Emerson 3051S User Manual

Reference Manual

00809-0200-4801, Rev BA

April 2007

Rosemount 3051S

Section 3 |

Configuration |

OVERVIEW

SAFETY MESSAGES

Warnings

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1 Device Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2 General Block Information . . . . . . . . . . . . . . . . . . . . . . . . . page 3-3 Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-4 Analog Input (AI) Function Block . . . . . . . . . . . . . . . . . . . page 3-8 Multiple Analog Input (MAI) Function Block . . . . . . . . . . page 3-16 LCD Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-18 Advanced Diagnostics Transducer Block (ADB) . . . . . . . page 3-21 Mass Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-27 Engineering Assistant Software . . . . . . . . . . . . . . . . . . . . page 3-28

This section covers basic operation, software functionality, and basic configuration procedures for the Rosemount 3051S pressure transmitter with FOUNDATION fieldbus. This section is organized by block information. For detailed information about the function blocks used in the Rosemount3051S pressure transmitter, refer to “Foundation Fieldbus Block Information” on page A-1 and the FOUNDATION fieldbus Block manual (00809-0100-4783).

Procedures and instructions in this section may require special precautions to ensure the safety of the personnel performing the operations. Information that raises potential safety issues is indicated by a warning symbol ( ). Refer to the following safety messages before performing an operation preceded by this symbol.

). Refer to the following safety messages before performing an operation preceded by this symbol.

Explosions can result in death or serious injury.

•Do not remove the transmitter covers in explosive environments when the circuit is live.

•Transmitter covers must be fully engaged to meet explosion proof requirements.

•Before connecting a configuration tool in an explosive atmosphere, make sure the instruments in the loop are installed in accordance with intrinsically safe or nonincendive field wiring practices.

Electrical shock can result in death or serious injury.

•Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical shock.

www.rosemount.com

Rosemount 3051S

Reference Manual

00809-0200-4801, Rev BA

April 2007

DEVICE CAPABILITIES

Link Active Scheduler

Capabilities

The Rosemount 3051S can be designated to act as the backup Link Active Scheduler (LAS) in the event that the LAS is disconnected from the segment. As the backup LAS, the 3051S will take over the management of communications until the host is restored.

The host system may provide a configuration tool specifically designed to designate a particular device as a backup LAS. Otherwise, this can be configured manually as follows:

1. Access the Management Information Bose (MIB) for the 3051S.

2.To activate the LAS capability, write 0x02 to the BOOT_OPERAT_FUNCTIONAL_CLASS object (Index 605). To deactivate, write 0x01.

Restart the processor.

Virtual Communication Relationship (VCRs)

There are a total of 20 VCRs. One is permanent and 19 are fully configurable by the host system. Twenty-five link objects are available.

Network Parameter |

Value |

|

|

Slot Time |

6 |

|

|

Maximum Response Delay |

4 |

Maximum Inactivity to Claim LAS Delay |

47 |

|

|

Minimum Inter DLPDU Delay |

7 |

Time Sync class |

4 (1ms) |

|

|

Maximum Scheduling Overhead |

21 |

Per CLPDU PhL Overhead |

4 |

|

|

Maximum Inter-channel Signal Skew |

0 |

Required Number of Post-transmission-gab-ext Units |

0 |

|

|

Required Number of Preamble-extension Units |

1 |

|

|

Host timer recommendations

T1 = 96000

T2 = 1920000

T3 = 480000

Block Execution times

Analog Input = 20 ms PID = 25 ms Arithmetic = 20 ms Input Selection = 20 ms

Signal Characterizer = 20 ms Integrator = 20 ms

Analog Output = 20 ms Output Splitter = 20 ms Multiple Analog Input = 20 ms Control Selector = 20 ms

