Page 1

FANUC Series 0

+

OPERATOR'S MANUAL

-PD

B-64554EN/01

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan. Further, re-export to another country may be subject to the license

of the government of the country from where the product is re-exported. Furthermore, the

product may also be controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

The products in this manual are manufactured under strict quality control. However, when

using any of the products in a facility in which a serious accident or loss is predicted due to

a failure of the product, install a safety device.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

Page 3

B-64554EN/01 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units.

It is essential that these precautions be observed by users to ensure the safe operation of machines

equipped with a CNC unit (all descriptions in this section assume this configuration). Note that some

precautions are related only to specific functions, and thus may not be applicable to certain CNC units.

Users must also observe the safety precautions related to the machine, as described in the relevant manual

supplied by the machine tool builder. Before attempting to operate the machine or create a program to

control the operation of the machine, the operator must become fully familiar with the contents of this

manual and relevant manual supplied by the machine tool builder.

CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE.........................................................................s-1

GENERAL WARNINGS AND CAUTIONS............................................................................................s-2

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING.......................................................s-3

WARNINGS AND CAUTIONS RELATED TO HANDLING ................................................................s-4

WARNINGS RELATED TO DAILY MAINTENANCE .........................................................................s-6

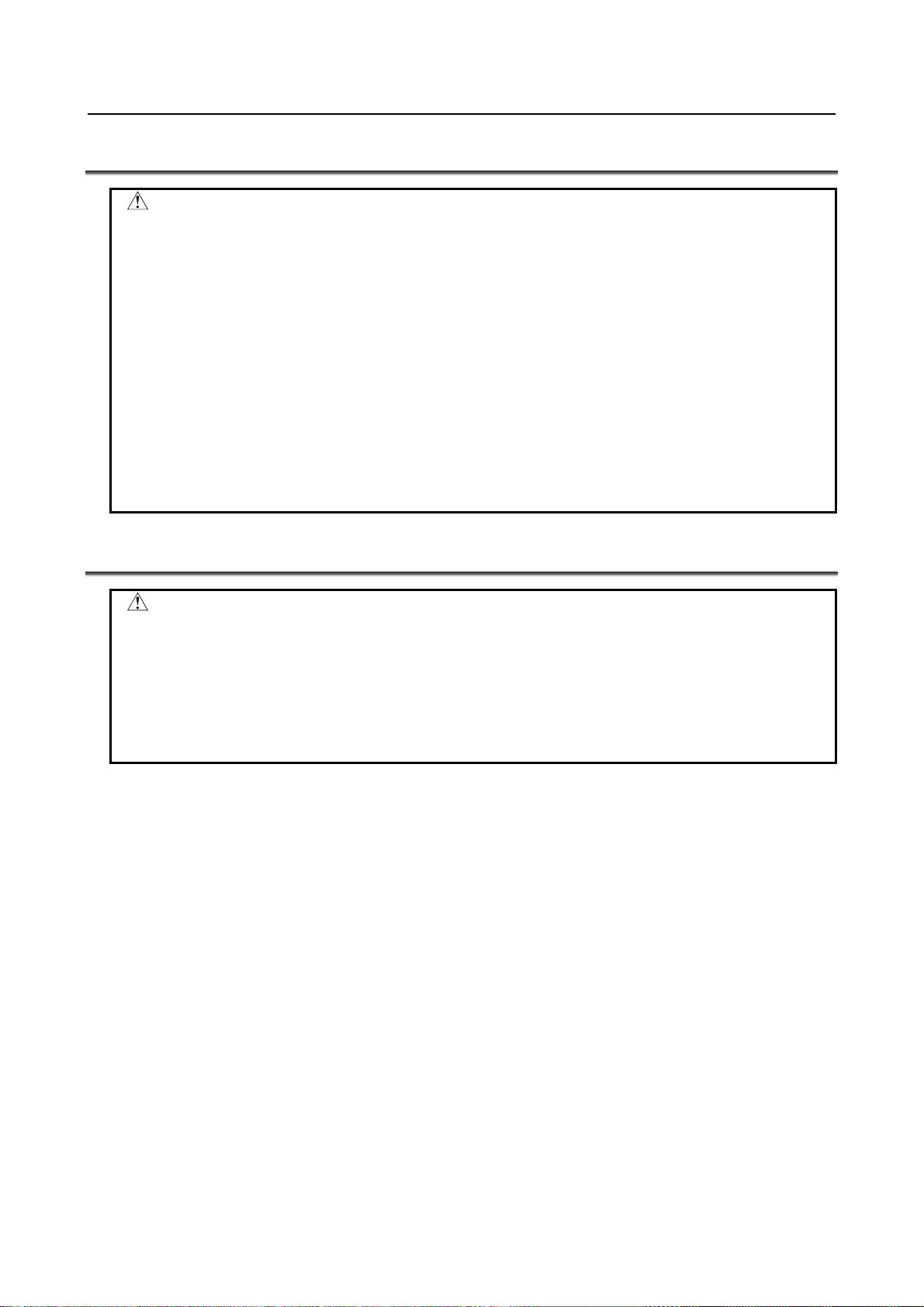

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

• Read this manual carefully, and store it in a safe place.

s-1

Page 4

SAFETY PRECAUTIONS B-64554EN/01

GENERAL WARNINGS AND CAUTIONS

WARNING

1 Never attempt to machine a workpiece without first checking the operation of the

machine. Before starting a production run, ensure that the machine is operating

correctly by performing a trial run using, for example, the single block, feedrate

override, or machine lock function or by operating the machine with neither a tool

nor workpiece mounted. Failure to confirm the correct operation of the machine

may result in the machine behaving unexpectedly, possibly causing damage to

the workpiece and/or machine itself, or injury to the user.

2 Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

3 Ensure that the specified feedrate is appropriate for the intended operation.

Generally, for each machine, there is a maximum allowable feedrate.

The appropriate feedrate varies with the intended operation. Refer to the manual

provided with the machine to determine the maximum allowable feedrate.

If a machine is run at other than the correct speed, it may behave unexpectedly,

possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

4 When using a tool compensation function, thoroughly check the direction and

amount of compensation.

Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

5 The parameters for the CNC and PMC are factory-set. Usually, there is not need

to change them. When, however, there is not alternative other than to change a

parameter, ensure that you fully understand the function of the parameter before

making any change.

Failure to set a parameter correctly may result in the machine behaving

unexpectedly, possibly causing damage to the workpiece and/or machine itself,

or injury to the user.

CAUTION

1 Immediately after switching on the power, do not touch any of the keys on the

MDI panel until the position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other

special operations. Pressing any of these keys may place the CNC unit in other

than its normal state. Starting the machine in this state may cause it to behave

unexpectedly.

2 The OPERATOR’S MANUAL and programming manual supplied with a CNC

unit provide an overall description of the machine's functions, including any

optional functions. Note that the optional functions will vary from one machine

model to another. Therefore, some functions described in the manuals may not

actually be available for a particular model. Check the specification of the

machine if in doubt.

s-2

Page 5

B-64554EN/01 SAFETY PRECAUTIONS

CAUTION

3 Some functions may have been implemented at the request of the machine-tool

builder. When using such functions, refer to the manual supplied by the

machine-tool builder for details of their use and any related cautions.

4 The liquid-crystal display is manufactured with very precise fabrication

technology. Some pixels may not be turned on or may remain on. This

phenomenon is a common attribute of LCDs and is not a defect.

NOTE

Programs, parameters, and macro variables are stored in nonvolatile memory in

the CNC unit. Usually, they are retained even if the power is turned off.

Such data may be deleted inadvertently, however, or it may prove necessary to

delete all data from nonvolatile memory as part of error recovery.

To guard against the occurrence of the above, and assure quick restoration of

deleted data, backup all vital data, and keep the backup copy in a safe place.

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING

This section covers the major safety precautions related to programming. Before attempting to perform

programming, read the supplied OPERATOR’S MANUAL carefully such that you are fully familiar with

their contents.

WARNING

1

Coordinate system setting

If a coordinate system is established incorrectly, the machine may behave

unexpectedly as a result of the program issuing an otherwise valid move

command. Such an unexpected operation may damage the tool, the machine

itself, the workpiece, or cause injury to the user.

