Page 1

MEN / MHP, MEN-TI

(Sealed for life

bearings)

ME-TI (AND OTHER PUMPS)

Motor-pump unit reserved exclusively for

fire-fighting purposes. Diesel engine cooled with a spent

water heat exchanger centrifugal pump

PCN=71576298 - 11-09 (E) Original instructions.

USER INSTRUCTIONS

Installation

Operation

Maintenance

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

Page 2

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

CONTENTS

PAGE

1 INTRODUCTION AND SAFETY ...........................4

1.1 G

ENERAL

1.2 CE

1.3 D

ISCLAIMER

1.4 C

OPYRIGHT

1.5 D

UTY CONDITIONS

1.6 S

AFETY

1.7 N

AMEPLATE AND SAFETY LABELS

1.8 S

PECIFIC MACHINE PERFORMANCE

1.9 N

OISE LEVEL

2 TRANSPORT AND STORAGE .............................7

2.1 C

ONSIGNMENT RECEIPT AND UNPACKING

2.2 H

ANDLING

2.3 L

IFTING

2.4 S

TORAGE

2.5 R

ECYCLING AND END OF PRODUCT LIFE

3 PUMP DESCRIPTION...........................................9

3.1 C

ONFIGURATIONS

3.2 N

OMENCLATURE

4 INSTALLATION....................................................11

4.1 L

OCATION

4.2 F

OUNDATION

4.3 G

ROUTING

4.4 I

NITIAL ALIGNMENT

4.5 P

IPING

4.6 E

LECTRICAL CONNECTIONS

4.7 C

ONNECTION

4.8 B

ATTERIES

4.9 S

WITCHING ON

4.10 C

4.11 F

4.12 P

4.13 O

5 COMMISSIONING, START-UP, OPERATION AND

SHUTDOWN...........................................................18

5.1 G

UARDING

5.2 P

RIMING AND AUXILIARY SUPPLIES

5.3 S

TARTING THE PUMP

5.4 R

UNNING THE PUMP

5.5 S

TOPPING AND SWITCHING OFF

.........................................................4

MARKING AND APPROVALS

......................................................4

......................................................4

............................................4

............................................................5

....................................................7

........................................................7

............................................................8

.........................................................8

.............................................9

.............................................10

.......................................................11

..................................................11

......................................................11

..........................................12

...........................................................13

..................................................16

.....................................................17

................................................17

HARGE STARTER BATTERIES

INAL SHAFT ALIGNMENT CHECK

ROTECTION SYSTEMS

THER CHECK

..............................................18

......................................................18

.......................................19

........................................24

...........................4

.......................6

....................6

.............................16

........................17

.....................17

..................................18

...................18

.......................25

............7

..............9

PAGE

6 MAINTENANCE...................................................25

6.1 G

ENERAL

6.2 M

AINTENANCE SCHEDULE

6.3 S

PARE PARTS

6.4 R

ECOMMENDED SPARES AND CONSUMABLE ITEMS

6.5 D

ISASSEMBLY

7 FAULTS; CAUSES AND REMEDIES ..................31

7.1 F

AULTS ON THE PUMP

7.2 E

LECTRICAL FAULTS

8 PARTS LIST AND DRAWINGS ...........................32

8.1 S

ECTIONAL DRAWINGS

8.2 S

ECTIONAL DRAWINGS PART LIST

8.3 G

ENERAL ARRANGEMENT DRAWING

9 CERTIFICATION .................................................35

10 OTHER RELEVANT DOCUMENTATION AND

MANUALS...............................................................35

10.1 S

10.2 C

10.3 A

........................................................25

................................26

..................................................29

.................................................29

.....................................31

........................................32

....................................32

.....................34

UPPLEMENTARY USER INSTRUCTIONS

HANGE NOTES

DDITIONAL SOURCES OF INFORMATION

............................................35

.................35

..........35

.........35

29

Page 2 of 36

Page 3

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

INDEX

PAGE

Additional sources (10.3).......................................35

Alignment of shafting (see 4.2, 4.4 and 4.11)

Batteries (4.8) ........................................................17

CE marking and approvals (1.2)..............................4

Certification (9) ......................................................35

Change notes (10.2)..............................................35

Charge starter batteries (4.10) ..............................17

Commissioning, start-up, operation (5) .................18

Configurations (3.1) .................................................9

Connection (4.7) ....................................................16

Copyright (1.4).........................................................4

Coupling assembly (4.4.1).....................................12

Disassembly (6.5)..................................................29

Disclaimer (1.3)........................................................4

Dismantling (see 6.5, Disassembly)......................29

Drawings (8.1) .......................................................32

Drive shaft assembly (4.4.2)..................................13

Duty conditions (1.5)................................................4

Electrical connections (4.6) ...................................16

End of product life (2.5) ...........................................9

Faults; causes and remedies (7) ...........................31

Final checks (4.5.3) ..............................................16

Foundation (4.2) ....................................................11

Forces and moments (see 4.5.1)...........................13

General arrangement drawing (8.3) ......................35

Gland packing (6.2.2) ............................................28

Grouting (4.3).........................................................11

Guarding (5.1)........................................................18

Handling (2.2) ..........................................................7

Installation (4) ........................................................11

Lifting (2.3)...............................................................8

Local signalization table (see 5.3.2.1)...................19

Location (4.1).........................................................11

Maintenance (5.3.2.3 and 6)

Maintenance schedule (6.2) ..................................26

Nomenclature (3.2)................................................10

Nameplate and safety labels (1.7)...........................6

Operating limits (see 3.1) ........................................9

Ordering spare parts (6.3.1) ..................................29

Parts lists (8.2).......................................................34

Piping (4.5) ............................................................13

Protection systems (4.12)......................................18

Pump masses (2.2.2) ..............................................8

Receipt and unpacking (2.1)....................................7

Recommended spares (6.4) ..................................29

Recycling (2.5).........................................................8

Replacement parts (see 6.3 and 6.4) ....................29

Running the pump (5.4).........................................24

Safety action (1.6.3).................................................5

Safety markings (1.6.1)............................................5

Safety, protection systems (see 1.6 and 4.12)

Sectional drawings (8.1) ........................................32

Sound level (see 1.9, Noise level)...........................7

Sources, additional information (10.3)...................35

Spare parts (6.3 and 6.4).......................................29

Specific machine performance (1.8)........................6

Standard maintenance (6.2.1) ..............................28

Starting the pump (5.3)..........................................19

Starting the diesel engine (5.3.2)...........................19

Stopping and switching off (5.5) ............................25

Storage, pump (2.4).................................................8

Storage, spare parts (6.3.2)...................................29

Supplementary manuals or information sources

(10.1)......................................................................35

Switching on (4.9) ..................................................17

Thermal expansion (4.4.1.1) .................................12

Transport and storage (2) .......................................7

Trouble-shooting (see 7)........................................31

PAGE

Page 3 of 36

Page 4

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve’s products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilizing sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not

take into account local regulations; ensure such

regulations are observed by all, including those

installing the product. Always coordinate repair

activity with operations personnel, and follow all

plant safety requirements and applicable safety and

health laws and regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all

the conditions relating to safety noted in the

instructions, have been met. Failure to follow

and apply the present user instructions is

considered to be misuse. Personal injury,

product damage, delay or failure caused by

misuse are not covered by the Flowserve

warranty.

1.2 CE marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives covering Machinery and, where

applicable, Low Voltage Equipment, Electromagnetic

Compatibility (EMC), Pressure Equipment Directive

(PED) and Equipment for Potentially Explosive

Atmospheres (ATEX).

Where applicable the Directives and any additional

Approvals cover important safety aspects relating to

machinery and equipment and the satisfactory

provision of technical documents and safety

instructions. Where applicable this document

incorporates information relevant to these Directives

and Approvals.

To confirm the Approvals applying and if the product is

CE marked, check the serial number plate markings

and the Certification. (See section 9, Certification.)

1.3 Disclaimer

Information in these User Instructions is believed

to be reliable. In spite of all the efforts of Flowserve

Pump Division to provide sound and all necessary

information the content of this manual may appear

insufficient and is not guaranteed by Flowserve as

to its completeness or accuracy.

Flowserve manufactures products to exacting

International Quality Management System Standards

as certified and audited by external Quality Assurance

organizations. Genuine parts and accessories have

been designed, tested and incorporated into the

products to help ensure their continued product quality

and performance in use. As Flowserve cannot test

parts and accessories sourced from other vendors the

incorrect incorporation of such parts and accessories

may adversely affect the performance and safety

features of the products. The failure to properly select,

install or use authorized Flowserve parts and

accessories is considered to be misuse. Damage or

failure caused by misuse is not covered by the

Flowserve warranty. In addition, any modification of

Flowserve products or removal of original components

may impair the safety of these products in their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without

prior permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

If the conditions of service on your purchase order

are going to be changed (for example liquid pumped

temperature or duty) it is requested that the user

seeks the written agreement of Flowserve before

start up.

Page 4 of 36

Page 5

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety

markings where non-observance of an instruction

would cause hazards. The specific safety markings

are:

This symbol indicates electrical safety

instructions where non-compliance will involve a

high risk to personal safety or the loss of life.