3-2

Reference Manual

00809-0200-4801, Rev BA

April 2007

Rosemount 3051S

GENERAL BLOCK

INFORMATION

Modes |

The Resource, Transducer, and all function blocks in the device have modes |

|||||||||||||

|

of operation. These modes govern the operation of the block. Every block |

|||||||||||||

|

supports both automatic (AUTO) and out of service (OOS) modes. Other |

|||||||||||||

|

modes may also be supported. |

|

|

|

|

|

|

|||||||

|

Changing Modes |

|

|

|

|

|

|

|

|

|||||

|

To change the operating mode, set the MODE_BLK.TARGET to the desired |

|||||||||||||

|

mode. After a short delay, the parameter MODE_BLOCK.ACTUAL should |

|||||||||||||

|

reflect the mode change if the block is operating properly. |

|

|

|||||||||||

|

Permitted Modes |

|

|

|

|

|

|

|

|

|||||

|

It is possible to prevent unauthorized changes to the operating mode of a |

|||||||||||||

|

block. To do this, configure MODE_BLOCK.PERMITTED to allow only the |

|||||||||||||

|

desired operating modes. It is recommended to always select OOS as one of |

|||||||||||||

|

the permitted modes. |

|

|

|

|

|

|

|

|

|||||

|

Types of Modes |

|

|

|

|

|

|

|

|

|||||

|

For the procedures described in this manual, it will be helpful to understand |

|||||||||||||

|

the following modes: |

|

|

|

|

|

|

|

|

|||||

|

|

|

AUTO |

|

|

|

|

|

|

|

|

|||

|

|

|

The functions performed by the block will execute. If the block has any |

|||||||||||

|

|

|

outputs, these will continue to update. This is typically the normal |

|||||||||||

|

|

|

operating mode. |

|

|

|

|

|

|

|

|

|||

|

|

|

Out of Service (OOS) |

|

|

|

|

|

|

|||||

|

|

|

The functions performed by the block will not execute. If the block has any |

|||||||||||

|

|

|

outputs, these will typically not update and the status of any values passed |

|||||||||||

|

|

|

to downstream blocks will be “BAD”. To make some changes to the |

|||||||||||

|

|

|

configuration of the block, change the mode of the block to OOS. When |

|||||||||||

|

|

|

the changes are complete, change the mode back to AUTO. |

|

|

|||||||||

|

|

|

MAN |

|

|

|

|

|

|

|

|

|||

|

|

|

In this mode, variables that are passed out of the block can be manually |

|||||||||||

|

|

|

set for testing or override purposes. |

|

|

|

|

|

|

|||||

|

|

|

Other Types of Modes |

|

|

|

|

|

|

|||||

|

|

|

Other types of modes are Cas, RCas, ROut, IMan and LO. Some of these |

|||||||||||

|

|

|

may be supported by different function blocks in the Rosemount3051S. |

|||||||||||

|

|

|

For more information, see the Function Block manual, document |

|||||||||||

|

00809-0100-4783. |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE |

|

|

|

|

|

|

|

|

|||||

|

When an upstream block is set to OOS, this will impact the output status of all |

|||||||||||||

|

downstream blocks. The figure below depicts the hierarchy of blocks: |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Resource |

|

|

|

Transducer |

|

Analog Input |

|

|

|

Other |

|

|

|

|

Block |

|

|

|

Block |

|

(AI Block) |

|

|

|

function |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

blocks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-3

Rosemount 3051S

Reference Manual

00809-0200-4801, Rev BA

April 2007

Block Instantiation

Simulation

The Rosemount 3051S supports the use of Function Block Instantiation. When a device supports block instantiation, the number of blocks and block types can be defined to match specific application needs.The number of blocks that can be instantiated is only limited by the amount of memory within the device and the block types that are supported by the device. Instantiation does not apply to standard device blocks like the Resource, Sensor Transducer, LCD Transducer, and Advanced Diagnostics Blocks.

By reading the parameter “FREE_SPACE” in the Resource block you can determine how many blocks you can instantiate. Each block that you instantiate takes up 4.5573% of the “FREE_SPACE”.

Block instantiation is done by the host control system or configuration tool, but not all hosts are required to implement this functionality. Please refer to your specific host or configuration tool manual for more information.

Simulation is the functionality of the AI block. To support testing, either change the mode of the block to manual and adjust the output value or enable simulation through the configuration tool and manually enter a value for the measurement value and its status (this single value will apply to all outputs). In both cases, first set the ENABLE jumper on the field device.

