Page 1

Gibbs and Associates

323 Science Drive

Moorpark, CA 93021

(805) 523-0004

March, 1999

MILL/TURN

Page 2

Proprietary Notice

This document contains propriety information of Gibbs and Associates and is to be used only pursuant to and in conjunction with the license granted to the licensee with respect to the accompanying Gibbs and Associates licensed software. Except as expressly permitted in the license, no part of

this document may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated

into any language or computer language, in any form or by any means, electronic, magnetic, optical,

chemical, manual or otherwise, without the prior expressed written permission from Gibbs and

Associates or a duly authorized representative thereof.

It is strongly advised that users carefully review the license in order to understand the rights and

obligations related to this licensed software and the accompanying documentation.

Use of the computer software and the user documentation has been provided pursuant to a Gibbs

and Associates licensing agreement.

© Copyright 1998 Gibbs and Associates, Inc.

All Rights Reserved

Acknowledgements:

Written by: Shannon McConville and Wil Gaffga

Thanks to Bill Gibbs, Alvaro Martins, Jeff Castanon, Bart Ehlers, Jeff Myers, Gary Esser, Michael

Kelley Charles Haden and Israel Klain for their input and assistance.

Special Thanks to Louise Burns for supplying the Clutch Basket tutorial part.

Trademarks:

Windows NT and Windows 95 are trademarks of Microsoft Corporation

Macintosh is a trademark of Apple Computers, Inc.

Printed in the United States of America

◆

Mill/Turn Manual GFK-1711

Page 3

Table of Contents

MILL TURN II

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PART SETUP 4

Machine Definition Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Coordinate Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Geometry Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tool Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MACHINING OPERATIONS 19

Machining. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Y-axis & C-axis Interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ROTARY MILLING & WRAPPING 23

MILL/TURN EXERCISES 26

Exercise 1 : Clutch Basket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Exercise 2 : Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

GFK-1711 T able of Contents

◆

i

Page 4

INTRODUCTION

The system provides for Mill/Turn capabilities when both the Mill module and Lathe module of the

software are present. When this is the case, the system will have an option to designate the machine

type as Mill/Turn, and the user can now apply any of the system's available milling machining

processes to a lathe part. All milling and turning functions are available for Mill/Turn parts.

Additional modules are available that increase the capabilities of Mill/Turn, most importantly the

Rotary Milling option which provides the ability to wrap any shape or toolpath around the C axis

using rotary axis interpolation.

The Mill/Turn functionality of the software provides capabilities for programming single spindle,

single turret lathes that have the capability of driving live tooling. The turret positions can drive live

tools such as endmills and drills which can be oriented along the Z axis, toward the chuck (face

machining), or along the X axis, toward the turret (OD machining). In order to perform milling

operations, the spindle must be changed from its normal function of spinning the part into a third

programmable axis, usually designated as the C axis. The Mill/Turn functionality allows users to

position the part by specifying angular rotations of the C axis.

Note: This symbol is used periodically in this manual to signify Mill/Turn functions that

are enhanced by the Advanced Mill module.

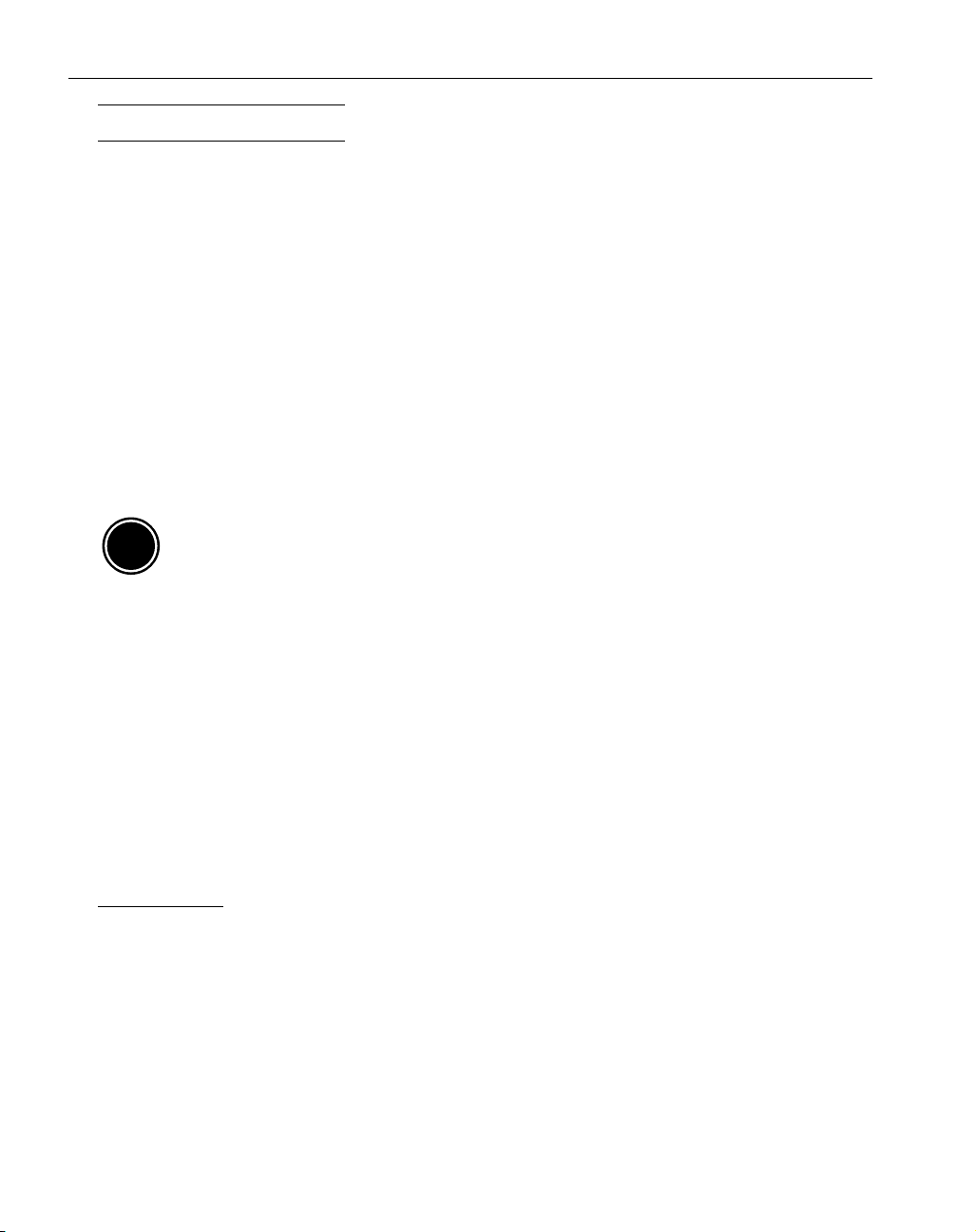

The following image is intended to clarify differences between different system modules and functions.

Mill/Turn allows the user to use a live mill tool with simple angle positions of the C-axis on the OD

or face of the part.

Rotary Mill allows the user to wrap geometry about the C-axis and allows continuous C-Axis rotation

when programming milling operations.

If the user’s machine has Y-axis capabilities any mill operation may be performed at any C-axis posi-

tion

TERMINOLOGY

Live Tool: When a live tool is used the lathe spindle stops rotating and engages C-axis rotary motion.

A milling tool is set to spin at a specified RPM.

Wrapped Geometry: A standard term for geometry that is drawn flat and wrapped or rotated around

the rotary axis.

ii

◆

Mill/Turn Manual GFK-1711

AM

Page 5

Figure 1: A comparison of capabilities in system modules.

1

GFK-1711 Mill/Turn

◆

Lathe module Mill/Turn capability

Rotary Mill Rotary Mill with Y-Axis capability

Page 6

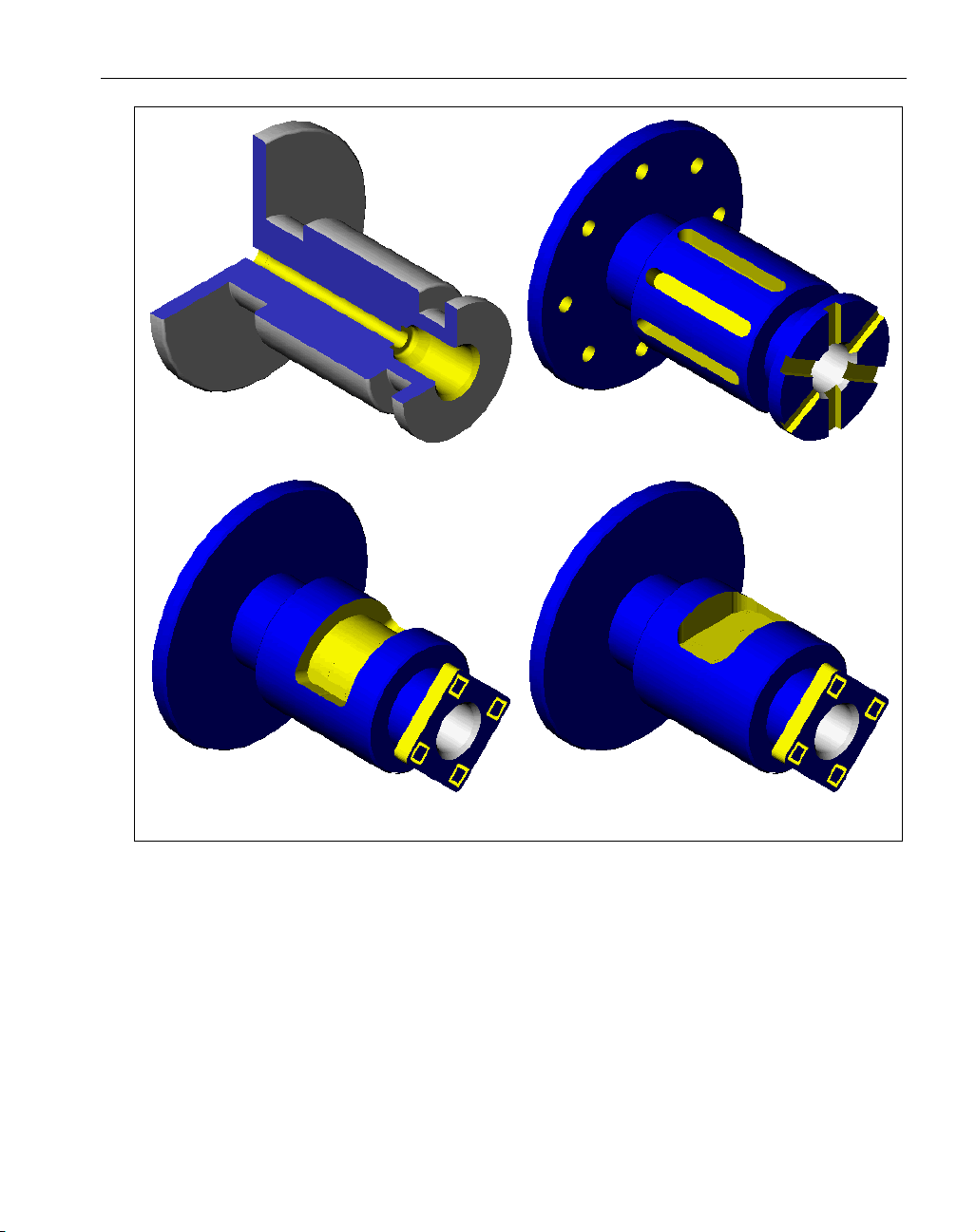

PREFERENCES

Graphics preference: The Graphics Preference

which is accessed from the Preferences sub-

menu under the File menu contains an item

called Grid Brightness. This affects the con-

trast and brightness of the CS grid drawn on

the screen. The brightness can be adjusted by moving the slider. Clicking on the Apply Button in

the Graphics Preference Dialog will apply the changes.

INTERFACE

The system has three different levels of functionality, Level 0, Level 1 and Level 2, providing more

advanced features as the level number is increased. All levels are available to users regardless of the

specific options that are installed with the system, however certain items may not be accessible

depending on the options installed. In order to use the Mill/Turn functions the user must be working

with the Level 2 interface.

Each level makes slight changes to the interface. The Level 1 interface contains a 7 button Top level

palette, while the Level 2 interface is characterized by a 14 button Top Level palette and a taskbar.

The interface level is specified in the Interface Preferences accessed from the Preferences submenu

under the File menu.

