Emerson MP45A4, MP45A5, MP105A5, MP155A4, MP155A5 User Manual

...

User Guide

Mentor MP

High performance DC drive

25A to 7400A, 480V to 690V

Two or four quadrant operation

Part Number: 0476-0000-03

Issue: 3

www.controltechniques.com

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect

installation or adjustment of the optional operating parameters of the equipment or from mismatching the variable speed

drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a policy

of continuous development and improvement, the manufacturer reserves the right to change the specification of the

product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or

mechanical including photocopying, recording or by an information storage or retrieval system, without permission in

writing from the publisher.

Drive software version

This product is supplied with the latest software version. If this drive is to be connected to an existing system or machine,

all drive software versions should be verified to confirm the same functionality as drives of the same model already

present. This may also apply to drives returned from a Control Techniques Service Centre or Repair Centre. If there is

any doubt please contact the supplier of the product.

The software version of the drive can be checked by looking at Pr 11.29 (di14/0.49) and Pr 11.34. This takes the form

of xx.yy.zz where Pr 11.29 (di14/0.49) displays xx.yy and Pr 11.34 displays zz. (e.g. for software version 01.01.00,

Pr 11.29 (di14/0.49) = 1.01 and Pr 11.34 displays 0).

Environmental statement

Control Techniques is committed to minimising the environmental impacts of its manufacturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is

certified to the International Standard ISO 14001. Further information on the EMS, our Environmental Policy and other

relevant information is available on request, or can be found at www.greendrives.com.

The electronic variable-speed drives manufactured by Control Techniques have the potential to save energy and

(through increased machine/process efficiency) reduce raw material consumption and scrap throughout their long

working lifetime. In typical applications, these positive environmental effects far outweigh the negative impacts of product

manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded but should

instead be recycled by a specialist recycler of electronic equipment. Recyclers will find the products easy to dismantle

into their major component parts for efficient recycling. Many parts snap together and can be separated without the use

of tools, while other parts are secured with conventional fasteners. Virtually all parts of the product are suitable for

recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller

products come in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these

containers can be recycled. Polythene, used on the protective film and bags for wrapping product, can be recycled in the

same way. Control Techniques' packaging strategy prefers easily-recyclable materials of low environmental impact, and

regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires

the supplier of an article to inform the recipient if it contains more than a specified proportion of any substance which is

considered by the European Chemicals Agency (ECHA) to be a Substance of Very High Concern (SVHC) and is

therefore listed by them as a candidate for compulsory authorisation.

For current information on how this requirement applies in relation to specific Control Techniques products, please

approach your usual contact in the first instance. Control Techniques position statement can be viewed at:

http://www.controltechniques.com/REACH

Copyright © April 2010 Control Techniques Ltd

Issue Number: 3

Software: 01.05.00 onwards

Contents

1 Safety Information .................................5

1.1 Warnings, Cautions and Notes .............................5

1.2 Electrical safety - general warning ........................5

1.3 System design and safety of personnel ................5

1.4 Environmental limits ..............................................5

1.5 Access ..................................................................5

1.6 Fire protection .......................................................5

1.7 Compliance with regulations .................................5

1.8 Motor .....................................................................5

1.9 Adjusting parameters ............................................5

1.10 Electrical installation .............................................5

2 Product information ..............................6

2.1 Ratings ..................................................................6

2.2 Model number .......................................................7

2.3 Compatible encoders ............................................8

2.4 Nameplate description ..........................................8

2.5 Drive features and options ....................................9

2.6 Items supplied with the drive ...............................12

3 Mechanical Installation .......................13

3.1 Safety ..................................................................13

3.2 Planning the installation ......................................13

3.3 Terminal cover removal ......................................14

3.4 Mounting method ................................................17

3.5 Installing and removing the terminal shrouds .....24

3.6 Enclosure ............................................................26

3.7 Heatsink fan operation ........................................27

3.8 IP rating (Ingress Protection) ..............................27

3.9 Electrical terminals ..............................................28

3.10 Routine maintenance ..........................................31

4 Electrical installation ..........................32

4.1 Electrical connections .........................................33

4.2 Ground connections ............................................35

4.3 AC supply requirements ......................................36

4.4 Line reactors .......................................................37

4.5 Control 24Vdc supply ..........................................37

4.6 Cable and fuse size ratings .................................38

4.7 External suppressor resistor ...............................44

4.8 Ground leakage ..................................................46

4.9 EMC (Electromagnetic compatibility) ..................46

4.10 Serial communications connections ....................48

4.11 Shield connections ..............................................49

4.12 Connecting the fan on size 2C and 2D drives .....49

4.13 Control connections ............................................50

4.14 General ...............................................................51

4.15 Connecting an encoder .......................................54

5 Getting started .....................................56

5.1 Understanding the display ..................................56

5.2 Keypad operation ................................................56

5.3 Menu 0 (sub block) .............................................58

5.4 Pre-defined sub blocks .......................................59

5.5 Menu 0 (linear) ....................................................60

5.6 Menu structure ....................................................60

5.7 Advanced menus ................................................61

5.8 Saving parameters ..............................................61

5.9 Restoring parameter defaults ..............................61

5.10 Differences between European and

USA defaults .......................................................62

5.11 Displaying parameters with non-default

values only ..........................................................62

5.12 Displaying destination parameters only ..............62

5.13 Parameter access level and security ..................62

5.14 Serial communications ........................................63

6 Basic parameters ................................64

6.1 Full descriptions ..................................................65

7 Running the motor ..............................72

7.1 Quick start commissioning / start-up (from

European defaults) ..............................................73

7.2 Quick start commissioning / start-up (from USA

defaults) ..............................................................75

7.3 CTSoft software commissioning / start-up tool ....76

7.4 Setting up a feedback device ..............................77

8 Optimization .........................................78

8.1 Armature current .................................................78

8.2 Speed feedback ..................................................78

8.3 Field current ........................................................78

8.4 Current loop gains self-tuning .............................78

8.5 Speed loop gains tuning .....................................79

8.6 Current limit tapers ..............................................80

9 SMARTCARD operation ......................81

9.1 Introduction .........................................................81

9.2 Easy saving and reading .....................................81

9.3 Transferring data .................................................81

9.4 Data block header information ............................83

9.5 SMARTCARD parameters ..................................83

9.6 SMARTCARD trips .............................................84

10 Onboard PLC .......................................86

10.1 Onboard PLC and SYPT Lite ..............................86

10.2 Benefits ...............................................................86

10.3 Limitations ...........................................................86

10.4 Getting started ....................................................87

10.5 Onboard PLC parameters ...................................87

10.6 Onboard PLC trips ..............................................88

10.7 Onboard PLC and the SMARTCARD .................88

Mentor MP User Guide 3

Issue : 3 www.controltechniques.com

11 Advanced parameters .........................89

11.1 Menu 1: Speed reference ....................................94

11.2 Menu 2: Ramps ...................................................98

11.3 Menu 3: Speed feedback and speed control .....101

11.4 Menu 4: Torque and current control ..................104

11.5 Menu 5: Motor and field control .........................108

11.6 Menu 6: Sequencer and clock ...........................112

11.7 Menu 7: Analog I/O ...........................................114

11.8 Menu 8: Digital I/O ............................................116

11.9 Menu 9: Programmable logic, motorized pot and

binary sum .........................................................120

11.10 Menu 10: Status and trips .................................123

11.11 Menu 11: General drive set-up ..........................124

11.12 Menu 12: Threshold detectors, variable selectors

and brake control function .................................125

11.13 Menu 13: Position control ..................................130

11.14 Menu 14: User PID controller ............................134

11.15 Menus 15, 16 and 17: Solutions Module slots ..137

11.16 Menu 18: Application menu 1 ............................138

11.17 Menu 19: Application menu 2 ............................138

11.18 Menu 20: Application menu 3 ............................138

11.19 Menu 21: Second motor parameters .................139

11.20 Menu 22: Additional Menu 0 set-up ..................139

11.21 Menu 23: Header selections .............................139

11.22 Advanced features ............................................140

12 Technical data ....................................145

12.1 Drive technical data ...........................................145

12.2 Cable and fuse size ratings ...............................151

12.3 Optional external EMC filters ............................166

13 Diagnostics ........................................167

13.1 Trip indications ..................................................167

13.2 Trip indications ..................................................167

13.3 Trip categories ..................................................174

13.4 Alarm indications ...............................................175

13.5 Status indications ..............................................175

13.6 Displaying the trip history ..................................175

13.7 Behaviour of the drive when tripped ..................175

13.8 Trip masking ......................................................175

14 UL information ...................................176

14.1 Common UL Information ...................................176

14.2 AC supply specification .....................................176

14.3 Maximum continuous output current .................176

14.4 Safety label .......................................................176

14.5 UL Listed accessories .......................................176

4 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

WARNING

CAUTION

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

1 Safety Information

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for

avoiding a safety hazard.

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of

the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive.

Specific warnings are given at the relevant places in this Guide.

1.3 System design and safety of

The drive is intended as a component for professional incorporation into

complete equipment or system. If installed incorrectly, the drive may

present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control equipment which can cause

injury.

System design, installation, commissioning / start-up and maintenance

must be carried out by personnel who have the necessary training and

experience. They must read this safety information and this guide

carefully.

The STOP and START controls or electrical inputs of the drive must

not be relied upon to ensure safety of personnel. They do not

isolate dangerous voltages from the output of the drive or from any

external option unit. The supply must be disconnected by an

approved electrical isolation device before gaining access to the

electrical connections.

The drive is not intended to be used for safety-related functions.

Careful consideration must be given to the function of the drive which

might result in a hazard, either through its intended behaviour or through

incorrect operation due to a fault. In any application where a malfunction

of the drive or its control system could lead to or allow damage, loss or

injury, a risk analysis must be carried out, and where necessary, further

measures taken to reduce the risk - for example, an over-speed

protection device in case of failure of the speed control, or a fail-safe

mechanical brake in case of loss of motor braking.

personnel

1.4 Environmental limits

Instructions within the supplied data and information within the Mentor

MP User Guide regarding transport, storage, installation and the use of

the drive must be complied with, including the specified environmental

limits. Drives must not be subjected to excessive physical force.

1.5 Access

Access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses and other protection, and protective ground (earth) connections.

The Mentor MP User Guide contains instructions for achieving

compliance with specific EMC standards.

Within the European Union, all machinery in which this product is used

must comply with the following directives:

2006/42/EC: Safety of machinery

2004/108/EC: Electromagnetic compatibility

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer's

recommendations. Ensure the motor shaft is not exposed.

Low speeds may cause the motor to overheat because the cooling fan

becomes less effective. The motor should be installed with a protection

thermistor. If necessary, an electric forced ventilation fan should be

used.

The values of the motor parameters set in the drive affect the protection

of the motor. The default values in the drive should not be relied upon.

It is essential that the correct value is entered into Pr 5.07 (SE07, 0.28),

Motor rated current. This affects the thermal protection of the motor.

1.9 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

1.10 Electrical installation

1.10.1 Electric shock risk

The voltages present in the following locations can cause severe electric

shock and may be lethal:

• AC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and

must not be touched.

1.10.2 Stored charge

The drive contains capacitors that remain charged to a potentially lethal

voltage after the AC supply has been disconnected. If the drive has been

energized, the AC supply must be isolated at least ten minutes before

work may continue.

Mentor MP User Guide 5

Issue: 3 www.controltechniques.com

Safety

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

2 Product information

Table 2-1 Model to frame size cross reference

Model

480V

EN/IEC

cULus

MP25A4(R) MP25A5(R)

MP75A4(R) MP75A5(R)

MP105A4(R) MP105A5(R)

MP210A4(R) MP210A5(R)

MP350A4(R) MP350A5(R) MP350A6(R)

MP420A4(R)

MP550A4(R)

MP700A4(R) MP700A5(R) MP700A6(R)

MP900A4(R)

MP1200A4 MP1200A5 MP1200A6

MP1850A4 MP1850A5 MP1850A6

MP1200A4R MP1200A5R MP1200A6R

MP1850A4R MP1850A5R MP1850A6R

2.1 Ratings

The power ratings for the 480V, 575V and 690V configurations are

shown in Table 2-2, Table 2-3 and Table 2-4.