NOTE

All fieldbus instruments have a simulation jumper. As a safety measure, the jumper has to be reset every time there is a power interruption. This measure is to prevent devices that went through simulation in the staging process from being installed with simulation enabled.

With simulation enabled, the actual measurement value has no impact on the OUT value or the status. The OUT values will all have the same value as determined by the simulate value.

RESOURCE BLOCK

FEATURES and

FEATURES_SEL

The FEATURES parameter is read only and defines which features are supported by the 3051S. Below is a list of the FEATURES the 3051S supports.

FEATURES_SEL is used to turn on any of the supported features that are found in the FEATURES parameter. The default setting of the Rosemount 3051S does not select any of these features. Choose one or more of the supported features if any.

UNICODE

All configurable string variables in the 3051S, except tag names, are octet strings. Either ASCII or Unicode may be used. If the configuration device is generating Unicode octet strings, you must set the Unicode option bit.

REPORTS

The 3051S supports alert reports. The Reports option bit must be set in the features bit string to use this feature. If it is not set, the host must poll for alerts. If this bit is set, the transmitter will actively report alerts.

3-4

Reference Manual

00809-0200-4801, Rev BA

April 2007

Rosemount 3051S

SOFT W LOCK and HARD W LOCK

Inputs to the security and write lock functions include the hardware security switch, the hardware and software write lock bits of the FEATURE_SEL parameter, the WRITE_LOCK parameter, and the DEFINE_WRITE_LOCK parameter.

The WRITE_LOCK parameter prevents modification of parameters within the device except to clear the WRITE_LOCK parameter. During this time, the block will function normally updating inputs and outputs and executing algorithms. When the WRITE_LOCK condition is cleared, a WRITE_ALM alert is generated with a priority that corresponds to the WRITE_PRI parameter.

The FEATURE_SEL parameter enables the user to select a hardware or software write lock or no write lock capability. To enable the hardware security function, enable the HW_SEL bit in the FEATURE_SEL parameter. When this bit has been enabled the WRITE_LOCK parameter becomes read only and will reflect the state of the hardware switch. In order to enable the software write lock, the SW_SEL bit must be set in the FEATURE_SEL parameter. Once this bit is set, the WRITE_LOCK parameter may be set to “Locked” or “Not Locked.” Once the WRITE_LOCK parameter is set to “Locked” by either the software or the hardware lock, all user requested writes as determined by the DEFINE_WRITE_LOCK parameter shall be rejected.

The DEFINE_WRITE_LOCK parameter allows the user to configure whether the write lock functions (both software and hardware) will control writing to all blocks, or only to the resource and transducer blocks. Internally updated data such as process variables and diagnostics will not be restricted by the security switch.

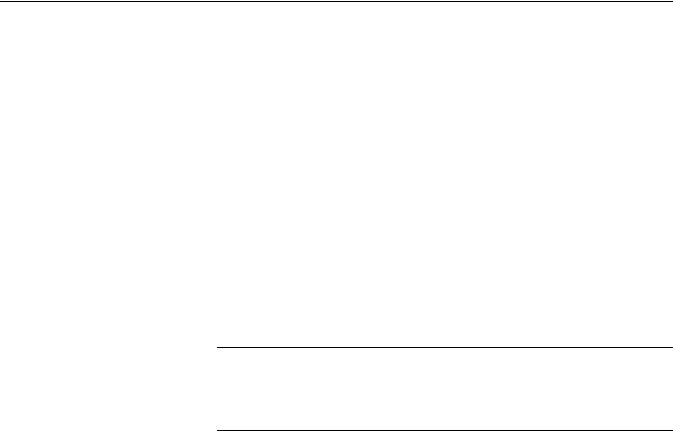

The following table displays all possible configurations of the WRITE_LOCK parameter.