This symbol indicates safety instructions where

non-compliance would affect personal safety and

could result in loss of life.

This symbol indicates “hazardous substances

and toxic fluid” safety instructions where noncompliance would affect personal safety and could

result in loss of life.

This symbol indicates safety

instructions where non-compliance will involve some

risk to safe operation and personal safety and would

damage the equipment or property.

This sign is not a safety symbol but indicates

an important instruction in the assembly process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the manufacturer/supplier

to provide applicable training.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant

safety requirements and applicable safety and health

laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

prevent injury to personnel and damage to the

environment and to equipment. For products

used in potentially explosive atmospheres

section 1.6.4 also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS OPERATIONAL

DRAIN THE PUMP AND ISOLATE

PIPEWORK BEFORE DISMANTLING THE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUORO-ELASTOMERS (When fitted.)

When a pump has experienced temperatures over

250 ºC (482 ºF), partial decomposition of fluoroelastomers (example: Viton) will occur. In this

condition these are extremely dangerous and skin

contact must be avoided.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment

is required when handling these components. To lift

heavy pieces above 25 kg (55 lb) use a crane

appropriate for the mass and in accordance with

current local regulations.

THERMAL SHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result

in damage or breakage of components and should

be avoided.

NEVER APPLY HEAT TO REMOVE

IMPELLER

Trapped lubricant or vapor could cause an explosion.

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators and

persons entering the immediate area action must be

taken to avoid accidental contact. If complete

protection is not possible, the machine access must

be limited to maintenance staff only, with clear visual

warnings and indicators to those entering the

immediate area. Note: bearing housings must not be

insulated and drive motors and bearings may be hot.

If the temperature is greater than 68 °C (155 °F)

or below -5 °C (23 °F) in a restricted zone, or

exceeds local regulations, action as above shall

be taken.

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate sitting of the pump, limiting personnel

access and by operator training. If the liquid is

flammable and/or explosive, strict safety procedures

must be applied.

Gland packing must not be used when pumping

hazardous liquids.

Page 5 of 36

Page 6

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

PREVENT EXCESSIVE EXTERNAL

PIPE LOAD

Do not use pump as a support for piping. Do not

mount expansion joints, unless allowed by

Flowserve in writing, so that their force, due to

internal pressure, acts on the pump flange.

ENSURE CORRECT LUBRICATION

(See section 5, Commissioning, startup, operation

and shutdown.)

START THE PUMP WITH OUTLET

VALVE PART OPENED

(Unless otherwise instructed at a specific point in the

User Instructions.)

This is recommended to minimize the risk of

overloading and damaging the pump motor at full or

zero flow. Pumps may be started with the valve

further open only on installations where this situation

cannot occur. Pump outlet valve shall may need to

be adjusted to comply with the duty following the

run-up process. (See section 5, Commissioning

start-up, operation and shutdown.)

1.7 Nameplate and safety labels

1.7.1 Nameplate

For details of nameplate, see the Declaration of

Conformity, or separate documentation included

with these User Instructions.

1.7.2 Safety labels

NEVER RUN THE PUMP DRY

INLET VALVES TO BE FULLY OPEN

WHEN PUMP IS RUNNING

Running the pump at zero flow or below the

recommended minimum flow continuously will cause

damage to the seal.

DO NOT RUN THE PUMP AT

ABNORMALLY HIGH OR LOW FLOW RATES

Operating at a flow rate higher than normal or at a

flow rate with no backpressure on the pump may

overload the motor and cause cavitations. Low flow

rates may cause a reduction in pump/bearing life,

overheating of the pump, instability and

cavitations/vibration.

1.6.4 Preventing the build up of explosive

mixtures

ENSURE PUMP IS PROPERLY FILLED AND

VENTED AND DOES NOT RUN DRY.

Ensure pump and relevant suction and discharge

pipeline system is totally filled with liquid at all times

during the pump operation, so that an explosive

atmosphere is prevented. In addition it is essential to

make sure that seal chambers, auxiliary shaft seal

systems and any heating and cooling systems are

properly filled.

If the operation of the system cannot avoid this

condition the fitting of an appropriate dry run

protection device is recommended (eg liquid

detection or power monitor).

Oil lubricated units only:

1.8 Specific machine performance

For performance parameters see section 1.5, Duty

conditions. When the contract requirement specifies

these to be incorporated into User Instructions these

are included here. Where performance data has

been supplied separately to the purchaser these

should be obtained and retained with these User

Instructions if required.

Page 6 of 36

Page 7

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

1.9 Noise level

Attention must be given to the exposure of

personnel to the noise, and local legislation will

define when guidance to personnel on noise

limitation is required, and when noise exposure

reduction is mandatory. This is typically 80 to 85

dBA.

The usual approach is to control the exposure time

to the noise or to enclose the machine to reduce

emitted sound. You may have already specified a

limiting noise level when the equipment was

ordered, however if no noise requirements were

defined, then attention is drawn to the following table

to give an indication of equipment noise level so that

you can take the appropriate action in your plant.

Pump noise level is dependent on a number of

operational factors, flow rate, pipework design and

acoustic characteristics of the building, and so the

values given are subject to a 3 dBA tolerance and

cannot be guaranteed.

Similarly the motor noise assumed in the “pump and

motor” noise is that typically expected from standard

and high efficiency motors when on load directly

driving the pump. Note that a motor driven by an

inverter may show an increased noise at some

speeds.

If a pump unit only has been purchased for fitting

with your own driver then the “pump only” noise

levels in the table should be combined with the level

for the driver obtained from the supplier. Consult

Flowserve or a noise specialist if assistance is

required in combining the values.

It is recommended that where exposure approaches

the prescribed limit, then site noise measurements

should be made.

The values are in sound pressure level LpA at 1 m

(3.3 ft) from the machine, for “free field conditions

over a reflecting plane”.

For estimating sound power level LWA (re 1 pW) then

add 17 dBA to the sound pressure value.

In areas where the staff has to intervene, remember

that when the level of the sound pressure is:

• Below 70 dBA: it is not necessary to take special

precautions.

• Above 70 dBA: people working continuously in

the machine room must be supplied with

protective devices against noise.

• Below 85 dBA: no particular measures need to

be taken for casual visitors staying in the room

during a limited period.

• Above 85 dBA: the room must be considered as

a dangerous area because of the noise and a

warning sign must be fixed at each entry

warning the people coming into the room, even

for a short period, that they must wear hearing

protection.

• Above 105 dBA: special hearing protection

adapted to this noise level and to the spectral

noise components must be installed and a

warning sign to this effect erected at each entry.

The staff in the room must wear ear protection.

Make sure that the noise, which travels through the

walls and windows, does not generate too high

noise levels in the machine room's surroundings.

In areas where the staff has to intervene, remember

that when the level of the sound pressure is:

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery and shipping

documents for its completeness and that there has

been no damage in transportation.

Note all reserves on the signed shipping note which

is given back to the hauler. Later, claims cannot be

accepted.

Check any crate, boxes and wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to

sidewalls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quotes this number in correspondence as

well as when ordering spare parts or further

accessories.

2.2 Handling

2.2.1 General instructions concerning handling

Boxes, crates, pallets or cartons may be unloaded

using forklift vehicles or slings dependent on their

size and construction.

To lift heavy pieces above 25 kg (55 lb), use a winch

adapted to the mass and in accordance with the

current local regulations.

To lift machines or pieces with one or several

suspension rings, only use hooks and chains in

compliance with the local regulations concerning

safety. Never put cables, chains or ropes directly on

or in the suspension rings. Cables, chains or lifting

ropes must never present excessive bending.

Page 7 of 36

Page 8

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

Never bend the lifting hooks, suspension rings,

chains, etc., which should only be made to endure

stresses within, calculated limits. Remember that the

capacity of a lifting device decreases when the

direction of the lifting force direction makes an angle

with the device axis.

To increase the safety and the efficiency of the lifting

device, all the lifting elements must be as

perpendicular as possible. If necessary a lifting

beam can be placed between the winch and the

load.

When heavy pieces are lifted up, never stay or work

under the load or in the area, which could be in the

path of the load if it were to swing or fall away.

Never leave a load hanging from a winch. The

acceleration or the slowing-down of lifting equipment

must stay in the safety limits for the staff.

A winch must be positioned in such a way that the

load will be raised perpendicularly. Where possible

necessary precautions must be taken to avoid the

swing of the load, using for example two winches

making approximately the same angle, below 30°,

with the vertical.

2.2.2 Pump masses

The masses of the pumps bare end of shaft are

shown on the nameplate.

All motors (for masses see the motor description

plate) must be handled with a winch.

