Garmin SA01535Wi-D System Maintenance Manual

G1000 / GFC 700

System Maintenance Manual

Hawker Beechcraft

Model 200/B200 Series King Air

Contains Instructions

For Continued Airworthiness

For STC SA01535WI-D

190-00915-01 |

October 2012 |

Revision 7 |

This page intentionally left blank.

© Copyright 2009-2012 Garmin Ltd. or its subsidiaries All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted, disseminated, downloaded or stored in any storage medium, for any purpose without the express prior written consent of Garmin. Garmin hereby grants permission to download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and to print one copy of this manual or of any revision hereto, provided that such electronic or printed copy of this manual or revision must contain the complete text of this copyright notice and provided further that any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Garmin International, Inc.

1200 E. 151st Street

Olathe, KS 66062 USA

Telephone: 913-397-8200

www.garmin.com

Garmin (Europe) Ltd.

Liberty House

Bulls Copse Road

Hounsdown Business Park

Southampton, SO40 9RB, UK

Phone: +44 (0) 23 8052 4000

Fax: +44 (0) 23 8052 4004

RECORD OF REVISIONS

Revision |

Revision Date |

Description |

ECO # |

|

3 |

7/17/09 |

Added GSM 86, TAWS-A, Radio Altimeter |

62341 |

|

4 |

11/1/10 |

Added GDL59, GSR 56, GTS 8XX and ESP |

76618 |

|

|

|

options |

|

|

5 |

5/11/12 |

Updated procedures for software version 0985.04 |

90414 |

|

6 |

7/19/12 |

Corrected GA drawing reference error in Section |

93256 |

|

3.8.2 |

||||

|

|

|

||

7 |

10/24/12 |

Add SW v0985.06, added GDC 7400 option, |

95300 |

|

updated section 4 airworthiness limitations |

||||

|

|

|

DOCUMENT PAGINATION

Section |

Pagination |

Table of Contents |

i – viii |

Section 1 |

1-1 – 1-6 |

Section 2 |

2-1 – 2-16 |

Section 3 |

3-1 – 3-54 |

Section 4 |

4-1 – 4-38 |

Section 5 |

5-1 – 5-90 |

Section 6 |

6-1 – 6-20 |

Section 7 |

7-1 – 7-66 |

Section 8 |

8-1 – 8-16 |

Page A |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Revision 7 |

190-00915-01 |

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration Regulations (“EAR”) issued by the United States Department of Commerce (15 CFR, Chapter VII Subchapter C) and which may not be exported, released or disclosed to foreign nationals inside or outside the United States without first obtaining an export license. The preceding statement is required to be included on any and all reproductions in whole or in part of this manual.

WARNING

This product, its packaging, and its components contain chemicals known to the State of California to cause cancer, birth defects, or reproductive harm. This Notice is being provided in accordance with California's Proposition 65. If you have any questions or would like additional information, please refer to our web site at www.garmin.com/prop65.

CAUTION

The GDU lens is coated with a special anti-reflective coating that is very sensitive to skin oils, waxes and abrasive cleaners. CLEANERS CONTAINING AMMONIA WILL HARM THE ANTI-REFLECTIVE COATING. It is very important to clean the lens using a clean, lint-free cloth and an eyeglass lens cleaner that is specified as safe for anti-reflective coatings.

IMPORTANT

All G1000 screen shots used in this document are current at the time of publication. Screen shots are intended to provide visual reference only. All information depicted in screen shots, including software file names, versions and part numbers, is subject to change and may not be up to date.

Page B |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Revision 7 |

190-00915-01 |

|

|

TABLE OF CONTENTS |

PARAGRAPH |

PAGE |

|

1 INTRODUCTION ............................................................................................................................ |

1-1 |

|

1.1 |

CONTENT, SCOPE, PURPOSE ........................................................................................................ |

1-1 |

1.2 |

ORGANIZATION............................................................................................................................ |

1-3 |

1.3 |

DEFINITIONS/ABBREVIATIONS |

....................................................................................................1-4 |

1.4 |

PUBLICATIONS ............................................................................................................................. |

1-5 |

1.5 |

REVISON AND DISTRIBUTION ...................................................................................................... |

1-6 |

2 SYSTEM DESCRIPTION ............................................................................................................... |

2-1 |

|

2.1 |

EQUIPMENT DESCRIPTIONS ......................................................................................................... |

2-1 |

2.2 |

G1000 OPTIONAL INTERFACES.................................................................................................. |

2-11 |

2.3 |

ELECTRICAL POWER DISTRIBUTION.......................................................................................... |

2-12 |

2.4 |

PITOT/STATIC SYSTEM .............................................................................................................. |

2-15 |

2.5 |

SHIELD BLOCK GROUNDS ......................................................................................................... |

2-16 |

2.6 |

G1000 /GFC700 BLOCK DIAGRAM ........................................................................................... |

2-16 |

3 G1000 CONTROL & OPERATION............................................................................................... |

3-1 |

||

3.1 |

GDU 1040A AND GDU 1500 DISPLAYS...................................................................................... |

3-1 |

|

3.2 |

GCU 477 - MFD CONTROLLER ................................................................................................... |

3-3 |

|

3.3 |

GMC 710 - AFCS CONTROLS...................................................................................................... |

3-3 |

|

3.4 |

GMA 1347D AUDIO PANEL ........................................................................................................ |

3-4 |

|

3.5 |

G1000 NORMAL MODE................................................................................................................ |

3-5 |

|

3.6 |

|

REVERSIONARY MODE ................................................................................................................ |

3-6 |

3.7 |

CONFIGURATION MODE OVERVIEW............................................................................................ |

3-7 |

|

3.8 |

G1000 / GFC 700 SOFTWARE INFORMATION ............................................................................ |

3-11 |

|

3.9 |

G1000 SOFTWARE/CONFIGURATION PROCEDURE .................................................................... |

3-18 |

|

3.10 |

TAWS-A SUPPORT CONFIGURATION .................................................................................... |

3-24 |

|

3.11 |

TAWS-A VOICE NO CALLOUT OPTION CONFIGURATION..................................................... |

3-25 |

|

3.12 |

TAWS-A VOICE CALLOUT OPTION CONFIGURATION........................................................... |

3-26 |

|

3.13 |

ADF OPTION CONFIGURATION .............................................................................................. |

3-27 |

|

3.14 |

DME OPTION CONFIGURATION ............................................................................................. |

3-28 |

|

3.15 |

RAD ALT OPTION CONFIGURATION ..................................................................................... |

3-29 |

|

3.16 |

NON-GARMIN TRAFFIC SYSTEM OPTION CONFIGURATION .................................................. |

3-30 |

|

3.17 |

GTS 8XX TRAFFIC SYSTEM CONFIGURATION ...................................................................... |

3-31 |

|

3.18 |

STORMSCOPE (WX-500) OPTION CONFIGURATION .............................................................. |

3-32 |

|

3.19 |

STORMSCOPE (WX-500) CONFIGURATION LOAD CONFIRMATION. ...................................... |

3-33 |

|

3.20 |

ESP SUPPORT (WITH AOA) OPTION CONFIGURATION .......................................................... |

3-34 |

|

3.21 |

ESP SUPPORT (NO AOA) OPTION CONFIGURATION .............................................................. |

3-35 |

|

3.22 |

GDL 59 WI-FI DATA LINK OPTION CONFIGURATION ........................................................... |

3-36 |

|

3.23 |

GSR 56 SATELLITE RECIEVER OPTION CONFIGURATION...................................................... |

3-37 |

|

3.24 |

POTS HANDSET CONFIGURATION ......................................................................................... |

3-38 |

|

3.25 |

GSM 85A SERVO MOUNT CONFIGURATION.......................................................................... |

3-38 |

|

3.26 |

GSM 86 SERVO MOUNT CONFIGURATION ............................................................................ |

3-39 |

|

3.27 |

VERIFICATION OF SERVO MOUNT CONFIGURATION.............................................................. |

3-40 |

|

3.28 |

FLITECHARTS CONFIGURATION............................................................................................. |

3-41 |

|

3.29 |

CHARTVIEW ENABLE............................................................................................................. |

