Page 1

®

ELECTRIC CHAIN SAW FKS 2200 F3

ELECTRIC CHAIN SAW

Translation of the original instructions

ELEKTRICKÁ ŘETĚZOVÁ PILA

Překlad originálního provozního návodu

ELEKTRO-KETTENSÄGE

Originalbetriebsanleitung

IAN 280275

ELEKTRIČNA VERIŽNA ŽAGA

Prevod originalnega navodila za uporabo

ELEKTRICKÁ REŤAZOVÁ PÍLA

Preklad originálneho návodu na obsluhu

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Pred branjem odprite stran s slikami in se nato seznanite z vsemi funkcijami naprave.

Před čtením si otevřete stranu s obrázky a potom se seznamte se všemi funkcemi přístroje.

Pred čítaním si odklopte stranu s obrázkami a potom sa oboznámte so všetkými funkciami prístroja.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

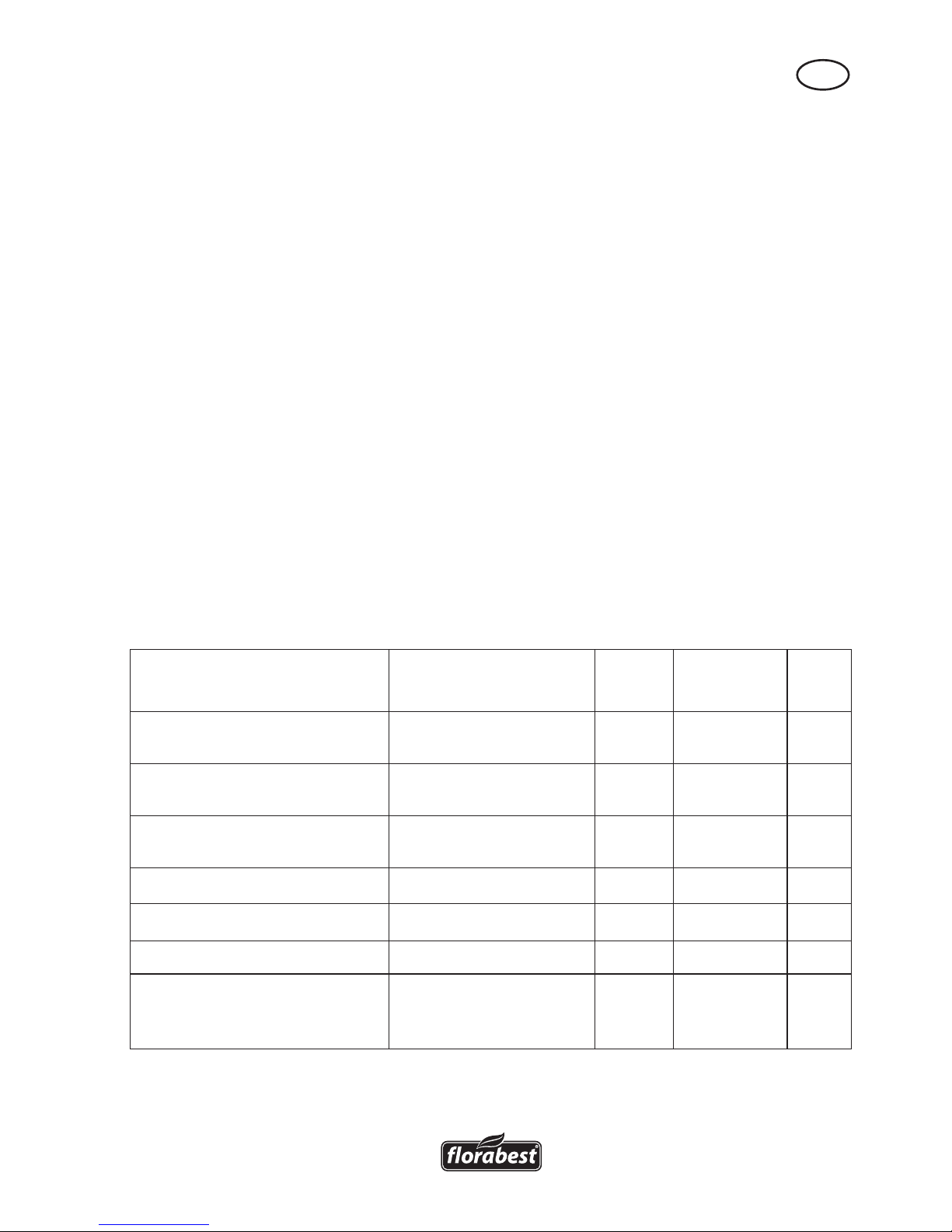

GB Translation of the original instructions Page

SI Prevod originalnega navodila za uporabo Stran

CZ Překlad originálního provozního návodu Strana

SK Preklad originálneho návodu na obsluhu Strana

DE / AT / CH Originalbetriebsanleitung Seite

5

29

53

77

102

Page 3

3

C

1 2 3

5 6

7

A

10 1198

13

13

14

14

17

18

19

B

2

4

12

16

15

3

8

20

21

22

Page 4

4

R

N

S

Q

P

O

M

L

K

1

2

1

2

3

Page 5

5

G B

The operating instructions constitute

part of this product. They contain

important information on safety, use

and disposal.

Before using the product, familiarise

yourself with all of the operating

and safety instructions. Use the

product only as described and for

the applications specied. Keep this

manual safely and in the event that

the product is passed on, hand over

all documents to the third party.

Content

Introduction .................................5

Intended purpose .........................6

General description ......................6

Extent of the delivery.......................6

Overview ......................................6

Function description ........................7

Technical Data ..............................7

Notes on safety............................8

Symbols used on the saw ................8

Symbols used

in the instructions ............................9

General notes on safety...................9

General safety instructions for power

tools .............................................9

Causes and operator ...................13

prevention of kickback ..................13

Further safety directions .................13

Safety functions ............................14

Assembly ...................................14

Mount the saw chain.....................14

Mount the saw bar .......................15

Tensioning the saw chain ...............15

Chain lubrication ..........................16

Operating the chainsaw .............16

Switching on ................................16

Checking the chain brake .............17

Checking the chain ......................17

lubrication ...................................17

Changing the saw bar ..................17

Sawing techniques .....................18

General.......................................18

Felling trees .................................18

Limbing ......................................19

Bucking .......................................20

Maintenance and cleaning .........20

Cleaning .....................................21

Maintenance intervals ...................21

Maintenance Interval Table ............21

Oiling the saw chain .....................22

Sharpening the saw chain .............22

Adjusting the chain tension ............23

Starting up a new saw chain .........23

Maintaining the chain bar .............23

Turn the chain bar.........................23

Waste disposal and environmental

protection ..................................24

Replacement parts/Accessories ..25

Trouble shooting ........................26

Guarantee .................................27

Repair Service ............................28

Service-Center ............................28

Importer ....................................28

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product. During production,

this equipment has been checked for qual-

ity and subjected to a nal inspection. The

functionality of your equipment is therefore

guaranteed. It cannot be ruled out that residual quantities of water or lubricants will

remain on or in the equipment/hose lines

in isolated cases. This is not a fault or defect and it represents no cause for concern.

Translation of the original

EC declaration of conformity ....130

Exploded Drawing ................... 136

Page 6

6

G B

Intended purpose

The electric chainsaw is constructed for

sawing wood only. The saw is not designed for any other types of application

(e.g. cutting of brickwork, plastic or food).

The chainsaw is designed for employment

in the do-it-yourselfer sector. It was not

designed for continuous employment in the

commercial sector.

The device is designed for use by adults.

Young people over 16 years old may use

the chainsaw under supervision only.

The manufacturer is not liable for damages, which were caused through use in

applications for which it was not designed,

or incorrect operation.

This electric chainsaw is to be used only

by one person and only for sawing wood.

The chainsaw must be held with the right

hand on the rear handle and the left hand

on the front handle. Before use, the user

must have read and understood all of the

information and directions in the operating

instructions. The user must wear appropriate personal protective equipment (PPE).

The chainsaw is to be used only for sawing

wood. Materials such as plastic, stone,

metal or wood containing foreign objects

(e.g. nails or screws) must not be cut with

the chain saw!