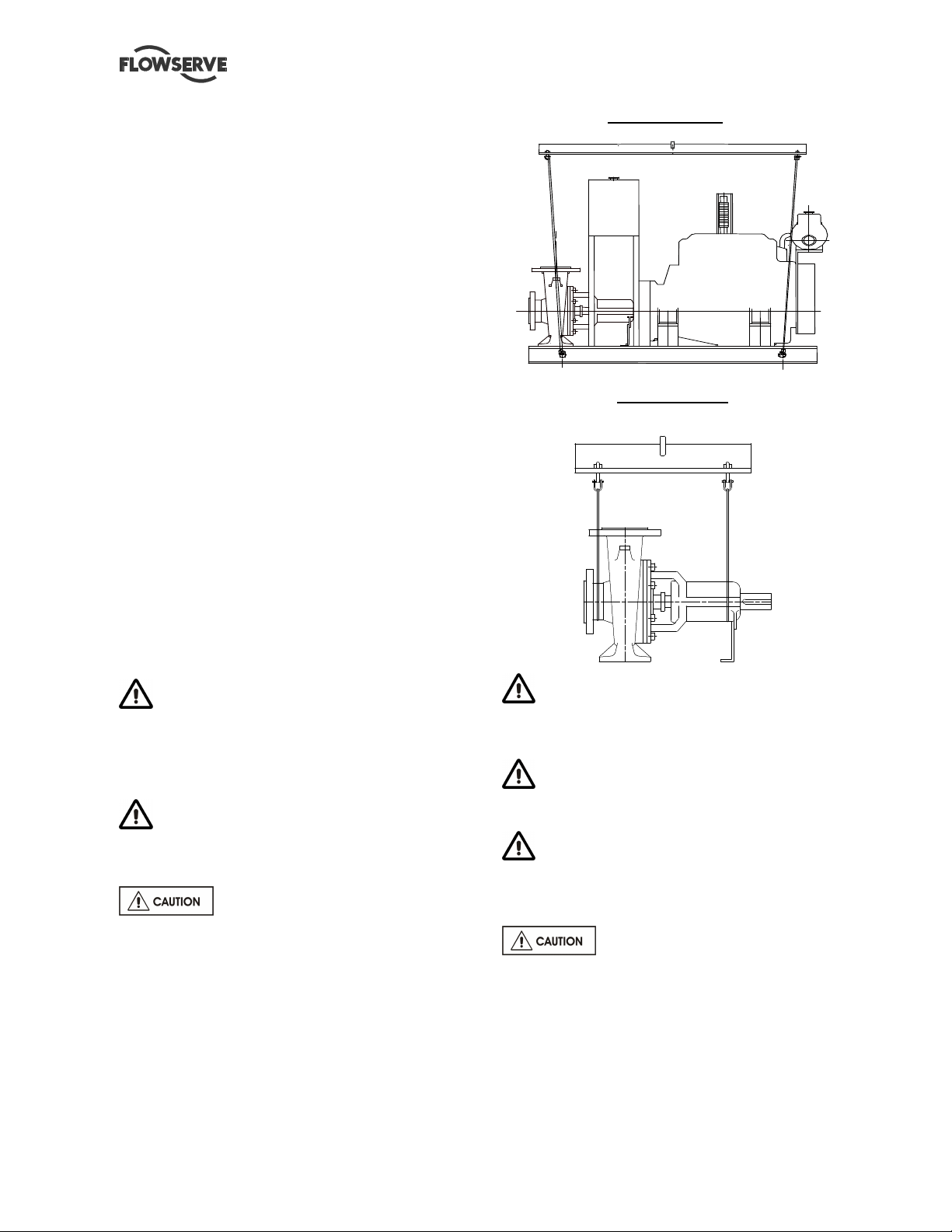

Motor pump unit

Bareshaft pump

For masses above 25 kg (55 lb), manual

handling is forbidden.

2.3 Lifting

2.3.1 Slinging of motor pumps units

Use handling means in accordance with motor

pump unit mass mentioned on the CE plate. For the

masses of the pumps bare end of shaft see table §

2.2.2 and nameplate.

To avoid distortion, the pump unit

should be lifted as shown.

Components weighing less than 25 kg (55 lb)

can be handled manually following the correct

actions and using the correct posture.

When handling always wear gloves, safety

boots and an industrial safety helmet.

For masses above 25 kg (55 lb), manual

handling is forbidden.

2.4 Storage

Store the pump in a clean, dry

location away from vibration. Leave piping

connection covers in place to keep dirt and other

foreign material out of pump casing. Turn pump at

intervals to prevent brinelling of the bearings and the

seal faces, if fitted, from sticking.

Do not store pumps starting on the fan guard.

The pump may be stored as above for up to 6

months. Consult Flowserve for preservative actions

when a longer storage period is needed.

Page 8 of 36

Page 9

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and local regulations. If the

product contains substances which are harmful to

the environment, these should be removed and

disposed of in accordance with current regulations.

This also includes the liquids and or gases in the

"seal system" or other utilities.

Make sure that hazardous substances or toxic

fluid are disposed of safely and that the correct

personal protective equipment is used. The safety

specifications must be in accordance with the

current regulations at all times.

3 PUMP DESCRIPTION

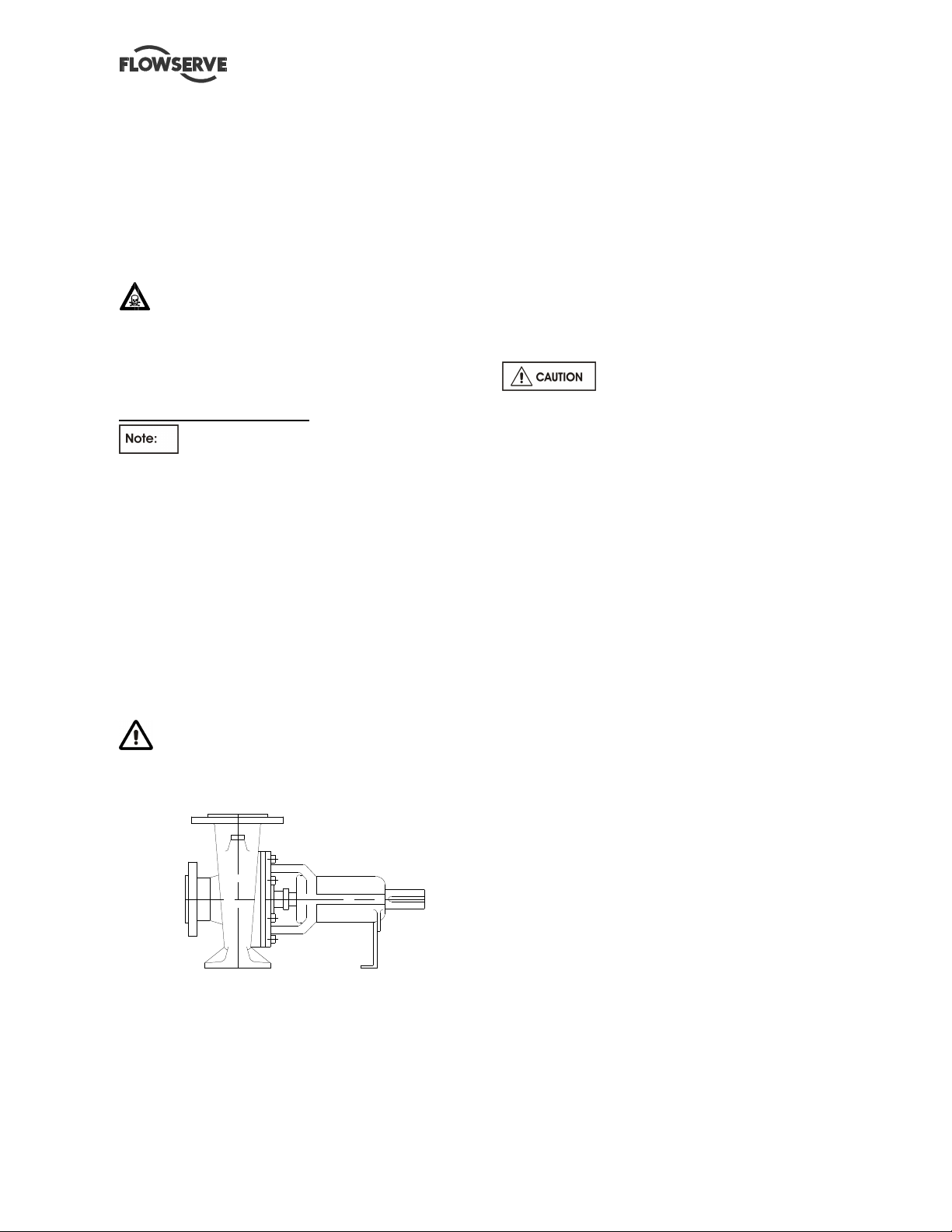

Refer to the standard instructions if the

pump used is different to that indicated below. In all

cases the liquid temperature is limited to 25 °C.

3.1 Configurations

This centrifugal pump unit is designed for the

pumping of water [taken from a clean, nonaggressive, particle-free water supply].

The MEN pump or MEN-TI or ME-TI or MHP is a

single stage centrifugal pump with an axial inlet and

a vertical outlet. The dimensions of the volute pump

casing of the suction and discharge diameters as

well as the settlement feet correspond to standards:

DIN 24225 and NF EN 733 (excepted ME-TI and

MHP).