3-41 |

|

3.30 |

TAWS-B ENABLE .................................................................................................................. |

3-42 |

|

3.31 |

TAWS-A ENABLE.................................................................................................................. |

3-43 |

|

3.32 |

SUPPLEMENTAL DATABASE LOADING................................................................................... |

3-44 |

|

3.33 |

SVS/PATHWAYS ENABLE ...................................................................................................... |

3-45 |

|

3.34 |

ESP ENABLE .......................................................................................................................... |

3-46 |

|

|

|

||

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page i |

||

190-00915-01 |

Revision 7 |

||

3.35 |

GDC 74B AIR DATA COMPUTER SOFTWARE/CONFIGURATION............................................ |

3-47 |

|

3.36 |

GDC 7400 AIR DATA COMPUTER SOFTWARE/CONFIGURATION........................................... |

3-48 |

|

3.37 |

AIRCRAFT REGISTRATION NUMBER ENTRY .......................................................................... |

3-49 |

|

3.38 |

SPLASH SCREEN LOADING ..................................................................................................... |

3-50 |

|

3.39 |

NAVIGATION DATABASE LOADING ....................................................................................... |

3-51 |

|

3.40 |

CONFIGURATION OF NAVIGATION MAP FOR TRAFFIC SYSTEM............................................. |

3-53 |

|

3.41 |

CLEARING DEFAULT USER SETTINGS.................................................................................... |

3-53 |

|

4 INSTRUCTIONS FOR CONTINUED AIRWORTHINESS........................................................ |

4-1 |

||

4.1 |

|

AIRWORTHINESS LIMITATIONS ................................................................................................... |

4-1 |

4.2 |

|

SERVICING INFORMATION ........................................................................................................... |

4-2 |

4.3 |

|

MAINTENANCE INTERVALS ......................................................................................................... |

4-4 |

4.4 |

|

VISUAL INSPECTION .................................................................................................................. |

4-10 |

4.5 |

|

ELECTRICAL BONDING TEST ..................................................................................................... |

4-15 |

4.6 |

GRS 77 EARTH MAGNETIC FIELD UPDATES ............................................................................. |

4-18 |

|

4.7 |

GSA 80 GREASING PROCEDURE................................................................................................ |

4-18 |

|

4.8 |

FLAPS-IN-MOTION DISCRETE INPUT CHECK.............................................................................. |

4-19 |

|

4.9 |

GSM 85A/GSM 86 SLIP CLUTCH TORQUE CHECK PROCEDURE .............................................. |

4-20 |

|

4.10 |

G1000 REDUNDANT CONNECTION CHECK ............................................................................ |

4-24 |

|

4.11 |

ENGINE DATA CHECK ............................................................................................................ |

4-27 |

|

4.12 |

TRIM ANNUNCIATOR CHECK ................................................................................................. |

4-30 |

|

4.13 |

G1000 MISCOMPARE CHECKS ............................................................................................... |

4-31 |

|

4.14 |

NOSE AVIONICS COMPARTMENT FANS OPERATIONAL CHECK ............................................. |

4-33 |

|

4.15 |

INSTRUMENT PANEL FANS OPERATIONAL CHECK ................................................................ |

4-33 |

|

4.16 |

STANDBY BATTERY PERIODIC CHECKS................................................................................. |

4-34 |

|

4.17 |

POWER BUS CHECK ............................................................................................................... |

4-37 |

|

5 TROUBLESHOOTING ................................................................................................................... |

5-1 |

||

5.1 |

G1000 ALERTING SYSTEM .......................................................................................................... |

5-2 |

|

5.2 |

|

SYSTEM ANNUNCIATIONS ........................................................................................................... |

5-4 |

5.3 |

|

200/B200 SPECIFIC ALERTS ...................................................................................................... |

5-25 |

5.4 |

|

TAWS TROUBLESHOOTING....................................................................................................... |

5-26 |

5.5 |

SYNTHETIC VISION AND PATHWAYS TROUBLESHOOTING........................................................ |

5-27 |

|

5.6 |

GFC 700 AFCS TROUBLESHOOTING......................................................................................... |

5-30 |

|

5.7 |

BACKUP COMMUNICATIONS PATH CHECKS.............................................................................. |

5-43 |

|

5.8 |

GDU 104X TROUBLESHOOTING................................................................................................ |

5-44 |

|

5.9 |

GDU 104X ALERTS ................................................................................................................... |

5-46 |

|

5.10 |

GIA 63 TROUBLESHOOTING .................................................................................................. |

5-54 |

|

5.11 |

GIA ALERT MESSAGES .......................................................................................................... |

5-56 |

|

5.12 |

GEA TROUBLESHOOTING ...................................................................................................... |

5-63 |

|

5.13 |

GTX TROUBLESHOOTING ...................................................................................................... |

5-64 |

|

5.14 |

GDL 69A TROUBLESHOOTING .............................................................................................. |

5-65 |

|

5.15 |

GRS 77/GMU 44 TROUBLESHOOTING................................................................................... |

5-67 |

|

5.16 |

GDC 74B/GDC 7400 TROUBLESHOOTING ............................................................................ |

5-73 |

|

5.17 |

GWX 68 TROUBLESHOOTING ................................................................................................ |

5-74 |

|

5.18 |

GMC 710 TROUBLESHOOTING .............................................................................................. |

5-75 |

|

5.19 |

GCU 477 TROUBLESHOOTING ............................................................................................... |

5-76 |

|

5.20 |

SOFTWARE/CONFIGURATION TROUBLESHOOTING ................................................................ |

5-77 |

|

5.21 |

BACKSHELL/BACKPLATE CONNECTORS................................................................................ |

5-79 |

|

5.22 |

STANDBY ATTITUDE INDICATOR TROUBLESHOOTING .......................................................... |

5-84 |

|

5.23 |

STANDBY AIRSPEED INDICATOR TROUBLESHOOTING........................................................... |

5-84 |

|

5.24 |

STANDBY ALTIMETER TROUBLESHOOTING........................................................................... |

5-85 |

|

5.25 |

SAFE FLIGHT LIFT COMPUTER TROUBLESHOOTING .............................................................. |

5-85 |

|

5.26 |

GDL 59 TROUBLESHOOTING ................................................................................................. |

5-87 |

|

|

|

||

Page ii |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

||

Revision 7 |

190-00915-01 |

||

5.27 |

GSR 56 TROUBLESHOOTING.................................................................................................. |