2

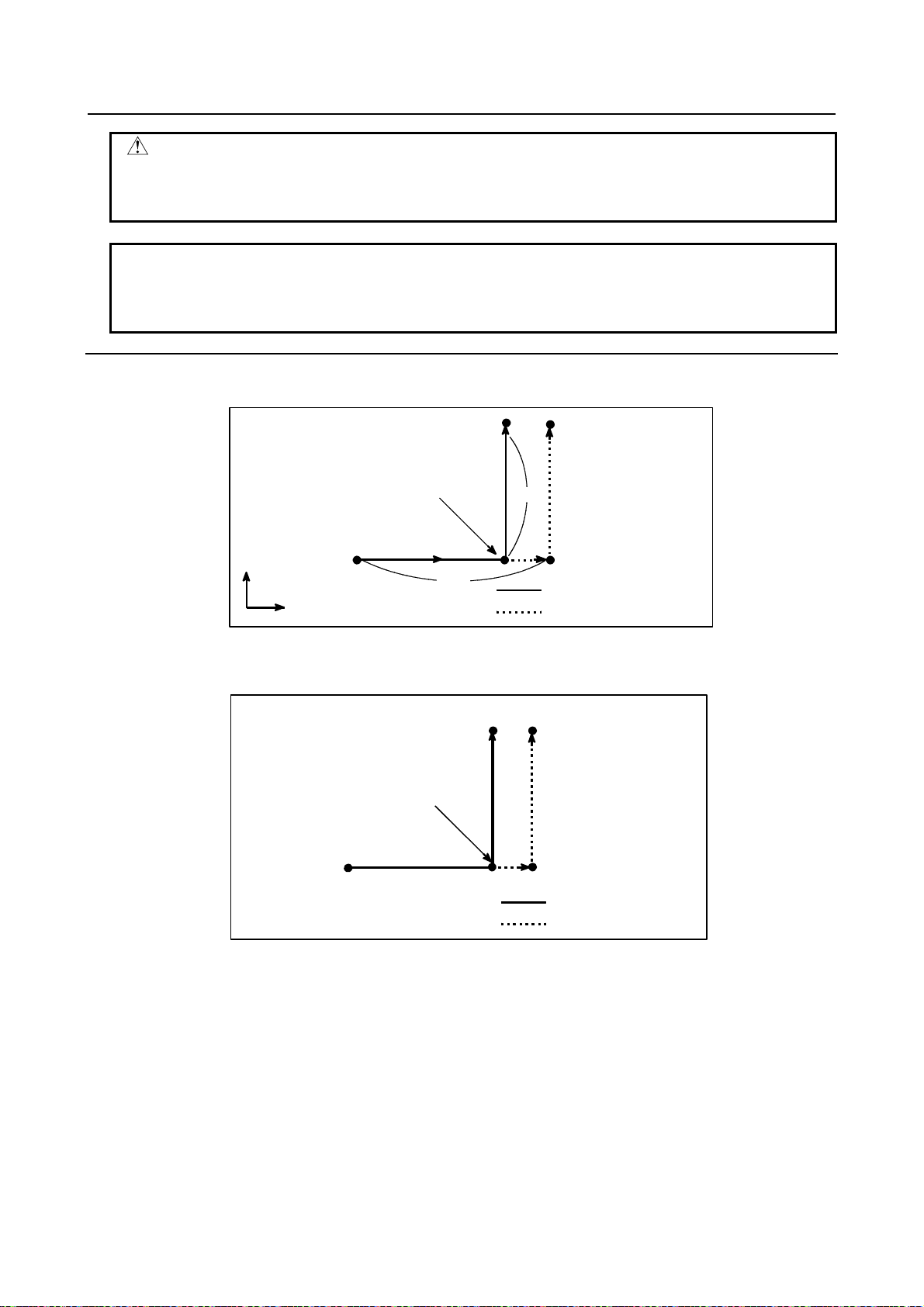

Positioning by nonlinear interpolation

When performing positioning by nonlinear interpolation (positioning by nonlinear

movement between the start and end points), the tool path must be carefully

confirmed before performing programming. Positioning involves rapid traverse. If

the tool collides with the workpiece, it may damage the tool, the machine itself,

the workpiece, or cause injury to the user.

3

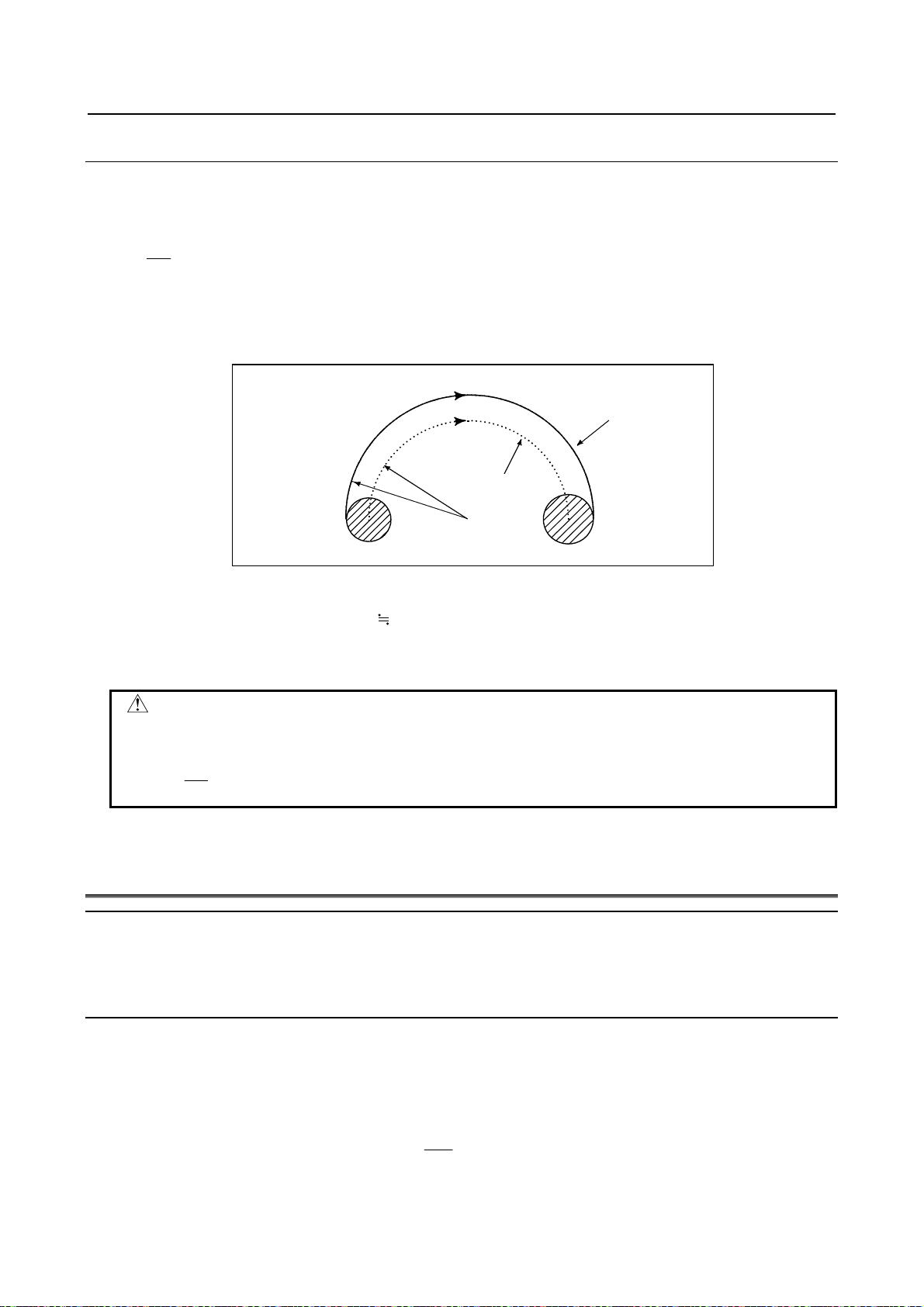

Function involving a rotation axis

When programming normal-direction (perpendicular) control, pay careful

attention to the speed of the rotation axis. Incorrect programming may result in

the rotation axis speed becoming excessively high, such that centrifugal force

causes the chuck to lose its grip on the workpiece if the latter is not mounted

securely. Such mishap is likely to damage the tool, the machine itself, the

workpiece, or cause injury to the user.

4

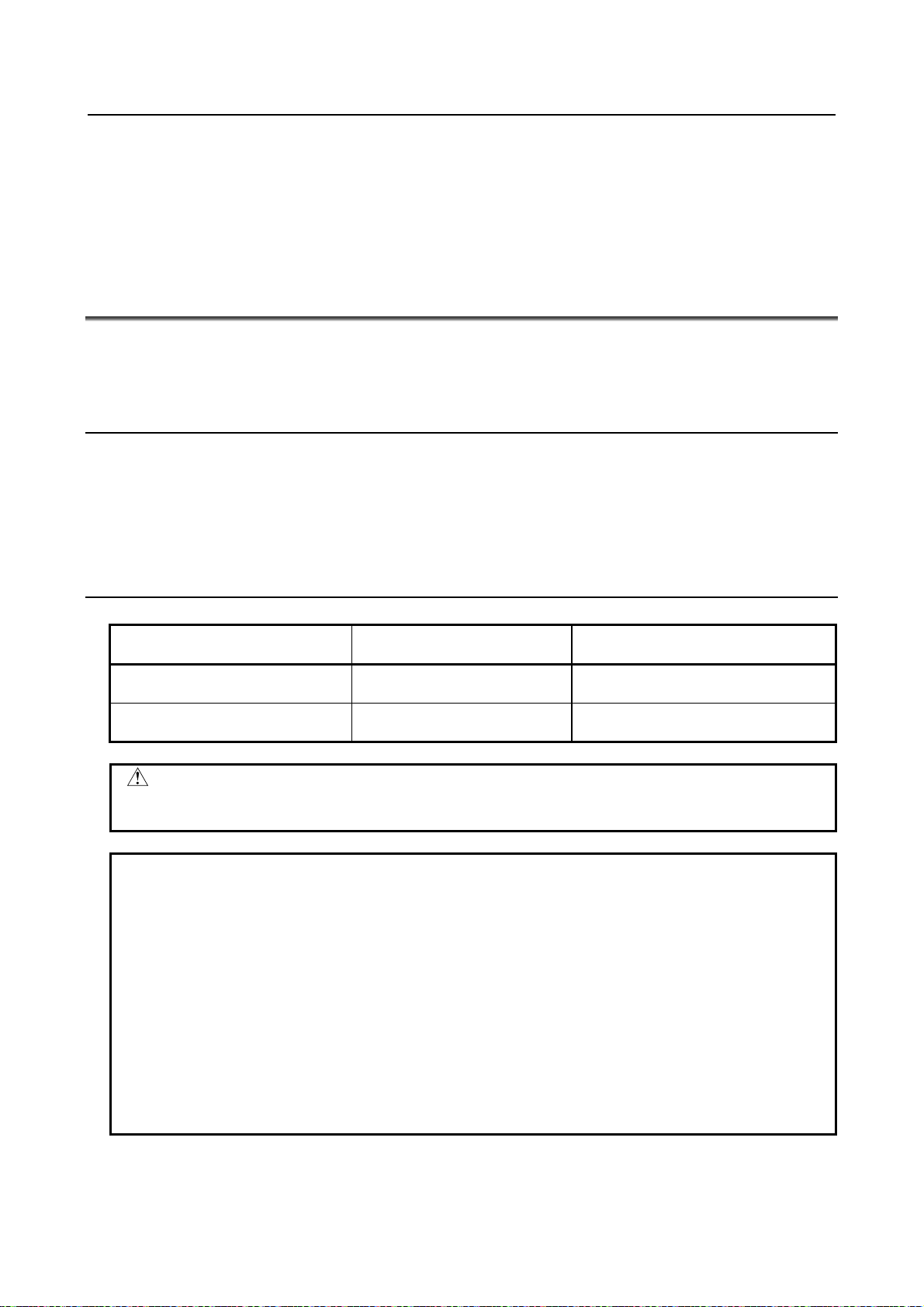

Inch/metric conversion

Switching between inch and metric inputs does not convert the measurement

units of data such as the workpiece origin offset, parameter, and current

position. Before starting the machine, therefore, determine which measurement

units are being used. Attempting to perform an operation with invalid data

specified may damage the tool, the machine itself, the workpiece, or cause injury

to the user.

s-3

Page 6

SAFETY PRECAUTIONS B-64554EN/01

WARNING

5

Stroke check

After switching on the power, perform a manual reference position return as

required. Stroke check is not possible before manual reference position return is

performed. Note that when stroke check is disabled, an alarm is not issued even

if a stroke limit is exceeded, possibly damaging the tool, the machine itself, the

workpiece, or causing injury to the user.

