Emerson 79U-002, 79E, 79U-003, 79U-006, 79U-036 Operating And Maintenance Instructions Manual

...

KEYSTONE FIGURE 79 PNEUMATIC ACTUATOR

OPERATING AND MAINTENANCE INSTRUCTIONS

Operating and Maintenance Instructions for: Figure 79 Pneumatic Actuators (U/E options)

4. If pipelines are hydraulically tested, then

the lines should be “blown down” with high

pressure air to clear all water, prior to

connecting lines to the actuator.

5. Where pipe fitting sealants are used, they

should be applied to the male threads only.

When applied to female threads, excess

compound can be transmitted into the

actuator control lines.

Double Acting Actuator

6. Where a system is dependent on Air Filter

Equipment, the air filters should be situated

in positions that allow easy access to

maintain and/or drain.

7. Where pneumatic valve positioners, or

pneumatic controllers are fitted to valve

actuator assemblies, oil mist lubricated air

should not be used unless the manufacturer

states specifically that the controllers are

compatible with lubricated air.

Single Acting Actuator

Introduction

The Keystone Figure 79 Pneumatic Actuator

range is available in three mounting options, as

follows: 79U - Keystone Mounting Standard

79E - ISO5211

General Pneumatic Systems Recommendations

All Keystone Pneumatic Actuators are factory

lubricated with Molyrace LT grease and, unless

the operating environment is extremely poor,

do not require re-lubrication. To maintain

maximum efficiency with this, or other

pneumatic actuators or pressure vessels,

we advise that the following basic system

recommendations are followed:

1. Where air pipelines are subjected to

extremes of temperature, the system should

be fitted with air drying equipment.

2. Air control lines should be run to a

‘Recommended Piping Practice’ and should

not have “exaggerated” loops which may

trap condensate.

3. All pipe ends should be thoroughly cleaned

and deburred after cutting to ensure that

the pipeline is clear of cuttings.

Note: Figure 79 Actuators are rated for air

pressure in the range 40psig (2.75barg)

to 120psig (8.3barg) and can withstand a

maximum of 150psig (10barg).

Construction

Figure 79 actuators are available in a range

of sizes producing up to 27624lb in/ 3121Nm

output torque and are designed to be mounted

to quarter turn valves either directly or using

the correct mounting brackets/adaptors and

sizing procedures.

All models are of the opposed piston type. Each

piston incorporates a wide toothed rack which

engages a one piece drive shaft. The drive

shaft is sealbond (TM) treated for maximum

protection. The actuator body is of extruded

aluminium and is fitted with “Engineered

polymer” bearings at the drive shaft locations.

Bearing and piston seals are dynamic ‘O’-ring

type. The actuator drive is by means of a double

keyed female shaft (79U/E). A comprehensive

range of double “D” adaptors is available for

fitting to both the top and bottom of the output

shaft for accessories (top) and valve stems

(bottom).

Emerson.com/FinalControl VCIOM-01733-EN 17/04

© 2017 Emerson. All Rights Reserved.

