Deutz 226B Operation Manual

';&

It!ffl

ifi*~226B~JU

~idlmf~ffl

f*jfi3iM

~

Operation

Deutz

226B

Series

.-.

-

-

-

--

WEICHAI

and

Maintenance

Generating

DEUTZ

Manual

Diesel

._,---""®

of

Engine

~tJj~~mfR~~Mm:fI~&*1§1

WeiIang Weichai Deulz Diesel Engine Company Ltd

~

1Ii.~9"

--

Special attention

• In ordertoprotect your legal interest, it is forbidden to dismantle the fuel pump lead seal optionally

•

If

the injection pump were adjusted or lead seal were removed, the quality guarantee of the

company would become invalid immediately.

• We would not provide free service for the dismantled injection pump.

part,

• Turbocharger rotor shaft is of precise

quality guarantees of the company will

forbid disassembling and colliding, Otherwise the

be

of invalid.

• There are strict torques

Users don

of invalid.

• Before starting the

• Connecting rod bolt can

• Meaning of identification:

• Exhaust gas contains noxious composition, therefore it must

t loose

and

and

dismantle

engine,

t

tum

angles for the main bearing bolts and connecting rod bolts,

them,

check coolant and oil whether they are filled up or not.

be

reused.

otherwise the quality guarantees of the company will

be

discharged outdoors.

he

Cautions

1.

The engine has been tested strictly in accordance with the test stipulations in delivery. The

throttle has been

tle. Otherwise

users would better pay attention to this.

2.

The engine operator must read this Opf..ration and Maintenance Manual carefullytoknow the engines structure, and abide by the operation and routine rules in this manual.

3.

During use new engine, a

load operation is allowed.

sealed,

we

would not provide free service for returning product, replacement and repair,

it is forbidden to dismantle the seal optionally and to enlarge the throt-

50

hours runin must be carried through, during which period no over-

4. Mter start cold engine, the speed should be increased slowly. It is forbidden to run the engine

in high speed suddenly

gine immediately and run the engine in idling for 5 - 10 minutes.

5. Mter stop the engine,

the coolant, the coolant in water tank and diesel engine should be drained

6.

It is forbidden that the engine works without

7.

Applied fuel and lubricating oil must

strainer, and the special clean container is used. The fuel should be settled more than

hours.

8. Assembly

9.

The oil seal period of the engine is one year. Inspect the engine and adopt necessary measures

and

maintenance of the engine must be done by specialized personnel.

and

in idling for a long time.

if

the ambient temperature is lower than

air

be

accord with specified trademark and be filtered by

Mter

filter and unfiltered

removed the

oee

and

air

load,

dont stop the en-

no antifreeze is used in

off.

enters into the cylinder.

72

if

beyond a year.

10. Rated power and power correction are in accordance

Its

11.

forbiddentosmoke when filling fuel and / or oil.

with

1503046 - 1.

Contents

J>reface

Diesel engine photo

000000

000

000 00000• 0 0 0

000

000

0 0 0

Diesel engine characteristic curve 0 0 0 • 0 0 0 0 0 0 0 0

1

Main perfonnance and specifications

2 Specifications of main accessa

Fuel system matching table

3.

Diesel engine construction

3.

1 Cross and longitudinal section view

30

2 Cylinder block subassembly .0

3.

3 Crank shaft and connecting rod mechanism

3.

4 Gear train

3.

5 Cylinder head and valve system 0

3.

6 Fuel supply system

3.

7 Lubricating system

3.

8 Cooling system 0 • 0 0 0 •

3.

9 Intake & exhaust system

3.

10

Electrical system .0 0 0 • 0 0 0

0000000 0 0 0 0 0 0 • •

.0

•••

0.00.000.00

000

00.000000

000

000

••

...

000000

000 000

000

0 • 0 0 • 0000 0 0 0 0 0 0

000

ies

000

•••

0 • 0 0 0 0 0 0 0 0

0 0••0o.0 • 0 0 0 0••00

..

00000.00

0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0

of

000000000000000000.00.00.

000 000

•••00••••

••

00000000.000

00000.

0

0 0 0

diesel engine

000

00'

••••

000000000

••••

•••••

••••

.00

000

.00

000

.00

000

.000000

.00o.0

0 • 0 0 • 0 • 0••00

0 • 0

000

000

0 0 0

000

000 000

• 0 0

000

0 0 0

000

0 0 0

000

000000

0 0 0 0 0 0 • 0 • • • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0 0 0 0 • • 0 • 0 0 0 0 0 0 • 0 0 0 0 0 • 0 0 • • 0 • • 4

o.

00'

• 0 0 0 0 0 0 0 0 0 • 0

00.0000000

000

000 000 000

00.

000

000000

000

000

0 0 0

0 0 •

000

000

000••000.000000000000.

••

00.0000000.0000000000.

••

0000000000000000.000

000

0 0 0

000

0.0000

00

••

o

0 o

0 0 0 • 0••000

00.00•••

0 0 0

00000000.

0 0 •

000

000 000

000000000000000000000000000000000000.00.000.0

0 0 0

0000000000000000.0

000000

000 000

0 0 0

000

000

•••

0 0 0 0 0

•••

0 0 0 0 0

0000000000000000000.000000000000.

000

000

00.000000 0 0 0 0 0 0 0 0 0

000

0 0 0

000000 0 • 0 0 0 0••0

0.0000.0.00.0

0

00000.

••

00000• 0 0 000• 0 0 0 0 0 0 0 0 •

.0.

o

•••

0 0 000••••

0 0 • 0 0 0 0 0

000

000

0.0.0.0000.00000.00000000000.

000••00••00• 0 0 • 0

•••0000000•••0••••

0 • 0 0 0 0

000

••0•••

000

0 0 •

000 000

••

0

000000.000

0 • 0

000000••0

000 000000

000

0000000

.00

0000000.00.00000000

0 0 •

000

••••00••

0 • 0 0 0 0 • 0 0

.0.

000

••

000.0.000000

00.

000000

•••••

•••

0 0••00

000 000

• • •

.00

0 • 0 • 0 0

0 0 0

00.

• • •

00.

000

000

• 0••0 0 • • •

000

0o.27

0 0

000

.00

0 0 0

000

1

0"

2

••

7

8

10

11

11

13

16

19

19

22

26

29

31

3.

11

Main bolts tightening torque

4.

Operating requirement and procedures

4.

1 Rules on the working fluid and the auxiliary material

4.

2 swinging requirement

4.

3 J>reparation before the start

4.

4 Start .0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0 0 • 0 • 0 0 0 0 • 0 0 0 0 0 • 0 0 0 0 0 0 0 0 0 0 • 0 0 • 0 0 • 0 0 0 0

4.5

Speed regulating

4.

6 stopping the engine

4.

7 Operating environment 0 0 0

5.

Maintenance

5.

1 Time table for Maintenance

5.

2 Maintenance procedure 0

6.

Trouble shooting 0 0 0 0 0 0 0 0 0 0 0 0 0

Appendix

1:

000 000

Relationship between crankshaft angle

Appendix 2 : Wear Limits of

0000.0

0000000000000000.00

00000.000

0 0 0 0 0 0.0• 0 0 0••0 0 • 0.0•

000••

J>arts

o.

0 0 0 0 0 0 0.00 0 • 0••0 0 0 0

.00

0 • 0

••

00.00000.00.0

0.0.000000

••

••

000000000.0000.0.0.00000000.000000

000

0 • 0 0 0 0 0 0 0 • 0 0

...