CAUTION

1

Absolute/incremental mode

If a program created with absolute values is run in incremental mode, or vice

versa, the machine may behave unexpectedly.

2

Plane selection

If an incorrect plane is specified for circular interpolation, helical interpolation, or

a canned cycle, the machine may behave unexpectedly. Refer to the

descriptions of the respective functions for details.

3

Torque limit skip

Before attempting a torque limit skip, apply the torque limit. If a torque limit skip

is specified without the torque limit actually being applied, a move command will

be executed without performing a skip.

4

Compensation function

If a command based on the machine coordinate system or a reference position

return command is issued in compensation function mode, compensation is

temporarily canceled, resulting in the unexpected behavior of the machine.

Before issuing any of the above commands, therefore, always cancel

compensation function mode.

WARNINGS AND CAUTIONS RELATED TO HANDLING

This section presents safety precautions related to the handling of machine tools. Before attempting to

operate your machine, read the supplied OPERATOR’S MANUAL carefully, such that you are fully

familiar with their contents.

WARNING

1

Manual operation

When operating the machine manually, determine the current position of the tool

and workpiece, and ensure that the movement axis, direction, and feedrate have

been specified correctly. Incorrect operation of the machine may damage the

tool, the machine itself, the workpiece, or cause injury to the operator.

2

Manual reference position return

After switching on the power, perform manual reference position return as

required.

If the machine is operated without first performing manual reference position

return, it may behave unexpectedly. Stroke check is not possible before manual

reference position return is performed.

An unexpected operation of the machine may damage the tool, the machine

itself, the workpiece, or cause injury to the user.

s-4

Page 7

B-64554EN/01 SAFETY PRECAUTIONS

WARNING

3

Manual handle feed

In manual handle feed, rotating the handle with a large scale factor, such as 100,

applied causes the tool and table to move rapidly. Careless handling may

damage the tool and/or machine, or cause injury to the user.

4

Disabled override

If override is disabled (according to the specification in a macro variable), the

speed cannot be predicted, possibly damaging the tool, the machine itself, the

workpiece, or causing injury to the operator.

5

Origin/preset operation

Basically, never attempt an origin/preset operation when the machine is

operating under the control of a program. Otherwise, the machine may behave

unexpectedly, possibly damaging the tool, the machine itself, the tool, or causing

injury to the user.

6

Workpiece coordinate system shift

Manual intervention, machine lock, or mirror imaging may shift the workpiece

coordinate system. Before attempting to operate the machine under the control

of a program, confirm the coordinate system carefully.

If the machine is operated under the control of a program without making

allowances for any shift in the workpiece coordinate system, the machine may

behave unexpectedly, possibly damaging the tool, the machine itself, the

workpiece, or causing injury to the operator.

7

Software operator's panel and menu switches

Using the software operator's panel and menu switches, in combination with the

MDI panel, it is possible to specify operations not supported by the machine

operator's panel, such as mode change, override value change, and jog feed

commands.

Note, however, that if the MDI panel keys are operated inadvertently, the

machine may behave unexpectedly, possibly damaging the tool, the machine

itself, the workpiece, or causing injury to the user.

8

RESET key

Pressing the RESET key stops the currently running program. As a result, the

servo axes are stopped. However, the RESET key may fail to function for

reasons such as an MDI panel problem. So, when the motors must be stopped,

use the emergency stop button instead of the RESET key to ensure security.

CAUTION

1

Manual intervention

If manual intervention is performed during programmed operation of the

machine, the tool path may vary when the machine is restarted. Before restarting

the machine after manual intervention, therefore, confirm the settings of

parameters, and absolute/incremental command mode.

2

Feed hold, override, and single block

The feed hold, feedrate override, and single block functions can be disabled

using custom macro system variable #3004. Be careful when operating the

machine in this case.

s-5

Page 8

SAFETY PRECAUTIONS B-64554EN/01

CAUTION

3

Dry run

Usually, a dry run is used to confirm the operation of the machine. During a dry

run, the machine operates at dry run speed, which differs from the

corresponding programmed feedrate. Note that the dry run speed may

sometimes be higher than the programmed feed rate.

4

Cutter radius compensation in MDI mode

Pay careful attention to a tool path specified by a command in MDI mode,

because cutter radius compensation is not applied. When a command is entered

from the MDI to interrupt in automatic operation in cutter radius compensation

mode, pay particular attention to the tool path when automatic operation is

subsequently resumed. Refer to the descriptions of the corresponding functions

for details.

5

Program editing

If the machine is stopped, after which the machining program is edited

(modification, insertion, or deletion), the machine may behave unexpectedly if

machining is resumed under the control of that program. Basically, do not

modify, insert, or delete commands from a machining program while it is in use.

WARNINGS RELATED TO DAILY MAINTENANCE

WARNING

1

Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine

(CNC) turned on, and apply an emergency stop to the machine. Because this

work is performed with the power on and the cabinet open, only those personnel

who have received approved safety and maintenance training may perform this

work.

When replacing the batteries, be careful not to touch the high-voltage circuits

(marked and fitted with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous

electric shock hazard.

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must

retain data such as programs, offsets, and parameters even while external

power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within a

week. Otherwise, the contents of the CNC's memory will be lost.

Refer to the Section “IV. MAINTENANCE - Method of replacing battery” in the

OPERATOR’S MANUAL for details of the battery replacement procedure.

s-6

Page 9

B-64554EN/01 SAFETY PRECAUTIONS

WARNING

2

Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine

(CNC) turned on, and apply an emergency stop to the machine. Because this

work is performed with the power on and the cabinet open, only those personnel

who have received approved safety and maintenance training may perform this

work.

When replacing the batteries, be careful not to touch the high-voltage circuits

(marked and fitted with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous

electric shock hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within a

week. Otherwise, the absolute position data held by the pulse coder will be lost.

Refer to the Section “IV. MAINTENANCE - Method of replacing battery” in the

OPERATOR’S MANUAL for details of the battery replacement procedure.

WARNING

3

Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and remove the

cause of the blown fuse.

For this reason, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the

high-voltage circuits (marked and fitted with an insulating cover).

Touching an uncovered high-voltage circuit presents an extremely dangerous

electric shock hazard.