5-88 |

|

5.28 |

GTS 820/850 TROUBLESHOOTING ......................................................................................... |

5-88 |

|

6 EQUIPMENT REMOVAL & INSTALLATION.......................................................................... |

6-1 |

||

6.1 |

|

GDU 1040A/1500........................................................................................................................ |

6-2 |

6.2 |

GMA 1347D AUDIO PANEL ........................................................................................................ |

6-2 |

|

6.3 |

GIA 63W INTEGRATED AVIONICS UNITS.................................................................................... |

6-3 |

|

6.4 |

GEA 71 ENGINE/AIRFRAME UNIT ............................................................................................... |

6-3 |

|

6.5 |

|

GTX 33( ) TRANSPONDER ........................................................................................................... |

6-4 |

6.6 |

GDC 74B/GDC 7400 AIR DATA COMPUTER .............................................................................. |

6-4 |

|

6.7 |

GTP 59 OAT PROBE.................................................................................................................... |

6-4 |

|

6.8 |

|

GRS 77 AHRS............................................................................................................................. |

6-5 |

6.9 |

GMU 44 MAGNETOMETER .......................................................................................................... |

6-5 |

|

6.10 |

GDL 69A ................................................................................................................................. |

6-5 |

|

6.11 |

GSA 80 SERVOS....................................................................................................................... |

6-6 |

|

6.12 |

GSM 85A/86 SERVO GEARBOX ............................................................................................... |

6-7 |

|

6.13 |

GCU 477 .................................................................................................................................. |

6-7 |

|

6.14 |

GMC 710 ................................................................................................................................. |

6-8 |

|

6.15 |

GWX 68 ................................................................................................................................... |

6-8 |

|

6.16 |

CONFIGURATION MODULE REMOVAL & REPLACEMENT ........................................................ |

6-9 |

|

6.17 |

GEA 71 BACKSHELL THERMOCOUPLE REMOVAL & REPLACEMENT.................................... |

6-11 |

|

6.18 |

GPS/WAAS ANTENNAS ........................................................................................................ |

6-12 |

|

6.19 |

DIVERSITY TRANSPONDER ANTENNA.................................................................................... |

6-12 |

|

6.20 |

IRIDIUM ANTENNA ................................................................................................................. |

6-13 |

|

6.21 |

WI-FI ANTENNA..................................................................................................................... |

6-13 |

|

6.22 |

SIGNAL CONDITIONERS.......................................................................................................... |

6-13 |

|

6.23 |

INSTRUMENT PANEL ANNUNCIATORS (PROP SYNCH AND STANDBY BATTERY) .................. |

6-14 |

|

6.24 |

L-3 AVIONICS (BF GOODRICH) PS-835(C OR D MODEL) EMERGENCY BATTERY ................ |

6-14 |

|

6.25 |

STANDBY AIRSPEED INDICATOR............................................................................................ |

6-15 |

|

6.26 |

STANDBY ALTIMETER............................................................................................................ |

6-15 |

|

6.27 |

STANDBY ATTITUDE INDICATOR ........................................................................................... |

6-16 |

|

6.28 |

NOSE AVIONICS BAY COOLING FANS.................................................................................... |

6-16 |

|

6.29 |

GDU COOLING FANS ............................................................................................................. |

6-16 |

|

6.30 |

GTS 8XX TRAFFIC UNIT ....................................................................................................... |

6-17 |

|

6.31 |

GPA 65 PA/LNA UNIT .......................................................................................................... |

6-17 |

|

6.32 |

GA 58 TRAFFIC ANTENNAS ................................................................................................... |

6-18 |

|

6.33 |

GDL 59 WI-FI DATALINK...................................................................................................... |

6-18 |

|

6.34 |

GSR 56 SATELLITE RECEIVER ............................................................................................... |

6-19 |

|

7 G1000 EQUIPMENT CONFIGURATION & TESTING............................................................. |

7-1 |

||

7.1 |

GDU 1040/1500 MFD & PFD..................................................................................................... |

7-1 |

|

7.2 |

GMA 1347D AUDIO PANEL ........................................................................................................ |

7-3 |

|

7.3 |

GIA 63W INTEGRATED AVIONICS UNIT...................................................................................... |

7-6 |

|

7.4 |

GEA 71 ENGINE/AIRFRAME UNIT ............................................................................................... |

7-9 |

|

7.5 |

|

GTX 33( ) TRANSPONDER ......................................................................................................... |

7-12 |

7.6 |

GDC 74B/GDC 7400 AIR DATA COMPUTER ............................................................................ |

7-13 |

|

7.7 |

GRS 77 AHRS / GMU 44 MAGNETOMETER ............................................................................. |

7-18 |

|

7.8 |

GDL 69A XM DATA LINK ........................................................................................................ |

7-26 |

|

7.9 |

GSA 80 SERVOS ........................................................................................................................ |

7-26 |

|

7.10 |

GCU 477 FMS CONTROLLER ................................................................................................ |

7-27 |

|

7.11 |

GMC 710 AFCS CONTROLLER.............................................................................................. |

7-29 |

|

7.12 |

GWX 68 WEATHER RADAR .................................................................................................. |

7-30 |

|

7.13 |

NON-GARMIN TRAFFIC SYSTEM FUNCTIONAL CHECK.......................................................... |

7-31 |

|

7.14 |

STORMSCOPE FUNCTIONAL CHECK ....................................................................................... |

7-32 |

|

|

|

||

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page iii |

||

190-00915-01 |

Revision 7 |

||

7.15 |

TAWS FUNCTIONAL CHECK.................................................................................................. |

7-34 |

7.16 |

FLITECHARTS FUNCTIONAL CHECK ...................................................................................... |

7-37 |

7.17 |

CHARTVIEW FUNCTIONAL CHECK ........................................................................................ |

7-38 |

7.18 |

SAFETAXI FUNCTIONAL CHECK ............................................................................................ |

7-39 |

7.19 |

DME FUNCTIONAL CHECK .................................................................................................... |

7-40 |

7.20 |

ADF FUNCTIONAL CHECK ..................................................................................................... |

7-41 |

7.21 |

RADIO ALTIMETER CHECK .................................................................................................... |

7-41 |

7.22 |

WEIGHT ON WHEELS AND LOW SPEED AWARENESS BAND CHECK...................................... |

7-42 |

7.23 |

RVSM CHECKS...................................................................................................................... |

7-43 |

7.24 |

SAFE FLIGHT LIFT COMPUTER GROUND CALIBRATION ........................................................ |

7-49 |

7.25 |

ESP FUNCTIONAL CHECK ...................................................................................................... |

7-57 |

7.26 |

GTS 8XX TRAFFIC SYSTEM FUNCTIONAL CHECK ................................................................ |

7-61 |

7.27 |

ACTIVATION OF GARMIN FLIGHT DATA SERVICES ............................................................... |

7-63 |

7.28 |

GDL 59 WI-FI DATA LINK FUNCTIONAL CHECK .................................................................. |

7-65 |

7.29 |

GSR 56 SATELLITE RECEIVER FUNCTIONAL CHECK............................................................. |

7-66 |

8 SYSTEM RETURN TO SERVICE PROCEDURE ...................................................................... |

8-1 |

|

8.1 BACKUP PATH SYSTEM TESTING................................................................................................. |