The continuous current ratings given are for a maximum ambient

temperature of 40°C (104°F) and an altitude of 1000m. For operation at

higher temperatures and altitudes de-rating is required.

For further information see Chapter 12 Technical data on page 145.

Table 2-2 480V current ratings

AC input

current

Model

MP25A4(R) 22 25 37.5 9 15

MP45A4(R) 40 45 67.5 15 27

MP75A4(R) 67 75 112.5 27 45

MP105A4(R) 94 105 157.5 37.5 60

MP155A4(R) 139 155 232.5 56 90

MP210A4(R) 188 210 315 75 125

MP350A4(R) 313 350 525 125 200

MP420A4(R) 376 420 630 150 250

MP550A4(R) 492 550 825 200 300

MP700A4(R) 626 700 1050 250 400

MP825A4(R) 738 825 1237.5 300 500

MP900A4(R) 805 900 1350 340 550

MP1200A4(R) 1073 1200 1800 450 750

MP1850A4(R) 1655 1850 2775 700 1150

Continuous Continuous

575V

EN/IEC

cULus to 600V

690V

EN/IEC

Frame

1AMP45A4(R) MP45A5( R)

1BMP155A4(R) MP155A5(R)

MP470A5(R) MP470A6(R)

2A

2BMP825A4(R) MP825A5(R) MP825A6(R)

2C

2D

DC output current

150%

overload

AAAkWhp

Typ i cal m otor

power

@

400Vdc@ 500Vdc

Table 2-3 575V current ratings

AC input

current

Model

MP25A5(R) 22 25 37.5 14 18

MP45A5(R) 40 45 67.5 25 33

MP75A5(R) 67 75 112.5 42 56

MP105A5(R) 94 105 157.5 58 78

MP155A5(R) 139 155 232.5 88 115

MP210A5(R) 188 210 315 120 160

MP350A5(R) 313 350 525 195 260

MP470A5(R) 420 470* 705 265 355

MP700A5(R) 626 700 1050 395 530

MP825A5(R) 738 825* 1237.5 465 620

MP1200A5(R) 1073 1200 1800 680 910

MP1850A5(R) 1655 1850 2775 1045 1400

Continuous Continuous

AAAkWhp

DC output current

150%

overload

Typ i cal m oto r

power

(With Vdc =

630V)

* For this rating at 575V, 150% overload time is 20s at 40°C and 30s at

35°C.

Table 2-4 690V current ratings

AC input

current

Model

MP350A6(R) 313 350 525 240 320

MP470A6(R) 420 470* 705 320 425

MP700A6(R) 626 700 1050 480 640

MP825A6(R) 738 825* 1237.5 650 850

MP1200A6(R) 1073 1200 1800 850 1150

MP1850A6(R) 1655 1850 2775 1300 1750

Continuous Continuous

AAAkWhp

DC output Current

150%

Overload

Typ i cal m otor

power (With

Vdc = 760V)

* For this rating at 690V, 150% overload time is 20s at 40°C and 30s at

35°C.

Maximum continuous input current

The values of maximum continuous input current are given to aid the

selection of cables and fuses. These values are stated for worst-case

condition.

For current ratings above 1850A then parallel connection of the drives is

required. However, this function is not implemented on firmware

versions V01.05.00 and earlier.

6 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

100

105

110

115

120

125

130

135

140

145

150

155

160

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

200

overload duration (seconds)

overload

(%)

NOTE

Mentor product line

MP

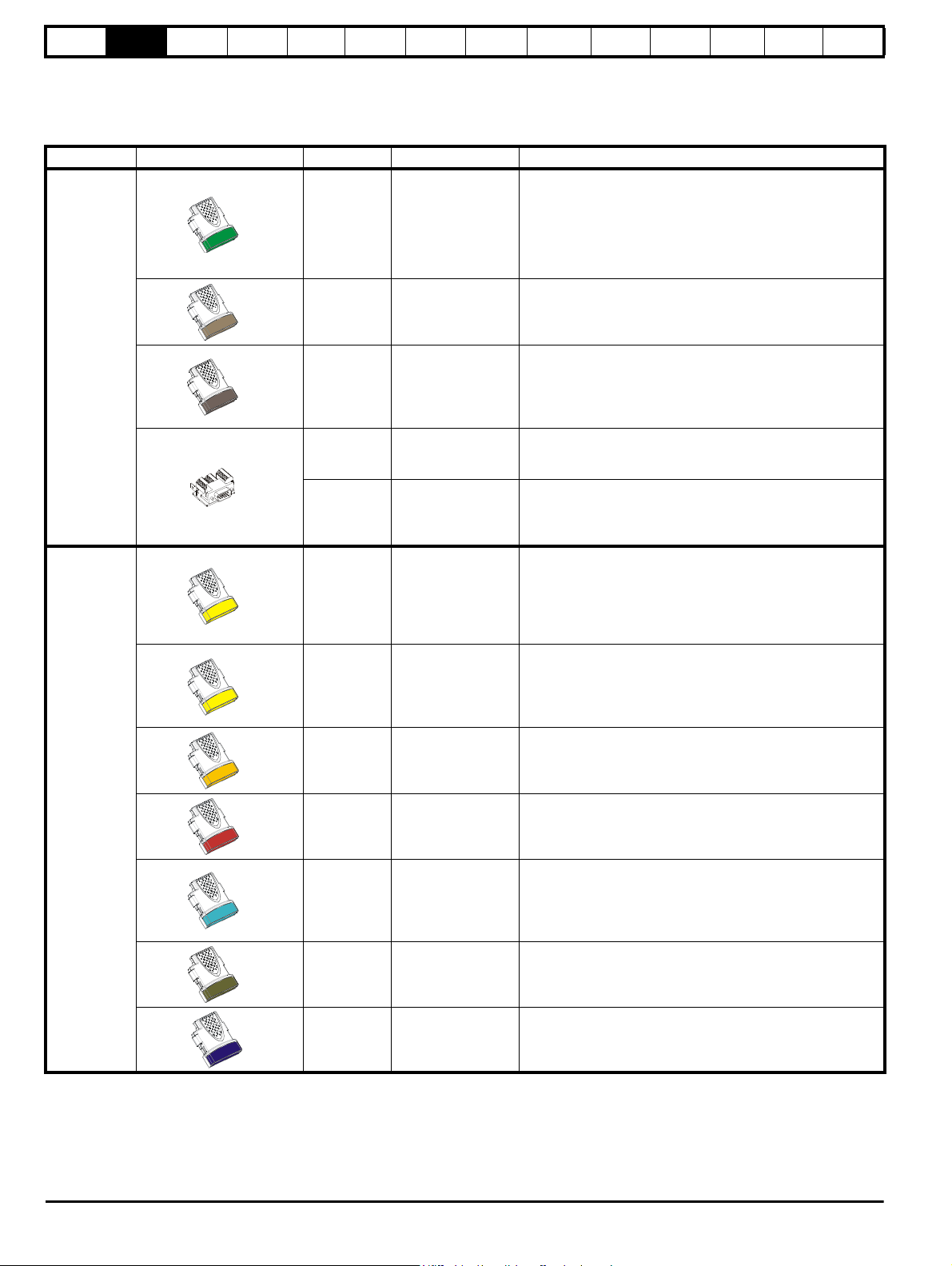

:

Continuous armature current rating (A)

Vol t age r a t ing

4 = 480V 24V to 480V -20% +10%

5 = 575V 500V to 575V -10% +10%

6 = 690V 500V to 690V -10% +10%

Mentor Platform

MP 2 0 01 4 R

R

Blank

-

4 quadrant operation

- 2 quadrant operation

A

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

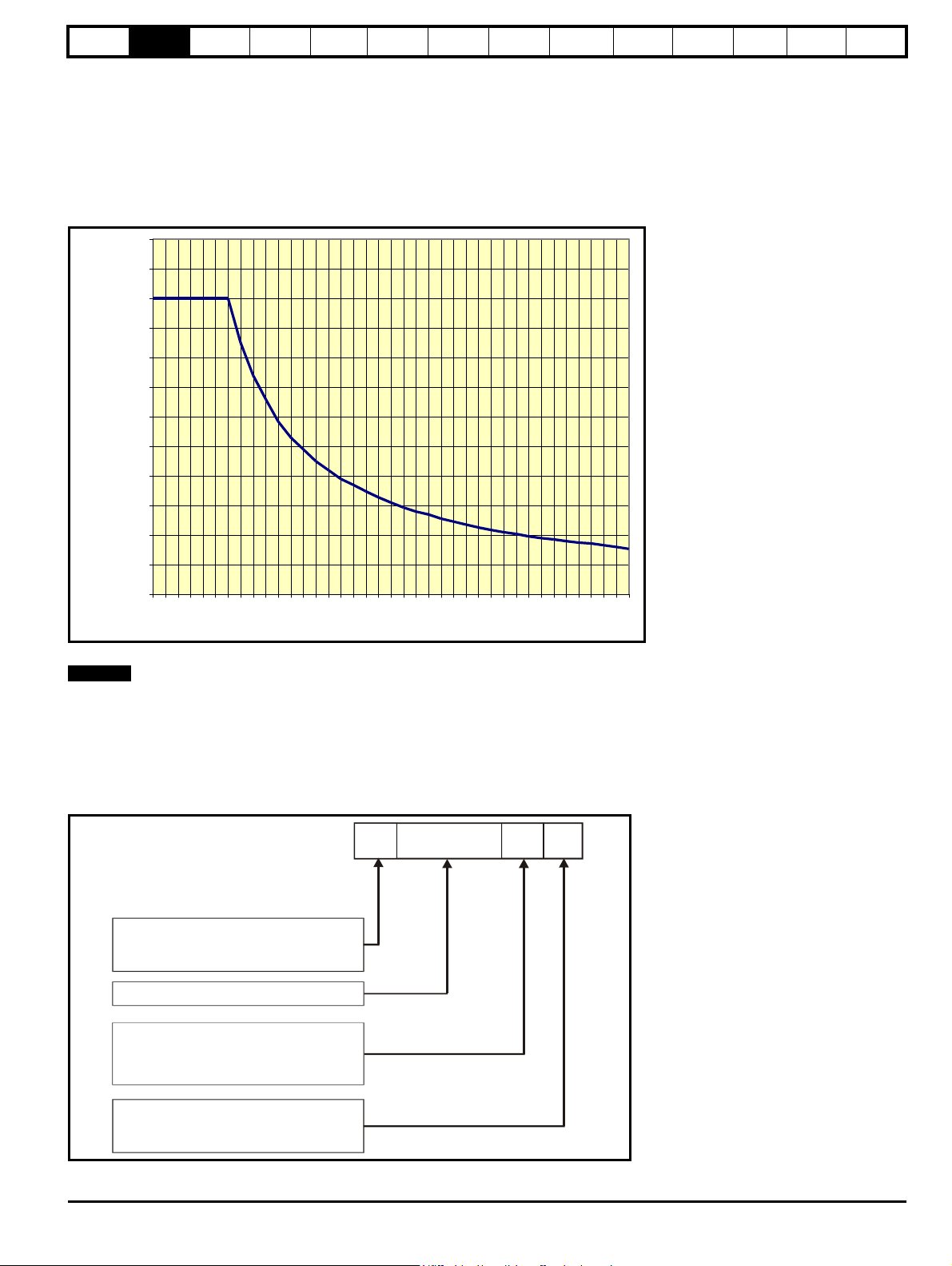

2.1.1 Typical short-term overload limits

The maximum percentage overload limit changes depending on the

selected motor.

Variations in motor rated current will result in changes in the maximum

possible overload as detailed in the Mentor MP Advanced User Guide.

Figure 2-1 can be used to determine the maximum overload duration

available for overloads between 100% and 150%. For example the

maximum overload available for a period of 60 seconds is 124%.