General description

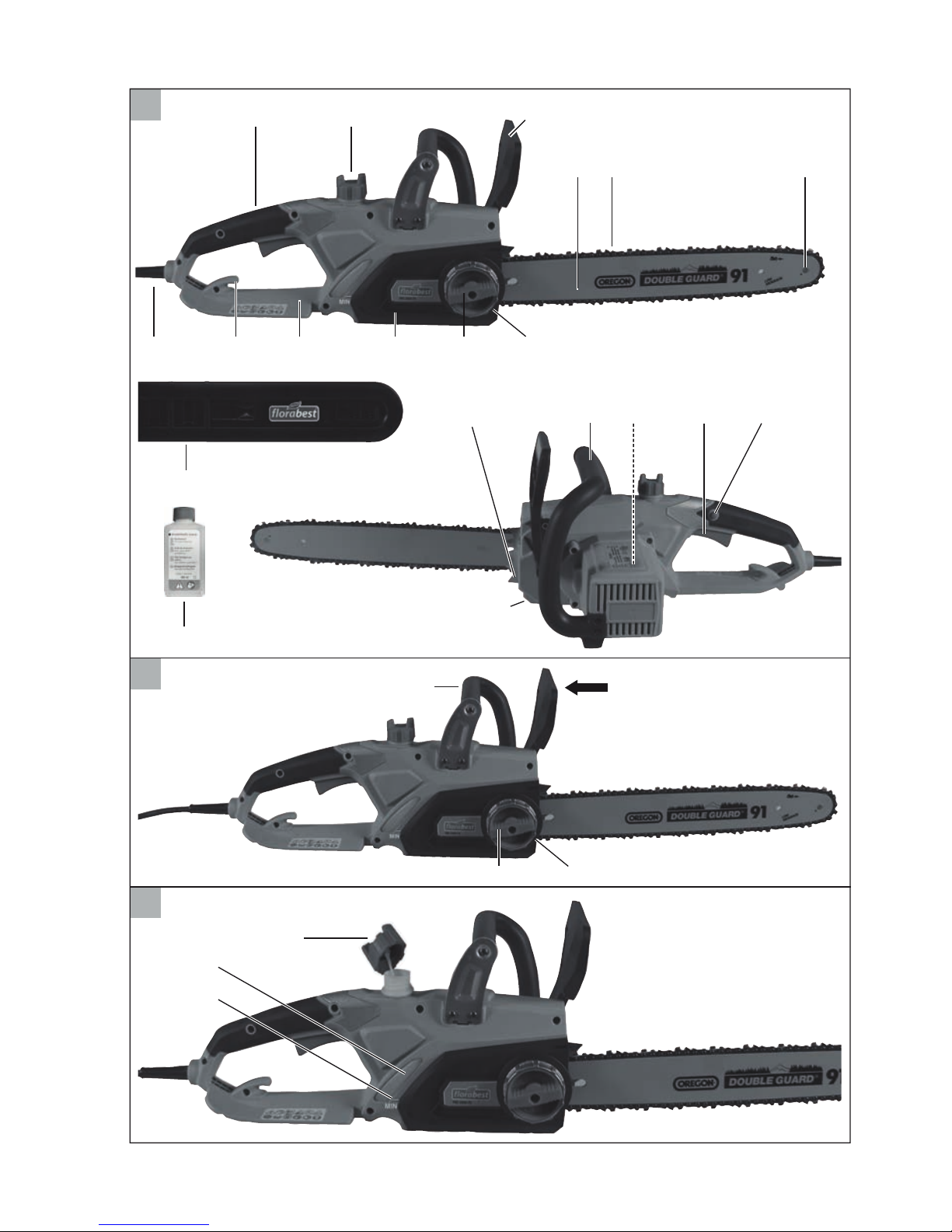

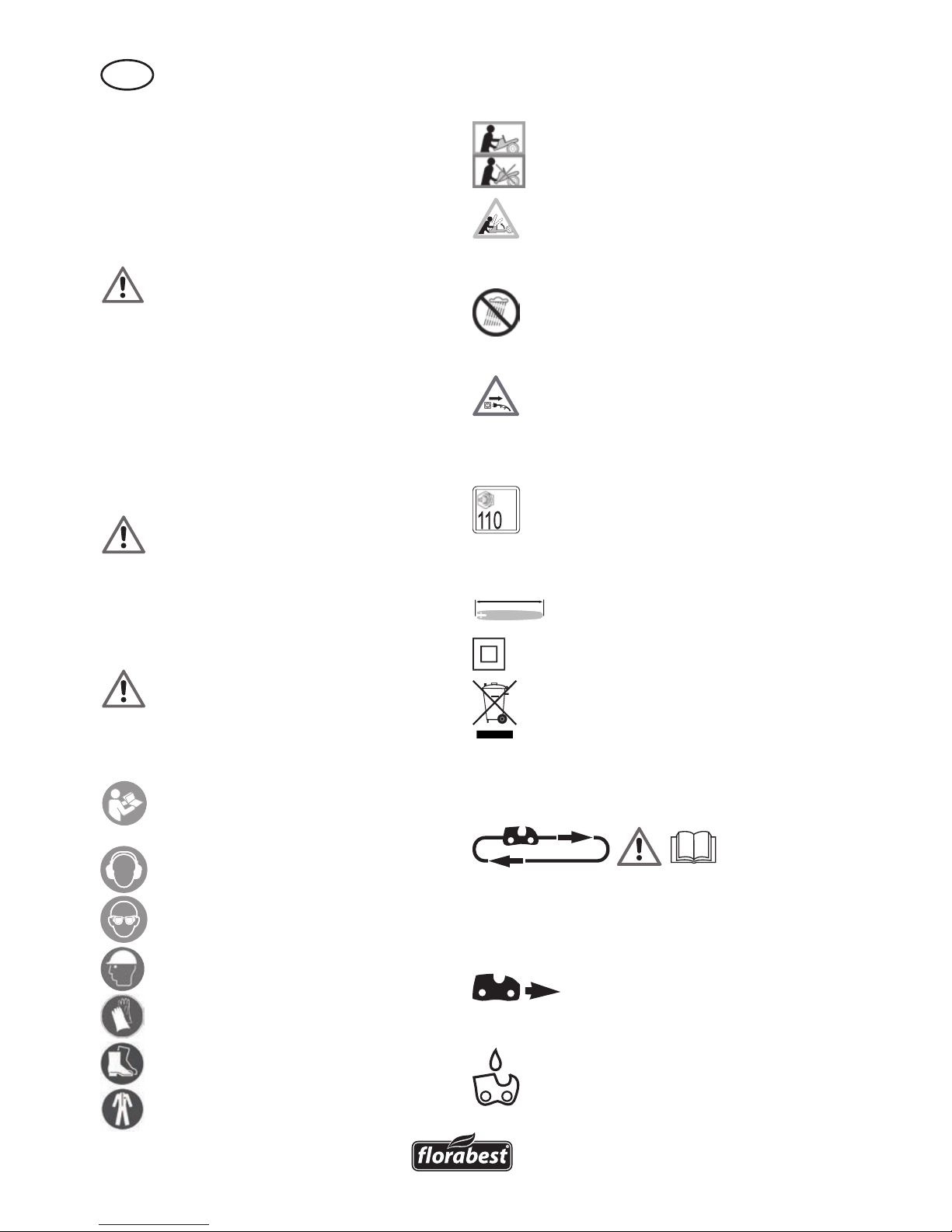

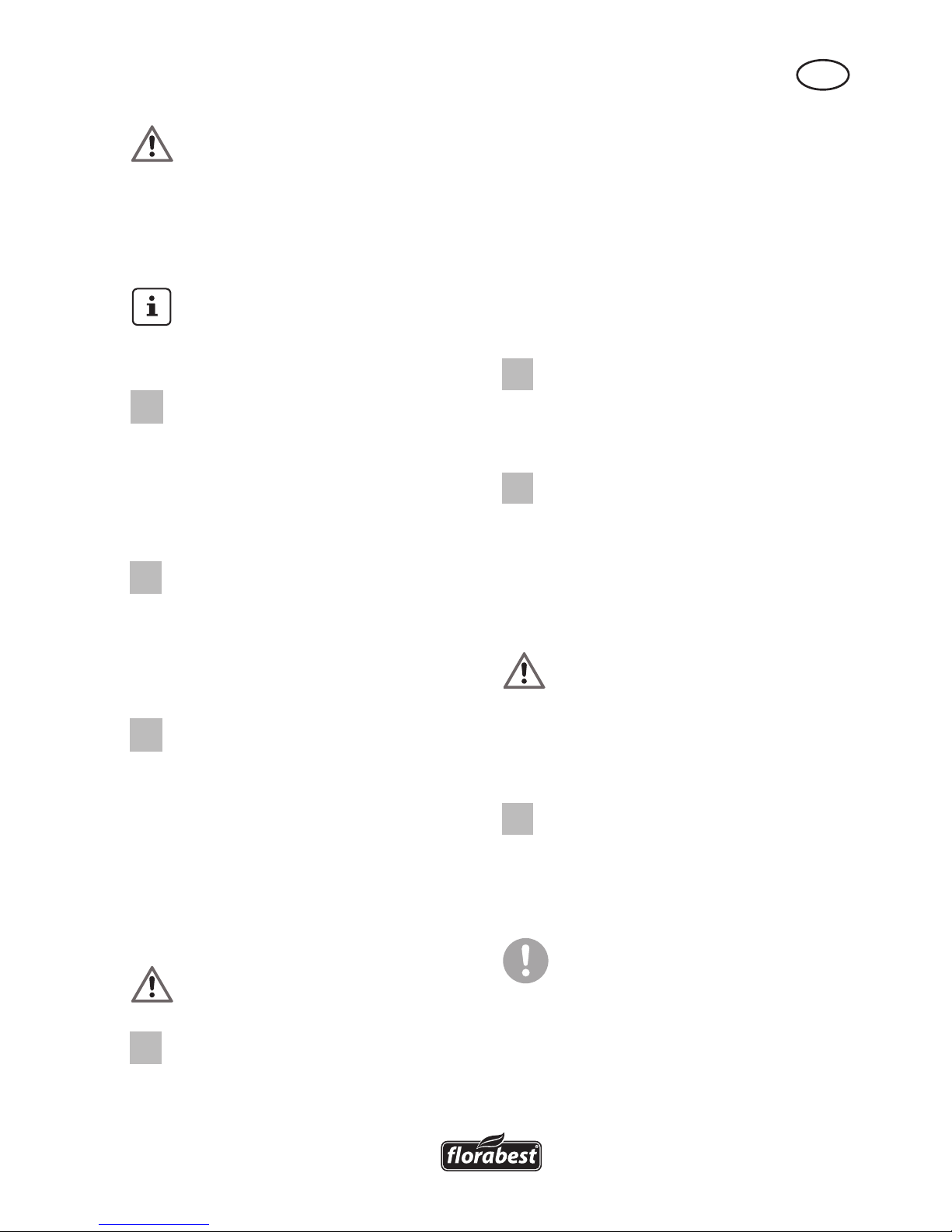

The illustration of the principal

functioning parts can be found

on the front and back foldout

pages.

Extent of the delivery

Carefully unpack the appliance and check

that it is complete:

- Chainsaw

- Chain bar (guide rail)

(already mounted)

- Saw chain (already mounted)

- Saw bar protection sheath

- Oil bottle with 180ml bio chain oil

- Instruction Manual

Dispose of the packaging material

correctly.

Overview

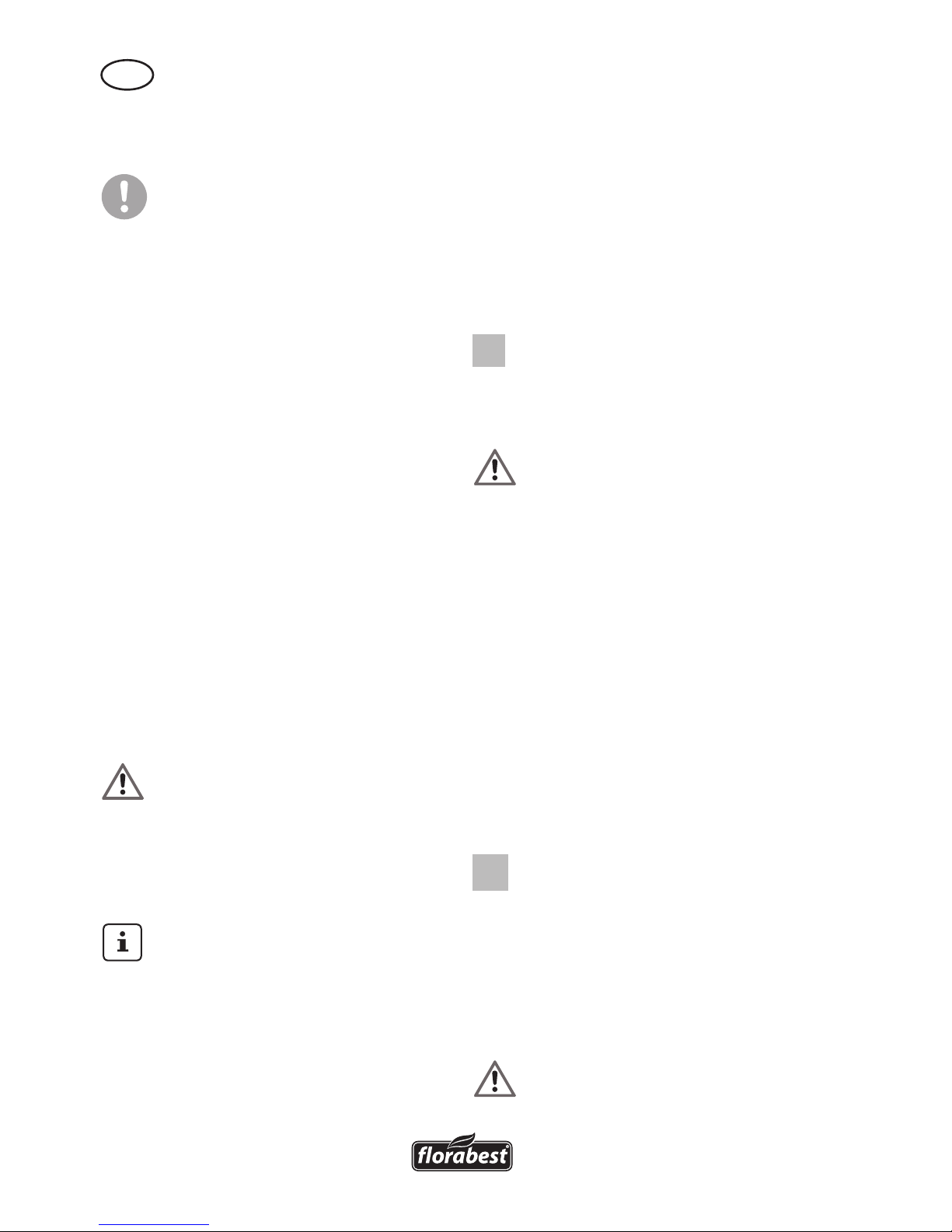

A

1 Rear handle

2 Oil ller cap

3 Chain brake handle, front hand

guard

4 Chain bar

5 Saw chain

6 Nose sprocket

7 Bumper

8 Front handle

9 Electric motor

10 On/off switch

11 Safety lock

12 Chain catcher

13 Chain adjustment ring

14 Fastening bolt for sprocket chain

wheel covering

15 Sprocket chain wheel covering

16 Rear hand guard

17 Cable holder

18 Mains cable

19 Saw bar protection sheath

20 Oil bottle

C

21 Oil level indicator

22 Minimum mark “MIN”

on the oil level indicator

Page 7

7

G B

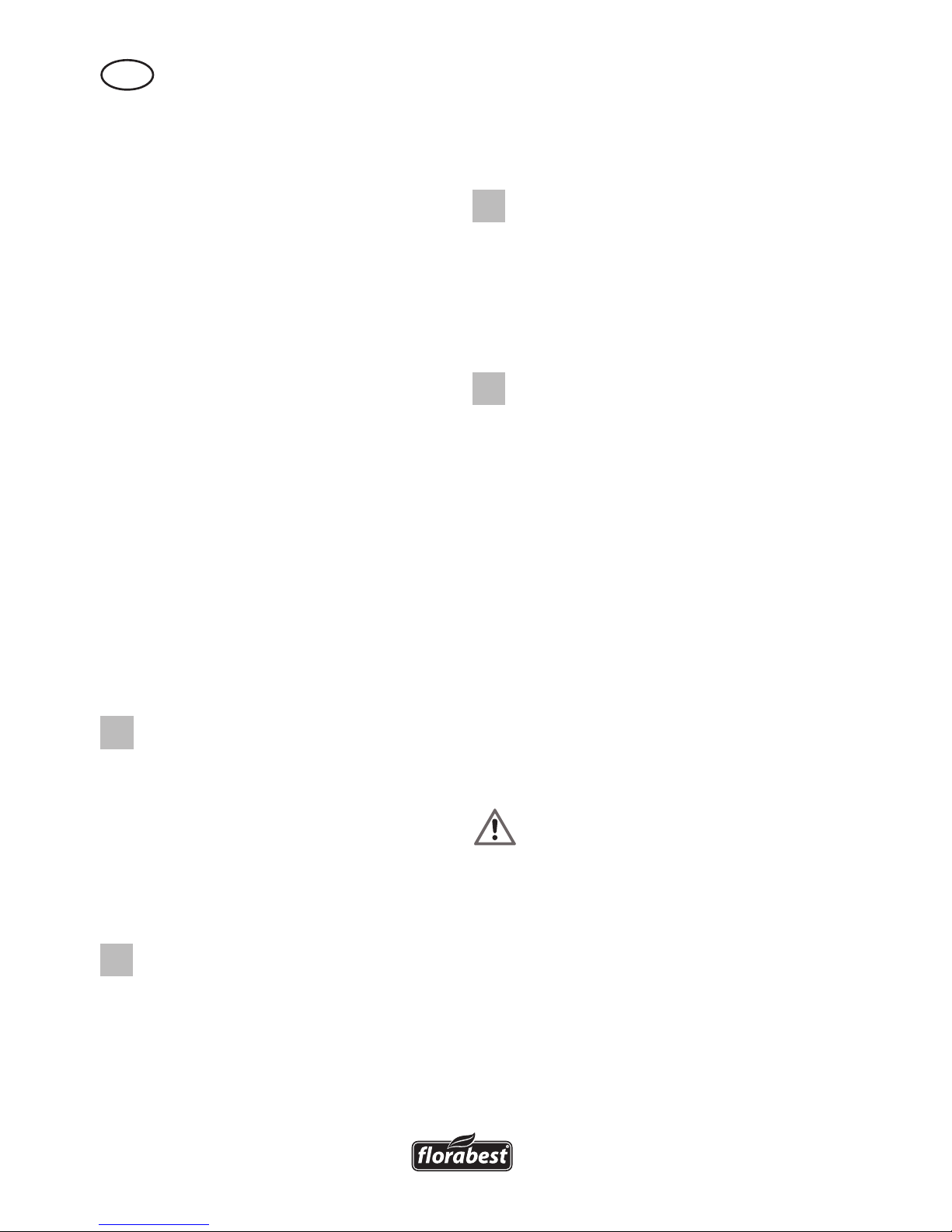

F

23 Bar bolt

24 Tensioning plate

G

25 Sprocket

26 Tab

J

27 Oil passages

28 Fixing screw

29 Clamping screw bolt

Function description

The chainsaw is driven by an electric motor. The circulating chain is led around a

saw bar (guide rail).

