Page 1

GAS COMBI - CONVECT OVENS

260450-260510 260462 260456

26045

260451-260511 260463 260457

2604

°

**

°

**

°

**

400

230

200

6GN1/1

(AOS061E)

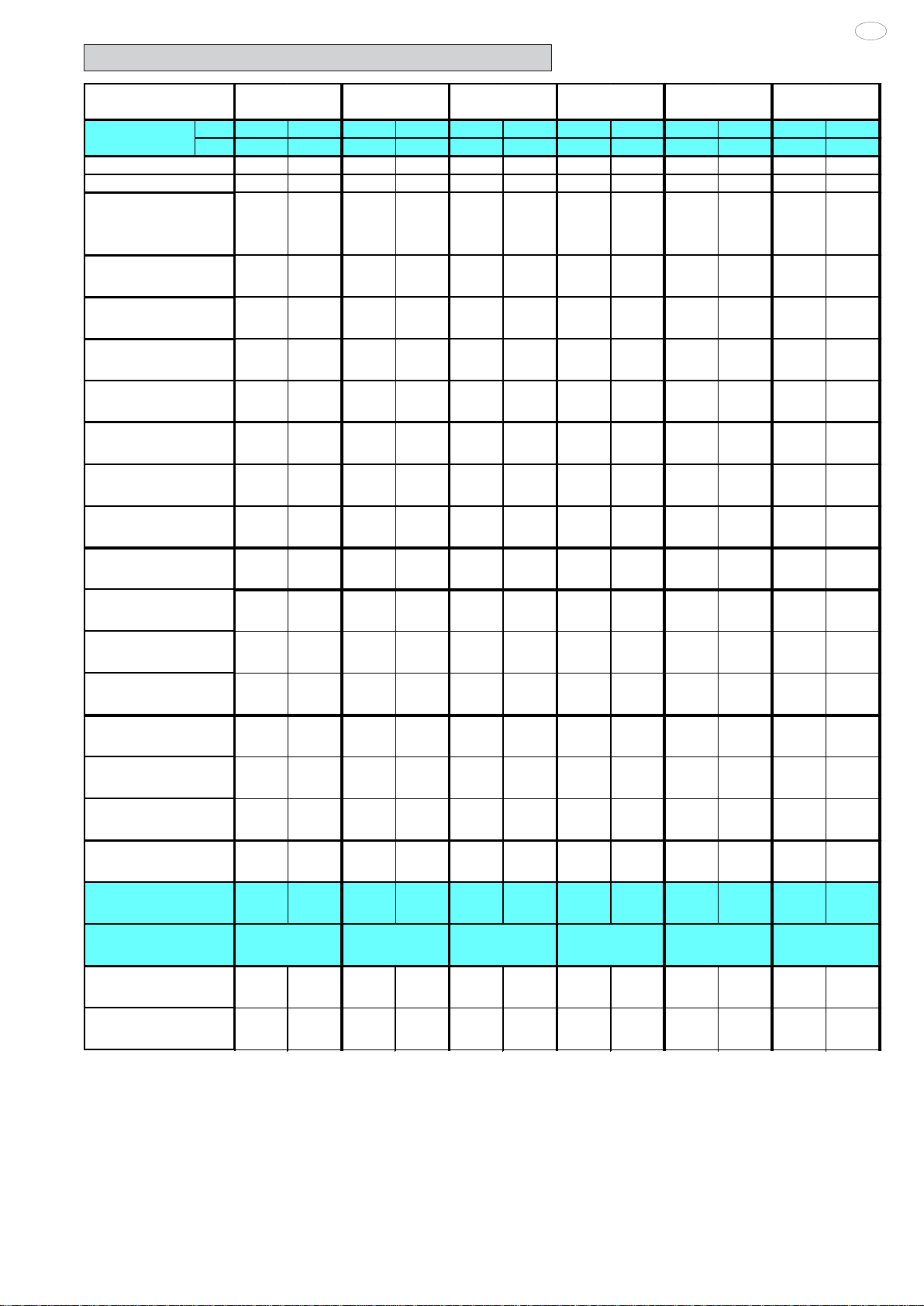

2. TABLE 1: TECHNICAL DATA

INSTRUCTIONS FOR INSTALLATION AND USE

Table of contents Page

- Installation diagram .......................................................... 2

- Appliance identification .................................................... 9

I. MAIN FEATURES ............................................................. 10

1. Description of appliance ............................................. 10

2. Table 1: Technical data ................................................. 11

3. Precautions .................................................................. 12

4. Safeguarding the environment ................................... 13

4.1 Packaging .............................................................. 13

4.2 Use ......................................................................... 13

4.3 Cleaning ................................................................ 13

4.4 Disposal ................................................................. 13

II. INSTRUCTIONS FOR INSTALLATION ............................ 14

1. Place of Installation ..................................................... 14

1.1 Ventilation ................................................................ 14

1.2 Reference standards ............................................... 14

1.3 Unpackaging ........................................................... 14

1.4 Immediately inspect for shipping damage .............. 14

2. Positioning ..................................................................... 14

3. Combusted gas discharge .......................................... 14

3.1 Foreword .................................................................. 14

Installation of accessories ................................15

3.2

3.3 Warnings regarding the fluimg system .................. 15

4. Electrical connection ................................................... 15

4.1 Installing the power supply cable .......................... 16

5. Water mains connection ............................................. 16

5.1 Water supply characteristics .................................. 16

5.2 Water drain system ................................................ 16

6. Gas connection ............................................................ 17

6.1 Warning .................................................................. 17

6.2 Nominal heat output .............................................. 17

6.3 Checking the supply pressure ............................... 17

7. Safety devices ............................................................. 18

8. Operation check .......................................................... 18

9. Servicing ....................................................................... 18

10. Troubleshooting ........................................................... 18

11. Layout of main components ...................................... 18

III. INSTRUCTIONS FOR USE ............................................. 19

1. Opening the oven door ................................................ 19

1.1 6- and 10-grid models ........................................... 19

1.2 20-GRID models .................................................... 19

2. Closing the oven door ................................................. 19

2.1 6- and 10-GRID models ......................................... 19

2.2 20-GRID models .................................................... 19

3. Description of the control panel ................................. 20

3.1 Introduction ............................................................ 20

3.2 Main controls ......................................................... 20

3.3 Main cooking modes ............................................. 20

3.4 Special cooking modes ......................................... 20

3.5 Additional functions ............................................... 21

USING THE OVEN ................................................................. 22

4. Introduction .................................................................. 22

4.1 Switching the oven on ........................................... 22

4.2 Selecting the controls ............................................ 22

4.3 Manual controls ..................................................... 22

4.4 Automatic controls ................................................. 26

5. Information and error codes ....................................... 29

6. SWITCHING off in the event of a fault ........................ 30

7. Care and maintenance ................................................ 30

7.1 Periodical maintenance of the BOILER ................. 31

7.2 Replacing CONSUMABLE components ............... 32

7.3 Special cleaning instructions ................................. 32

- CONTROL PANEL FIGURES .......................................... 105

USA

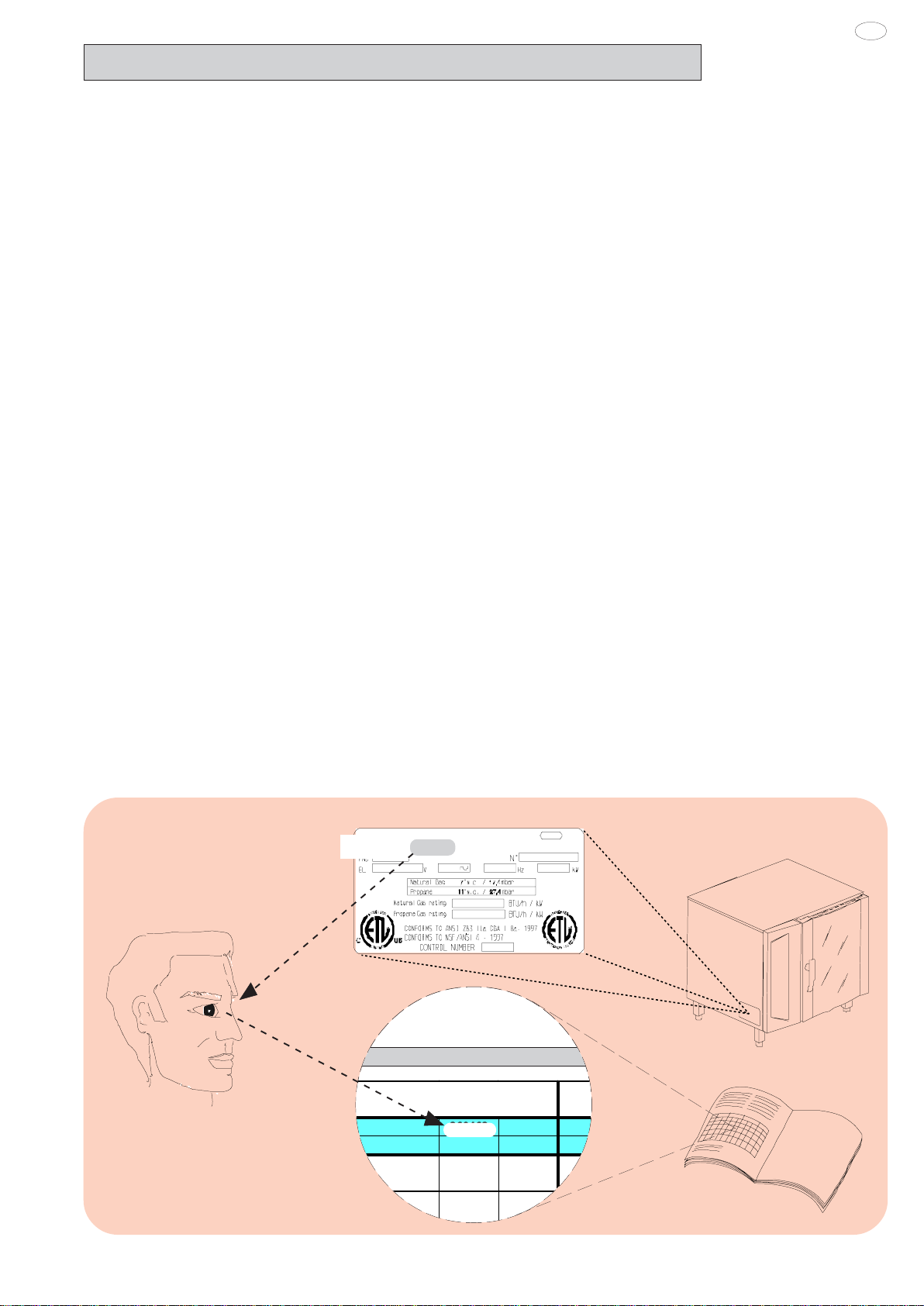

- APPLIANCE IDENTIFICATION

5938 036 01

Rating plate

PNC 9PDX 260462 05

260462

9

Page 2

USA

I. MAIN FEATURES

1. DESCRIPTION OF APPLIANCE

This booklet describes a number of appliance models.