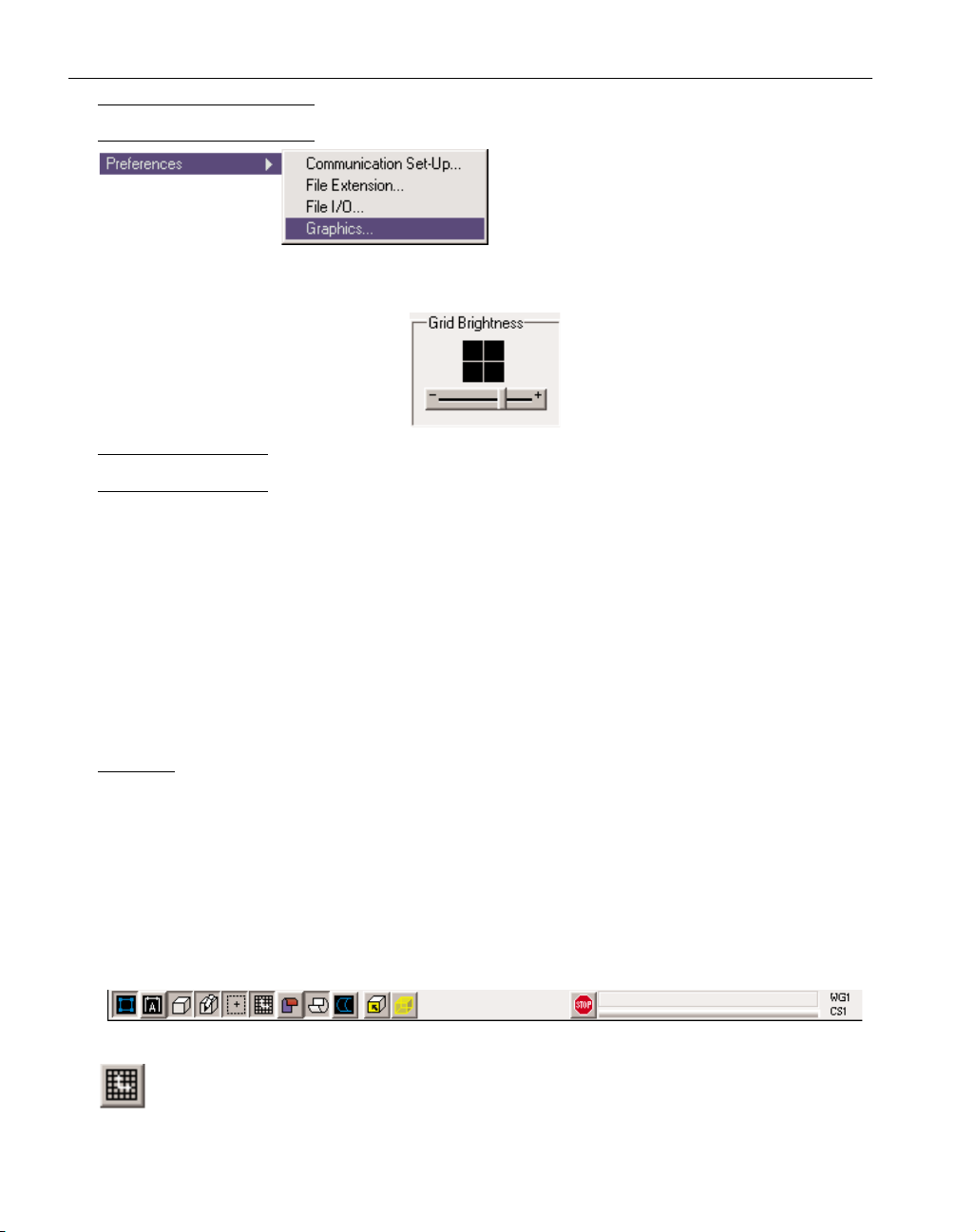

TASKBAR

When working with the Level 2 interface, there is a taskbar located along the top of the drawing

window, directly below the menu bar. The taskbar contains a series of buttons which affect the

drawing and selection of items in the drawing window. Each of the buttons has two states, depressed

(on) or raised (off). The taskbar also contains a progress bar and message display. The progress messages indicate the function the system is performing and the progress bar gives the status of the

function. The Stop button can be depressed to stop the current function. The current workgroup and

coordinate system are displayed next to the progress bar. Again, certain items may be unavailable

depending on the options installed with the system. There are two taskbar buttons which are used

specifically for Mill/Turn parts.

Show CS Grid Button: When it is turned on, (the button is depressed), the CS grid and axis

markers for the current Coordinate System will be drawn on the screen.

2

◆

Mill/Turn Manual GFK-1711

Page 7

Stock Cutaway: This button affects the cut part rendering function only. When turned on, the

stock used for the cut part rendering will have a quarter section cut out. This is useful when

rendering lathe parts which contain ID operations. When turned off, the stock used for cut

part rendering will be a full cylinder. When rendering Mill/Turn parts, it is recommended that Stock

Cutaway be turned off to ensure that OD milling operations are viewed in the cut part rendering

process.

Wrap Geometry: This button affects geometry creation. It is only available when the Rotary

Milling option is installed. The Rotary Milling function provides continuous C axis rotation

on milling operations, also referred to as wrapping. When this button is turned on, geometry

can be created and viewed radially, wrapped around the OD of the part. Rather than creating "flat"

geometry using XYZ coordinates, the system allows users to create radial geometry using XZC

coordinates, where X designates the radius or diameter. The user can either create flat geometry and

then wrap it or simply create geometry using radial values. Any geometry can be wrapped, including

lines, closed shapes and text. In order to create and view geometry radially, this button must be

depressed. Effectively, geometry will be wrapped on the OD of the part. In addition, the Rotary

Milling checkbox in the WG Info dialog must be checked. This issue will be discussed further in the

Rotary Milling section of this manual.

HOME VIEW

The Home View is an additional view available from the Trackball that is useful when working with

different coordinate systems. When selected, the system rotates the view of the part to a view normal (3D perpendicular) to the current coordinate system. The Home View always displays the part

with the positive depth axis projecting out of the screen, signified by the “+” at the center of the axis

markers. Using the part model on the trackball in the center of the View Control Palette allows the

user to get an idea of the positioning of the plane in 3D space relative to the overall part.

Figure 2: Home View

GEOMETRY COLOR SCHEME

The system uses colors to graphically differentiate between certain items drawn on the screen.

Additional meaning is added to the color scheme when working with multiple coordinate systems.

Blue and Yellow: Geometry drawn on the screen in either blue or yellow indicates that it is contained

in the current workgroup and based on the current coordinate system. The current coordinate system

is the coordinate system that is being worked in and is highlighted in the CS List Dialog.

Magenta: This color is added when working with multiple coordinate systems. Geometry drawn in

magenta indicates that the geometry is not based on the current coordinate system. Magenta geome-

3

GFK-1711 Mill/Turn

◆

Home View

Page 8

try can be selected, modified and used for machining operations. The color change merely indicates that the geometry was not created while working in the current coordinate system.

Gray: Geometry drawn in grey is contained in a background workgroup. It may or may not be based

on the current CS. Geometry in a background workgroup cannot be selected or modified.

Part Set-Up

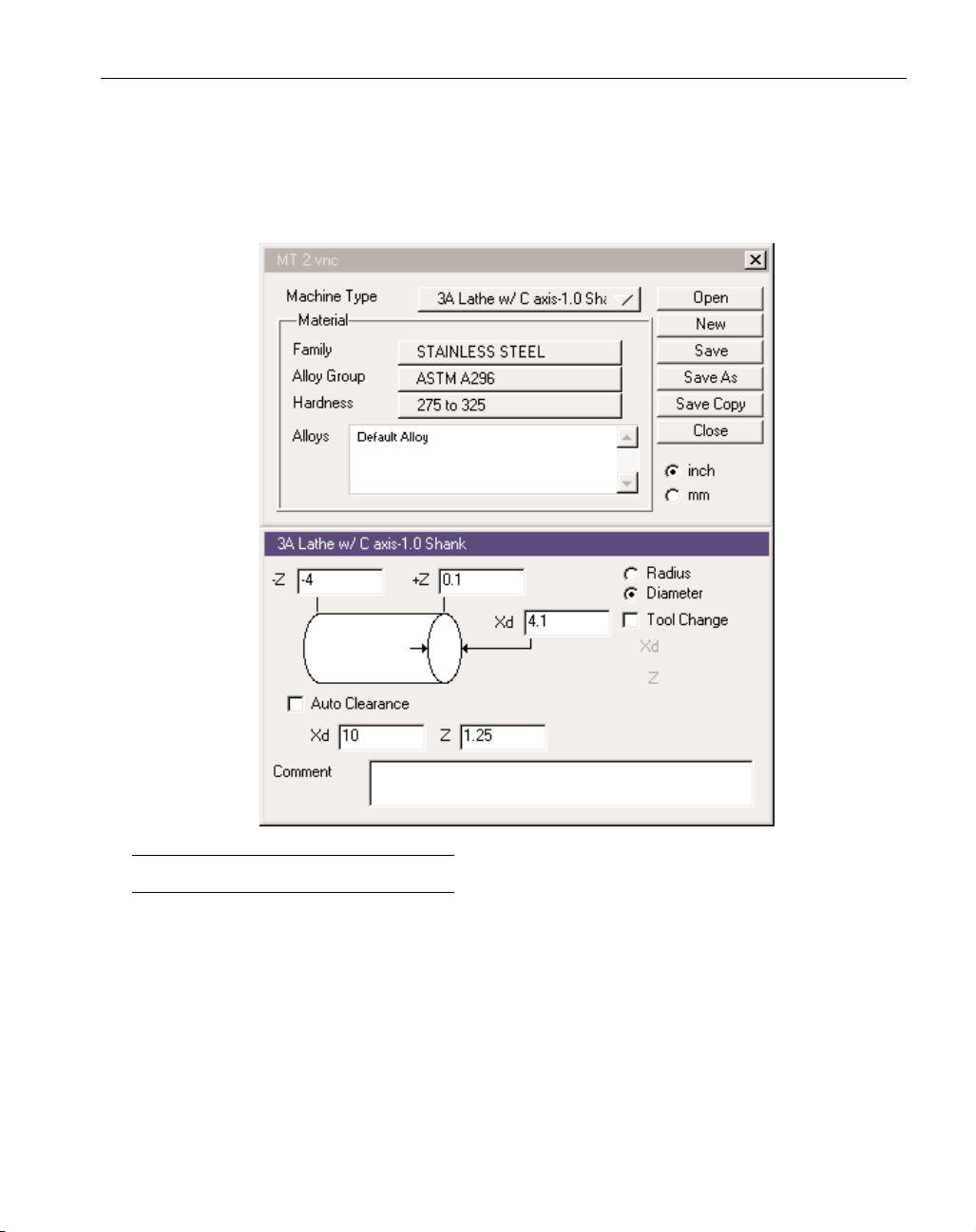

MACHINE DEFINITION DOCUMENTS

Setting up a mill turn part is very similar to that of a standard lathe part. The stock is designated in

the same manner and the options for designating clearance planes are identical to that for turning

parts. With both the Mill and Lathe modules installed, additional Machine Definition Documents

(MDD’s) will be available in the Machine Type pull-down menu in the Document Control Dialog.

The Mill/Turn MDD's are similar to Lathe MDD's in that different shank sizes are available.

Figure 3: New Machine Definition Documents (MDD’s) for Mill/Turn

Selecting a Mill/Turn MDD signals the system that the part will contain both milling and turning

operations. When the Mill/Turn MDD is selected, the system automatically creates four coordinate

systems: the XZ plane which is used for turning operations, the YZ plane, which is used for OD

milling operations, the XY plane which is used for face milling operations, and the HY backside

plane which represents the back face of the part. Coordinate systems can be viewed and changed

using the CS list dialog which is accessed from the Top Level palette.

The Document Control Dialog for lathe and mill/turn parts contains options for programming the

part using radius values or diameter values. Either is a valid selection for Mill/Turn parts. However

the diameter selection will only apply to geometry and machining processes used for turning operations as noted. The ZX plane is used for all turning operations. When working in this CS, if the part

is being programmed in diameter, the user can enter diameter values. In all of the other coordinate

systems, which are used to create milling operations, all values will be treated as radius values

regardless of the selection made in the Document Control dialog. All text edit boxes, which require

4

◆

Mill/Turn Manual GFK-1711

Page 9

input from the user, are labeled indicating the type of value that should be entered. The labels on all

text edit boxes will read Xr (for radius) and Xd (for diameter) indicating the type of value to be

entered. The user should make sure the label is appropriate for the value being entered.

All other information entered in the Document Control Dialog is used as it is when programming

lathe parts. For more information about the information contained in this dialog, refer to the Lathe

Module manual.

COORDINATE SYSTEMS

NOTE: The terms coordinate system, plane and CS are used interchangeably throughout this manual.

When a 3 axis lathe with C axis MDD is selected, four coordinate systems are automatically created. CS’s are used to create geometry and machining operations on different areas of the part. The

first is the ZX plane which is used for turning operations. The second is the XY plane which is used

for face machining. The third CS is the HY backside plane which is used for machining the back

face with milling operations. The final CS is the YZ plane which is used for OD milling operations.

These four coordinate systems can not be modified.

5

GFK-1711 Mill/Turn

◆

Page 10

It should be noted that the system has an additional option referred to as the Advanced

Milling option which allows users to create and modify coordinate systems into any planar orientation and program positioning moves for milling operations. For the mill/turn

capabilities the Advanced Milling option provides the ability to create additional coordinate systems in any orientation and create milling operations which will use the non-standard coordinate systems for the machining CS. The four base CS’s created by the system

are not modifiable by Advanced Mill.

OVERVIEW

▲ A Coordinate System is a plane in space with an origin and three axes.

The origin is the point at which the axes intersect and serves as a zero reference point. The three

axes are the horizontal, vertical and depth axes. In the standard XY Plane, the X axis is the horizontal axis, the Y axis is the vertical axis and the Z axis is the depth axis. The current coordinate system

is the active coordinate system that is selected in the CS List Dialog. It refers to the CS that is currently being worked in.

▲ A Coordinate System is NOT a Workgroup.

Coordinate systems are completely independent of workgroups. Multiple coordinate systems can be

used in one workgroup and the same coordinate system can be used in multiple workgroups. Often

times it is helpful to have one coordinate system per workgroup, however that is only a convenience, not a rule.

▲ A coordinate system is an attribute of geometry elements (points, lines, circles, etc.).

Geometry is not contained in a coordinate system the way it can be said that geometry is contained

in a workgroup. When geometry is created, dimensional information must be entered to indicate

where the geometry should be located. When locational data is entered, there must be a referencing

system that makes the dimensional data meaningful. This is the role a coordinate system plays in the

creation of geometry. When using the Mill/Turn functionality, turning geometry is created in the ZX

plane and milling geometry is created in the XY plane for face work and the YZ plane for OD work.

CS LIST

Coordinate System button: This button gives the user access to the CS List Pop-Up menu and

the CS List dialog. It is found among the 14 buttons in the Top Level palette.

CS List Pop-Up menu: Holding down the mouse button while selecting

CS Button will bring up a pop-up menu showing all of the coordinate

systems contained in the part file. The user can change the current

coordinate system by selecting one from the list and letting go of the

mouse button. After a coordinate system has been selected, the list will

disappear.

