Page 1

GESTRA

GESTRA Steam Systems

MK 45

MK 45A

Installation Instructions 810348-06Steam Traps

Steam Traps

MK 45, MK 45A

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ............................................................................................................ 7

Safety note ........................................................................................................................................... 7

Danger ................................................................................................................................................. 7

Rating pursuant to article 9 of the PED ................................................................................................. 7

Explanatory Notes

Scope of supply...................................................................................................................................... 8

Description............................................................................................................................................. 8

Function ................................................................................................................................................. 8

Technical data MK 45 ............................................................................................................................ 9

Technical data MK 45A ........................................................................................................................ 10

Name plate MK 45 ............................................................................................................................... 11

Name plate MK 45A ............................................................................................................................. 11

Installation

MK 45, MK 45A .................................................................................................................................... 12

Design with flanges.............................................................................................................................. 12

Design with screwed-sockets ............................................................................................................. 12

Design with socket-weld ends ............................................................................................................ 13

Design with butt-weld ends................................................................................................................. 13

Check capsule ....................................................................................................................................... 5

Heat treatment of welds ....................................................................................................................... 13

Maintenance

Check steam trap ................................................................................................................................. 13

Check capsule ....................................................................................................................................... 5

Clean / exchange capsule and nozzle seat ........................................................................................... 14

Clean / exchange strainer..................................................................................................................... 14

Torques................................................................................................................................................ 15

Spare Parts

Spare parts list ..................................................................................................................................... 15

2

Page 3

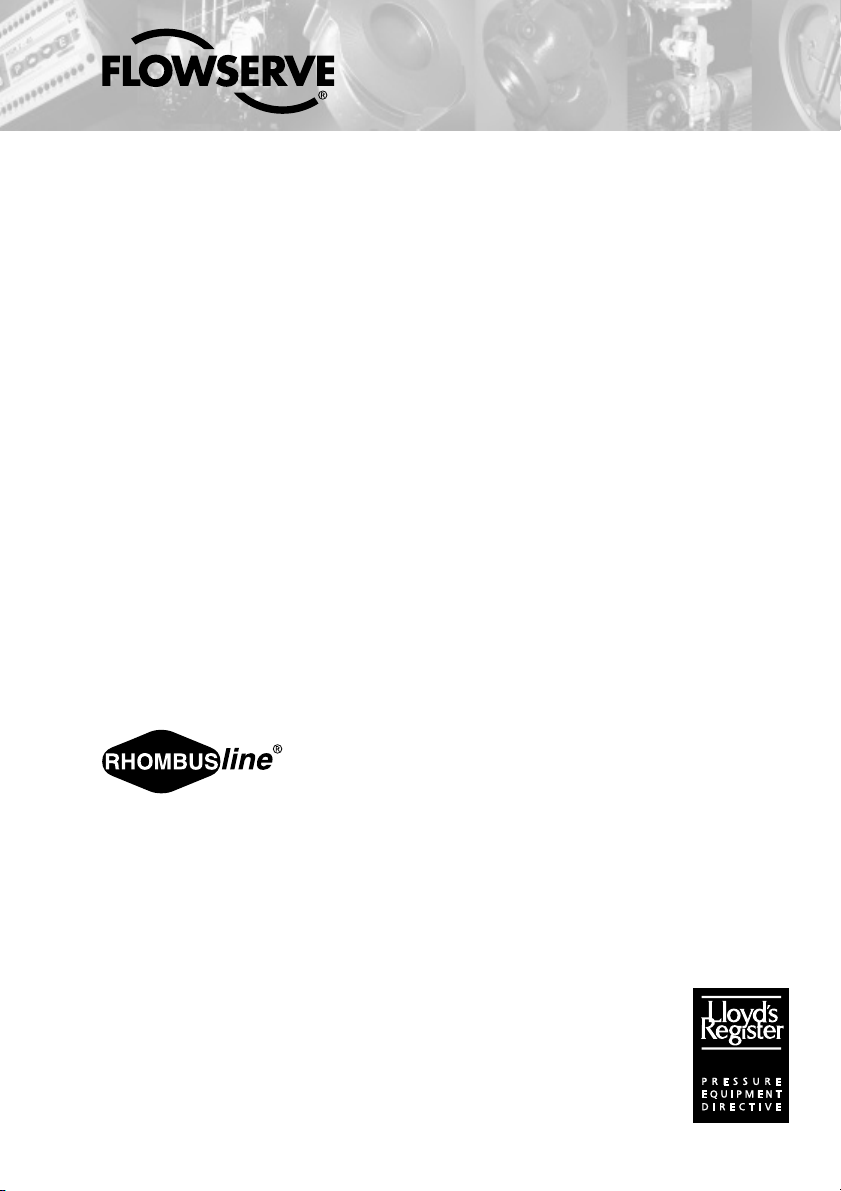

Capacity Chart

[lb/h]