For more detailed information about the model in your possession,

refer to "Technical Data" table 1.

The appliance has the following features:

• Digital temperature controlle.

• Thermostatic probe for measuring the core temperature of products (core temperature probe).

• Automatic flush to drain every two hour to prevent the build-up of

lime-scale in the boiler.

• Periodic draining and automatic washing of the boiler to prevent

the build-up of lime-scale (only available on certain models).

• Boiler lime-scale level indicator (see corresponding paragraph).

• Oven chamber automatic fast steam drain device for gratins.

• Air-break (anti-backup drain) device to prevent backflows from

the drain system from entering the oven (only available on certain

models).

• Halogen lighting in the cooking chamber.

• Double-action door opening safety mechanism designed to

protect the user from scalding steam (only available on certain

models).

• Double-glazed oven door for reduced heat dispersion into the

kitchen and low temperatures on the exterior of the oven.

• Daily oven chamber cleaning cycle (CLEANING SYSTEM)

• Self-diagnostics system indicating oven faults using error codes

(see "Information and error codes ").

.

10

5938 036 01

Page 3

2. TABLE 1: TECHNICAL DATA

Boil

Boil

USA

GRIDS

PNC *

A^

C^

CONVECTOR °

BOILER **

SUPPLY VOLTAGE

Total Watts

Maximum load capacities

(food)

Net weight

Shipping weight

Shipping width

Shipping height

Shipping depth

ISO 7/1 gas

connectionDiame ter

Nominal heat output

NATURAL

er unit nominal

hea t output

NATURAL

Convector unit nominal

heat output

NATURAL

Nominal heat output

PROPANE

er unit nominal

hea t output

PROPANE

Convector unit nominal

heat output

PROPANE

Gas type

6 GN 1/1 10 GN 1/1 10 GN 2/1 20 GN 1/1 20 GN 2/1

6 GN 2/1

267550 267551 267552 267553 267554 267555

269550 269551 269552 269553 269554 269555

° ° ° ° ° ° ° ° ° ° ° °

** ** ** ** ** **

120V

1ph

60Hz

10amp

0,45 k W 0,45 k W 0,9 kW 0,9 k W 0,5 k W 0,5 k W 1 kW 1 kW 0,85 k W 0,85 k W 2 kW 2 k W

66 lbs.

(30 kg)

254 lbs.

(115 kg)

287 lbs.

(130 kg)

3/4"inch

(940 mm)

1/8"inch

(1040 mm)

5/8"inch

(980 mm)

38

42

37

120V

1ph

60Hz

10amp

66 lbs.

(30 kg)

254 lbs.

(115 kg)

287 lbs.

(130 kg)

38

3/4"inch

(940 mm)

42

1/8"inch

(1040 mm)

37

5/8"inch

(980 mm)

120V

1ph

60Hz

10amp

122 lbs.

(60 kg )

353 lbs.

(160 kg)

386 lbs.

(130 kg)

44

11/16"inch

(1135 mm)

42

1/8"inch

(1040 mm)

44

13/16"inch

(1265 mm)

120V

1ph

60Hz

10amp

122 lbs.

(60 kg)

353 lbs.

(160 kg)

386 lbs.

(130 kg)

44

11/16"inch

(1135 mm)

42

1/8"inch

(1040 mm)

44

13/16"inch

(1265 mm)

120V

1ph

60Hz

10amps

110 lbs.

(50 kg)

320 lbs

(145 kg)

364 lbs.

(165 kg)

38

3/4"inch

(985 mm)

52

3/16"inch

(1325 mm)

37

5/8"inch

(955 mm)

120V

1ph

60Hz

10amps

110 lbs.

(50 kg)

320 lbs

(145 kg)

364 lbs.

(165 kg)

38

3/4"inch

(985 mm)

52

3/16"inch

(1325 mm)

37

5/8"inch

(955 mm)

120V

1ph

60Hz

10amps

220 lbs.

(100 kg)

505 lbs

(229 kg)

538 lbs

(244 kg)

44

11/16"inch

(1135 mm)

52

3/16"inch

(1325 mm)

44

13/16"inch

(1265 mm)

120V

1ph

60Hz

10amps

220 lbs.

(100 kg)

505 lbs

(229 kg)

538 lbs

(244 kg)

44

11/16"inch

(1135 mm)

52

3/16"inch

(1325 mm)

44

13/16"inch

(1265 mm)

120V

1ph

60Hz

10amps

220 lbs.

(100 kg)

551 lbs.

(250 kg)

617 lbs.

(280 kg)

38

3/4"inch

(985 mm)

81

1/8"inch

(2060 mm)

41

3/4"inch

(1060 mm)

120V

1ph

60Hz

10amps

220 lbs.

(100 k g)

551 lbs.

(250 kg)

617 lbs.

(280 kg)

38

3/4"inch

(985 mm)

81

1/8"inch

(2060 mm)

41

3/4"inch

(1060 mm)

120V

1ph

60Hz

20amps

440 lbs.

(200 kg)

1058 lbs

(480 kg)

1080 lbs

(490 kg)

44

11/16"inch

(1135 mm)

81

1/8"inch

(2060 mm)

51

3/16"inch

(1300 mm)

120V

1ph

60Hz

20amps

440 lbs.

(200 kg)

1058 lbs

(480 kg)

1080 lbs

(490 kg)

44

11/16"inch

(1135 mm)

81

1/8"inch

(2060 mm)

51

3/16"inch

(1300 mm)

1/2" M 1/2" M 1/ 2" M 1/2" M 1/2" M 1/2" M 1/2" M 1/2" M 1" M 1" M 1" M 1" M

683046

btu/h

(20 kW )

40982

btu/h

(12 kW )

40982

btu/h

(12 kW )

61473

btu/h

(18 kW )

35859.4

btu/h

(10. 5 k W)

35859

btu/h

(10. 5 k W)

NATURAL

PROPANE

40982

btu/h

(12 kW )

_

40982

btu/h

(12 kW )

35859

btu/h

(10. 5 k W)

_

35859

btu/h

(10. 5 k W)

NATURAL

PROPANE

122946

btu/h

(36 kW)

61473

btu/h

(18 kW)

78549

btu/h

(23 kW)

110993

btu/h

(32.5 kW)

54643

btu/h

(16 kW)

71719

btu/h

(21 kW)

NATURAL

PROPA NE

78549

btu/h

(23 kW)

_

78549

btu/h

(23 kW)

71719

btu/h

(21 kW)

_

71719

btu/h

(21 kW)

NATURAL

PROPANE

136607

btu/h

(40 kW )

78549

btu/h

(23 kW )

78549

btu/h

(23 kW )

126362

btu/h

(37 kW )

71719

btu/h

(21 kW )

71719

btu/h

(21 kW )

NATURAL

PROPANE

78549

btu/h

(23 kW )

_

78549

btu/h

(23 kW )

71719

btu/h

(21 kW )

_

71719

btu/h

(21 kW )

NATURAL

PROPA NE

177589

btu/h

(52 kW)

102455.4

btu/h

(30 kW)

105871

btu/h

(31 kW)

160513.4

btu/h

(47 kW)

88795

btu/h

(26 kW)

95625.0

btu/h

(28 kW)

NATURAL

PROPANE

105871

btu/h

(31 kW )

_

105871

btu/h

(31 kW )

95625.0

btu/h

(28 kW )

_

95625.0

btu/h

(28 kW )

NATURAL

PROPANE

232232

btu/h

(68 kW )

102455.4

btu/h

(30 kW )

160513.4

btu/h

(47 kW )

208326

btu/h

(61 kW )

88795

btu/h

(26 kW )

143438

btu/h

(42 kW )

NATURAL

PROPANE

160513

btu/h

(47 kW)

_

160513

btu/h

(47 kW)

143438

btu/h

(42 kW)

_

143438

btu/h

(42 kW)

NATURAL

PROPA NE

379085

btu/h

(111 kW)

218571

btu/h

(64 kW)

218571

btu/h

(64 kW)

334688

btu/h

(98 kW)

191250

btu/h

(56 kW)

191250

btu/h

(56 kW)

NATURAL

PROPANE

218571

btu/h

(64 kW )

_

218571

btu/h

(64 kW )

191250.0

btu/h

(56 kW )

_

191250

btu/h

(56 kW )

NATURAL

PROPANE

Con str u ction type

D i ag ra m of fu mes

discharge system

NATURAL pre ssure

PROPANE pressure

A3

B13A3B13A3B13A3B13A3B13A3B13A3B13A3B13A3B13A3B13A3B13A3B13

1a-1b-1c

7"w c

(17,4mbar)

11"w c

(27,4mbar)

7"w c

(17,4mbar)

11"w c

(27,4mbar)

7"w c

(17,4mbar)

11"wc

(27,4mbar)

Noise emission data: Noise emissions generated by the appliances described in this booklet do not exceed 70 dB (A).

Your appliance model is indicated in the box marked PNC on

*

the Identification dataplate affixed to the bottom left hand side of

the oven.