The tool is tted with a rapid-action chain-

tensioning system and a fast-acting chain

brake. An automatic oil dosing regulator

ensures continuous chain lubrication.

The chainsaw is equipped with various pro-

tection ttings for the protection of the user.

Refer to the following descriptions for the

function of control elements.

Technical Data

Electrical chainsaw ................FKS 2200 F3

Rated input

voltage U ................. 230-240 V~, 50 Hz

Input power P ............................2200 W

Safety class ......................................

II

Protection category...........................IP20

Chain speed v

0

.........................15.3 m/s

Weight (without guide rail and chain) .4.4 kg

Weight (with guide rail and chain) ..5.3 kg

Oiltank ...........................approx. 190 ml

Chain ..........................Oregon 91P057X

Chrome cutting teeth, low-kickback

Chain bar .......Oregon 16“ Double-Guard

......................... 160SDEA041 - 112364

Chain link separation ...................10 mm

Chain width ...............................1.3 mm

Teeth of the sprocket chain wheel ........... 7

Length of the chain bar ............... 460 mm

Sawing length ...........................395 mm

Acoustic pressure level

(L

pA

) .................. 84.9 dB (A); KpA= 3 dB

Sound power level (L

WA

)

measured .. 107.7 dB (A); K

WA

= 2.58 dB

guaranteed ......................... 110 dB(A)

Vibration (a

h

) .... 7.612 m/s2 ; K= 1.5 m/s

2

Noise and vibration values were determined

according to the standards and stipulations

mentioned in the declaration of conformity.

Technical and optical changes can be

carried out in the course of further development without notice. All dimensions, references and information of this instruction

manual are therefore without guarantee.

Legal claims, which are made on the basis

of the instruction manual, cannot thus be

considered as valid.

The stated vibration emission value was

measured in accordance with a standard

testing procedure and may be used to compare one power tool to another.

The stated vibration emission value may

also be used for a preliminary exposure

assessment.

Warning: The vibration emission

value may differ during actual use

of the power tool from the stated

value depending on the manner in

which the power tool is used.

Safety precautions aimed at protect-

ing the user should be based on

estimated exposure under actual

usage conditions (all parts of the

operating cycle are to be considered, including, for example, times

during which the power tool is

turned off and times when the tool

is turned on but is running idle).

Page 8

8

G B

Only use the saw with

both hands on the device

Caution! Spring-back - Be careful of

spring-back of the machine during

work.

Do not expose the unit to rain. The

device must not be wet, nor should it

be operated in a moist environment.

Caution! Remove the plug immedi-

ately from the plug socket in case

of damage or cutting through of the

mains cable

dB

L

WA

Information of the acoustic power

level L

WA

in dB.

Graphical symbol on the nameplate:

460 mm

Length of the chain bar

Safety class II

Machines do not belong with do-

mestic waste.

Graphical symbol beneath the chain sprocket cover:

Observe direction of travel of the saw chain.

Caution! Read the operating instructions.

Graphical symbol on the blade:

Direction of travel

of the saw chain

Graphical symbol on the oil tank

cap: Saw chain lubrication.

Notes on safety

This section deals with the basic safety

regulations while working with the electric

chainsaw.

An electric chainsaw is a dangerous

device, which can cause serious or

even fatal injuries with incorrect or

careless use. Thus, for your own safety

and the safety of others, you should

always take note of the instructions

on safety and, in case of difculties,

consult a specialist for advice.

Symbols used on the saw

Make yourself familiar with all

control elements before any work.

Practice handling the saw and have

explained the functions, operating

methods and sawing techniques by

a practiced user or specialist.

The motor cannot be turned on if the

chain brake has engaged. Release

the chain brake by shifting the brake

arm over against the front grip.

Read and take note of the operating

manual belonging to the machine!

Wear personal

protective equipment.

Basically, wear protective goggles

and ear protection

Wear a safety helmet!

Wear cut-resistant gloves!

Wear anti-slip safety shoes!

Use protective clothing!

Page 9

9

G B

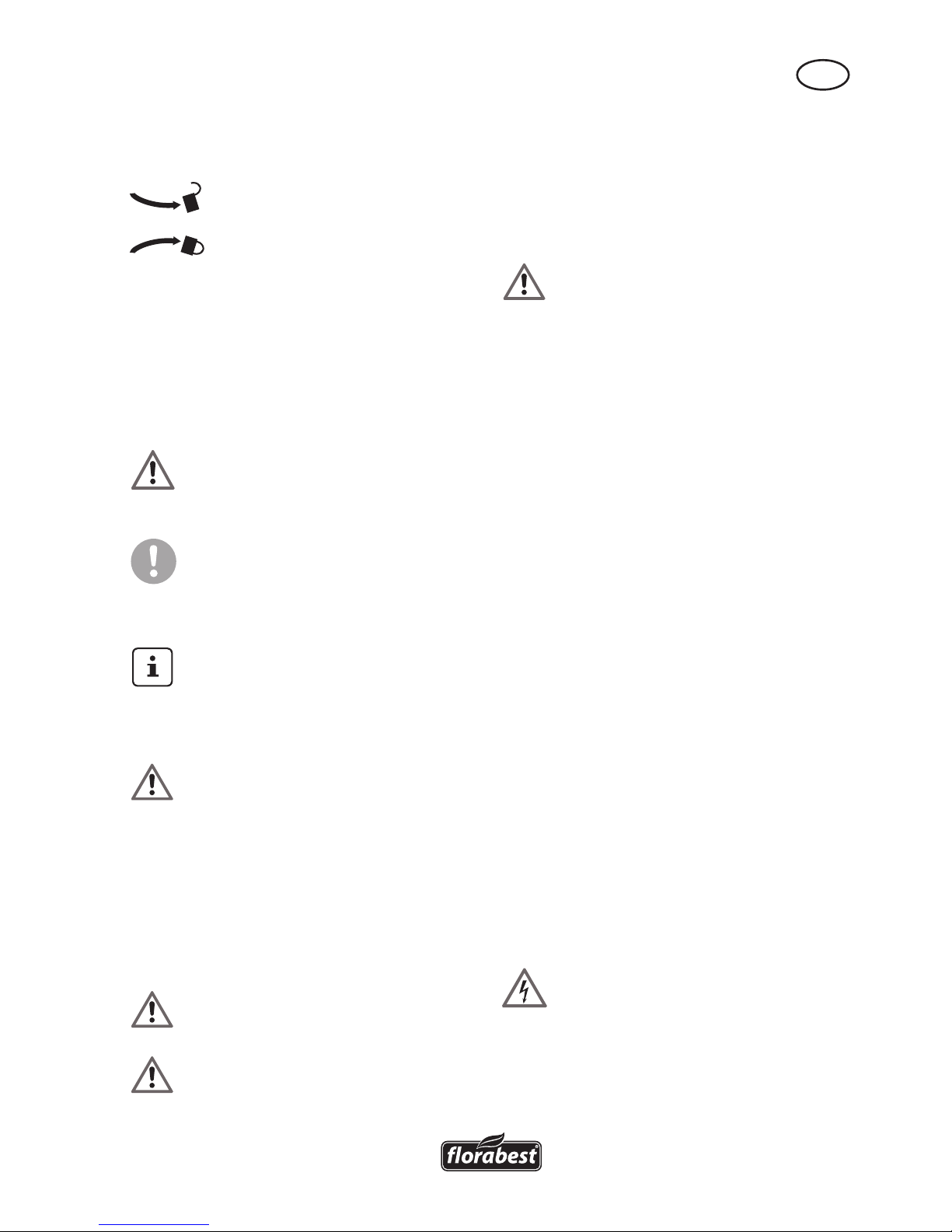

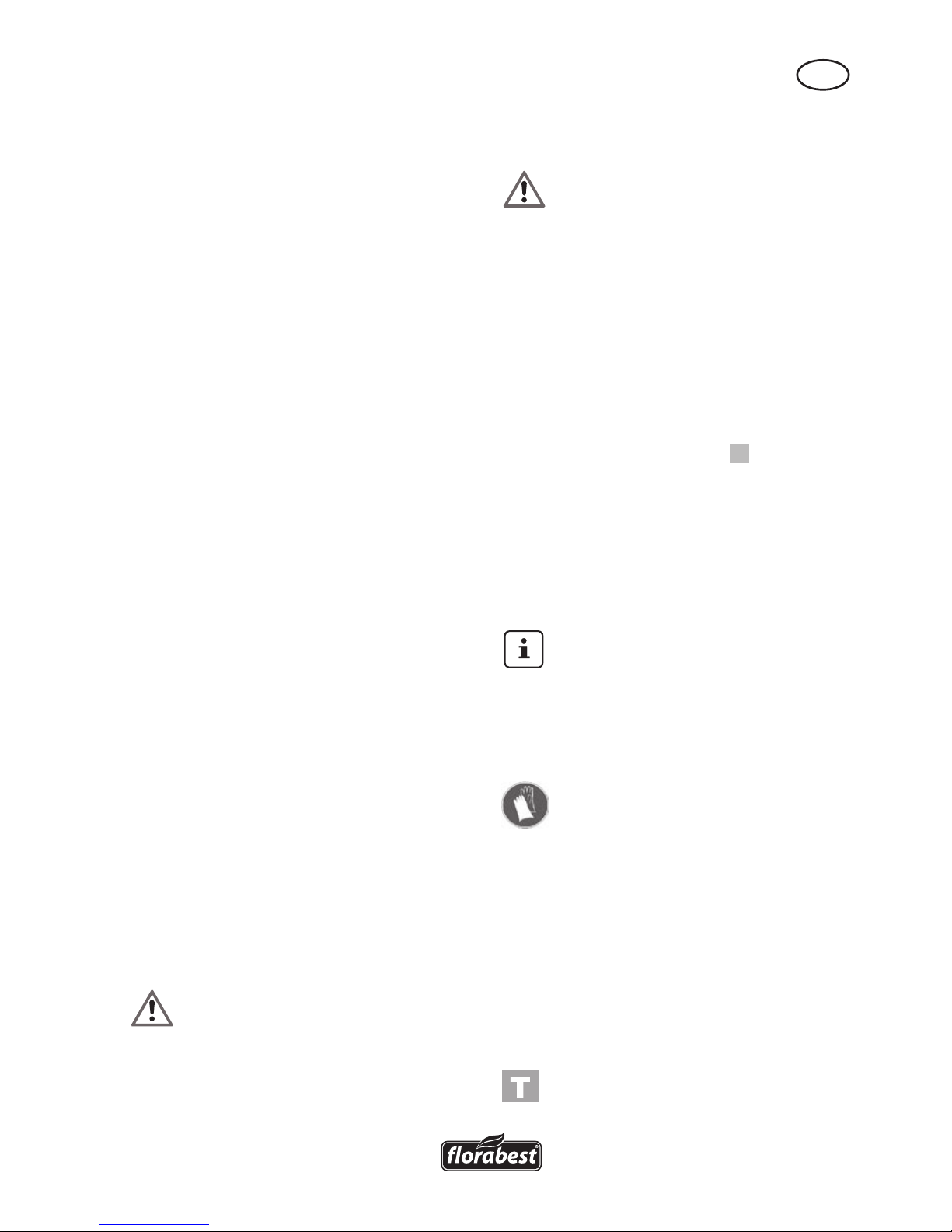

Graphical symbol on the xing screw for

the chain sprocket cover:

OPEN

CLOSE

Graphical symbol on the chain brake lever:

O chain brake: OFF

I chain brake: ON

Symbols used

in the instructions

Hazard symbols with informa-

tion on prevention of personal

injury and property damage.