Capacity

[kg/h]

0.1 0.3 0.6 1 3 6 10

0.2 0.4 0.8 2 4 8 22

1

2

3

4

[bar]

[psi]

Fig. 1

∆PMX

Max. flowrate of cold condensate

11

1

11

for MK 45-2, MK 45A-2.

Max. flowrate of cold condensate

22

2

22

for MK 45-1, MK 45A-1.

Max. flowrate of hot condensate

33

3

33

for MK 45-2, MK 45A-2.

Max. flowrate of hot condensate

44

4

44

for MK 45-1, MK 45A-1.

3

Page 4

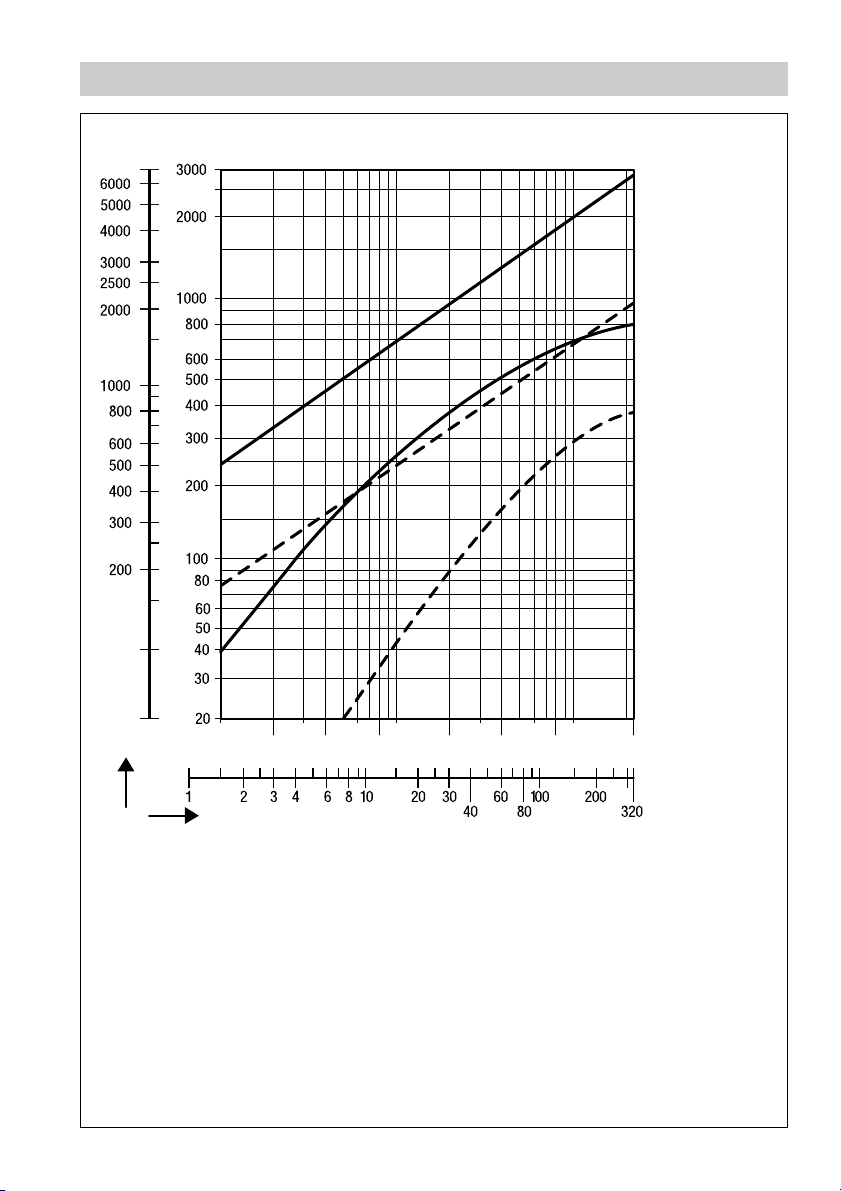

Design

A

B

C

D

E

F

G

H

o o

p

I

2

2

p

J

K

L

Fig. 2

4

Page 5

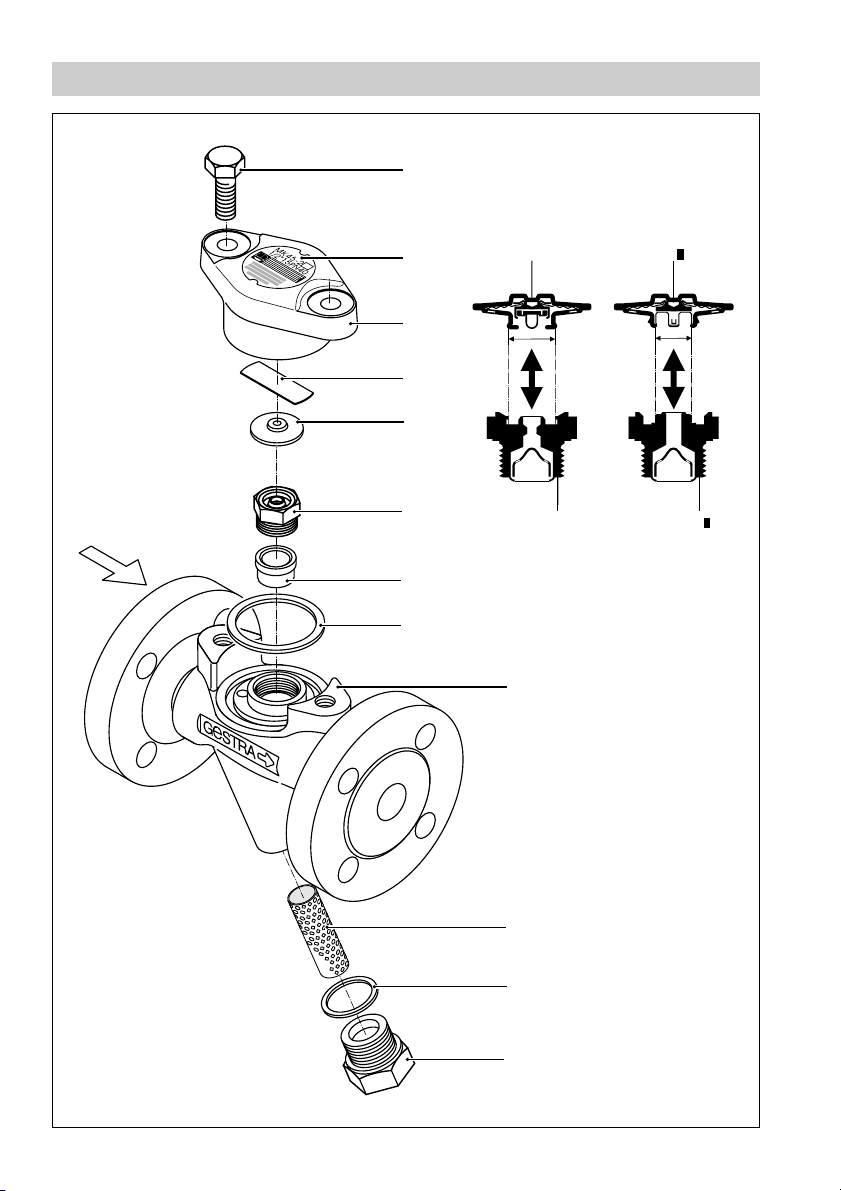

Checking of Capsule

Capsule o for nozzle insert with tandem seat p: 5 N 1, 5 U 1

Capsule intact Capsule defective

≥ 3.2 mm

Capsule o for nozzle insert with single seat p: 5 N 2, 5 U 2

2

2

Capsule intact Capsule defective

≥ 4.4 mm

M N O

≤ 2.6 mm

≤ 3.8 mm

Fig. 3

P

5

Page 6

Key

Hexagon-head screw M 10x 25

A

Name plate

B

Cover

C

Spring

D

Capsule

E

Capsule for tandem seat

o

2

o

Capsule for single seat

Nozzle insert with non-return valve action

F

p Nozzle insert with tandem seat

2

p

Nozzle insert with single seat

Bush (interference-fitted, cannot be replaced)

G

Gasket 40 x 48 x 2

H

Body

I

Strainer

J

Plug gasket A 24x 29

K

Plug M 24x1.5

L

Code number of pressure rating

M

5= ∆p 22 bar

Code letter of opening temperature

N

N = Standard, ∆t appox. 10 K

U = Undercooling, ∆t approx. 30 K

Code number of capacity

O

1 = Low capacity

2 = High capacity

Manufacturing code number

P

6

Page 7

Important Notes

Usage for the intended purpose

Use steam traps MK 45, MK 45A only for the discharge of condensed water or for air venting from

steam spaces.