8-2 |

|

8.2 GFC 700 GROUND CHECKOUT .................................................................................................. |

8-10 |

|

8.3 |

MAINTENANCE RECORDS .......................................................................................................... |

8-15 |

Page iv |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Revision 7 |

190-00915-01 |

FIGURE |

LIST OF ILLUSTRATIONS |

PAGE |

|

||

Figure 2-1, Display Units........................................................................................................................... |

2-1 |

|

Figure 2-2, Audio Panel............................................................................................................................. |

2-2 |

|

Figure 2-3, AFCS Controller ..................................................................................................................... |

2-2 |

|

Figure 2-4, FMS Controller ....................................................................................................................... |

2-3 |

|

Figure 2-5, Transponder............................................................................................................................. |

2-3 |

|

Figure 2-6, GIA unit .................................................................................................................................. |

2-4 |

|

Figure 2-7, GEA unit ................................................................................................................................. |

2-5 |

|

Figure 2-9, OAT probe .............................................................................................................................. |

2-6 |

|

Figure 2-10, AHRS .................................................................................................................................... |

2-7 |

|

Figure 2-11, Magnetometer ....................................................................................................................... |

2-7 |

|

Figure 2-12, GDL 69A Datalink................................................................................................................ |

2-8 |

|

Figure 2-13, GDL 59 Wi-Fi Datalink ........................................................................................................ |

2-8 |

|

Figure 2-14, GSR 56 Satellite Receiver..................................................................................................... |

2-9 |

|

Figure 2-15, GTS 8XX Traffic System...................................................................................................... |

2-9 |

|

Figure 2-16, Weather Radar....................................................................................................................... |

2-9 |

|

Figure 2-17, Servo ................................................................................................................................... |

2-10 |

|

Figure 2-18, 200/B200 Electrical Distribution (Post G1000 STC).......................................................... |

2-13 |

|

Figure 2-19, G1000 Component Power Sources...................................................................................... |

2-14 |

|

Figure 2-20, Pitot/Static System (Post G1000 STC)................................................................................ |

2-15 |

|

Figure 2-21, G1000/GFC 700 Block Diagram......................................................................................... |

2-16 |

|

Figure 3-1, GDU 1040A Control Interface................................................................................................ |

3-1 |

|

Figure 3-2, GDU 1500 Control Interface................................................................................................... |

3-2 |

|

Figure 3-3, G1000 Softkeys....................................................................................................................... |

3-2 |

|

Figure 3-4, MFD Controls (GCU 477 shown)........................................................................................... |

3-3 |

|

Figure 3-5, AFCS Controls (GMC 710 shown)......................................................................................... |

3-3 |

|

Figure 3-6, GMA 1347D Controls............................................................................................................. |

3-4 |

|

Figure 3-7, Normal Mode .......................................................................................................................... |

3-5 |

|

Figure 3-8, Automatic Reversion with MFD failure................................................................................. |

3-6 |

|

Figure 3-9, |

Manual Reversion with pilot PFD failure .............................................................................. |

3-6 |

Figure 3-10, SET>ACTV Diagram........................................................................................................... |

3-8 |

|

Figure 3-11, Loss of Communication ....................................................................................................... |

3-9 |

|

Figure 3-12, |

Configuration Status............................................................................................................. |

3-9 |

Figure 3-13, |

Data Transmission Indicators............................................................................................... |

3-9 |

Figure 3-14, G1000 LRU Configuration File Storage ............................................................................ |

3-16 |

|

Figure 3-15, GRS/GDC Configuration Settings Storage ........................................................................ |

3-17 |

|

Figure 3-16, |

Software/Configuration Overview ..................................................................................... |

3-18 |

Figure 3-17, Airframe Options ................................................................................................................ |

3-20 |

|

Figure 3-18, Propeller Options ................................................................................................................ |

3-20 |

|

Figure 3-19, |

Configuration/Software Load Page.................................................................................... |

3-21 |

Figure 3-20, System Status ...................................................................................................................... |

3-22 |

|

Figure 3-21, TAWS-A Support Configuration ........................................................................................ |

3-24 |

|

Figure 3-22, TAWS-A Voice No Callout Configuration......................................................................... |

3-25 |

|

Figure 3-23, TAWS-A Voice Callout Configuration............................................................................... |

3-26 |

|

Figure 3-24, ADF Configuration ............................................................................................................ |

3-27 |

|

Figure 3-25, DME Configuration............................................................................................................. |

3-28 |

|

Figure 3-26, RAD ALT Configuration .................................................................................................... |

3-29 |

|

Figure 3-27, Non-Garmin Traffic System Configuration ........................................................................ |

3-30 |

|

Figure 3-28, GTS 8XX TAS/TCAS1 Configuration ............................................................................... |

3-31 |

|

Figure 3-29, Lightning System Option Configuration............................................................................. |

3-32 |

|

Figure 3-30, |

Stormscope Configuration Page......................................................................................... |

3-33 |

Figure 3-31, |

Stormscope Configuration.................................................................................................. |

3-33 |

|

|

|

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page v |

|

190-00915-01 |

Revision 7 |

|

Figure 3-32, ESP Support Configuration................................................................................................. |

3-34 |

|

Figure 3-33, ESP Support Configuration................................................................................................. |

3-35 |

|

Figure 3-34, GDL 59 Configuration ........................................................................................................ |

3-36 |

|

Figure 3-35, GSR 56 Configuration......................................................................................................... |

3-37 |

|

Figure 3-36, GSM 85A Servo Mount Configuration............................................................................... |

3-38 |

|

Figure 3-37, GSM 86 Servo Mount Configuration.................................................................................. |

3-39 |

|

Figure 3-38, Servo Mount Configuration Verification ............................................................................ |

3-40 |

|

Figure 3-39, ChartView Enable ............................................................................................................... |

3-41 |

|

Figure 3-40, TAWS-B Enable ................................................................................................................. |

3-42 |

|

Figure 3-41, TAWS-A Enable ................................................................................................................. |

3-43 |

|

Figure 3-42, Supplemental Database Synchronization ............................................................................ |

3-44 |

|

Figure 3-43, SVS Enable ......................................................................................................................... |

3-45 |

|

Figure 3-44, ESP Enable.......................................................................................................................... |

3-46 |

|

Figure 3-45, GDC 74B Configuration ..................................................................................................... |

3-47 |

|

Figure 3-46, GDC 7400 Configuration .................................................................................................... |

3-48 |

|

Figure 3-47, Aircraft Registration............................................................................................................ |

3-49 |

|

Figure 3-48, Navigation Database Synchronization ................................................................................ |

3-52 |

|

Figure 4-1, GIA I/O Page........................................................................................................................ |

4-19 |

|

Figure 4-2, Discrete Valid/Invalid Indications ........................................................................................ |

4-19 |

|

Figure 4-3, GFC Status Page................................................................................................................... |

4-20 |

|

Figure 4-4, GFC Status Page................................................................................................................... |

4-21 |

|

Figure 4-5, Ambient Temperature Conversion Chart .............................................................................. |

4-28 |

|

Figure 4-7, Power Supply Connection.................................................................................................... |

4-36 |

|

Figure 5-1, AUX – System Status Page.................................................................................................... |

5-1 |

|

Figure 5-2, |

Alerts & Annunciations.......................................................................................................... |