* Maximum working pressure at discharge:

- MEN, MEN-T: 16 bars

- ME-TI 200-400, ME-TI 250-400, ME-TI 200-500,

ME-TI 250-500 Cast iron GL :12 bars

- ME-TI 200-400 and ME-TI 250-400

Cast iron GS :12 bars

- ME-TI 200-500, ME-TI 250-500

Cast iron GS :15 bars

- MHP : 16 bars

* Maximum working pressure at suction : 10 bars

* Maximum pumped fluid temperature : 90 °C

* Maximum solid suspension : 50 g/m3

* Density : 1

* Viscosity : 1 mm²/s

The nominal speed is shown on the

pump nameplate.

The pump must be stored in a non-explosive,

ventilated location, sheltered from bad weather, dust

and vibrations.

The reliability of the delivered machine can only be

ensured if it is used and serviced according to the

conditions given in this manual. The maximum

values specified in this manual must never be

exceeded.

Page 9 of 36

Page 10

®

Type kg Refer.

Q

Manuf. N

H m

t

emp. °C

Satndard

Type

Engine

Type

Q

m3/h

H m

%

P

KW

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

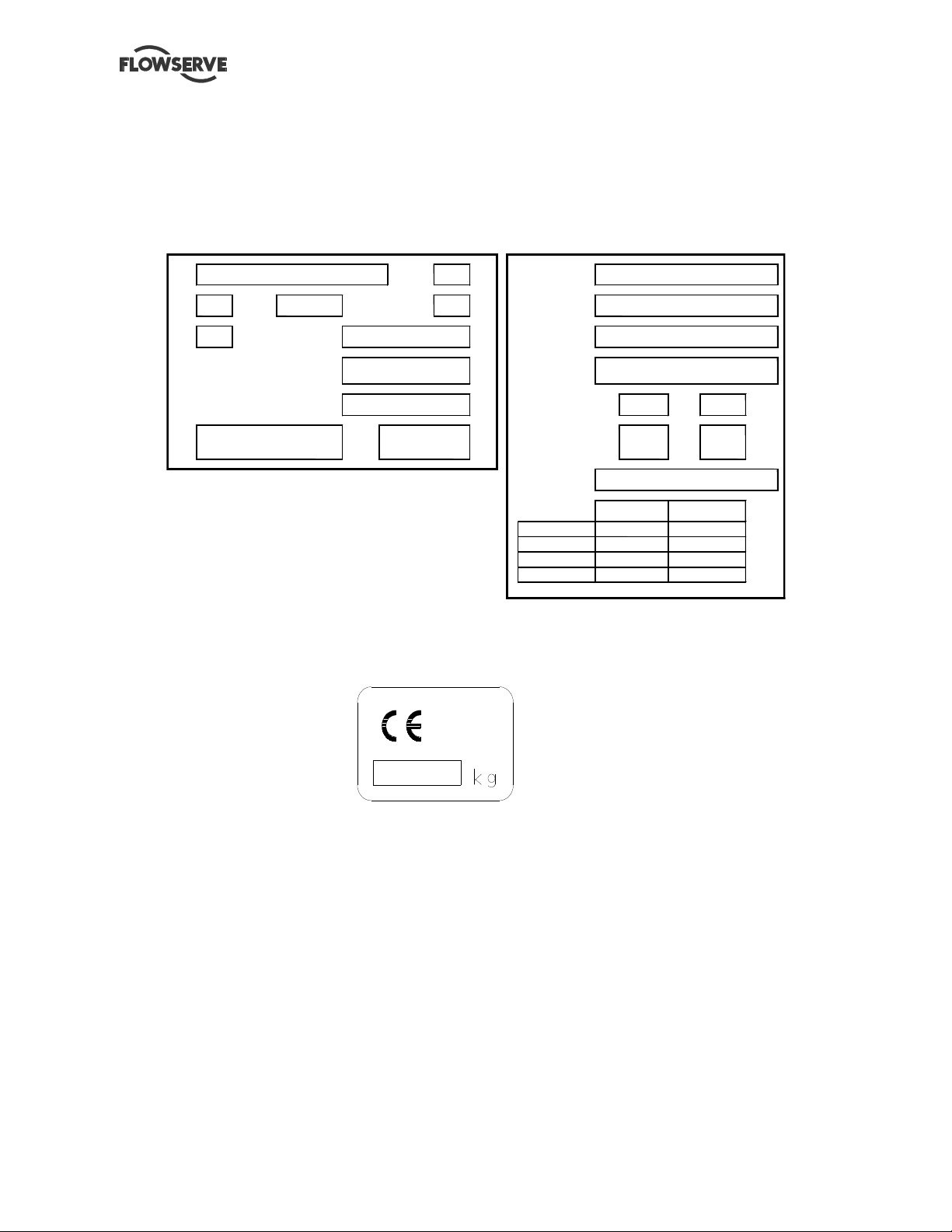

3.2 Nomenclature

Characteristics shown on the nameplate fixed on the pump are as shown below:

Each pump is supplied with the following nameplate:

Pump

m3/h

Max/min

Bearing

rad/thrust

Year +

Manuf. N

min-1 Max pr.

bar

Unit

Year +

Power Nom.

Power Max.

Pump Type

100%

KW for

KW for

min-1

min-1

130%

Each pump unit is supplied with the following nameplate:

Mass of the set:

Eff.

Page 10 of 36

Page 11

®

NF E 27 811

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

4 INSTALLATION

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection with

ample headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped, and

to the venting system.

Disconnect the switching enclosure support from the

pump support by removing the fastening bolts. The

switching enclosure support must be off-set with

respect to the pump motor base.

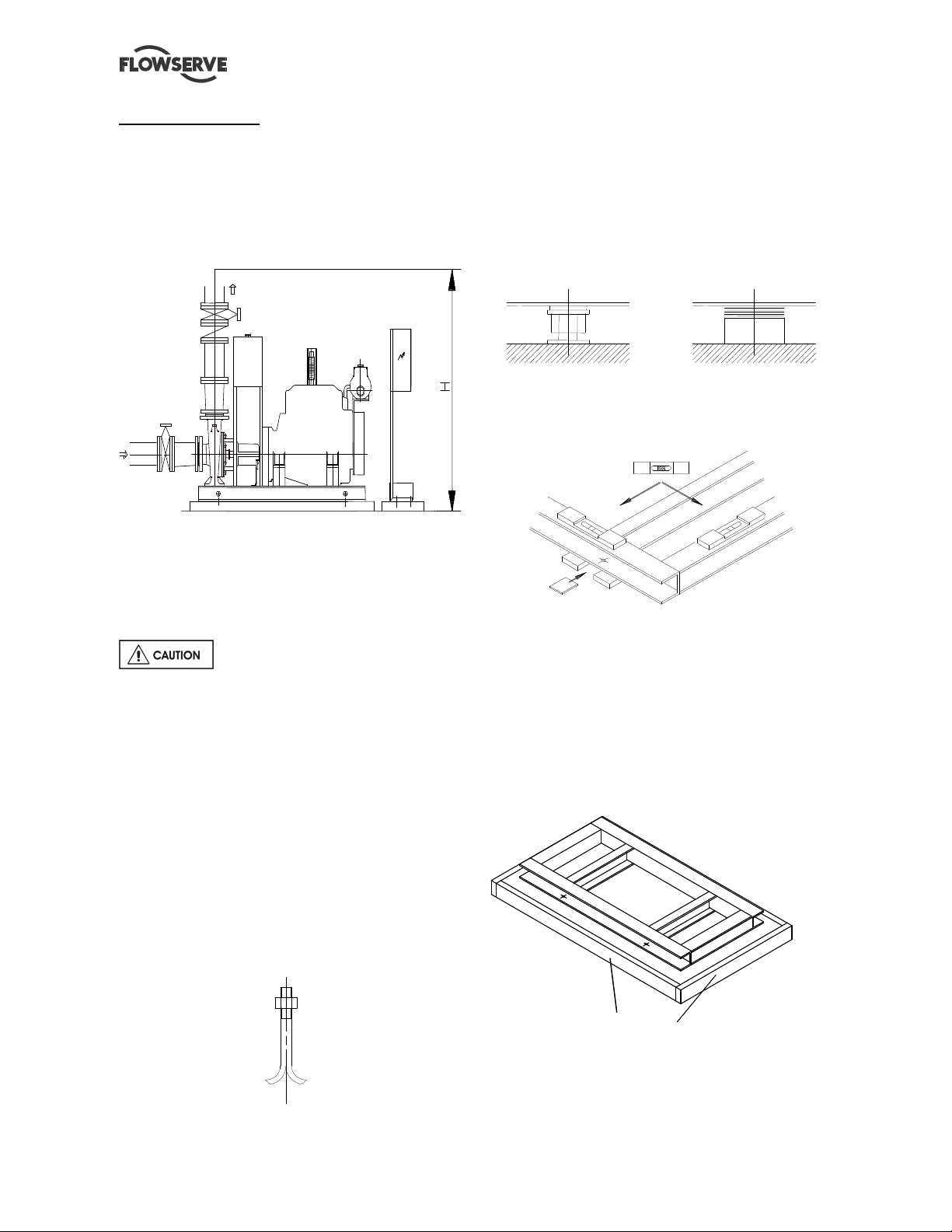

4.2 Foundation

There are many methods of installing

pump units to their foundations. The correct method

depends on the size of the pump unit, its location

and noise vibration limitations. Non-compliance with

the provision of correct foundation and installation

may lead to failure of the pump and, as such, would

be outside the terms of the warranty. The base plate

should be mounted onto a firm foundation, either an

appropriate thickness of quality concrete or sturdy

steel framework. It should NOT be distorted or pulled

down onto the surface of the foundation, but should

be supported to maintain the original alignment.