^ FUNCTIONAL LEVEL. (C = Convect, Convection)

5938 036 01

7"w c

(17,4mbar)

11"w c

(27,4mbar)

7"w c

(17,4mbar)

11"w c

(27,4mbar)

11

7"w c

(17,4mbar)

11"w c

(27,4mbar)

7"wc

(17,4mbar)

11"wc

(27,4mbar)

7"w c

(17,4mbar)

11"w c

(27,4mbar)

1a-1b-1c 1a-1b-1c1a-1b-1c 1a-1b-1c 1a-1b-1c

7"w c

(17,4mbar)

11"w c

(27,4mbar)

7"w c

(17,4mbar)

11"w c

(27,4mbar)

7"w c

(17,4mbar)

11"w c

(27,4mbar)

7"w c

(17,4mbar)

11"w c

(27,4mbar)

Page 4

USA

3. PRECAUTIONS

• The following terms alert you to potentially dangerous conditions

to the operator, service personnel or to the equipment.

• Danger! This term warns of immediate hazards which will result in

severe injury or death.

• Warning! This term refers to a potential hazard or unsafe

practice which could result in injury or death.

• Notice. This term refers to information that needs special

attention or must be fully understood, even though not dangerous.

• Keep the appliance area free and clear from combustibles.

Warning

For your safety, do not store or use gasoline or other

flammable, vapors and liquids in the vicinity of this or any other

appliance.

Keep area around appliances free and clear of combustibles

Warning!

Failure to properly vent the oven can be hazardous to the

health of the operator; and will result in operational problems,

unsatisfactory baking, and possible damage to the equipment.

Damage sustained as a direct result of improper ventilation will

not be covered by the Manufacturer's warranty.

NOTICE: INTENDED FOR COMMERCIAL USE ONLY. NOT

FOR HOUSEHOLD USE.

CAUTION: Do not locate unit adjacent to any high heat or

grease producing piece of equipment, such as a range top,

griddle, fryer, etc., that could allow radiant heat to raise the

exterior temperature of the Oven.

Fire hazard.

CAUTION HOT SURFACES

CAUTION RISK ELECTRIC SHOCK

Important: The installation instructions contained herein

are for the use of qualified installation and service

personnel only. Installation or service by other than

qualified personnel may result in damage to the appliance

and/or injury to the operator. FAILURE TO COMPLY

WITH INSTALLATION INSTRUCTION OR IMPROPER

INSTALLATION WILL VOID WARRANTY AND

RESPONSIBLITIES OF THE MANUFACTURE.

• Our appliances have been studied and optimized to give the

highest performance. This appliance is intended for industrial use

only and is specifically designed to cook food. Any other use will be

considered “improper use” and will void the warranty and

manufacturer liability.

• This appliance is not intended for use by people (including

children) with limited physical, sensory or mental abilities or without

experience and knowledge of it, unless they are supervised or

instructed in its use by a person responsible for their safety.

WARNING: ANY POTENTIAL USER OF THE EQUIPMENT

SHOULD BE TRAINED IN SAFE AND CORRECT OPERATIONG

PROCEDURES.

WARNING: BEFORE SERVICING, DISCONNET THE

ELECTRICAL SERVICE AND PLACE A RED TAG AT THE

DISCONNECT SWITCH TO INDICATED WORK IS BEING DONE

ON THAT CIRCUIT.

NOTICE: Using any parts other than OEM original spare parts

relieves the manufacturer of all warranty and liability.

NOTICE: Manufacturer reserves the right to change specifications

at any time without notice.

Failure to comply with the above requirement may jeopardise

the safety of the appliance and invalidate the guarantee.

WARNING: DO NOT SPRAY THE OUTSIDE OF THE

APPLIANCE WITH WATER OR CLEAN WITH A WATER JET.

CLEANING WITH A WATER JET CAN IMPREGNAT

CHLORIDES INTO THE STAINLESS STEEL, CAUSING THE

ONSET OF CORROSION.

• Carefully read this instruction booklet, as it contains important

advice for safe installation, operation and maintenance.

• Keep this instruction booklet in a safe place for future reference.

• The installation of this unit must conform to local codes or, in the

absence of local codes, to all National Codes governing plumbing,

sanitation, safety and good trade practices.

WARNING: The equipment warranty is not valid unless the

appliance is installed, started and demonstrated under the

supervision of a factory trained installer.

WARNING: The unit must be installed by Personnel who are

qualified to work with electricity and plumbing. Improper installation

can cause injury to personnel and/or damage to the equipment.

The unit must be installed in accordance with applicable codes.

WARNING: DO NOT USE PRODUCTS CONTAINING

CHLORINE (BLEACH, HYDROCHLORIC ACID ETC.) EVEN

DILUTED, TO CLEAN STEEL SURFACES.

WARNING: DO NOT USE CORROSIVE SUBSTANCES (E.G.

MURIATIC ACID) TO CLEAN THE FLOOR UNDER THE

APPLIANCE.

12

5938 036 01

Page 5

4. SAFEGUARDING THE ENVIRONMENT

4.1 PACKAGING

• All the packaging materials used are environmentally safe and

friendly. They may be stored without fear or danger. They may be

recycled or burned in a special waste incineration plant. Recyclable

plastic components are marked as follows:

polyethylene : external wrapping film, instructions

PE booklet bag and gas injectors bag

polypropylene: top packaging panels and straps

pp

expanded polystyrene: protective surround elements

PS

4.2 USE

• The appliance has been designed and perfected under laboratory

testing conditions to offer exceptional levels of performance.

However, to minimise energy consumption (electricity, gas and

water), do not leave the appliance in operation for long periods

without food in the oven chamber and avoid conditions that

reduce efficiency (e.g. door open). We also recommend preheating

the appliance immediately prior to use.

USA

4.3 CLEANING

• To minimise the emission of pollutants into the environment,

clean the appliance (externally and, where necessary, internally)

with products that are at least 90% biodegradable.

4.4 DISPOSAL

• Appliances that have reached the end of their service life should

be suitably disposed of.

• The appliance is made from more than 90% recyclable materials

(stainless steel, iron, aluminium, galvanised sheet steel, etc.).

These materials may therefore be scrapped in accordance with

local waste disposal regulations at a conventional recycling plant.

• Make the appliance unusable by cutting off the power cord. Also

remove any compartment or interior closure device fitted on the

appliance to prevent persons from becoming trapped inside.

5938 036 01

13

Page 6

USA

II. INSTRUCTIONS FOR INSTALLATION

Important: The oven outer panels must be removed to

perform the operations described in this chapter. Since the

appliance must be switched on to make certain

adjustments, exercise the utmost care when working in the

vicinity of live electrical parts.

1. PLACE OF INSTALLATION

1.1 VENTILATION

The necessity for a properly designed and installed ventilation

system cannot be over emphasized. The ventilation system will

allow the unit to function properly while removing unwanted vapors

and products of combustion from the operating area.

The appliance must be vented with a properly designed mechanically

driven exhaust hood. The hood should be sized to completely

cover the equipment plus an overhang of a least 6"/15.3cm on all

sides not adjacent to a wall. The capacity of the should be sized

appropriately and provisions for adequate makeup air.

Refer to your local ventilation codes. In the absence of local codes,

refer to the National ventilation code titled, “Standard for the

Installation of Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equipment”, NFPA-96Latest Edition.

It is recommended that the ventilation system and duct work be

checked at prevailing intervals as specified by the hood manufactured

• The appliance must only be installed in adequately ventilated

premises.

NOTICE: Proper ventilation is the owner's is responsibility. Any

problem due to improper ventilation will not be covered by the

warranty.

1.2 REFERENCE STANDARDS

Note: The electric supply installation must satisfy the requirements

of the appropriate statutory authority, such as the National

Electrical Code (NEC) ANSI/NFPA70, (U.S.A..): the Canadian

Electrical Code, CSA C22.2; or other applicable regulations.

Note: The electric supply connection must meet all national and

local electrical code requirements.

Note: The installation of this unit must conform to local codes or,

in the absence of local codes, to all National Codes governing

plumbing, sanitation, safety and good trade practices, and to the

National Gas Code ANSI Z223.1.

• Local codes regarding installation vary greatle from one area to

another. This equipment is to be installed to comply with the

applicable federal, state or local codes.

The installation instructions contained herein are for the use of

qualified installation and service personnel only. Installation or

service by other than qualified personnel may result in damage to

the appliance and/or injury to the operator.

FAILURE TO COMPLY WITH INSTALLATION INSTRUCTION

OR IMPROPER INSTALLATION WILL VOID WARRANTY AND

RESPONSIBLITIES OF THE MANUFACTURE.

The National Fire Protection Association, Inc states in its NFPA

96 latest edition that local codes are the "authority having

jurisdiction" when it comes to installation requirements for

equipment. Therefore, installations should comply with all local

codes.

1.3 UNPACKAGING

• Remove the appliance from the packaging and take away the

protective film that covers the appliance's external panels carefully to avoid leaving any trace of glue. If necessary remove the

glue using an a non-corrosive solvent, rinsing it off and drying

carefully.

• Dispose of packaging material in compliance with the regulations

in force in the country where the product is to be used.

1.4 IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

The container should be examined for damage before and during

unloading. The freight carrier has assumed responsibility for its

safe transit and delivery. If damaged equipment is received,

either apparent or concealed, a claim must be made with the

delivering carrier. Apparent damage or loss must be noted on the

freight bill at the time of delivery. The freight bill must then be

signed by the carrier representative (Driver). If the bill is not

signed, the carrier may refuse the claim. The supply can supply

the necessary forms. A request for inspection must be made to

the carrier within 15 days if there is concealed damage or loss that

is not apparent until after the equipment is uncrated. The carrier

should arrange an inspection. Be certain to hold all contents plus

all packing material. Under no circumstances should a damaged

appliance be returned to the manufacturer without prior notice

and written authorization.

2. POSITIONING

• Refer to the installation diagrams at the beginning of this

booklet for the space requirements and connection dimensions of

the appliance.

• Clearance of approximately 23.62" (50cm) must be left between

the appliance’s left side panel and adjacent structures in order to

provide space for maintenance operations when needed; the

right side panel and the rear panel of the appliance must be at

least 3.94" (10cm) from adjacent structures.

• Place the appliance in the required position and level the oven

with a slight pitch toward the rear to help drain water from

chamber using the appropriate bullet feet.