FEATURE_SEL |

FEATURE_SEL |

|

|

|

|

WRITE_LOCK |

|

Write access |

|

HW_SEL bit |

SW_SEL bit |

SECURITY SWITCH |

WRITE_LOCK |

Read/Write |

DEFINE_WRITE_LOCK |

to blocks |

|||

|

|

|

|

|

|

|

|

|

|

0 (off) |

0 |

(off) |

NA |

1 |

(unlocked) |

Read only |

NA |

All |

|

|

|

|

|

|

|

|

|

|

|

0 (off) |

1 |

(on) |

NA |

1 |

(unlocked) |

Read/Write |

NA |

All |

|

0 (off) |

1 |

(on) |

NA |

2 |

(locked) |

Read/Write |

Physical |

Function |

|

|

|

|

|

|

|

|

|

|

Blocks only |

|

|

|

|

|

|

|

|

|

|

0 (off) |

1 |

(on) |

NA |

2 |

(locked) |

Read/Write |

Everything |

None |

|

1 (on) |

0 |

(off)(1) |

0 |

(unlocked) |

1 |

(unlocked) |

Read only |

NA |

All |

1 (on) |

0 |

(off) |

1 |

(locked) |

2 |

(locked) |

Read only |

Physical |

Function |

|

|

|

|

|

|

|

|

|

Blocks only |

1 (on) |

0 |

(off) |

1 |

(locked) |

2 |

(locked) |

Read only |

Everything |

None |

(1)The hardware and software write lock select bits are mutually exclusive and the hardware select has the highest priority. When the HW_SEL bit if set to 1 (on), the SW_SEL bit is automatically set to 0 (off) and is read only.

MAX_NOTIFY

The MAX_NOTIFY parameter value is the maximum number of alert reports that the resource can have sent without getting a confirmation, corresponding to the amount of buffer space available for alert messages. The number can be set lower, to control alert flooding, by adjusting the LIM_NOTIFY parameter value. If LIM_NOTIFY is set to zero, then no alerts are reported.

3-5

Rosemount 3051S

Reference Manual

00809-0200-4801, Rev BA

April 2007

PlantWeb™ Alarms |

The alarms and recommended actions should be used in conjunction with |

|

|

Section 2: Troubleshooting. |

|

|

The Resource Block will act as a coordinator for PlantWeb alarms. There will |

|

|

be three alarm parameters (FAILED_ALARM, MAINT_ALARM, and |

|

|

ADVISE_ALARM) which will contain information regarding some of the device |

|

|

errors which are detected by the transmitter software. There will be a |

|

|

RECOMMENDED_ACTION parameter which will be used to display the |

|

|

recommended action text for the highest priority alarm. FAILED_ALARM will |

|

|

have the highest priority followed by MAINT_ALARM and ADVISE_ALARM |

|

|

will be the lowest priority. |

|

|

|

|

|

NOTE |

|

|

PlantWeb alerts for ADB and mass flow cannot be simulated. |

|

|

|

|

|

FAILED_ALARMS |

|

|

A failure alarm indicates a failure within a device that will make the device or |

|

|

some part of the device non-operational. This implies that the device is in |

|

|

need of repair and must be fixed immediately. There are five parameters |

|

|

associated with FAILED_ALARMS specifically, they are described below. |

|

|

FAILED_ENABLED |

|

|

This parameter contains a list of failures in the device which makes the |

|

|

device non-operational that will cause an alarm to be sent. Below is a list |

|

|

of the failures with the highest priority first. |

|

|

1. |

Memory Failure |

|

2. |

NV Memory Failure |

|

3. |

Primary Value Failure |

|

4. |

Secondary Value Failure |

|

5. |

Sensor Module Memory Failure |

|

6. |

Sensor Module Failure |

FAILED_MASK

This parameter will mask any of the failed conditions listed in FAILED_ENABLED. A bit on means that the condition is masked out from alarming and will not be reported.

FAILED_PRI

Designates the alarming priority of the FAILED_ALM, see “Alarm Priority” on page 3-15. The default is 0 and the recommended value are between 8 and 15.

FAILED_ACTIVE

This parameter displays which of the alarms is active. Only the alarm with the highest priority will be displayed. This priority is not the same as the FAILED_PRI parameter described above. This priority is hard coded within the device and is not user configurable.

FAILED_ALM

Alarm indicating a failure within a device which makes the device non-operational.

3-6

Reference Manual

00809-0200-4801, Rev BA

April 2007

Rosemount 3051S

MAINT_ALARMS

A maintenance alarm indicates the device or some part of the device needs maintenance soon. If the condition is ignored, the device will eventually fail. There are five parameters associated with MAINT_ALARMS, they are described below.