Anchor bolts must be in accordance with the foot

bolt holes. Use anchor bolts of accepted standards

and sufficient to ensure safe fitting in the foundation.

Particularly, this applies to individual plates where

the anchor bolts have to withstand the driving

torque.

Provide sufficient space in the foundation to

accommodate the anchor bolts. If necessary,

provide concrete risers.

4.2.1 Setting the base plate for anchoring

- Clean the foundation surface thoroughly.

- Put shims on the foundation surface (approx 20-25

mm thick), one on each side of the bolt hole (as an

alternative, leveling screws can be used).

- Lay the base plate and level in both directions with

extra shims. The base plate should be level to within

0.5 mm per 1 m.

If anchor bolts have been pre-cast in the foundation

slightly tighten the anchor bolts. Otherwise let them

hang in the foundation holes.

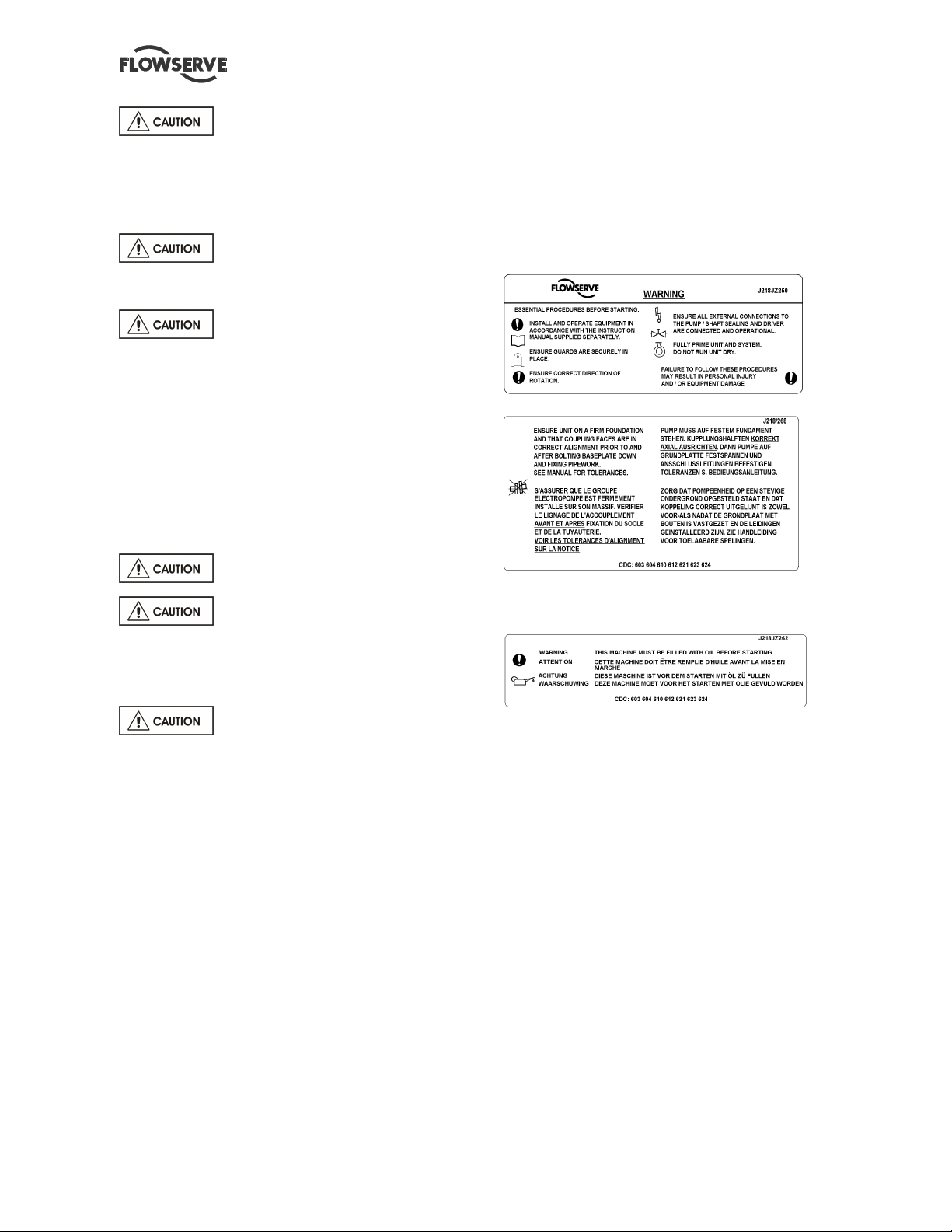

4.3 Grouting

4.3.1 Base plate grouting

Prepare the site for grouting. Before grouting clean

the foundation surface thoroughly and provide

external barriers as shown:

barriers

Prepare grouting product (concrete, resin) in

accordance with manufacturers' instructions.

Page 11 of 36

Page 12

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

Use grouting products with anti-shrinking

components.

- To grout up to the required level. Polish surfaces.

Take necessary precautions to avoid air bubbles.

- Lay-down the barrier, break external angles, and

polish the different surfaces.

- After grout starts to cure, definitively tighten

anchor bolts.

- Control the alignment such as described as

follows:

4.4 Initial alignment

4.4.1 Coupling assembly

4.4.1.1 Thermal expansion

The pump and motor will normally

have to be aligned at ambient temperature and

should be corrected to allow for thermal expansion

at operating temperature. In pump installations

involving high liquid temperatures, the unit should be

run at the actual operating temperature, shut down

and the alignment checked immediately.

4.4.1.2 Alignment methods

Ensure pump and driver are isolated

electrically; that the batteries and start-up shunt are

disconnected and the half couplings are

disconnected. Ensure that the pump piping, suction

and discharge, is disconnected.

The alignment MUST be checked.

Although the pump will have been aligned at the

factory it is most likely that this alignment will have

been disturbed during transportation or handling. If

necessary, align the motor to the pump, not the

pump to the motor.

Alignment

Parallelism and concentricity check

Operations to be carried out by

qualified FLOWSERVE employees only.

Check the alignment at three or four

points, before piping assembly.

with a rule with a comparator

Admissible margin for a motor with roller bearings:

= 0.15 mm parallel checking

= 0.1 mm angular checking

Angular checking:

with a sliding rule with a caliper gauge

The alignment will be definitive only

after piping connection (see § 4.5.1).

After alignment, the coupling protection cover

must be refitted.

If necessary, improve the machine alignment:

→

Complete unit mounted on common base plate:

The machines are first aligned accurately in our

workshops. Usually, any misalignment observed onsite is due to a wrong adjustment under the base

plate (disturbed during transport or because of

forces exerted by the piping). It is only necessary to

rectify the adjustment under base plate. If it proves

to be insufficient, modify the motor and/or the piping

and pump adjustment.

Page 12 of 36

Page 13

®

Reference A/B

Reference C/D

Reference A/B

Reference C/D

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

4.4.2 Drive shaft assembly

The battery must be disconnected. The distance

between the end of the pump shaft and the engine

flywheel must be 380 mm ± 5 mm. The pump and

diesel engine must be aligned once the cardan link

is fitted between the pump shaft and the engine

flywheel.

The maximum axial misalignment allowed between

the pump and the engine flywheel shaft is 9 mm ±

4.5 mm on each side of the shaft used as a

reference for alignment (see fig.1).

All that is required to align the pump and engine

drive shafts correctly is a measuring tape or ruler

graded in millimeters.

Alignment is checked as indicated below:

1) See fig.2

Place the marking A/B engraved on the surface of

the cardan link flange at the top in the vertical

position (12 o’clock).

Measure the distance X between the flange and the

outside of the cardan shaft (point A). This distance

must be 76 mm ± 3 mm.

With the cardan in the same position as above,

measure the distance Y between the flange and the

outside of the cardan shaft (point B). This distance

must be equal to the distance X ± 1mm.

2) See fig.3

Turn the cardan 90° and place markings C/D

engraved on the surface of the cardan link flange at

the top in the vertical position.

Measure the distance X1 between the plate and

outside of the cardan shaft (point A). This distance

must be 78 mm ± 1 mm.

With the cardan in the same position as above,

measure the distance Y1 between the flange and

outside of the cardan shaft (point B). This distance

must be equal to the distance X1 ± 1mm.

Alignment is achieved by moving and/or shimming

one or both of the elements.

Pump side

Pump side

Pump side

Pump side

The maximum misalignment

allowed between the pump and

engine axis is 9 mm ± 4.5 mm

Motor side

Motor side

on drive shaft

on drive shaft

flange

flange

Motor side

Motor side

on drive shaft

on drive shaft

flange

flange

Motor side Pump side

Motor side Pump side

4.5 Piping

Protective covers are fitted to the

pipe connections to prevent foreign bodies entering

during transportation and installation. Ensure that

these covers are removed from the pump before

connecting any pipes.