0••0 0••0 • 0 • 0 0 0 0 0 0 0 0 0 0 0 • 0.0••

000

0 • 0 0 0 • 000• 0 0000 0 0 • 0

••••

0 0 0 • 0 0 0 • 0

0.000.00.000.0000

000

0 0 0

••00•••

••

0000000.0000000000000

•••

000

.00

0 0 0 • • 0 0 0 0

•••

0 0 0 0 0 0 • 0 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0 0 0 0 0 0 0 0 0••0

of the Engine

000 000

.00

000

0 0 0 0 • 0 0 0••0 0o.0

00••00

000.0.00000000000.00.00.

••0.0••00000000.0000000000000000.0

0 • 0 0 0 • 0 0 0

0.0000000000000000.

.00

0 0 0

000

0000••

•••0••

0 • 0 • 0

<I>

and piston displacement S

• 0 0••0

000

000••0

000

0.0

••0••

000000

0 0 0 0 0 0

0

•••

0.0••0000000

000 000

0 • 0

000

• 0 0 0 • 0.00

0 0

000

0 0 0

000

0000••0••••000

0 0

000000000000000000.00000

0 • 0 0

•••

0 0 • 0 0

00.00••00000 000

000

0 • 0 0 • 0 0 • 0 0 0 000•

000

• 0 •000••0

0 0

000.000.00

•••

••••

000000

•••

0 0 0000 0 • 0

.00

•••••

000.00000••0

0 0 0 • 0 0 0 0 0 0 • 0 0 0 • 0 • 0 0 0 0 0 0

••000.00

000

0 0 0

00000• 0 • 0 0 0 0

0000.0

000 000

000

00000•

• 0 0

•••••

0 •00•

o

••

••••

000

000

0 0 0

••••0••

0000.000

••

0 0 0 0 0

0 0 0

0000

00.

00.000000000

000 000

• • 0 0 • 0

0.000000.

00000.

000000

•••000

.00

0 0 0

0 0 0 • 0

0 0 0000

••00.0000

.0.

.00

•••

00'

000

.00

0 0 0

34

36

36

39

39

41

42

42

43

44

44

45

50

51

52

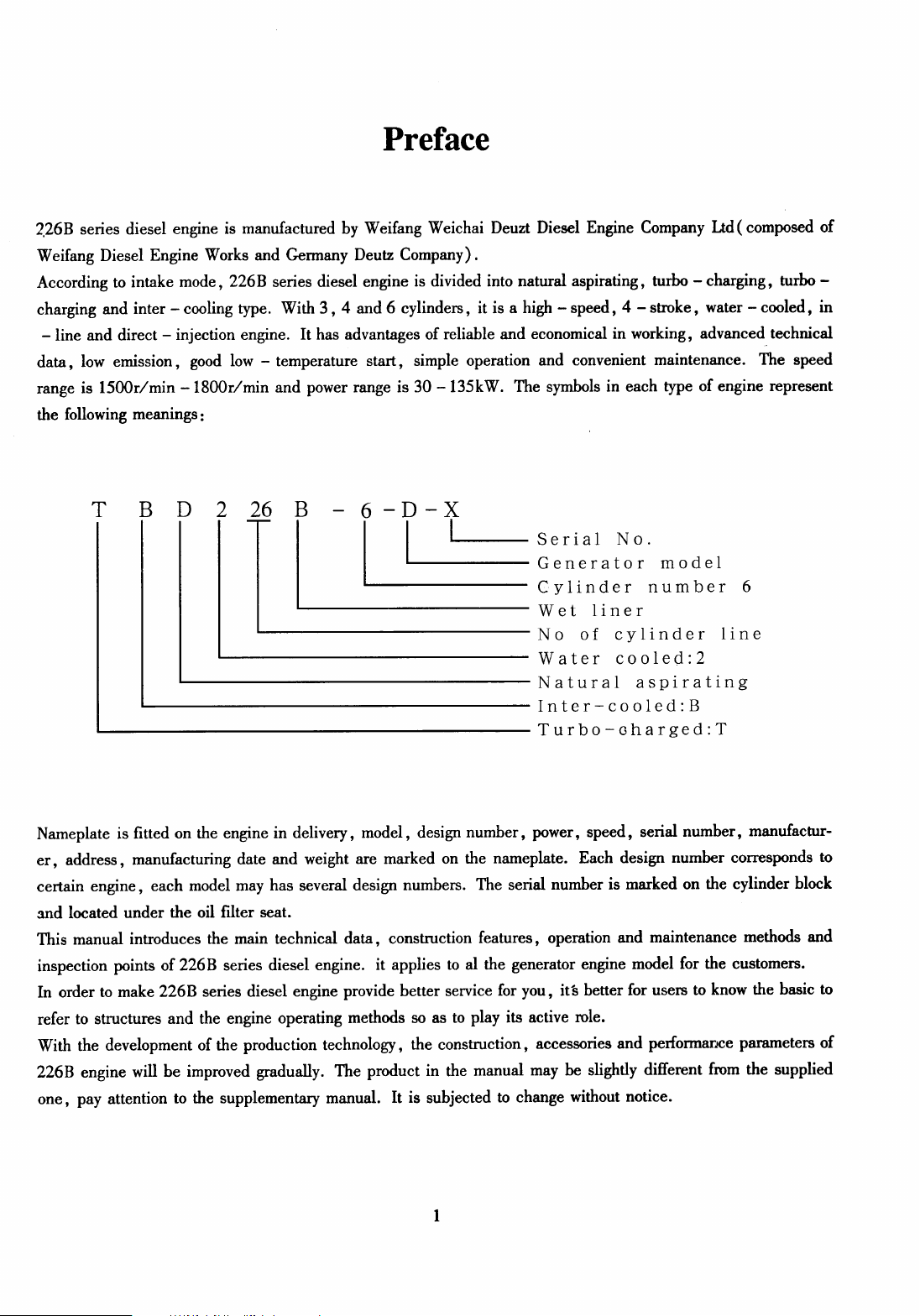

Preface

2,26B

series diesel engine is manufactured by Weifang Weichai Deuzt Diesel Engine Company Ltd ( composed

Weifang Diesel Engine Works and Germany Deutz Company).

According to intake mode, 226B series diesel engine is divided into natural aspirating, turbo - charging,

charging and inter - cooling type. With3,4 and 6 cylinders, it is a high - speed, 4 - stroke, water - cooled, in

- line and direct - injection engine. It has advantages of reliable and economical in working, advanced technical

data,

low emission, good

range is

the following meanings:

1500r/min

T

-1800r/min

B D 2 26 B 6 - D - X

low

- temperature start, simple operation and convenient maintenance. The speed

and

power range is 30

-135kW.

The symbols in each typeofengine represent

turbo-

of

I

I

..

I

I

'-------

1...-

1...-

1...-

L.-

Nameplate is fitted on the engine in delivery, model, design number, power, speed, serial number, manufacturer,

address, manufacturing date and weight are marked on the nameplate. Each design number corresponds to

certain engine, each model may has several design numbers. The serial number is marked on the cylinder block

3.Ild

located under the oil filter seat.

data,

This manual introduces the main technical

inspection points of 226B series diesel engine. it applies

to

In order

refertostructures and the engine operating methods so astoplay its active role.

With the development of the production technology, the construction, accessories and performance parameters of

226B engine will

one,

make 226B series diesel engine provide better service

be

improved gradually. The product in the manual maybeslightly different

pay attention to the supplementary manual. It is subjectedtochange without notice.

construction features, operation and maintenance methods and

to

al the generator engine model for the customers.

Serial

No.