6

◆

Mill/Turn Manual GFK-1711

AM

Page 11

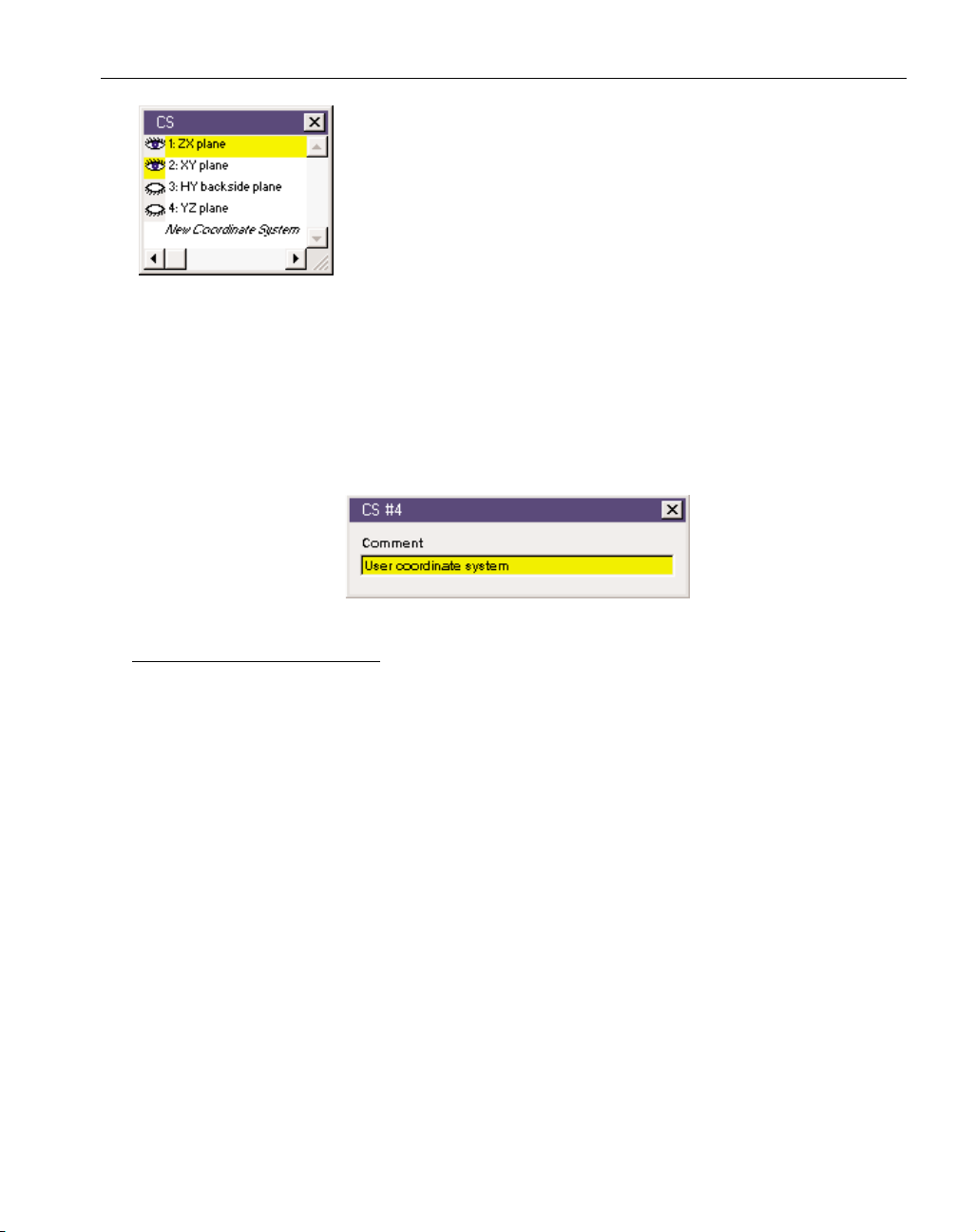

CS List dialog: Clicking on the CS Button will bring up the CS List

Dialog on the screen. This dialog displays a list of all existing coordinate systems, highlighting the current coordinate system. It is strongly

recommended that the CS List Dialog remain on the screen at all

times when working with multiple coordinate systems.

The CS List Dialog contains eyeball icons next to each of the coordi-

nate systems. Double-clicking a closed eyeball opens it, and viceversa. When open, the CS Frame Indicator for that coordinate system will be displayed on the

screen. This action does not affect the current CS, which will remain highlighted in the CS List

Dialog. The CS grid and axis markers will be based on the current CS.

Double-clicking on the name of a coordinate system in the CS List will open the CS Info Dialog for

that coordinate system. This dialog allows the user to enter a comment for each coordinate system.

The text entered in the Comment text box will appear in the CS List Dialog and as the title for the

CS Palette. Because the system names all new coordinate systems, User coordinate system, it is

strongly recommended to give each CS a unique name.

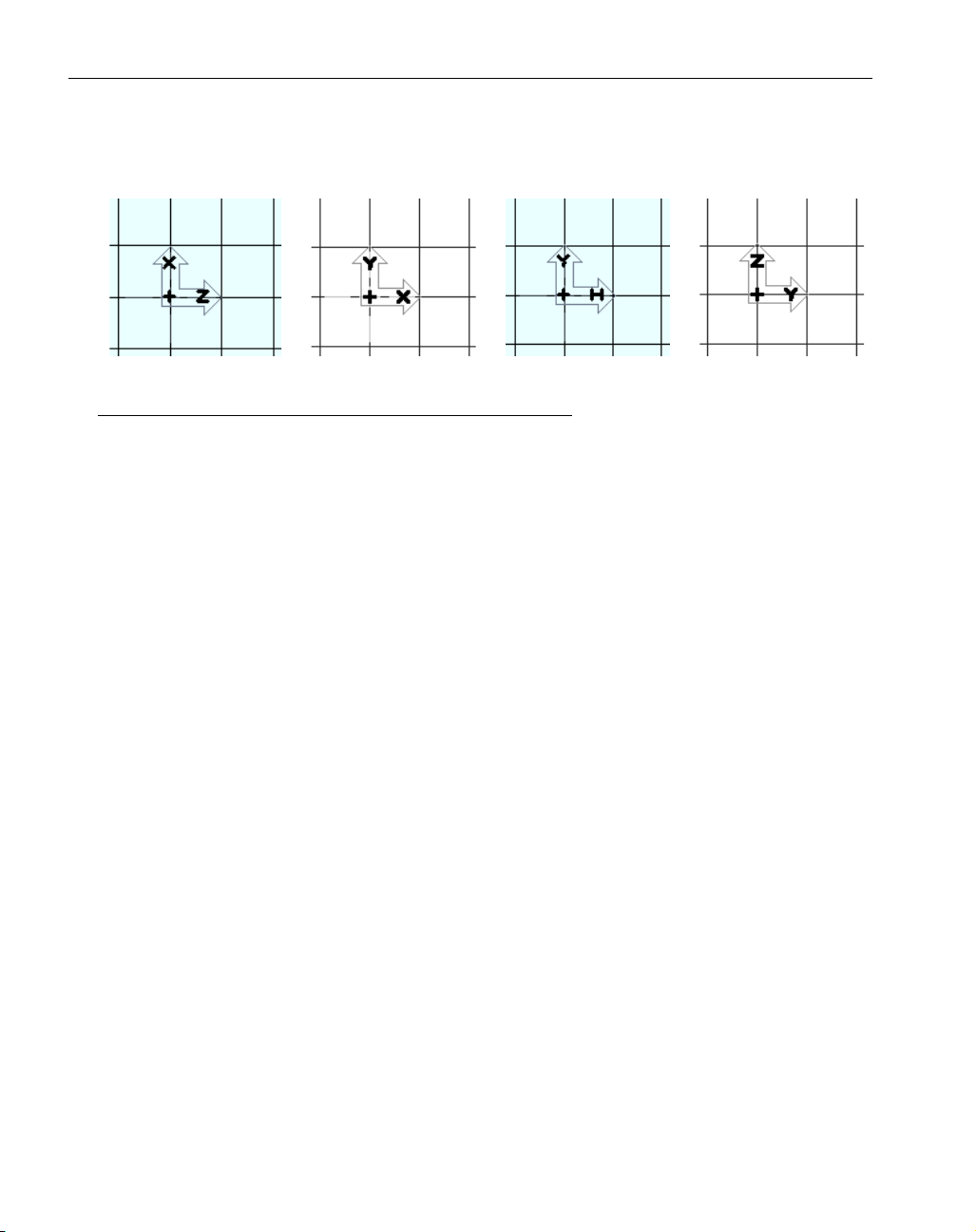

CS GRID AND AXIS MARKERS

The coordinate system (CS) grid and axis markers are very important tools when working with multiple coordinate systems. The CS grid graphically displays the planar orientation of the current coordinate system. The CS grid and axis markers will be drawn on the screen when the Show CS Button

in the taskbar is turned on (button depressed). When creating multiple coordinate systems, the CS

grid should be displayed on the screen at all times.

The axis markers will be placed at the origin of the current coordinate system. The axis marker

arrows show the positive direction of the horizontal (H) and vertical (V) axes. When the horizontal

and vertical axes align with one of the primary axes, the system labels the axis markers with X, Y

and Z. This is the case with three of the four coordinate systems used with Mill/Turn parts, the ZX

plane, the XY plane and the YZ plane. The other CS is labeled with HY because the X axis is

flipped in the opposite direction. At the intersection of the axis marker arrows, there is either a plus

“+” or minus “-”sign. This indicates the polarity (positive/negative direction) of the depth (D) axis

with respect to the current view.

7

GFK-1711 Mill/Turn

◆

Page 12

The grid is drawn in dark gray and shows the plane of the current coordinate system. Additional

light gray lines will be drawn showing where the coordinate system intersects with the stock size.

ZX Plane CS XY Plane CS HY Backside CS YZ Plane CS

USE OF COORDINATE SYSTEMS WITH MILL/TURN PARTS

For turning operations the designation of the machining coordinate system is set by the selection

made in the Lathe process dialog for OD, ID or front face. The selection made for the approach type

signifies the area of the part being machined and designates the appropriate machining coordinate

system. However, with milling operations, the proper CS must be set by the user, usually through

the tool orientation.

The machining CS is used to determine how the tool will approach the part. For turning operations,

the Approach Type selection designates the axis along which the tool will approach and cut the part,

while for milling operations the tool orientation typically designates the axis of tool approach.

Turning operations also require the tool orientation to be specified, however, this information is not

used to determine the machining CS, however it is very important to designate the appropriate orientation in order to achieve the correct toolpath.