5-2 |

Figure 5-3, ADVISORY Softkey Annunciation ....................................................................................... |

5-2 |

|

Figure 5-4, |

System Annunciations............................................................................................................ |

5-4 |

Figure 5-5, AFCS Annunciation Field.................................................................................................... |

5-30 |

|

Figure 5-6, GFC Status Page ................................................................................................................... |

5-31 |

|

Figure 5-7, |

Magnetometer Interference Test .......................................................................................... |

5-70 |

Figure 5-8, GIA 63W Backplate Connectors.......................................................................................... |

5-79 |

|

Figure 5-9, GEA 71 Backplate Connectors ............................................................................................ |

5-80 |

|

Figure 5-10, GMA 1347D Backplate Connectors................................................................................... |

5-80 |

|

Figure 5-11, GTX 33/33D Backplate Connectors................................................................................... |

5-80 |

|

Figure 5-12, GDU 1040A/1500 Backshell Connector (P10401 or P15001)........................................... |

5-81 |

|

Figure 5-13, GRS 77 Backshell Connector (P771)................................................................................. |

5-81 |

|

Figure 5-14, GDC 74B Backshell Connector (P74B1)........................................................................... |

5-81 |

|

Figure 5-15, GDC 7400 Mating Connector (P74001) ............................................................................ |

5-81 |

|

Figure 5-16, GDL 69A Backplate Connector (P69A1) .......................................................................... |

5-81 |

|

Figure 5-17, GCU 477 Backshell Connector (P4751) ............................................................................ |

5-82 |

|

Figure 5-18, GMC 710 Backshell Connector (P7101)............................................................................ |

5-82 |

|

Figure 5-19, GWX 68 Backshell Connector (P681) ............................................................................... |

5-82 |

|

Figure 5-20, GTS 820/850 Mating Connectors (P8001 and P8002)....................................................... |

5-82 |

|

Figure 5-21, GTS 820/850 Mating Connector (P8003) .......................................................................... |

5-82 |

|

Figure 5-22, GPA 65 Mating Connector (P651)..................................................................................... |

5-83 |

|

Figure 5-23, Signal Conditioner (1PVIB1 and 2PVIB1) ........................................................................ |

5-83 |

|

Figure 5-24, GDL 59 Mating Connector (1P591)................................................................................... |

5-83 |

|

Figure 5-25, GSR 56 Mating Connector (1P561) .................................................................................... |

5-83 |

|

Figure 6-1, Servo Gear............................................................................................................................... |

6-6 |

|

Figure 6-2, |

Configuration Module Installation ......................................................................................... |

6-9 |

Figure 6-3, GEA Backshell Thermocouple............................................................................................. |

6-11 |

|

Figure 7-1, G1000 Normal Mode Check .................................................................................................. |

7-2 |

|

Figure 7-2, Marker Beacon Symbology.................................................................................................... |

7-4 |

|

|

|

|

Page vi |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

|

Revision 7 |

|

190-00915-01 |

Figure 7-3, AUX – GPS STATUS Page (MFD)....................................................................................... |

7-6 |

|

Figure 7-4, Normal Engine Instrument Markings (MFD) ........................................................................ |

7-9 |

|

Figure 7-5, Aircraft Registration.............................................................................................................. |

7-12 |

|

Figure 7-6, Engine Run-Up Test Page ..................................................................................................... |

7-24 |

|

Figure 7-7, Normal Mode AHRS Check ................................................................................................ |

7-25 |

|

Figure 7-8, Low Speed Awareness Band Symbolization........................................................................ |

7-42 |

|

Figure 7-9, RVSM Critical Region.......................................................................................................... |

7-44 |

|

Figure 7-10, Dial Indicator ...................................................................................................................... |

7-45 |

|

Figure 7-11, Static Port Measurement ..................................................................................................... |

7-45 |

|

Figure 7-12, Static Port Measurement locations...................................................................................... |

7-46 |

|

Figure 7-13, Static Port Measurement Log.............................................................................................. |

7-46 |

|

Figure 7-14, C-05606-1 Lift Computer.................................................................................................... |

7-54 |

|

Figure 7-15, Breakout Box ...................................................................................................................... |

7-55 |

|

Figure 7-16, Force Applicator Usage Instructions................................................................................... |

7-56 |

|

Figure 7-17, GTS 8XX GND TEST softkey............................................................................................ |

7-61 |

|

Figure 7-18, GSR56 Configuration Page................................................................................................. |

7-66 |

|

Figure 7-19, AUX-TELEPHONE page ................................................................................................... |

7-66 |

|

Figure 8-1, GDU Data Verification (ARINC 429) .................................................................................... |

8-7 |

|

Figure 8-2, GIA Data Verification (ARINC429/RS-232).......................................................................... |

8-8 |

|

Figure 8-3, GIA Data Verification (RS-485) ............................................................................................. |

8-9 |

|

Figure 8-4, |

Pre-Flight Test...................................................................................................................... |

8-10 |

TABLE |

LIST OF TABLES |

PAGE |

|

||

Table 1-1, G1000 System Software Version ............................................................................................ |

1-1 |

|

Table 1-2, Required Documents ............................................................................................................... |

1-5 |

|

Table 1-3, |

Reference Publications ............................................................................................................ |

1-6 |

Table 3-1, Software Verification ............................................................................................................. |

3-23 |

|

Table 4-1, |

Maintenance Intervals.............................................................................................................. |

4-4 |

Table 4-2, |

Discontinued Maintenance Intervals ....................................................................................... |

4-9 |

Table 4-3, |

Nose Section Visual Inspection Procedure............................................................................ |

4-10 |

Table 4-4, |

Nose Avionics Compartment Visual Inspection Procedure .................................................. |

4-10 |

Table 4-5, |

Pilot’s Compartment Visual Inspection Procedure................................................................ |

4-11 |

Table 4-6, |

Instrument Panel G1000 Equipment Visual Inspection Procedure ....................................... |

4-11 |

Table 4-7, |

Cabin Area Visual Inspection Procedure............................................................................... |

4-13 |

Table 4-8, |

Rear Fuselage and Empennage Visual Inspection Procedure................................................ |

4-14 |

Table 4-9, Lightning Strike Inspection Procedure ................................................................................... |

4-14 |

|

Table 4-10, Measured Torque................................................................................................................. |

4-22 |

|

Table 4-11, GSM 85A/GSM 86 Slip Clutch Torque Settings ................................................................ |

4-23 |

|

Table 4-12, Engine Data Check Test Equipment..................................................................................... |

4-27 |

|

Table 4-13, Oil Pressure Indication Test Points....................................................................................... |

4-27 |

|

Table 4-14, ITT Indication Test Points.................................................................................................... |

4-28 |

|

Table 4-15, Torque Indication Test Points............................................................................................... |

4-29 |

|

Table 4-16, Standby Battery Required Equipment .................................................................................. |

4-34 |

|

Table 5-1, SVS Troubleshooting ............................................................................................................. |

5-27 |

|

Table 5-2, |

SVS-Related Alert Messages................................................................................................. |

5-27 |

Table 5-3, AFCS Annunciation Troubleshooting ................................................................................... |

5-28 |

|

Table 5-4, AFCS General Troubleshooting ............................................................................................ |

5-29 |

|

Table 5-5, |

Magnetometer Interference Test Sequence ........................................................................... |