4.5.1 Suction and discharge piping

The dimensions of the pipes do not directly depend

on suction and discharge diameters of the pump:

a) First, choose a flow speed < 2 m/s at suction, and

about 3 m/s at discharge.

b) Take into account the available NPSH, which

must be superior to the required NPSH of the pump.

Never use pump as a support for piping. Do not

mount expansion joints in such a way that their

force, due to internal pressure, may act on the pump

flange.

Maximum forces and moments allowed on the pump

flanges vary with the pump size and type. These

external strains may cause misalignment, hot

bearings, worn couplings, vibrations and the

possible failure of the pump casing.

Page 13 of 36

Page 14

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

When designing the pipes (§ 4.5.2.1, § 4.5.2.2) take

necessary precautions in order not to exceed

maximum allowed strains.

Forces and moments applied to the pump flanges

must never exceed the values shown in the table

below.

If the pump used is different to that

indicated below, refer to the standard instructions

corresponding to this pump.

ME-TI

PUMP

150 160 200 180 310 45 60 80 110

200 215 265 240 415 85 100 125 180

Vertical 250 270 335 300 520 125 145 180 260

300 320 400 360 625 170 200 240 355

Discharge 350 375 465 420 730 220 255 310 455

400 430 530 480 835 275 320 390 570

450 485 600 540 940 340 390 480 705

500 540 665 600 1040 410 470 580 850

150 180 160 200 315 45 60 80 110

200 240 215 265 415 85 100 125 180

Horizontal 250 300 270 335 520 125 145 180 260

300 360 320 400 625 170 200 240 355

Suction 350 420 375 465 730 220 255 310 455

400 480 430 530 835 275 320 390 570

450 540 485 600 940 340 390 480 705

500 600 540 665 1040 410 470 580 850

PUMP

50-32-125 50 32 125 95 20

50-32-160 50 32 125 95 17

50-32-200 50 32 125 95 17

50-32-200L 50 32 125 95 17

65-40-125 65 40 135 100

65-40-160 65 40 135 100

65-40-200L 65 40 135 100

65-40-250 65 40 135 100

65-40-250L 65 40 135 100

65-50-125 65 50 135 100

65-50-160 65 50 135 100

65-50-200L 65 50 135 100

65-50-250L 65 50 135 100

80-65-125 80 65 145 105

80-65-160 80 65 145 105

80-65-200L 80 65 145 105

80-65-250L 80 65 145 105

80-65-315 80 65 145 105

100-80-160 100 80 180 125

100-80-200L 100 80 180 125

100-80-250L 100 80 180 125

100-80-315 100 80 180 125

125-100-200L 125 100 320 190

125-100-250L 125 100 330 200 102

125-100-315 125 100 310 185

125-100-315L 125 100 310 185

125-100-400 125 100 285 170

125-100-400L 125 100 285 170

150-125-250L 150 125 450 290 155

150-125-315L 150 125 415 260 140

150-125-400L 150 125 410 255 137

200-150-315L 200 150 500 325 175

200-150-400L 200 150 500 325 175

DN Force (daN) Moments (m.daN)

Flange Fy Fz Fx

DNA

Discharg

e

DNR

(mm)

Suction

(mm)

∑F

Force

(daN)

Fv

max

My Mz Mx

Moments

(mdaN) MEN –TI

Fh

Σ Mt max

max

22

22

20

25

25

22

22

20

25

27

27

27

27

27

47

47

47

47

95

92

92

82

82

∑M

Page 14 of 36

Page 15

®

Battery

Sufficient

immersion : I

I ≥ 3 x D

with glycerin bath

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

4.5.2.2 Design of a suction lift line

The inlet pipe must be as short and as direct as

possible, never place an elbow directly on the pump

inlet nozzle.

Forces and moments values are applied to the

whole flanges and not flange-by-flange. For their

sharing out on the pump flanges, refer to standard

NFCR 13 391.

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is

arranged to allow pump flushing before removal of

the pump.

4.5.2 Suction piping

4.5.2.1 Design of a flooded suction line

The suction line must be as short and direct as

possible, never mount an elbow directly on the inlet

flange of the pump.

Non return

valve

Valve

Switching

enclosure Tank

Non return

valve

Valve

Tank

Sump suction configuration

a) Avoid sharp elbows or sudden narrowing. Use

convergent ≤ 20° (total angle) with upright

generating.

b) Arrange that the suction piping is inclined

upwards towards the pump ensuring that there are

no peaks.

c) In case of frost risks, the piping in question has to

be marked out.

d) If a foot valve is necessary, do not oversize it

because it would generate pulsations (valve

beating).

Switching

enclosure

Diesel engine

Battery

Diesel engine

Flooded suction configuration

a) Avoid sharp elbows or sudden narrowing. Use

convergent ≤ 20° (total angle).

b) Arrange the piping so that there are no air

pockets (no bulges).

c) If high points cannot be avoided in suction line,

provide them with air relief cocks.

d) In case of frost risks, the piping in question has to

be marked out.

e) If a strainer is necessary, its net area should be

three or four times the area of the suction pipe.

f) If an inlet valve is necessary, choose a model with

direct crossing.

Do not tighten flanges before the final

check (see § 4.5.3).

Do not tighten flanges before the final

check (see § 4.5.3).

If necessary, a control manometer can be connected

on the piping.

Control manometer

(discharge) with

glycerin bath

Control manometer (suction)

Installation of control manometers Class I

Do not tighten flanges before the final

check (see § 4.5.3).

Page 15 of 36

Page 16

®

3 5 3 6

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

4.5.3 Final checks

a) Check the tightening of anchor bolts. Tighten

them if necessary.

b) Check that protective covers on suction and

discharge flanges are removed.

c) Check that holes of piping flanges are parallel and

correspond to those of the pump.

d) Tighten suction and discharge flanges.

e) Check the alignment pump-motor according to the

procedure § 4.4.2.

Rectify if necessary by adjusting the motor only!

f) If it is planned, connect piping (hydraulic,

pneumatic, sealing system).

g) Control seal and the working of auxiliary piping.

4.6 Electrical connections

Electrical connections must be made

by a qualified Electrician in accordance with relevant

local national and international regulations. This

includes any grounding.

It is important to be aware of the EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiring up and installing equipment on site. Attention

must be paid to ensure that the techniques used during

wiring/installation do not increase electromagnetic

emissions or decrease the electromagnetic immunity of

the equipment, wiring or any connected devices. If in

doubt, contact Flowserve for advice.

The installation comprises all appropriate safety

devices such as magnetic overload, current

overload, earth leakage relays, etc.... Ensure the

power supply corresponds to the power rating given

for the switching enclosure, i.e.: 5 kVA (220 V).

An electrical protection device shall be fitted.

Carry out the ground connections according to the

current local regulations.

4.7 Connection

Proceed with electrical connections to the terminals

in accordance with instructions 71576402 01-06.

Connect the switching enclosure to the mains power

supply and check the supply voltage on terminals 39

and 40 (220 V single-phase).

Connect the start-up signal wires:

Double terminal n° 11: pressure switch N° 1. B-

contacts of these pressure switches must be

potential free.

Double terminal n° 12: pressure switch N° 2.

Actual recommendations require the startup signal contact to be open-started. All delivered

units meet this requirement.

Information regarding the cabinet:

Sensor connection at recovery tank level on #15

double terminal. The contact will be opened in case

of lack of water in the main tank and potential free.

Opening the circuit controlling the

primer tank starts the engine.

Options:

Sensor connection at the bottom of the primer tank

on #16 double terminal. The contact will be opened

in case of lack of water at the bottom of the primer

tank and is potential free.

Sluice blade or ventilation damper connection on

#43 and 44 double terminal (220 V servomotor).

Sluice blade opening limit connection on #15 double

terminal. The contact will be closed when ventilation

sluice blades are open and potential free.

Alarm report:

All alarm reports are proposed on 2 changeover

contacts (A and B) by 2 triple terminals.

Connection of running data motor on terminals

n° 35 and n° 36

1 0 4 1 0 7

1 0 5 1 0 8

1 0 6 1 0 9

A B

Manual connection of switching fault data on

terminals n° 33 and n° 34

A B

9 8 1 0 1

9 9 1 0 2

1 0 0 1 0 3

3 3 3 4

Page 16 of 36

Page 17

®

3 0 3 1

28

29

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

Connection of general fault data on terminals n° 30

and n° 31

8 9 9 2

9 0 9 3

9 1 9 4

A B

Information connection Failure risk on n° 28 and n°

29 terminals

83 8 6

8 4 87

85 8 8

A B

Information connection

No start-up on n° 37 and n° 38 terminals

1 1 1

A B

1 1 0

1 1 2

3 7 3 8

1 1 4

1 1 3

1 1 5

4.8 Batteries

The lead-cell batteries are supplied "dry charged".

Switch off the "AUTO-STOP-MANUAL" key switches

on the front panel of the switching enclosure.

Electrolyte is supplied by FLOWSERVE separately

in 1.7-litre plastic containers.

Electrolyte is a sulphuric acid-based liquid.