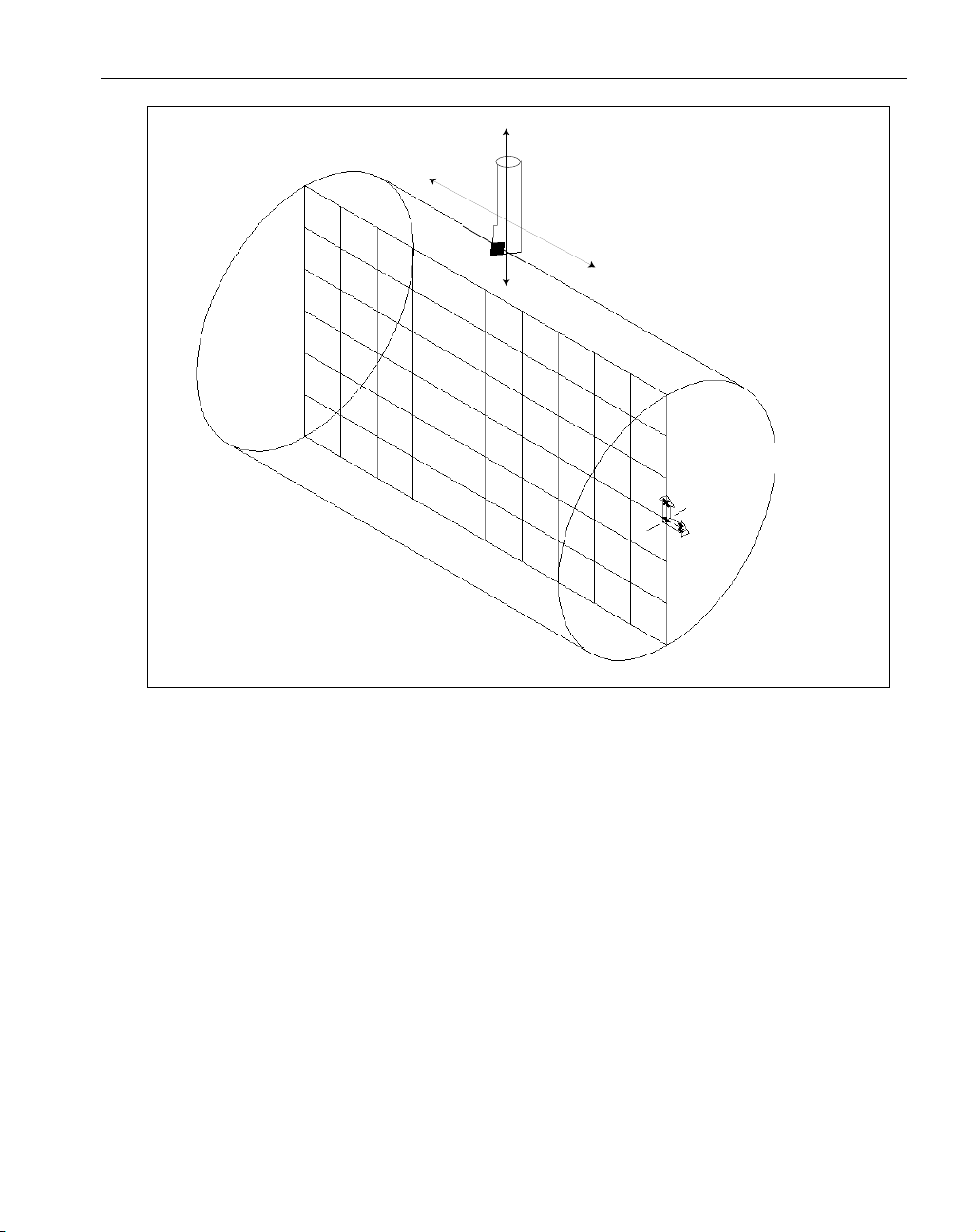

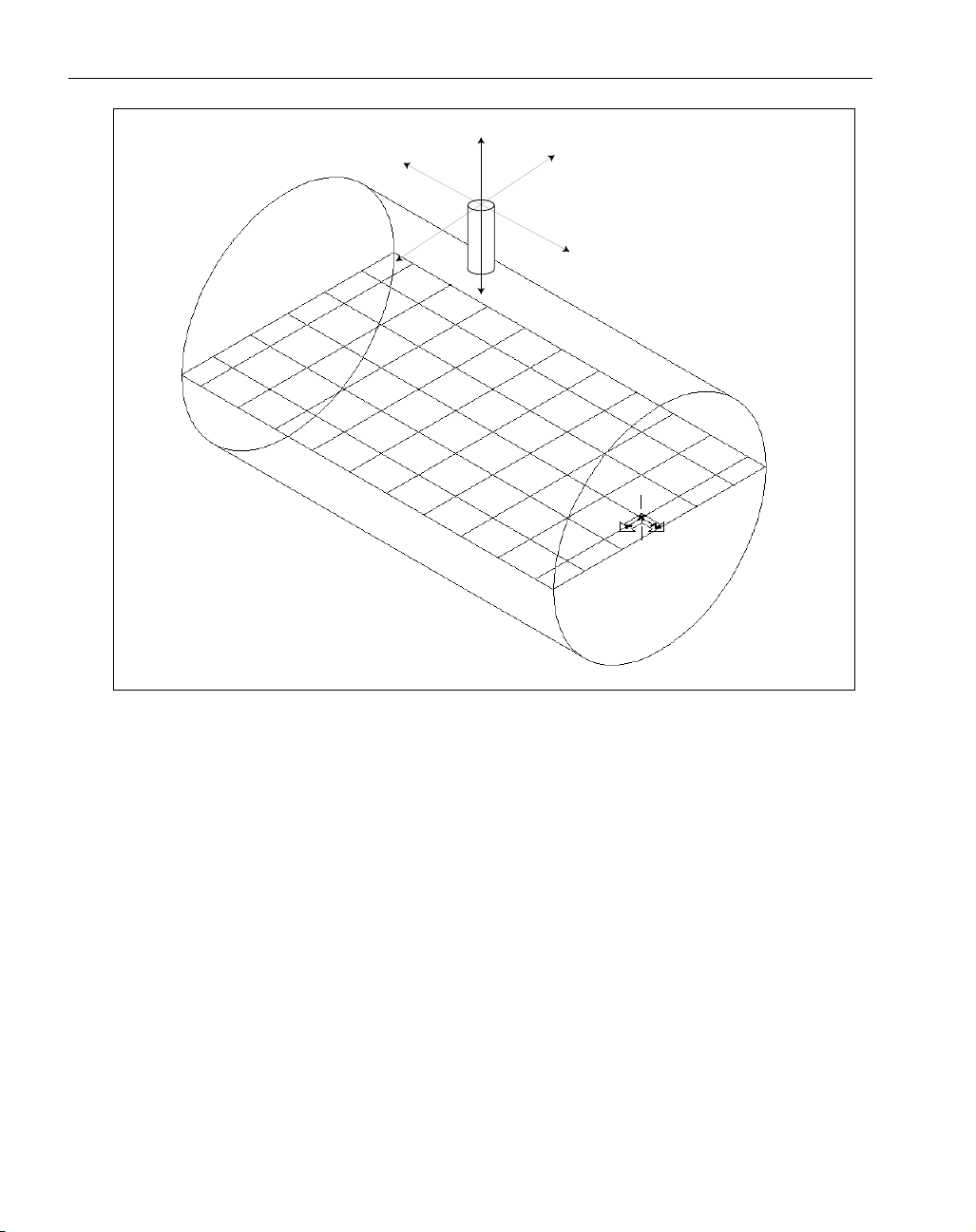

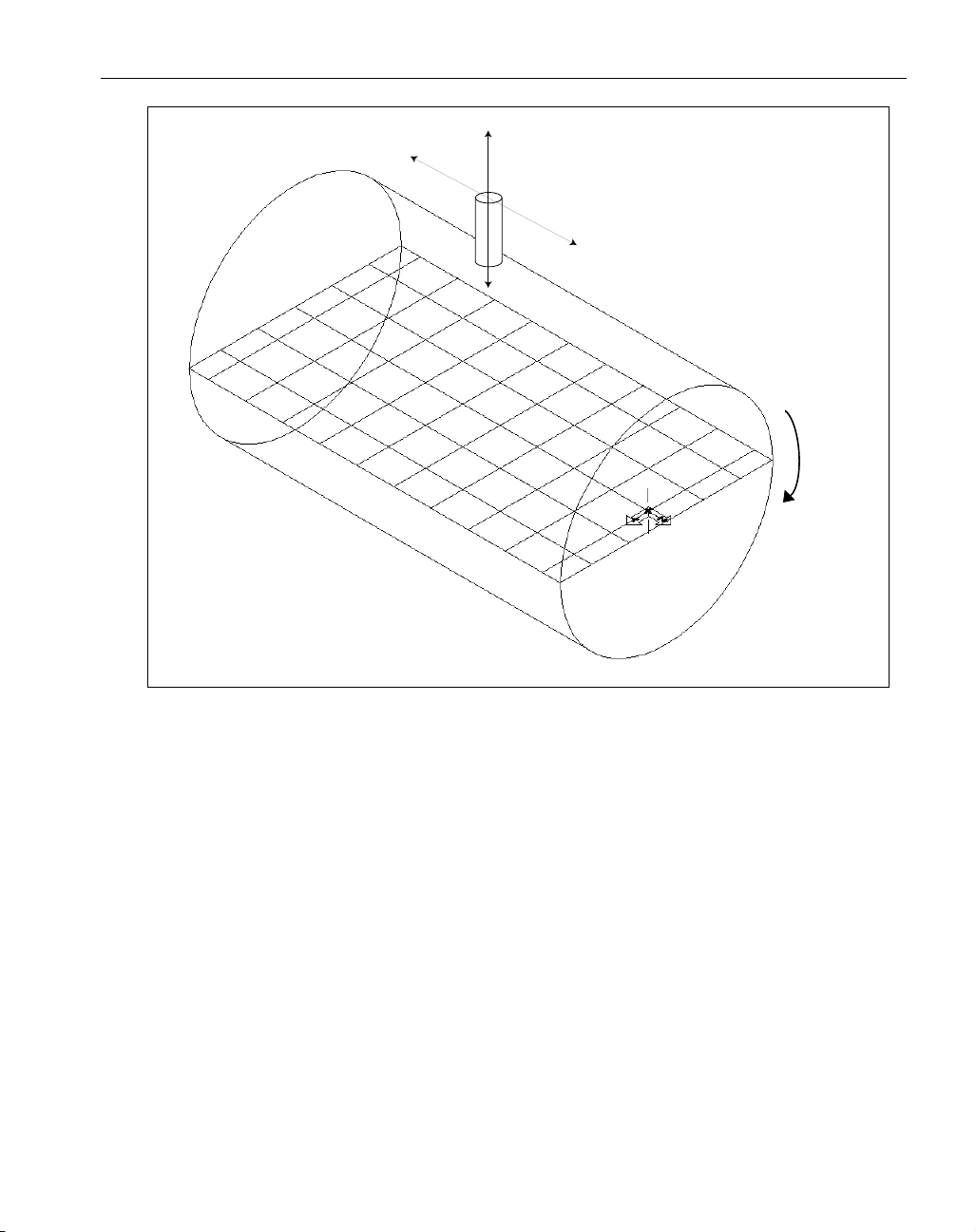

The various coordinate systems are primarily used for creating milling operations. As the following

figures illustrate, the system does support Y axis moves for milling operations. Some mill/turn

machines do not support the Y axis, and instead use the C axis to facilitate these type of moves. C

axis continuous moves will be discussed in the Rotary Milling section. Users should know whether

their mill/turn machines support the Y axis and program their parts accordingly. This issue is discussed further in the Machining and Rotary Milling sections of this manual.