s-7

Page 10

Page 11

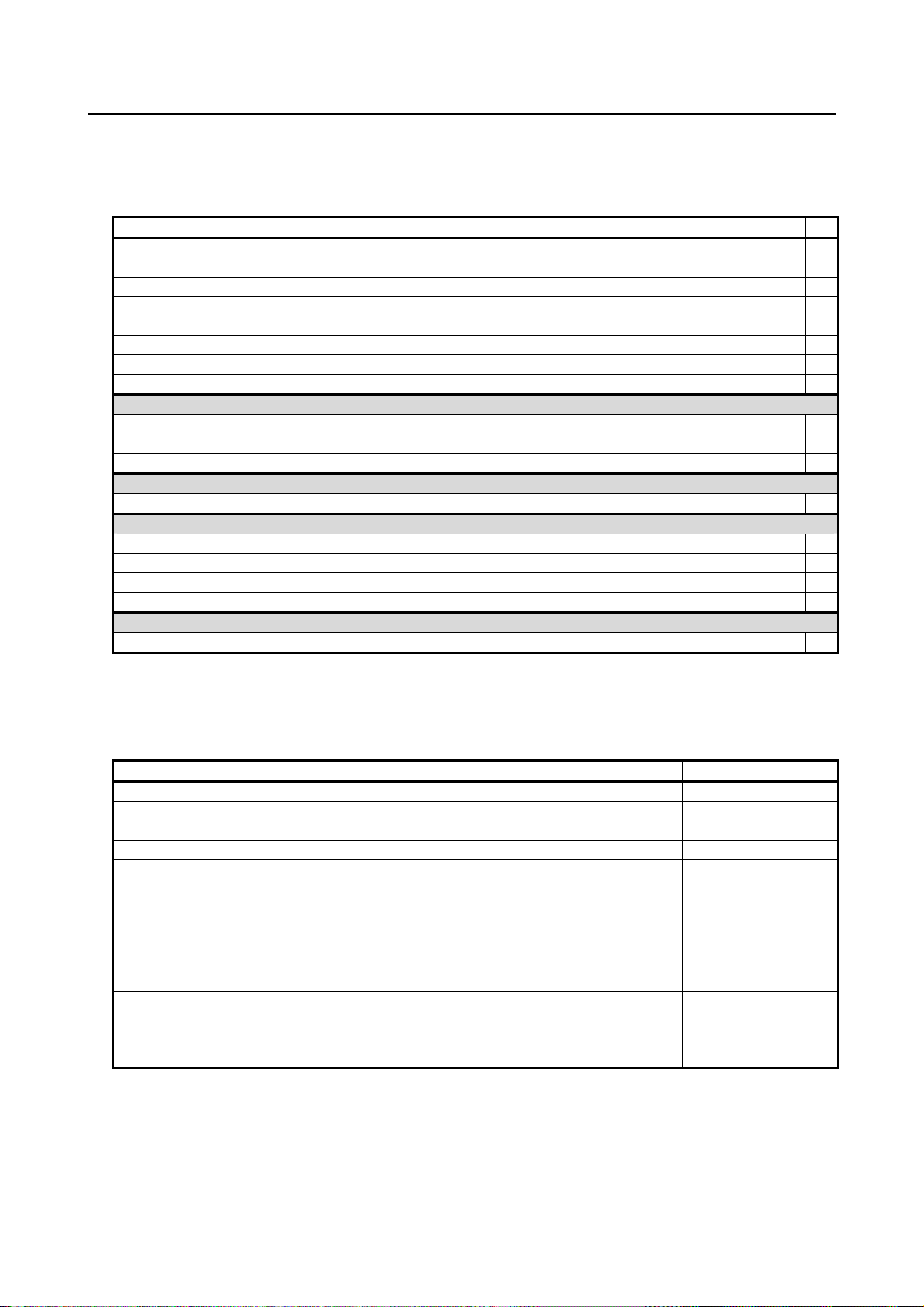

B-64554EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

DEFINITION OF WARNING, CAUTION, AND NOTE.............................................s-1

GENERAL WARNINGS AND CAUTIONS...............................................................s-2

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING ............................s-3

WARNINGS AND CAUTIONS RELATED TO HANDLING......................................s-4

WARNINGS RELATED TO DAILY MAINTENANCE...............................................s-6

I. GENERAL

1 GENERAL...............................................................................................3

1.1 NOTES ON READING THIS MANUAL..........................................................5

1.2 NOTES ON VARIOUS KINDS OF DATA ......................................................5

II. PROGRAMMING

1 GENERAL...............................................................................................9

1.1 TOOL MOVEMENT ALONG WORKPIECE PARTS

FIGURE-INTERPOLATION.........................................................................10

1.2 FEED-FEED FUNCTION.............................................................................12

1.3 PART DRAWING AND TOOL MOVEMENT................................................12

1.3.1 Reference Position (Machine-specific Position) ....................................................12

1.3.2 Coordinate System on Part Drawing and Coordinate System Specified by CNC -

Coordinate System .................................................................................................13

1.3.3 How to Indicate Command Dimensions for Moving the Tool (Absolute and

Incremental Programming).....................................................................................15

