Danfoss ETS 400, ETS 250, ETS 100, ETS 50, ETS 12.5 Data sheet

Data sheet

Electric expansion valve

Type ETS 12.5 - ETS 400

ETS is a series of electric expansion valves for precise liquid injection in evaporators for air conditioning and refrigeration applications.

The valve piston and linear positioning design is fully balanced, providing bi-flow feature as well as solenoid tight shut-off function in both flow directions.

The valve design uses bi-polar drive providing very precise flow regulation.

ETS valves are compatible with electronic control solutions from Danfoss and other manufacturers.

Features |

• Precise positioning for optimal control of |

|

liquid injection. |

|

• Wide range for all common refrigerants. |

|

• ETS 250, ETS 400 provides 34 bar / 493 psig. |

|

• All ETS can be operated with flow in both |

|

directions and are solenoid tight. |

|

• ETS 50 to ETS 400 have a balanced design. |

|

• ETS 50 and ETS 100 feature improved process |

|

and productivity due to waterless brazing i.e |

|

soldering without wet cloth for cooling. |

|

• Special ETS 250 and ETS 400 available for oil |

|

free applications. |

•ETS 50 – ETS 400 are all designed with built-in sight glass with moisture indicator.

•Internal and external corrosion resistant design.

•Low power consumption.

•Cable and connector assemblies as accessories.

•Danfoss EKE 1A, EKE 1B, EKE 1C, MCX061V, MCX152V are examples of Danfoss controllers with drivers matching the ETS needs.

•For manual operation and service of ETS valves an AST-g service driver is available.

© Danfoss | DCS (rm) | 2019.02 |

DKRCC.PD.VD1.3C.02 | 1 |

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Approvals

Approvals

089

Technical data

NOTE:

NOTE:

Technical data also applicable for ETS 250 and ETS 400 oil free version.

Electrical data

|

Wide range for all common refrigerants R1234ze, R134A, R22, R404A, R407A, R407C, |

||

|

R407F, R410A, R422B, R422D, R438A, R448A, R449A, R450A, R452A, R507, R513A and other |

||

Compatible refrigerants |

refrigerants. |

|

|

|

Special valves for R744 (CO2) are available. |

||

|

For other refrigerants, please contact your local Danfoss representative. |

||

|

|

||

Refrigerant oil |

All mineral oils and ester oils and special ETS 250 and ETS 400 support oil free applications |

||

Comply with P.E.D. |

Yes |

|

|

|

|

|

|

Max. opening pressure |

33 bar (478.6 psi) |

|

|

differential (MOPD) normal flow |

|

||

|

|

||

|

|

||

Max. opening pressure |

ETS 12.5, ETS 25, ETS 50, ETS 100: 33 bar (478.6 psi) |

||

differential (MOPD) reverse flow |

ETS 250, ETS 400: |

10 bar (145 psi) |

|

Max. working pressure (PS/MWP) |

ETS 12.5, ETS 25, ETS 50, ETS 100: 45.5 bar (660 psig) |

||

ETS 250, ETS 400: |

34 bar (493 psig) |

||

|

|||

Inlet fluid temperature |

-40 °C – 65 °C (-40 °F – 149 °F). For higher temperature valve, please contact Danfoss. |

||

|

|

||

Ambient temperature |

-40 °C – 60 °C (-40 °F – 140 °F) |

||

|

ETS 50, ETS 100: Body and AST enclosure in brass, connections in bi-metal |

||

Material of Construction |

(stainless steel/copper). |

|

|

|

ETS 12.5, ETS 25, ETS 250, ETS 400: Body and AST enclosure in brass, connections in copper. |