Figure 2-1 Maximum overload duration available

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

Overload of 150% for 30s is available up to a maximum of 10 repetitions

per hour.

2.2 Model number

The way in which the model numbers for the Mentor MP range are formed is described in Figure 2-2.

Figure 2-2 Model number

Mentor MP User Guide 7

Issue: 3 www.controltechniques.com

Safety

Model

Auxiliary input voltage/

frequency/current

Field output

voltage current

Line input voltage/

frequency/current

Armature output voltage/

current/overload

Rating

Customer and

date code

Approvals

Serial number

IP Rating

Key to approvals

UL approval Worldwide

CE approval Europe

C Tick approval Australia

RoHS compliant Europe

R

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

2.3 Compatible encoders

Table 2-5 Encoders compatible with Mentor MP

Encoder type

Quadrature incremental encoders with or without

marker pulse

Frequency and direction incremental encoders with

or without marker pulse

Forward / reverse incremental encoders with or

without marker pulse

2.4 Nameplate description

Figure 2-3 Typical drive rating label

Basic

parameters

Pr 3.38

(Fb07, 0.77)

setting

Running the

Ab (0)

Fd (1)

Fr (2)

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

2.4.1 Output current

The continuous output current ratings given on the rating label are for maximum 40°C (104°F) and 1000m altitude. Derating is required for higher

ambient temperatures >40°C (104°F) and higher altitude. For derating information, refer to section 12.1.12 Altitude on page 150.

2.4.2 Input current

The input current is affected by the supply voltage, frequency and load inductance. The input current given on the rating label is the typical input

current.

8 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

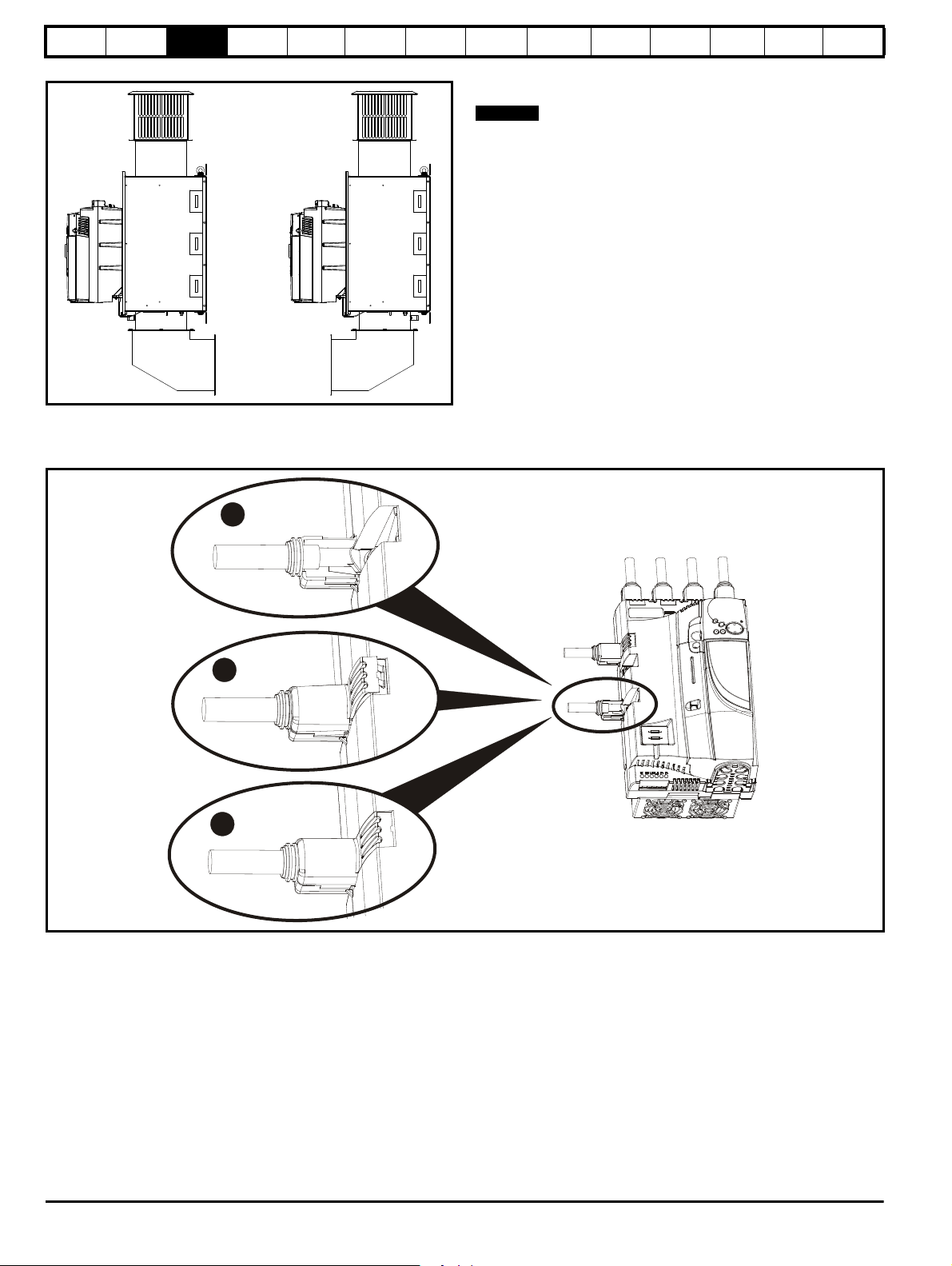

SM-Keypad /

MP-Keypad

Automation Fieldbus

Feedback

SMARTCARD*

Keypad

connection

Slot 1

Slot 2

Slot 3

Solutions Modules

Serial port connector

Control terminals

FXMP25 connection

Auxiliary connections

and field

Field fuses

DC

terminals

AC terminals

CT Comms cable

Identification

marker rail

Machine

feedback

terminals

FXMP25

M

STORED CHARGE

10 min

Mode /Reset

FXMP25 Field regulator

Automation

Fieldbus

Feedback

SMARTCARD*

SM-Keypad /

MP-Keypad

Keypad

connection

Slot 1

Slot 2

Slot 3

Solutions Modules

Serial port connector

Control terminals

FXMP25 connection

Auxiliary connections

and field

Field fuses

AC terminals

CT Comms cable

Identification

marker rail

Machine

feedback

terminals

DC

terminals

Paralleling port

FXMP25

M

STORED CHARGE

10 min

Mode /Reset

Internal

fans

FXMP25 Field regulator

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

2.5 Drive features and options

Figure 2-4 Drive features and options on size 1

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

Figure 2-5 Drive features and options for size 2

* A SMARTCARD is provided as standard. For further information, refer to Chapter 9 SMARTCARD operation on page 81.

Mentor MP User Guide 9

Issue: 3 www.controltechniques.com

Safety

Inputs Outputs

• Incremental encoders • Quadrature

• SinCos encoders • Frequency and direction

• SSI encoders • SSI simulated outputs

• EnDat encoders

• Digital inputs x 3

• Analog output (voltage) x 1

• Digital I/O x 3 • Relay x 2

• Analog inputs (voltage) x 2

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

2.5.1 Options available for Mentor MP

All Solutions Modules are color-coded in order to make identification easy. The following table shows the color-code key and gives further details on

their function.

Table 2-6 Solutions Module identification

Type Solutions Module Color Name Further Details

Universal Feedback interface

Feedback interface for the following devices:

Light Green

Brown SM-Encoder Plus

Feedback

Dark Brown

N/A

N/A

Yellow SM-I/O Plus

SM-Universal

Encoder Plus

SM-Encoder Output

Plus

15-way D-type

converter

Single ended

encoder interface

(15V or 24V)

Incremental encoder interface

Feedback interface for incremental encoders without

commutation signals.

No simulated encoder outputs available

Incremental encoder interface

Feedback interface for incremental encoders without

commutation signals.

Simulated encoder output for quadrature, frequency and

direction signals

Drive encoder input converter

Provides screw terminal interface for encoder wiring and spade

terminal for shield

Single ended encoder interface

Provides an interface for single ended ABZ encoder signals,

such as those from hall effect sensors. 15V and 24V versions

are available.

Extended I/O interface

Increases the I/O capability by adding the following to the

existing I/O in the drive:

Automation

(I/O

Expansion)

Yellow SM-I/O 32

Dark Yellow SM-I/O Lite

Dark Red SM-I/O Timer

Turquoise SM-I/O PELV

Olive SM-I/O 120V

Cobalt Blue

SM-I/O 24V

Protected

Extended I/O interface

Increase the I/O capability by adding the following to the

existing I/O in the drive:

• High speed digital I/O x 32

• +24V output

Additional I/O

1 x Analog input (± 10V bi-polar or current modes)

1 x Analog output (0 to 10V or current modes)

3 x Digital input and 1 x Relay

Additional I/O with real time clock

As per SM-I/O Lite but with the addition of a Real Time Clock

for scheduling drive running

Isolated I/O to NAMUR NE37 specifications

For chemical industry applications

1 x Analog input (current modes)

2 x Analog outputs (current modes)

4 x Digital input / outputs, 1 x Digital input, 2 x Relay outputs

Additional I/O conforming to IEC 61131-2 120Vac

6 digital inputs and 2 relay outputs rated for 120Vac operation

Additional I/O with overvoltage protection up to 48V

2 x Analog outputs (current modes)

4 x Digital input / outputs, 3 x Digital inputs, 2 x Relay outputs

10 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

FXMP25

M

STORED CHARGE

10 min

Mode /Reset

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Table 2-6 Solutions Module identification

Type Solutions Module Color Name Further Details

Applications Processor (with CTNet)

Moss Green

SM-Applications

Plus

nd

2

processor for running pre-defined and /or customer created

application software with CTNet support. Enhanced

performance over SM-Applications

Applications Processor

Automation

(Applications)

White

SM-Applications Lite

V2

nd

2

processor for running pre-defined and /or customer created

application software. Enhanced performance over SMApplications Lite

Applications Processor

Green brown SM-Register

nd

2

processor for running position capture functionality with

CTNet support.

Technical

data

Diagnostics

UL

information

Fieldbus

Table 2-7 Keypad identification

Keypad Name Further Details

SM-Keypad

Purple

SM-PROFIBUS DP-V1Profibus option

Medium Grey SM-DeviceNet

Dark Grey SM-INTERBUS

Light Grey SM-CANopen

Beige SM-Ethernet

Brown Red SM-EtherCAT

LED keypad option

Keypad with a LED display

PROFIBUS DP adapter for communications with the drive

DeviceNet option

Devicenet adapter for communications with the drive

Interbus option

Interbus adapter for communications with the drive

CANopen option

CANopen adapter for communications with the drive

Ethernet option

10 base-T / 100 base-T; Supports web pages, SMTP mail and

multiple protocols: DHCP IP addressing; Standard RJ45

connection

EtherCAT option

EtherCAT adapter for communications with the drive

MP-Keypad

LCD keypad option

Keypad with an alpha-numeric LCD display with Help function

Table 2-8 Serial comms lead

Serial comms lead Name Further Details

CT Comms cable

CT EIA (RS) -232 (4500-0087)

CT USB (4500-0096)

Table 2-9 External field control

External field controller Name Further Details

FXMP25

Mentor MP User Guide 11

For external control of field windings up to 25A, with field reversal capability. For further

information, please see the FXMP25 User Guide.

Issue: 3 www.controltechniques.com

Safety

CAUTION

Risk of Electric Shock

Power down unit 10minutes

before removing cover

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

2.6 Items supplied with the drive

The drive is supplied with a printed manual, a SMARTCARD, a safety

information booklet, the Certificate of Quality, an accessory kit box

including the items shown in Table 2-10, and a CD ROM containing all

related product documentation and software tools.