Precaution symbol (explanation of

precaution instead of exclamation

mark) with information on prevention of harm / damage.

Notice symbol with information on

how to handle the device properly.

General notes on safety

Before you do any work with the elec-

tric chainsaw, make yourself familiar

with all operating parts. Practise using

the saw (sawing logs on a sawhorse)

and get an experienced user or a specialist to explain to you the function of

the saw, the way of working, the techniques of sawing and the personal

protection equipment.

Observe noise control and local

regulations.

Caution! When using power tools,

observe the following basic safety

measures for the prevention of

electric shocks and the risk of injury

and re. There is a risk of injury!

General safety instructions

for power tools

WARNING! Read all safety

directions and instructions.

Omissions in the compliance with

safety directions and instructions

can cause electrical shock, re

and/or severe injuries.

Retain all safety directions and instructions for future use.

The term “Power Tools” used in the safety

instructions refers to mains-operated power

tools (with power cord) and to battery-operated power tools (without power cord).

Work area safety

• Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

• Do not operate power tools in

explosive atmospheres, such as

in the presence of ammable

Iiquids, gases or dust. Power tools

create sparks which may ignite the

dust or fumes.

• Keep children and bystanders

away while operating a power

tool. Distractions can cause you to

lose control.

Electrical safety

CAUTION! The following states

how to avoid accidents and injuries

due to electric shock:

• Power tool plugs must match

the outlet. Never modify the

plug in any way. Do not use

Page 10

1 0

G B

• Use only approved power cable of

type H05RN-F, which are no more than

75 m in length and intended for use

outdoors. The conductor cross section

of the cord must be at least 2.5 mm

2

.

Always fully unroll a cable drum before

use. Check the power cord for damage.

Personal safety

CAUTION: In this way you avoid

accidents and injuries:

• Stay alert, watch what you are

doing and use common sense

when operating a power tool.

Do not use a power tool while

you are tired or under the inuence of drugs, alcohol or medication. A moment of inattention white

operating power tools may result in

serious personal injury.

• Wear personal protective equip-

ment and always wear safety

glasses. Wearing personal protective

equipment such as nonslip safety boots,

cut protection trousers, a hard hat or ear

protection reduces the risk of injuries.

• Prevent unintentional starting.

Ensure the switch is in the offposition before connecting to

power source and/or battery

pack, picking up or carrying

the tool. Carrying power tools with

your nger on the switch or energising

power tools that have the switch on

invites accidents.

• Remove any adjusting key or

wrench before turning the power tool on. A wrench or a key left at-

tached to a rotating part of the power

tool may result in personal injury.

• Do not overreach. Keep proper

footing and balance at all times.

any adapter plugs with earthed

(grounded) power tools. Unmodi-

ed plugs and matching outlets will

reduce risk of electric shock

• Avoid body contact with

earthed or grounded surfaces,

such as pipes, radiators, ranges

and refrigerators. There is an in-

creased risk of electric shock if your

body is earthed or grounded.

• Do not expose power tools to

rain or wet conditions. Water

entering a power tool will increase the

risk of electric shock.

• If the supply cord of this power tool

is damaged, it must be replaced by

a specially prepared cord available

through the service organization.

• If it is necessary to replace the connection cable, we recommend that this be

performed by the manufacturer or an

authorised representative (e.g. authorised workshop, customer service, etc.).

• Do not abuse the cord. Never

use the cord for carrying, pulling

or unplugging the power tool.

Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a

cord suitable for outdoor use reduces

the risk of electric shock.

• If operating a power tool in a

damp location is unavoidable,

use a residual current device

(RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

Connect the appliance to a power

socket with a residual current circuit

breaker of rated residual current no

more than 30 mA.

Page 11

1 1

G B

This enables better control of the power tool in unexpected situations.

• Keep your hair, clothing and

gloves away from moving

parts. Jewellery or long hair can be

caught in moving parts.

• Warning! During operation, this

electric tool generates an electromagnetic eld which, under certain circumstances, may impair the functionality of

active or passive medical implants. To

reduce the risk of serious or lethal injuries, we recommend that persons with

medical implants consult their doctor

and the manufacturer of their medical

implant before operating the machine.

Power tool use and care

• Do not force the power tool. Use

the correct power tool for your

application. The correct power tool

will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the

switch does not turn it on and

off. Any power tool that cannot be

controlled with the switch is dangerous

and must be repaired.

• Disconnect the plug from the

power source and/or the battery pack from the power tool

before making any adjustments, changing accessories, or

storing power tools. Such preven-

tive safety measures reduce the risk of

starting the power tool accidentaIly.

• Store idle power tools out of the

reach of children and do not allow persons unfamiliar with the

power tool or these instructions

to operate the power tool. Power

tools are dangerous in the hands of

untrained users.

• Maintain power tools. Check

for misalignment or binding

of moving parts, breakage of

parts and any other condition

that may affect the power tool’s

operation. If damaged, have

the power tool repaired before

use. Many accidents are caused by

poorly maintained power tools.

• Keep cutting tools sharp and

clean. Properly maintained cutting

tools with sharp cutting edges are less

Iikely to bind and are easier to control.

• Use the power tool, accessories

and tool bits etc. in accordance

with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for op-

erations different from those intended

could result in a hazardous situation.

• For sawing work on a slope, always

stand above the tree trunk. To keep

control at the moment of “sawing

through”, reduce the contact pressure

at the end of the cut without loosening

the rm grip on the chainsaw handles.

Ensure that the saw chain does not

come into contact with the ground.

After completing the cut, wait for the

chainsaw to come to a standstill before

removing the chainsaw. Always switch

off the chainsaw motor before moving

from one tree to another.

• Dirt, stones, loose bark, nails, staples

and wire must be removed from the tree.

Service

• Have your power tool serviced

by a qualied repair person using only identical replacement

parts. This will ensure that the safety

of the power tool is maintained.

Page 12

1 2

G B

• Follow the maintenance, control and service instructions in this manual carefully.

Damaged safety equipment and parts

must be repaired or replaced professionally by our service centre, unless

otherwise indicated in the operating

instructions.

Chain saw safety warnings:

• Keep all parts of the body

away from the saw chain when

the chain saw is operating. Before you start the chain saw,

make sure the saw chain is not

contacting anything. A moment of

inattention white operating chain saws

may cause entanglement of your clothing or body with the saw chain.

• Always hold the chain saw with

your right hand on the rear

handle and your left hand on

the front handle. Holding the chain

saw with a reversed hand conguration increases the risk of personal injury and should never be done.

• Hold the power tool only on the

insulated handle surfaces, as

the saw chain may come into

contact with concealed power

cables. Contact between the saw

chain and a live cable may render metallic components live and result in an

electric shock

• Wear safety glasses and ear

protection. Other protective

equipment for the head, hands,

legs and feet is compulsory. Ad-

equate protective clothing will reduce

personal injury by ying debris or accidentaI contact with the saw chain.

• Do not operate a chain saw in a

tree. Operation of a chain saw white up

in a tree may result in personal in jury.

• Always keep proper footing and

operate the chain saw only when

standing on xed, secure and

level surface. Slippery or unstable surfaces such as ladders may cause a loss

of balance or control of the chain saw.

• When cutting a branch that is

under tension be alert for spring

back. When the tension in the wood

bres is released the spring loaded Iimb

may strike the operator and/or throw

the chain saw out of control.

• Use extreme caution when cut-

ting brush and saplings. The slender material may catch the saw chain

and be whipped toward you or pull

you off balance.

• Carry the chain saw by the

front handle with the chain saw

switched off and away from

your body. When transporting

or storing the chain saw always

t the guide bar cover. Proper

handling of the chain saw will reduce

the Iikelihood of accidentaI contact

with the moving saw chain.

• Follow instructions for lubri-

cating, chain tensioning and

changing accessories.

Improperly tensioned or lubricated

chain may either break or increase the

chance for kickback.

• Keep handles dry, clean, and

free from oil and grease. Greasy,

oily handles are slippery causing loss

of control.

• Cut wood only. Do not use chain

saw for purposes not intended.

For example: do not use chain

saw for cutting plastic, masonry

or non-wood building materials.

Use of the chain saw for operations

different than intended could result in a

hazardous situation

Page 13

1 3

G B

Causes and operator

prevention of kickback

Beware of kickback! Be careful of

kickback of the machine during

work. There is danger of injury

here. You can avoid kickbacks by

exercising caution and using a correct sawing technique.

Fig. 1

• Kickback may occur when the nose or

tip of the guide bar touches an object,

or when the wood closes in and pinches the saw chain in the cut

(cf. image 1/g. B).

• Tip contact in some cases may cause

a sudden reverse reaction, kicking the

guide bar up and back towards the

operator (cf. image 1/g. A).

• Pinching the saw chain along the top

of the guide bar may push the guide

bar rapidly back towards the operator.

• Either of these reactions may cause

you to lose control of the saw which

could result in serious personal injury.

Do not rely exclusively upon the safety

devices built into your saw. As a chain

saw user, you should take several steps

to keep your cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/

or incorrect operating procedures or conditions and can be avoided by taking proper

precautions as given below:

• Maintain a rm grip, with

thumbs and ngers encircling

the chain saw handles, with

both hands on the saw and position your body and arm to allow

you to resist kickback forces.

Kickback forces can be controlled by

the operator, if proper precautions are

taken. Do not let go of the chain saw.

• Do not overreach and do not cut

above shoulder height. This helps

prevent unintended tip contact and

enables better control of the chain saw

in unexpected situations.

• Only use replacement bars and

chains specied by the manufacturer. Incorrect replacement bars

and chains may cause chain breakage

and/or kickback.

• Follow the manufacturer´s

sharpening and maintenance

instructions for the saw chain.

Decreasing the depth gauge height

can lead to increased kickback.

Further safety directions

• If the supply cord of this power tool

is damaged, it must be replaced by

a specially prepared cord available

through the service organization.

• If it is necessary to replace the connection cable, we recommend that this be

performed by the manufacturer or an

authorised representative (e.g. authorised workshop, customer service, etc.).

• Lay the extension cable in such a way

that it will not be caught by branches

or similar during sawing.

• Use a surge protector with a release

current of 30 mA or less.

• Comply carefully with maintenance,

control and service instructions in this

manual.

Page 14

1 4

G B

Damaged protective devices and parts

have to be repared or changed except

as noted otherwise in this manual.

Safety functions

A

1 Rear grip

with hand guard (16)

Protects the hand against branch-

es and boughs in the case of

springing away by the chain.

3 Chain braking lever/

hand guard

Control system, which stops the

saw chain immediately in case

of a spring-back; lever can also

be activated manually; protects

the left hand of the operator if it

slides from the front grip.

The motor cannot be turned on if

the chain brake has engaged.

5 Saw chain with small

spring-back

Helps you to catch spring-backs

with specially developed control

systems.

7 Metal stop claw

Reinforces the stability when

vertical cuts are carried out and

facilitates sawing.

9 Electric motor

Double insulated for safety

reasons.

10 On-off switch with safety

chain brake

On releasing the On/Off switch,

the device immediately switches off.

11 Switch-on block

The switch-on block must be

released for switching on the

device.

12 Chain catcher

Decreases the danger of injuries if

the chain breaks or if it comes off.

Assembly

Always wear protective

gloves when working with

the chainsaw and employ

only original parts. Pull out

the power plug before doing

any work on the chainsaw

itself -– injury hazard!

Before putting the electric chain saw into

operation, you must:

- install the blade, saw chain and chain

cover where necessary,

- adjust the saw chain tension,

- pour in chain oil,

- check the function of the chain brake

and the automatic oil pump.

Mount the saw chain

G

1. Spread the chain (5) out into a

loop with the cutting edges running clockwise .

2. Relax the tensioning screw (24)

against the clockwise

direction.

3. Slide the saw chain (5) into the

bar guide groove. To mount the

guide bar (4), raise it to an angle

of approx. 45 degrees. This will

make it easier to replace the saw

chain (5) onto the sprocket (25).

It is normal that the saw chain (5)

is slack. Sagging in the chain is

normal.

4. Pre-tighten the chain (5) by turning the tensioning plate (24)

clockwise.

Page 15

1 5

G B

5. Position the sprocket chain wheel

covering (15). First place the tab

(26) on the cover into the corresponding notch on the plate (15).

Only lightly tighten the fastening

bolt (14), as you will still have to

tension the saw.

Note that the saw can re-oil.

Please note that the saw re-oils after use

and oil may leak out if it is stored on its

side or on the head. This is a normal

process due to the necessary ventilation

opening on the upper edge of the tank and

does not constitute a reason for complaint.

As each saw is checked during production

and tested with oil, a small residue may

be in the tank despite draining, which may

slightly dirty the housing with oil in transit.