8

◆

Mill/Turn Manual GFK-1711

Page 13

Figure 4: XZ Plane: Turning

9

GFK-1711 Mill/Turn

◆

X axis

Lathe Tool

Z axis

Page 14

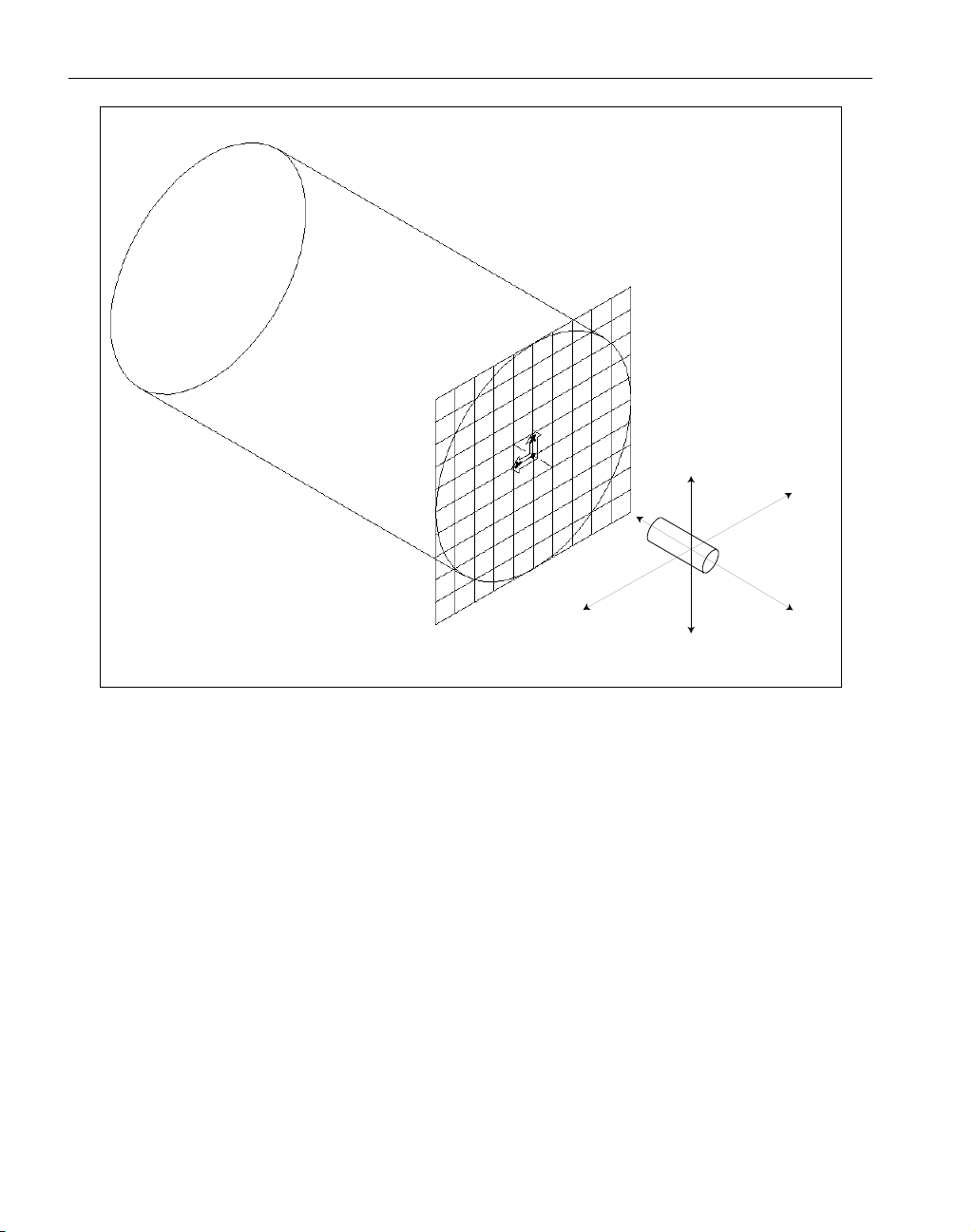

Figure 5: YZ Plane: OD Milling with Y axis moves

10

◆

Mill/Turn Manual GFK-1711

X axis

Mill Tool

Y axis

Z axis

Page 15

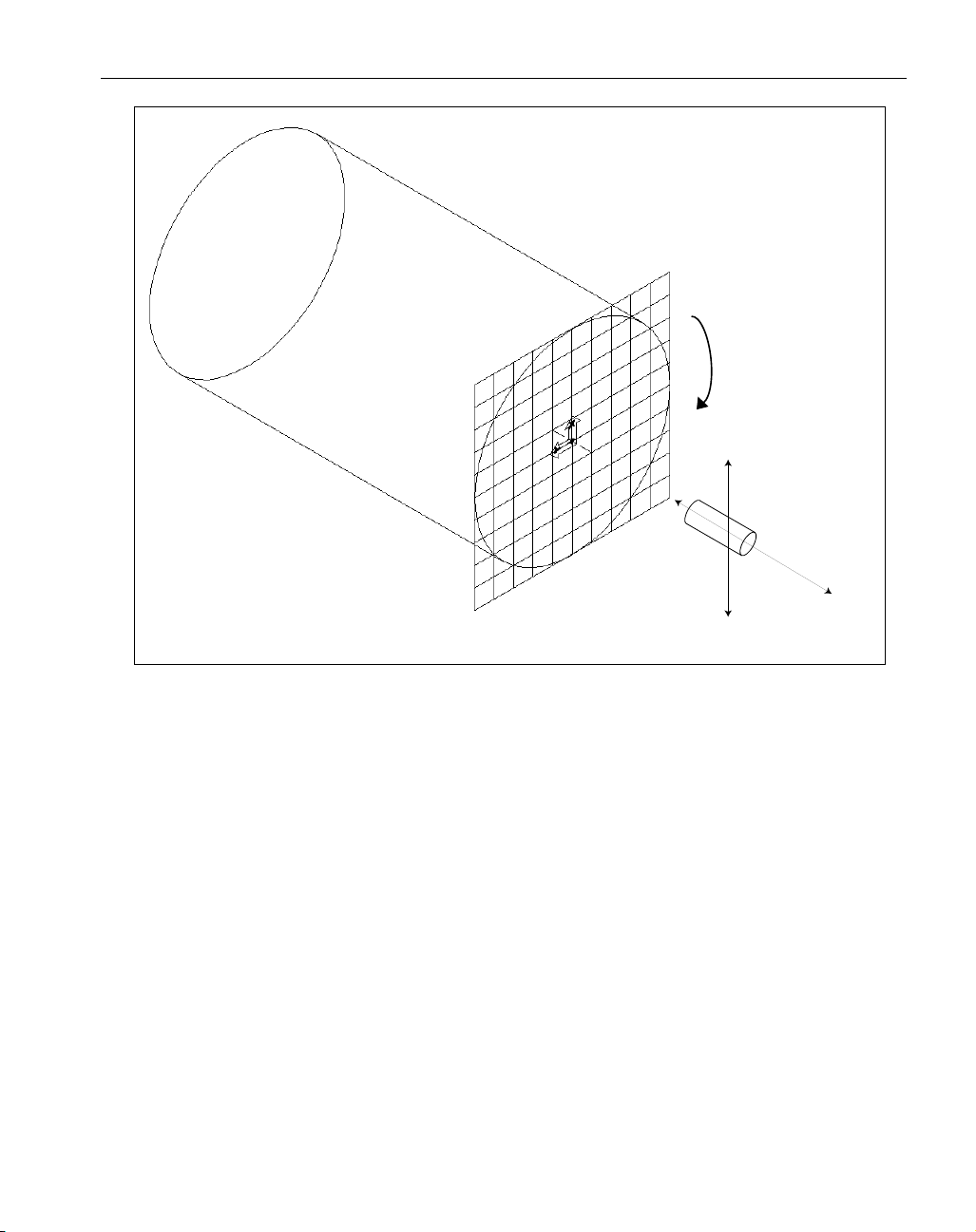

Figure 6: YZ plane, OD Milling with C axis moves

11

GFK-1711 Mill/Turn

◆

X axis

Z axis

Mill Tool

C axis

Page 16

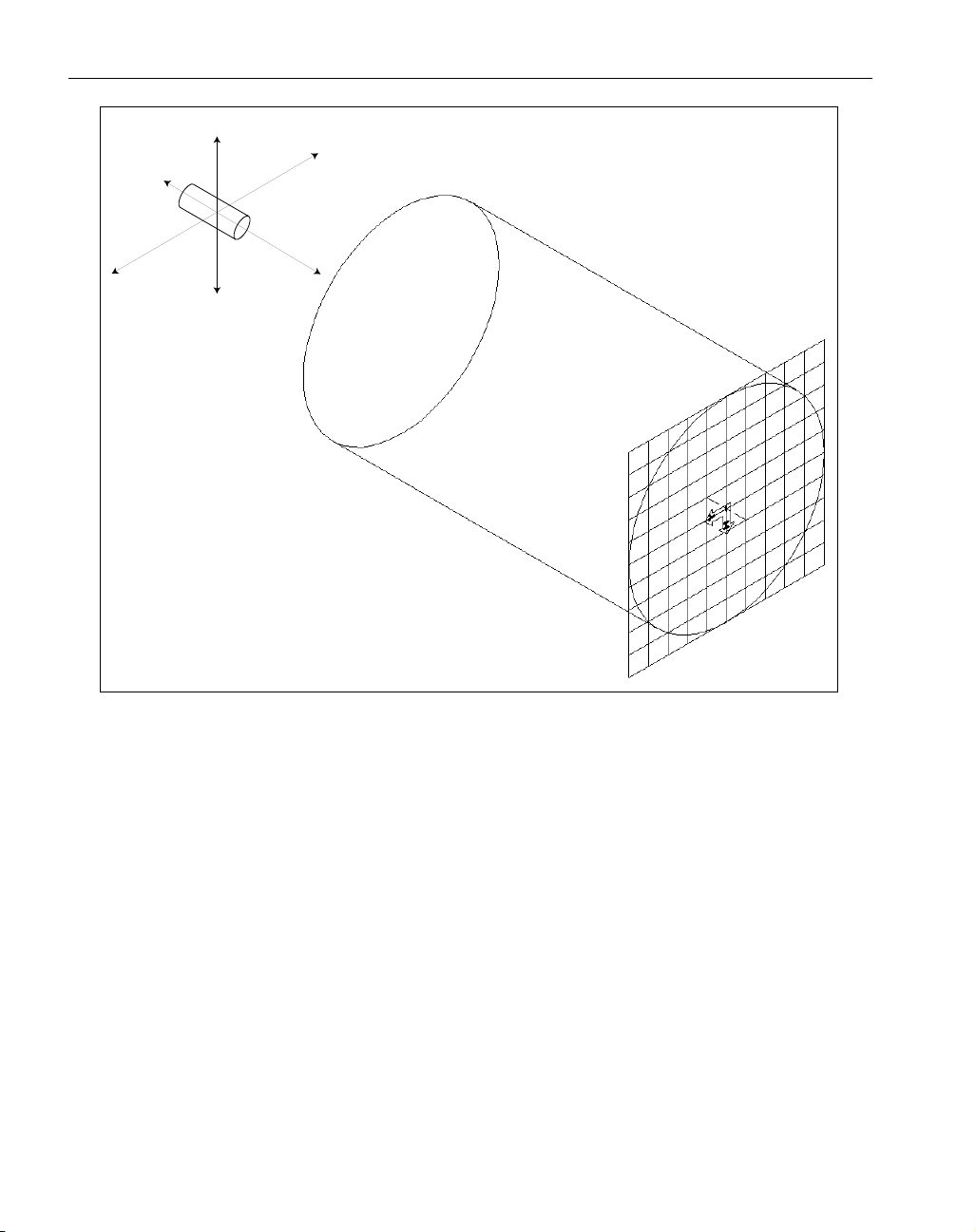

Figure 7: XY Plane, Front Face Milling with Y axis moves

12

◆

Mill/Turn Manual GFK-1711

X axis

Y axis

Mill Tool

Z axis

Page 17

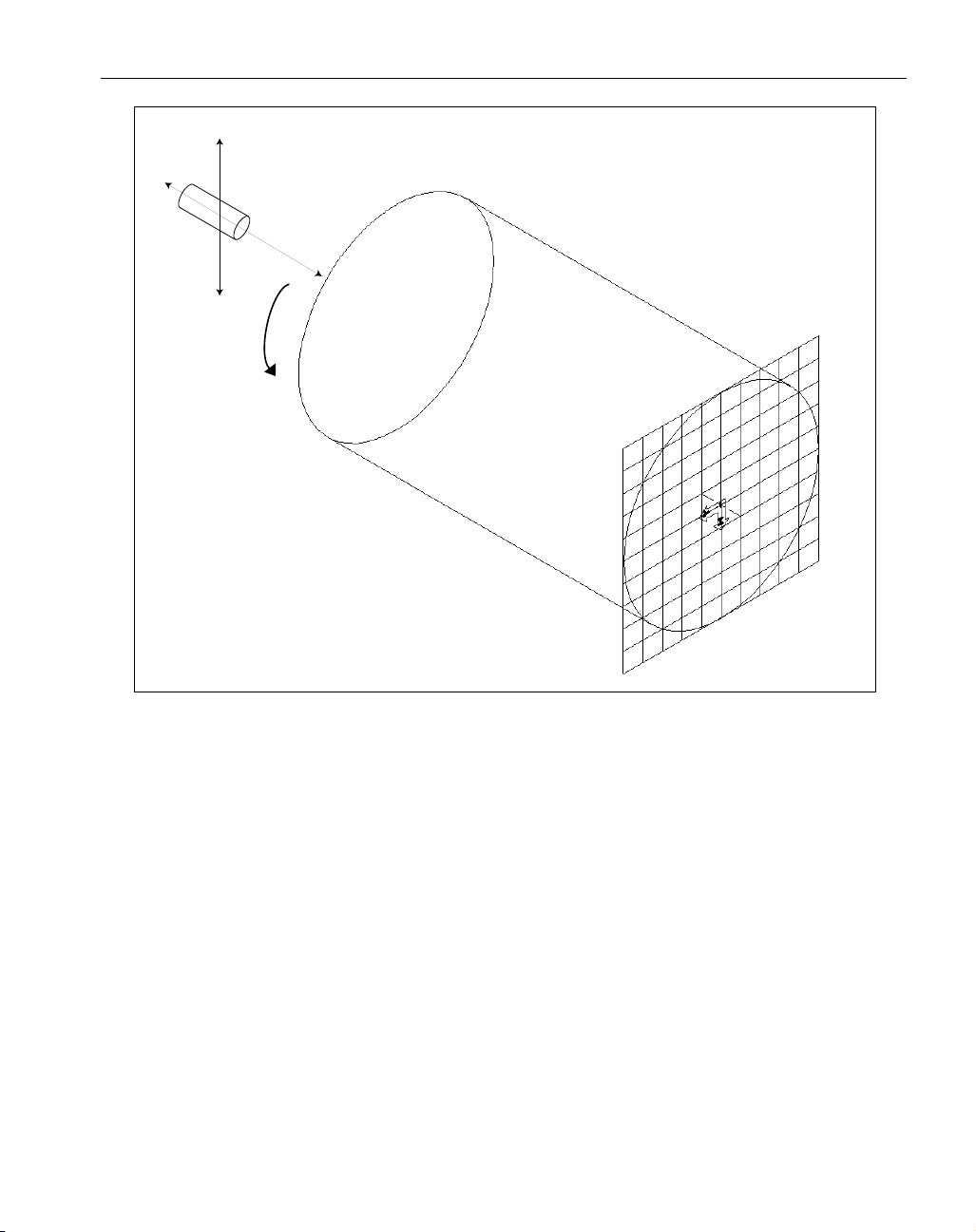

Figure 8: XY Plane, Front Face milling with C axis moves

13

GFK-1711 Mill/Turn

◆

C axis

X axis

Mill Tool

Z axis

Page 18

Figure 9: HY Plane: Back Face Milling with Y axis moves

14

◆

Mill/Turn Manual GFK-1711

X axis

Y axis

Mill Tool

Z axis

Page 19

Figure 10: HY Plane: Back Face Milling with C axis moves

At first glance CS2: XY Plane and CS3: HY Backside plane may appear identical when seen from

an isometric view. The user may wonder why there are two CS’s in the same location. A close

examination of the two CS’s shows the difference between them. The difference between the XY

plane and the HY backside plane is the axis markers.

The XY plane, which represents the front face has a "+" sign at the intersection of the markers indicating that the positive direction of the depth axis is projecting outward. The Back face plane

(labeled as HY) has a “–” sign on the axis markers, indicating that the view is from the negative

depth axis. The positive depth axis projects out from the backside of the part. Essentially the difference between the XY plane and the HY backside plane involves the depth axis along which the tool

will approach the part.

When machining either the front face or the back face, the tool must approach the part along the Z

axis. The question is whether it will approach along the positive Z axis (front face) or the negative Z

axis (back face). The way the system is set up, a tool must approach the part along the positive Z

axis.

Therefore in order for the tool to approach the part to machine the back face, the machining coordi-

15

GFK-1711 Mill/Turn

◆

X axis

Mill Tool

Z axis

C axis

Page 20

nate system must be flipped so that the positive direction of the Z axis is projecting outward from

the backside of the part. This is the reason that two coordinate systems are created to facilitate face

machining.

GEOMETRY CREATION

Geometry can be created in any coordinate system. The CS the geometry is assigned to does not

have any bearing on the machining CS. Typically, the machining CS is designated by the tool orientation. If geometry is not created in the appropriate CS for the type of operation that is being created, it is very likely that the resulting toolpath will not produce the desired results. The toolpath will

be created based on the machining CS, regardless of the CS of the geometry. Geometry will be

machined as it is viewed from the machining CS.

Geometry should be created in the appropriate coordinate system for the type of machining operation to be created. Geometry that defines the cut shape for OD machining operations should be created in the YZ plane. Likewise, geometry for front face operations should be created in the XY

plane and geometry for back face operations should be created in the HY backside plane. It may be

helpful when creating geometry to be machined on the back face to force the depth of the geometry

so that when viewed on the screen, it appears in the correct location. This is recommended for visualization purposes only, as the machining operation and depths of cut will be calculated from the

information entered in the machining process dialogs not the location of the selected geometry.

All geometry for OD milling operations must be created in the YZ plane. Geometry is created in a

position as if it were to be machined in the C0 position. The rotation is accomplished when the toolpath is created by entering an angle value in the machining process dialog. The position C0 is along

the positive direction of the X axis in the standard YZ plane. The system allows the user to designate a start angle when positioning the C axis. All geometry for OD operations must be created in

the standard YZ plane, regardless of the start angle. As a result, often times geometry will not be

created in the exact planar location in which it will be machined. For example, if a flat slot is created on the OD to be machined at a start angle C90, the geometry would be created at C0 and when

the toolpath is created it will be rotated into position.

Geometry can also be created and viewed radially or wrapped when the Rotary Milling option is

installed. Refer to the Rotary Milling section at the end of this manual for more information.

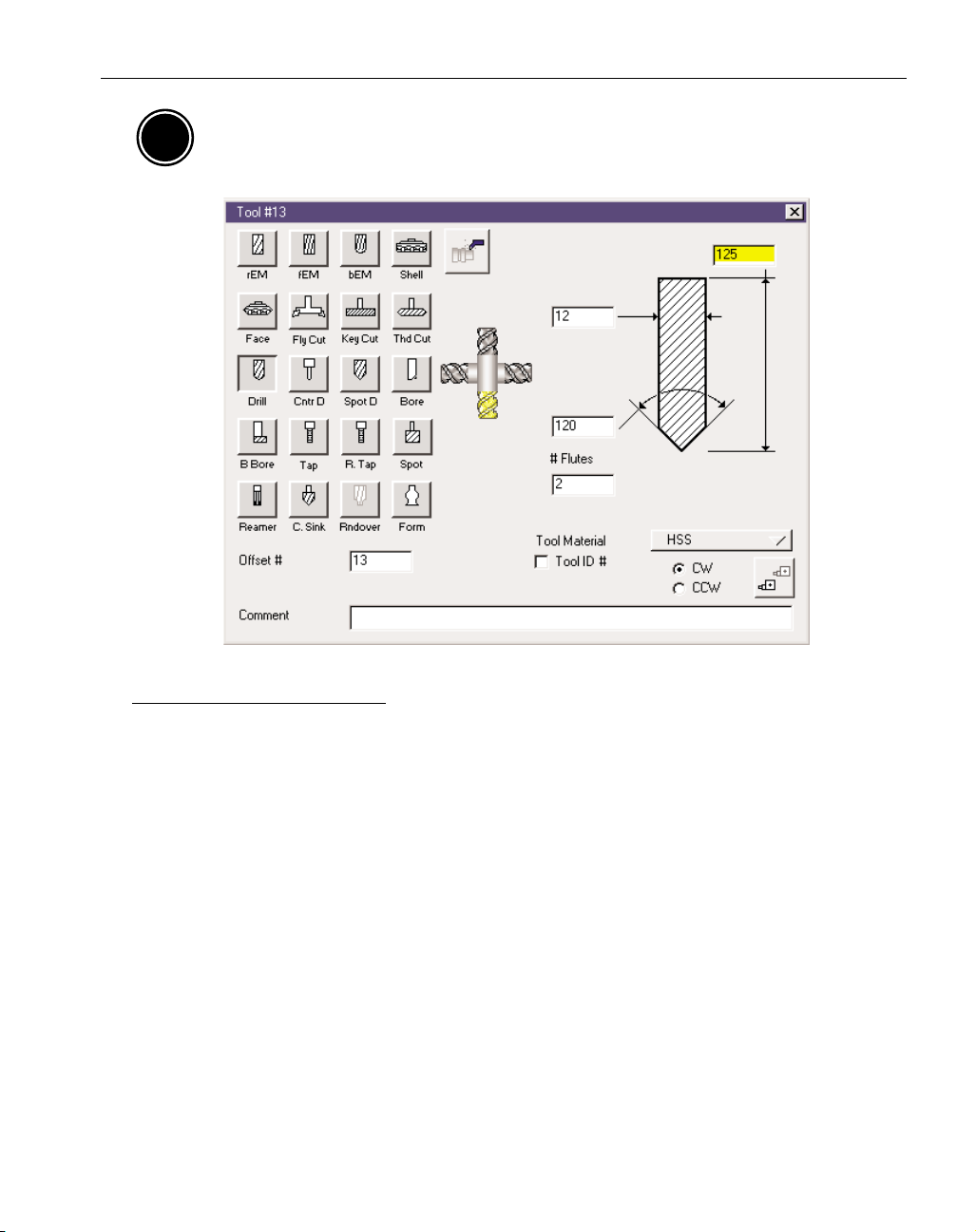

TOOL ORIENTATION

The Mill tool creation dialog contains an orientation diagram when creating a Mill/Turn part.