Generator

Cylinder

Wet

No

Water

Nat

In

T u r b 0 - G h a r g e d : T

for

you,

liner

of

cylinder

cooled:2

u r a 1

t e r -

coole

its

better for users to know the basic

model

number

asp

d : B

ira

tin

from

line

g

6

to

the supplied

1

2

4

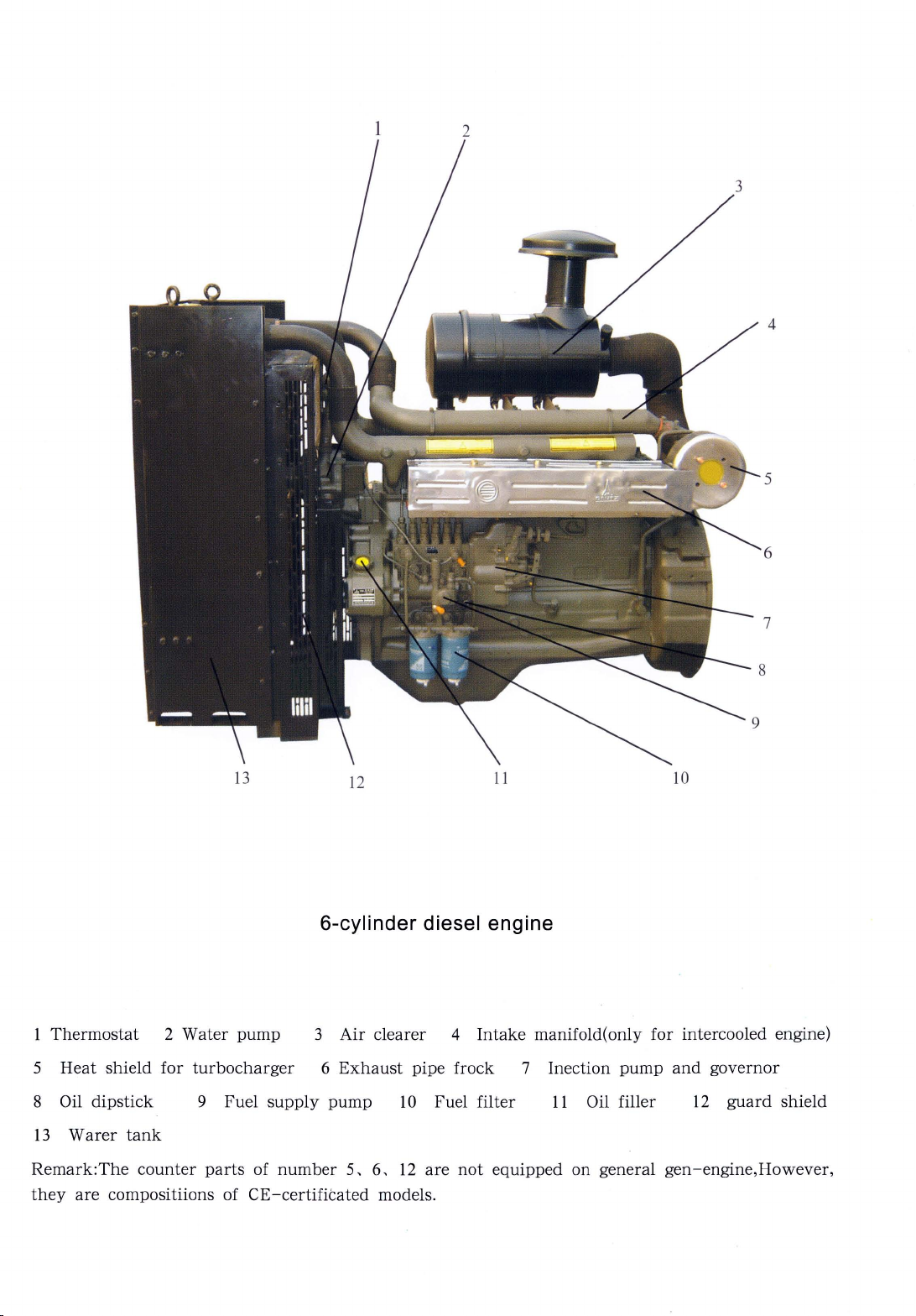

Thermostat

Heat

5

8 Oil

13

shield for

dipstick

Warer

Remark:The

they

are

compositiions of

tank

counter

2 Water

turbocharger

9 Fuel

parts

13

6-cylinder diesel engine

pump

of

CE-certifitated

3

6

supply

number

12

Air

Exhaust

pump

5,

11

clearer 4

Intake

pipe frock 7 Inection

10

Fuel filter

6,

12

are

not

equipped on general gen

models.

10

manifold(only for intercooled engine)

11

pump

Oil filler

and

12

-engine,

governor

guard

However,

shield

2

3

4

Warer

5

tank

Exhaust

7 Oil dipstick 8

Remark:The

they

are

counter

compositiions of

11

2

Air

pipe frock(

parts

10

4-cylinder

clearer

Only

Fuel filter

of

CE-certificated

for

number

3

turbocharged

9 8 7 6 5

diesel engine

Turbocharger

engine) 6 Inection

9 Fuel supply

4,

5,

11

are

models.