Please clean the housing with a cloth.

Prior to changing the chain, the nut of the

guide rail must be cleaned of dirt because

dirt deposits available can cause the chain

to break out of the rail. The deposits can

also absorb the chain oil. So the consequence would be that the chain oil would

not or only a small part of it would reach

the underside of the rail and the lubrication

would be reduced.

Mount the saw bar

F

1. Lay the saw on a at surface.

2. Turn the fastening bolt (14) anticlockwise (

) to remove

the sprocket chain wheel covering (15).

3. To t the new bar, place the bar

(4) onto the bar bolt (23) with

the tensioning plate pointing outwards (24).

Tensioning the saw chain

Regularly tightening the saw chain provides

safety for the user and reduces and/or prevents wear and chain damages. Before the

start of work and in approx. 10 minute intervals, we recommend the user to examine the

chain tension and correct it, if necessary.

The chain warms up when working with

the saw and thus expands slightly. These

“expansions” can be expected especially

from newer chains.

Do not re-tighten or change the chain

when it is hot because it shrinks slightly once it has cooled down. In case of

non-observance, this can lead to damages on the guide rail or the engine

because now the chain is too taut on

the blade. Chain tension and chain

lubrication have a signicant impact on the service life of the chain.

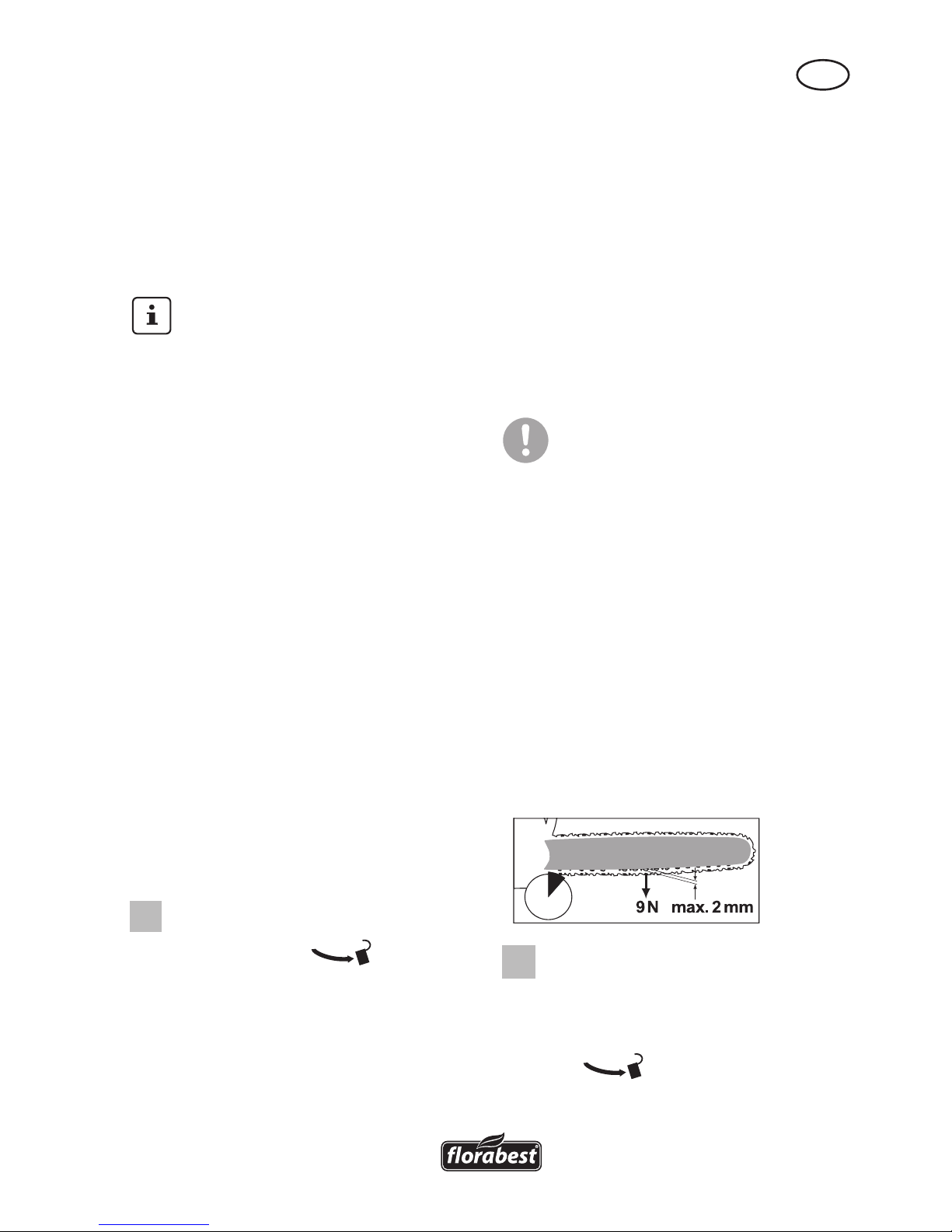

The chain is correctly tensioned if it does

not sag at the rail underside and can be

rotated completely around with the gloved

hand. When the saw chain is tensioned

with 9 N (approx. 1 kg), the gap between

the saw chain and the guide rail may not

be more than 2 mm.

10 min

B

1. Ensure that the chain brake has

been released, that is, that the chain

brake lever (3) is pulled up against

the front grip (8) (position

O).

2. Unscrew the fastening bolt (14)

(

).

3. To tighten the saw, turn the chain

adjustment ring (13) clockwise.

Page 16

1 6

G B

To loosen the tension, turn the

chain adjustment ring anti-

clockwise.

4. Tighten up the fastening bolt (14)

again (

).

With a new saw chain, you must

readjust the chain tension after at

least 5 cutting operations.

Chain lubrication

The rail and chain must never be

without oil. If you operate the electric chainsaw with too little oil, the

cutting performance and the lifetime

of the saw chain is reduced, since

the chain becomes blunt faster. You

can identify a case of too little oil

where smoke development or discoloration of the rail occurs.

As soon as the motor is speeded up, the oil

also ows faster to the chain bar (4).

Filling up with chain oil:

• Check the oil level indicator (

C

21)

regularly and top-up the oil if the minimum mark „MIN“ (

C

22) is reached on

the oil level indicator. The oil tank holds

about 190 ml of oil.

• Use Parkside bio-oil; this product contains additives that reduce wear and

tear and does not damage the pump

system. bio-oil is available from our

Service-Center.

• If you have no Grizzly bio-oil available,

use chain lubrication oil with low adhesive additive content.

• Empty the oil tank before longer periods

(6-8 weeks) of non-use.

C

1. Unscrew the oil ll cap (2) and ll

up with chain oil.

2. Wipe off any spilled oil and

close the cap (2) again.

Always switch off the device

and allow the motor to cool

before lling with chain oil.

There is a risk of re if oil

overows.

Operating the chainsaw

Switch on the chainsaw only when

chain bar, saw chain and sprocket

chain wheel covering are correctly

assembled. Ensure the voltage of the

mains connection agrees with the

label on the device. Make sure you

have a secure stance. Make sure

before you start that the electric

chain saw is not touching anything.

Caution! Saw can oil up, see notes

on “Assembly“.

Switching on

D

1. Check before the start, whether

sufcient chain oil is in the tank

and, if necessary, rell with

chain oil (see Chapter Operation

Startup).

2. Form a loop from the end of the

extension cable and hang this

into the tension relief (17) on the

rear grip (1).

3. Connect the device to the mains

voltage.

4. Release the chain brake, where

you shift the brake arm (3) back

against the front grip (8).

5. Hold the electric chainsaw rmly

with both hands, with the right

hand on the rear grip (1) and

the left hand on the front handle

Page 17

1 7

G B

(8). Thumb and nger must close

securely over the handles.

6. For switching on, activate the

switch-on block (11) with the right

thumb and then press the On/Off

switch (10), the electric power saw

runs with highest speed. Release

the switch-on block (11)again.

7. The power saw switches off when

you release the On/Off switch

(10) again. Switching for continuous running is not possible.

Checking the chain brake

The motor cannot be turned on if the

chain brake has engaged. Do not

employ the chain brake in order to

start the chainsaw or to switch it off.

E

1. Place the electric chainsaw onto

a solid, at surface. It must not

contact any objects.

2. Connect the device to the mains

voltage.

3. Release the chain brake by shifting the brake arm (3) over against

the front grip (8) (position

O).

4. Hold the electric chainsaw rmly

with both hands, with the right

hand on the rear handle (

A

1)

and the left hand on the front

handle (8). Thumb and nger

must close securely over the handles.

5. Turn on the electric chainsaw.

6. Activate the chain braking lever

(3), with running motor, with

the left hand. To do so, push the

chain braking lever/front hand

protection (3) away from the front

handle (8) (position

I). Chain

should stop abruptly.

7. Once the chain brake is working properly, release the on/off

switch and the chain brake.

If the chain brake does not

function correctly, you must

not use the electric chainsaw.

A slack saw chain leads to

danger of injury.

Return the electric chainsaw to

our Service-Center for repair.

Checking the chain

lubrication

Check the oil level and the chain lubrication system before commencement of work.

• Switch on the chainsaw and hold it

above a bright background. The saw

must not touch the ground.

If an oil trace can be seen, the chainsaw is

working trouble-free.

If no oil trace can be seen clean the

oil passages or turn the chainsaw

to our Service-Center for repair.

J

4. Clean the oil passages of the chain

bar (27), in order to guarantee a

trouble-free, automatic oiling of the

saw chain during operation. Use

a brush or a cloth to help remove

residues from the oil passage.

Changing the saw bar

F

1. Switch the saw off and unplug it

from the mains (

A

18).

2. Lay the saw on a at surface.

3. Turn the fastening bolt (14) anticlockwise (

) and loose

the chain adjustment ring (

A

13) to

Page 18

1 8

G B

remove the sprocket chain wheel

covering (15).

4. Remove the saw bar (4) and saw

chain (5). To remove the guide

bar (4), raise it to an angle of approx. 45 degrees. This will make

it easier to take the saw chain (5)

off the sprocket

(25).

5. Loosen the screw (28) on the

reverse side of the tension adjustment screw (24). Re-install the

tension adjustment screw (24) in

reverse order.

In doing so, ensure that the tensi-

on adjustment screw bolt (29), as

shown in Figure

, is underneath

(see also “turn blade“

+ ).

6. To t the new bar, place the bar

(4) onto the bar bolt (23) with

the tensioning plate pointing outwards (24).

Sawing techniques

General

• You have better control when you saw

with the bottom side of the chain bar

(with pulling saw chain) and not to

with the top side of the chain bar (with

pushing saw chain).

• The saw chain must not contact either the

ground or another object during sawing

through or after sawing completion.

• Make sure that the saw chain does not

become jammed in the wood. Do not

let the tree trunk break or split off.

• Consider also the precautions against

spring-back (see notes on safety).

If the saw chain jams, you

do not attempt to pull out the

electric chainsaw using power. There is a danger of injury

here. Switch off the motor

and use a lever or wedge to

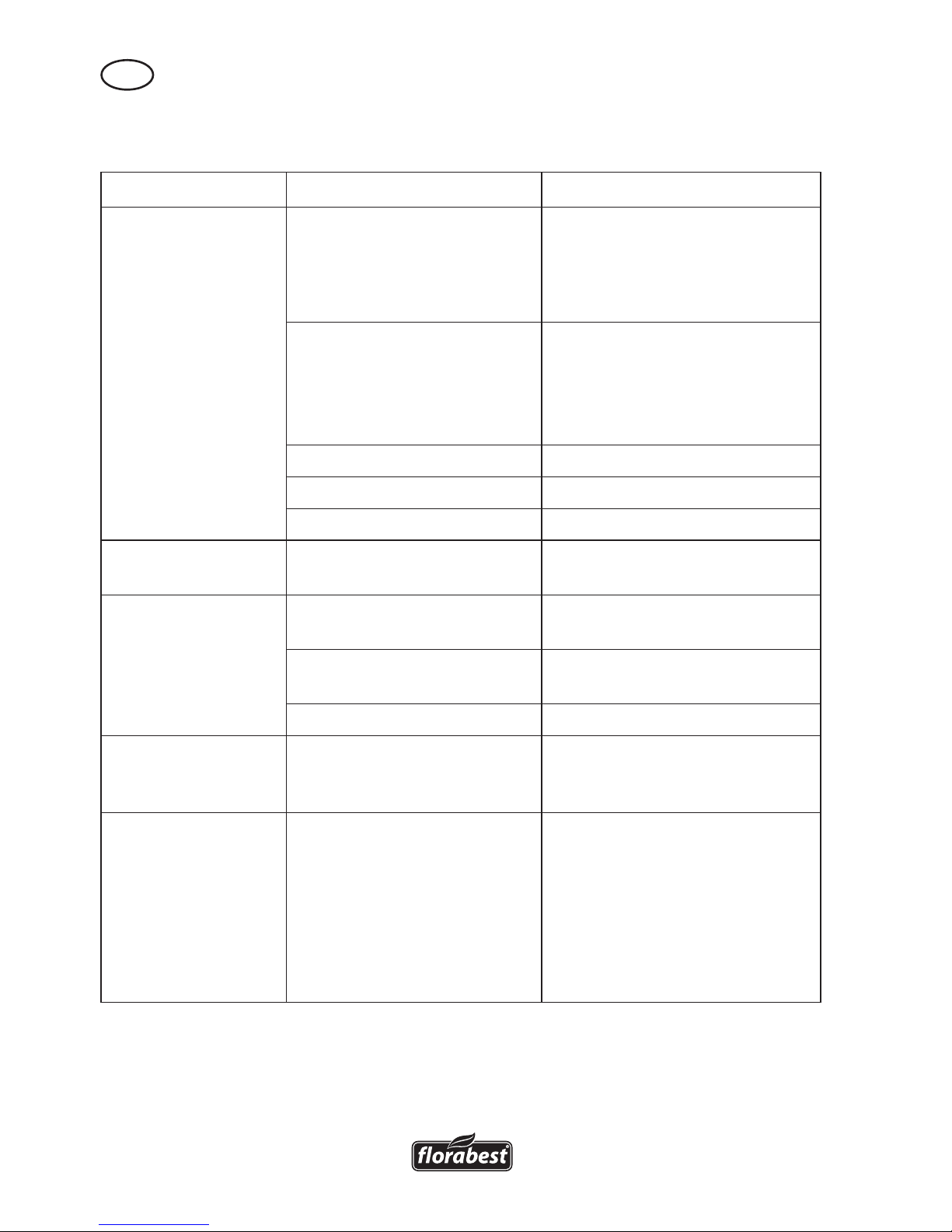

free the electric chainsaw.