1.4 SELECTION OF TOOL USED FOR VARIOUS MACHINING - TOOL

FUNCTION..................................................................................................16

1.5 COMMAND FOR MACHINE OPERATIONS - AUXILIARY FUNCTION......16

1.6 PROGRAM CONFIGURATION...................................................................17

1.7 TOOL MOVEMENT RANGE - STROKE......................................................19

2 CONTROLLED AXES...........................................................................20

2.1 NUMBER OF CONTROLLED AXES...........................................................20

2.2 NAMES OF AXES .......................................................................................20

2.3 INCREMENT SYSTEM................................................................................20

2.4 MAXIMUM STROKE....................................................................................21

3 PREPARATORY FUNCTION (G FUNCTION)......................................22

3.1 G CODE LIST..............................................................................................23

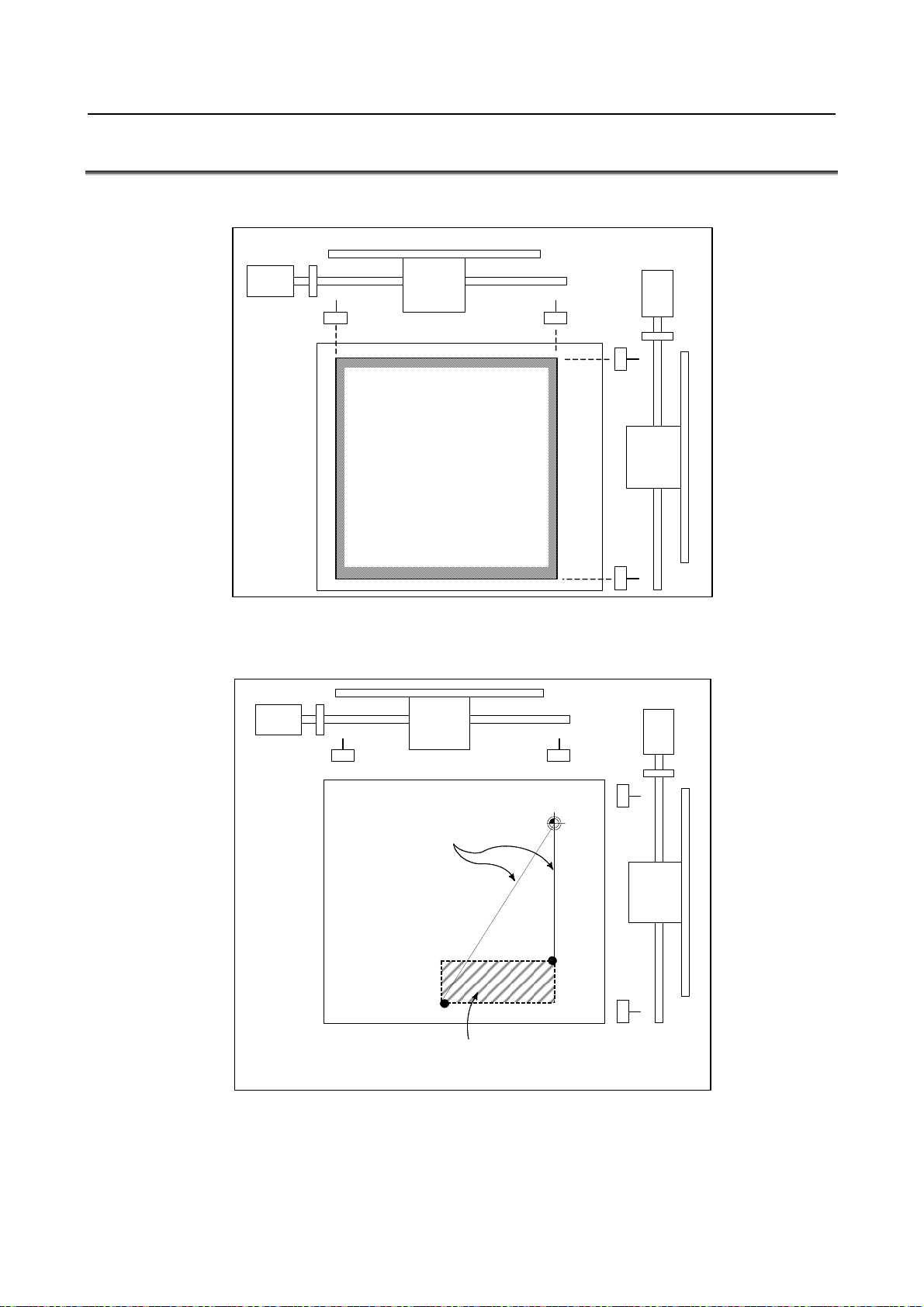

4 INTERPOLATION FUNCTIONS............................................................25

4.1 POSITIONING (G00)...................................................................................25

4.2 LINEAR INTERPOLATION (G01)................................................................26

4.3 CIRCULAR INTERPOLATION (G02, G03)..................................................28

4.4 HELICAL INTERPOLATION (G02, G03).....................................................32

4.5 SKIP FUNCTION (G33)...............................................................................33

c-1

Page 12

TABLE OF CONTENTS B-64554EN/01

4.6 MULTI-STEP SKIP (G33)............................................................................35

4.7 HIGH-SPEED SKIP SIGNAL (G33).............................................................36

4.8 SKIP POSITION MACRO VARIABLE IMPROVEMENT..............................36

4.9 TORQUE LIMIT SKIP..................................................................................36

5 FEED FUNCTIONS ...............................................................................40

5.1 OVERVIEW .................................................................................................40

5.2 RAPID TRAVERSE .....................................................................................41

5.2.1 Rapid Traverse Rate by F Command .....................................................................41

5.2.2 F1-digit (Programmable Rapid Traverse Override) ...............................................42

5.3 CUTTING FEED..........................................................................................42

5.4 CUTTING FEEDRATE CONTROL..............................................................43

5.4.1 Exact Stop (G09, G61), Cutting Mode (G64) ........................................................44

5.4.2 Automatic Corner Override....................................................................................45

5.4.2.1 Automatic override for inner corners (G62)......................................................45

5.4.2.2 Internal circular cutting feedrate change ........................................................... 47

5.5 FEEDRATE INSTRUCTION ON IMAGINARY CIRCLE FOR A ROTARY

AXIS ............................................................................................................47

5.6 DWELL........................................................................................................50

6 REFERENCE POSITION.......................................................................52

6.1 REFERENCE POSITION RETURN.............................................................52

7 COORDINATE SYSTEM.......................................................................56

7.1 MACHINE COORDINATE SYSTEM............................................................56

7.2 WORKPIECE COORDINATE SYSTEM ......................................................58

7.2.1 Setting a Workpiece Coordinate System................................................................58

7.2.2 Selecting a Workpiece Coordinate System ............................................................59

7.2.3 Changing Workpiece Coordinate System ..............................................................60

7.2.4 Workpiece Coordinate System Preset (G92.1).......................................................61

7.2.5 Automatic Coordinate System Setting ...................................................................63

7.3 LOCAL COORDINATE SYSTEM ................................................................63

7.4 PLANE SELECTION....................................................................................65

8 COORDINATE VALUE AND DIMENSION ...........................................66

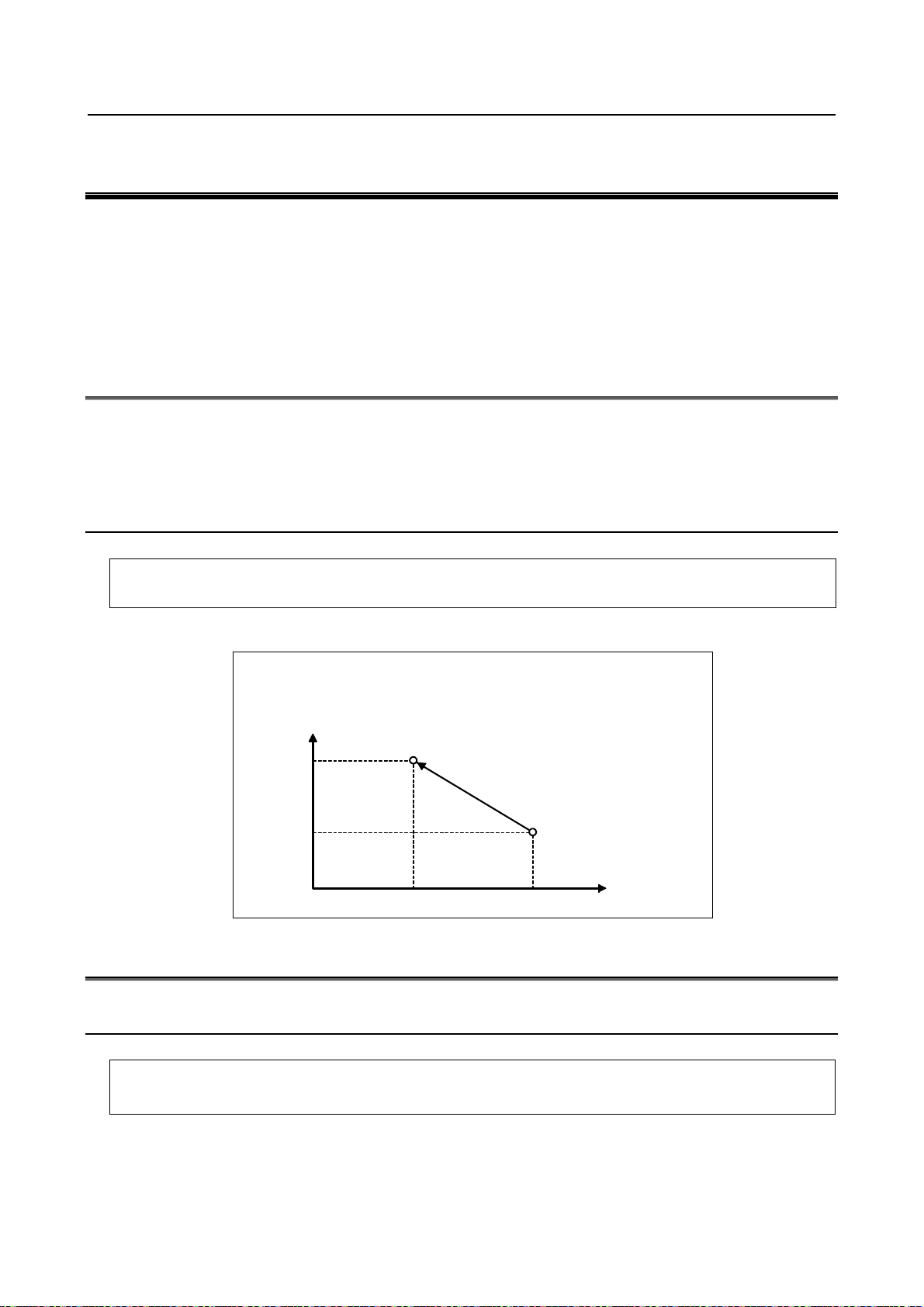

8.1 ABSOLUTE AND INCREMENTAL PROGRAMMING (G90, G91)...............66

8.2 INCH/METRIC CONVERSION (G20, G21).................................................66

8.3 DECIMAL POINT PROGRAMMING............................................................69

9 PRESS FUNCTION...............................................................................71

9.1 PUNCH FUNCTION (1-CYCLE PRESSING)...............................................71

9.1.1 Block in which Punching is Made..........................................................................71

9.2 POSITIONING & PRESSING OFF (G70)....................................................73

9.3 NIBBLING FUNCTION ................................................................................73

9.3.1 Circular Nibbling (G68) .........................................................................................75

9.3.2 Linear Nibbling (G69)............................................................................................79

9.3.3 Notes on Circular Nibbling (G68) and Linear Nibbling (G69)..............................80

9.4 NIBBLING BY M FUNCTION.......................................................................82

9.4.1 G00 Command in Nibbling Mode..........................................................................82

9.4.2 G01, G02, and G03 Commands in Nibbling Mode................................................83

9.4.3 Notes on Nibbling by M Function..........................................................................86

c-2

Page 13

B-64554EN/01 TABLE OF CONTENTS

9.5 EXTERNAL MOTION FUNCTION...............................................................86

10 S FUNCTION.........................................................................................87

10.1 SPECIFYING THE S CODE WITH A BINARY CODE.................................87

11 TOOL FUNCTION (T FUNCTION)........................................................88

11.1 TOOL SELECTION FUNCTION..................................................................88

11.2 T COMMAND NEGLECT.............................................................................89

11.3 TOOL OFFSET............................................................................................90

11.4 CONTROLLING THE TURRET-AXIS (T-AXIS)...........................................90

11.5 MULTIPLE TOOL CONTROL......................................................................90

11.5.1 Tool Number ..........................................................................................................91

11.5.2 Relationship between the Multiple–Tool System and the C Axis..........................92

11.5.3 Tool Compensation ................................................................................................92

11.5.4 Operational Notes...................................................................................................93

11.6 TOOL LIFE MANAGEMENT FUNCTION....................................................93

11.6.1 Tool Life Management Data ..................................................................................93

11.6.2 Register and Change of Tool Life Management Data............................................93

11.6.3 Tool Life.................................................................................................................94

12 AUXILIARY FUNCTION........................................................................95

12.1 AUXILIARY FUNCTION (M FUNCTION).....................................................95

12.2 MULTIPLE M COMMANDS IN A SINGLE BLOCK......................................97

12.3 SECOND AUXILIARY FUNCTIONS (B CODES) ........................................98

12.4 M COMMAND FOR SWITCHING THE PUNCH AND LASER MODE.......100

13 PROGRAM MANAGEMENT...............................................................101

13.1 PROGRAM ATTRIBUTES.........................................................................101

13.2 RELATED PARAMETERS.........................................................................101

13.3 PART PROGRAM STORAGE SIZE / NUMBER OF REGISTERABLE

PROGRAMS..............................................................................................102

14 PROGRAM CONFIGURATION...........................................................103

14.1 PROGRAM COMPONENTS OTHER THAN PROGRAM SECTIONS.......104

14.2 PROGRAM SECTION CONFIGURATION................................................106

14.3 SUBPROGRAM (M98, M99) .....................................................................112

15 FUNCTIONS TO SIMPLIFY PROGRAMMING ...................................116

15.1 PATTERN FUNCTION ..............................................................................116

15.1.1 Base Point Command (G72).................................................................................117

15.1.2 Bolt Hole Circle (G26).........................................................................................118

15.1.3 Line at Angle (G76) .............................................................................................120

15.1.4 Arc (G77) .............................................................................................................121

15.1.5 Grid (G78, G79)...................................................................................................122

15.1.6 Share Proofs (G86)...............................................................................................125

15.1.7 Square (G87) ........................................................................................................127

15.1.8 Radius (G88) ........................................................................................................129

15.1.9 Cut at Angle (G89)...............................................................................................130