pump

not

4

Heat

equipped

shield

10

on

for

Oil filler

general

turbocharger

pump

11

and

guard

governor

shield

gen-engine,However,

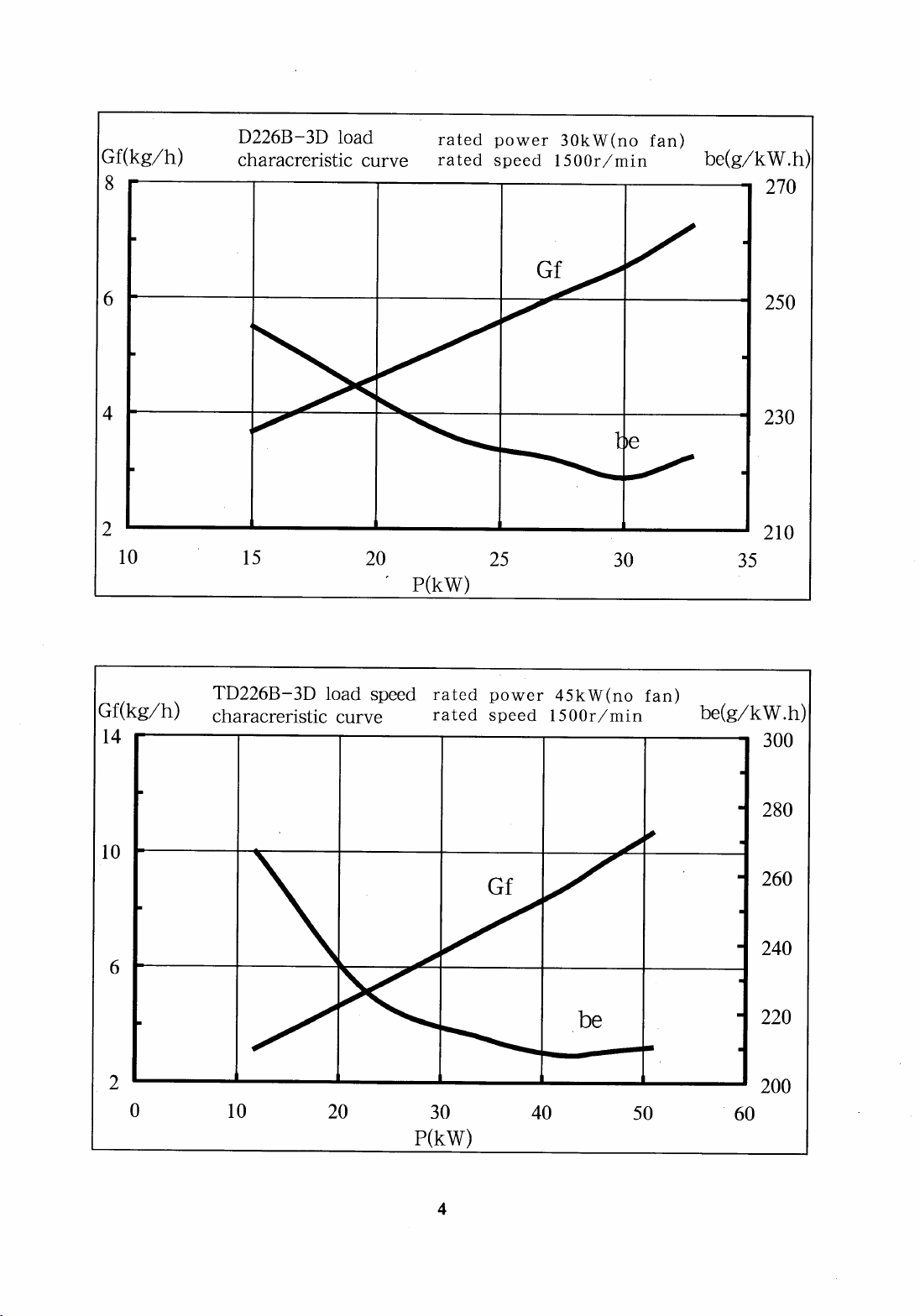

Gf(kg/h)

8

D226B-3Dload

characreristic curve

rated

rated

power

speed

30kW(no

1500r

/min

fan)

be(g/kW.h)

270

6

4

2

10

Gf(kg/h)

14

15

TD226B-3D load speed

characreristic curve

20

P(kW)

rated

rated

25

power

speed

30

45kW(no

1500r/min

250

230

210

35

fan)

be(g/kW.h)

300

10

280

260

240

6

220

2

o

10

20

30

P(kW)

4

40

50

200

60

Gf(kg/h)

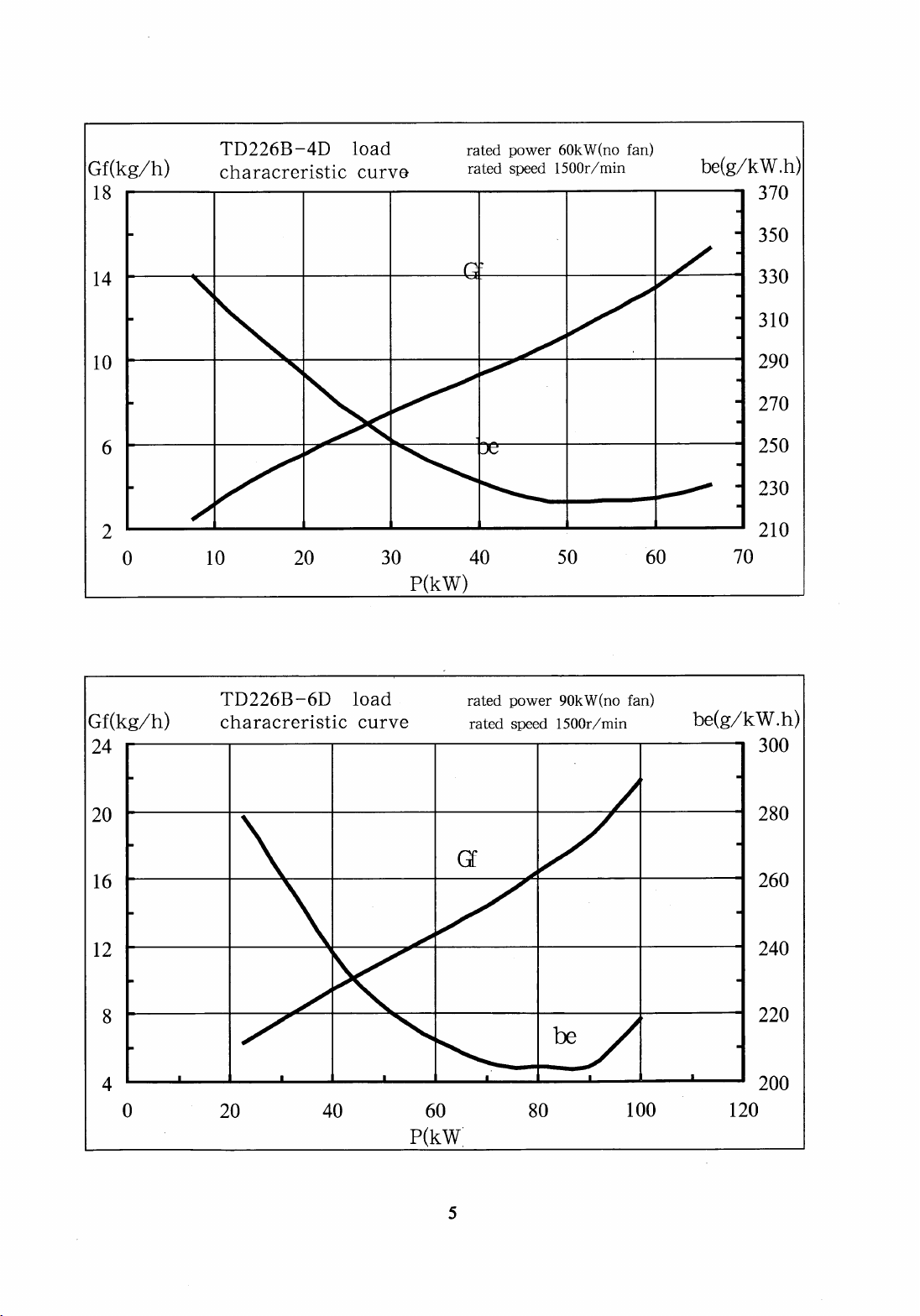

18

TD226B-4D

characreristic

load

curVE}

rated

power

rated speed

60kW(no fan)

1500r/min

be(g/kW.h)

370

350

14

10

6

2

o

Gf(kg/h)

24

10

TD226B-6D

characreristic

20

load

curve

30

P(kW)

40

rated

rated

power

speed

50

90kW(no fan)

1500r/min

60

330

310

290

270

250

230

210

70

be(g/kW.h)

300

20

16

12

280

260

240

8

4

o

20

40

60

80

100

P(kW

5

220

200

120

Gf(kg/h)

30

TBD226B-6D load

characreristic curve

rated

rated

power

speed

°120k

1500r

W(no

Imin

fan)

be(g/kW.h)

240

20

10

o

o

Gf(kg/h)

40

20

TBD226B-6D5 load

characreristic curve

40

60

P(kW)

rated

rated

80

power

speed

100

132kW(no

1500r

Imin

120

fan)

220

200

180

140

be(g/kW.h

240

30

20

10

o

o

220

200

,

20

40

60

80

P(kW)