• The appliance is not suitable for built-in installation.

Warning: The oven must be installed on an even (level) nonflammable flooring and any adjacent walls must be non-flammable.

Recommended minimum clearance are specified in this manaul.

Important:

Make sure steam from the oven’s drain or adjacent

appliances does not enter the aeration vents under the

appliance, designed to cool internal components

located at the bottom of the appliance.

3. COMBUSTED GAS DISCHARGE

3.1 FOREWORD

In relation to the combustion technology utilised, gas fired steam/

convection ovens are classified in accordance with their

"Construction Type". For each of these types of appliances

applicable regulations stipulate a specific type of combusted gas

discharge system.

Consequently, before installing the discharge system:

a) identify the "Construction type" of your model in Table 1

(technical data) or by checking the appliance identification

dataplate;

b) choose the diagram with the type of construction among

those shown as follows (fig. 1a-1b-1c), depending on how you

intend to exhaust the appliance fumes from the place of installation

(e.g. discharge under extraction hood, direct to the outside, or in

a central flue).

5938 036 01

14

Page 7

USA

3.2 WARNINGS REGARDING THE FLUING SYSTEM

Before installation check, on the basis of the contents of the

reference standard, to ensure that the volume aspirated by the

fumes exhausting system is greater than the volume of combusted

gas produced by the appliance (see point 1.1).

If the solution of combusted gas discharge under an extractor

hood is chosen, observe the distance (shown in the figure)

between the top of the discharge pipe and the lowest point of the

hood filters. This distance is defined on the basis of discharge

pipe diameter "D".

In the case of discharge direction to the outside or into a central

flue (Fig. "1c"), the discharge ducts must NOT present an overall

length in excess of 762"(3 metres), must NOT have any reductions

in diameter, and must be subjected to periodic inspection and,

when necessary, cleaning.

Warning: Since combusted gas (see figure) can reach very

high temperatures, check the heat resistant properties of

extension ducts if fitted and the filters in the extractor hood

to ensure the materials are compatible with the temperature

conditions. In addition, periodically check the condition of

the filters which, if excessively fouled with fat and dirt, will

reduce the efficiency of the suction system and may catch

fire.

3.3 INSTALLATION OF ACCESSORIES

Accessories can be easily installed by following the figures below

together with the relative key.

The screw holes for fixing accessories "A" and "F" are 0.14"(3.5

mm) in diameter and they must be drilled in-situ on the oven cover

in correspondence with the punch marks.

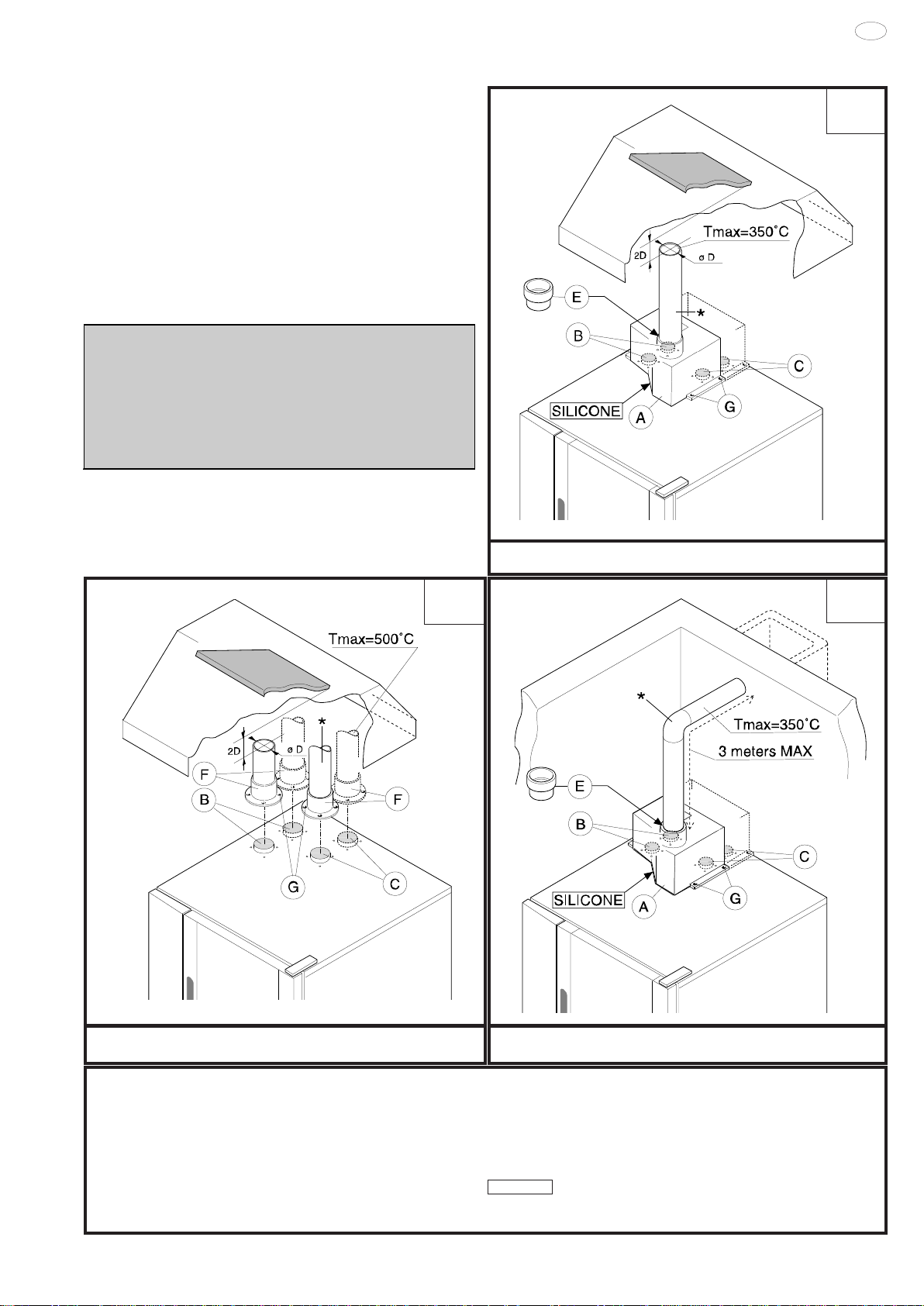

CONSTRUCTION TYPE

B13

DISCHARGE WITH SHROUD UNDER EXTRACTOR HOOD

1b

CONSTRUCTION TYPE

A3

1a

CONSTRUCTION TYPE

B13

1c

DIRECT UNDUCTED DISCHARGE UNDER EXTRACTOR HOOD

LEGENDA:

A: Cam / draught damper accessory

(to be ordered from manufacturer)

B: Boiler combusted gas discharge

C: Oven chamber convector combusted gas discharge

E: Adapter ring for commercial ducts

(to be ordered from manufacturer)

5938 036 01

DISCHARGE TO THE OUTSIDE OR CENTRAL FLUE WITH SHROUD

F: Conical connections for single outlet (supplied)

(always install)

G: Fixing screws (supplied);

*: Commercial extension pipes (not supplied)

SILICONE :

Apply silicone sealant between contact surfaces

15

Page 8

USA

4. ELECTRICAL CONNECTION

• A fused disconnect switch or main circuit breaker (customer

furnished) MUST be installed in the electric supply line for the

appliance. It is recommended that this switch/circuit breaker

have lockout/tagout capability. Before making any electrical

connections to this appliance, check that the power supply is

adequate for the voltage, amperage, and phase requirements

on the rating plate.

• A safety cutout switch of suitable capacity with a contact

breaking distance of at least 3 mm must be fitted upstream of

the appliance.

The cutout switch must be installed near the appliance in the

permanent electrical system of the premises.

• The appliance must be electrically grounded in accordance

with local codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.2, as applicable.

The grounding conductor must therefore be connected to the

terminal marked Gon the connection terminal board. The

appliance must also be connected to an earth grounding

system.

This connection is made using the stop screw marked E

located on the outside of the appliance near the power cable

inlet.

The grounding wire must have a minimum cross-section of

8 AWG (10 mm

2

).