||

|

|

|

|

Motor enclosure |

IP67 |

|

|

Stepper motor type |

Bi-polar - permanent magnet. |

||

Step mode |

2 phase full step. |

|

|

Phase resistance |

52 Ω ±10% |

|

|

Phase inductance |

85 mH |

|

|

|

|

|

|

|

7.5° (motor), |

|

|

Step angle |

0.9° (lead screw), |

|

|

|

Gearing ration 8.5:1. (38/13)2:1 |

||

Nominal voltage |

Constant voltage drive: 12 V dc -4% – 15%, |

||

150 steps/sec. |

|

||

|

|

||

Phase current |

Using chopper drive: 100 mA RMS -4% – 15% |

||

|

|

||

Holding current |

Constant voltage drive: Depends on application. |

||

Chopper drive: full current allowed (100% duty cycle) |

|||

|

|||

|

|

||

Max. total power |

Voltage / current drive: 5.5 / 1.3 W (UL: NEC class 2) |

||

Step rate |

Constant voltage drive: 150 steps/sec. |

||

Chopper current drive: 0 – 300 steps/sec. 300 recommended |

|||

|

|||

|

ETS 12.5, ETS 25, ETS 50: |

2625 [160 / -0] steps |

|

Total steps |

ETS 100: |

3530 [160 / -0] steps |

|

|

ETS 250, ETS 400: |

3810 [160 / -0] steps |

|

|

ETS 12.5, ETS 25, ETS 50: 17 / 8.5 sec. (voltage / current) |

||

Full travel time |

ETS 100: |

23 / 11.5 sec. (voltage / current) |

|

|

ETS 250, ETS 400: |

25.4 / 12.7 sec. (voltage / current) |

|

|

|

|

|

|

ETS 12.5, ETS 25, ETS 50: |

13 mm (0.5 in.) |

|

Lifting height |

ETS 100: |

16 mm (0.6 in.) |

|

|

ETS 250, ETS 400: |

17.2 mm (0.7 in.) |

|

|

|

||

Reference position |

Overdriving against the full close position |

||

Electrical connection |

M12 connector |

|

|

Compatible Danfoss controllers Danfoss EKE 1A, EKE 1B, EKE 1C, MCX061V, MCX152V and more

NOTE:

NOTE:

Full life time of standard ETS can only be ensured if oil is present in the system.

Oil free applications: Special ETS 250 and ETS 400 are available for higher capacity and use ETS Colibri for smaller capacity.

