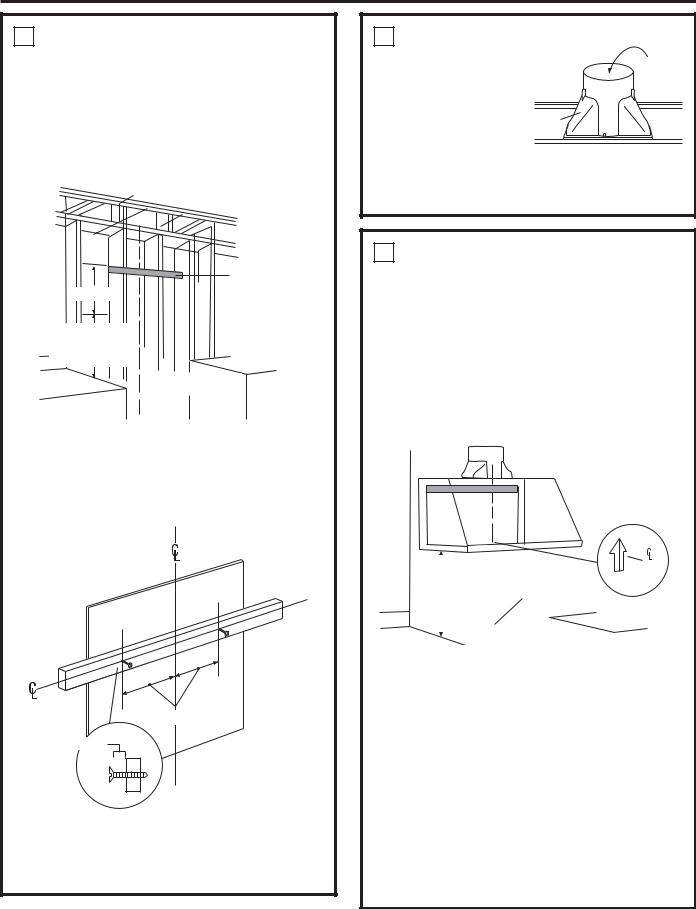

1 INSTALL HOOD SUPPORT

IMPORTANT: Framing must be capable of supporting 100 lbs.

•Locate at least 2 vertical studs at the wood mounting location by tapping drywall with a hammer or use a stud finder.

•Center the supplied wood horizontal support, left to right, and below the marked line.

7” Min. Opening for Ductwork

Wood Support

15-3/8”

24” Required

Minimum and 36”

Recommended

Maximum

Centerline of

Centerline of

Installation Space

•Drill 1/8” pilot holes through the support, drywall and into the studs. Secure the support to 2 or more vertical studs with supplied wood screws.

IMPORTANT: Screws must penetrate at least 1-1/2” into vertical studs. Countersink screws into support.

13-1/16”

1/4” gap

•Install mounting screws in the center of the wood support, 13-1/6” from the centerline. The screws should protrude forward 1/4”. This 1/4” gap will provide clearance to hang the hood.

2 INSTALL TRANSITION

IMPORTANT: |

Remove |

Remove shipping |

Shipping |

Tape on |

|

tape from damper and |

Damper |

check that damper |

Duct |

Top of |

|

moves freely. |

|||

Transition |

Hood |

•Place the transition piece over the hood exhaust. Secure transition to hood with 4 screws provided.

•Use duct tape to seal the connection.

3INSTALL HOOD ONTO WALL

•Lift the hood and place over the wood support. The top keyhole slots in the hood should engage the protruding mounting screws. Allow the hood to slide down into position.

•Pull house wiring through knockout at the rear or top of the hood.

•Check to be sure the hood is level and centered. The arrow shaped cutout in the back of the hood allows viewing the marked centerline.

•Remove cover from junction box.

|

|

|

|

|

|

|

|

|

|

|

|

24” Required |

|

|

|

Cutout |

|

Minimum and 36” |

|

Centerline of |

|||

Recommended |

|

Installation Space |

|||

Maximum |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drill Bottom Mounting Hole Locations

•Drill 1/8” pilot holes into the two lower mounting holes. Enlarge the holes if they do not enter studs to 3/8”. Tap anchors for wall fasteners into bottom holes. Install screws by hand into the fasteners to allow anchors to expand against the wall. Remove screws.

•Using two large flat washers (supplied), install wood screws or wall fastener screws, loosely, into lower mounting holes. Do not tighten.

•Check hood level. Tighten upper screws. Tighten lower mounting screws.

•For additional security, drive screws through the original wood support screw holes in the back of the hood.

INSTRUCTIONS INSTALLATION

49-2000061 Rev. 2 |

15 |

Loading...

Loading...