Setting the proper tool orientation is very important because the tool orientation determines the

machining coordinate system for the process. The system uses the designated machining CS in order

to properly rotate the part. The system rotates the part so that the tool will approach normal to the

cutting plane of the machining coordinate system. In other words the tool will approach and cut

along the positive depth axis of the machining coordinate system.

16

◆

Mill/Turn Manual GFK-1711

Page 21

If the Advanced Milling option is installed users are able to explicitly set the appropriate

machining coordinate system. However, if the advanced Milling option is not installed,

the machining CS will be set by the orientation of the tool.

TOOL ORIENTATION DIAGRAM

Setting the proper tool orientation is very important as it determines the axis along which the tool

will approach and machine the part. There are two basic axes along which the tool will travel, the X

axis, for OD operations, and the Z axis for face operations. To select the tool orientation, click on

one of the four positions on the diagram so that it becomes highlighted.

If the tool orientation is not set correctly, the toolpath that will be generated will not produce the

desired results. Often times, the system will not be able to create a toolpath if the tool orientation is

not set correctly. Always check the tool orientation diagram if the toolpath (or lack thereof) does not

seem correct.

Figure 11 labels the tool orientation diagram according to the approach axis of the selection and also

what section of the part should be cut given the selection. It should be noted that a tool approaching

along the X axis, while typically used for OD work can also be applied to milling operations cutting

the face.

17

GFK-1711 Mill/Turn

◆

AM

Page 22

Figure 11: Tool Orientation Diagram

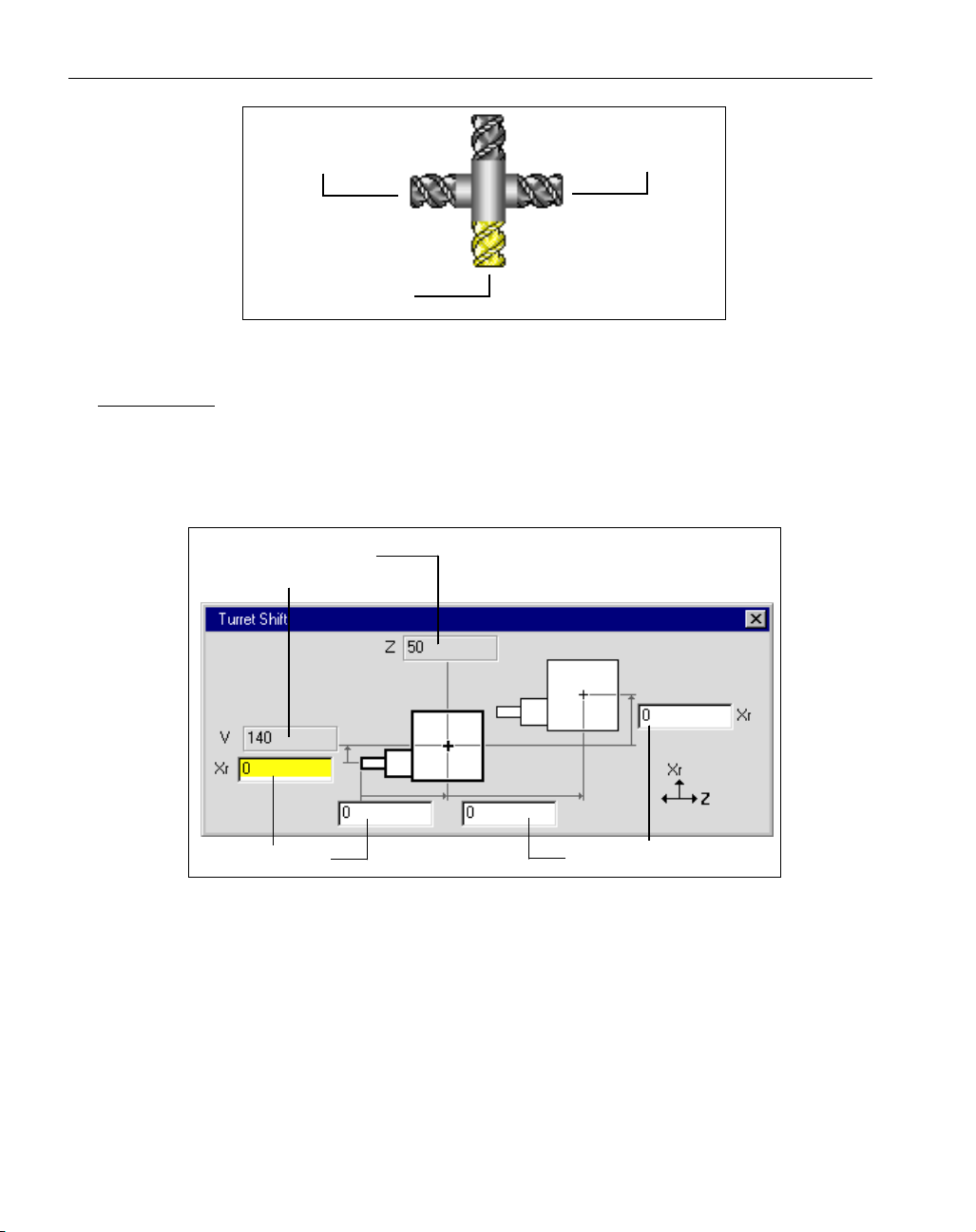

TURRET SHIFT

The tool creation dialog for milling tools contains a turret shift button when programming a

Mill/Turn part. The turret shift for milling tools functions as it does for turning tools. Turret shift

allows users to specify a distance from the preset point, the theoretical tip of the tool, to the center

of the turret. This dialog can also be used to specify a different tool change position for individual

tools.

Figure 12: Mill Turret Shift

18

◆

Mill/Turn Manual GFK-1711

Z Axis Approach

(Front Face)

X Axis Approach

(OD)

Z Axis Approach

(Back Face)

Default Tool

Change Position

Preset Point

Turret Shift

Page 23

Machining Operations

MACHINING

When one of the Mill/Turn MDD's is selected, the machining palette can be used to create milling

operations and turning operations. The available machining processes are the same as those contained in the standard Mill and Lathe modules. Either type of process can now be applied to a single

part, a mill/turn part. Turning functions include contouring, roughing, threading and center line

drilling. Milling functions include live tool drilling, contouring, roughing, surfacing and threadmilling. (The Surfacing process requires the SolidSurfacer option.) All of these processes operate in

the same manner as they do when working on either mill only or lathe only parts. For more information on the specific processes, please refer to the appropriate machining module manual.

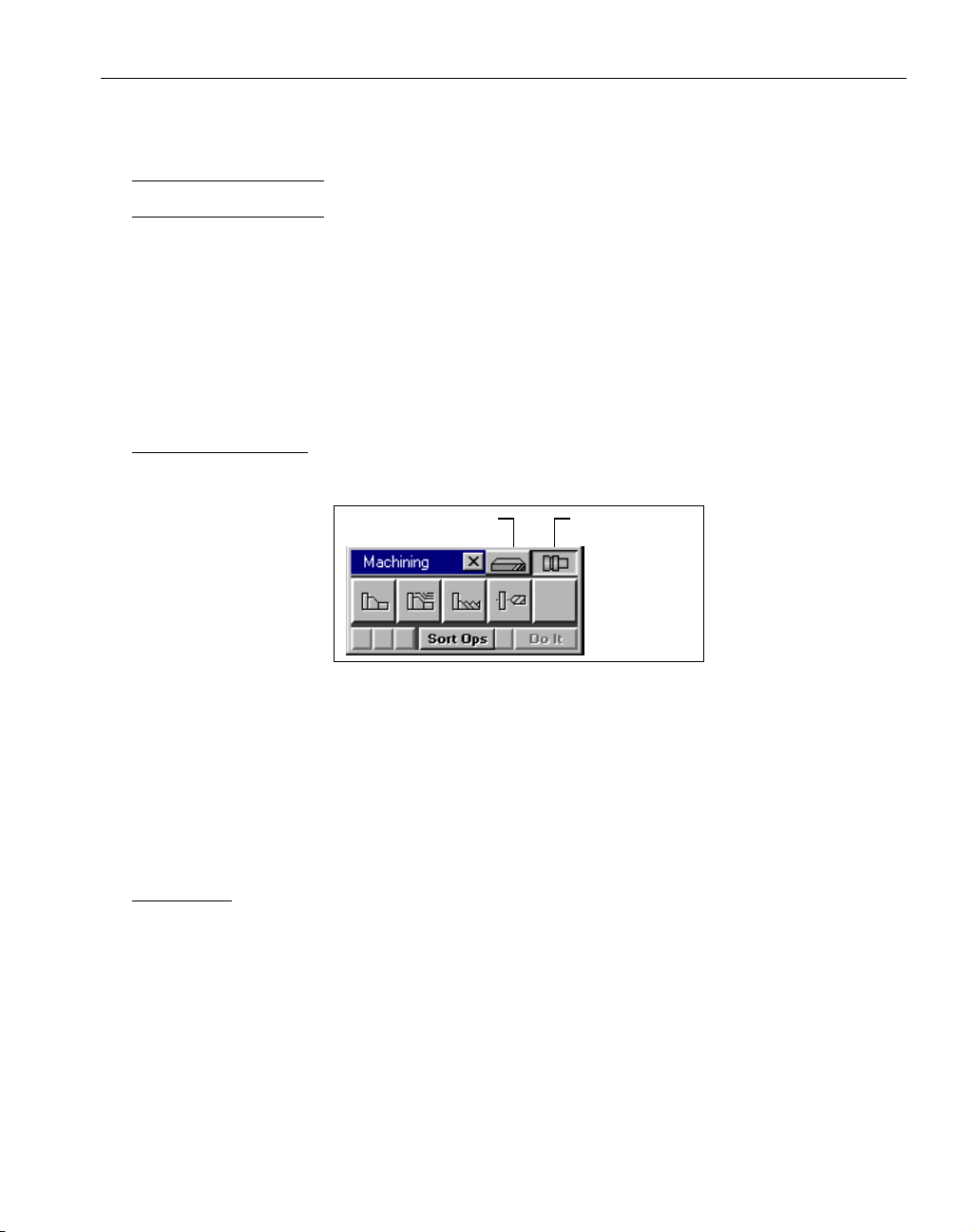

MACHINING PALETTE

When a Mill/Turn MDD is selected, the Machining Palette contains two buttons in the title bar

which allow users to toggle between mill and lathe processes.

Figure 13: Mill/Turn Machining Palette

When toggling between the milling and turning processes, the Process List will be cleared of any

existing Process Tiles. A Process Group (multiple process tiles in one process list) can not contain a

combination of milling and turning processes. Milling and turning processes must be created in different process groups. Turning machining processes function as they do with the standard Lathe

module. Milling functionality has been enhanced to provide specifically for milling operations on

turning parts.

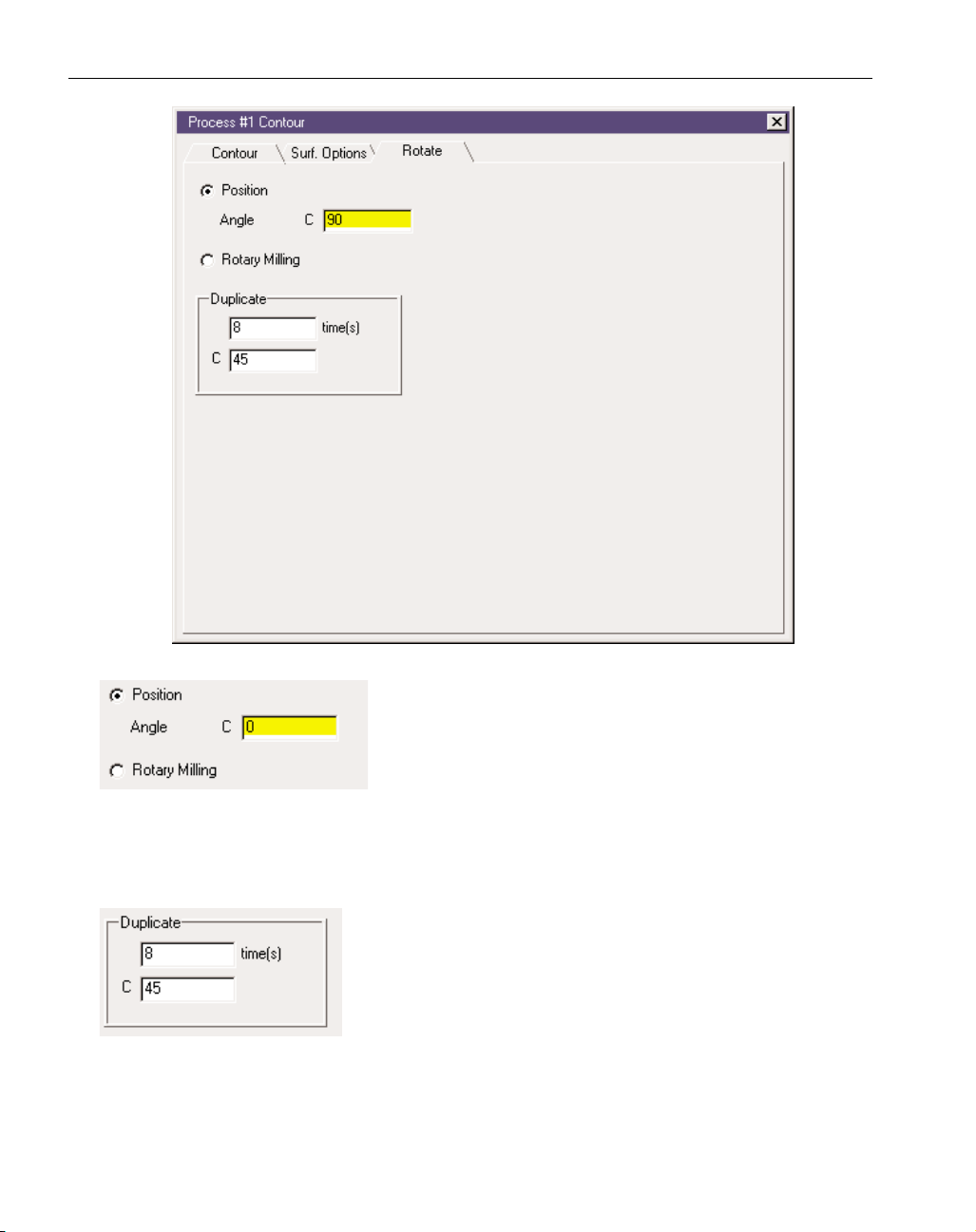

ROTATE TAB

Milling Process dialogs (Drilling, Contouring, Roughing, Surfacing and Threadmilling) contain a

Rotate tab when a Mill/Turn MDD is selected. The Rotate tab allows the user to designate C axis

rotation for the operation.