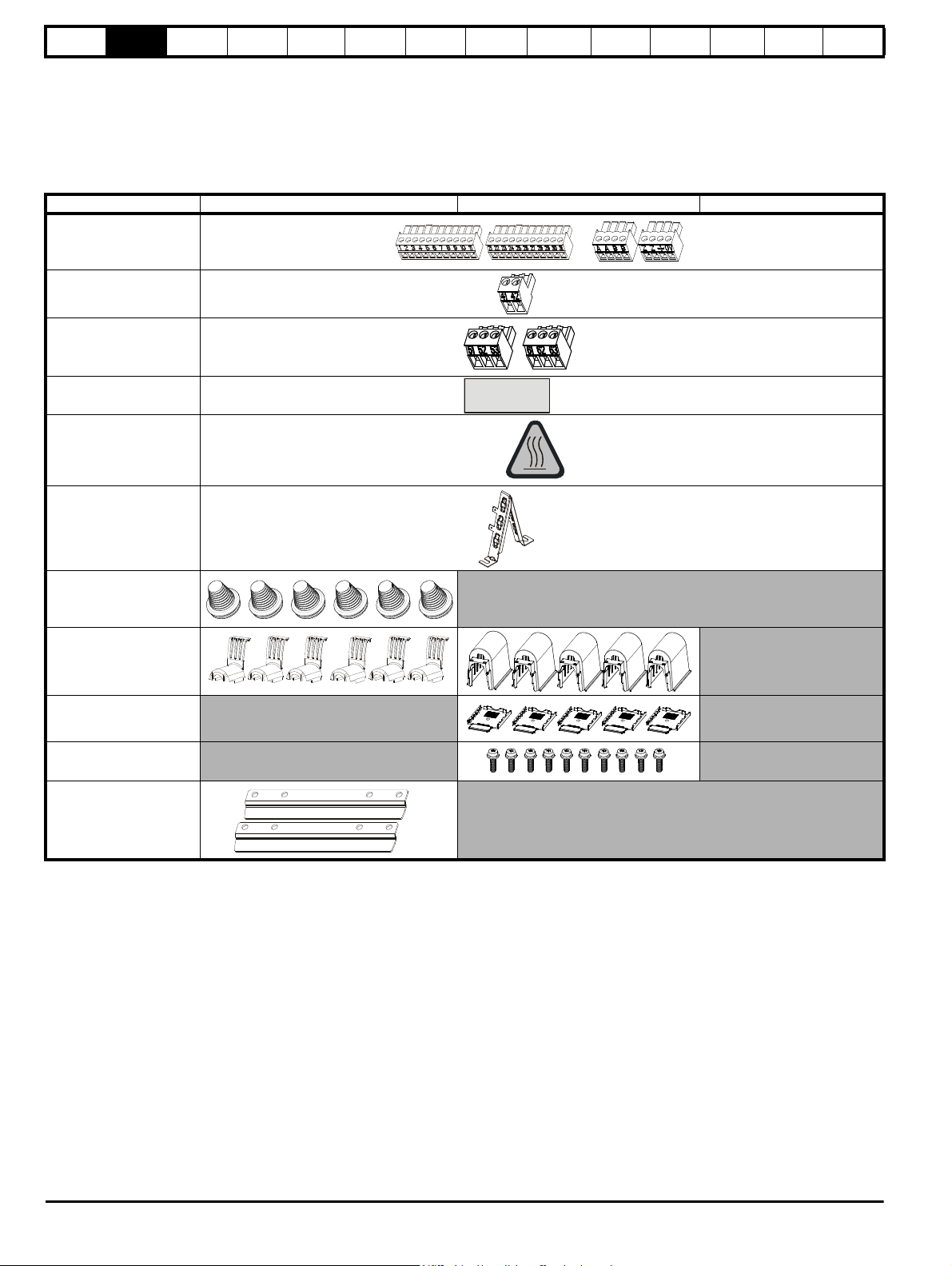

Table 2-10 Parts supplied with the drive

Description Size 1 Size 2A / 2B Size 2C / 2D

Control connectors

Tacho connector

Relay connectors

UL warning label

UL warning label for

heatsink temperature

Diagnostics

UL

information

Grounding bracket

Terminal cover grommets

Terminal shrouds

Terminal shroud base

covers

M4 Screws

Mounting feet bracket

12 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

3 Mechanical Installation

3.1 Safety

Follow the instructions

The mechanical and electrical installation instructions must

be adhered to. Any questions or doubt should be referred to

the supplier of the equipment. It is the responsibility of the

owner or user to ensure that the installation of the drive and

any external option unit, and the way in which they are

operated and maintained, comply with the requirements of

the Health and Safety at Work Act in the United Kingdom or

applicable legislation and regulations and codes of practice

in the country in which the equipment is used.

Competence of the installer

The drive must be installed by professional assemblers who

are familiar with the requirements for safety and EMC. The

assembler is responsible for ensuring that the end product or

system complies with all the relevant laws in the country

where it is to be used.

If the drive has been used at high load levels for a period of

time, the heatsink can reach temperatures in excess of 70°C

(158°F). Human contact with the heatsink should be

prevented.

Enclosure

The drive is intended to be mounted in an enclosure which

prevents access except by trained and authorized

personnel, and which prevents the ingress of contamination.

It is designed for use in an environment classified as

pollution degree 2 in accordance with IEC 60664-1. This

means that only dry, non-conducting contamination is

acceptable.

3.2.3 Cooling

The heat produced by the drive must be removed without its specified

operating temperature being exceeded. Note that a sealed enclosure

gives much reduced cooling compared with a ventilated one, and may

need to be larger and/or use internal air circulating fans.

For further information, refer to section 3.6.2 Enclosure sizing on

page 26.

3.2.4 Electrical safety

The installation must be safe under normal and fault conditions.

Electrical installation instructions are given in Chapter 4 Electrical

installation on page 32.

3.2.5 Electromagnetic compatibility

If it is necessary to meet strict emission limits, or if it is known that

electromagnetically sensitive equipment is located nearby, then full

precautions must be observed. The use of an external EMC filter may be

required at the drive inputs, which must be located very close to the

drives.

Space must be made available for the filters and allowance made for

carefully segregated wiring. Both levels of precautions are covered in

Table 12-42 Drive power stage terminals on size 2 drives on page 164.

3.2.6 Hazardous areas

The drive must not be located in a classified hazardous area unless it is

installed in an approved enclosure and the installation is certified.

The drive enclosure is not classified as a fire enclosure. A

separate fire enclosure must be provided.

Many of the drives in this product range weigh in excess of

15kg (33lb). Use appropriate safeguards when lifting these

models.

See section 3.4 Mounting method on page 17.

3.2 Planning the installation

The following considerations must be made when planning the

installation:

3.2.1 Access

Access must be restricted to personnel only. Safety regulations which

apply at the place of use must be complied with.

3.2.2 Environmental protection

The drive must be protected from:

• moisture, including dripping water or spraying water and

condensation. An anti-condensation heater may be required, which

must be switched off when the drive is running

• contamination with electrically conductive material

• contamination with any form of dust which may restrict the fan, or

impair airflow over various components

• temperature beyond the specified operating and storage ranges

• corrosive gasses

Mentor MP User Guide 13

Issue: 3 www.controltechniques.com

Safety

WARNING

WARNING

Pozi Pz2

1

2

All sizes

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

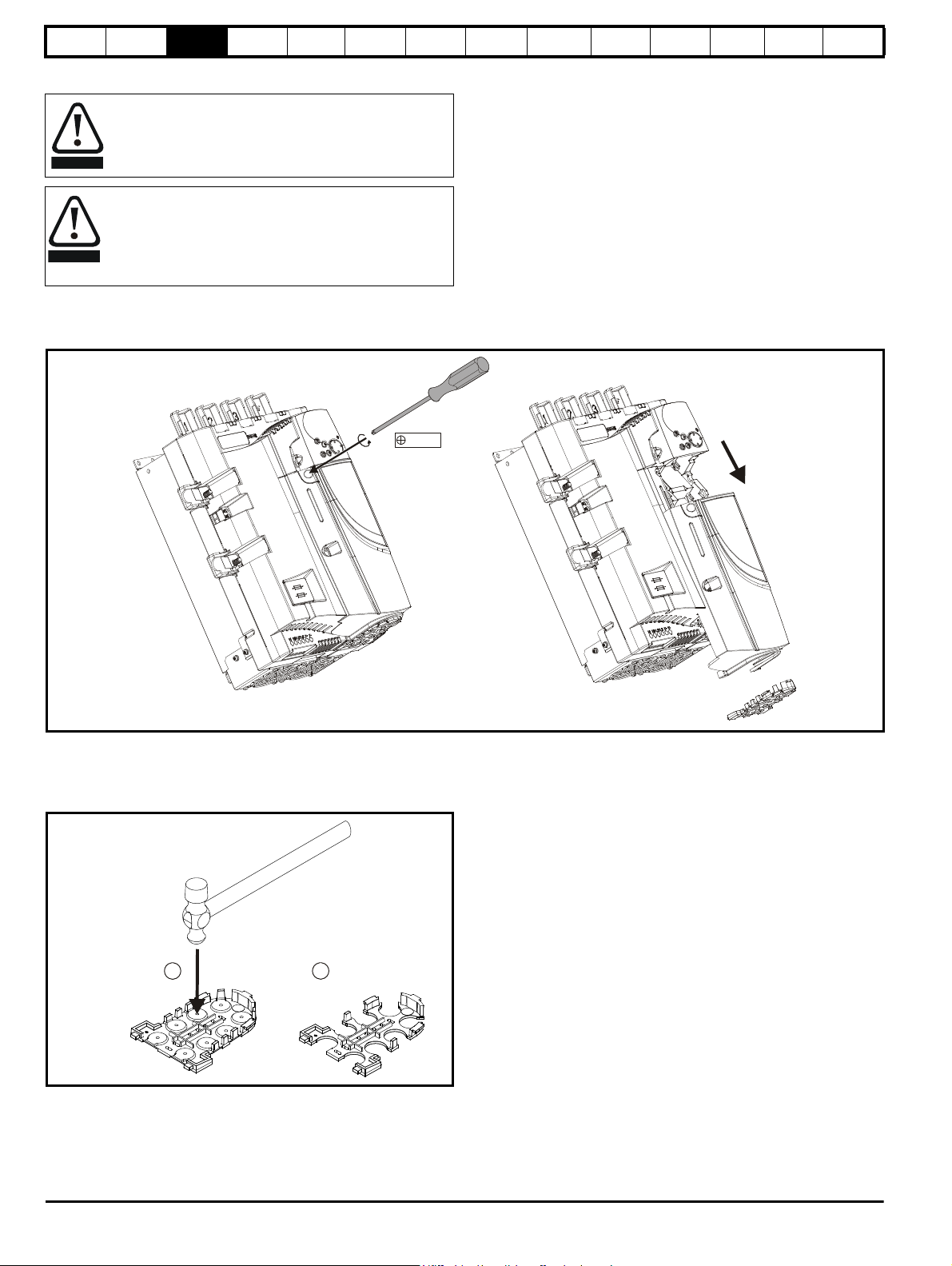

3.3 Terminal cover removal

Isolation device

The AC supply must be disconnected from the drive using an

approved isolation device before any cover is removed from

the drive or before any servicing work is performed.

Stored charge

The drive contains capacitors that remain charged to a

potentially lethal voltage after the AC supply has been

disconnected. If the drive has been energized, the AC

supply must be isolated at least ten minutes before work

may continue.

3.3.1 Removing the terminal covers

The drive is installed with one control terminal cover.

Figure 3-1 Removing the control terminal cover (size 1 shown)

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

To remove the terminal cover, undo the screw and slide the terminal cover downwards.

When replacing the terminal covers the screw should be tightened with a maximum torque of 1 Nm (0.7 Ib ft).

3.3.2 Removing the finger-guard and break-outs

Figure 3-2 Removing the finger-guard break-outs

Place finger-guard on a flat solid surface and hit relevant break-outs with

hammer as shown (1). Continue until all required break-outs are removed

(2). Remove any flash / sharp edges once the break-outs are removed.