6

100

120

140

160

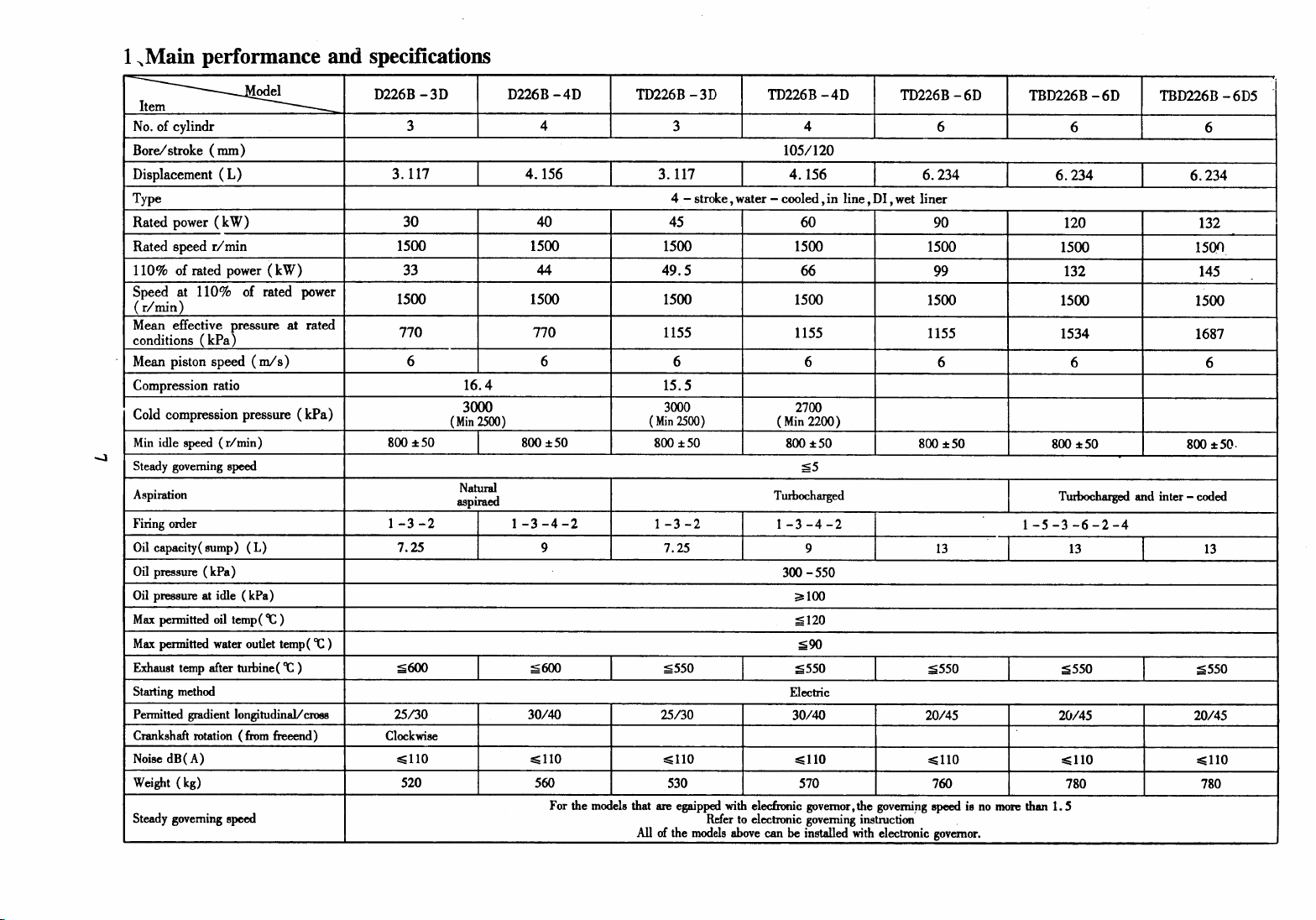

1

"Main

Item

No.

Borel

Displacement

Type

Rated

Rated

110%ofrated power

Speedat110%ofrated power

(

rfmin)

Mean effective pressureatrated

conditions

Mean piston

Compression ratio

Cold compression pressure

Min

-J

Steady governing speed

Aspiration

Firing order

Oil

Oil

Oil

Max

Max

Exhaust

Starting

Permitted gradient longitudinall

Crankshaft rotation (from freeend)

Noise

Weight

Steady governing speed

performance and specifications

of

cylindr

stroke

(mm)

(L)

power(kW)

speedrlmin

(kPa)

speed

idle speed

capacity( sump)

pressure

pressure at idle

permitted

permitted water outlet

dB(A)

temp

method

(kg)

(r/min)

(kPa)

(kPa)

oil

temp

after turbine(

(m1s)

(L)

( 'C)

(kW)

temp

'C

(kPa)

(

'C

)

CI'088

D226B

-3D

3

-4D

4

TD226B

-3D

3

TD226B

-4D

4

TD226B

-6D

6 6

TBD226B

-6D

TBD226B

6

-6D5

D226B

105/120

25(0)

4.156

40

44

770

800

:1:50

1-3-4-2

9 7.25

3.117

4.- stroke, water -

45

1500

49.5

1500

1155

15.5

3000

(Min

25(0)

800

:1:50

1

-3-2

3.117

30

1500 1500

33

1500 1500

770

6 6 6 6

16.4

3000

(Min

800

:1:50

Natural

aspiraed

1

-3-2

7.25

4.156

cooled,inline,DI,wet

60

1500

66

1500

1155 1155

2700

22(0)

(Min

800

:1:50

~5

Turbocharged

1-3-4

-2

9

300

-550

6.234

liner

90

1500

99

1500

6

800

:1:50

1

-5 -3-6-2-4

13 13

6.234

120

1500

132

1500

1534 1687

6

800

:1:50

Turbocharged and inter- coded

6.234

132

15Qll

145

1500

800

6

:1:50.

13

;;,100

~120

)

~600

25130

Clockwise

=E;110

520

~600

30/40

=E;110

560

For the

models

~550

25130

=E;110

530

that are egaipped

Allofthe

Refertoelectronic

models

with

above

~90

;,;;550

Electric

30/40

=E;110 =E;110

570

elecfronic governor,the

governing

can be installed

instruction

with

governipg

electronic

~550

20/45

760

speed

governor.

isnomore

than

:ii550

2(}/45

=E;110

780

1.