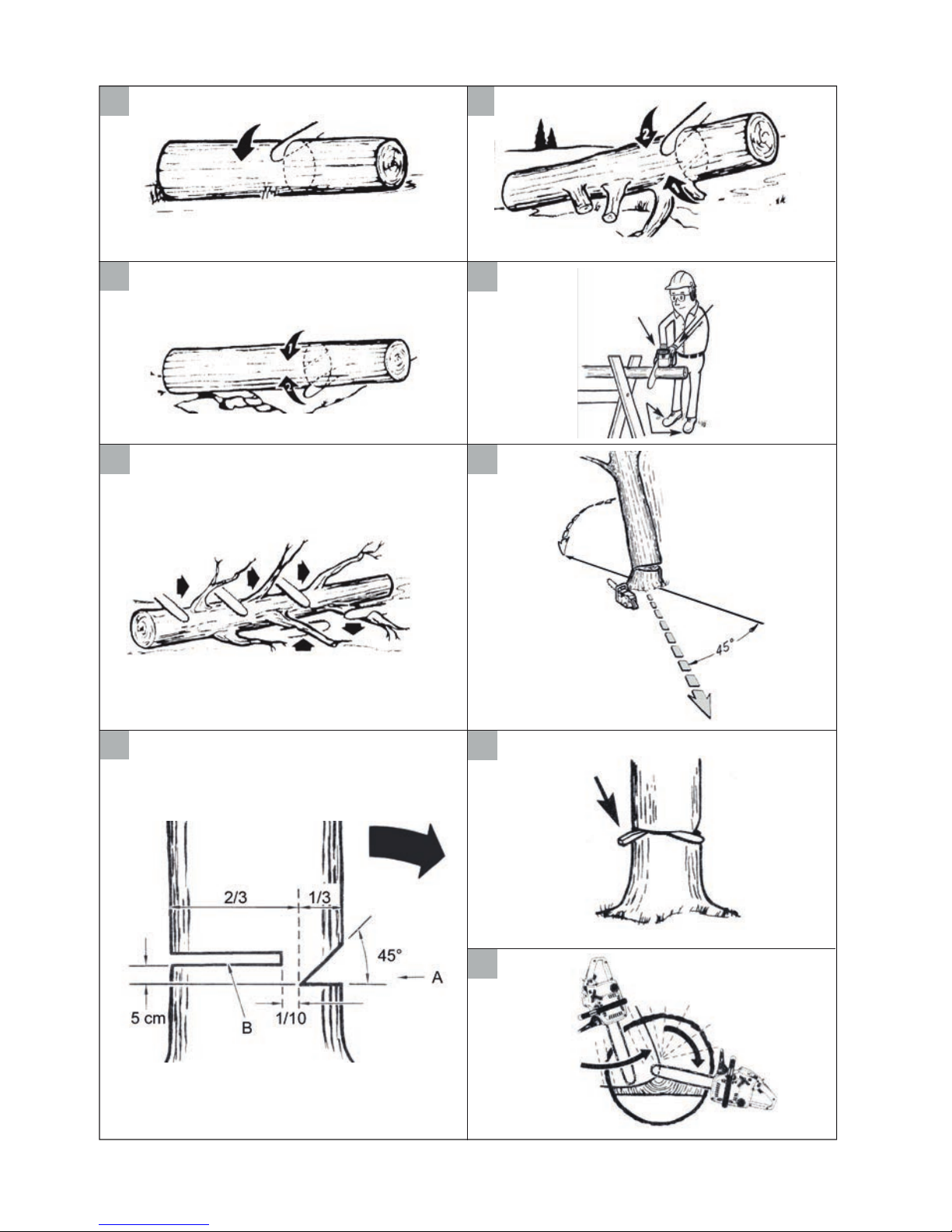

Felling trees

A lot of experience is nec-

essary in felling trees. Cut

down trees only when you

can safely handle the electric

chainsaw. In no case should

you use the electric chainsaw

if you feel unsure about anything.

For safety reasons, we advise inex-

perienced users not to fell any logs

with a rail length which is smaller

than the trunk diameter.

• Ensure that no people or animals are

in the eld of action. The safety distance between the tree to be felled and

the nearest-located workplace must be

2 ½ tree lengths.

• Note the felling direction:

The user must be able to move safely

near the felled tree, to saw off the tree

easily and remove branches.It is to be

avoided that the felled tree snags itself

on another tree. Note the natural felling direction, which is dependent on

the slope and curvature characteristic

of the tree, wind direction and the

number of branches.

• In the case of sloping ground, stand

above the tree to be felled.

• Small trees, with a diameter of 15-18

cm, can usually be sawn off with one

cut.

• In case of trees with a larger diameter,

a notched cut and a back cut must be

implemented (see diagram

Q

).

Page 19

1 9

G B

Do not fell any trees when

a strong or changing wind

is blowing, if the danger of

property damage exists or if

the tree could fall on electric

wires.

Immediately after termination of

the sawing procedure, remove the

ear protection so that you can hear

hooter and alarm signals.

1. Removal of branches:

Remove hanging branches by

positioning the cut from above

the branch. With removal of

branches, never work higher than

shoulder level.

P

2. Escape area:

Remove the undergrowth around

the tree to ensure an easy escape. The escape area (1) should

be around 45° either side behind

the planned felling direction (2).

Q

3. Cutting notch (A):

Make a felling notch in the direc-

tion in which you wish the tree to

fall. Start with the bottom, horizontal cut. The cut depth should

be around 1/3 of the trunk diameter. Now make a slanted saw

cut from above at an angle of

roughly 45° to meet exactly with

the bottom saw cut.

Never step in front of a tree

which is notched.

Q

4. Felling back cut (B):

Make the back cut from the other

side of the log, where you stand

to the left of the log and saw with

the chainsaw pulling. The back

cut must run horizontally 5 cm

above the horizontal notched cut.

The back cut should be so deep

that the separation distance between the back cut and the notch

cutting line is at least 1/10 of the

trunk diameter. The part of the

log not sawed through is designated as a break dimension.

R

5. Insert a felling wedge or a crowbar into the back cut, as soon as

the depth of cut permits this, in

order to prevent a jamming of the

chain bar.

S

6. If the trunk diameter is larger than

the length of the chain bar, make

two cuts.

7. After carrying out of the back cut,

the tree falls by itself or with the

aid of the felling wedge or crowbar.

As soon as the tree begins to

fall, pull out the saw from the

section, stop the motor, place

the electric chainsaw down

and leave the workplace using the withdrawal path.

O

Limbing

Limbing is the designation for the sawing

off of branches and boughs from a felled

tree.

Many accidents occur during the

removal of branches. Never cut tree

limbs when you are standing on the

log. Keep the spring-back area in

mind if branches are under tension.

• Do not remove support branches until

after the sawing off.

Page 20

2 0

G B

the rst cut to prevent the bar

from becoming jammed in the

wood.

M

3. Log is supported at both

ends:

Start from the top and work down

(with the lower edge of the bar)

to a third of the diameter of the

trunk. Then saw from underneath

with the upper edge of the bar

until the two cuts meet.

N

4. Sawing on a sawhorse:

Hold the electric chainsaw steady

with both hands, keeping the

saw in front of you while sawing. Once the saw is through

the wood, guide the machine

passed you on the right (1). Hold

your left arm as straight as you

can (2). Watch out for the falling

trunk. Position yourself to prevent

any danger from the separated

trunk. Watch your feet. The trunk

may cause injuries when falling.

Keep your balance (3).

Maintenance and

cleaning

Basically, carry out mainte-

nance and cleaning works

with switched-off motor and

power plug removed. Danger

of injury!

Leave any maintenance and

servicing work not covered

by this manual to our Service-Center. Use only original

spare parts.

Allow the machine to cool

down before all maintenance

and cleaning works. Danger

of burn injuries!

• Branches under tension must be sawed

from below to above, in order to prevent jamming of the chainsaw.

• When working on thicker branches,

use the same technique as when you

are sawing up a felled trunk.

Work to the left of the log and as near

as possible to the electric chainsaw. As

far as possible, the weight of the saw

should rest on the log.

• Change position to saw off branches

on the other side of the trunk.

• Branches sticking out are cut off separately.

Bucking

This refers to sawing up a felled tree trunk

into smaller sections.

• Ensure that the saw chain does not

come in contact with the ground during

sawing.

• Make sure you have a secure stance

and, in the case of sloping ground,

stand above the log.

K

1. Log is lying on the ground:

Saw through the log completely

from above and ensure at the

end of the cut not to contact the

ground.

If you can turn the tree trunk, saw

two-thirds of the way through it.

Then turn the trunk around and

saw the rest of the way through

from above.

L

2. Log is supported at one end:

Start sawing from the bottom and

work your way up (with the upper edge of the bar) a third of the

way into the diameter of the trunk

to prevent splitting. Then saw

from the top downwards with the

lower edge of the bar towards

Page 21

2 1

G B

Cleaning

• Clean the machine thoroughly after

every use. In this way, you extend the

life of the machine and avoid accidents.

• Keep the gripping handles free of petrol, oil or grease. Clean the gripping

handles, where appropriate, with a

moist cloth soaked in soap. Use no solvents or petrol for cleaning!

• Clean the saw chain after every use.

Use a paint brush or wipe for that. Do

not use any liquids to clean the chain.

After cleaning, oil the chain lightly with

chain oil.

• When cleaning, also remove the chain

wheel cover (15) so that this area can

be cleaned as well.

• Clean the chain bar (Guide) (4).

• Clean the ventilation slots and the

surfaces of the machine with a paint

brush, whisk or dry cloth. Do not use

any liquids for cleaning.

• Clean the oil passages of the chain

bar (27), in order to guarantee a trouble-free, automatic oiling of the saw

chain during operation.