© Danfoss | DCS (rm) | 2019.02 |

DKRCC.PD.VD1.3C.02 | 2 |

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

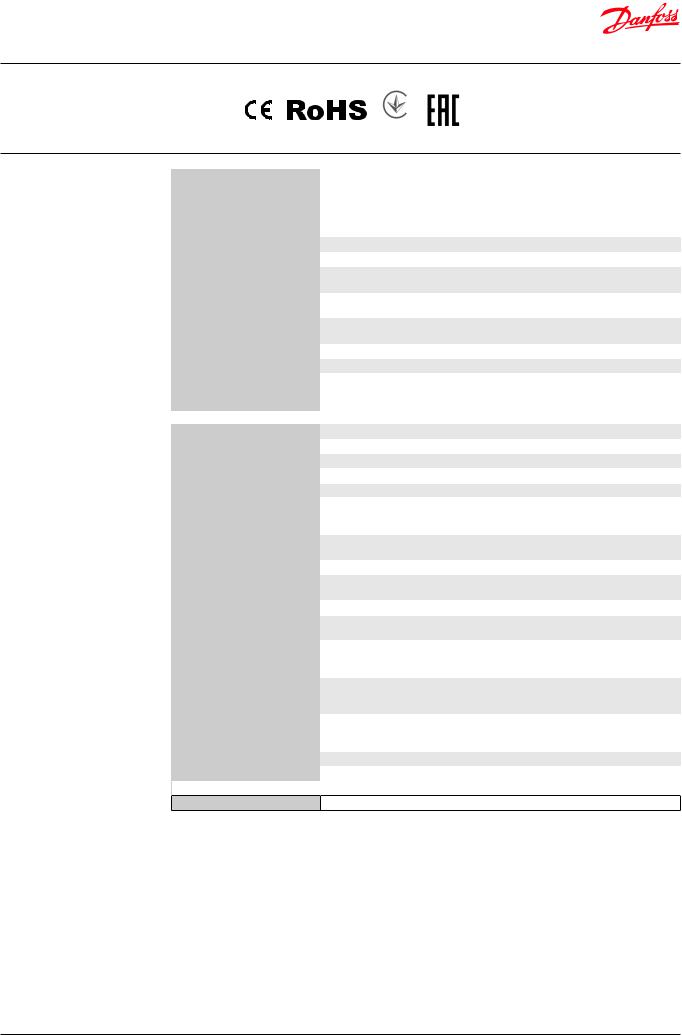

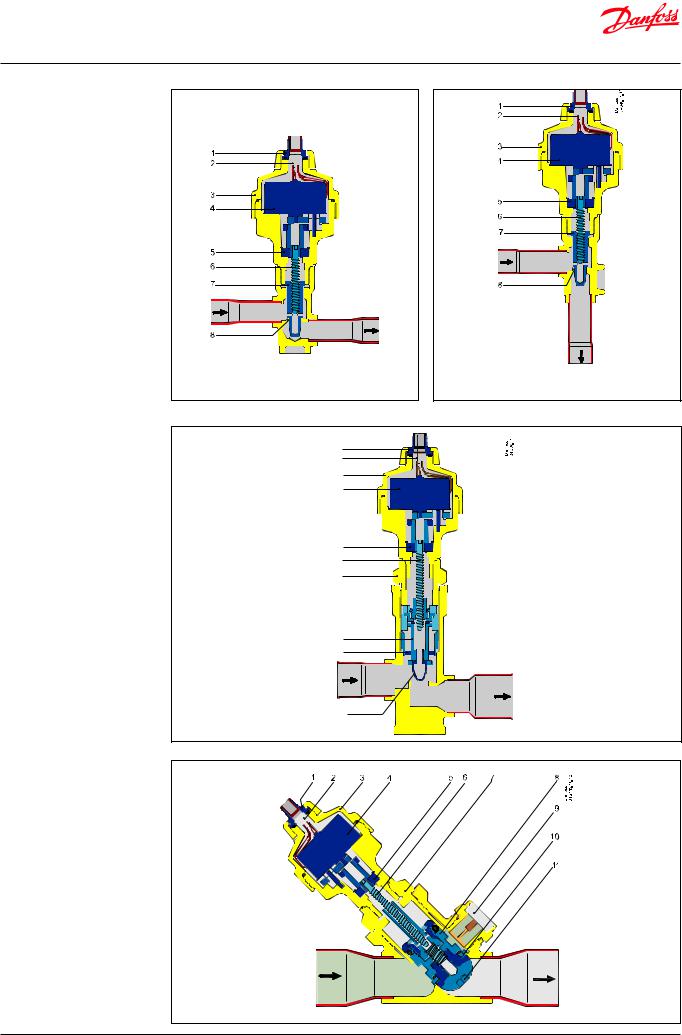

Design

Note:

Note:

Flow direction from A to B refers to the normal flow

1.M12 connection

2.Glass seal

3.AST motor housing

4.Stepper motor

5.Bearing

6.Spindle

7.Cone and lead nut

8.Valve seat

1.M12 connector

2.Glass seal

3.AST motor housing

4.Stepper motor

5.Bearing

6.Spindle

7.Top Nut

8.Valve piston

9.Valve seat

10.Valve cone

1.M12 connector

2.Glass seal

3.AST motor housing

4.Stepper motor

5.Bearing

6.Spindle

7.Top Nut

8.Valve piston

9.Sight glass with indicator

10.Valve seat

11.Valve cone

|

<![if ! IE]> <![endif]>Danfoss 34G45.12.10 |

A |

|

|

|

A |

|

|

|

|

B |

|

|

B |

ETS 12.5, ETS 25 - straight |

|

ETS 12.5, ETS 25 - angleway |

|

|

<![if ! IE]> <![endif]>.10 |

|

|

1 |

|

|

2 |

3

4

5

6

7

8

9

A

B

10

ETS 50 & 100

A |

B |

|

ETS 250 & 400

© Danfoss | DCS (rm) | 2019.02 |

DKRCC.PD.VD1.3C.02 | 3 |

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

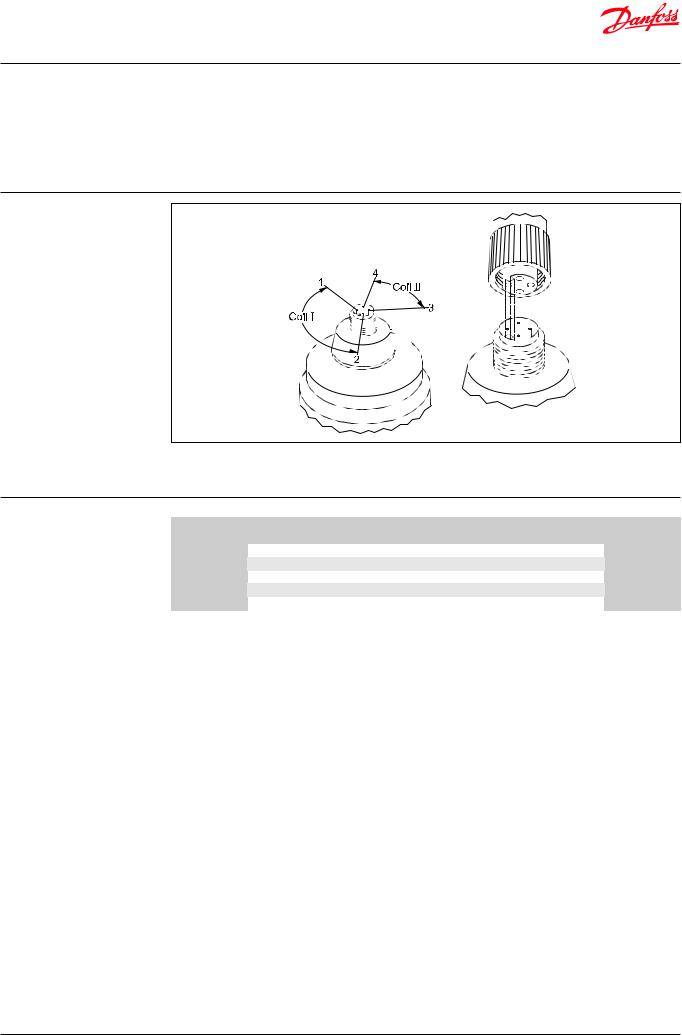

Sight glass and indicator |

ETS 50, ETS 100, ETS 250 and ETS 400 are |

|

equipped with sight glass with moisture |

|

indicator. The physical position of the piston in |

|

the valve can be checked through the sight glass. |

|

It also helps to determine the flow direction of |

|

the refrigerant in the system (ETS 50 and |

|

ETS 100). |

Insufficient sub cooling can produce flash gas which is visible through the sight glass. The moisture indicator in the sight glass indicates dry or wet state of the refrigerant by changing its colour.

Electrical wiring

<![if ! IE]><![endif]>Danfoss 34G212.10

Note:

Note:

Electrical check of stepper motor and wiring: Coil I = 52 ohm, coil II = 52 ohm

Stepper motor |

|

STEP |

Coil I |

|

|

Coil II |

|

||

switch sequence |

|

Red |

|

Green |

White |

|

Black |

|

|

|

|

|

|

|

|||||

|

|

1 |

+ |

|

- |

+ |

|

- |

|

|

↑CLOSING ↑ |

2 |

+ |

|

- |

- |

|

+ |

↓OPENING ↓ |

|

|

3 |

- |

|

+ |

- |

|

+ |

|

|

|

4 |

- |

|

+ |

+ |

|

- |

|

|

|

1 |

+ |

|

- |

+ |

|

- |

|

If the controller driving the ETS valve is from another manufacturer than Danfoss or a custom design, the following points must be considered in order to overcome potential step loss.

a.To ensure total closing of the valve, the controller should have a function to overdrive the valve in the closing direction. It is recommended to overdrive ten percent of the full step range at appropriate intervals.

b.The amount of lost steps may increase as a function of the amount of changes of the opening degree. Such designed controller should be able to compensate the lost steps after a defined number of changes in opening degree.

Warning:

Warning:

At power failure the ETS valve will remain in the opening position it has at the moment of power failure, unless a safety device in the form of a battery backup is installed.