S

~550

20145

=E;110

780

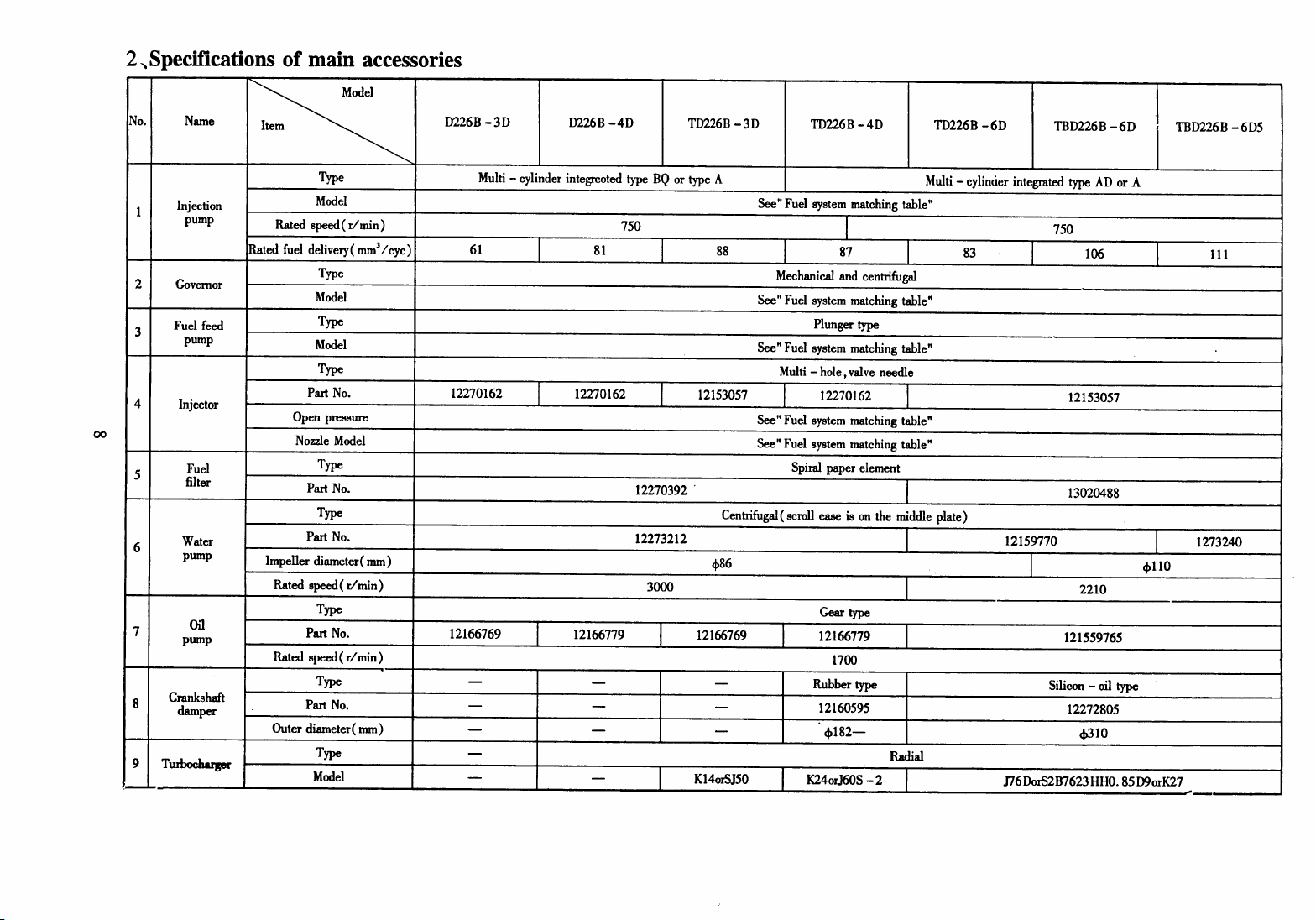

2"Specifications

No.

00

Name

Injection

1

pump

2

Governor

Fuel

3

pump

4 Injector

5

6

7

8

9

Fuel

filter

Water

pump

Oil

pump

Crankshaft

damper

TurhochaIt.er

feed

of

main accessories

Item

~

Rated

speed

Rated

fuel

delivery(mm3/cyc)

Part

Open

Nozzle

Part

Part

Impeller diamcter(

Rated

speed

Part

Rated

speed(r/

Part

Outer diameter(

D226B

-3D

Multi

Type

Model

(r/min)

Type

Model

Type

Model

Type

No.

pressure

Model

Type

No.

Type

No.

mm)

(r/min) 3000

Type

No.

min)

Type

No.

mm)

Type

Model

12270162

12166769

- cylinder

61

- -

-

-

- Radial

-

D226B

-4D

integrcoted

81

12270162

12166779

- -

-

-

type

750

12270392 .

12273212

TD226B

BQortype

-3D

A

88

12153057

Centrifugal

4>86

12166769

-

-

K14orSJ50

See"

Fuel

Mechanical

See"

Fuel

See"

Fuel

Multi

See"

Fuel

See"

Fuel

(scroll

TD226B

system

system

Plunger

system

- hole,

12270162

system

system

Spiral

caseison

Gear

12166779

Rubber type

12160595

K240rJ60S

matching

I

87

and

matching

matching

valve

matching

matching

paper

type

1700

4>182-

-4D

centrifugal

type

needle

element

the

- 2

table"

table"

table"

table"

table"

middle

TD226B

-6D

Multi

- cylinder integrated typeADor

83

plate)

12159770

Silicon-oil

n6

DorS2B7623

TBD226B

750

106

12153057

13020488

2210

121559765

12272805

4>3

HHO.

-6D

type

1

0

A

4>HO

85D9orK27

TBD226B

HI

1273240

-6D5

Specifications

No.

10

Name

Oil

filter

of

main accessories(2)

~

Type

Part

No.

D226B

-3D

0226B

-4D

12272453

T02268

-3D

Spiral

TD226B

paper

-4D

element

T0226B

-6D

TB0226B

01174421

-6D

TBD226B-6D5

11

12

13

\0

14

15

16

17

Oil

cooler

Thermostat

/

Starter

Generator

Intercooler

Water

cooler

Fan

Full open temperature('C)

Type

Type

Opentemperature('C)

Type

Power

Voltage

Type

Part

No.

Power

Voltage!current

Type

Type

Model(or

Radiation

area

Type

Part

Outer dia(

part

No.

No.

(m

mm)

2

Three

- phase

12903819

-

Air

cooled

finand

)

)

and

tube type

13025078

20

Exhaust

13021367 13020367

~6

-

Air

cooled

finand

and

tube

type

13025078 13025078 13025078

20

Exhaust

~

-

Air

cooled

finand

and

tube

type

20

Exhaust Exhaust

13021367

~

Round

plate type

Wax

75

90

DC,

selfexcitation

4kW

24

V(12Visoptional)

AC,

commutated

0.75kW

28V127A(14V

Air

cooled

finand

13021367

~

-

tube

20

type

and

is

optional)

and

type

voltage

regulated

13020748

Air-oiv

Air

finand

13024933

Exhaust

13021535

intercooled

cooled

tube

30

cf>54O

and

type

Air-oiv

Air

finand

13024933

13021190

intercooled

cooled

tube type

40

Exhaust

clJ600

and

Air-oil'

Air

finand

13024933

13021190

intercooled

cooled

tube

40

Exhaust

clJ600

and

type

Fuel System Matching Table

Diesel

engine

Model

TBD226B

-6D

TD226B

-6D

TD226B

-4D

D226B

-3D

TD226B

-3D

TBD226B

-6D5

Injection

pump

Injection

Governor

Electronic

(I2V,24Vare

Supply

Fuel

delivery

Injector

assembly

pump

model

governor

optional)

pump

model

advance

number

model

model

anggle

no.

13020436

CPES6AD100

D320RS2139

CRSV450

CDES6ADlOO

D320RS2140

...

13021799

CRSV450

...

750ADOC139R750ADOC139R

SAD/H2206

16

±0.5

12153057

SAD/H2206

18

±0.5

12153057

13021656

CPES4AD95

D320RS2152

CRSV450

750ADOC139R

ESG

2000

ESGI500Cl

SAD/H2206

18

±0.5 20.5 ±0.5 20.5 ±0.5

12270162

13021938

BH3QT80R9

BH3A95R504

...

1'300

-750Z

msv330

-

750A504

- D

SVHZ2204

SAlH2208 SAlH2208

12270162

13022109

BH3QT85R9

BH3A95R501

TI00-750Z

'mSV33O

-750A501

SVHZ2204

12153057

13023574

BP1213

+TRSUV

4500

-750P

ESG2000

ESGI

oooC

5505

14

±O.

12153057

1

5

Injector

InjectIon

Injection

High-pressure

pipe

body

nozzle

pressure

Cuter

model

model

(MPa)

dia

dia{mm)

•

inrer

KBEL90S3/13

DLLA151S972

KBEL90S3/13

DLLA151S972

10

KBEL90S3/13

DLLA152S1l80

22

6.1.