14 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

CAUTION

A

B

Solutions Module

in slot 1

Solutions Module

in slot 2

Solutions Module

in slot 3

A

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

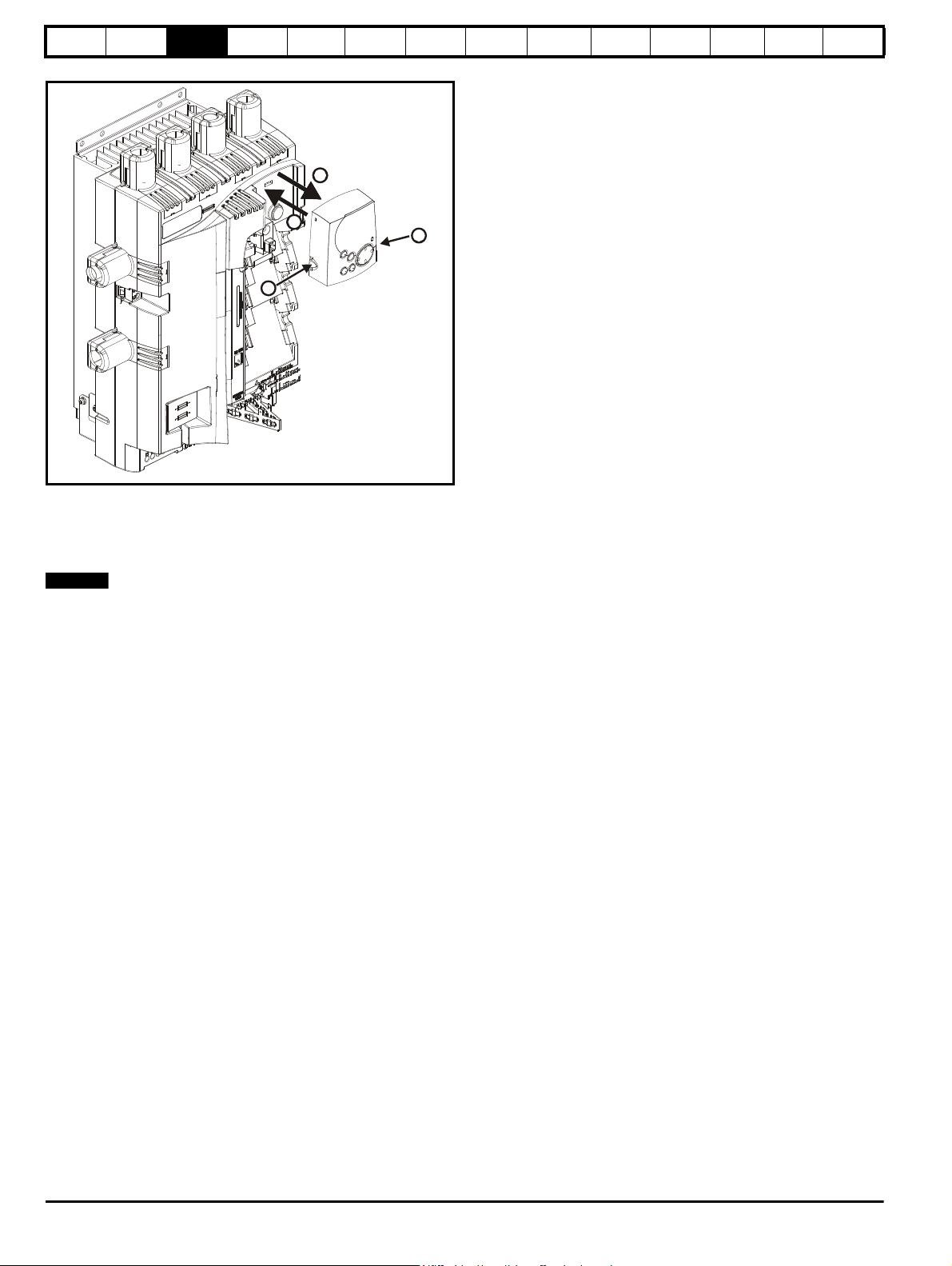

3.3.3 Installation and removal of a Solutions Module

Please power down the drive before removing / installing the

Solutions Module. Failure to do so may cause damage to

product

Figure 3-3 Installation and removal of the Solutions Module

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

1. To install the Solutions Module, press down in the direction shown

above until it clicks into place.

2. To remove the Solutions Module, press inwards at the points shown

(A) and pull in the direction shown (B).

3. The drive has the facility for all three Solutions Module slots to be

used at the same time, as illustrated.

It is recommended that the Solutions Module slots are used in the

following order: slot 3, slot 2 and slot 1.

Mentor MP User Guide 15

Issue: 3 www.controltechniques.com

Safety

B

B

C

A

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Figure 3-4 Removal and installation of a keypad

To fit, align the MP-Keypad and press gently in the direction shown until

it clicks into position (A).

To remove, while pressing the tabs inwards (B), gently lift the MPKeypad in the direction indicated (C).

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

The keypad can be installed / removed while the drive is powered up and

running a motor, providing that the drive is not operating in keypad

mode.

16 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

WARNING

WARNING

293mm (11.54in)

250mm (9.84in)

444mm

(17.48in)

222mm

(8.74in)

95mm

(3.74in)

222mm (8.74in)

170mm (6.69in)

6.5mm (0.26in)

250mm (9.84in)

40mm

(1.58in)

22mm

(0.87in)

380mm

(14.96in)

4 holes to

suit M6

1

1

1

1

MA1

MA2

NOTE

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

3.4 Mounting method

The Mentor MP can only be surface mounted.

If the drive has been used at high load levels for a period of

time, the heatsink can reach temperatures in excess of 70°C

(158°F). Human contact with the heatsink should be

prevented.

Many of the drives in this product range weigh in excess of

15kg (33lb). Use appropriate safeguards when lifting these

models.

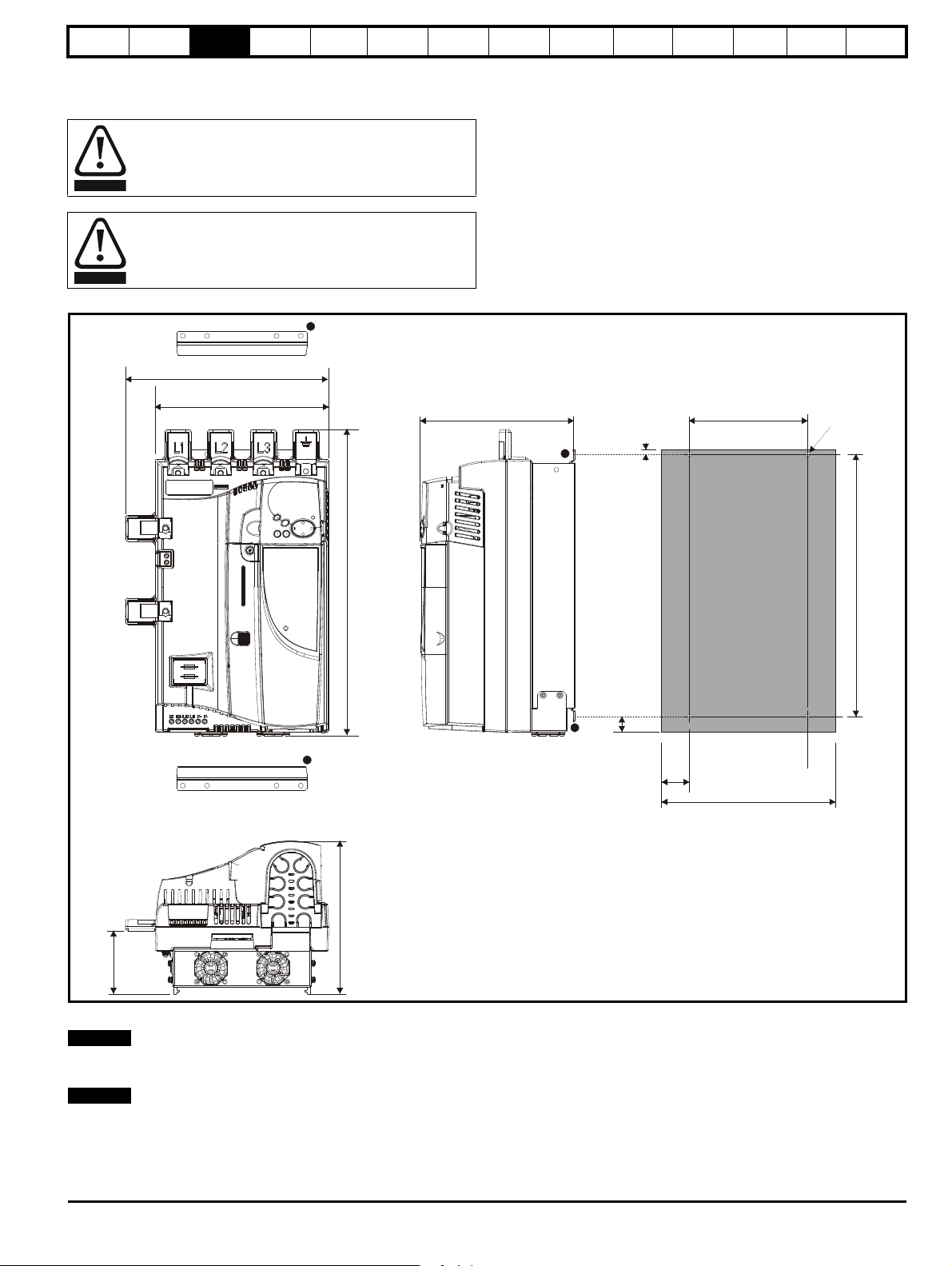

Figure 3-5 Overall size 1A dimensions

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

1. The two outer holes must be used for mounting the Mentor MP.

With the SMARTCARD installed to the drive, the depth measurement

increases by 7.6mm (0.30 in).

Fans are only installed to the MP75A4(R) and MP75A5(R).

Mentor MP User Guide 17

Issue: 3 www.controltechniques.com

Safety

293mm (11.54in)

250mm (9.84in)

444mm

(17.48in)

251mm

(9.88in)

124mm

(4.88in)

170mm (6.69in)

6.5mm (0.26in)

250mm (9.84in)

40mm

(1.58in)

22mm

(0.87in)

380mm

(14.96in)