Appropriate protective clothing must be worn during

handling. Avoid any contact with skin or clothing. In

case of splashing, rinse thoroughly with running

water (in case of contact with eyes, consult a doctor

immediately).

Prepare the batteries 1 week before commissioning.

Fill the batteries with electrolyte up to the maximum

fill level indicated with a line in the top section of the

battery.

The cables must not be exposed to oil, diesel or acid

splashing and should be run accordingly.

Check that the batteries are connected to the right

poles and securely fastened (++ and --).

4.9 Switching on

The pump unit is supplied with the starter solenoid

disconnected to avoid accidental start-up of the

diesel engine during commissioning preparation

work.

Reconnection may only be carried out by an

employee qualified by FLOWSERVE, after

examination before start-up.

The unit may only be switched on by an employee

qualified by FLOWSERVE.

- Place the operating mode selector switch in the

"Off" position.

- Close the switching terminals 5 and 6.

- Close fuse holders F1 to F4 and the circuit-breaker

DD1.

A siren sounds when these electrical

circuits are closed, press the "Siren off" and "cancel

fault" push-buttons.

- Close the main circuit-breaker.

- The following indicators white/power on,

green/electronics on, green/ charge batteries 1 or 2

and orange/non-auto, must be on.

4.10 Charge starter batteries

Both batteries are connected independently and

alternatively to a self-regulated battery charger.

A possible charge fault is signaled by the "Charger 1

or charger 2 fault" indicator on the front panel of the

enclosure, with activation of a local audible alarm

signal and tripping of the general fault contact.

Each charger supplies the corresponding battery

with a variable charge current in accordance with the

battery charge level.

- Keep a bottle of distilled water available for topping

up of electrolyte level.

The battery voltage selector switch enables

monitoring of the battery voltage with charger supply

interrupted.

4.11 Final shaft alignment check

Check the alignment pump-motor according to the

procedure § 4.4.2.

Rectify if necessary by adjusting the motor only!

- If it is planned, connect piping (hydraulic,

pneumatic, sealing system)

- Control seal and the working of auxiliary piping.

Page 17 of 36

Page 18

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

4.12 Protection systems

If leakage of product from the pump or its associated

sealing system can cause a hazard it is

recommended that an appropriate leakage detection

system is installed.

To prevent excessive surface temperatures at

bearings it is recommended that temperature or

vibration monitoring are carried out.

4.13 Other check

See § 6.2

5 COMMISSIONING, START-UP,

OPERATION AND SHUTDOWN

These operations must be carried out by

fully qualified personnel. The operator must

monitor the machine as long as it is in operation.

5.1 Guarding

Guarding is supplied fitted to the pump set.

If this has been removed or disturbed ensure that all

the protective guards around the pump coupling and

exposed parts of the shaft are securely fixed.

5.2 Priming and auxiliary supplies

Ensure all electrical, hydraulic,

pneumatic, sealant and lubrication systems (as

applicable) are connected and operational.

Check that the supply pressures are

compatible with the equipment to be supplied.

The discharge pipe is headed and there is a by-pass

valve on the check valve, open slightly the discharge

valve.

When the pump is totally free of air bubbles, replace

the plugs.

Air escape

Fit a 1-inch pipe to enable

cooling of the combustion

engine

Priming of a flooded pump

5.2.2 Priming of a sump suction pump

Installation of a foot valve is imperative.

Fill the pump and suction pipe with liquid via the

priming tank.

Let air escape by removing the plugs located on the

piping.

When the pump is totally free of air bubbles, replace

the plugs.

Ensure the inlet pipe and pump

casing are completely full of liquid before starting

Priming tank

continuous duty operation.

5.2.1 Priming of a flooded pump

Air escape

Close the discharge valve, fill the pump by opening

the suction valve. Let air escape by removing the

plug located on the piping.

Fit a 1-inch pipe to enable

cooling of the combustion

engine

Priming of a sump suction pump

Page 18 of 36

Page 19

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

5.3 Starting the pump

5.3.1 Bring controls and preparation before the

first starting and after each service call

Necessarily:

Check the tightening of the different plugs.

Check that the gland lightly tightens the packing

rings.

Risk of seal ring overheating.

If a mechanical seal is fitted, refer to the

standard pump instructions.

5.3.2 Start the pump and diesel engine

This initial start-up of pump and diesel

engine may only be carried out by a qualified

FLOWSERVE employee.

A noise protection helmet must be worn by all

persons present in the vicinity.

Suction valves must be fully open

when pump is running. Never run the pump dry, it

will cause damage.

*Close the valve at discharge

* Start up the diesel engine and check the discharge

pressure.

If pressure is satisfactory, slowly OPEN the outlet

valve.

Do not run the pump with the outlet valve closed

during initial start-up and after each maintenance

intervention.

If NO pressure, or LOW pressure, STOP the pump.

Refer to fault finding chart for fault diagnosis.

5.3.2.1 Starting the diesel engine

→ Initial start-up:

* Start the plant at moderate speed with push

buttons to emergency start-up position 1 or 2.

* Check that the oil pressure indicated on the

switching enclosure pressure gauge complies with

the values given in the engine manual. If the oil

pressure indicated on the pressure gauge is low with

respect to these instructions, place the switch in the

“Off” position and stop the engine using the direct

stop control indicated "STOP" located on the

injection pump until the engine is entirely at

standstill.

→ Check engine cooling system:

* Check that the water in the primary cooling circuit

is flowing freely (evacuation of lost water, discharge

from heat exchanger), it must be possible to see and

feel this flow.

* Water flow must be visibly unrestricted on the

pump discharge side, with no shut-off elements

incorporated. This discharge generally occurs at

35/45 °C.

* Cooling water flow-rate is limited by an adjustable

throttle to obtain a flow-rate of approximately 30

liters/hour per kW.

* New circuits often contain impurities which may

quickly clog the protection filter. If the raw water flow

decreases, simply remove the filter and clean it until

the circuit is clean. This operation is to be repeated.

* The manual by-pass on the cooling circuit main

pipe is only used to ensure cooling, if necessary,

when the plant cannot be shut-down during an

intervention on the raw water filter or the hydraulic

valve.

ENSURE THE RAW WATER FILTER ON THE

MAIN COOLING CIRCUIT IS WEEKLY CLEANED.

→ Checks and adjustments:

* Progressively increase the engine speed until the

setting limiter is attained. This limiter is set to obtain

an off-load speed of 50 to 100 rpm above nominal

speed in order to compensate for approximately 5 %

motor slip between off-load and full-load engine

speeds.

* With the plant running normally, progressively

open the pump discharge valve until the specified

performance is attained.

* Check the water temperature with the thermostat

on the switching enclosure; this is only attained

progressively, especially at low pump flow-rate.

If the temperature is above 95 °C, turn the selector

switch to “Off” and activate the switch-off control

marked STOP.

In the beginning, when on load, the new

plant sometimes emits exhaust smoke after

start-up. This is perfectly normal and quickly

disappears. Allow sufficient air circulation

during initial start-up (work with doors open),

and/or wear a protection mask.

The switching enclosure is designed to detect and

signal certain anomalies.

→ When running:

* Oil pressure too low

* Overheating

Page 19 of 36

Page 20

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

If one of these faults occurs, the alarm is triggered

and signaled by:

- activation of the siren;

- illumination of the corresponding indicator;

- repeated signal on the terminal for transmission.

However, a fault does not stop the plant.

Immediate intervention is required to remedy the

fault.

- The siren may be switched off by pressing the

push-button "STOP SIREN". This operation does not

cancel the siren if the fault signal is present at the

alarm terminal.

- Turning the rotary key switch "CANCEL FAULT"

remains ineffective as long as the fault persists and

resets the audible alarm signal.

→ Simulation of faults:

The safety devices may be checked by simulating

faults:

a) Excess water temperature fault simulation by

circuit opening between 55 wires and grounds.

b) Oil pressure low by circuit opening between 35

and 56 wires. [No oil pressure by circuit opening

between wires 035 and 56] if the engine is at

standstill and by circuit closing (035 and 56) when

the engine is running.

Water temperature fault function is activated only

after an initial time period of approximately 10

seconds.

Oil pressure fault function is efficient only after an

initial time period of approximately 1 minute.

→ Check room ventilation:

Ensure that room ventilation is correct by

incorporating top and bottom air vents as standard

practice. These vents must each have a minimum

size of 0.5 m².

Engine overheating is generally due to:

- defective engine and/or room cooling,

- an exhaust pipe of insufficient diameter,

- non-standard utilization of the plant, in excess of its

design characteristics.

- insufficient room ventilation

The temperature read on the thermometer located

on the front panel of the switching enclosure must

be stable between 70 and 90 °C when the plant is

on-load and conform to nominal characteristics

indicated in the specifications.

If the cooling water temperature rises above this

threshold value, an audible alarm is triggered and a

light indicator switches on.

Do not run the pump at zero flow-rate for more

than 10 minutes as this will heat up the cooling

water intended to cool the engine.

After approximately one hour of operation, the plant

may be switched off by pressing the control button

marked STOP.

ACTION MAINTAINED UNTIL TOTAL

STANDSTILL OF THE ENGINE.