KBEL90S3/13

DLLA152S1180

+0

••

75

KBEL90S3/13

DLLA151S972

KBEL90S3/13

DLLA151S972

3. Diesel engine construction

3. 1Cross and longitudinal section view of diesel engine

3.1.1

Longitudinal section view of D226B

-4

diesel engine

13

10

9

8----t

7---~tt¥:~~~~

6----~

14

15

16

17

18

II-++-+---t+-+--

,~--24

22

23

2

1 Oil sump 2

5 4 3

Two

- stage balancing mechanism 3 Pre - filter 4 Oil pipe 5 Oil dipstick

6 Gear case cover 7 Oil pump 8 Crankshaft belt pulley 9 Speed sensor

10Fan

15

19

11

Inspirator 12 Water pump

Cylinder head cover

16

Piston 20 Cylinder liner

13

Cylinder head

Water outlet pipe

21

Connecting rod 22 Rear oil seal cover 23 Flywheel

17

Intake valve

14

Rocker arm and rocker arm support

18

Exhaust valve

24 Flywheel housing

11

1

(on

the flywheel housing)

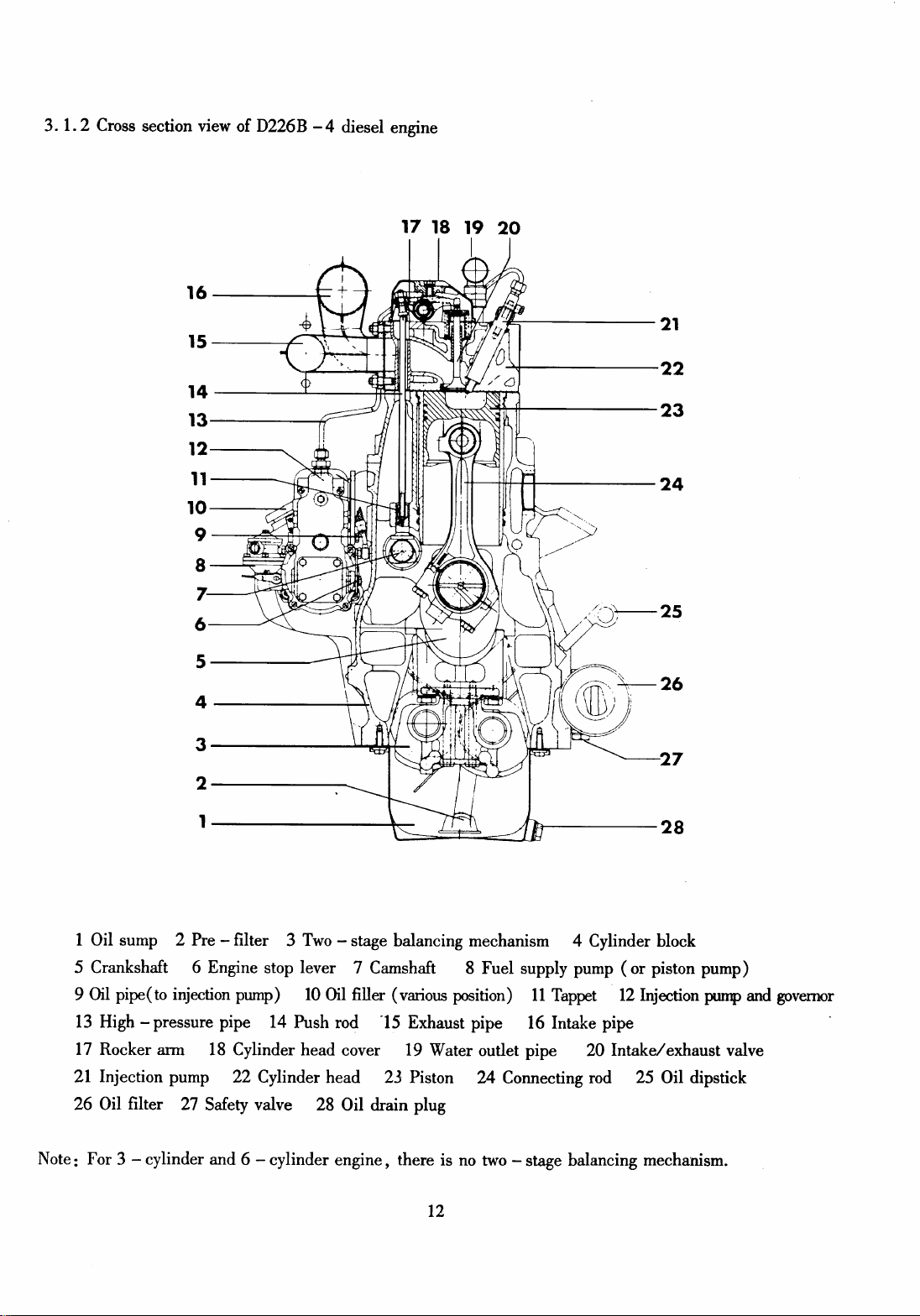

3.1.2

Cross section view of D226B

16

----___+_

15----F-

14

------l~-___=+~.t"rn~..,.,~~

13--------k"

12-----....

-4

diesel engine

17

18

19

20

I

-"I!=-------

~------22

~~~\-~--tt-------

21

23

11-----

10-----"....:~---W

9

---::~=_fI4---,.._r~1f';1

8-----'-oo~-r

7---r---1'n,;;\i

~~~

6-----

5-----~

4

-------;--'1-\

3-------~~'-

I

ft---+liH-++------

/<:JT--25

/

2--------

1--------~

1 Oil sump 2 Pre - filter 3

Two

- stage balancing mechanism 4 Cylinder block

\......::::=-.+----.;;;::::.:..JJt::i

5 Crankshaft 6 Engine stop lever 7 Camshaft 8 Fuel supply pump

Oil

pipe(toinjection pump)

9

13

High - pressure pipe 14 Push rod

17 Rocker

21

Injection pump 22 Cylinder head

ann

18

Cylinder head cover 19 Water outlet pipe 20 Intake/exhaust valve

10

Oil

filler (various position)

"15

23

Exhaust pipe 16 Intake pipe

Piston 24 Connecting rod 25 Oil dipstick

26 Oil filter 27 Safety valve 28 Oil drain plug

~-----28

11

Tappet

24

27

(or

piston pump)

12

Injection

pump

and

governor

Note: For 3 - cylinder and 6 - cylinder engine, there is

12

no

two

- stage balancing mechanism.