15.1.10 Incremental Command Just After Pattern Function .............................................130

15.1.11 Notes on Pattern Functions...................................................................................133

15.2 MEMORY AND CALL BY A/B MACRO.....................................................134

c-3

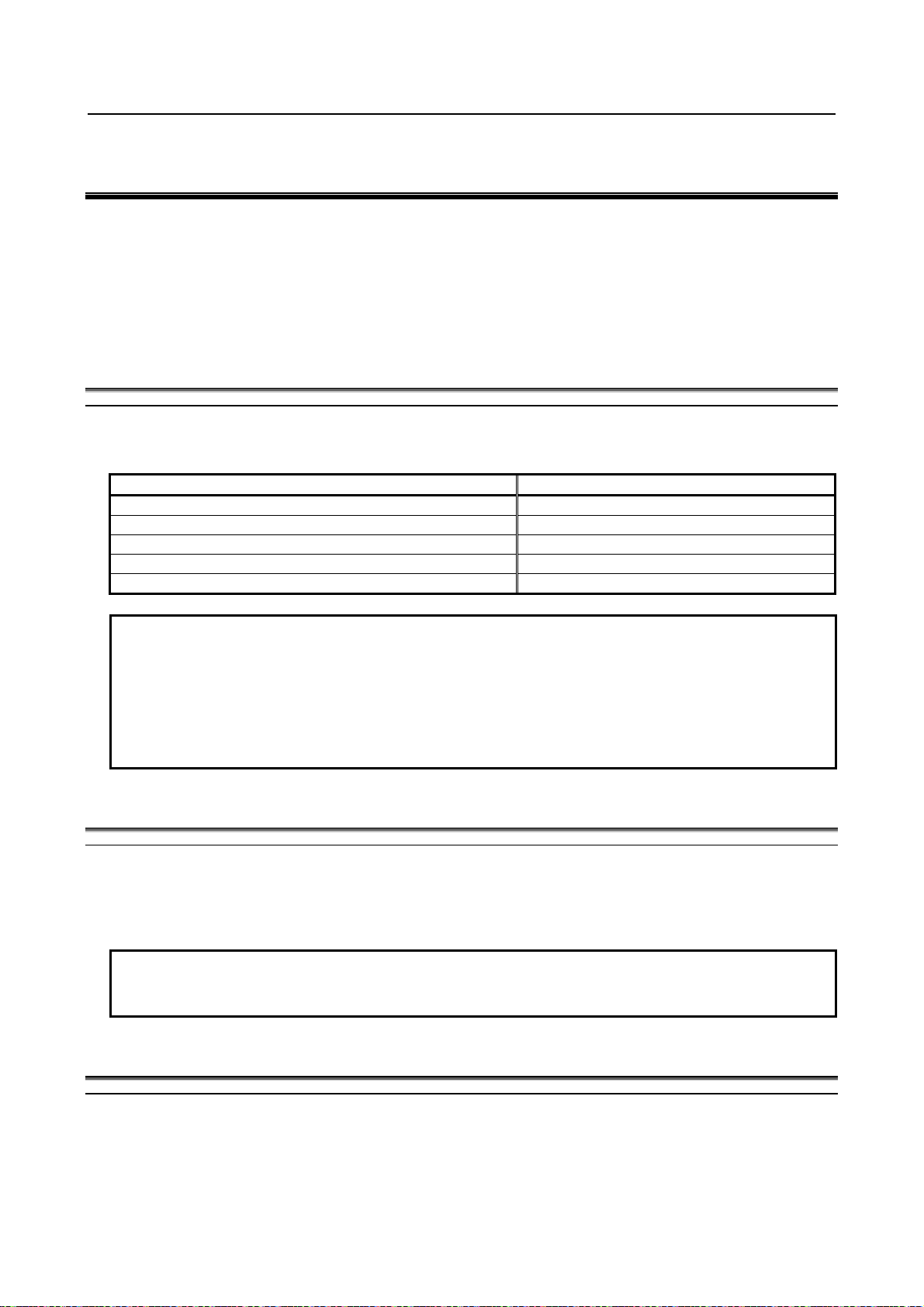

Page 14

TABLE OF CONTENTS B-64554EN/01

15.3 AUTOMATIC REPOSITIONING (G75)......................................................135

15.4 U/V/W MACRO FUNCTION ......................................................................141

15.4.1 Storage of Macros ................................................................................................141

15.4.2 Macro Call............................................................................................................142

15.4.3 Nesting Call of Macros.........................................................................................143

15.4.4 Macro Storage Capacity.......................................................................................144

15.4.5 Storage and Call of Multiple Macros (Macro Numbers 90 to 99)........................144

15.4.6 Deletion of Stored Macros ...................................................................................145

15.5 MULTI–PIECE MACHINING FUNCTION ..................................................145

15.5.1 Base Point Command of Multi-Piece Machining (G98)......................................145

15.5.2 Multi–Piece Machining Commands (G73, G74)..................................................148

15.5.3 Setting of Machining Method for Multi–Piece Machining..................................149

15.5.4 Command for Restarting Machining Multiple Products......................................150

15.6 BENDING COMPENSATION (G38, G39) .................................................152

15.7 LINEAR AND CIRCULAR PUNCH COMMAND ........................................154

15.7.1 Linear Punch Command (G45) ............................................................................154

15.7.2 Circular Punch Commands (G46 and G47)..........................................................157

15.7.3 Controlling the C–axis..........................................................................................158

15.8 Y–AXIS CRACK CANCEL.........................................................................159

16 COMPENSATION FUNCTION............................................................160

16.1 SCALING (G50, G51)................................................................................160

16.2 NORMAL DIRECTION CONTROL (G40.1,G41.1,G42.1, or G150,G151,

G152).........................................................................................................166

16.3 OVERVIEW OF TOOL COMPENSATION (G40-G42)...............................170

16.4 DETAILS OF TOOL RADIUS COMPENSATION.......................................175

16.4.1 Overview..............................................................................................................175

16.4.2 Tool Movement in Start-up..................................................................................179

16.4.3 Tool Movement in Offset Mode...........................................................................184

16.4.4 Tool Movement in Offset Mode Cancel...............................................................202

16.4.5 Prevention of Overcutting Due to Tool Radius Compensation............................208

16.4.6 Interference Check ...............................................................................................211

16.4.6.1 Operation to be performed if an interference is judged to occur..................... 214

16.4.6.2 Interference check alarm function ...................................................................215

16.4.6.3 Interference check avoidance function ............................................................216

16.4.7 Tool Radius Compensation for Input from MDI..................................................222

16.5 TOOL COMPENSATION VALUES, NUMBER OF COMPENSATION

VALUES, AND ENTERING VALUES FROM THE PROGRAM (G10).......223

16.6 COORDINATE SYSTEM ROTATION (G84, G85).....................................224

17 CUSTOM MACRO...............................................................................231

17.1 VARIABLES...............................................................................................231

17.2 SYSTEM VARIABLES...............................................................................236

17.3 ARITHMETIC AND LOGIC OPERATION..................................................256

17.4 READING PARAMETERS.........................................................................262

17.5 MACRO STATEMENTS AND NC STATEMENTS.....................................263

17.6 BRANCH AND REPETITION.....................................................................264

17.6.1 Unconditional Branch (GOTO Statement)...........................................................264

17.6.2 GOTO Statement Using Stored Sequence Numbers............................................264

17.6.3 Conditional Branch (IF Statement) ......................................................................265

17.6.4 Repetition (WHILE Statement)............................................................................266

c-4

Page 15

B-64554EN/01 TABLE OF CONTENTS

17.7 MACRO CALL ...........................................................................................268

17.7.1 Simple Call (G65) ................................................................................................269

17.7.2 Modal Call: Call After the Move Command (G66) .............................................272

17.7.3 Macro Call Using a G Code.................................................................................273

17.7.4 Macro Call Using a G Code (Specification of Multiple Definitions)...................275

17.7.5 Macro Call Using an M Code...............................................................................275

17.7.6 Macro Call Using an M Code (Specification of Multiple Definitions)................276

17.7.7 Subprogram Call Using an M Code.....................................................................277

17.7.8 Subprogram Call Using an M Code (Specification of Multiple Definitions).......278

17.7.9 Subprogram Calls Using a T Code.......................................................................278

17.7.10 Subprogram Call Using a Specific Address.........................................................279

17.8 PROCESSING MACRO STATEMENTS ...................................................281

17.9 REGISTERING CUSTOM MACRO PROGRAMS .....................................283

17.10 CODES AND RESERVED WORDS USED IN CUSTOM MACROS .........283

17.11 EXTERNAL OUTPUT COMMANDS..........................................................284

17.12 RESTRICTIONS........................................................................................287

17.13 INTERRUPTION TYPE CUSTOM MACRO...............................................288

17.13.1 Specification Method ...........................................................................................289

17.13.2 Details of Functions..............................................................................................290

18 PROGRAMMABLE PARAMETER INPUT (G10)................................296

18.1 PROGRAMMABLE PARAMETER INPUT.................................................296

18.2 TOOL DATA INPUT...................................................................................298

19 HIGH-SPEED CUTTING FUNCTIONS................................................300

19.1 AI ADVANCED PREVIEW CONTROL (G05.1) .........................................300

20 AXIS CONTROL FUNCTIONS............................................................311

20.1 AXIS SYNCHRONOUS CONTROL...........................................................311

20.1.1 Axis Configuration for Axis Synchronous Control..............................................311

20.1.2 Synchronous Establishment .................................................................................314

20.1.3 Automatic Setting for Grid Position Matching ....................................................315

20.1.4 Synchronous Error Check ....................................................................................316

20.1.5 Methods of Alarm Recovery by Synchronous Error Check.................................317

20.1.6 Axis Synchronous Control Torque Difference Alarm..........................................318

20.2 ROTARY AXIS ROLL-OVER.....................................................................320

20.2.1 Rotary Axis Roll-over..........................................................................................320

20.3 TANDEM CONTROL.................................................................................321

20.4 C AXIS CONTROL (DIE ANGLE INDEXING)............................................321

20.4.1 Simultaneously Controlled Axes..........................................................................322

20.4.2 Increment System.................................................................................................322

20.4.3 Maximum Programmable Dimension ..................................................................322

20.4.4 Automatic Acceleration/Deceleration ..................................................................322

20.4.5 Manual Continuous Feed, Incremental Feed, Manual Reference Point Return...322

20.4.6 Relationship with Absolute/Incremental Command (G90/G91)..........................323

20.4.7 Positioning in Smaller Angle Rotating Direction.................................................323

20.4.8 Blocks Where C–axis Command is Possible........................................................323

20.4.9 C–axis Command and its Operation.....................................................................323

20.4.10 Pattern Function, Nibbling Function and C–axis Command................................324

20.4.11 C–axis Command in Nibbling Mode....................................................................325

20.4.12 T–axis Command Ignore Signal TNG and C–axis Command .............................325

20.4.13 Compensating the Position of the C–axis.............................................................326

20.4.14 Compensating Backlash Along the C–axis for Each Tool Group........................326

c-5

Page 16

TABLE OF CONTENTS B-64554EN/01

20.5 RAM-AXIS CONTROL...............................................................................326

20.5.1 Setting RAM-axis Motion Pattern........................................................................326

20.5.2 Press Motion by RAM-axis Control.....................................................................327

20.5.3 RAM-axis Up Motion ..........................................................................................327

III. OPERATION

1 GENERAL...........................................................................................331

1.1 MANUAL OPERATION..............................................................................331

1.2 TOOL MOVEMENT BY PROGRAMING - AUTOMATIC OPERATION .....332

1.3 AUTOMATIC OPERATION .......................................................................333

1.4 TESTING A PROGRAM............................................................................334

1.4.1 Check by Running the Machine ...........................................................................334

1.4.2 How to View the Position Display Change without Running the Machine .........336

1.5 EDITING A PROGRAM.............................................................................336

1.6 DISPLAYING AND SETTING DATA..........................................................336

1.7 DISPLAY ...................................................................................................339

1.7.1 Program Display...................................................................................................339

1.7.2 Current Position Display ......................................................................................340

1.7.3 Alarm Display ......................................................................................................341