© Danfoss | DCS (rm) | 2019.02 |

DKRCC.PD.VD1.3C.02 | 4 |

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

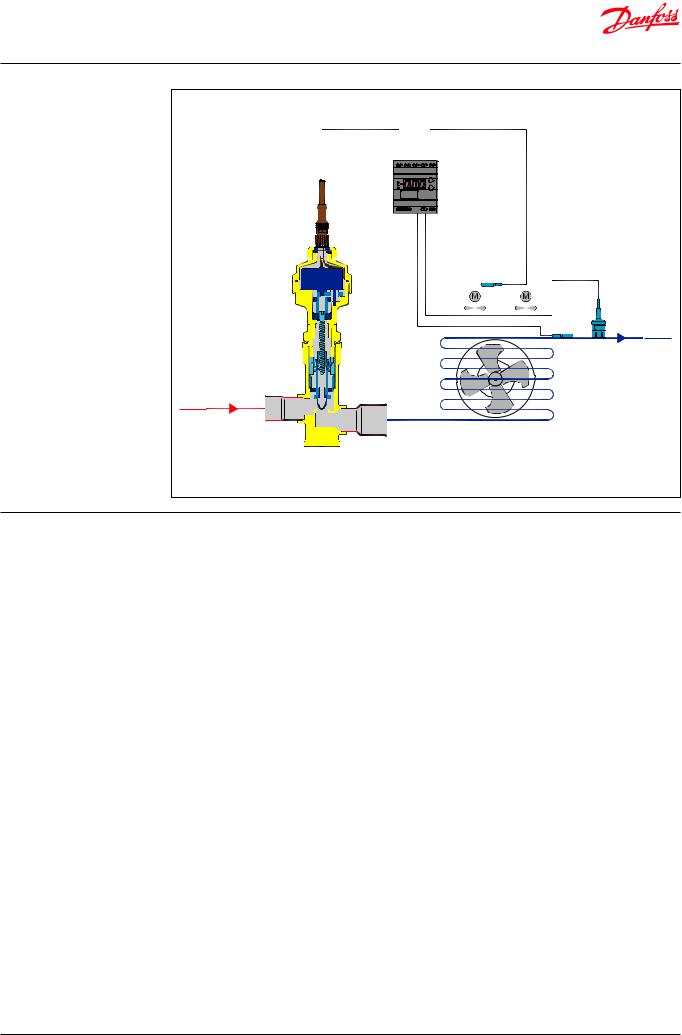

Valve application

| <![if ! IE]> <![endif]>Danfoss 93G18.14 |

Controller/Driver |

Temperature sensor |

Pressure transmitter |

Temperature sensor |

Evaporator |

ETS |

Valve operation |

The ETS valves operate modulating by |

|

electronically controlled activation of the AST |

|

stepper motor. The motor is a type 2-phase |

|

bi-polar, which stays in position, unless power |

|

pulses from a driver initiate the two discrete sets |

|

of motor stator windings for rotation in either |

|

directions. |

|

The direction of the rotation of the spindle |

|

depends on the phase relationship of the power |

|

pulses. This is decisive for the travel of the piston. |

|

The motor is operating the spindle, whose |

|

rotating movements are transformed into linear |

|

motion by the transmission in the cage assembly. |

|

The AST motor housing has a glass sealed M12 |

|

connection as standard, which can be connected |

|

with customized cable and plug/socket |

|

combinations. |

|

The piston design inside the ETS valve is pressure |

|

balanced, giving identical bi-flow performance |

|

capabilities and nearby identical maximum |

|

capacities. |

|

Closing the valve by overdriving, ensures that the |

|

reference number in steps is always correct. |

Operating the ETS series requires a controller with either 12 V DC voltage drive (5.5 W) or using chopper current drive (100 mA RMS).

Note:

Note:

Depending on the type of controller or driver, there will be limitations in cable length between valve actuator and driver.

Both the actual cable length, the level of EMC emission on the location and driver circuit has an impact on the actual distortion of the current to the actuator motor.

In order to increase max. cable length considerably, install a 10 mH filter type Danfoss AKA 211 on the four power terminals.

Please contact Danfoss for further information how and when to apply this countermeasure in cases with questionable cable length.

© Danfoss | DCS (rm) | 2019.02 |

DKRCC.PD.VD1.3C.02 | 5 |

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Coolselector2®

For easy and precise selection of valve, use Danfoss’ CoolSelector2® software. You can find the ETS valves on the group, “Electronic expansion valves”.