30

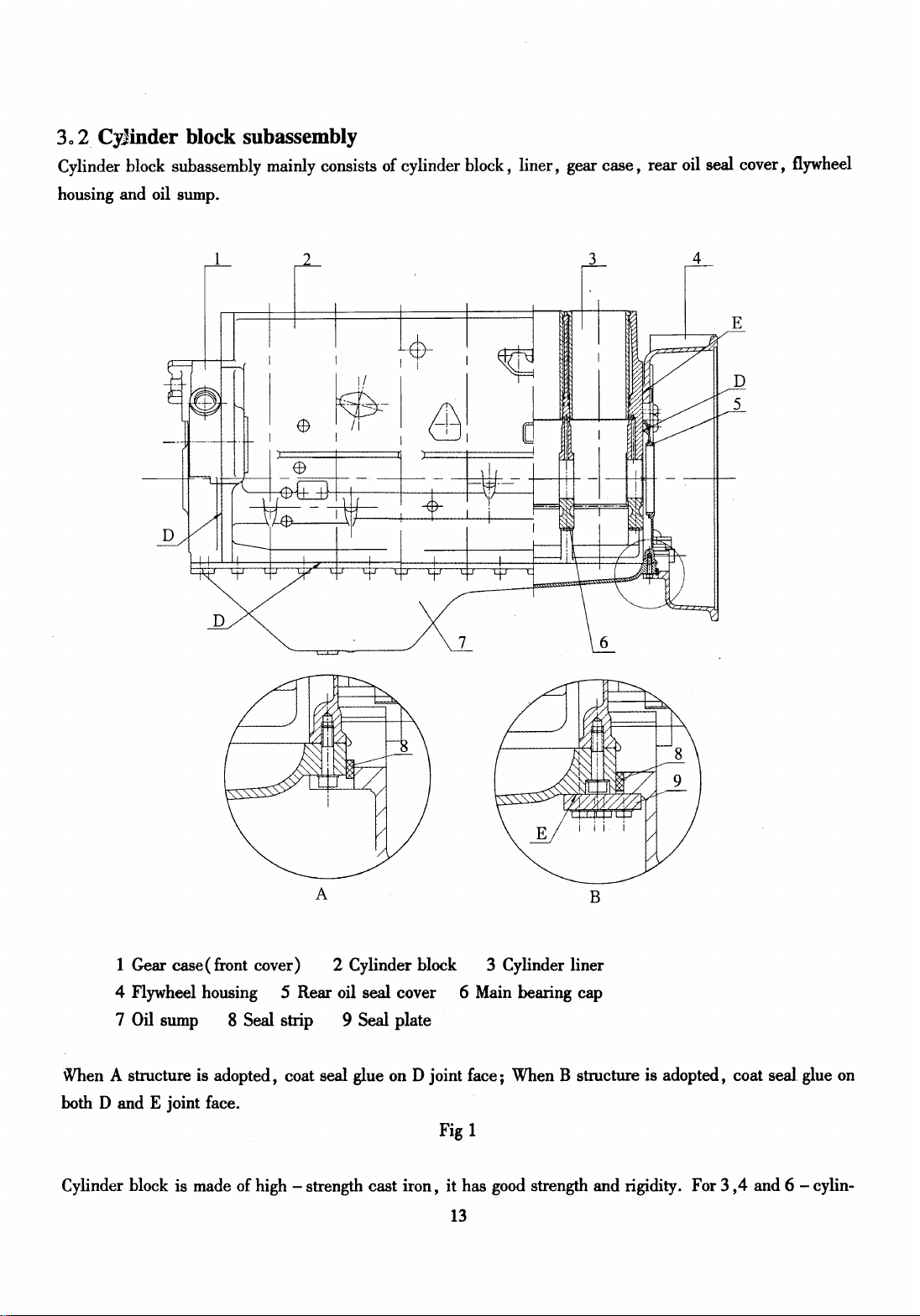

2 CyJ.inder block subassembly

Cylinder hlock suhassemhly mainly consists of cylinder hlock, liner, gear case, rear oil seal cover, flywheel

housing and oil sump.

(£1

2

3

4

E

D

5

ctJl

A

1 Gear case(front cover) 2 Cylinder hlock

4 Flywheel housing 5 Rear oil seal cover

7

Oil

sump 8 Seal strip 9 Seal plate

When

A structure is adopted, coat seal glue on Djoint face; When B structure is adopted, coat seal glue

both

D and E joint face.

Cylinder hlock is made of high - strength cast iron, it has

3 Cylinder liner

6 Main bearing cap

Fig 1

good

strength and rigidity. For

13

B

3,4

and 6 - cylin-

on

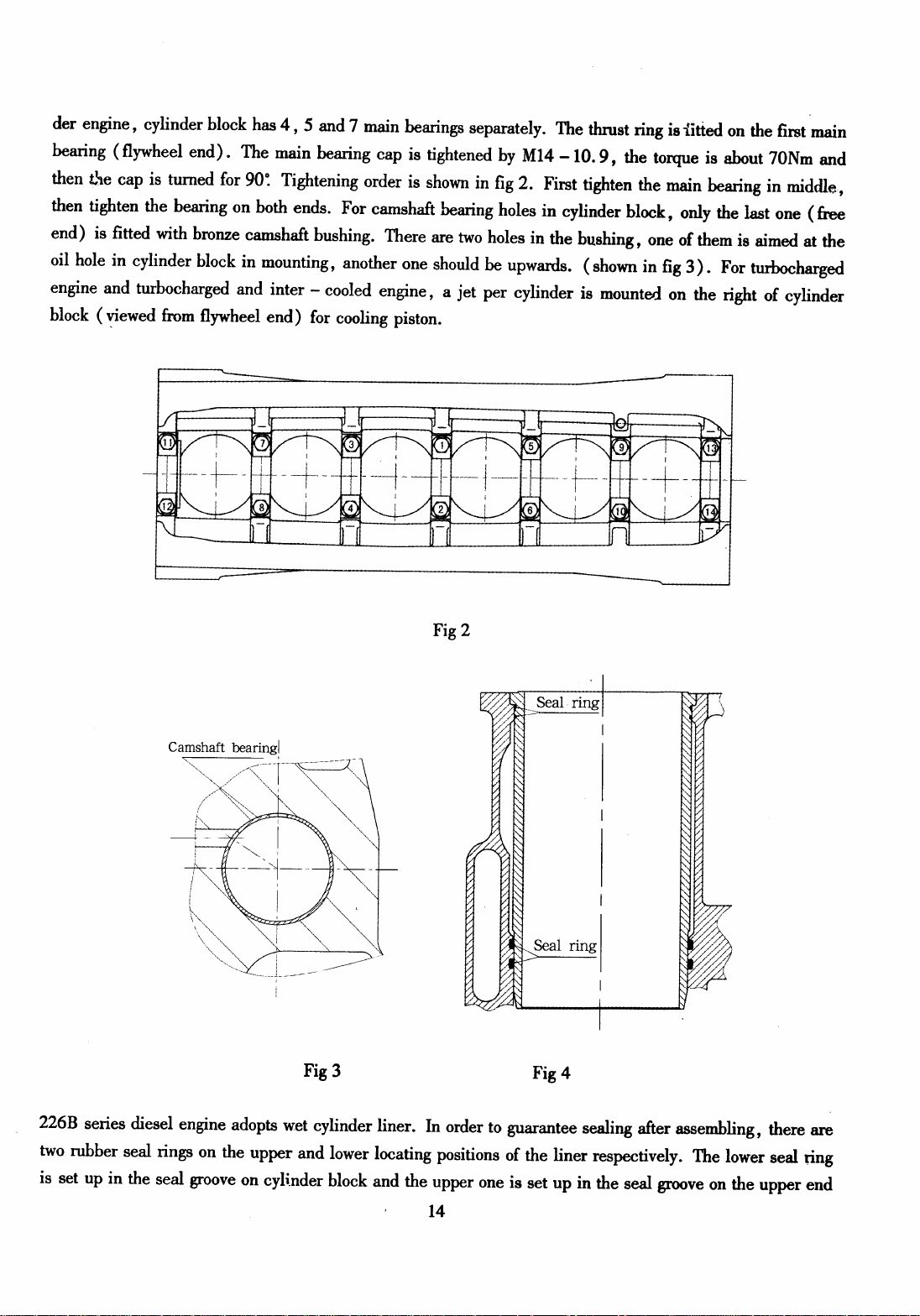

der engine, cylinder block has4,5 and 7 main bearings separately. The thrust ring isfitted on the first main

bearing (flywheel

then

t"e

cap is turned for 90: Tightening order is

then tighten the bearing on both ends. For camshaft hearing holes

end)

is fitted with bronze camshaft bushing. There are

oil hole in cylinder block in mounting, another one should

engine and turbocharged and inter - cooled engine, a jet per cylinder is mounted on the right of cylinder

block

(~ewed

end).

from flywheel

The main bearing cap is tightened by

end)

for cooling piston.

showninfig

two

holes in the bushing, one of them is aimed at the

be upwards. (shown in fig

MI4

-10.9,

the torque is about 70Nm and

2. First tighten the main bearing in middle,

in

cylinder block, only the last one (free

3).

For turbocharged

Fig 2

Camshaft bearingl

"'XA~:i'~:-'\

r:

"'<~>

i

l,

I>"",

\\

""''''.

"',.,.,.,

....

""

.~...........

"'"

I

v1'"

~

>-[

----

1 _

'"

--~~

Fig 3

""".,,"

'"

Fig 4

226B series diesel engine adopts wet cylinder liner. In order to guarantee sealing after assembling, there are

two

rubber seal rings on the upper and lower locating positions of the liner respectively. The lower seal ring

is set up in the seal groove on cyHnder block and the upper one is set up in the seal groove on the upper end

14

Loading...

Loading...