Use this equipment only for the discharge of condensate from steam lines within the specified

pressure and temperature ratings and check corrosion resistance and chemical suitability for the

application in question.

Safety Notes

Installation must only be performed by qualified staff.

Qualified staff are those persons who – through adequate training in engineering, the use and

application of equipment in accordance with regulations concerning steam systems, and first aid &

accident prevention – have achieved a recognised level of competence appropriate to the installation

and commissioning of this device.

Danger

The steam trap is under pressure during operation.

When loosening flanged connections, plugs or the regulator, hot water and/or steam

may escape. This presents the risk of severe scalding.

Installation and maintenance work should only be carried out when the system is

depressurized: isolate the trap from both upstream and downstream pressure.

The trap becomes hot during operation.

This presents the danger of severe burns to hands and arms. Installation and

maintenance work should only be carried out when the system is cold.

Sharp edges on internal parts present a danger of cuts to hands. Always wear industrial

gloves for installation and maintenance work.

Conformity with EC Pressure Equipment Directive No. 97/23

The equipment has been checked and tested by us and is excluded from the scope of the Directive

(Article 3, Section 3). The equipment is not entitled to bear the CE marking.

7

Page 8

Explanatory Notes

Scope of Supply

MK45

1 Steam trap MK 45

1 Installation manual

MK 45A

1 Steam trap MK 45 A

1 Installation manual

Description

Thermostatic steam trap with corrosion-resistant thermostatic capsule unaffected by waterhammer.

Integral Y-type strainer and non-return valve. Asbestos-free cover gasket (graphite/CrNi). Installation in

any position.

The traps with standard capsule “N” discharge condensate with virtually no banking-up, the traps with

special capsule “U” with an undercooling of approx. 30 K (degC).

■

MK 45-1 with tandem seat (double sealing)

Particularly suitable for low condensate flowrates.

Optionally either with standard capsule “5 N 1” or

undercooling capsule “5 U 1”.

■

MK 45-2 with single seat

For larger condensate flowrates.

Optionally either with standard capsule “5 N 2” or

undercooling capsule “5 U 2”.

■

MK 45A-1 with tandem seat (double sealing)

Particularly suitable for low condensate flowrates.

Optionally either with standard capsule “5 N 1” or

undercooling capsule “5 U 1”.

■

MK 45A-2 with single seat

For larger condensate flowrates.

Optionally either with standard capsule “5 N 2” or

undercooling capsule “5 U 2”.

Function

The MK 45... is a thermostatic steam trap with membrane regulator. The capsule is filled with a liquid

which boils at a temperature a few degrees lower than water. As long as condensate flows through the

steam trap the liquid in the capsule is completely condensed due to the low ambient temperature. The

pressure inside the capsule is lower than the surrounding pressure (service pressure) and the

membrane with the valve disc is pushed in the opening direction. As the condensate temperature

approaches steam temperature, the liquid filling of the capsule starts to boil and evaporate. The

pressure in the capsule rises and the membrane with the valve disc is moved in the closing direction.

Automatic air-venting is provided both, during start-up and during normal operation. The correct

functioning of the MK 45 is neither affected by fluctuations in the upstream pressure nor by back

pressure.The MK 45 can also be used for thermal air venting.

8

Page 9

Explanatory Notes – continued –

Technical Data MK 45

seiresT-p 0E3puorglairetam,1-2901NEot.cca

lairetaM 501AMTSA/)]8.22C[HG052P(0640.1

)ND(eziS52,02,51

noitcennoC 003ssalCEMSA,04NPNIDsegnalF

AMPerusserpecivreS

AMTerutarepmetdetaleR

seiresT-p 1.1puorglairetam,051ssalC,43.61BEMSAot.cca

lairetaM 501AMTSA/)]8.22C[HG052P(0640.1

)ND(eziS52,02,51

noitcennoC051ssalCEMSAsegnalF

AMPerusserpecivreS

AMTerutarepmetdetaleR

04NP54KMsgnitaRerutarepmeT/erusserP

]grab[

]gisp[

]C°[

]F°[

0.04

085

05otpu01–

221otpu41

2.03

634

002

293

8.52

073

003

275

0.42

843

053

266

1.32

533

004

257

051ssalC54KMsgnitaRerutarepmeT/erusserP

]grab[

]gisp[

]C°[

]F°[

7.91

782

02

86

41

302

002

293

2.01

841

003

275

4.8

121

053

266

6.5

18

524

797

1)2

erusserplaitnereffidelbissimdA

)