1.7.4 Parts Count Display, Run Time Display ..............................................................341

2 OPERATIONAL DEVICES..................................................................343

2.1 POWER ON/OFF.......................................................................................343

2.1.1 Turning on the Power...........................................................................................343

2.1.2 Power Disconnection............................................................................................344

2.2 SETTING AND DISPLAY UNITS...............................................................344

2.2.1 8.4" LCD/MDI .....................................................................................................345

2.2.2 10.4" LCD ............................................................................................................346

2.2.3 Standard MDI Unit (ONG Key)...........................................................................347

2.2.4 Small MDI Unit (ONG Key)................................................................................347

2.3 EXPLANATION OF THE MDI UNIT...........................................................349

2.4 FUNCTION KEYS AND SOFT KEYS........................................................350

2.4.1 General Screen Operations...................................................................................350

2.4.2 Function Keys ......................................................................................................351

2.4.3 Soft Keys..............................................................................................................352

2.4.4 Key Input and Input Buffer ..................................................................................359

2.4.5 Warning Messages ...............................................................................................360

2.5 EXTERNAL I/O DEVICES .........................................................................360

3 MANUAL OPERATION.......................................................................362

3.1 MANUAL REFERENCE POSITION RETURN...........................................362

3.2 JOG FEED (JOG)......................................................................................363

3.3 INCREMENTAL FEED ..............................................................................364

3.4 MANUAL HANDLE FEED..........................................................................365

3.5 MANUAL ABSOLUTE ON .........................................................................368

3.6 DISTANCE CODED LINEAR SCALE INTERFACE...................................372

3.6.1 Procedure for Reference Position Establishment .................................................372

3.6.2 Reference Position Return....................................................................................373

3.6.3 Distance Coded Rotary Encoder ..........................................................................374

3.6.4 Axis Synchronization Control..............................................................................374

c-6

Page 17

B-64554EN/01 TABLE OF CONTENTS

3.6.5 Axis Control by PMC...........................................................................................375

3.6.6 Note......................................................................................................................375

3.7 LINEAR SCALE WITH DISTANCE-CODED REFERENCE MARKS

(SERIAL) ...................................................................................................376

4 AUTOMATIC OPERATION.................................................................380

4.1 MEMORY OPERATION ............................................................................380

4.2 MDI OPERATION......................................................................................382

4.3 DNC OPERATION.....................................................................................385

4.4 SCHEDULE OPERATION.........................................................................387

4.5 EXTERNAL SUBPROGRAM CALL (M198) ...............................................391

4.6 MANUAL HANDLE INTERRUPTION ........................................................393

4.7 MIRROR IMAGE........................................................................................399

5 TEST OPERATION .............................................................................401

5.1 MACHINE LOCK AND AUXILIARY FUNCTION LOCK.............................401

5.2 FEEDRATE OVERRIDE............................................................................402

5.3 RAPID TRAVERSE OVERRIDE................................................................403

5.4 DRY RUN ..................................................................................................404

5.5 SINGLE BLOCK ........................................................................................405

5.6 PUNCH......................................................................................................406

5.7 MANUAL PUNCH......................................................................................407

6 SAFETY FUNCTIONS .........................................................................408

6.1 EMERGENCY STOP.................................................................................408

6.2 OVERTRAVEL...........................................................................................408

6.3 STORED STROKE CHECK.......................................................................409

6.4 STROKE LIMIT CHECK BEFORE MOVE.................................................412

6.5 WRONG OPERATION PREVENTION FUNCTIONS ................................414

6.5.1 Functions that are Used When Data is Set ...........................................................415

6.5.1.1 Input data range check.....................................................................................415

6.5.1.2 Confirmation of incremental input ..................................................................416

6.5.1.3 Prohibition of the absolute input by the soft key.............................................417

6.5.1.4 Confirmation of the deletion of the program...................................................417

6.5.1.5 Confirmation of the deletion of all data........................................................... 418

6.5.1.6 Confirmation of a data update during the data setting process........................418

6.5.2 Functions that are Used when the Program is Executed ......................................418

6.5.2.1 Display of updated modal information............................................................ 419

6.5.2.2 Start check signal.............................................................................................419

6.5.2.3 Axis status display........................................................................................... 420

6.5.2.4 Confirmation of the start from a middle block................................................420

6.5.2.5 Data range check ............................................................................................. 421

6.5.2.6 Maximum incremental value check.................................................................421

6.5.2.7 Warning display during a reset in program operation .....................................422

6.5.3 Setting Screen.......................................................................................................422

6.5.3.1 Operation confirmation function setting screen...............................................423

6.5.3.2 Tool offset range setting screen.......................................................................424

6.5.3.3 Workpiece origin offset range setting screen .................................................. 426

6.6 SAFETY ZONE CHECK ............................................................................427

6.6.1 Punch Forbidden Area and Approach Forbidden Area (Type A) ........................428

6.6.2 Punch Forbidden Area and Approach Forbidden Area (Type B).........................429

6.6.3 Setting the Safety Zone ........................................................................................430

c-7

Page 18

TABLE OF CONTENTS B-64554EN/01

6.6.4 Setting the Tool Shape Area.................................................................................430

6.6.5 Automatic Setting of the Safety Zone ..................................................................431

6.6.6 Displaying the Safety Zones and Tool Zone........................................................432

7 ALARM AND SELF-DIAGNOSIS FUNCTIONS..................................434

7.1 ALARM DISPLAY......................................................................................434

7.2 ALARM HISTORY DISPLAY .....................................................................436

7.3 CHECKING BY DIAGNOSTIC DISPLAY...................................................437

7.4 RETURN FROM THE ALARM SCREEN...................................................438

8 DATA INPUT/OUTPUT .......................................................................440

8.1 OVERWRITING FILES ON A MEMORY CARD........................................441

8.2 INPUT/OUTPUT ON EACH SCREEN.......................................................443

8.2.1 Inputting and Outputting a Program.....................................................................443

8.2.1.1 Inputting a program.........................................................................................443

8.2.1.2 Outputting a program.......................................................................................444

8.2.2 Inputting and Outputting Parameters....................................................................445

8.2.2.1 Inputting parameters........................................................................................ 445

8.2.2.2 Outputting parameters .....................................................................................445

8.2.3 Inputting and Outputting Offset Data...................................................................446

8.2.3.1 Inputting offset data.........................................................................................446

8.2.3.2 Outputting offset data......................................................................................447

8.2.4 Inputting and Outputting Pitch Error Compensation Data...................................447

8.2.4.1 Inputting pitch error compensation data.......................................................... 447

8.2.4.2 Outputting pitch error compensation data .......................................................448

8.2.4.3 Input/output format of pitch error compensation data..................................... 448

8.2.5 Inputting and Outputting Custom Macro Common Variables .............................449

8.2.5.1 Inputting custom macro common variables..................................................... 449

8.2.5.2 Outputting custom macro common variables.................................................. 450

8.2.6 Inputting and Outputting Workpiece Coordinates System Data ..........................451

8.2.6.1 Inputting workpiece coordinate system data....................................................451

8.2.6.2 Outputting workpiece coordinate system data.................................................452

8.2.7 Inputting and Outputting Operation History Data................................................452

8.2.7.1 Outputting operation history data.................................................................... 452

8.2.8 Inputting Outputting Tool Data............................................................................453

8.2.8.1 Inputting tool data............................................................................................ 453

8.2.8.2 Outputting tool data......................................................................................... 453

8.2.8.3 Output format of tool data ...............................................................................454

8.3 INPUT/OUTPUT ON THE ALL IO SCREEN..............................................454

8.3.1 Inputting/Outputting a Program ...........................................................................455

8.3.2 Inputting and Outputting Parameters....................................................................456

8.3.3 Inputting and Outputting Offset Data...................................................................457

8.3.4 Inputting/Outputting Pitch Error Compensation Data..........................................458

8.3.5 Inputting/Outputting Custom Macro Common Variables....................................459

8.3.6 Inputting and Outputting Workpiece Coordinates System Data ..........................460

8.3.7 Inputting and Outputting Operation History Data................................................460

8.3.8 File Format...........................................................................................................461

8.4 MEMORY CARD SCREEN........................................................................461

8.4.1 Displaying the Memory Card Screen ...................................................................461

8.4.2 Displaying and Operating the File List ................................................................462

8.4.3 Inputting/Outputting a File...................................................................................463

8.5 EMBEDDED ETHERNET OPERATIONS..................................................465

8.5.1 FTP File Transfer Function ..................................................................................465

8.6 FLOPPY CASSETTE SCREEN.................................................................469

c-8

Page 19

B-64554EN/01 TABLE OF CONTENTS

8.6.1 Displaying the Floppy Cassette Screen................................................................469

8.6.2 Displaying and Operating the File List ................................................................469

8.6.3 Inputting/Outputting a File...................................................................................470

8.7 SCREEN HARD COPY FUNCTION..........................................................471

9 CREATING PROGRAMS....................................................................473

9.1 CREATING PROGRAMS USING THE MDI PANEL..................................473

9.2 AUTOMATIC INSERTION OF SEQUENCE NUMBERS ...........................474

9.3 CONVERSATIONAL PROGRAMMING WITH GRAPHIC FUNCTION......475

10 EDITING PROGRAMS........................................................................480

10.1 EDIT DISABLE ATTRIBUTE......................................................................480

10.2 INSERTING, ALTERING AND DELETING A WORD................................481

10.2.1 Word Search.........................................................................................................482

10.2.2 Heading a Program...............................................................................................483

10.2.3 Inserting a Word...................................................................................................484

10.2.4 Altering a Word....................................................................................................485

10.2.5 Deleting a Word ...................................................................................................485

10.3 DELETING BLOCKS.................................................................................486

10.3.1 Deleting a Block...................................................................................................486