4 holes to

suit M6

1

1

1

1

1

MA1

MA2

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

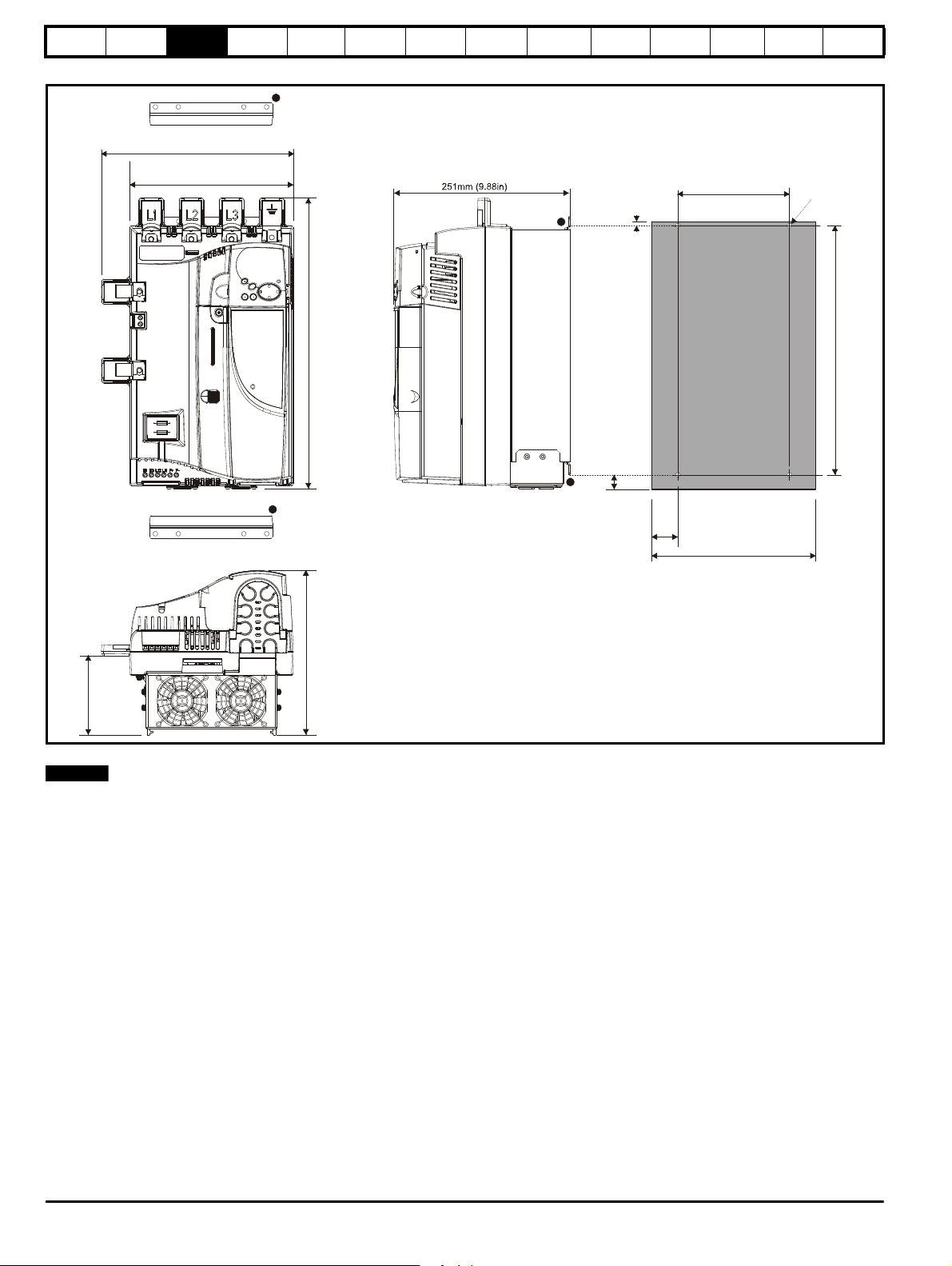

Figure 3-6 Overall size 1B dimensions

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

1. The two outer holes must be used for mounting the Mentor MP.

With the SMARTCARD installed to the drive, the depth measurement increases by 7.6mm (0.30 in).

18 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

1

1

2

MA1

MA2

453mm (17.84in)

495mm (19.49in)

640mm

(25.20in)

85mm

(3.35in)

301mm (11.85in)

472mm (18.58)

68mm

(2.68in)

126mm

(4.96in)

11.5mm (0.45in)

495mm (19.49in)

80mm

(3.15in)

80mm

(3.15in)

65mm

(2.56in)

8 holes to

suit M8

302mm

(11.89in)

93mm

(3.66in)

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

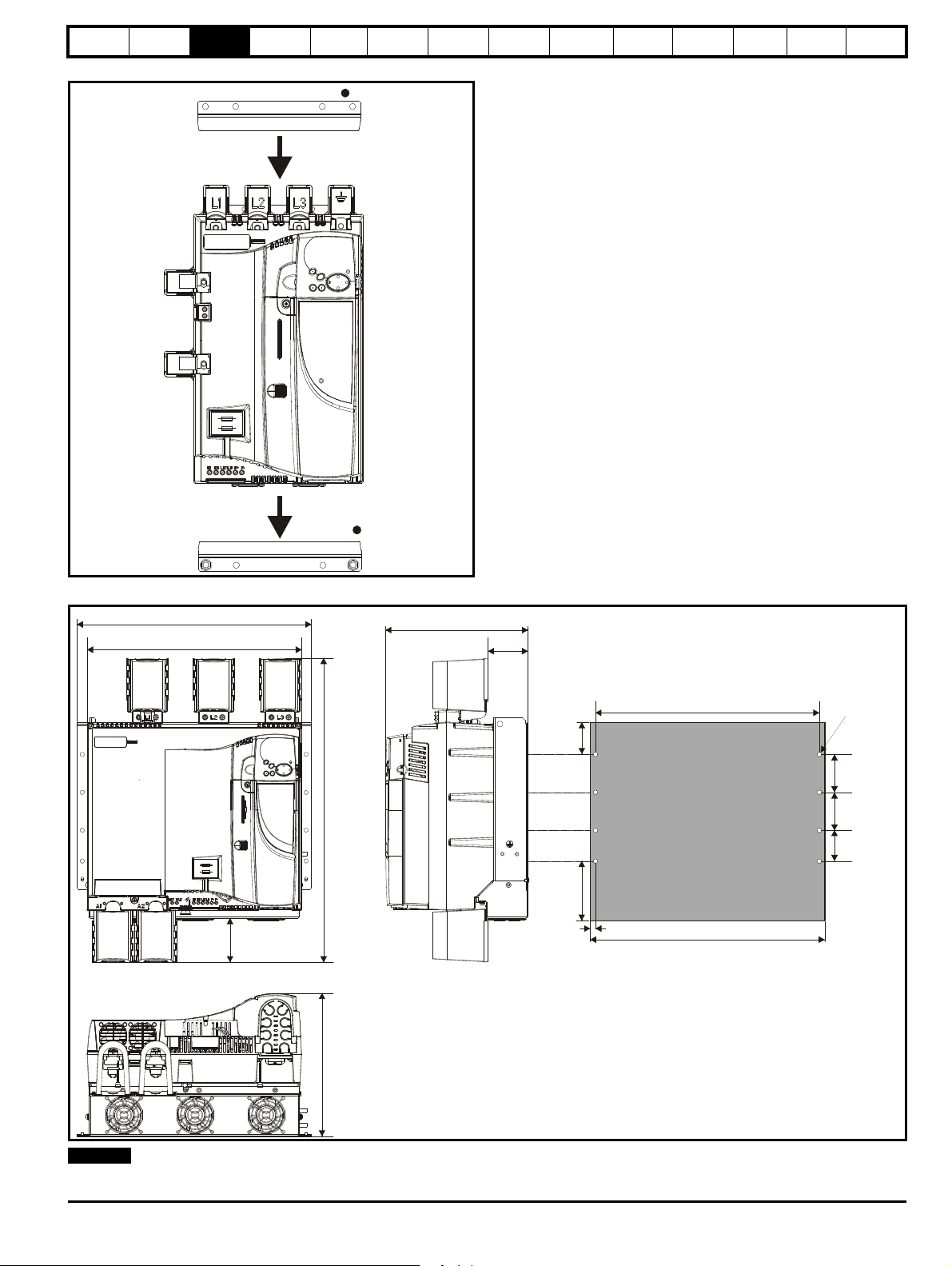

Figure 3-7 Installing the mounting feet bracket on size 1 drives

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

The bottom mounting bracket (1) should be installed to the back plate first

with the screws fully tightened. The drive should then be lowered onto the

bracket and slotted in. The top mounting bracket (2) should then be slotted

into the drive and the top holes marked for mounting (380mm [14.96 in]

from the centre of the holes on the bottom mounting bracket). Once the

holes have been drilled, fix the top mounting bracket accordingly and

tighten the screws.

It is not necessary to tighten the bottom mounting brackets with the drive in

place. The brackets are designed to clamp the drive heatsink against the

back plate.

UL

information

Figure 3-8 Overall size 2A / 2B dimensions

With the SMARTCARD installed to the drive, the depth measurement increases by 7.6mm (0.30 in).

Mentor MP User Guide 19

Issue: 3 www.controltechniques.com

Safety

6mm (0.24in)

175mm (6.9in)

5mm

(0.2in)

175mm (6.9in)

405mm (15.94)

248mm (9.76in)

202mm (7.95in)

321mm (12.64in)

605mm (23.82in)

124mm

(4.89in)

175mm (6.9in)

555mm (21.85in)

452mm (17.8in)

2

0

2

mm (7.95in)

390mm (15.35in)

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

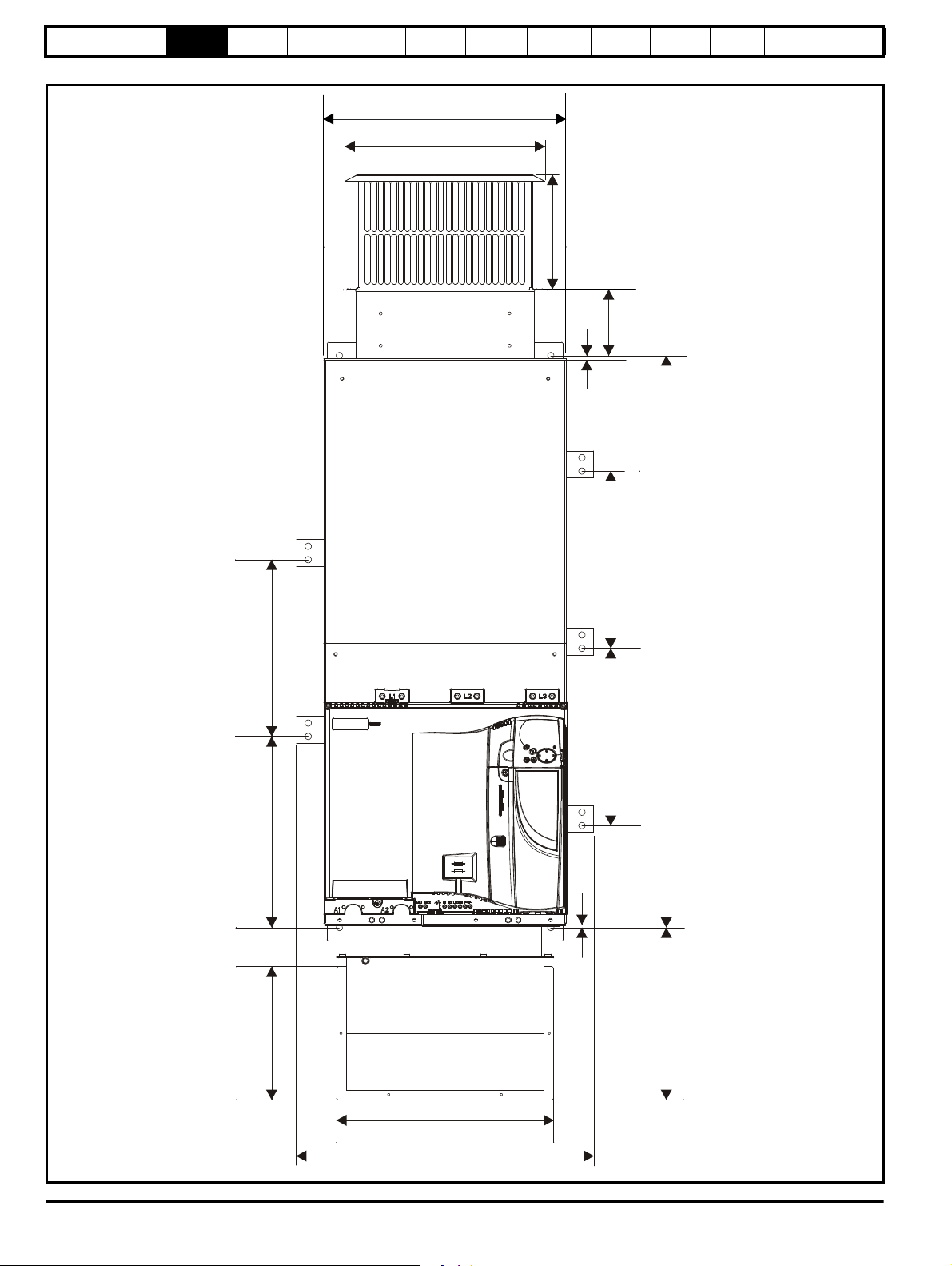

Figure 3-9 Size 2C front view and mounting dimensions

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

20 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

394mm (15.51in)

605mm

(23.82in)

53mm

(2.09in)

288mm

(11.34in)

450mm (17.72in)

1050mm (41.34in)

306mm (12.05in)

611mm (24.05in)

35mm

(1.38in)

38mm (1.5in)

59mm

(2.32in)

270mm

(10.63in)

4 holes

to suit M10

260mm

(10.24in)

180mm (7.09in)

180mm (7.09in)

90mm

(3.54in)

90mm

(3.54in)

68.5mm

(2.70in)

50mm

(1.97in)

190mm

(7.48in)

240mm

(9.45in)

333mm (13.11in)

83.5

(3.29in)

210mm

(8.27in)

Rear

Front

8 holes

∅

7mm

1

NOTE

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

parameters

Figure 3-10 Size 2C back-plate and mounting detail

Basic

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

1. M10 eye-bolts can be inserted in the location shown for lifting the drive. These are not supplied with the drive.

With the SMARTCARD installed in the drive, the depth measurement increases by 7.6mm (0.30 in).