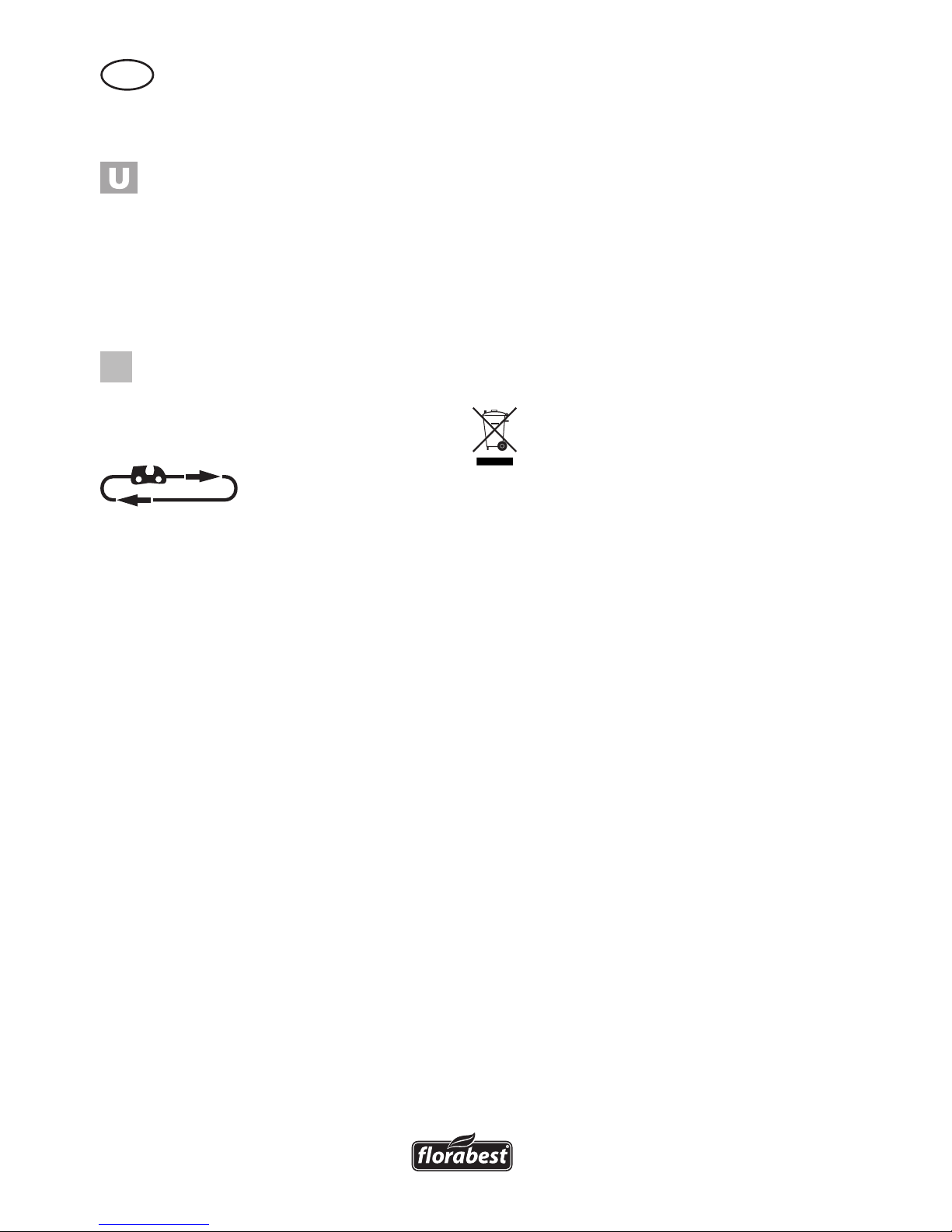

Maintenance intervals

Regularly carry out the maintenance operations listed in the following table. The life

of the saw is extended by regular maintenance of your chainsaw. Furthermore,

you get optimum cutting performance and

avoid accidents.

Maintenance Interval Table

Machine part Action

Before

every

use

After 10

hours

of operation

After

every

use

Components of the chain brake

Check, replace if required

Sprocket chain wheel (25)

Check, replace if required

Saw chain (5)

Check oil, regrind or

replace if required

Saw chain (5) Clean and oil

Guide bar (4) Check, clean and oil

Guide bar (4) turn around

Oil automatic system

check and, where

appropriate, clean oil

outow duct

Page 22

2 2

G B

• The sawing parts of the chain are the

cutting elements, which consist of a cutting tooth and a depth limiting projection. The vertical separation distance

between these two determines the

sharpness depth.

• The following values must be noted in

sharpening the cutting teeth:

H

- Sharp edge angle (30°)

- Breast angle (85°)

- Sharpness depth (0.65 mm)

- Round le diameter (4.0 mm)

Deviations from the meas-

urement data of the cutting

geometry can lead to an

increase of the spring-back

slope of the machine. Increased danger of accident!

Special tools are necessary for sharpening

the chain, which guarantee that the cutting

edges are sharpened at the correct angle

and to the correct depth. For the inexperienced user of chainsaws, we recommend

to have the saw chain sharpened by a

specialist or a specialist workshop. If you

think yourself capable of sharpening the

chain, you can acquire the special tools in

the specialist trade.

I

1. Switch the saw off and unplug it

from the mains.

2. Remove the saw chain (refer to the

section on operating the saw). The

chain should be well-tensioned to

ensure proper sharpening.

3. For the sharpening, a round le

with 4.0mm diameter is necessary.

Other diameters damage the

chain and can lead to danger

during work!

Oiling the saw chain

Clean and oil the chain regularly. In

this way, you keep the chain sharp

and get optimum machine performance. In case of damage due to

inadequate maintenance of the saw

chain, the guarantee claim is invalid.

Remove the power plug and use

cut-protection gloves when you are

handling the chain or the chain bar.

• Oil the chain after cleaning, after 10

hours of use or at least once weekly,

depending on which comes rst.

• Before oiling, the chain bar must be

cleaned thoroughly, in particular the

teeth of the rail. Use a whisk and a dry

cloth for that.

• Oil the individual chain links with the

aid of an oil suction gun with pinpoint

tip (available in the specialist trade).

Place individual oil drops onto the articulated links and onto the tooth tips of

the individual chain links.

Sharpening the saw chain

An incorrectly sharpened

saw chain increases the danger of spring-back!

Use cut-protection gloves

when you are handling the

chain or the chain bar.

A sharp chain guarantees an optimal

cutting performance. It eats effortlessly

through the wood and leaves large,

long wooden chips. A saw chain is

blunt if you have to press the cutting

equipment through the wood and the

wooden chips are very small. In the

case of a very blunt saw chain, no chip

cuttings result at all, only sawdust.

Page 23

2 3

G B

4. Sharpen only from the inside to

the outside. Guide the le from

the inner side of the cutting teeth

to the outer side. Lift the le when

you are withdrawing it.

5. Sharpen rst the teeth on one side.

Turn the saw around and sharpen

the teeth of the other side.

6. The chain is worn and must be

replaced by a new saw chain if

only approx. 4 mm of the cutting

teeth is remaining.

7. After the sharpening, all cutting

elements must now be equal in

length and width.

8. After every third sharpening, the

sharpness depth (depth limitation)

must be checked and the height led

with the aid of a at le. The depth

limitation should be set back about

0.65 mm from the cutting tooth.

After the setting back of depth limitation, round it off a little at the front.

Adjusting the chain tension

The adjustment of the chain tension is described in the chapter: Assembly, tension-

ing chainsaw.

Starting up a new saw chain

In the case of a new chain, the tensioning

force decreases after some time. Therefore,

you have to re-tension the chain after the

rst 5 cuts and no later than after 10 minutes’ sawing time.

Never attach a new chain to

a worn drive pinion or place

onto a damaged or worn

chain bar. The chain could

spring back or break, potentially leading to serious injury.

Maintaining the chain bar

Use cut-protection gloves

when handling the chain or

the chain bar.

1. Switch off the saw and pull out the

power plug (18).

2. Remove the sprocket chain wheel covering (15), the saw chain (5) and the

chain bar (4).

3. Check the chain bar (4) for wear. Remove burrs and straighten the guide

surfaces with a at le.

4. Clean the oil passages (

J

27) of

the chain bar, in order to guarantee

a trouble-free, automatic oiling of the

saw chain during operation.

5. Mount chain bar (4), chainsaw (5) and

sprocket chain wheel covering (15)

and tighten the chainsaw.

With the oil nozzles in good condi-

tion and the oil regulator set correctly, the saw chain will spray a

little oil off after starting.

Turn the chain bar

Use cut-protection gloves

when handling the chain or

the chain bar.

The blade (4) has to be reversed regularly

after a working time of approximately 10

hours in order to ensure even wear.

1. Switch off the saw and pull out

the power plug (18).

2. Remove the sprocket chain wheel

covering (15), the saw chain (5)

and the chain bar (4).

3. Put the sword (4) front and rotate

it on the back. Loosen the xation

Page 24

2 4

G B

screw (28) and remove the ten-

sioning plate (24).

4. Attach the tensioning plate (24)

with the xing screw (28) from

the other side to the sword (4).

This, make sure that the clamping

screw bolt (29) is down. The

round nose (24a) the clamping

screw sprocket must point in the

direction.

F

5. Mount chain bar (4), chainsaw

(5) and sprocket chain wheel

covering (15) and tighten the

chainsaw.

Direction of travel of the

saw chain

Use the graphical symbol below the chain

sprocket cover (15) as a guide to the alignment of the saw chain (5) when the blade

is rotated. The illustrated direction of travel

on the blade is no longer true.

Storage

• Clean the device prior to storage.

• Empty the oil tank prior to longer periods of non-use. Dispose of used oil

in an environmentally-responsible way

(see „Disposal/Environmental Protection“).

• Attach the protective blade cover.

• Store the device in a dry and dustproof

location and out of reach of children.

Waste disposal

and environmental

protection

Do not dispose of used oil in the sewage

system or drains. Dispose of used oil in an

environmentally correct manner - bring it to

a waste disposal center.

Be environmentally friendly. Return the

tool, accessories and packaging to a recy-

cling centre when you have nished with

them.

Machines do not belong with do-

mestic waste.

Labelled products must not be disposed of

with normal household waste but must be

returned to a collection point for the recycling of electrical and electronic equipment.

Recycling helps to reduce both the consumption of raw materials and the environmental impact. Information about disposal

and the location of the nearest recycling

centre may be obtained, for example, from

your local waste management department

or from Yellow Pages.

Empty the oil tank carefully and hand in

your electric chainsaw at a disposal center.

The plastic and metal parts employed can

be separated out and thus recycled use

can be implemented. Ask our ServiceCenter for details.

Page 25

2 5

G B

Replacement parts/Accessories

Spare parts and accessories can be obtained at

www.grizzly-service.eu

If you do not have internet access, please contact the Service Centre via telephone (see

“Service-Center” Page 28). Please have the order number mentioned below ready.

Oil ller cap ...........................................................................................75118246

Saw chain Oregon 91P057X ...................................................................30091571

Saw chain Oregon 91VXL ........................................................................30091598

16“ Chain bar ........................................................................................30100420

Bio chain oil 1 liter ..................................................................................30230001

Bio chain oil 5 liter ..................................................................................30230002

The Oregon replacement saw chain is to be used only in conjunc-

tion with the associated Oregon blade and the electric chainsaw

approved for this. There is a risk of injury.

Page 26

2 6

G B

Trouble shooting

Problem Possible cause Fault correction

Device does not start

Chain brake locked into

place.

Check chain brake.

Possibly release chain brake

Mains voltage defective

House protection fuse

activated

Check plug socket, cable, line

and plug, where appropriate,

repair by electrical specialist.

Check house protection fuse,

see note

Defective On/Off switch (10) Repair by customer service

Worn carbon brushes Repair by customer service

Defective motor Repair by customer service

Chain does not

rotate

Chain brake blocks saw

chain (5)

Check chain brake.

Possibly release chain brake

Inferior cutting

performance

Incorrectly mounted saw

chain (5)

Mount saw chain correctly

Saw chain (5) blunt

Sharpen cutting teeth or place

on new chain

Chain tension insufcient Check chain tension

Saw runs with

difculty, chain

comes off

Chain tension insufcient Check chain tension

Chain becomes hot,

smoke development

during sawing,

discoloration of the

rail

Too little chain oil

Check oil level and, where

appropriate, rell with chain oil,

check oil automatic system and,

where appropriate, clean oil

outow duct or have repaired by

customer service

Page 27

2 7

G B

Guarantee

Dear Customer,

This equipment is provided with a 3-year

guarantee from the date of purchase.

In case of defects, you have statutory rights

against the seller of the product. These

statutory rights are not restricted by our

guarantee presented below.

Terms of Guarantee

The term of the guarantee begins on the

date of purchase. Please retain the original

receipt. This document is required as proof

of purchase.

If a material or manufacturing defect

occurs within three years of the date of

purchase of this product, we will repair or

replace – at our choice – the product for

you free of charge. This guarantee requires

the defective equipment and proof of purchase to be presented within the three-year

period with a brief written description of

what constitutes the defect and when it occurred.

If the defect is covered by our guarantee,

you will receive either the repaired product

or a new product. No new guarantee period begins on repair or replacement of the

product.

Guarantee Period and Statutory

Claims for Defects

The guarantee period is not extended by

the guarantee service. This also applies for

replaced or repaired parts. Any damages

and defects already present at the time of

purchase must be reported immediately after unpacking. Repairs arising after expiry

of the guarantee period are chargeable.

Guarantee Cover

The equipment has been carefully produced in accordance with strict quality

guidelines and conscientiously checked

prior to delivery.

The guarantee applies for all material and

manufacturing defects. This guarantee

does not extend to cover product parts that

are subject to normal wear and may therefore be considered as wearing parts (e.g.

saw chain) or to cover damage to breakable parts (e.g. switches).

This guarantee shall be invalid if the product has been damaged, used incorrectly or

not maintained. Precise adherence to all of

the instructions specied in the operating

manual is required for proper use of the

product. Intended uses and actions against

which the operating manual advises or

warns must be categorically avoided.

The product is designed only for private

and not commercial use. The guarantee

will be invalidated in case of misuse or

improper handling, use of force, or interventions not undertaken by our authorised

service branch.

Processing in Case of Guarantee

To ensure quick handling of you issue,

please follow the following directions:

• Please have the receipt and item number (IAN 280275) ready as proof of

purchase for all enquiries.

• Please nd the item number on the rating plate.

• Should functional errors or other defects occur, please initially contact the

service department specied below by

telephone or by e-mail. You will then

receive further information on the processing of your complaint.