KEYSTONE FIGURE 79 PNEUMATIC ACTUATOR

OPERATING AND MAINTENANCE INSTRUCTIONS

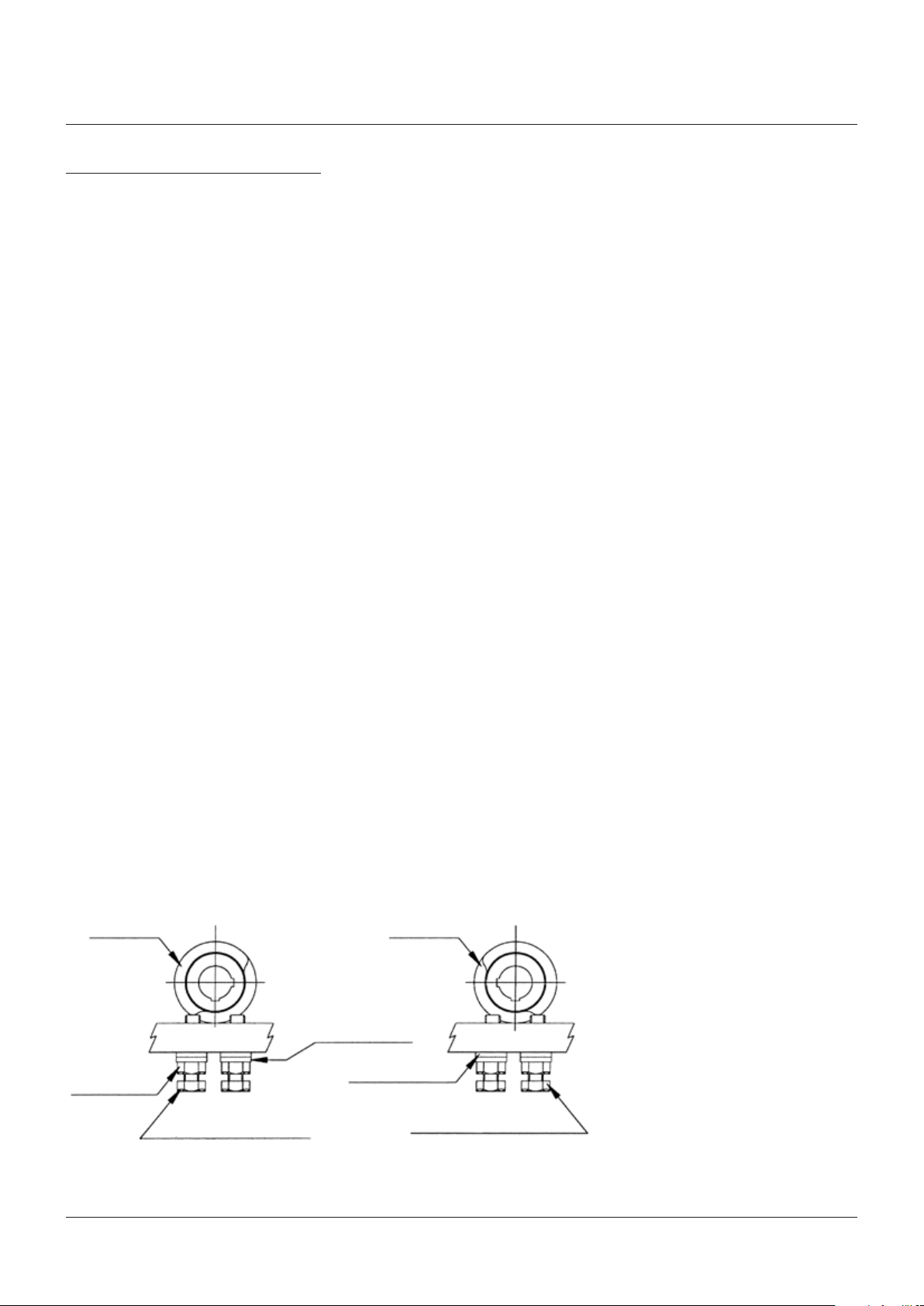

STANDARD INSTALLATION - DOUBLE &

SINGLE ACTING UNITS

These instructions assume that the actuators

are installed with the cylinder axis parallel to

the axis of the valve bore (In Line).

Single acting actuators are supplied as

FAIL-CLOSE units as standard.

Reverse acting FAIL-OPEN must be specified at

the time of order.

The actuator is mounted as follows:

1. Ensure that the valve and actuator are both

in the following positions:

Double Acting units - fully closed

Single Acting units - air fail mode

(normallyclosed)

2. Check that the actuator mounting studs are

tightly secured in the actuator housing.

3. Install the correct adaptor, if required, into

the actuator (fig. 1 - direct mounting) or

install the correct coupling and bracketry,

if required, to the valve (fig. 2 - bracket

mounted option).

See Notes 1 & 2

4. Mount the actuator onto the valve flange or

the bracket and secure using a lockwasher

and nut on each mounting stud.

5. Before installing the valve/actuator

assembly in a piping system, the disc travel

should be verified.