erusserplaitnereffid.xaM ∆ XMP

1

) Observe pressure/temperature ratings!

2

) Inlet pressure minus outlet pressure

54KMslairetaMNEMTSA

ydoB)0640.1(HG052P501A

revoC)0640.1(HG052P501A

swercsydoB)5227.1(4oMrC247B391A

eluspaccitatsomrehTyolletsaH

slanretnirehtOleetssselniats

teksagydoBiNrC/etihparg

]gisp023[grab22

9

Page 10

Explanatory Notes – continued –

Technical Data MK 45A (Stainless Steel Design)

seiresT-p 0E31puorglairetam1-2901NEot.cca

lairetaM L613F-281AMTSA/)22171oMiNrC2X(4044.1

)ND(eziS52,02,51

noitcennoC 003ssalCEMSA,04NPNIDsegnalF

AMPerusserpecivreS

AMTerutarepmetdetaleR

seiresT-p 3.2puorglairetam,051ssalC,43.61BEMSAot.cca

lairetaM L613F-281AMTSA/)22171oMiNrC2X(4044.1

)ND(eziS52,02,51

noitcennoC051ssalCEMSAsegnalF

AMPerusserpecivreS

AMTerutarepmetdetaleR

]grab[

]gisp[

]C°[

]F°[

]grab[

]gisp[

]C°[

]F°[

04NPA54KMsgnitaRerutarepmeT/erusserP

0.04

085

02

86

0.92

6.024

002

293

0.52

6.263

003

275

0.42

843

053

266

0.42

843

004

257

051ssalCA54KMsgnitaRerutarepmeT/erusserP

9.51

6.032

02

86

1.11

161

002

293

7.9

6.041

003

275

4.8

121

053

266

6.5

18

524

797

1)2

erusserplaitnereffidelbissimdA

)

erusserplaitnereffid.xaM ∆ XMP

1

) Observe pressure/temperature ratings!