• After consultation with our customer

service, a product recorded as defective can be sent postage paid to the

service address communicated to you,

Page 28

2 8

G B

with the proof of purchase (receipt)

and specication of what constitutes

the defect and when it occurred. In order to avoid acceptance problems and

additional costs, please be sure to use

only the address communicated to you.

Ensure that the consignment is not sent

carriage forward or by bulky goods,

express or other special freight. Please

send the equipment inc. all accessories

supplied at the time of purchase and

ensure adequate, safe transport packaging.

Repair Service

For a charge, repairs not covered by the

guarantee can be carried out by our service branch, which will be happy to issue

a cost estimate for you.

We can handle only equipment that has

been sent with adequate packaging and

postage.

Attention: Please send your equipment to

our service branch in clean condition and

with an indication of the defect.

Equipment sent carriage forward or by

bulky goods, express or other special

freight will not be accepted.

We will dispose of your defective devices

free of charge when you send them to us.

Service-Center

G B

Service Great Britain

Tel.: 0871 5000 720

(£ 0.10/Min.)

E-Mail: grizzly@lidl.co.uk

IAN 280275

Importer

Please note that the following address is

not a service address. Please initially con-

tact the service centre specied above.

Grizzly Tools GmbH & Co. KG

Stockstädter Straße 20

63762 Großostheim

Germany

www.grizzly-service.eu

Page 29

2 9

S I

Kazalo

Úvod......................................... 29

Namen uporaba ....................... 30

Splošni opis .............................. 30

Obseg dobave ............................ 30

Pregled ...................................... 30

Opis funkcij ................................ 31

Tehnični podatki ........................ 31

Varnostna navodila .................. 31

Varnostna navodila/

simboli na žagi ........................... 32

Simboli v navodilih

za uporabo ................................ 33

Splošna varnostna navodila .......... 33

Splošni varnostni napotki

za električna orodja ..................... 33

Previdnostni ukrepi proti

Prevod originalne izjave o

skladnosti CE ...........................133

Eksplozijska risba ....................136

Úvod

Čestitke ob nakupu vaše nove naprave.

Odločili ste se za visokokakovosten izde-

lek.

Kakovost naprave je bila preverjena med

postopkom proizvodnje in pri končnem

preverjanju, s čimer je zagotovljeno pravilno delovanje vaše naprave. Kljub temu ni

mogoče izključiti, da so v posameznih pri-

merih v napravi oz. v ceveh ostanki vode

ali maziv. To ni napaka ali pomanjkljivost

in ni vzrok za skrb.

Izdelku so priložena navodila za

uporabo. Vsebujejo pomembna

navodila glede varnosti uporabe in

odstranitve. Pred uporabo izdelka

se seznanite z navodili za uporabo

in varnostnimi navodili. Izdelek

uporabljajte zgolj na opisani način

in v naštete namene.

Navodila skrbno shranite in pri

predaji naprave tretji osebi priložite

tudi vso dokumentacijo.

povratnemu udarcu ...................... 37

Dodatni varnostni napotki ............. 38

Varnostne funkcije ....................... 38

Montaža ................................... 39

Montaža verige ........................... 39

Montaža meča ............................ 39

Napenjanje verige ...................... 40

Oljenje verige ............................. 40

Upravljanje verižne žage .......... 41

Vklop ......................................... 41

Preverjanje verižne zavore ............ 41

Preverjanje avtomatike za oljenje .. 42

Menjava meča ............................ 42

Tehnike žaganja........................ 42

Splošno ...................................... 42

Podiranje dreves .......................... 42

Obvejevanje ............................... 44

Rezanje na dolžino ...................... 44

Vzdrževanje in čiščenje ............. 45

Čiščenje ..................................... 45

Intervali vzdrževanja ................... 46

Tabela intervalov vzdrževanj......... 46

Oljenje verige ............................. 46

Brušenje verige ........................... 47

Nova veriga se mora uteči ........... 48

Vzdrževanje meča ....................... 48

Pa meča ..................................... 48

Shranjevanje ............................. 48

Nadomestni deli / Pribor .......... 49

Odstranjevanje/varstvo okolja . 49

Odpravljanje napak .................. 50

Garancijski list .......................... 51

Page 30

3 0

S I

Namen uporaba

Električna verižna žaga je primerna samo

za žaganje lesa in ni namenjena obdelo-

vanju drugih materialov, npr. zidov, ume-

tnih snovi ali živil.

Električna žaga je namenjena domači

uporabi in ni primerna za profesionalno

uporabo.

Žago lahko uporabljajo samo odrasli. Mladoletniki, starejši od 16 let, smejo žago upo-

rabljati samo pod nadzorom odrasle osebe.

Proizvajalec ne odgovarja za škodo,

povzročeno zaradi nenamenske ali napačne uporabe.

Električno verižno žago lahko uporablja

zgolj ena oseba za žaganje lesa. Verižno

žago z desno roko držite za zadnji ročaj

in z levo roko za sprednji ročaj. Uporabnik

mora pred uporabo verižne žage prebrati

in razumeti vse opozorila in navodila v

navodilih za uporabo. Uporabnik mora

nositi ustrezno osebno zaščitno opremo.

Z verižno žago je dovoljeno žagati le

les. Žaganje materialov, kot so plastika,

kamen, kovina ali les, ki vsebuje tujke (npr.

žeblje ali vijake), ni dovoljeno!

Splošni opis

Slikovni prikaz najpomembnej-

ših funkcijskih delov najdete na

sprednji in zadnji razklopni strani.

Obseg dobave

- Električna verižna žaga

- Meč (vodilna tirnica) (že montirani)

- Veriga (že montirani)

- Ščitnik meča

- Steklenica s 180 ml bioolja

za verigo žage

- Navodila za uporabo

Pregled

A

1 Zadnji ročaj

2 Pokrovček posode za olje

3 Ročica verižne zavore / prednja

zaščita za roke

4 Meč (vodilna tirnica)

5 Veriga

6 Menjalna konica

7 Zobati prislon

8 Sprednji ročaj

9 Elektromotor

10 Stikalo za vklop/izklop

11 Zapora vklopa

12 Lovilec verige

13 Obroček za napenjanje verige

14 Pritrdilni vijak pokrova verižnika

15 Pokrov verižnika

16 Zadnja zaščita za roke

17 Držalo za kabel

18 Priključni kabel

20 Steklenica za olje

C

21 Prikaz nivoja olja

22 Oznaka za minimum „MIN“ na

prikazu nivoja olja

F

23 Železniškega vijaka

24 Pritrdilni vijak

G

25 Zobnik

26 Nos

J

27 Olje prehod

28 Vijak za pritrjevanje

29 Pritrdilni vijak vijak

Page 31

3 1

S I

Opis funkcij

Verižno žago poganja elektromotor. Veriga

žage teče okrog meča (vodilna tirnica).

Naprava je opremljena s sistemom za hitro

napenjanje verige in verižno zavoro za

hitro zaustavitev. Avtomatika skrbi za stalno podmazovanje verige. Zaradi varnosti

uporabnika je verižna žaga opremljena z

različnimi varovalnimi napravami.

Funkcije delov za upravljanje so navedene

v naslednjem opisu.

Tehnični podatki

Električna

verižna žaga ...............FKS 2200 F3

Nazivna napetost U .. 230-240 V~, 50 Hz

Nazivna moč P ..........................2200 W

Razred zaščite .................................

II

Vrsta zaščite ....................................IP20

Hitrost verige v

0

.......................15,3 m/s

Teža (brez meča in verige) .............4,4 kg

Teža (z mečem in verigo) ...............5,3 kg

Prostornina posode

za olje znaša .................... pribl. 190 ml

Veriga ........................Oregon 91P057X

......................................... kromiran zob

......zmanjšana možnost povratnih udarcev

Meč ...............Oregon 16“ Double-Guard

........................... 160SDEA041-112364

Razmak verige ............................. 10 mm

Širina verige ............................... 1,3 mm

Ozobje verižnika ................................. 7

Meč (vodilna tirnica) ................. 460 mm

Dolžina reza ............................ 395 mm

Raven zvočnega

tlaka (L

pA

) ............ 84,9 dB (A); KpA=3 dB

Raven zvočne moči

(L

WA

) ............. 107,7 dB (A); KWA=2,58 dB

Zajamčena raven zvočne moči 110 dB (A)

Vibracije (a

h

) ..... 7,612 m/s2 ; K=1,5 m/s

2

Navedena vrednost vibracij je izmerjena

po standardiziranem postopku ter jo je

možno uporabiti za medsebojno primerjavo električnih orodij.

Navedeno vrednost vibracij je prav tako

možno uporabiti za oceno izpostavljenosti

uporabnika.

Opozorilo:

Vrednost vibracij med dejansko

uporabo se lahko razlikuje od nave-

dene vrednosti, odvisno od načina

uporabe električnega orodja.

Določiti je treba varnostne ukrepe

za zaščito uporabnika, ki so odvis-

ni od ocene izpostavljenosti med

dejansko uporabo (pri tem je treba

upoštevati tudi čas, ko je orodje

izključeno, in čas, ko je vključeno,

vendar deluje brez obremenitve).

Pridržujemo si pravico do tehničnih in

oblikovnih sprememb, ki so povezane z

nadaljnjim razvojem žage.

Zaradi tega ne jamčimo za mere, navodila

in podatke v teh navodilih za uporabo.

Pravnih zahtevkov na podlagi navodil za

uporabo ni možno uveljavljati.

Varnostna navodila

V tem poglavju so podana osnovna varno-

stna navodila za delo z električno verižno

žago.

Električna verižna žaga je nevarna

naprava, ki lahko pri napačni ali

malomarni uporabi povzroči resne ali

celo smrtne poškodbe. Da bi zagotovili lastno varnost in varnost drugih,

vedno upoštevajte naslednja varnostna navodila ter v primeru negotovosti prosite za nasvet strokovnjaka.

Page 32

3 2

S I

Varnostna navodila/

simboli na žagi

Pred delom se dobro seznanite z vse-

mi upravljalnimi elementi naprave.

Vadite delo z žago ter prosite strokovnjaka, da vam razloži funkcije,

način delovanja in tehnike žaganja.

Veriga žage se ne vrti, če je aktivira-

na verižna zavora. Sprostite verižno

zavoro tako, da potisnete zavorno

ročico proti sprednjemu ročaju.

Preberite in upoštevajte navodila za

uporabo naprave!

Nosite zaščitna očala

in zaščito za sluh

Nosite zaščito glave!

Nosite zaščitne rokavice, da

preprečite ureznine!

Nosite varnostne čevlje s stabilnim

podplatom!

Nosite zaščitno obleko!

Verižno žago vedno

uporabljajte z dvema

rokama

Pozor! Nevarnost povratnih udar-

cev! Pri delu pazite na povratne

udarce naprave.

Naprave ne izpostavljajte dežju ali

vlagi. Naprave ne uporabljajte v

vlažnem okolju.

Pozor! V primeru, da se priključni

kabel med žaganjem poškoduje ali

prereže, ga nemudoma izvlecite iz

vtičnice.

dB

L

WA

Zajamčena raven zvočne moči

Simboli na tablici s podatki:

Električne naprave ne odstranite z

gospodinjskimi odpadki.

460 mm

Meč (vodilna tirnica)

Zaščitni razred II

Simboli pod pokrovom zobnika:

Upoštevajte smer vrtenja verige žage.Pozor! Preberite navodila za uporabo.

Simboli na meču:

Smer vrtenja verige žage

Simbol na pokrovu posode za olje:

Naoljite verigo žage

Simbola na pritrdilnem vijaku pokrova

zobnika:

ODPRTO

ZAPRTO

Simboli na ročici verižne zavore:

O Verižna zavora: izključena

I Verižna zavora: vključena

Page 33

3 3

S I

Simboli v navodilih

za uporabo

Opozorilni simboli z napotki

za preprečevanje poškodb in

materialne škode.

Simbol za obveznost (namesto kli-

caja je podana zapoved) z naved-

bami za preprečevanje škode.

Obvestilni simbol z informacijami

za boljše rokovanje z napravo.

Splošna varnostna navodila

Pred uporabo žage se seznanite z

vsemi upravljalnimi elementi. Vadite

žaganje (žagajte hlodovino na kozi

za žaganje) in prosite izkušeno osebo ali strokovnjaka, da vam razloži

funkcije, način delovanja in tehnike

žaganja ter vas seznani z osebno

zaščitno opremo.

Upoštevajte navodila za zaščito

pred hrupom in lokalne predpise za

podiranje dreves. V skladu z lokalnimi predpisi je morebiti potreben

preizkus sposobnosti. Povprašajte

pri svojem gozdarskem uradu.

Pozor! Pri uporabi električnih orodij

je treba za zaščito pred električnim

udarom, nevarnostjo telesnih

poškodb in požara upoštevati naslednje temeljne varnostne ukrepe:

Obstaja nevarnost telesnih

poškodb.

Splošni varnostni napotki

za električna orodja

OPOZORILO! Preberite vsa