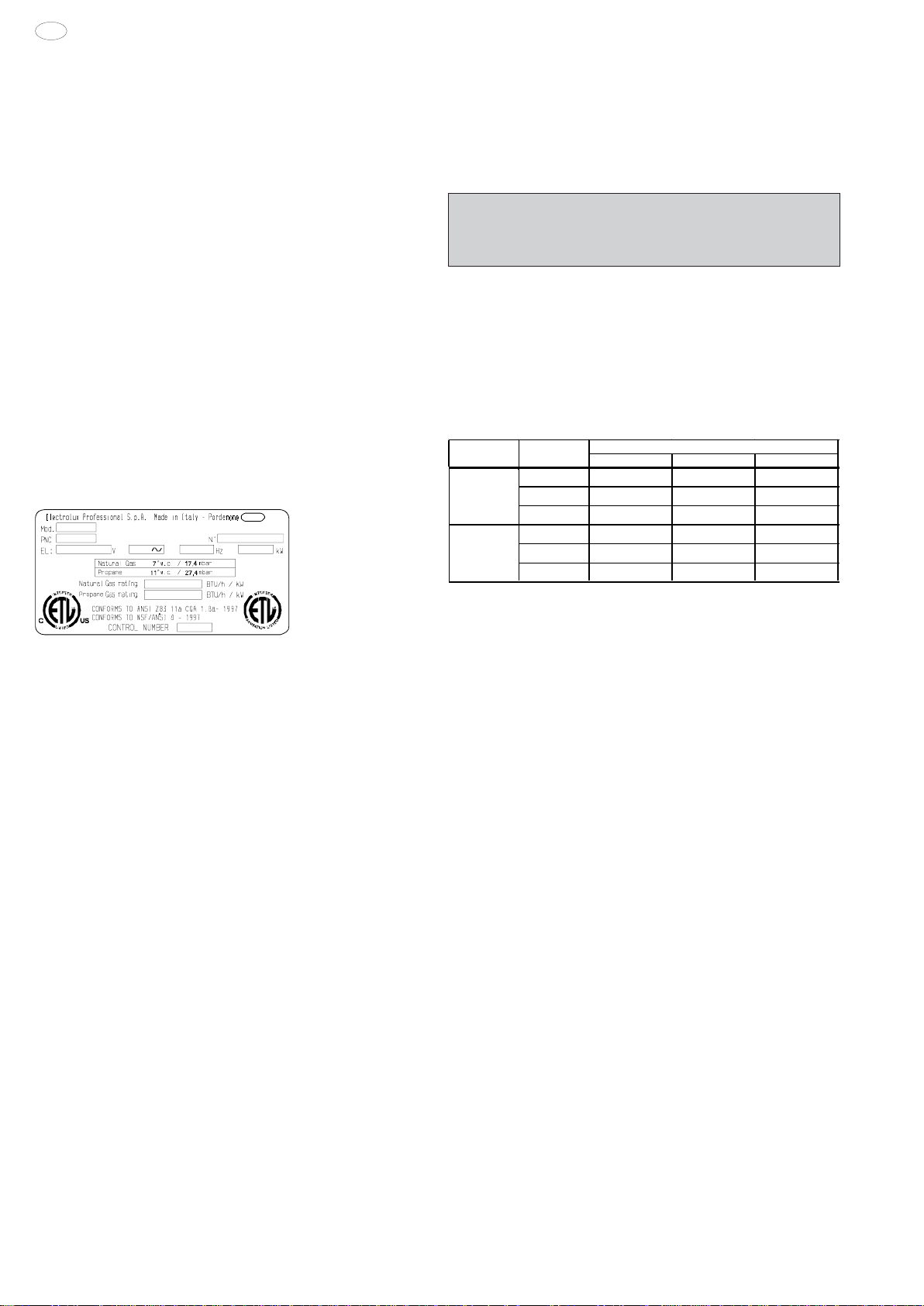

RATING PLATE

4.1 INSTALLING THE POWER SUPPLY CABLE

To access the power supply cable connection terminal board,

proceed as follows:

Model 6 - 10 - 20 GN

• Remove the left side panel.

• Connect the power supply cable to the terminal board accord-

ing to the instructions given in the wiring diagram and fasten the

power supply cable by means of strain-relief fitting (not furnished

with the oven).

Failure to comply with safety rules and regulations relieves

the manufacturer of all liability.

The manufacturer requires when stacking units each appliance

have its own branch circuit protection. An oven unit stacked with

an blast chiller unit should have a separate protection for the upper

and lower units.

5. WATER MAINS CONNECTION

(Refer to the installation diagrams at the beginning of this booklet).

This equipment is to be installed to comply with the applicable

Federal, State, Local plumbing codes, or the Basic Plumbing

Code of the Building Officials and Code Administrators

International Inc. (BOCA) and Food Service Sanitation Manual

of the Food and Drug Administration (FDA).

When connecting the appliance to the water system with

flexible tubes they must be new and not used.

The appliance is fitted with two separate water inlets ("B" and "N").

The water lines supplying both inlets must be fitted with a

mechanical filter and shut-off valve (keeping with local plumbing

codes).

Before fitting the filters allow the water to flow out for sufficient time

to flush any solid particles from the piping.

Pressure between 22 and 65 psi (150-450 kPa).

WATER INLET “N”

Attention (water inlet N)

If the supply pipes provided with the appliance are not long

enough for installation, use longer ones with int. diameter at

least 3/4" (20 mm) and free of elbow unions.

Note:

To check correct water installation, make sure the rotating wash

arm (CLEANING SYSTEM) does not turn below 100 rpm (120

max).

5.1 WATER SUPPLY CHARACTERISTICS

The appliance must be supplied with drinking water having

specific characteristics given in this section.

HARDNESS FILTER

Water

in le t

B

N

^ OPERATING LEVEL (C = Convect, Convection).

The hardness values given in the table are for reducing scaling

inside the steam generator and possible cooking compartment

washing system.

If the available water does not have these hardness characteristics

a water softener must be installed.

Therefore the Automatic Water Softener with automatic

regeneration for installing on the inlet line, can be requested as

an accessory; it has a Resin Sterilizer kit (also by request).

HARDNESS AND CHLORIDE FILTERS

The chloride concentration (Cl-) (ppm - mg/l) values with pH

(>7) and Conductivity (µS/cm) (measured at 68°F)(20°C) must

be such as to not damage the steel structures inside the oven

(only water inlet B).

Therefore the characteristics of the available water must be

identified in the graph given at the end of this handbook (page

107), if necessary installing at the inlet the type of filter indicated

in the relevant area of the values.

The filters indicated are:

- No filter for chloride (Cl-) in the conforming area (Normal)

- Nanofilter

as an accessory on request, called Water Filter.

- Osmotizer.

Make sure the water coming out the filter is inside the optimum

area (Normal).

These filters also have the function of reducing the water

hardness to optimum values (below 50ppm)(5°fH), and therefore

also act as a water softener.

ATTENTION: Periodical checking according to the filter

manufacturer’s instructions is important to maintain its efficiency

and avoid the risk of corrosion in the appliance.

Level C ovens are convection ovens. If water having

characteristics outside those specified is used to create humidity

inside the oven, there will be the risk corrosion of the compartment

and that present inside it.

Carry out regular maintenance of the water softeners and filters

to ensure their optimum efficiency.

To avoid damage to the appliance, after every periodical

regeneration do a filter cleaning cycle without introducing water

in the oven.

Appl. Hardness

°f pp m °dH

A ^ 0,5 - 5 5 - 50 0,28 - 2,8

B ^ 0,5 - 5 5 - 50 0,28 - 2,8

C ^ m ax 5 m ax 50 m ax 2,8

A ^ m ax 5 m ax 50 m ax 2,8

B ^ m ax 40 m ax 400 m ax 22

C ^ m ax 5 m ax 50 m ax 2,8

5938 036 01

16

Page 9

The manufacturer declines any liability in case of incorrect

maintenance.

Important:

The use of dosing systems designed to prevent the buildup of lime-scale in pipes (i.e. polyphosphate dosing

systems) is prohibited since such systems may impair the

performance of the appliance.

5.2 WATER DRAIN SYSTEM

- OVEN level A -

The oven is supplied with an air-break system to prevent any

backflow from the drainage system from reaching the oven’s internal circuits and the cooking chamber. The presence of this

system means that the drain pipe can be connected directly to

the mains drainage system or routed to a floor gulley with grating.

The flexible drainage hose or rigid pipe can be directed to the

side or rear of the appliance if the oven is not positioned against

a wall; this line must not be directed towards the front of the

appliance to prevent interference with roll-in grid racks. The drainage pipe internal diameter must be no smaller than the oven

drain outlet (1 1/4"), no longer than 3 feet (1 metre) and must

resist temperatures of up to at least 212°F (100°C). Avoid restrictions in the case of flexible hose pipes, do not fit elbows on

metal pipes anywhere along the drainage line. Also avoid

horizontal sections in which water might collect (minimum gradient 5%).

WARING: BLOCKING THE DRAIN IS HAZARDOUS.

C - Oven drain

C1 - Safety outlet

USA

OK

max 3m

min 0,5m

0,08 m

AIR-BREAK

C

min 5°

T max = 100°C

O

AIR-BREAK

C

O

KO

6. GAS CONNECTION

6.1 WARNINGS

• Make sure the appliance is set up for the type of gas with

which it will be supplied.

• The gas inlet connector is yellow in colour.

• Before installing consult your local gas utility company to check

the compatibility between the available supply and the

consumption of the appliance.

• Before hooking up the appliance to the gas pipeline remove the

plastic protective plug from the gas connector.

• Fit a rapid gas shut-off cock upline from the appliance in an

easily accessible position.

• On completion of installation, use soapy water to check gas

connections for leaks.

• It is not possible to adjust the combustion air ventilation capacity.

• If the appliance is hooked up to a supply with a different gas type

with respect to the factory setting, after making the necessary

changes check that it is working correctly (see heading 8

"Operation Check").

Important:

- Do not obstruct the safety outlet C1.

- Do not connect the safety outlet C1 to the drainage system.

Note:

If water comes out of the AIR-BREAK (safety outlet C1) this means

the drain C is blocked. Any elimination of the obstruction must

be carried out by specialised technical personnel.

- OVEN level C -

Connect drain fitting “C” to a drain pipe of the same diameter

which is between 0.5 and 3 metres in length and is resistant to

temperatures of at least 100°C. The drain pipe must be siphoned

(height 80 mm) to an open drain “O” (“Air-Break”) or floor grating

(see Fig. 12b) in order to prevent any back-flow from the sewage

system from reaching the piping inside the oven or oven chamber.

Check the hoses and elbows on metal pipes for kinks or pinching

along the entire drain line and make sure the drain line has a

minimum gradient of 5° to prevent water from collecting inside

the system.

Important: The drain system must be installed so that any

vapours from the open drain do not enter the aeration vents

under the appliance.

5938 036 01

6.2 NOMINAL HEAT OUTPUT

For data concerning the nominal heat output refer to "Technical

Data" in Table 1.

This parameter is determined by the pressure of the gas supply

and the diameter of the gas valve diaphragm (nozzle).

The appliance nominal heat output must always be checked (by

the authorised installer or by the gas utility company), both in the

case of new installations or following maintenance work.

It is strictly prohibited to make changes to the nominal heat output.

6.3 CHECKING THE SUPPLY PRESSURE (Fig. 2a)

The gas supply pressure must be measured upline from the gas

shut-off cock with the appliance operating, using a pressure

gauge with minimum resolution of 0.1 mbar and proceeding as

outlined below:

1) Remove the left hand side panel to gain access to the gas valve;

2) Loosen sealing screw "C" from the gas valve pressure test point

and connect the pressure gauge hose in its place;

3) Open the gas shut-off cock;

4) Start a mixed cooking cycle (see "Instructions for use") in

such a way that all the burners can be lit;

5) Check that the pressure reading is within the values given in

the following table:

GAS TYPE PRESSURE (MBAR)

Nom. Min. Max.

NATURAL

PROPANE

If the values are not within the values shown in the table the

appliance will not function.