Mentor MP User Guide 21

Issue: 3 www.controltechniques.com

Safety

124m

m

(4.88

in)

6mm

(0.24in)

1065mm (41.93in)

356mm (14.02in)

248mm (9.76in)

405mm (15.94in)

4mm

(0.16in)

321mm (12.64in)

330mm (13.0in)

555mm (21.85in)

330mm (13.0in)

330mm (13.0in)

452mm (17.8in)

202mm (7.95in)

390mm (15.35in)

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Figure 3-11 Size 2D front view and mounting dimensions

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

22 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

53mm

(2.09in)

1065mm (41.93in)

288mm (11.34in)

450mm (17.72in)

394mm (15.51in)

1510mm (59.45in)

611mm (24.06in)

306mm (12.05in)

4 holes

to suit M10

35mm

(1.38in)

260mm

(10.24in)

180mm (7.09in)

180mm (7.09in)

90mm

(3.54in)

90mm

(3.54in)

68.5mm

(2.70in)

50mm

(1.97in)

190mm

(7.48in)

240mm

(9.45in)

333mm (13.11in)

8 holes

∅

7mm

83.5mm

(3.29in)

210mm

(8.27in)

1

NOTE

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

parameters

Figure 3-12 Size 2D back-plate and mounting detail

Basic

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

1. M10 eye-bolts can be inserted in the location shown for lifting the drive. These are not supplied with the drive.

With the SMARTCARD installed to the drive, the depth measurement increases by 7.6mm (0.30 in).

Mentor MP User Guide 23

Issue: 3 www.controltechniques.com

Safety

NOTE

1

2

3

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

Figure 3-13 Mounting methods of size 2C / 2D air duct The Mentor MP size 2C and 2D air duct can be turned 180° to suit the

customers infrastructure.

There is no seal provided with this product for sealing off the gap around

the air duct when mounted.

3.5 Installing and removing the terminal shrouds

Figure 3-14 Installing the terminal shrouds on size 1 drives

1. Thread the AC supply and DC output connectors through the grommets provided and connect them to the drive.

2. Place the terminal shroud over the top of the connectors and click into place (3).

24 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

1

2

L1 L2

L3

A1 A2

1

2

3

NOTE

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Figure 3-15 Removing the terminal shrouds on size 1 drives

1. Insert the screwdriver as shown.

2. Lever in the direction shown to unclip the terminal shroud and remove.

Figure 3-16 Installing the terminal shrouds on size 2 drives

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

1. Assemble the cable to the busbar.

2. Place the terminal shroud base cover underneath the cable in the orientation shown.

3. Place the terminal shroud over the cable in the orientation shown, slide the terminal shroud on to the base cover in the direction shown until it

clicks in to place.

4. For all power connections slide in the terminal shroud sub-assembly in the direction as shown.

5. Insert the 2 x M4 x 16 screws using a pozi drive screwdriver.

To remove the terminal shrouds, please reverse the process above.

Mentor MP User Guide 25

Issue: 3 www.controltechniques.com

Safety

Enclosure

AC supply contactor,

line chokes and fuses

External

controller

Ensure minimum clearances

are maintained for the drive.

Forced or convection air-flow

must not be restricted by any

object or cabling

Auxillary

supply

Signal cables

Plan for all signal cables

to be routed at least

300mm (12in) from the

drive and any power cable

Armature

connection

cable

Field

connection cable

≥

100mm(4in)

≥

100mm

(4in)

A

A

MA1

MA2

Note

For EMC compliance:

1) Power cabling must be at

least 100mm (4in) from the

drive in all directions

2) Ensure direct metal contact

at drive and filter mounting

points (any paint must be

removed)

100mm for Size 1 drives

200mm for Size 2A/2B drives

A

Note

For Size 2C/2D drives

leave a clearance of 100mm

around the drive.

A

e

P

kT

intText

–()

----------------------------------------

=

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

3.6 Enclosure

3.6.1 Enclosure layout

Please observe the clearances in the diagram below taking into account any appropriate notes for other devices / auxiliary equipment when planning

the installation.

Figure 3-17 Enclosure layout

3.6.2 Enclosure sizing

Refer to section 12.1.2 Typical short-term overload limits on page 145

for drive losses.

Add the dissipation figures for each drive that is to be installed in the

enclosure.

Add the power dissipation figures for each EMC filter that is to be

installed in the enclosure.

Calculate the total heat dissipation (in Watts) of any other equipment to

be installed in the enclosure.

Add the figures of all of the above to get a total heat dissipation figure (in

Watts) for the equipment in the enclosure.

Calculating the size of a sealed enclosure

The enclosure transfers internally generated heat into the surrounding

air by natural convection. The larger the surface area of the enclosure

walls, the better is the dissipation capability. Only the surfaces of the

enclosure that are not in contact with a wall or floor can dissipate heat.

Calculate the minimum required unobstructed surface area A

enclosure from:

for the

e

Where:

Unobstructed surface area in m2 (1 m2 = 10.9 ft2)

A

e

T

ext

Maximum expected temperature in oC outside the

enclosure

int

P Power in Watts dissipated by all heat sources in the

k Heat transmission coefficient of the enclosure material

Example

To calculate the size of an enclosure for the following:

enclosure

enclosure

2/o

in W/m

C

Maximum permissible temperature in oC inside the

T

• Two MP25A4 models operating under full load conditions

• Maximum ambient temperature inside the enclosure: 40°C

• Maximum ambient temperature outside the enclosure: 30°C

Dissipation of each drive: 125W

Dissipation from other heat generating equipment in the enclosure. 11W

(max).

Total dissipation: 2 x (125 + 11) = 272W

26 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

W

H

D

A

e

272W

5.5 40 30–()

---------------------------------

=

W

A

e

2HD–

HD+

--------------------------

=

W

4.945 2 2× 0.6×()–

20.6+

-----------------------------------------------------

=

V

3kP

T

intText

–

---------------------------

=

P

o

P

l

-------

V

31.3× 549×

40 30–

----------------------------------

=

WARNING

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

The enclosure is to be made from painted 2mm (0.079in) sheet steel

having a heat transmission coefficient of 5.5 W/m

2/o

C. Only the top,

front, and two sides of the enclosure are free to dissipate heat.

The value of 5.5 W/m

2

/ºC can generally be used with a sheet steel

enclosure (exact values can be obtained by the supplier of the material).

If in any doubt, allow for a greater margin in the temperature rise.

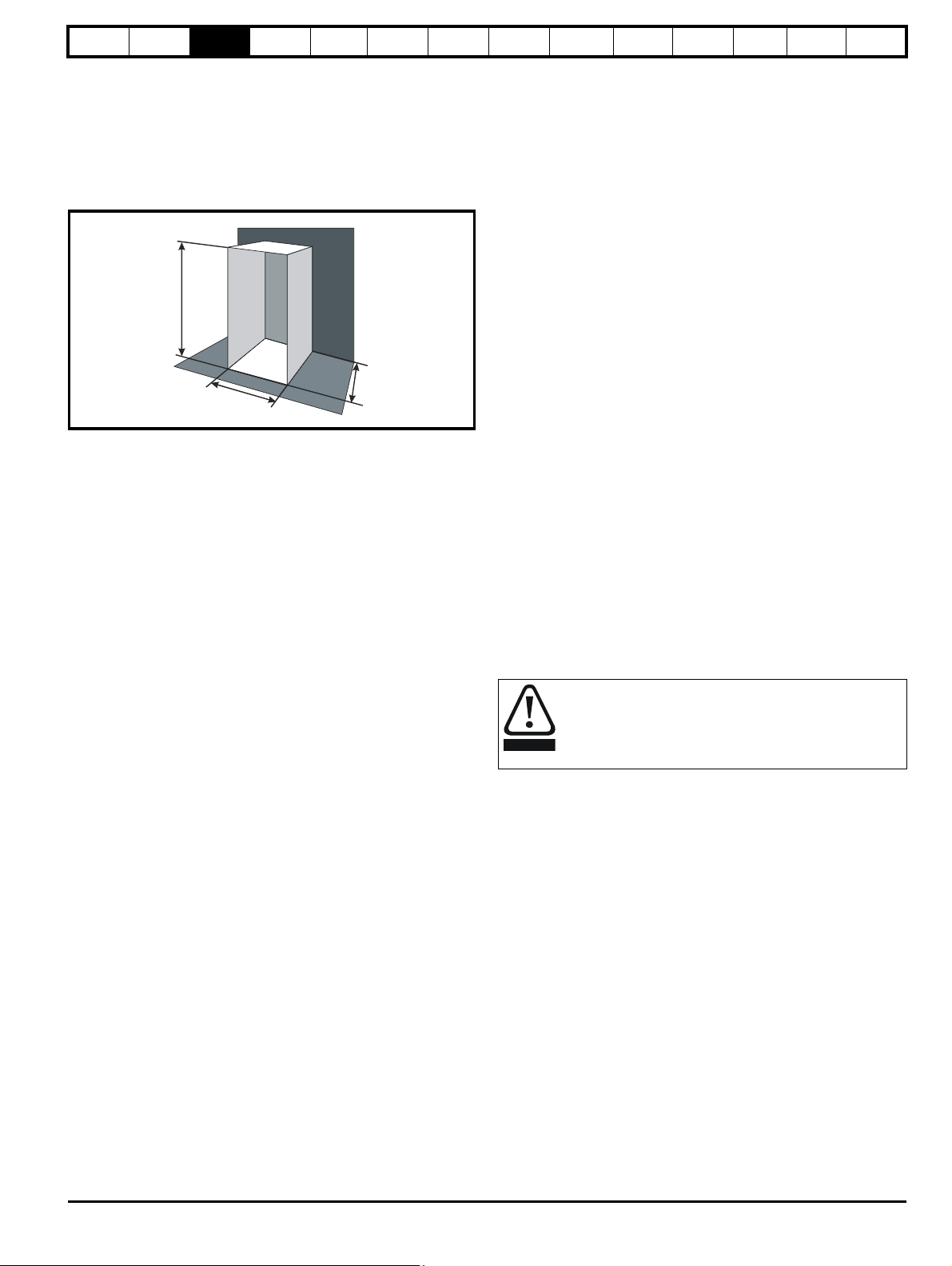

Figure 3-18 Enclosure having front, sides and top panels free to

dissipate heat

Insert the following values:

T

40°C

int

30°C

T

ext

k 5.5

P 272W

The minimum required heat conducting area is then:

2

= 4.945 m

(53.90 ft2) (1 m2 = 10.9 ft2)

Estimate two of the enclosure dimensions - the height (H) and depth (D),

for instance. Calculate the width (W) from:

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

information

Where:

P

is the air pressure at sea level

0

is the air pressure at the installation

P

I

Typically use a factor of 1.2 to 1.3, to allow also for pressure-drops in

dirty air-filters.

Example

To calculate the size of an enclosure for the following:

• Three MP45A4 models operating under full load conditions

• Maximum ambient temperature inside the enclosure: 40°C

• Maximum ambient temperature outside the enclosure: 30°C

Dissipation of each drive: 168W

Dissipation from other heat generating equipment. 15 W

Total dissipation: 3 x (168 + 15) = 549W

Insert the following values:

40°C

T

int

T

30°C

ext

k 1.3

P 549W

Then:

= 214.1 m

3

/hr (126.3 ft3 /min) (1 m3/ hr = 0.59 ft3/min)

3.7 Heatsink fan operation

Mentor MP drive rated 75A and above are ventilated by internally

supplied fans.