5-71 |

Table 7-1, Fuel Flow Indication Special Equipment ............................................................................... |

7-10 |

|

Table 7-2, Fuel Flow Test Points............................................................................................................. |

7-10 |

|

Table 7-3, Oil Pressure Indication Special Equipment ............................................................................ |

7-11 |

|

Table 7-4, Oil Pressure Test Points.......................................................................................................... |

7-11 |

|

Table 7-5, |

Air Data System Test............................................................................................................. |

7-15 |

|

|

|

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page vii |

|

190-00915-01 |

Revision 7 |

|

Table 7-6, Vertical Speed Table ............................................................................................................. |

7-17 |

Table 7-7, Required GRS/GMU Calibrations......................................................................................... |

7-19 |

Table 7-8, RVSM Required Avionics...................................................................................................... |

7-43 |

Table 7-9, In-Flight Altitude Hold Performance Test.............................................................................. |

7-48 |

Page viii |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Revision 7 |

190-00915-01 |

1 INTRODUCTION

1.1Content, Scope, Purpose

This document provides Instructions for Continued Airworthiness (ICA) for the Garmin G1000 Integrated Flight Deck including the GFC700 Automatic Flight Control System (AFCS) as installed in the Hawker Beechcraft Model 200/B200 series King Air, under STC SA01535WI-D. This document satisfies the requirements for continued airworthiness as defined by 14 CFR Part 23.1529 and Appendix G. Information in this document is required to maintain the continued airworthiness of the G1000 and GFC700.

1.1.1Applicability

This document applies to all Model 200/B200 series King Air aircraft equipped with the G1000 and GFC700 AFCS systems.

Modification of an aircraft by this Supplemental Type Certificate (STC) obligates the aircraft operator to include the maintenance information provided by this document in the operator’s Aircraft Maintenance Manual and the operator’s Aircraft Scheduled Maintenance Program.

Aircraft modified by this STC have been shown to qualify for operation in Reduced Vertical Separation Minimum (RVSM) airspace as a group aircraft in accordance with Title 14 of the Code of Federal Regulations (14 CFR) Part 91, Appendix G, “Operations in Reduced Vertical Separation Minimum (RVSM) Airspace”, and Federal Aviation Administration (FAA) Document No. 91-RVSM, Change 2 dated 2/10/2004, “Guidance Material On The Approval Of Operators/Aircraft For RVSM Operations”. This qualification is based on analysis of the configuration and performance of the air data, automatic altitude control, altitude alerting, and altitude reporting systems. These systems must be maintained in accordance with the inspections and tests specified in this document and other current maintenance practices to guarantee continued compliance to RVSM specifications.

1.1.2Identifying an STC Configuration

Table 1-1 lists the G1000 System Software Version numbers approved for this STC.

Table 1-1, G1000 System Software Version

Aircraft Model |

G1000 System |

Notes |

|

Software Version |

|||

|

|

||

|

|

|

|

200/B200 Series King Air |

0985.01 |

Updated GIA software |

|

superseded |

|||

|

|

||

200/B200 Series King Air |

0985.02 |

Updated GDU and GIA software |

|

|

|

|

|

200/B200 Series King Air |

0985.03 |

Updated GDU and GIA software |

|

|

|

|

|

200/B200 Series King Air |

0985.04 |

Updated GDU and GIA software |

|

|

|

|

|

200/B200 Series King Air |

0985.06 |

Updated GDU and GRS software |

|

|

|

|

This STC allows multiple configurations for the King Air 200/B200 series. The correct configuration for a particular aircraft is loaded by choosing the applicable airframe/engine/propeller configuration. Refer to Table 6 of the General Arrangement Drawing, Garmin Part Number 005-00421-03, for configuration information for eligible engine and propeller combinations.

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page 1-1 |

190-00915-01 |

Revision 7 |

IMPORTANT!

If the technician is unsure of an aircraft’s STC configuration, perform the following:

After acknowledgement of the splash screen, use the FMS knob on the GCU 477 controller to go to the AUX – SYSTEM STATUS page on the MFD. In the AIRFRAME section (upper right corner,) the display shows the current G1000 airframe configuration and system software version number. The airframe configuration is shown in the AIRFRAME field and the system software version number is shown in the following format: ‘SYS SOFTWARE VERSION XXXX.XX’. It correlates to the software image used to load the software to the system:

EXAMPLE:

System Software Version ‘0985.01’ = Software Image P/N 006-B0985-01

Restart the MFD in configuration mode (see section 3.7) and use the FMS knob on the GCU 477 controller to go to the GDU-AIRFRAME CONFIGURATION page. In the AIRFRAME section (upper right corner), verify the correct configuration for SERIES, ENGINE and PROP.

EXAMPLE:

For a configuration that loaded “King Air B200 PT6A-42” with a “McCauley 3-BLADE” propeller, the AIRFRAME section should display:

SERIES: |

B200 |

ENGINE: |

PT6A-42 |

PROP: |

MCCAULEY 3 |

Page 1-2 |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Revision 7 |

190-00915-01 |

1.2Organization

The following outline briefly describes the organization of this manual:

Section 2: System Description

Provides a complete description of the type design change associated with installing the G1000 integrated cockpit system in the 200/B200 Series King Air. An overview of the G1000 and GFC 700 system interface is also provided.

Section 3: G1000 Control & Operation

Presents basic control and operation information specifically tailored to maintenance practices. Basic G1000 Configuration Mode operation is also described.

Section 4: Instructions for Continued Airworthiness

Provides maintenance instructions for continued airworthiness of the G1000 and GFC 700 systems.

Section 5: Troubleshooting

Provides troubleshooting information to aid in diagnosing and resolving potential problems with the G1000 and GFC 700 systems.

Section 6: G1000 Equipment Removal & Replacement

Gives instructions for the removal and replacement of G1000 and GFC700 equipment.

Section 7: G1000 Equipment Configuration & Testing

Gives instructions for loading software, configuring, and testing of G1000 equipment.

Section 8: System Return to Service Procedure

Specifies return-to-service procedures to be performed upon completion of maintenance of the G1000 system.

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page 1-3 |

190-00915-01 |

Revision 7 |

1.3 |

Definitions/Abbreviations |

ADF: |

Automatic Direction Finder |

ADTS: |

Air Data Test Set |

AFCS: |

Automatic Flight Control System |

AFM: |

Airplane Flight Manual |

AFMS: |

Airplane Flight Manual Supplement |

AHRS: |

Attitude Heading Reference System |

CDU: |

Control Display Unit |

CFR: |

Code of Federal Regulations |

DME: |

Distance Measuring Equipment |

EAU: |

Engine/Airframe Unit |

ESP |

Electronic Stability and Protection |

GPS: |

Global Positioning System |

GPWS: |

Ground Proximity Warning System |

HSDB: |

High-Speed Data Bus (Ethernet) |

IAU: |

Integrated Avionics Unit |

ICS: |

Inter-Com System |

ITT: |

Interstage Turbine Temperature |

LRU: |

Line Replaceable Unit |

MFD: |

Multi-Function Display |

OAT: |

Outside Air Temperature |

PFD: |

Primary Flight Display |

RVSM: |

Reduced Vertical Separation Minimum |

STBY: |

Standby |

STBY ATT: |

Standby Attitude Indicator |

STBY ALT: |

Standby Altimeter |

STBY A/S: |

Standby Airspeed Indicator |

STC: |

Supplemental Type Certificate |

TAWS: |

Terrain Awareness & Warning System |

WAAS: |

Wide Area Augmentation System |

VHF: |

Very High Frequency |

1.3.1Units of Measure

Unless otherwise stated, all units of measure are English units.

