Emerson MRLDS-250 User Manual

Document Part # 026-4413 Rev 2 Page 1 of 4

©2018 Emerson Climate Technologies Retail Solutions, Inc. This document may be photocopied for personal use.

Visit our website at http://www.emerson.com for the latest technical documentation and updates.

The Modular Refrigeration Leak Detection Sensor is

Emerson’s state-of-the-art infrared refrigerant gas

detector that can detect a wide range of gases. The

MRLDS-250 can be used on a stand-alone basis or

integrated into supervisory controls. The MRLDS-250

can be used in locations that require continuous

monitoring and to add gas detection solutions to an

existing system.

The MRLDS-250 is available in two versions:

• The broadband gas detector is used as a general

purpose gross leak detector and is factory tested and

certified to +/- 35% accuracy.

• The gas specific versions come factory certified and

calibrated with +/- 3% accuracy to the target refrigerant

when there is a need for more accurate detection.

For complete part number and installation information, see

the full MRLDS-250 manual (P/N 026-1315).

MRLDS-250 Installation

Mounting the MRLDS-250

1. To open the housing as received, use a flat blade

screwdriver and depress the top latch. While pushing

the latch, grasp the back edge of the housing near the

latch and pull the back away.

2. Position the base to the pre-determined mounting

location.

3. For Wall Mount, attach the MRLDS-250 base to the

mounting surface using two #6 screws (provided)

through two of the seven mounting holes

(see Figure 2). For Junction Box Mount, attach the

MRLDS-250 base to the junction box through the two

junction box holes.

Figure 1 - MRLDS-250 Components

Figure 2 - Front and Back of the MRLDS-250 Base

Quick Setup Guide

MRLDS-250

Document Part # 026-4413 Rev 2 Page 2 of 4

©2018 Emerson Climate Technologies Retail Solutions, Inc. This document may be photocopied for personal use.

Visit our website at http://www.emerson.com for the latest technical documentation and updates.

Wiring and Configuration

Either 24VAC or 24VDC may be used to power the

MRLDS-250. Connect wiring to the appropriate terminal

locations. Use two wires, between 14 and 22 AWG.

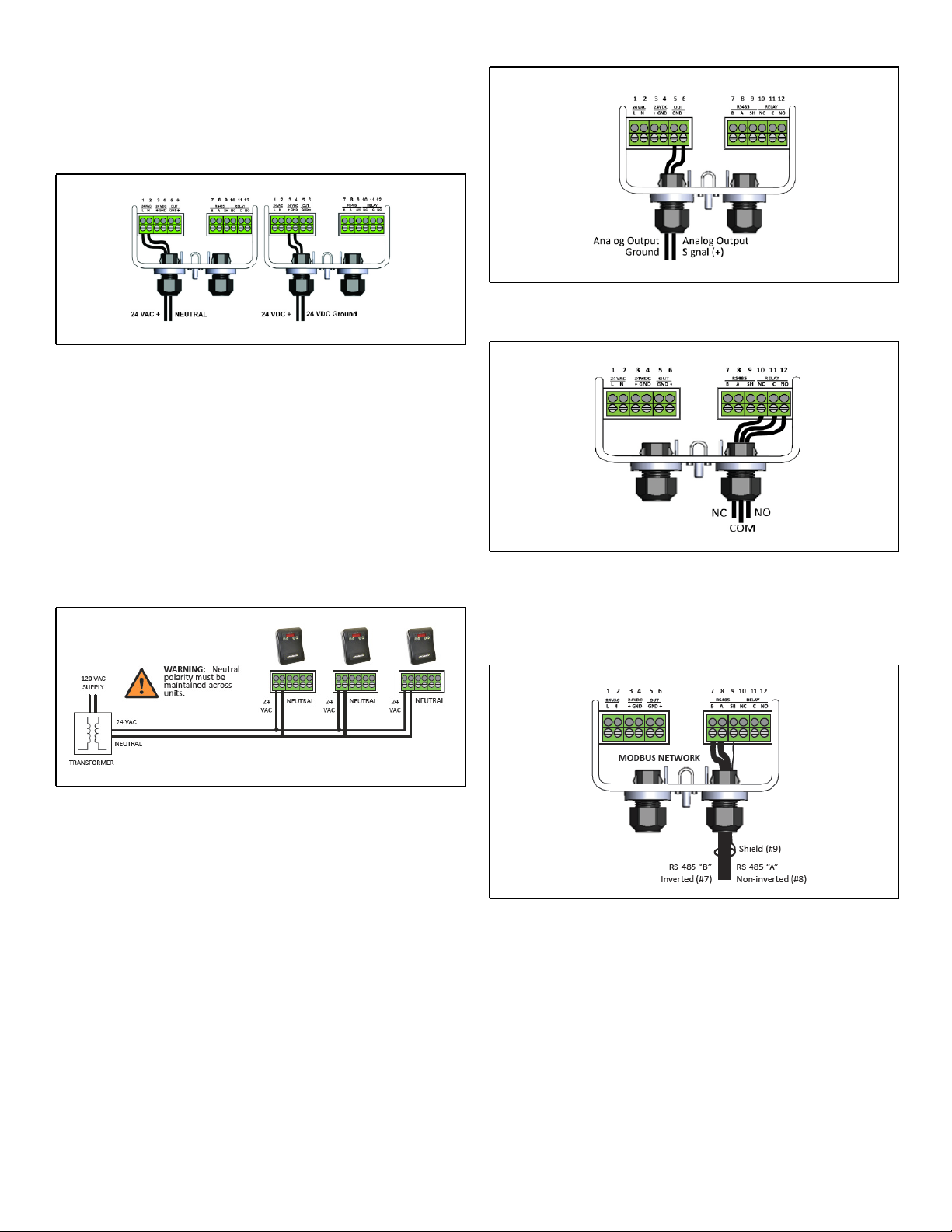

Refer to Figure 3 for AC wiring (left) or DC wiring (right):

WARNING: The MRLDS-250 must be powered by:

• A suitable UL 60950/CSA certified power supply

that is isolated from line voltage by double

insulation.

• An appropriately rated UL listed/CA Class 2

Transformer; a 10VA Transformer is

recommended.

• For multiple devices cascaded, a 50VA Class 2

Transformer is recommended.

The MRLDS-250 provides an analog output signal that is

proportional to the level of gas detected. Connect two

18 to 20 AWG wires to terminal block positions 5 and 6

(see Figure 5A), noting ground and signal polarity.

Make relay connections (NO, NC, or both) using 18 to 20

AWG wires to terminal block positions 10, 11, and 12

(see Figure 5B), noting normally open, normally closed,

and common connectors.

NOTE: For MODBUS network communications wiring,

use only 18-24 AWG shielded twisted pair wire with 120

ohm characteristic impedance.

Figure 3 - Supply and Power Wiring Options

Figure 4 - Power Wiring of a Device Network

Figure 5A - Analog Output Wiring

Figure 5B - Sample Relay Output Wiring

Figure 6 - MODBUS Network Communication Wiring

Loading...

Loading...