→ Automatic start-up pressure switch n °1 :

With the selector pressure switch n° 1 in the "AUTO"

position and selector pressure switch n° 2 on stop,

the contact given by one of the control pressure

switches provokes immediate start-up of the plant at

the set nominal speed.

* Supervision of start-up sequence

The engine should normally start up first time.

However, to overcome an anomaly such as:

- Low batteries, pump packing gland too tight

- No fuel

- Slight presence of air in the fuel circuit

- Engine and room insufficiently heated during cold

weather

The automatic system is designed to energize the

starter motor with 8-second impulses from each set

of batteries alternatively.

The standard setting is 4 impulses of 8 seconds with

a rest period of 3 seconds between each impulse.

At the end of a complete cycle, if the engine has not

started, the alarm "FAIL START" is triggered,

followed by:

- Activation of the siren

- Illumination of the "Fail start" indicator

- Repeated signal at the terminals for transmission.

The operator informed may attempt a manual start

by pressing the "EMERGENCY START" pushbutton.

→ Automatic start-up pressure switch n °2:

Same automatic start-up procedure with pressure

switch n °1 but in the reversed order.

* Simulation of a start-up sequence

It can be done by any of both selector pressure

switch n °1 and n° 2.

The first pressure switch contact to be opened will

initiate its start-up sequence.

To check the start-up sequence, a simulation may

be carried out in which the injection is blocked by

pressing and holding the stop control while the plant

is in "AUTO" mode and the contact of a pressure

switch is closed (pressure drop in the network).

Page 20 of 36

Page 21

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

NOTE: The "FAIL START" alarm is cancelled by:

- Pressing the "STOP SIREN" push-button

- Pressing the "CANCEL FAULT" turn-key switch

This operation also resets the automatic cycle.

All pressure switches have a differential

pressure. The contact triggered by a drop in

pressure is only re-established when this pressure

returns to a value greater than the pressure switch

set value.

→ Battery fault:

At standstill:

The plant comprises a starter battery voltagemonitoring device. If the battery voltage is not in the

required range, the battery fault is triggered,

followed by:

- illumination of the corresponding indicator for

battery 1 or battery 2,

- repeated signal on the terminals for transmission.

However, the plant continues to operate on the other

battery.

→ Technical room temperature control (optional):

A technical room temperature inferior to + 10 °C

lights up the "TEMPERATURE LOCAL

SPRINKLER" red LED and activates the siren and

the "FAILURE RISK" relay.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

→ Ventilation sluice blade control:

The ventilation sluice blade correct opening control

is in service after motor start-up and activates the

"VENTILATION SLUICE BLADE" red LED. The siren

and the "FAILURE RISK" relay are activated if the

sluice blade opening is not correct only after an

initial time period of approximately 10 seconds.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

→ Starter cabinet electric connection control:

A cut-off in the wiring between the cabinet and the

starter solenoid lights up the "CABINET STARTER

CONNECTION" red LED and activates the siren and

the "FAILURE RISK" relay.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

This fault is present only 1min30sec after start-up

attempt.

→ Recovery tank level control:

In case of insufficient water level in the recovery

tank, the "RECOVERY TANK LEVEL" LED lights up

and the siren and the "FAILURE RISK" relay are

activated.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

→ Filter clogging control (optional):

In case of raw water filter clogging or in case of

engine temperature increase (independently from

the water temperature alarm), the "FILTER

CLOGGING" red LED lights up and the siren and the

"FAILURE RISK" relay are activated.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

→ Diesel level control:

In case of low diesel level in fuel tank, the "DIESEL

LOW" LED lights up and the siren and the "FAILURE

RISK" relay are activated.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

→ Engine water reheating control:

When the engine water reheating protection circuitbreaker or reheating button are switched off, a red

"ENGINE REHEATING" light indicator, audible alarm

and "GENERAL FAULT relay are triggered

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

Page 21 of 36

Page 22

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

When the engine is operating, the engine water

reheating is inhibited.

Mains cut-off lights up the reheating fault LED.

→ Engine water level control:

In case of low cooling water level in the engine, the

"ENGINE WATER LEVEL" red LED lights up and the

siren and the "FAILURE RISK" relay and plant

start-up are activated.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

→ Priming tank level control (optional):

In case of low water level in priming tank, the

"PRIMING TANK LEVEL" red LED lights up and the

siren and the "FAILURE RISK" relay are activated.

The unit then starts.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

Check that the priming tank level is correct and stop

the unit using the STOP handle on the engine.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm and

restarts the motor pump if the level is not correct.

→ Control of pressure switch line:

In the case of a short circuit on the pressure switch

connection cables, the warning light "Pressure

Switch Line" lights up, and the alarm and "Risk of

failure" relay are activated.

The siren can be stopped by pressing the "STOP

SIREN" pushbutton. But this does not clear the fault

which is reported on the alarm base station.

The "CLEAR DEFAULT" turn-key button is not

working as long as the fault is present. If it is

activated, it re-initiates the audible alarm.

Page 22 of 36

Page 23

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

→ Local signalization table:

Green Live electronics Live electronic circuits (at least one of both power sources is

x Yellow x Mains shortage Pre-heating and charger electric circuits are not powered by

Green Battery 1 loading or Battery 2 loading Shows that corresponding battery is loading (1 LED per battery)

x Yellow x Charger 1 fault or Charger 2 fault Shows that corresponding battery charger does not deliver the

x Yellow x Battery 1 fault or Battery 2 fault Shows that corresponding battery cannot assume its function (1

x Red x Cabinet-starter connection Cabinet-starter connection non guaranteed

x Green Motor in operation Shows that the pump is operating

Green Pressure switch 1 start-up Shows that the pump has been started by pressure switch 1 or

Yellow Pressure switch 2 start-up Shows that the pump has been started by pressure switch 2 or

Green Auto position Pressure switch 1 or 2 controller is in automatic mode [element

x Red Non auto position Pressure switch 1 or 2 controller is on STOP or MANUAL

x Red x Not started Shows that the pump did not start automatically at the end of the

x Red x Water temperature Shows that cooling water temperature exceeds its limit (engine

x Red x Filter clogging (optional) Shows a filter clogging [indicates that the heat-exchanger circuit

x Red x Oil pressure Shows an insufficient oil pressure

x Red x Diesel level Shows an insufficient diesel level

x Red x Engine reheating Shows that the preheating system is out of service

x Red x Engine water level Shows an insufficient tank water level

x Red x Recovery tank water level Shows an insufficient level in the recovery or secondary tank

x Red x Priming tank level (optional) Shows an insufficient water level in the priming tank (for sump

x Red x Local sprinkler temperature Shows that temperature is < 8°C in the local sprinkler water tank

x Red x Ventilation sluice blades (optional) Shows that the ventilation sluice blades in the source room are

x Red x Pressure switch lines Shows that a short circuit between the cables of the pressure-

Non auto position switch fault

General fault

Failure risk

Not starting

Motor in operation

LED color

Audible alarm

Description Meaning

present)

mains anymore (180s delay)

necessary voltage at output during loading period (1 LED per

charger) or that the mains power supply is absent.

LED per battery)

that the start-up sequence in progress was initiated by pressure

switch 1

that the start-up sequence in progress was initiated by pressure

switch 2

controlled with the corresponding pressure switches 1 or 2, in

automatic mode]

position [element controlled with the corresponding pressure

switches 1 or 2 and STOP position or MANUAL mode]

start-up sequence

overheating)

water filter is clogged]

suction pumps) and triggers an engine start-up.

not opened when diesel engine is operating

switch

* No red or yellow indicators may be on when the operator leaves the room.

Page 23 of 36

Page 24

®

MEN USER INSTRUCTIONS ENGLISH 71576288 – 11-09

5.3.2.2 Putting into service:

After completion of these checks and tests, the plant

may be put into service:

- Turn the selector switch to the "AUTO" position

- Valves of the cooling circuit locked in the open

position and the discharge valve of the pump

positioned.

- Check all fill levels.

- Power-on displayed with light indicator.

5.3.2.3 Plant maintenance and servicing:

Once a week, check the voltage and electrolyte level

of each battery; the water level of the internal

cooling circuit, the engine oil fuel tank levels.

Respect all instructions given in the pump and

engine manuals, as well as the regulations R1 given

in appendix IV of the APSAD.

Do not run the pump with the outlet valve closed for

a period longer than 10 minutes.

If NO pressure, or LOW pressure, STOP the pump.

Refer to fault finding chart for fault diagnosis.

The pump must never run at a capacity of less than

40 % of that at the best efficiency for a longer

period.

5.4.1 Pump fitted with a stuffing box

If the pump has a packed gland there must be some

leakage from the gland. Gland nuts should initially

be finger-tight only. Leakage should take place soon

after the stuffing box is pressurized. If no leakage

takes place the packing will begin to overheat. If

overheating takes place the pump should be

stopped and allowed to cool before being re-started.

When the pump is re-started it should be checked to

ensure leakage is taking place at the packed gland.

The pump should be run for ten minutes with steady

leakage and the gland nuts tightened by 10 degrees

at a time until leakage is reduced a steady thin

continuous stream is acceptable. The temperature of