Page 1-4 |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Revision 7 |

190-00915-01 |

1.4Publications

The following documents are required by this maintenance manual to perform maintenance. It is the responsibility of the owner / operator to ensure latest versions of these documents are used during operation, servicing or maintenance of the airplane.

|

Table 1-2, Required Documents |

|

Part Number |

Garmin Document |

|

005-00421-00 |

Master Drawing List, Garmin G1000/GFC 700 in Hawker Beechcraft Model 200/B200 |

|

Series King Air |

|

|

|

|

|

005-W0025-00 |

Wiring Diagram, G1000/GFC 700 King 200/B200 |

|

005-00421-03 |

General Arrangement, G1000/GFC700 AFCS, in Hawker Beechcraft 200/B200 Series King Air |

|

005-00421-32 |

GWX 68 Radar Install, King Air 200/B200 |

|

005-00421-33 |

Antenna Install, King Air 200/B200 |

|

005-00421-30 |

Main Instrument Panel Installation, King Air 200/B200 |

|

005-00421-34 |

Electrical Equipment Install, Nose Bay, King Air 200/B200 |

|

005-00421-35 |

Roll Servo Install, w/GSM 85A King Air 200/B200 |

|

005-00421-36 |

Yaw Servo Install, w/GSM 85A King Air 200/B200 |

|

005-00421-37 |

Pitch Servo Install, w/GSM 85A King Air 200/B200 |

|

005-00421-38 |

Pitch Trim Servo Install, w/GSM 85A King Air 200/B200 |

|

005-00421-39 |

Magnetometer Install, King Air 200/B200 |

|

005-00421-40 |

OAT Sensor Install, King Air 200/B200 |

|

005-00421-42 |

Datalink Install, King Air 200/B200 |

|

005-00421-45 |

Roll Servo Install, w/GSM 86 King Air 200/B200 |

|

005-00421-46 |

Yaw Servo Install, w/GSM 86 King Air 200/B200 |

|

005-00421-47 |

Pitch Servo Install, w/GSM 86 King Air 200/B200 |

|

005-00421-48 |

Pitch Trim Servo Install, w/GSM 86 King Air 200/B200 |

|

005-00421-51 |

Wire Harness Installation, Nose, King Air 200/B200 |

|

005-00421-52 |

Wire Harness Installation, Cabin, King Air 200/B200 |

|

005-00421-53 |

Wire Harness Installation, Tail, King Air 200/B200 |

|

005-00421-54 |

Control Wheel Modification,G1000/GFC 700, King Air 200/B200 |

|

005-00421-55 |

Overhead Control Panel Modification, G1000/GFC 700, King Air 200/B200 |

|

005-00421-31 |

Pedestal Re-Configuration, King Air 200/B200 |

|

005-00421-56 |

Circuit Breaker Panel Modification, King Air 200/B200 |

|

005-00421-58 |

Glareshield Lighting Modification, King Air 200/B200 |

|

|

Hawker Beechcraft Document |

|

101-590010-39 |

Beech Super King Air 200 and 200T Wiring Diagram Manual |

|

101-590010-133 |

Super King Air Wiring Diagram Manual |

|

101-590010-161 |

Super King Air Wiring Diagram Manual |

|

101-590010-19 |

Super King Air 200 Series Maintenance Manual |

|

101-590010-453 |

Super King Air 200 Series Airworthiness Limitations Manual |

|

101-590097-13 |

King Air Series Component Maintenance Manual |

|

98-39006 |

Structural Inspection and Repair Manual |

|

|

Other Documents |

|

85-292-1-1033 |

Signal Conditioner Installation Manual (Meggitt/Vibro-Meter) |

|

9016182 |

Mid-Continent Instruments - Installation Manual and Operating Instructions, |

|

4200 Series Attitude Indicator |

|

|

|

|

|

TP-336 |

L-3 Avionics Systems – Emergency Power Supply Installation Manual, PS-835 |

|

|

|

|

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page 1-5 |

|

190-00915-01 |

|

Revision 7 |

The following publications are recommended to be on hand during the performance of maintenance activities.

|

Table 1-3, Reference Publications |

|

Part Number |

Garmin Document |

|

|

|

|

190-00915-02 |

Airplane Flight Manual Supplement, G1000 Integrated Avionics System and |

|

GFC 700 AFCS in Hawker Beechcraft 200/B200 King Air |

||

|

||

|

|

|

190-00929-01 |

G1000 King Air 200/B200 Cockpit Reference Guide |

|

|

|

|

190-00355-04 |

GDL 69/69A XM Satellite Radio Activation Instructions |

|

|

|

|

190-00907-00 |

G1000 System Maintenance Manual |

|

|

|

|

190-00303-72 |

GSA8X/GSM85(A) Installation Manual |

|

|

|

|

190-00303-83 |

GSM 86 Installation Manual |

|

|

|

|

190-00313-63 |

GMU 44 Installation Location Magnetic Interference Survey Procedure |

|

|

|

Generic installation manuals for individual Garmin LRUs are also available through the ‘Dealer Resource Center’ section of the Garmin web site; refer to Section 1.5 for details.

1.5Revison and Distribution

This document is required for maintaining the continued airworthiness of the aircraft. When this document is revised, every page will be revised to indicate current revision level.

Garmin Dealers may obtain the latest revision of this document on the Garmin Dealer Resource Center website.

Owner/operators may obtain the latest revision of this document from the https://fly.garmin.com/ Support page, or by contacting a Garmin dealer, contacting Garmin Product Support at 913-397-8200, toll free 866-739-5687, or using around the world contact information on https://fly.garmin.com/.

A Garmin Service Bulletin describing the revision to this document will be sent to Garmin dealers if the revision is determined to be significant.