7"wc (17,4mbar) 3"w c (8,7mbar) 10"wc (26,1m bar)

11"wc (27,4mbar) 8"wc (19,9mbar) 13"wc (32,3,4mbar)

17

Page 10

USA

C

E

D

E1

In this case inform your gas utility company of the problem;

6) Once you have measured the supply pressure stop the cooking

cycle and close the gas shut-off cock.

7) Disconnect the pressure gauge and carefully refit and tighten

sealing screw "C";

8) Refit the previously removed side panel.

2a

7. SAFETY DEVICES

The appliance is fitted with the following safety devices:

- Fuses (see electrical circuit diagram) located behind the control

panel.

To change a fuse unscrew and remove the retainer cap and

replace the blown fuse with an identically rated component; the

fuse rating value is specified on the relative dataplate.

- Oven chamber safety thermostat with manual reset, located

behind the control panel; when this device trips, convection

heating power is disconnected.

Notice: CONTACT YOUR AUTHORIZED SERVICE COMPANY

TO PERFORM MANINTENANCE AND REPAIRS.

- Automatic reset thermal protection inside the cavity fan

motor: this device trips in the event of overheating of the cavity

fan motor; this cut-out protects the appliance by disconnecting the

power supply to the main PC board and an error message is display

EFUN.

8. OPERATION CHECK

- Switch on the appliance in accordance with the following

section "Instructions for use".

- With the aid of the Instruction Booklet, explain operation,

routine maintenance, and cleaning to the user.

Important:

- Exercise due care since certain areas of the oven exterior

become hot during use.

- Do not cover the exhaust outlets on top of the appliance.

9. SERVICING

All components requiring routine maintenance may be easily

reached by opening the control panel, removing the left side

panel, or removing the rear panel.

Danger: Live voltage is present with panels removed and unit

switch on. Exercise extreme caution when work with live voltage.

NOTICE: Using any parts other than OEM original spare parts

relieves the manufacturer of all warranty and liability.

10. TROUBLESHOOTING

Malfunctions may occur even when the appliance is used correctly.

Burner fails to light (message "burn" appears on display TM ,

see "Instructions for use" chapter 5).

Possible causes:

- The ignition electrode is incorrectly positioned or the insulation

is damaged.

- The ignition / flame control device is damaged.

- The ignition electrode high tension lead is broken or shorting

to ground.

- Insufficient gas pressure.

- Faulty gas valve.

- Burner fan unit damaged, insufficient air pressure in combustion

chamber.

- Electronic control panel is damaged.

- Blown fuse, check electrical diagram.

- Oven chamber temperature probe damaged (error EPt1 - see

"Instructions for use" chapter 5).

- Temperature limiter trip.

- High room air humidity (condensation): ventilate the kitchen.

Burner flame extinguishes (message "burn" appears on display

TM, see "Instructions for use" chapter 5).

Possible causes:

- Power supply polarity (Phase/Neutral) inverted.

- Electrical supply to oven is "Phase/Phase" type. In this case fit the

special "Transformer Kit" available from the manufacturer on request.

- Faulty gas valve.

- Flame detector electrode incorrectly positioned or in open

circuit.

- Burner fan unit damaged (lockout situation).

- Flame control device damaged

- High room air humidity (condensation): ventilate the kitchen.

Oven chamber temperature thermostat control is incorrect.

Possible causes:

- Electronic control panel faulty.

- Oven chamber temperature probe is dirty, faulty, or interrupted,

see error EPt1 (see "Instructions for use" chapter 5).

Oven fails to turn on. Possible causes:

- Electronic control panel is damaged.

- Fuse F2 blown due to damaged control circuit components.

Oven chamber lamps damaged

CAUTION: Before changing oven chamber lamps switch off the

appliance.

11. LAYOUT OF MAIN COMPONENTS

(All work inside the appliance must be carried out exclusively

by a trained installer authorised by the manufacturer)

Removing the control panel provides access to the following

components:

Danger: Live voltage is present with panels removed and unit

switch on. Exercise extreme caution when work with live voltage.

- Electronic circuit boards

- Oven chamber temperature limit thermostat

- Fuses

- Door microswitch

- Oven chamber lamp transformer

- Geared motor for the oven chamber pressure relief butterfly valve.

WARNING: Before servicing unit switch off power at the main

circuit breaker and place a red tag on the breaker to indicate work

is being done on the circuit.

Remove the appliance left hand side panel to gain access to all

the other components.

5938 036 01

18

Page 11

III. INSTRUCTIONS FOR USE

Before switching on the appliance, read this instruction booklet

carefully because it contains important information concerning

correct use of the appliance. If you require further information

about the oven's features and cooking performance, consult your

local dealer.

ANY POTENTIAL USER OF THE EQUIPMENT SHOULD BE

TRAINED IN SAFE AND CORRECT OPERATING PROCEDURES.

• This appliance is intended for industrial use only and is specifically

designed to cook food. Any other use will be considered "improper

use" and will void the warranty and manufacturer liability.

• Do not place pans or utensils on top of the oven. Avoid

obstructing the fumes and steam exhaust outlets.

• Do not insert objects (eg, trays) below the bottom of the oven

so as not to obstruct the holes of entry or exit of cooling air.

• Periodically the appliance should undergo a general inspection.

For this purpose we recommend taking out a service contract.

• The core temperature probe is a precision instrument and must be

handled with care. Avoid knocks, do not apply excessive force when

inserting the probe, and do not pull on the lead (take care particularly

when using roll-in racks). The warranty e does not cover damage to

the temperature probe caused by improper use.

• When using the mixed cooking cycle, do not exceed cooking

temperatures of 392-410°F. Higher temperatures might impair

the performance of the oven chamber seals.

• When placing food in the oven leave a gap of at least 1.5"(40 mm)

between each pan to facilitate circulation of hot air.

• If the oven is installed near appliances that produce greasy

fumes (e.g. fryer), make sure to use the air filter (not supplied),

to be placed under the control panel, to protect the internal

electronic components.

• During preheating of the oven 20 GN 1/1 or 2/1, insert the trolley

(without food) to close the bottom opening between the

compartment and door. This prevents steam from coming out

and into the control panel with consequent damage to the

electronic board.

• Do not add salt to foods when inside the oven chamber,

particularly during cooking cycles with humidification.

• Do not cook with flammable liquids such as alcoholic spirits.

USA

MODELS with SAFETY SYSTEM (by request)

The oven is equipped with a safety system to protect the user

against scalding steam when the door is opened wide. Proceed

as follows:

a) Turn the oven door handle clockwise as far as it will go.

The door opens slightly and is arrested by the door safety

device.

If there is a cooking program in progress it will be interrupted.

b) Turn the handle all the way counter-clockwise to open

the oven door fully.

Attention

Cooking containers can not be inserted at a height greater than

63" (1.6m) from the level where the user operate.

If supporting accessories other than the original ones are to be

used, do not exceed the above specified height since this

could result a spill hazard caused by hot cooking liquids

(sauces, oil, melted fat, etc...) contained in the uppermost pans,

which are not visible during handling operations.

1. OPENING THE OVEN DOOR

1.1 6- AND 10-GRID MODELS

Important! Risk of burns.

Open the door with due care when the appliance is hot.

a) Turn the door handle all the way in either direction (indifferently)

to fully open the oven door.

If there is a cooking program in progress it will be interrupted.

5938 036 01

1.2 20-GRID MODELS

Important! Risk of burns.

Open the door with due care when the appliance is hot.

a) Turn the handle 90° anticlockwise to open the door fully.

If there is a cooking program in progress it will be interrupted.

2. CLOSING THE OVEN DOOR

2.1 6- AND 10-GRID MODELS

To close the oven door press it until it locks.

2.2 20-GRID MODELS

a) Turn the door handle anticlockwise as far as it will go and

press the door closed against the oven.

b) Keeping the door pressed closed, lock it by turning the

handle to the vertical position.

19

Page 12

USA

3. DESCRIPTION OF THE CONTROL PANEL

3.1 INTRODUCTION

To aid understanding of the operation of the oven, find the folding

double page showing the control panel for your model among

those included at the back of this handbook and then open it out

and keep it open while reading this section.

The following headings describe all the functions available on the

various models in the range.

Some functions are shared by all models, others are available

on specific models.

Timer to control cooking time.

Digital thermometer/thermostat: to control product core tem-

perature.

3.2 MAIN CONTROLS

Main switch

Cooking cycle/program start/stop.

3.3 MAIN COOKING MODES

/

Air-convection cycle: To roast and gratin with a maximum

temperature of 572°F(300°C)

Mixed cycle: superheated steam. Uses the oven chamber heaters

and steam generation system at the same time to keep food soft

(maximum temperature 482°F)(250°C).

3.4 SPECIAL COOKING MODES

Utilities

Functions useful for the type of cooking to be executed.

Pause phase: set a time in this mode to delay the start of cooking

programs or to set a pause interval between two cooking cycles

(e.g. for dough proving).

Regeneration cycle: gives ideal humidity conditions for rapid

heating of products to be regenerated (maximum temperature

572°F)(300°C).

The regeneration program is composed of a single phase with the

following characteristics:

- a special cycle with controlled humidity of 20 % (adjustable if

required);

- preset temperature of 248°F (120°C)(can be altered if necessary);

- use of maximum power;

- a preset time of 30 minutes (adjustable if required) and once

started, remains active with door open or closed.

DANGER: CAVITY FAN AND STEAM WILL CONTINUE TO

OPERATE WHEN DOOR IS OPEN. WHEN IN

REGENERATION CYCLE. OPEN DOOR SLOWLY TO

AVOID THE RISK OF BURNS.

Steaming cycle: ideal for steam cooking (operating temperature

automatically set at 212°F)(100°C).

You can set low temperature steam for gentle cooking of foods

in vacuum packs and for thawing (temperature from 77°F to

210°F)(25° to 99°C).

Displaying the humidity value: allows you to display the humidity

level of the air-convection, mixed and regeneration cycles.

Digital thermometer/thermostat: to control the temperature in

the oven chamber.

Alternatively to the set cooking time it can also accept Cont

cooking time or the core probe.