MAINT_ENABLED

The MAINT_ENABLED parameter contains a list of conditions indicating the device or some part of the device needs maintenance soon. If the condition is ignored, the device will eventually fail.

Below is a list of the conditions with the highest priority first.

1.Sensor Module Memory Warning

2.Primary Value Degraded

3.Secondary Value Degraded

4.Plugged Impulse Line Detected

MAINT_MASK

The MAINT_MASK parameter will mask any of the failed conditions listed in MAINT_ENABLED. A bit on means that the condition is masked out from alarming and will not be reported.

MAINT_PRI

MAINT_PRI designates the alarming priority of the MAINT_ALM, “Process Alarms” on page 3-15. The default is 0 and the recommended values is 3 to 7.

MAINT_ACTIVE

The MAINT_ACTIVE parameter displays which of the alarms is active. Only the condition with the highest priority will be displayed. This priority is not the same as the MAINT_PRI parameter described above. This priority is hard coded within the device and is not user configurable.

MAINT_ALM

An alarm indicating the device needs maintenance soon. If the condition is ignored, the device will eventually fail.

Advisory Alarms

An advisory alarm indicates informative conditions that do not have a direct impact on the device's primary functions There are five parameters associated with ADVISE_ALARMS, they are described below.

ADVISE_ENABLED

The ADVISE_ENABLED parameter contains a list of informative conditions that do not have a direct impact on the device's primary functions. Below is a list of the advisories with the highest priority first.

3-7

|

Reference Manual |

Rosemount 3051S |

00809-0200-4801, Rev BA |

April 2007 |

|

|

|

1. |

Process Anomaly Detected (SPM) |

2. |

LOI Failure |

3. |

PWA Simulate Active |

4. |

Defer NV Memory Write Detected |

5. |

Mass Flow Transducer Block Reverse Flow |

6. |

Mass Flow Transducer Block Sensor Out of Range |

7. |

Mass Flow Transducer Block Out of Range |

8. |

Process Anomaly Detected (SPM) |

ADVISE_MASK

The ADVISE_MASK parameter will mask any of the failed conditions listed in ADVISE_ENABLED. A bit on means the condition is masked out from alarming and will not be reported.

ADVISE_PRI

ADVISE_PRI designates the alarming priority of the ADVISE_ALM, see “Process Alarms” on page 3-15. The default is 0 and the recommended values are 1 or 2.

ADVISE_ACTIVE

The ADVISE_ACTIVE parameter displays which of the advisories is active. Only the advisory with the highest priority will be displayed. This priority is not the same as the ADVISE_PRI parameter described above. This priority is hard coded within the device and is not user configurable.

ADVISE_ALM

ADVISE_ALM is an alarm indicating advisory alarms. These conditions do not have a direct impact on the process or device integrity.

Recommended Actions for PlantWeb Alarms

RECOMMENDED_ACTION

The RECOMMENDED_ACTION parameter displays a text string that will give a recommended course of action to take based on which type and which specific event of the PlantWeb alarms is active (See Table 5-12 on page 5-10).

ANALOG INPUT (AI) FUNCTION BLOCK

Configure the AI block

A minimum of four parameters are required to configure the AI Block. The parameters are described below with example configurations shown at the end of this section.

A minimum of four parameters are required to configure the AI Block. The parameters are described below with example configurations shown at the end of this section.

3-8

Reference Manual

00809-0200-4801, Rev BA

April 2007

Rosemount 3051S

CHANNEL

Select the channel that corresponds to the desired sensor measurement. The 3051S measures both pressure (channel 1) and sensor temperature (channel 2).