Page 1-6 |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Revision 7 |

190-00915-01 |

2 SYSTEM DESCRIPTION

2.1Equipment Descriptions

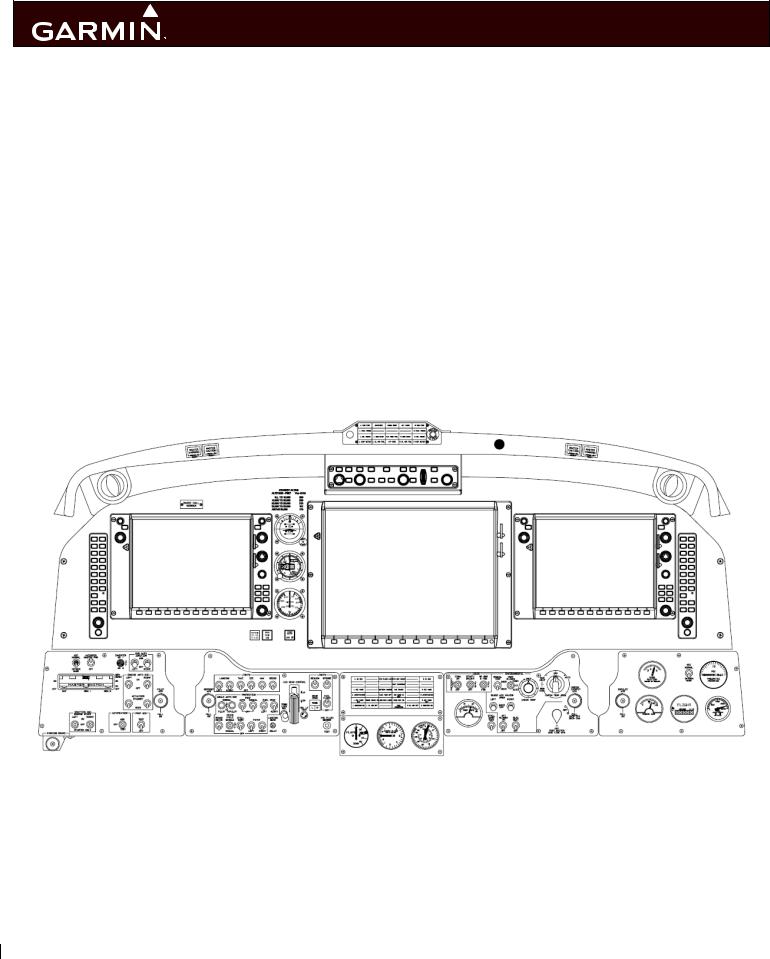

2.1.1GDU 1040A PFD (2) & GDU 1500 MFD

Two Garmin GDU 1040A displays and one GDU 1500 display are installed in the King Air instrument panel. The GDU 1040A units, 10.4 inch LCD displays with 1024x768 resolution, are configured as PFD 1 and PFD 2; the GDU 1500 unit, a 15 inch LCD display with 1024x768 resolution, is configured as a MFD. All displays provide control and display of nearly all functions of the G1000 integrated cockpit system. The PFD displays are located on either side of the MFD, with the stand-by instruments located between the Pilot’s PFD (PFD 1) and the MFD. GMA 1347D Audio Panels are located outboard of each PFD. Additionally, a GMC 710 AFCS Controller is located in the upper instrument panel, above the MFD, and a GCU 477 is installed in the pedestal. The GCU 477 provides the control interface for the MFD.

The GDU 1500 communicates with the GDU 1040A units, GDL 69A datalink, GWX68 weather radar, optional GDL59 wi-fi datalink and optional GTS 8XX traffic through a high-speed data bus (HSDB) Ethernet connection. The GDU 1500 communicates with the GCU 477 via RS-232 digital interface.

The GDU 1040A units communicate with each other and the GIA 63W units through a high-speed data bus (HSDB) Ethernet connection.

PFD 1 receives primary electrical power from the new Essential Bus and secondary electrical power from Dual Fed Bus No. 1. PFD 2 receives electrical power from Dual Fed Bus No. 2. Electrical power to the MFD is also provided by the Essential Bus. The displays will power-up immediately with external or aircraft power or battery operation.

All displays are installed in the King Air panel using ¼-turn fasteners. Three CDU cooling fans are also installed behind the panel for PFD and MFD cooling.

Figure 2-1, Display Units

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page 2-1 |

190-00915-01 |

Revision 7 |

2.1.2GMA 1347D Audio Panel (2)

The Garmin GMA 1347D Audio Panel integrates NAV/COM digital audio, intercom system and marker beacon controls. The 200/B200 installation includes two GMA 1347D panels. The GMA 1347D panels provide control of all cockpit intercom/mic systems as well as NAV/COM/ILS audio. The units also provide display reversion mode control through a large red button. Warning and alert audio received by the GMA 1347Ds is processed by and received from the GIA 63W Integrated Avionics Units (IAUs). Electrical power to GMA 1 is provided from the Essential bus. Electrical power to GMA 2 is provided from Avionics Bus No. 1. GMA 1 will be powered immediately with external or aircraft power or battery operation. GMA 2 will operate after selecting Avionics Master on. The GMA 1347D units interface with the existing marker beacon antenna, as well as existing mic and phone jacks and oxygen mask mic.

Figure 2-2, Audio Panel

2.1.3GMC 710 AFCS Control Unit

The dedicated AFCS controls on the GMC 710 allow crew control interface with the various GFC 700 autopilot / flight director functions. GMC 710 controls are discussed in detail in the G1000/King Air 200/B200 Series Cockpit Reference Guide. The GMC 710 is powered by Dual Fed Bus No. 1.

Figure 2-3, AFCS Controller

Page 2-2 |

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Revision 7 |

190-00915-01 |

2.1.4GCU 477 FMS Control Unit

The GCU 477 functions as the primary control interface to the GDU 1500 MFD. The GCU 477 provides alphanumeric, softkey, and flight planning function keys used to interface with the G1000; the MFD does not possess any knobs or controls other than softkeys. The GCU 477 is powered by the Essential Bus. The GCU 477 also provides the crew with the added functionality of tuning their receivers via the GCU as well as the PFD. Detailed instructions regarding the controls are discussed in the G1000 Cockpit Reference Guide.

Figure 2-4, FMS Controller

2.1.5GTX 33( ) Extended Squitter Transponder (2)

The Garmin GTX 33( ) transponders communicates with the on-side GIA 63W through RS-232 digital interface. This STC installation allows for installation of two GTX 33 non-diversity transponders, two GTX 33D Diversity transponders, or one of each type. The units are mounted under the floor in the cabin just aft of fuselage station 246.750. Power is provided by the No. 1 GTX 33( ) from the Essential Bus. The No. 2 GTX 33( ) is powered from the Avionics Bus No. 1. Each GTX 33( ) transponder interfaces with a transponder antenna mounted to the bottom of the fuselage. Each GTX33D diversity transponder interfaces to a transponder antenna mounted to the top of the fuselage.

Figure 2-5, Transponder

G1000 / GFC 700 System Maintenance Manual - 200/B200 Series King Air |

Page 2-3 |

190-00915-01 |

Revision 7 |

2.1.6GIA 63W Integrated Avionics Unit (2)

Two Garmin GIA 63W Integrated Avionics Units (IAUs) contain the VHF COM/NAV receivers, WAAS GPS receiver, Flight Director, and system integration microprocessors. The GIAs also serve as a communication interface to all other G1000 LRUs in the system. Each GIA 63W communicates directly with the on-side GDU 1040A display using a HSDB Ethernet connection. Both GIAs are located remotely in the nose equipment bay.

GIA 1 receives primary electrical power from the Essential Bus and a secondary electrical power supply from Dual Fed Bus No.1. GIA 2 receives electrical power from Dual Fed Bus No. 2. The GIA 1’s COMM power supply (COMM 1) is provided by the Essential Bus. GIA 2’s COMM power supply (COMM 2) is provided by Avionics Bus No. 1. Therefore, both GIAs power-up immediately with external or aircraft power or battery operation, with the exception of COMM 2 operation which will become active after selection of Avionics Master on.

Both GIA 63Ws interface to the following equipment:

•Existing VOR/LOC/Glideslope Antenna System

•Existing VHF COM #1 & #2 Antennas

•Newly installed GA 36 and GA 37 GPS/WAAS Antennas

•GMA 1347D, #1 & #2

•GEA 71, #1 & #2

•GDU 1040A, #1 & #2

•GSA 80

•GRS 77, #1 & #2