HOLD

Cook and hold cycle: for long slow cooking, typically for meat

(

large piece of meat for roasting).

It can be used in combination with convection, mixed, steam

and regeneration modes.

Fan operation is intermittent.

HACCP

HACCP: serves to record the cooking program in compliance with

HACCP standards (Hazard Analysis and Critical Control

Points). Depending on the system requested you can record

cooking data on a dedicated printer or directly on a PC.

Clean Cycle: automatic or semiautomatic oven cleaning cycle

(see section 7. CARE AND MAINTENANCE).

20

5938 036 01

Page 13

Low speed cycle (fan): for delicate cooking such as for baking

cakes. Can be combined with any other cycle.

USA

/

Automatic sequence phases: to execute a 2-phase cooking

cycle switching from one phase to the other automatically

(LEVEL C ONLY).

Reduced power cycle (heating): for delicate cooking such as for

baking cakes. Can be combined with any other cycle.

Cooking with ECO-DELTA: for cooking large pieces of food (5kg

and above, e.g. whole turkey, leg of pork, etc.).

In this cooking mode a temperature setting of between 1°C and

120°C is chosen.

In this case, cooking is moderate and long, because the CHAMBER temperature is automatically adjusted according to that

inside the food (CORE PROBE), maintaining a constant difference (ECO-DELTA) between them, from start to end of cooking.

E.g:

COOKING: START ...... END

ECO-DELTA = 80°... 80...80... 80... 80°C (set)

CORE PROBE = 10°... 11...12... 40... 60°C (set)

CHAMBER = 90°... 91...92... 120... 140°C

(result)

Air-convection cycle with oven chamber vent open: suitable

for very dry cooking cycles; allows evacuation of humidity when

necessary (maximum temperature 572°F)(300°C).

3.5 ADDITIONAL FUNCTIONS

Set of controls for management of the programs library:

control keys to store, edit or delete cooking programs (LEVEL A

only).

Program selector : to find and select the cooking programs stored

in the memory (LEVEL A only).

Manual water injection into cooking chamber: serves to boost

humidity levels during the cooking cycle.

Door open indicator LED.

Limescale LED: when this LED starts flashing the boiler needs to

be descaled. Follow the instructions in section 7.

Boiler status LED:

- LED off: boiler ready;

- LED flashing: boiler filling or no water. Make sure the oven

water supply is working!

Cooking parameter adjustment: allows adjustment of cooking

values (humidity, temperature and time).

5938 036 01

Boiler manual water draining: press this button to drain the water

from the boiler.

Important! To prevent the build-up of lime-scale inside the

boiler:

Make sure the water supply corresponds with the required

characteristics - see Installation.

Always empty the boiler at the end of each day.

Rapid oven cooling: useful for passing from one type of cooking to

another that requires a lower temperature; it allows the fan to run and

automatic water (TS < 356°F)(180°C) injection even when oven

door is open.

Important! Risk of burns.

Open the door with due care when the appliance is hot.

Before using the oven check that:

- the external safety electric switch is on;

- the water and gas supply valve is open;

- the fumes and steam discharge outlets are not blocked.

21

Page 14

USA

USING THE OVEN

OPERATING LEVEL A and C

(C = Convect, Convection)

4. INTRODUCTION

Cooking of food is carried out by heating it and can be achieved in

a specific MODE, at a specific TEMPERATURE, a specific TIME

and HUMIDITY level. Therefore these parameters must be set in

order to execute a COOKING CYCLE.

On this basis, the oven functions mainly by carrying out the

operations shown in the following headings:

--- SETTING THE COOKING CYCLE ---

- SELECTING COOKING MODE

- SETTING COOKING TEMPERATURE

- SETTING COOKING TIME

- SETTING AND USING THE PROBE

- SETTING COOKING HUMIDITY

- COOKING CYCLE START

There are also several other headings illustrating support functions

such as:

- MANUAL CYCLE (CONTINUOUS COOKING)

- UTILITIES

- COOKING PHASES IN AUTOMATIC SEQUENCE

Lastly there is a heading describing the storage of cooking cycles

as recipes (e.g. CHICKEN RECIPE) or programs, entitled:

- STORING RECIPES OR PROGRAMS

4.2 SELECTING THE CONTROLS

(MANUAL or AUTOMATIC)

The control panel is divided in two parts, one for MANUAL controls

and the other additional section for AUTOMATIC controls .

MANUAL controls AUTOMATIC controls

Use one of the two control modes according to your cooking needs

in the level A oven.

The level C oven is equipped exclusively with MANUAL controls.

4.3 MANUAL CONTROLS

SETTING THE COOKING CYCLE

4.3.1 SELECTING COOKING MODE

After SWITCHING THE OVEN ON select one of the following

cooking modes by pressing the relative illuminated button (button

lights up):

4.1 SWITCHING THE OVEN ON

To switch the oven on press button I of this switch:

The following will occur:

- the relative button lights up;

- the control panel switches on and various functions flash;

- the Thermometer/Thermostat TS display shows the oven chamber

temperature;

- the oven chamber lamp switches on;

- boiler in filling

phase

- boiler ready

(flashing LED);

(LED off)

/

steam conv/steam air-conv.

Set the cooking parameters as indicated in the following

paragraphs.

Note:

The temperature and time displays flash for 5 seconds awaiting

setting; if no value is set, the preset value (default value) will remain

stored, which stops flashing.

4.3.2 SETTING THE COOKING TEMPERATURE

Press the following illuminated button (button lights up) to select

cooking temperature:

TS

The relative DISPLAY will show the TEMPERATURE in the

CHAMBER (large numbers) and the TEMPERATURE TO BE SET

(small numbers - flash for 5 seconds).

E.g.: 93°F

CHAMBER

TEMPERATURE

E.g.: 392°F

COOKING

TEMPERATURE

4.1.1 SWITCHING THE OVEN OFF

To switch the oven off press button O of this switch:

Turn the knob clockwise (to increase the value) or counter clockwise

(to decrease the value) to set the desired COOKING

TEMPERATURE in the small DISPLAY.

22

5938 036 01

Page 15

USA

d

e

After 5 seconds the COOKING TEMPERATURE stops flashing to

indicate that it has been SET.

Note 1

The temperature of the steam cycle is automatically set at

212°F(100°C). You can, however, set low temperature steam

from 77°F to 210°F(25° to 99°C) by turning the knob.

Note 2

With the COMBI cycle it is possible to do a dough proving cycle

by setting a temperature below 122°F(77 to 121°F), 50°C(25 to

49°C).

When the dough proving cycle is set as a first stage compartment

preheatingis excluded.

4.3.3 SETTING THE COOKING TIME

Press the following illuminated button (button lights up) to set

cooking time:

TM

The relative DISPLAY will show the TOTAL REMAINING TIME of

the cooking cycle (large numbers) and the TIME TO BE SET (small

numbers - flash for 5 seconds).

E.g. : 1 h 30'

TOTAL REMAINING

TIME

E.g..: 1 h 30'

CURRENT

REMAINING TIME

time LED on

Turn the knob clockwise (to increase the value) or counter clockwise

(to decrease the value) to set the desired cooking TIME on the small

DISPLAY.

After 5 seconds the COOKING TIME display stops flashing to

indicate that it has been SET.

Note:

In this case there is only one cooking cycle or phase so CURRENT

remaining time and TOTAL remaining time will coincide.

1) Switch on the oven.

Remove the product core temperature probe "C" from its seat "D"

and insert it into the product without forcing it and making sure that

the tip (sensitive element) is located in the proximity of the centre

of the product.

LEVEL C LEVEL A

probe with 1 sensor MULTIPOINT probe with 6 sensors

The LEVEL A oven is equipped with a MULTIPOINT probe with

6 sensors located at intervals along the wand, enabling the

correct temperature to be read in the centre of the product even

if the probe tip is not positioned at the product core.

Close the oven door.

2) Select the desired cooking cycle and set the cooking

temperature on thermostat TS.

Important: do not set the cooking time on Timer TM.

3) Set the TEMPERATURE of the CORE PROBE by pressing the

following illuminated button twice (button lights up):

PRB

The relative DISPLAY will show the PROBE TEMPERATURE

(large numbers) and the TEMPERATURE TO SET (small numbers

- flash for 5 seconds).

E.g.: 135°F

CURRENT PROBE

TEMPERATURE

4.3.4 SETTING AND USING THE PROBE (TO MONITOR

PRODUCT CORE TEMPERATURE)

This temperature probe allows high precision control of the

temperature reached at the core of the product being cooked so that

the desired value can be set and the cooking cycle stopped

automatically when the product core reaches the set temperature.

Important: The temperature probe is a precision

instrument and must be handled with care. Avoid knocks,

do not apply excessive force when inserting the probe, an

do not pull on the lead (take care particularly when using

roll-in racks). The guarantee does not cover damage to th

core temperature probe caused by improper use.

5938 036 01

E.g.: 176°F

REQUIRED

PROBE

TEMPERATURE

temperature probe

LED on

Turn the knob clockwise (to increase the value) or counter clockwise

(to decrease the value) to set the DESIRED PROBE

TEMPERATURE on the small DISPLAY.

After 5 seconds the DESIRED PROBE TEMPERATURE stops

flashing to indicate that it has been SET.

23

Page 16

USA

Note:

Press the button again to switch from the PROBE function to the

TIME function: the relative LED on the DISPLAY will light up.

4) Start the cycle. Press the Cooking Start/Stop button.

5) Stop the cycle. When the required product core temperature

reaches the set temperature the oven stops automatically as

described in heading 4.3.7 STOPPING THE COOKING CYCLE

and elapsed cooking cycle time is shown on the large DISPLAY.

7) Deactivating core probe mode. (Possible only with no cooking

cycle active). Set a cooking time on Timer TM.

Probe cooking mode is also deactivated when the oven is switched off.

At the end of the cycle total cooking cycle TIME is shown on the

large DISPLAY.

4.3.5 SETTING COOKING HUMIDITY

(Only in CONVECTION, MIXED and REGENERATION

cooking modes)

Attention

When switching on the oven after several hours in which it has

not been used, wait about 20 seconds (LAMBDA probe

stabilisation time) to ensure accurate reading of the HUMIDITY

value.