Ensure the minimum clearances around the drive are maintained to

allow the air to flow freely.

The drive controls the fan operation based on the temperature of the

heatsink and the drives thermal model system.

UL

Inserting H = 2m and D = 0.6m, obtain the minimum width:

=0.979 m (38.5 in)

If the enclosure is too large for the space available, it can be made

smaller only by attending to one or all of the following:

• Reducing the ambient temperature outside the enclosure, and/or

applying forced-air cooling to the outside of the enclosure

• Reducing the number of drives in the enclosure

• Removing other heat-generating equipment

Calculating the air-flow in a ventilated enclosure

The dimensions of the enclosure are required only for accommodating

the equipment. The equipment is cooled by the forced air flow.

Calculate the minimum required volume of ventilating air from:

Where:

V Air-flow in m

T

Maximum expected temperature in °C outside the

ext

enclosure

T

Maximum permissible temperature in °C inside the

int

enclosure

P Power in Watts dissipated by all heat sources in the

enclosure

3

per hour (1 m3/hr = 0.59 ft3/min)

3.8 IP rating (Ingress Protection)

IP rating

It is the installer’s responsibility to ensure that any enclosure

which allows access to drives from frame sizes 2A to 2D

while the product is energized, provides protection against

contact and ingress to the requirements of IP20.

An explanation of IP rating is provided in section 12.1.13 IP rating on

page 150.

Mentor MP User Guide 27

Issue: 3 www.controltechniques.com

k Ratio of

Safety

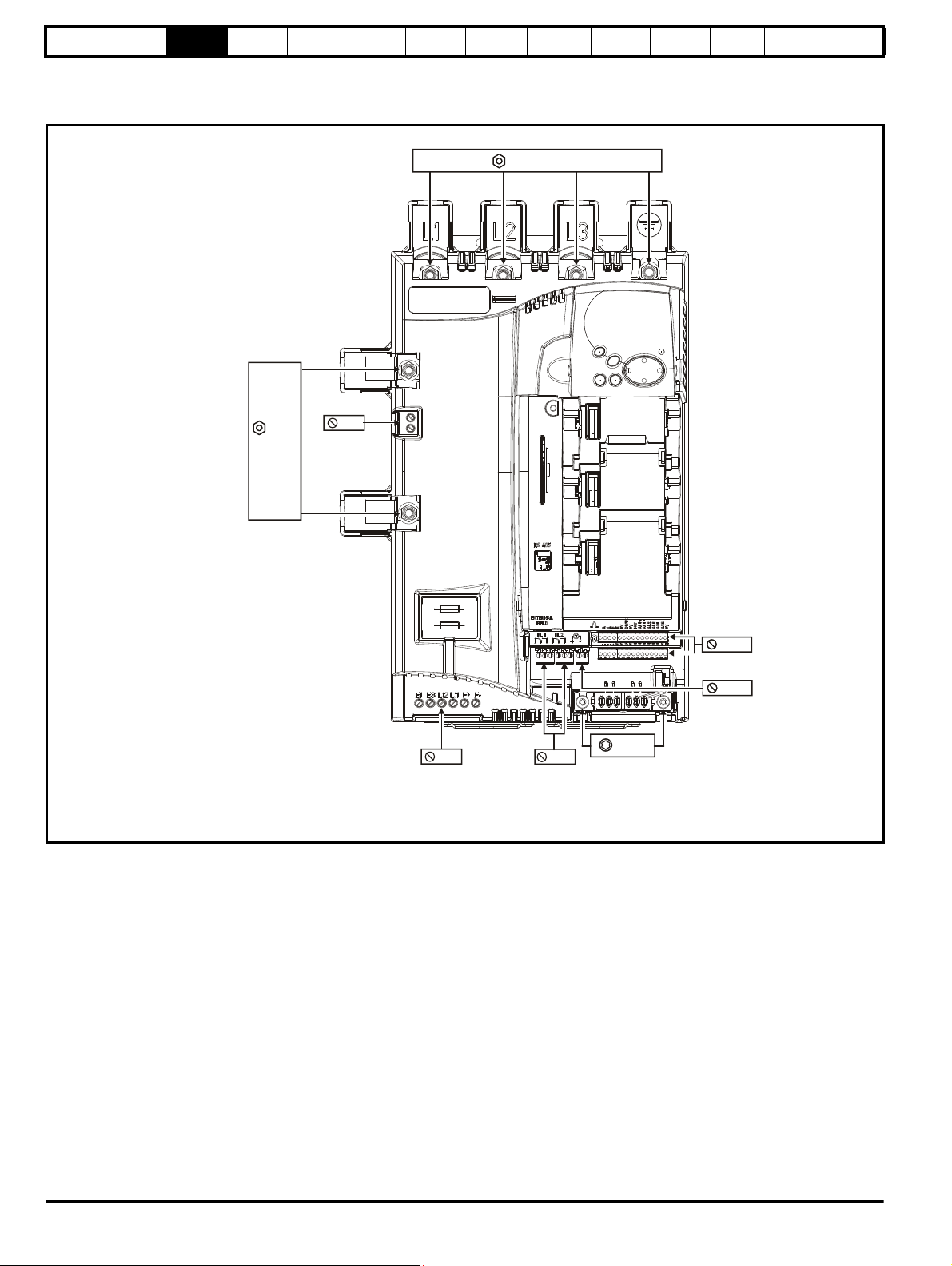

M8 nut / 13 mm AF

AC input

M8 nut

13mm AF

DC output

T25 Torx

Ground

connections

Tac h o

connections

3.5 mm

Relay

connections

3.5mm

5mm

Auxiliary

connections

Control and

encoder

connections

2.5 mm

5mm

Machine

feedback

terminals

MA1

MA2

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

3.9 Electrical terminals

3.9.1 Location of the power and ground terminals

Figure 3-19 Location of the power and ground terminals on size 1 drives

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

28 Mentor MP User Guide

www.controltechniques.com Issue: 3

Safety

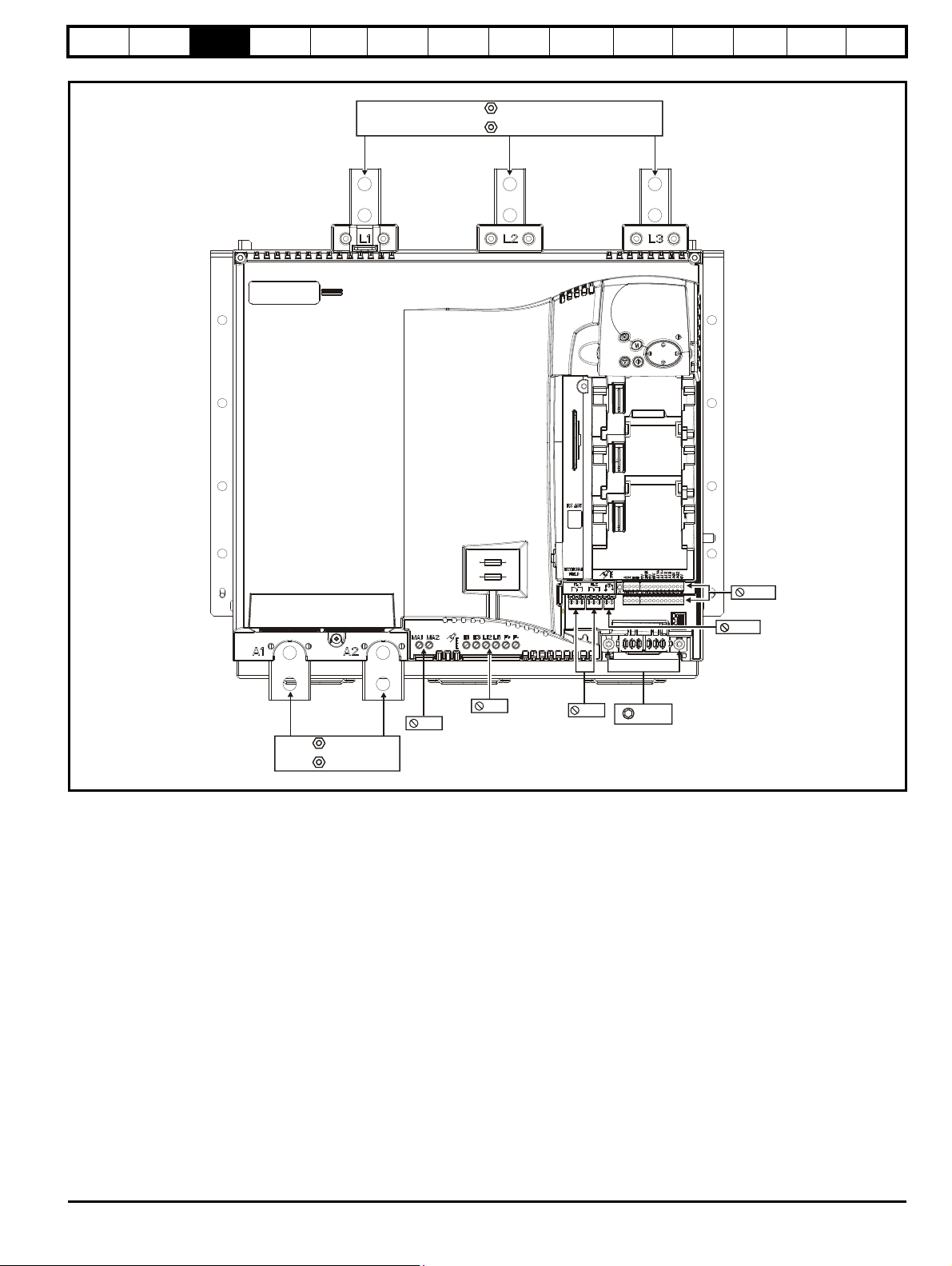

5mm

Machine

feedback

terminals

Tac h o

connections

5mm

Auxiliary

connections

Control and

encoder

connections

2.5 mm

Relay

connections

3.5mm

3.5 mm

T25 Torx

Ground

connections

M12 nut 19

mm AF

DC output

Size 2A:

Size 2B:

M10 nut 17

mm AF

AC input

M12 nut 19mm AF

Size 2A:

Size 2B:

M10 nut 17mm AF

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

Figure 3-20 Location of the power and ground terminals on size 2A and 2B drives

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

Mentor MP User Guide 29

Issue: 3 www.controltechniques.com

Safety

Control and

encoder

connections

2.5mm

Size 2C / 2D:

M12 nut 19mm AF

5mm

Machine

feedback

terminals

5mm

Auxiliary

connections

Relay

connections

3.5mm

T25 Torx

Ground

connections

Ta ch o

connections

3.5mm

Size 2C / 2D:

M12 nut 19mm AF

AC Input

DC Output

WARNING

Information

Product

information

Mechanical

Installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization

SMARTCARD

Figure 3-21 Location of the power and ground terminals on size 2C and 2D drives

operation

Onboard

PLC

Advanced

parameters

Technical

data

Diagnostics

UL

information

3.9.2 Terminal sizes and torque settings

To avoid a fire hazard and maintain validity of the UL listing,

adhere to the specified tightening torques for the power and

ground terminals. Refer to the following tables.

Table 3-4 Drive power stage terminals on size 2 drives

Model Connection type Torque setting

Size 2A M10 stud 15 Nm (11.06 lb ft)

Size 2B

M12 stud 30 Nm (22.12 Ib ft)Size 2C

3.9.3 Torque settings

Size 2D

Table 3-1 Drive control, status relay and encoder terminal data

Model Connection type Torque setting

All Plug-in terminal block 0.5 Nm 0.4 lb ft

Table 3-2 Drive auxiliary and machine armature terminal data

Model Connection type Torque setting

All Terminal block 0.5 Nm 0.4 lb ft

Table 3-3 Drive power stage terminals on size 1 drives

Model Connection type Torque setting

All M8 stud 10 Nm 7.4 lb ft

30 Mentor MP User Guide

www.controltechniques.com Issue: 3

Loading...

Loading...