The Rotate tab in milling processes contains two selections for rotating the part, Position and Rotary

Milling. The Rotary Milling selection will only be available if the Rotary Milling option is installed.

Rotary Milling is discussed in the following section.

19

GFK-1711 Mill/Turn

◆

Mill Toggle Lathe Toggle

Page 24

The Position selection allows the user to enter an angle of rotation for the C axis, which designates the position in which the

toolpath will be created. When the toolpath is generated, the system will display it in the proper location based on the angle

value entered. It is independent of the geometry selected.

Geometry created for face operations should be based on the XY plane and geometry for OD operations should be created in the YZ plane. All geometry for OD operations is created in the YZ plane

in the C0 position. The position rotation is accomplished when the toolpath is created. The posted

code will contain the appropriate C axis positioning moves.

The Duplicate function allows for subroutine repeats at equal angular intervals of the toolpath generated by the operation. The system

will create the toolpath dictated by the Position information and

duplicate that toolpath a specified number of times at the interval

angle position entered in the C text box. The value entered in the

times text box is the additional number of times the toolpath will be

repeated. For example, if you are creating a toolpath using Position at a specified C angle, the

process will create the toolpath at that angle and then duplicate it the given number of times at the

given angle intervals. Thus the Duplicate # is the total number of subroutines the operation is to be

performed minus one for the original step.

20

◆

Mill/Turn Manual GFK-1711

Page 25

Figure 14: C Axis Angular Positions

Figure 14 is viewed from the front face of the part (XY plane) and illustrates the angular positions

associated with positioning the C axis. The C0 position corresponds to the positive direction of the

X axis. Angular rotation proceeds in a clockwise direction. Negative values are valid for start angle

positions. For example, a value of -45 could be used which is identical to entering 315. The value

entered for the start position should be in angle measured in degrees.

Y-AXIS INTERPOLATION & C-AXIS INTERPOLATION

To perform Y-axis moves the user must have a mill/turn machine which supports Y axis. However,

often times machines that do not support the Y axis can create Y-axis moves by continuous rotary

movement of the C axis, C-axis interpolation. The rotation of the C-axis will be used to achieve any

movements needed in Y. To achieve this, be sure to select Rotary Milling in the Process dialog.

A Y-axis toolpath cannot be wrapped. The system only produces Y axis moves when the Position

option is used in the Process dialog. In other words, Y axis moves will not be generated when creating a wrapped or rotary milling toolpath. When Rotary Milling is being used, all movements are

converted to C-Axis Interpolation.

The following images illustrate some of the differences in Y-axis and C-axis moves. Figure 15

shows the same process being machined. The first set of images comes from a machine that does

not have Y-axis capabilities, the second set from a machine that does support Y-axis. (NOTE: a Yaxis capable machine can produce this same movement by selecting Rotary Milling in the machining dialog.)

Figure 16 illustrates a contour being cut on a part’s face. The first set of images illustrates how a

machine without Y-axis would handle the contour while the second image shows a machine with Yaxis. The last image in both sets shows the tool as an overlay to demonstrate all movement.

21

GFK-1711 Mill/Turn

◆

C0

C45

C270 (-90)

C180

C90

Page 26

Figure 15: OD milling, C-Axis vs. Y-axis interpolation

Figure 16: Face milling, C-Axis vs. Y-axis interpolation

22

◆

Mill/Turn Manual GFK-1711

C-Axis Interpolation

Y-Axis Interpolation

C-Axis Interpolation

Y-Axis Interpolation

Page 27

Rotary Milling & Wrapping

The Rotary Milling option is an add-on option which enhances the Mill/Turn functionality. The

Rotary milling option allows for continuous C axis rotation when programming milling operations.

This is often referred to as wrapping. This section describes functions that are specific to the system

when the Rotary Milling option is installed. This section assumes a familiarity with the standard

Mill/Turn functionality described previously in this manual.

ROTARY MILLING VIA C AXIS INTERPOLATION

The term rotary is used to signify the continuous or simultaneous movement of a rotary axis. In the

case of mill/turn parts, the rotary axis is referred to as the C axis. The Rotary Milling option allows

for the wrapping of toolpaths about the C axis by rotary interpolation of the C axis during a milling

operation. When the Rotary Milling option is installed, the Rotate tab for milling processes contains

two rotation options: Position and Rotary Milling. The operation can either be programmed as a

simple position move (Position) or as a wrapped toolpath which will have continuous C axis motion

(Rotary Milling). The Position option is described in the preceding Machining section. The Rotary

Milling option is described in this section.

FLAT VS RADIAL GEOMETRY

Geometry can either be created as flat geometry or radial geometry. Flat geometry is defined using

XYZ values, while radial geometry is defined using XZC values, where X designates the radius or

diameter and C designates an angle of rotation for the C axis. Geometry does not need to be

wrapped in order to be machined using the Rotary milling function. The toolpath that results with

the Rotary Milling option checked will be the same whether the geometry selected for the cut shape

is flat or wrapped.

Two interface items must be used in order to create and view radial geometry. First, the Rotary

Milling option must be checked in the Workgroup Info dialog. The Workgroup info dialog is

accessed from the Workgroup List context menu, which comes up by right mouse clicking on the

23

GFK-1711 Mill/Turn

◆

Page 28

title bar of the Workgroup List dialog.

Figure 17: WG List context menu and WG Info Dialog

In addition to the Rotary Milling checkbox, the Wrap Geometry button in the Taskbar must

be depressed in order to view geometry radially on the screen. When both of these items are

appropriately checked and depressed, the system will be in radial mode. When working in

radial mode, geometry dialogs which require coordinate input will contain specifications for a C

value, which is the angle of rotation and a radius value. For example, with point creation using coordinates, the dialog will not be labeled with X, Y and Z, but rather Z, C and R.

Figure 18: Geometry Dialog in Radial mode

Modify Menu items

When working in radial mode certain Modify functions are enhanced to provide for radial value

input. The two primary functions are the Force Depth item and the Translate item. The Force Depth

item is a Force Radius item when in radial mode. Users can enter an absolute radius value and the

selected geometry will be changed to that radius.

24

◆

Mill/Turn Manual GFK-1711

Page 29

Figure 19: Geometry and toolpath variations with Wrap Geometry button active.

25

GFK-1711 Mill/Turn

◆

Designated as

Designated as

Position

Rotary Milling

in the machining dialog Designated as

in the machining dialog Designated as

Rotary Milling

Position

in the machining dialog

in the machining dialog

Page 30

◆

Mill/Turn Manual GFK-1711

26

EXERCISE 1 : CLUTCH BASKET

This exercise provides instruction on creating milling operations on

mill/turn parts. There is minimal turning work included in the exercise, rather we will begin from a casting and primarily create milling

operations to be applied to the casting.

The installation CD contains sample parts which can be installed on

your system. In order to do this exercise, you will need to install the

Clutch Basket.vnc file.

Following are instructions for installing the part file.

• Right mouse click on the CD icon and select the Open item.

• Open the Samples folder.

• Open the Disk 1 folder and double click on the Setup.exe icon.

This will initiate the setup for the installation of the sample parts.

• Follow the prompts to complete the installation process.

If you did not change any of the destination directory information in

the installation, the Sample Parts folder will be located in the Gibbs

folder. There will be a Mill/Turn folder in the Sample Parts folder

which contains the necessary part to complete this exercise.

In order to use the Mill/turn capabilities of the system, you must be

working in the Level 2 interface. The Level 2 interface has a 14 button Top Level palette. You will need to make sure that you are working in the Level 2 interface for this exercise.

• Select the Interface item from the Preferences sub-menu which is under the

File menu.

• Make sure that the Level 2 radio button is selected under the New Part

section.

• Open the Clutch Basket.vnc file.

In the Document Control Dialog, the Machine Type selected is a 3A

Lathe w/ C axis-1.0 shank. There are four different Machine

Definition Documents (MDD) contained in the Machine Type pop-up

Page 31

GFK-1711 Mill/Turn Exercise

◆

27

menu that are used to create MIll/Turn part files. They are all labeled

3A Lathe w/C axis, but have different shank sizes. In this case we

have selected a 1.0 shank.

When one of the 3 axis lathe MDD's is selected, four coordinate systems are automatically created by the system: ZX plane, XY plane,

HY backside plane and YZ plane. These coordinate systems are used

to properly position geometry in order to cut the various areas of the

part. There is a coordinate system section at the beginning of this

document which describes their use.

• Click on the CS button in the Top Level Palette.

The CS List dialog will come up on the screen and contain these four

coordinate systems.

In order to simplify this exercise, the file contains geometry and

tools that have already been created.

The tools for this part have already been created. There should be a

total of five tools in the tool list including a 2” drill, .25” Rough

Endmill, .52” Form Tool, .625” Spot Drill and .375” Drill

• Click on the WG button in the Top Level palette.

The Workgroup List dialog should have three workgroups which

contain the geometry for different elements of the part.

Page 32

◆

Mill/Turn Manual GFK-1711

28

Following are images of the geometry that is contained in each

workgroup. You should look through all of the workgroups to ensure

that the geometry in your file matches the geometry shown here.

The first workgroup, named Casting, is designated as Part Stock in

the WG info dialog. The casting geometry is defined in the ZX plane

which is the standard plane for turning operations. Nothing will be

done with this geometry, it simply provides the initial part stock to

which we will apply several milling operations. When the part is rendered the initial stock condition will be based on this geometry.

WG 1: Casting

Page 33

GFK-1711 Mill/Turn Exercise

◆

29

Workgroup 2 contains geometry defined in the YZ plane. This geometry will be used to create angled slots on the OD of the part.

WG2: Teeth geometry

Workgroup 3 contains geometry defined in the YZ plane which will

be used to cut slots on the OD of the part. This workgroup also contains a point which will be used to create bolt holes on the front of

the part.

Page 34

◆

Mill/Turn Manual GFK-1711

30

WG3: Drill point and Contour geometry

• Open the Tool list by depressing the Tool List button in the Top Level

palette.

• Open Tool #1 dialog.

The first machining operation will be to drill out the center of the

part so the tool orientation for the first four tools is set to approach

along the Z axis.The tool orientation diagram should look like the

following image.

This orientation designates a Z axis approach which is the necessary

orientation for front face operations.

The first operation will be the only Lathe operation in this exercise.

In order to create lathe operations the Machining palette needs to be

toggled to the Lathe processes.

Selected Tool Orientation

Page 35

GFK-1711 Mill/Turn Exercise

◆

31

• Click on the Lathe toggle button in the title bar of the Machining palette so

that the Lathe process tiles are displayed.

• Create a Hole process using Tool #1 and enter the following information in

the Hole Process dialog.

• Click on Do It in the Machining palette.

The next operation to be created will be a contour. All of the remaining machining operations created in this exercise are milling operations. In order to create milling operations the Machining palette

needs to be toggled to the Mill processes.

• Click on the Mill toggle button in the title bar of the Machining palette so

that the Mill process tiles are displayed.

• Open Tool #2 dialog.

The tool orientation diagram should look like the following image.

This orientation designates an X axis approach which is the necessary orientation for OD operations.

• Be sure you are in WG3: Drill & Contour

• Switch to CS4: YZ plane for better visualization of the operation.

Selected Tool Orientation

Page 36

◆

Mill/Turn Manual GFK-1711

32

• Create a contour operation using tool #2, the .25” Endmill. Enter values in

the contour process dialog as seen in the following image.

• Click on the Rotate tab and enter the following values. For the proper tool-

path be sure to specify that we are working in the YZ plane.

This will create an operation that starts at C0 then gets rotated clockwise by 30˚ and machined 11 more times.

Page 37

GFK-1711 Mill/Turn Exercise

◆

33

• Select the geometry at the location shown in the following image.

• Orient the machining markers so the cut is on the inside of the geometry

as indicated in the following image.

Page 38

◆

Mill/Turn Manual GFK-1711

34

• Click on Do It. The results of the operation should look like the following

image.

• Open the Rendering palette and press Play.

Page 39

GFK-1711 Mill/Turn Exercise

◆

35

The third and fourth operation will create bolt holes.

• Switch to CS2: XY plane for better visualization of the operation.

• Create a Hole operation using tool #4, the .625” Spot Drill. Enter values in

the hole process dialog as seen in the following image.

• Click on the Rotate tab and enter the following values. For the proper tool-

path be sure to specify that we are working in the XY plane.

Page 40

◆

Mill/Turn Manual GFK-1711

36

• In the same process group create a second Hole operation using tool #5,

the .375” Drill. Enter values in the hole process dialog as seen in the following image. There is no need to check the Rotate tab as the values will not

change from the prior drill process.

• Select the point shown in the following image and click on Do It.

Page 41

GFK-1711 Mill/Turn Exercise

◆

37

The results of the operation should look like the following image.

• Switch to CS4: YZ plane

• Change to WG 2: Teeth.

Page 42

◆

Mill/Turn Manual GFK-1711

38

• Create a Contour operation using tool #3, the .52” Form tool. Enter the

following information in the Process dialog.

• Click on the Rotate tab and enter the following information. Be sure to

specify the YZ plane as the machining CS.

Page 43

GFK-1711 Mill/Turn Exercise

◆

39

This will create a contour operation that starts ar C90˚ and repeats 39

times in 9˚ intervals.

• Click on the line in this workgroup. Place the Machining Markers as indicated.

• Be sure to place the start and stop indicators clear of the casting geometry.

Double clicking on the eye icon for the Casting workgroup will display this

geometry in gray. This will help you to properly place the markers.

Page 44

◆

Mill/Turn Manual GFK-1711

40

• Click on Do It. The results of the operation will look like the following

image.