Note

To set humidity in AIR-CONVECTION cooking mode press the

relative cycle selection button twice.

After selecting AIR-CONVECTION or MIXED cooking mode the large

DISPLAY (LEVEL A only) will show OVEN CHAMBER HUMIDITY and

the small display (LEVEL A 1%...100% and C 1

/10...10/10) will show the

humidity to be SET (flashes for 5 seconds).

E.g.: 60 %

OVEN CHAMBER

HUMIDITY

E.g.: 80 %

COOKING

HUMIDITY

The displays will show:

- HU humidity inside the compartment;

- TS automatic compartment preheating (PrEH). To skip preheating press the START button again.

- TM time remaining for end of cooking / PRB core probe temperature.

Note: In TIMED cooking, during preheating the set cooking

time remains unchanged (COUNT-DOWN not activated).

At the end of preheating the message LOAD appears on the

display TS:

- open the oven door and load the food.

- close the door, and the message Strt (START) appears on the

display TS

- press the start cooking luminous button again; it will light up

(FIXED light);

Start COOKING CYCLE

(light FIXED)

(COUNT-DOWN activated)

Note:

- No cooking cycle will be available (steam, mixed, air-convection

or regeneration) until the boiler is ready (boiler LED switches off

- see heading 4.1).

During this interval the time count will not start and the Start

cooking button will flash (the same will occur when the oven door

is opened).

Important! Risk of burns.

Open the door with due care when the appliance is hot.

4.3.7 STOPPING THE COOKING CYCLE

When the set time has elapsed the cooking cycle will stop

automatically and the appliance's audible alarm will emit a

continuous beep.

Open the door and remove the product.

Important! Risk of burns.

Open the door with due care when the appliance is hot.

Note:

- The audible alarm can be muted by performing any operation on

the control panel or by opening the door.

To stop the cooking cycle manually press the cycle Start/Stop

button and keep it pressed for two seconds.

Turn the knob clockwise (to increase the value) or counter clockwise

(to decrease the value) to set the desired COOKING HUMIDITY on

the small DISPLAY.

After 5 seconds the COOKING HUMIDITY value stops flashing to

indicate that it has been SET.

4.3.6 STARTING THE COOKING CYCLE

- make sure the oven door is closed;

- press the luminous start cooking button, which will light up

(light FLASHING), for COMPARTMENT PREHEATING;

PrEH

Start COMPARTMENT PREHEATING

(light FLASHING)

If this button is pressed for less than 2 seconds it will produce no

result.

To repeat the last cooking cycle with identical parameters press

the Start/Stop button again.

4.3.8 MANUAL CYCLE (CONTINUOUS COOKING)

Manual cooking cycles can be set by excluding the timer. Follow

the instructions in heading 4.3.2 SETTING THE COOKING TIME

until the display shows the word "cont", i.e. continuous cooking

mode.

In this case the cooking cycle must be stopped manually by

holding down the Start/Stop button for two seconds or by switching

off the oven.

24

5938 036 01

Page 17

USA

4.3.9 UTILITIES

- Switch on the oven by pressing button I.

- Set a cooking cycle for the following UTILITIES:

UTILITIES with cycle presetting;

this is not necessary for the other utilities as they are already

specific cycles.

- Press button U (UTILITY):

U (UTILITY)

- The green UTILITY LEDs will light up and one will be flashing.

E.g.: UTILITY selected

(flashing GREEN LED)

- Turn the knob clockwise or counter clockwise to select the utility

required - the relative LED will flash (flashing GREEN color).

- Press button U until the flashing LED relative to the UTILITY

selected changes colour (flashing ORANGE color).

- Wait a further 5 seconds for the LEDs relative to the selected

utilities to illuminate steadily (steady ORANGE color).

- Finally, start the cycle by pressing the START/STOP button.

A complete description of the different UTILITIES available is

included in heading 3.4 SPECIAL COOKING MODES (page 20).

Note:

If the UTILITIES are not used for 7 seconds they are

automatically cut out, signalled by the relative button switching

off.

- To cancel one of the following preset UTILITIES (ORANGE

steady):

2) Set the desired cooking mode, oven chamber temperature,

and cooking time (or, alternatively, core probe temperature) as

described in this handbook.

3) Press the "1-2" /

"PHASE" button:

Phase 1 (I) LED

Phase 2 (II) LED

the phase 2 LED switches to RED (active phase) while the phase

1 LED is GREEN (inactive phase); at the same time the cooking

modes button LEDs start flashing again to request a new setting

for phase 2.

5) Select:

- phase 2 cooking mode;

- phase 2 oven chamber temperature;

- time (or core probe temperature) relative to phase 2;

6) The two-phase cooking cycle has now been set. Place the

product to be cooked in the oven and press the START/STOP

button to start the cooking cycle.

The cooking cycle will start from phase 1 (phase 1 LED RED) and

switch automatically to phase 2 (phase 2 LED RED) when the

first phase terminates.

When the oven switches from phase 1 to phase 2 the operator will

be alerted by a brief audible signal.

When phase 2 is terminated the cooking cycle will stop

automatically as already described.

4.3.11 Delta Cooking

This is an advanced method of cooking, by which the oven

chamber temperature varies in function of the core temperature

of the food.

The operator is able to select a delta value between 1°C <

120°C, we recommend using between 20°C < 70°C. The chamber

temperature will be adjusted to automatically remain above the

rising core temperature exactly by the set value.

This type of cooking is ideally suited to large joints of meat.

How to use it: Manual cooking mode.

1) Select the cooking mode, Ex.

2) Set a target core temperature value,

3) Go into advanced utility functions (Bottom row on Control

Panel) and select

ECO - Delta.

Combi.

press the U button and turn the knob to select it so that it flashes

(ORANGE flashing).

Press the U button again so that the UTILITY changes colour

(GREEN flashing) and is thus cancelled.

- To cancel the other UTILITIES set another cooking cycle.

In case of cycle already started, stop it, keeping the START/

STOP button pressed for 2 seconds before cancelling the UTILITY.

4.3.10 COOKING WITH TWO PHASES IN AUTOMATIC

SEQUENCE

(LEVEL C ONLY)

Level B ovens allow the execution of cooking cycles composed

of two sequential phases. For example:

- Phase 1: - air-convection 200°C

- probe 70°C

- Phase 2: - mixed cycle 220°C

- 40 minutes

The oven switches automatically from phase 1 to phase 2. To set

a two-phase cycle proceed as follows:

1) Switch the oven;

5938 036 01

At this point you will see on the oven temperature display

which is a Delta value (you can change it by highlighting the

temp area and turning the dial to reach the desired Delta – for

example 50°C.)

Close the oven door and press the start button to activate the

cooking cycle.

The core temperature of the meat may be for example 14 °C

when the cooking cycle is started, the oven temperature will go

to 75°C, (50°C above core temp), and then keep rising as the

core temperature rises, maintaining a difference of 50°C(As the

core temperature of the meat rises by one degree so too does

the oven temperature). The two temperatures will displayed in

the lower line on the display.

If you selected a final core temperature of for ex. 67 °C, the final

oven

chamber temperature will be 117 °C at the end of the cooking

cycle.

This cooking method is much slower than the ‘normal ‘ way of

cooking but the benefits are higher yields and better quality.

25

25 °C

Page 18

USA

4.4 AUTOMATIC CONTROLS

SOLO LIVELLO A

Introduction: the automatic controls make it possible to perform

cooking cycles in special modes and also to store cycles after

manual setting. For information on manual setting procedures

refer first to heading 4.3 MANUAL CONTROLS.

Note:

If the oven is switched off after you have set up a cooking cycle

manually the data you have entered will be lost since, in manual

mode, the controller does not store the cooking cycle.

To store manually set cooking programs for future use proceed

as described in the following headings.

The cooking cycles (or RECIPES) and programs (e.g. CLEAN)

are managed by means of the following commands:

Recipes or

programs ---------- DISPLAY

Menu* ----------------

^

<

v

* list of commands (items) necessary for executing the various

management functions:

S 00 M E N U

S 06 A D D P H A S E

S 03 S K I P P H A S E

S 07 A D D D E L A Y

S 09 C L E A R P H A S E

S 17 C O N F I R M

S 18 R E T U R N

S 10 C L E A R R E C I P E

S 17 C O N F I R M

S 18 R E T U R N

S 11 M E M O R I Z E R E C I P E

S 13 S E L E C T N U M B E R

S 02 C O N F I R M

S 14 E D I T N A M E

S 02 C O N F I R M

S 15 S A V E R E C I P E

S 16 R E T U R N

S 04 S E A R C H B Y N A M E

S 01 C O N F I R M

S 05 S E A R C H B Y N U M B E R

S 12 E X I T

S 17 C O N F I R M

S 18 R E T U R N

S 19 P A S S W O R D

S 20 N E W P A S S W O R D

S 21 C O N F I R M P A S S W O R D

S 22 C H A N G E P A S S W O R D

P (Program) = button to:

- open the list of recipes and programs

- open the menu of recipes or programs

- confirm the items selected from the menus

(^) (v) = "arrow" buttons (up and down)

(or use the knob) to:

- select recipes, programs or relative names

- select menu items

- select the utilities

- set the values

(<) (>) = "arrow" buttons (left and right) to:

- return to menu

- select the phases

DISPLAY = displays the operations

described above

>

4.4.1 AUTOMATIC SEQUENTIAL MULTIPHASE COOKING

Food can be cooked using different temperatures during the

cooking cycle (i.e. in several different stages).

The oven allows the execution of programs composed of several

sequential phases. For example:

- Phase 1: - air-convection cycle 392°F (200°C)

- core probe 158°F (70°C)

- Phase 2: - mixed cycle 428°F(220°C)

- time 40 minutes

- Phase 3: - air-convection cycle 482°F (250°C)

- time 15 minutes

and so on up to a maximum of 7 phases.

During the cooking cycle the oven advances from one phase to

the next one automatically until the cooking program is completed

and then stops automatically as soon as the last phase has been

terminated.

To set a multiple phase cooking program proceed as follows:

1) Switch on the oven.