2

) Inlet pressure minus outlet pressure

A54KMslairetaMNEMTSA

ydoB)22171oMiNrC2X(4044.1L613F-281A

revoC)22171oMiNrC2X(4044.1L613F-281A

swercsydoB07-2A8B391A

eluspaccitatsomrehTyolletsaH

slanretnirehtOleetssselniats

teksagydoBiNrC/etihparg

10

]gisp023[grab22

Page 11

Explanatory Notes – continued –

Name Plate MK 45

Capacity rating 1

Low flowrate

MK45-1 MK45-2

Thermostatic

capsule

5N1

U

5U1

MADE BY GESTRA

Fig. 4 Fig. 5

Name Plate MK 45 A

Capacity rating 1

Low flowrate

Thermostatic

capsule

5N1

U

5U1

Fig. 6 Fig. 7

Capacity rating 2

High flowrate

MADE BY GESTRA

Capacity rating 2

High flowrate

Thermostatic

capsule

5N2

U

5U2

Thermostatic

capsule

5N2

U

5U2

11

Page 12

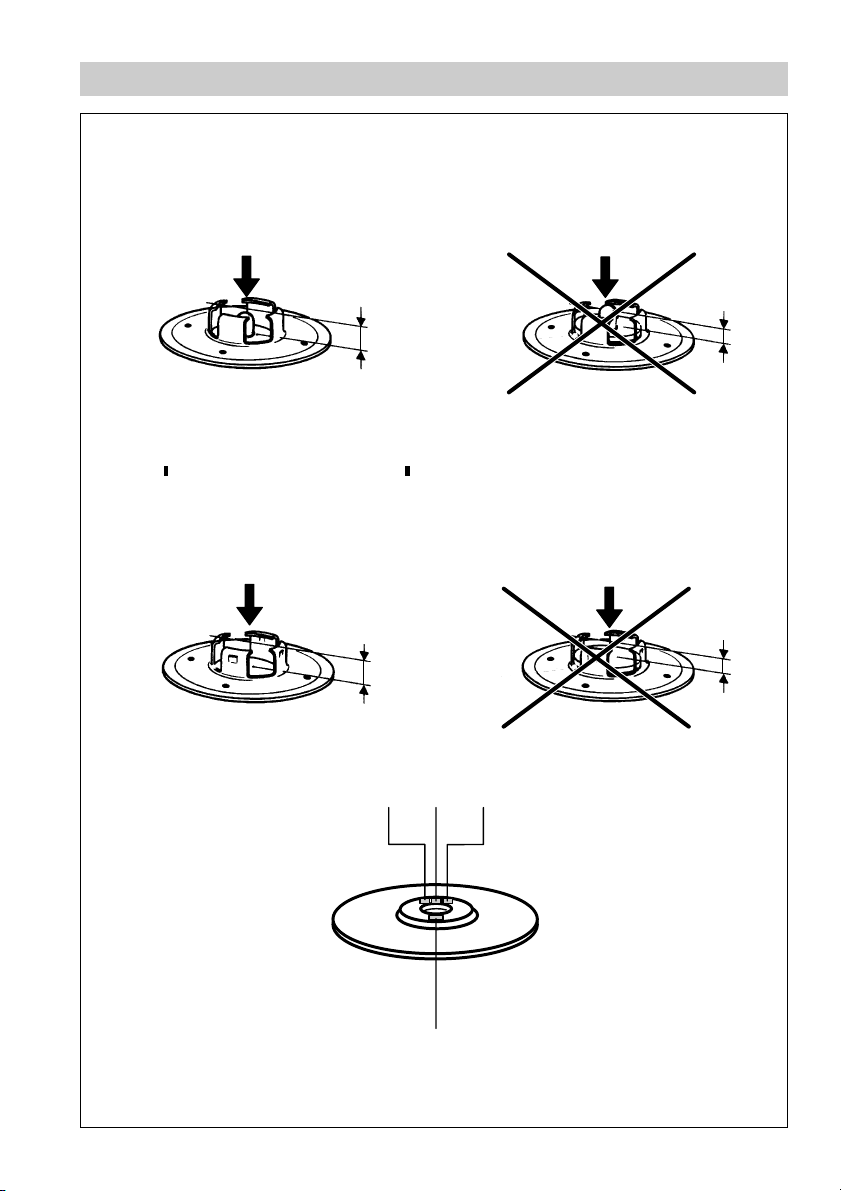

Installation

MK45, MK 45A

The steam traps MK 45, MK 45A can be installed in any position. In the case of a horizontal installation,

make sure that the cover is at the top.

Flanged Traps

1. Observe correct position of installation.

2. Observe direction of flow. The flow arrow is on the trap body.

3. Consider space required for opening trap. When the trap is installed a minimum space of 30 mm

is required for removing cover C.

4. Remove plastic plugs. They are only used as transit protection.

5. Clean seating surfaces of both flanges.

6. Install steam trap.

Screwed-Socket Traps

1. Observe correct position of installation.

2. Observe direction of flow. The flow arrow is on the trap body.

3. Consider space required for opening trap. When the trap is installed a minimum space of 30 mm

is required for removing the cover C.

4. Remove plastic plugs. They are only used as transit protection.

5. Clean thread of screwed sockets.

6. Install steam trap.

Socket-Weld Traps

1. Observe correct position of installation.

2. Observe direction of flow. The flow arrow is on the trap body.

3. Consider space required for opening trap. When the trap is installed a minimum space of 30 mm

is required for removing the cover C.

4. Remove plastic plugs. They are only used as transit protection.

5. Clean thermostatic capsule as described under Maintenance.

6. Clean socket-weld ends.

7. Apply arc welding processes 111 and 141 in accordance with DIN EN 24053.

12

Page 13

Installation – continued –

Butt-Weld Traps

1. Observe correct position of installation.

2. Observe direction of flow. The flow arrow is on the trap body.

3. Consider space required for opening trap. When the trap is installed a minimum space of 30 mm

is required for removing the cover C.

4. Remove plastic plugs. They are only used as transit protection.

5. Clean thermostatic capsule as described under Maintenance.

6. Clean butt-weld ends.

7. Apply arc welding processes 111 and 141 in accordance with DIN EN 24053 or gas welding

process 3 to DIN EN 24063.