6. When installing the valve/actuator assembly

into pipeline, ensure that the specific

instructions relating to the valve installation

are followed. For valves which need to be

fitted with the valve in a position other than

fully closed, it may be necessary to fit the

valve into the pipeline prior to mounting the

actuator to the valve. Rubber lined butterfly

valves are an example of this.

7. For valves which need to be installed in the

pipeline prior to fitting the actuator, ensure

that the valve is operated into its failsafe

position before mounting the actuator onto

the valve.

3. Refit actuator to the top of the valve. (note:on models 036/065/090 adaptors may not be

required to be fitted ie directly mounted, in

this case simply use the previously unused

keyway.)

NOTES

1. The adaptor should be lightly tapped or pressed

into the actuator.

2. The coupling should be lightly tapped or pressed

onto the valve stem.

Excessive force should not be used (the use of a

lubricant such as Coppaslip is recommended).

FIGURE 1

Lockwasher

FIGURE 2

Lockwasher

Nut

Bolt

Pneumatic

actuator

Valve

Pneumatic

actuator

Adaptor

ifrequired

Adaptor

ifrequired

Stud

Nut

Stud

Coupling

if required

NON STANDARD INSTALLATION - DOUBLE &

SINGLE ACTING UNITS

In circumstances where the actuator is

required to be installed in the transverse

position i.e. at right angles to the valve bore

(Across Line), the actuator must be rotated

through 90°.

This is achieved in the following manner:

1. Remove the actuator from the valve or the

bracket by unscrewing the 4 fixing nuts and

withdraw it vertically from the valve.

2. 79U/E Models - remove the double ‘D’

adaptor located in the bore at the bottom of

the actuator and re-fit, locating in previously

unused keyway of shaft.

Ball

valve

Bracket

if required

2

KEYSTONE FIGURE 79 PNEUMATIC ACTUATOR

OPERATING AND MAINTENANCE INSTRUCTIONS

DISASSEMBLY - DOUBLE ACTING UNITS

Note: Please refer to the relevant exploded

views further on.

CAUTION

Remove all air pressure and observe normal

safety precautions including the use of eye

protection.

1. Pull off the indicator cap (item 17) from

the top of the actuator. If this cap is too

tight, light pressure may be applied to the

underside via a short length of round bar

or a similar blunt ended tool, inserted from

the bottom end of the actuator shaft. (Note:

levering with a screwdriver is considered

to be a potentially dangerous practice and

should be avoided.)

`The position relative to the shaft should

be noted to ensure correct position for

assembly.

2. Remove both travel stop bolts, if fitted

(items 19 to 22, see page 10 for all items)

3.

Loosen endcap fixing screws evenly (item 15)

4. Remove endcaps (item 3)

5. Rotate output shaft (item 5) in a anticlockwise direction to drive pistons apart,

and remove pistons (item 2) complete with

backing pads/rings - if fitted.

6. Remove circlip (item 12) from bottom bore

of actuator.

7. Tap shaft downward and remove. Take care

to protect the actuator bore from possible

damage from the pinion gear teeth.

8. Remove top bearing (item 9) from the

actuator body (the bottom bearing

(item 6) will have been removed along with

the pinion shaft).

DISASSEMBLY - SINGLE ACTING UNITS

Note: Please refer to the relevant exploded

views further on.

CAUTION

Remove all air pressure and observe normal

safety precautions including the use of eye

protection. Always ensure that spring return

actuators are in fail safe position before

attempting any maintenance. Pay particular

attention to this requirement when manual

operators are fitted.

For safety reasons DONOT ‘Air Assist’ Single

Acting Pneumatic actuators.

1. Pull off the indicator cap (item 17) from

the top of the actuator. If this cap is too

tight, light pressure may be applied to the

underside via a short length of round bar

or a similar blunt ended tool, inserted from

the bottom end of the actuator shaft. (Note:

levering with a screwdriver is considered

to be a potentially dangerous practice and

should be avoided.)

The position relative to the shaft should

be noted to ensure correct position for

assembly.

2. Remove both travel stop bolts, if fitted

(items 19 to 22, see page 11 for all items).

3. Loosen endcap/spring return housing fixing

screws (item 15) evenly until the spring load

is relaxed (3 - 5 mm).