Table 3-1. I/O Channel Definitions

Channel Number |

Channel Description |

|

|

1 |

differential pressure in AI.XD_SCALE units |

|

|

2 |

sensor temperature in AI.XD_SCALE units |

3 |

differential pressure in inH20 @68°F (ADB) |

|

|

4 |

mean differential pressure |

5 |

absolute pressure (AO.OUT) |

|

|

6 |

process temperature (AO.OUT) |

7 |

mass flow |

|

|

8 |

absolute pressure (AO.CAS_IN shadow) |

9 |

process temperature (AO.CAS_IN shadow) |

|

|

10 |

differential pressure in inH20 @68°F (MFTB) |

11 |

All MAI channels (12-19 below) |

|

|

12 |

SPM1 mean (ADB) |

13 |

SPM1 standard deviation (ADB) |

|

|

14 |

SPM2 mean (ADB) |

15 |

SPM2 standard deviation (ADB) |

|

|

16 |

SPM3 mean (ADB) |

17 |

SPM3 standard deviation (ADB) |

|

|

18 |

SPM4 mean (ADB) |

19 |

SPM4 standard deviation (ADB) |

NOTE

Channel 3 and channels 12-19 are only available when the Advanced Diagnostic Block is licensed. Channels 5-9 are only available when the Mass Flow Block is licensed.

L_TYPE

The L_TYPE parameter defines the relationship of the sensor measurement (pressure or sensor temperature) to the desired output of the AI Block (e.g. pressure, level, flow, etc.). The relationship can be direct, indirect, or indirect square root.

Direct

Select direct when the desired output will be the same as the sensor measurement (pressure or sensor temperature).

Indirect

Select indirect when the desired output is a calculated measurement based on the sensor measurement (e.g. a pressure measurement is made to determine level in a tank). The relationship between the sensor measurement and the calculated measurement will be linear.

Indirect Square Root

Select indirect square root when the desired output is an inferred measurement based on the sensor measurement and the relationship between the sensor measurement and the inferred measurement is square root (e.g. flow).

3-9

Rosemount 3051S

Reference Manual

00809-0200-4801, Rev BA

April 2007

XD_SCALE and OUT_SCALE

The XD_SCALE and OUT_SCALE each include three parameters: 0%, 100%, and, engineering units. Set these based on the L_TYPE:

L_TYPE is Direct

When the desired output is the measured variable, set the XD_SCALE to the “Primary_Value_Range”. This is found in the Sensor Transducer Block. Set OUT_SCALE to match XD_SCALE.

L_TYPE is Indirect

When an inferred measurement is made based on the sensor measurement, set the XD_SCALE to represent the operating range that the sensor will see in the process. Determine the inferred measurement values that correspond to the XD_SCALE 0 and 100% points and set these for the OUT_SCALE.

L_TYPE is Indirect Square Root

When an inferred measurement is made based on the sensor measurement AND the relationship between the inferred measurement and sensor measurement is square root, set the XD_SCALE to represent the operating range that the sensor will see in the process. Determine the inferred measurement values that correspond to the XD_SCALE 0 and 100% points and set these for the OUT_SCALE.:

Pressure (Channel 1) |

Temperature (Channel 2) |

Flow (Channel 7) |

|

|

|

Pa |

°C |

lbm/sec |

|

|

|

kPa |

°F |

lbm/min |

bar |

°K |

lbm/hour |

|

|

|

mPa |

|

lbm/day |

mbar |

|

kg/sec |

|

|

|

torr |

|

kg/min |

atm |

|

kg/hour |

|

|

|

psi |

|

grams/sec |

g/cm2 |

|

grams/min |

|

|

|

kg/cm2 |

|

grams/hour |

inH2O at 68 °F |

|

StdCuFt/sec |

mmH2O at 68 °F |

|

StdCuFt/min |

in.H2O at 4 °F |

|

StdCuFt/min |

mmH2O at 4 °F |

|

StdCuFt/hour |

ftH2O at 68 °F |

|

StdCuFt/day |

inHg at 0 °C |

|

StdCuM/hour |

mmHg at 0 °C |

|

StdCuM/day |

|

|

|

|

|

NmlCuM/hour |

|

|

NmlCuM/day |

NOTE

When the engineering units of the XD_SCALE are selected, this causes the engineering units of the PRIMARY_VALUE_RANGE in the Transducer Block to change to the same units. THIS IS THE ONLY WAY TO CHANGE THE ENGINEERING UNITS IN THE SENSOR TRANSDUCER BLOCK, PRIMARY_VALUE_RANGE parameter.

3-10

Loading...

Loading...