You can download it from http://coolselector.danfoss.com

ETS 250, ETS 400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated capacity1) |

|

|

|

|

|

Connection |

|

||||

Valve incl. actuator |

|

Type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R410A |

R407C |

R22 |

R134a |

R404A |

|

ODF × ODF (A × B) |

Code no. |

||||||||

|

|

|

||||||||||||||

|

|

|

[kW] |

[TR] |

[kW] |

[TR] |

[kW] |

[TR] |

[kW] |

[TR] |

[kW] |

[TR] |

|

[in.] |

[mm] |

Single pack |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 1/8 × 1 1/8 |

28 × 28 |

034G2600 |

|

|

ETS 250 |

– |

– |

1212 |

349 |

1106 |

319 |

874 |

252 |

828 |

239 |

|

1 3/8 × 1 3/8 |

35 × 35 |

034G2601 |

|

|

|

1 5/8 × 1 5/8 |

– |

034G2602 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

42 × 42 |

034G2611* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

B |

|

|

|

|

|

|

|

|

|

|

|

|

2 1/8 × 2 1/8 |

– |

034G2624 |

ETS 400 |

– |

– |

1933 |

556 |

1764 |

509 |

1394 |

402 |

1320 |

381 |

|

1 5/8 × 1 5/8 |

– |

034G3500 |

||

|

|

|

||||||||||||||

|

|

|

2 1/8 × 2 1/8 |

54 × 54 |

034G3501 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1) The Rated capacity is based on: |

|

|

|

Evaporating temperature te : |

5 |

°C |

/ 40 °F |

Liquid temperature tl : |

28 |

°C |

/ 82 °F |

Condensing temperature tc : |

32 |

°C |

/ 90 °F |

Full stroke opening in normal flow direction

ETS 250 and ETS 400 have integrated sight glass except 034G2611.

ETS for oil free applications Valve incl. actuator

A B

|

|

|

|

Rated capacity1) |

|

|

|

|||||

Type |

R410A |

R407C |

|

|

R22 |

R134a |

R404A |

|||||

|

[kW] |

[TR] |

[kW] |

[TR] |

|

[kW] |

[TR] |

[kW] |

[TR] |

[kW] |

[TR] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil free |

– |

– |

1212 |

349 |

|

1106 |

319 |

874 |

252 |

828 |

239 |

|

ETS 250 |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil free |

– |

– |

1933 |

556 |

|

1764 |

509 |

1394 |

402 |

1320 |

381 |

|

ETS 400 |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1) The Rated capacity is based on: |

|

|

|

|

|

|

|

|

||||

Evaporating temperature te : |

5 |

°C |

/ 40 °F |

|

|

|

|

|||||

Liquid temperature tl : |

|

28 |

°C |

/ 82 °F |

|

|

|

|

||||

Condensing temperature tc : |

32 |

°C |

/ 90 °F |

|

|

|

|

|||||

Full stroke opening in normal flow direction

For smaller capacities of ETS oil free valves see ETS Colibri

Connection

ODF × ODF (A × B) |

Code no. |

|

[in.] |

[mm] |

Single pack |

|

|

|

1 3/8 × 1 3/8 |

35 × 35 |

034G2625 |

1 5/8 × 1 5/8 |

– |

034G2626 |

1 5/8 × 1 5/8 |

– |

034G3514 |

2 1/8 × 2 1/8 |

54 × 54 |

034G3515 |

ETS 250 and ETS 400 have integrated sight glass

Spare parts |

Cone/piston for ETS 12.5 / ETS 25 |

|

|

||

|

|

|

|||

|

Items |

|

Description |

Quantity |

Code no. |

|

|

[pcs] |

|||

|

|

|

|

|

|

|

|

|

Cone/piston for ETS 12.5 + metal gasket |

1 |

034G2345 |

|

|

Danfoss |

Cone/piston for ETS 25 + metal gasket |

1 |

034G2346 |

|

|

34G181.10 |

|||

Actuator with integrated M12 connection

Items

10.34G179 Danfoss

10.34G179 Danfoss

Description |

Quantity |

Code no. |

|

|

|||

[pcs] |

|||

|

|

||

Actuator with integrated M12 with Ceramic bearing |

1 |

034G2088 |

|

(incl. metal gasket) for ETS 12.5, ETS 25 |

|||

|

|

Actuator with integrated M12 with ceramic bearing

(incl. metal gasket) for ETS 25B, ETS 50, ETS 100, ETS 1 034G2087* 250, ETS 400

Metal Gasket |

1 |

034G2344 |

*For oil free spare parts of ETS 250 and ETS 400. Please contact Danfoss.

© Danfoss | DCS (rm) | 2019.02 |

DKRCC.PD.VD1.3C.02 | 6 |

Loading...

Loading...