10.3.2 Deleting Multiple Blocks .....................................................................................486

10.4 PROGRAM SEARCH................................................................................487

10.5 SEQUENCE NUMBER SEARCH..............................................................488

10.6 DELETING PROGRAMS...........................................................................490

10.6.1 Deleting One Program..........................................................................................490

10.6.2 Deleting All Programs..........................................................................................490

10.7 COPYING/MOVING PROGRAMS.............................................................491

10.7.1 Copying a Part of a Program................................................................................491

10.7.2 Moving a Part of a Program.................................................................................494

10.7.3 Copying an Entire Program..................................................................................497

10.7.4 Moving an Entire Program...................................................................................499

10.7.5 Copy Specifying a Program Number ...................................................................501

10.7.6 Copying/Moving to the Key-in Buffer.................................................................502

10.8 REPLACING..............................................................................................503

10.9 EDITING OF CUSTOM MACROS.............................................................503

10.10 PASSWORD FUNCTION..........................................................................504

10.11 COMPACT-TYPE MDI KEY INPUT...........................................................505

11 PROGRAM MANAGEMENT...............................................................508

11.1 SELECTING A DEVICE.............................................................................508

11.1.1 Selecting a Memory Card Program as a Device...................................................509

11.1.2 Selecting a From Cassette as a Device.................................................................512

11.2 DELETING A PROGRAM..........................................................................513

11.3 CHANGING PROGRAM ATTRIBUTES.....................................................513

11.4 SELECTING A MAIN PROGRAM..............................................................514

11.5 MAKING A PROGRAM COMPACT...........................................................514

12 SETTING AND DISPLAYING DATA...................................................516

12.1 SCREENS DISPLAYED BY FUNCTION KEY ...................................526

12.1.1 Position Display in the Workpiece Coordinate System .......................................526

12.1.2 Position Display in the Relative Coordinate System............................................527

c-9

Page 20

TABLE OF CONTENTS B-64554EN/01

12.1.3 Overall Position Display ......................................................................................529

12.1.4 Workpiece Coordinate System Preset..................................................................530

12.1.5 Actual Feedrate Display.......................................................................................531

12.1.6 Display of Run Time and Parts Count..................................................................533

12.1.7 Operating Monitor Display ..................................................................................534

12.2 SCREENS DISPLAYED BY FUNCTION KEY ...................................535

12.2.1 Program Contents Display....................................................................................535

12.2.2 Editing a Program.................................................................................................536

12.2.3 Program Screen for MDI Operation.....................................................................538

12.2.4 Program List Screen.............................................................................................538

12.2.5 Next Block Display Screen .................................................................................. 539

12.2.6 Program Check Screen.........................................................................................540

12.2.7 Current Block Display Screen (Only for the 8.4-Inch Display Unit)...................541

12.2.8 Graphical Conversational Programming Screen ..................................................541

12.2.9 Background Editing..............................................................................................543

12.3 SCREENS DISPLAYED BY FUNCTION KEY ...................................547

12.3.1 Setting and Displaying the Tool Compensation Value ........................................547

12.3.2 Displaying and Entering Setting Data..................................................................549

12.3.3 Sequence Number Comparison and Stop.............................................................551

12.3.4 Displaying and Setting Run Time, Parts Count, and Time ..................................553

12.3.5 Displaying and Setting the Workpiece Origin Offset Value................................555

12.3.6 Direct Input of Workpiece Origin Offset Value Measured..................................555

12.3.7 Displaying and Setting Custom Macro Common Variables.................................557

12.3.8 Displaying and Setting the Software Operator’s Panel........................................558

12.3.9 Displaying and Switching the Display Language ................................................561

12.3.10 Protection of Data at Eight Levels........................................................................562

12.3.10.1 Operation level setting.....................................................................................562

12.3.10.2 Password modification.....................................................................................564

12.3.10.3 Protection level setting .................................................................................... 565

12.3.11 Displaying and Setting Items on the Tool Registration Screens..........................567

12.3.11.1 Displaying and setting items on the initial tool registration screen.................567

12.3.11.2 Displaying and setting items on the tool number registration screen..............569

12.3.11.3 Displaying and setting items on the screen for the number of press

operations.........................................................................................................570

12.3.11.4 Displaying and setting items on the tool figure registration screen (for

drawing figures)............................................................................................... 572

12.3.12 Displaying and Setting Items on the Tool Registration Screen for Multiple

Tools.....................................................................................................................574

12.3.12.1 Displaying and setting items on the tool number registration screen for

multiple tools................................................................................................... 574

12.3.12.2 Displaying and setting items on the tool figure registration screen for

multiple tools (for drawing figures)................................................................. 575

12.3.13 Displaying and Setting Items on the Safety Zone Setting Screen........................578

12.4 SCREENS DISPLAYED BY FUNCTION KEY ...................................582

12.4.1 Displaying and Setting Parameters.......................................................................582

12.4.2 Displaying and Setting Pitch Error Compensation Data......................................584

12.4.3 Servo Setting ........................................................................................................587

12.4.4 Servo Tuning........................................................................................................590

12.4.5 Color Setting Screen.............................................................................................591

12.4.6 Parameter Setting Support Screen........................................................................593

12.4.6.1 Displaying the menu screen and selecting a menu item ..................................593

12.4.6.2 Displaying and setting the axis setting screen .................................................596

12.4.6.3 Displaying and setting the FSSB amplifier setting screen...............................597

c-10

Page 21

B-64554EN/01 TABLE OF CONTENTS

12.4.6.4 Displaying and setting the FSSB axis setting screen....................................... 598

12.4.6.5 Displaying and setting the servo setting screen............................................... 599

12.4.6.6 Displaying and setting the servo setting screen............................................... 599

12.4.6.7 Displaying and setting the servo gain tuning screen........................................ 601

12.4.6.8 Displaying and setting the high-precision setting screen................................. 611

12.4.6.9 Displaying and setting the miscellaneous setting screen.................................613

12.4.6.10 Displaying and setting the servo tuning screen ............................................... 613

12.4.7 Periodic Maintenance Screen...............................................................................615

12.4.8 System Configuration Screen...............................................................................622

12.4.9 Overview of the History Function........................................................................624

12.4.9.1 Operation history............................................................................................. 624

12.4.9.2 Selecting operation history signals.................................................................. 629

12.4.9.3 Outputting all history data ...............................................................................630

12.5 SCREENS DISPLAYED BY FUNCTION KEY ...................................633

12.6 DISPLAYING THE PROGRAM NUMBER, SEQUENCE NUMBER, AND

STATUS, AND WARNING MESSAGES FOR DATA SETTING OR

INPUT/OUTPUT OPERATION..................................................................633

12.6.1 Displaying the Program Number, and Sequence Number....................................633

12.6.2 Displaying the Status and Warning for Data Setting or Input/Output Operation.634

12.7 SCREEN ERASURE FUNCTION AND AUTOMATIC SCREEN

ERASURE FUNCTION..............................................................................636

13 GRAPHIC FUNCTION .........................................................................638

13.1 OPERATION..............................................................................................639

13.2 REGISTERING THE TOOL FIGURE.........................................................639

13.3 SPECIFYING DRAWING PARAMETERS.................................................640

13.4 GRAPHIC DISPLAY SCREEN AND DRAWING........................................644

13.5 EXAMPLE..................................................................................................647

14 VIRTUAL MDI KEY FUNCTION..........................................................650

14.1 VIRTUAL MDI KEY....................................................................................650

14.1.1 Limitations............................................................................................................653

IV. MAINTENANCE

1 ROUTINE MAINTENANCE.................................................................657

1.1 ACTION TO BE TAKEN WHEN A PROBLEM OCCURRED.....................658

1.2 BACKING UP VARIOUS DATA ITEMS.....................................................659

1.3 METHOD OF REPLACING BATTERY......................................................660

1.3.1 Replacing Battery for CNC Control Unit.............................................................660

1.3.2 Battery in the PANEL i (3 VDC) .........................................................................664

1.3.3 Replacing Battery for Absolute Pulsecoders........................................................665

1.3.3.1 Overview ......................................................................................................... 665

1.3.3.2 Replacing batteries...........................................................................................666

1.3.3.3 Replacing the batteries in a separate battery case............................................666

1.3.3.4 Replacing the battery built into the servo amplifier.........................................667

APPENDIX

A PARAMETERS....................................................................................671

A.1 DESCRIPTION OF PARAMETERS...........................................................671

A.2 DATA TYPE...............................................................................................781

c-11

Page 22

TABLE OF CONTENTS B-64554EN/01

A.3 STANDARD PARAMETER SETTING TABLES.........................................783

B PROGRAM CODE LIST......................................................................784

C LIST OF FUNCTIONS AND PROGRAM FORMAT............................786

D RANGE OF COMMAND VALUE.........................................................791

E NOMOGRAPHS ..................................................................................793

E.1 TOOL PATH AT CORNER ........................................................................793

E.2 RADIUS DIRECTION ERROR AT CIRCLE CUTTING..............................796

F SETTINGS AT POWER-ON, IN THE CLEAR STATE, OR IN

THE RESET STATE............................................................................797

G CHARACTER-TO-CODES CORRESPONDENCE TABLE ................799

G.1 CHARACTER-TO-CODES CORRESPONDENCE TABLE........................799

G.2 FANUC DOUBLE-BYTE CHARACTER CODE TABLE .............................800

H ALARM LIST.......................................................................................806

I PC TOOL FOR MEMORY CARD PROGRAM

OPERATION/EDITING........................................................................831

I.1 PC TOOL FOR MEMORY CARD PROGRAM OPERATION/EDITING.....831

I.1.1 Usage Notes..........................................................................................................831

I.1.2 List of Functions of PC Tool................................................................................831

I.1.3 Explanation of Operations....................................................................................832

I.2 NAMING RULES .......................................................................................840

I.2.1 Naming Rules of Program File.............................................................................840

I.2.2 Naming Rules of Folder.......................................................................................841

I.3 RULES OF CHARACTERS IN PROGRAM FILE.......................................841

I.3.1 Usable Characters in Program File.......................................................................841