Attention

■

Only qualified welders certified e. g. according to DIN EN 287 may weld the steam

trap into pressurized lines.

■

Do not insulate steam trap.

Heat treatment of welds

A subsequent heat treatment of the welds is not required.

Maintenance

GESTRA steam trap MK 45... does not require any special maintenance. However, if used in new

installations which have not been rinsed it may be necessary to check and clean the trap.

Check steam trap

You can check the steam trap MK 45... for steam loss during operation using the ultrasonic measuring

unit VAPOPHONE

Should you detect any loss of live steam clean the trap and/or replace the capsule.

®

or the test unit TRAPtest®.

13

Page 14

Maintenance – continued –

Clean/exchange capsule and nozzle insert

1. Observe note “Danger” on page 7.

2. Undo body screws A. Remove cover C from the body I.

3. Remove and clean capsule E. Unscrew nozzle insert F.

4. Replace capsule E in case of visible signs of wear or damage.

5. Clean body, internals and all gasket surfaces.

6. Apply heat-resistant lubricant to all threads and the seating surfaces of the nozzle insert and

the cover (use for instance WINIX

7. Screw in nozzle insert and tighten with a torque of 90 Nm.

8. Position capsule E onto the nozzle insert F and press evenly, such that the capsule snaps

into place.

9. Replace gasket H if there are visual signs of damage. Use the same cover C.

Always replace gasket H when using a new cover C or the cover of another steam trap.

10. Put cover onto the body. Tighten hexagon-head screws A alternately and in

several steps to a torque of 25 Nm.

Tools

■

Spanner A.F.16 mm to DIN 3113, form B

■

Spanner A.F. 22 mm to DIN 3113, form B

■

Torque spanner 20 – 120 Nm to DIN ISO 6789

®

2150).

Clean/exchange strainer

1. Observe note “Danger” on page 7.

2. Unscrew sealing plug L and remove strainer J.

3. Clean strainer, sealing plug and gasket seats.

4. Exchange strainer and sealing in case of visible signs of wear or damage.

5. Exchange gasket K if damaged.

6. Apply heat-resistant lubricant to the thread of the sealing plug (use for instance WINIX

®

2150).

7. Install sealing plug L with gasket K and strainer J. Tighten sealing plug with a torque of 120 Nm.

Tools

■

Spanner A. F. 30 mm to DIN 3113, form B

■

Torque spanner 20 – 120 Nm to DIN ISO 6789

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

14

Page 15

Maintenance – continued –

Torques

Item Designation Torque [Nm]

F

A

L

All torques are based at 20 °C room temperature.

Nozzle insert 90

Body screws 25

Sealing plug 120

Spare Parts

Spare Parts List

Item

Designation

Membrane regulator, complete 5N1

opH

Membrane regulator, complete 5U1

Membrane regulator, complete 5N2

2o2

opH

p

KJL

Membrane regulator, complete 5U2

Strainer set, complete

Thermostatic capsule 5N1

o

Thermostatic capsule 5U1

MK 45-1

MK 45A-1

375 109

375 111

375 113

375 382

376165

376166

Stock code

1

)

1

)

MK 45-2

MK 45 A-2

375 110

375 112

375 113

375 382

Thermostatic capsule 5N2

2

o

o

H

K

1

) Packaged 10 per box. Contact your local dealer for smaller quantities.

2

) Minimum purchasing quantity 50 pcs. Contact your local dealer for smaller quantities.

Thermostatic capsule 5U2

Cover gasket2) 40 x 48 x 2, graphite

2

Plug gasket

) A 24 x29, stainless steel

375 159 375159

375 162 375162

376 167

376 168

1

)

1

)

15

Page 16

Agencies all over the world

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 003491 /51 52032

Fax 00 34 91 /41 36 747; 51 52 036

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 003902 /66 32 51

Fax 00 39 02/66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 /306 10 -02 od 10

Fax 00 48 58 /306 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0035122/619 87 70

Fax 0035122/6107575

E-mail: jtavares@flowserve.com

USA

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel.: 00 15 02 / 4 95 01 54, 4 95 17 88

Fax: 00 15 02 / 4 95 16 08

E-Mail: dgoodwin@flowserve.com

GESTRA AG

Postfach 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telefon +49 (0) 421 35 03- 0

Telefax +49 (0) 421 35 03 - 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

810348-06/105cm · © 1999 GESTRA AG · Bremen · Printed in Germany

16

Loading...

Loading...