Warning: If, after loosening the screws

by 5mm there is still compression on the

spring pack, re-tighten the endcap screws

and return the unit to the factory for service.

4. Remove endcap/spring housing assemblies.

Warning: Under no circumstances should

the spring retaining bolt be loosened or

adjusted without first consulting the factory.

5. Rotate output shaft (item 5) in an anticlockwise direction to drive pistons apart

and remove pistons (item 2) complete with

backing pads/rings - if fitted.

6. Remove circlip (item 12) from bottom bore

of actuator.

7. Tap shaft downward and remove. Take

care to protect actuator bore from possible

damage from the pinion gear teeth.

8. Remove top bearing (item 9) from the

actuator body (the bottom bearing (item

6) will have been removed along with the

pinion shaft).

3

KEYSTONE FIGURE 79 PNEUMATIC ACTUATOR

OPERATING AND MAINTENANCE INSTRUCTIONS

ASSEMBLY - DOUBLE ACTING UNITS

Note: Please refer to the relevant exploded

views further on.

Liberally grease actuator bore, pistons and

pinion assembly with Molyrace LT lubricant.

1. Coat all ‘O’-ring seals with Molyrace LT

lubricant.

2. Output shaft assembly:-

a) Fit the top bearing assembly (item 9) into

the top bore of the actuator body (item 1)

with the outer o-ring uppermost.

b) Fit the bottom bearing assembly (item 6)

on to the bottom of the pinion shaft (item

5) with internal o-ring uppermost.

3. Insert pinion shaft assembly from underside

of the actuator as shown in fig. 4.

4. Fit internal circlip (item 12) to bottom recess

of body to locate the shaft assembly.

5.

Fit ‘O’-ring seals (item 13) on pistons (item 2).

6. Orientate output shaft at 45° ± 2°.

7. Insert pistons (item 2) complete with

backing pads(1) (item 18) and backing rings

(5), with piston legs on left side of bore

(when viewed from the o-ring end of the

piston), until racks engages with pinion and

then push fully inward, the actuator is now

in the fully closed position.

* If no travel stops are fitted proceed to

instruction 12.

8. Turn the pinion shaft anti-clockwise

approximately 5° until it is orientated in line

with the major axis of the actuator body. The

shaft is now in the closed position.

9. Insert CLOSE travel stop bolt (item 19/20)

together with sealing nut or lock nut (2)(3),

flat washer (2)(3) and sealing washer (2)(3)

until the bolt hits the travel stop cam. Tighten

the lock nut.

10. Turn the pinion shaft anti-clockwise through

90° to bring it in line with the center line of

the actuator bore, the actuator is now in the

open position.

11. Insert Open travel stop bolt (item 19/20)

(together with sealing nut or lock nut (2)

(3), flat washer (2)(3) and sealing washer (2)

(3)) until the bolt hits the travel stop cam.

Tighten the lock nut.

12.

Fit ‘O’-ring seals (item 14) to endcaps (item 3)

using a light smear of grease.

13. Fit endcaps to body and alternately tighten

the endcap screws (item 15) until secure

(see recommended torque table).

14. Fit position indicator to top of actuator.

15. Operate the actuator to OPEN & CLOSE

positions using compressed air and note the

actual positions. If the required travel is not

achieved refer to page 12.

NOTES

1 Backing pads are not required on 002/003 models

which have nylon pistons.

2 Lock nuts, flat washers and sealing washers are

only fitted to models 065-180.

3 On models 003/036 the lock nut & sealing nut are

one item.

4 Gear shim is required on models 006 and 012 only.

5 Backing rings and pads are only fitted to models

065/090/180.

Note: Backing pads and rings need only a smear of

grease on the undersides before fitting to pistons.

FIGURE 3

Camshaft

Locking nut

(Models 065 to 180)

Open position

Actuator body

Open adjustment bolt

Camshaft

Flat washer

(Models 065 to 180)

Sealing washer

(Models 065 to 180)

Viewed from top of actuator

Close position

Actuator body

Close adjustment bolt

4

Loading...

Loading...