Page 45

GFK-1711 Mill/Turn Exercise

◆

41

• Open the Rendering palette and click Play.

EXERCISE 2 : COUPLING

This exercise provides instruction on creating milling operations on

mill/turn parts. There is no turning work included in the exercise,

rather we will begin from a casting and only create milling operations to be applied to the casting. For turning information, please

refer to the Lathe module manual.

This part file may be found on the system CD, please see exercise #1

for information on retrieving the part file.

You will need to make sure that you are working in the Level 2 interface for this exercise.

• Open the Coupling.vnc file.

In the Document Control Dialog, the Machine Type selected is a 3A

Lathe w/ C axis-1.0 shank. There are four different Machine

Definition Documents (MDD) contained in the Machine Type pop-up

Page 46

◆

Mill/Turn Manual GFK-1711

42

menu that are used to create MIll/Turn part files. They are all labeled

3A Lathe w/C axis, but have different shank sizes. In this case we

have selected a 1.0 shank.

When one of the 3 axis lathe MDD's is selected, four coordinate systems are automatically created by the system: ZX plane, XY plane,

HY backside plane and YZ plane. These coordinate systems are used

to properly position geometry in order to cut the various areas of the

part. There is a coordinate system section at the beginning of this

document which describes their use.

In order to simplify this exercise, the file contains geometry and

tools that have already been created.

• Click on the WG button in the Top Level palette.

The Workgroup List dialog should have four workgroups which contain the geometry for different elements of the part.

Following are images of the geometry that is contained in each

workgroup. You should look through all of the workgroups to ensure

that the geometry in your file matches the geometry shown here.

Page 47

GFK-1711 Mill/Turn Exercise

◆

43

The first workgroup, named Casting, is designated as Part Stock in

the WG info dialog. The casting geometry is defined in the ZX plane

which is the standard plane for turning operations. Nothing will be

done with this geometry, it simply provides the initial part stock to

which we will apply several milling operations. When the part is rendered the initial stock condition will be based on this geometry.

WG 1: Casting

Workgroup 2 contains geometry defined in the XY plane which will

be used to contour a flange on the front face of the part. This workgroup also contains points which will be used to create bolt holes on

the front and back flanges of the part.

Page 48

◆

Mill/Turn Manual GFK-1711

44

WG2: Front Flange

Workgroup 3 contains geometry defined in the YZ plane. This geometry will be used to create flat slots and holes on the OD of the part.

WG3: OD Flat Slots

Page 49

GFK-1711 Mill/Turn Exercise

◆

45

Workgroup 4 also contains geometry defined in the YZ plane, which

will be used to create a radial slot on the OD of the part.

WG4: OD Radial Slots

The first set of machining operations will create bolt holes on the

front face of the part.

• Change to WG2: Front Flange.

• Change to CS 2: XY Plane.

• Open the Tool list by depressing the Tool List button in the Top Level

palette.

The tools for this part have already been created. There should be a

total of eleven tools in the Tool list. The tool creation dialog for mill

tools contains a tool orientation diagram when creating a Mill/Turn

part.

The first set of operations will be machining the face of the part so

the tool orientation for the first four tools is set to approach along the

Z axis.

• Open Tool #1 dialog.

Page 50

◆

Mill/Turn Manual GFK-1711

46

The tool orientation diagram should look like the following image.

This orientation designates a Z axis approach which is the necessary

orientation for front face operations.

All of the machining operations created in this exercise are milling

operations. In order to create milling operations the Machining

palette needs to be toggled to the Mill processes.

• Click on the Mill toggle button in the title bar of the Machining palette so

that the Mill process tiles are displayed.

• Create a Hole process using Tool #1 and enter the following information in

the Drilling Process dialog.

Selected Tool Orientation

Page 51

GFK-1711 Mill/Turn Exercise

◆

47

• Click on the Rotate tab and enter the following information in the Rotate

window.

If you do not have the Advanced Milling option installed, the

Machining CS pop-up menu at the top of the Rotate window will not

be there. The Machining CS will be set by the tool in that case. The

Machining CS pop-up menu will default to the CS designated by the

tool, although the user does have the ability to designate a different

Machining CS using the pop-up menu. The Z axis approach, which is

set for this tool, designates the XY plane as the machining CS. The

XY plane is the coordinate system used for front face operations.

• Create another Hole process in the same Process list using Tool #2 and

enter the following information in the Hole Process dialog.

Page 52

◆

Mill/Turn Manual GFK-1711

48

The information in the Rotate window is the same as the previous

operation so you should not need to change any of the information.

• Select the point just inside the square flange in the XY plane.

• Click on the Do it Button in the Machining palette.

Page 53

GFK-1711 Mill/Turn Exercise

◆

49

The resulting toolpath should look like the following image.

Now, we will create a series of bolt holes that will be machined on

the back flange.

• Create a Hole process with Tool #1 and enter the following information in

the Hole Process dialog.

Page 54

◆

Mill/Turn Manual GFK-1711

50

• Click on the Rotate tab and enter the following information in the Rotate

window.

• In the same process group, create another Hole process using Tool #3 and

enter the following information in the Hole Process dialog.

The information in the Rotate window is the same as the previous

operation so you should not need to change any of the information.

Page 55

GFK-1711 Mill/Turn Exercise

◆

51

• In the same process group, create a final Hole operation using Tool #4 and

enter the following information in the Hole Process dialog.

Again, no changes need to be made in the Rotate window.

• Select the point near the end of the cylinder as shown in the following

image.

Page 56

◆

Mill/Turn Manual GFK-1711

52

• Click on the Do it button in the Machining palette.

The resulting toolpath should look like the following image.

The cut part rendered image should look like the following image.

If your cut part rendered image has the quarter section removed,

check the taskbar and turn off the Stock Cutaway button.

Now, we will contour the front flange.

Page 57

GFK-1711 Mill/Turn Exercise

◆

53

• Create a contouring process with Tool #4 and enter the following information in the Contouring Process dialog.

• Click on the Rotate tab and enter the following information in the Rotate

window.

Page 58

◆

Mill/Turn Manual GFK-1711

54

The Rotary Milling selection is only available when the Rotary

Milling option is installed. The rotary milling option provides for C

axis rotary interpolation.

The same toolpath can be generated using the Position selection. If

the position selection is chosen, the system will use Y axis interpolation to generate the necessary toolpath.

• If you do not have the Rotary Milling selection available, select the

Position option.

This will create the identical toolpath, although it will require Y axis

moves. As not all Mill/Turn machines support the Y axis, your

machine may not be able to cut this toolpath.

• Select the diamond shape on the front face and position the machining

markers so that you are climb cutting with the tool offset to the outside.

Page 59

GFK-1711 Mill/Turn Exercise

◆

55

The resulting toolpath, regardless of whether you selected the Rotary

Milling or Position option, should look like the following image.

This completes the face operations for this part. Now, we will create

milling operations on the OD.

The first set of milling operations will face mill a flat at 45°angles on

both sides of the 2.0" diameter of the casting.

• Change coordinate systems to the YZ plane.

• Change to WG3: OD Flat Slots.

Notice that the geometry for these operations is created flat in the YZ

plane. These shapes will actually be cut at 45° planes, but are positioned as if they will cut without any rotation. When creating cut

shape geometry for OD operations, the geometry should be created

as if it were being machined at a position C0 (no rotation). The rotation is accomplished when the toolpath is generated.

You should also note that the remaining tools in the Tool list are all

set up to cut OD operations. Therefore, the tool orientation diagram

designates an X axis approach, which is used to machine the OD.

Page 60

◆

Mill/Turn Manual GFK-1711

56

The tool orientation diagram in tools 5-11 in the tool list should look

like the following image.

• Create a contouring process with Tool #5 and enter the following information in the Contour Process dialog.

The Entry and Exit Clearance Positions entered for all milling

processes are always radius values, regardless of the selection made

in the Document Control dialog (Radius vs. Diameter). It is very

important that the Entry and Exit Clearance values be set appropriately so that the tool is clear when the part is rotated. In this case, we

are working on an area of the part that has a 1.0" radius. That is why

we have set the clearance plane values just above that radius.

Selected Tool Orientation

Page 61

GFK-1711 Mill/Turn Exercise

◆

57

Also, it should be noted that the Exit Clearance Plane entered in the

process dialogs is used as the position that the tool will retract to

when making indexing moves. As such it is imperative that the Exit

Clearance value be high enough to clear the part when it is positioned.

• Click on the Rotate tab and enter the following information in the Rotate

window.

We have entered a start angle for the C axis. The toolpath will be

created at a 45° angle from the C0 position.

Page 62

◆

Mill/Turn Manual GFK-1711

58

• Select the line and position the machining markers so that you are conventional cutting with center offset circle selected.

• Click on the Do it in the Machining Palette.

The resulting toolpath should look like the following image.

We will now create an identical operation to machine the opposite

45° plane. The only change that we need to make is in the rotation

angle.

• Use the same contouring process that was used in the previous operation.

Make sure that the operation tile in the Operations list is deselected

so that you do not redo the previous operation.

Page 63

GFK-1711 Mill/Turn Exercise

◆

59

• Click on the Rotate tab and change the Position angle from

-45° to 45°.

• Select the same line and position the machining markers in the same manner as was done with the previous operation.

• Click on the Do it button in the Machining palette.

The cut part rendered image should look like the following picture.

Page 64

◆

Mill/Turn Manual GFK-1711

60

The next operations will contour a gasket on the flats that we have

created. The machining of the gasket and the subsequent pockets

require Y axis tool moves. The system supports Y axis interpolation,

however, your machine will also need to support Y axis moves in

order to cut this part.

• Create a contouring process with Tool #6 and enter the following information in the Contour Process dialog.

Page 65

GFK-1711 Mill/Turn Exercise

◆

61

• Click on the Rotate tab and enter the following information.

• Select the outer rectangular slot. Position the machining markers so that

you are conventional cutting and select the inside offset circle.

Page 66

◆

Mill/Turn Manual GFK-1711

62

• Click on the Do it button in the Machining palette.

The resulting toolpath should look like the following image.

Again, we will perform an identical operation on the opposing 45°

flat.

• Use the identical contouring process, but change the Position angle in the

Rotate Tab to 45°.

The machining markers should be positioned exactly as they were

for the previous operation.

• Click on the Do it button in the Machining palette.

Page 67

GFK-1711 Mill/Turn Exercise

◆

63

The cut part rendered image should look like the following image.

The next group of operations are drilling operations which will spot

drill, drill and tap the four holes surrounding the gasket. These

drilling operations will be performed on both 45° flats like the previous sets of operations.

• Create a Hole process using Tool #9 and enter the following information in

the Hole process dialog.

Page 68

◆

Mill/Turn Manual GFK-1711

64

Notice that the entry and exit clearance values are still set to clear

the 1.0" radius of this area of the part. Although the flats that have

been machined are at a radial depth of 0.7", it is still necessary to set

the clearance planes so that they clear the 1.0" radius during indexing. The system will retract to the Exit Clearance Plane position

when the part is indexed. It is very important that the Exit Clearance

value is set high enough so that no tool interference will occur when

the part is rotated.

• Click on the Rotate tab and enter the following information in the Rotate

window.

Page 69

GFK-1711 Mill/Turn Exercise

◆

65

• In the same process group, create a Hole process using Tool #7 and enter

the following information in the Hole Process dialog. The information in the

Rotate window is the same as in the previous drilling operation and should

not need to be changed.

• In the same process group, create a Hole process using Tool #8 and enter

the following information in the Hole Process dialog. The information in the

Rotate window is the same as in the previous Hole operation and should not

need to be changed.

Page 70

◆

Mill/Turn Manual GFK-1711

66

• Select the four holes surrounding the gasket.

• Click on the Do it button in the Machining palette.

• Create the same group of operations for the opposing 45° flat by changing

the Position angle in the Rotate tab.

The cut part rendered image should look like the following picture.

The final set of operations that will machine this area of the part will

pocket out the area inside the gasket. Again, this set of operations

requires Y axis interpolation, which may not be supported by your

Mill/Turn machine.

Page 71

GFK-1711 Mill/Turn Exercise

◆

67

• Create a roughing process with Tool #10 and enter the following information in the Roughing Process dialog.

• Click on the Rotate tab and enter the following information in the Rotate

window.

Page 72

◆

Mill/Turn Manual GFK-1711

68

• Select the inner rectangular slot.

• Click on the Do it button in the Machining palette.

• Perform the identical operation for the opposing 45° area by changing the

Position angle.

The cut part rendered image should look like the following picture.

If you do not have the Rotary Milling option installed, the exercise is

now complete. Rotary Milling is an add-on option which provides

for wrapping a toolpath using rotary interpolation.

Page 73

GFK-1711 Mill/Turn Exercise

◆

69

The final operation that will complete the machining of this part is a

radial slot that will be machined on the bottom side of the part. In

order to perform this operation, you will need the Rotary Milling

option installed.

• Change to WG 4: OD Radial slot.

The geometry should be positioned flat in the YZ plane. First, we

need to wrap the geometry and then rotate it into position on the bottom of the part.

• Open the WG info dialog for Workgroup #4.

• Check the Rotary Milling option.

• In the taskbar, depress the Wrap Geometry button.

The geometry should now be displayed as wrapped.

Page 74

◆

Mill/Turn Manual GFK-1711

70

Viewing the geometry from the front face will clearly show how the

geometry is wrapped at a given diameter.

• Select the wrapped shape.

• From the Modify menu, select the Translate item.

When the system is in radial mode, some of the Modify dialogs

allow for radial input--an angle of rotation and a radius value.

• Enter the following information in the Translate dialog and click on the Do

it button.

Page 75

GFK-1711 Mill/Turn Exercise

◆

71

The geometry should be positioned radially at the bottom of the part

as shown in the following picture.

• Create a Roughing process with Tool #10 and enter the following information in the Roughing Process dialog.

Page 76

◆

Mill/Turn Manual GFK-1711

72

• Click on the Rotary tab and enter the following information in the Rotary

window.

When the Rotary Milling choice is selected, the system will generate

the toolpath using C axis rotary interpolation.

• In the same process group, create a contouring process with Tool #11 and

enter the following information in the Contour Process dialog.

Page 77

GFK-1711 Mill/Turn Exercise

◆

73

• Click on the Rotate tab and make sure the Rotary Milling choice is selected.

• Select the wrapped geometry and click on the Do it button in the Machining

palette.

Page 78

◆

Mill/Turn Manual GFK-1711

74

The resulting toolpath should look like the following image.

The final cut part rendered image, viewed from the bottom, should

look like the following image.

Loading...

Loading...