Danfoss EXP 203, EXP 204, EXP 403, EXP 205, EXP 206 Data sheet

...

Data sheet

MAKE UP LINE Substations

Make Up substations for secondary heating circuits with heat load up to 8000 KW, and the static height up to 60 mwc

Compact substations for water expansion control in heating installations (secondary side), with atmospheric tank and automatic make / fill up functions Designed for floor mounting

Description

Purpose

This system is suitable for maintaining the pressure between an overpressure given by water dilatation and an underpressure limit given by loses of water from different reasons in secondary heating circuit.

Installation

The MAKE UP LINE is a range of systems mounted on the secondary side of district heating systems or thermal plants with a maximum temperature of 115 oC and PN 6 / PN 10 in the flow circuit.

Function

The Make Up system has the function to discharge the soft water into an atmospheric tank via pressure relief valve(s) if the heating circuit develops a pressure value over the maximum set value or has the function to fill up the heating installation circuit via make up pump(s) if the pressure decreases below the minimum set value. The volume of filling up water or the leakage water from heating circuit is automatically replaced in water tank via solenoid valve.

Also, the system:

-is able to protect the pump in case of water lack;

-can assure a sequential start of pumps;

-is able to stop functioning pumps in case of pipe breaking;

-can make automate switching on the second pump in case of failure function of the first;

-assures the permanent monitoring of the water level in the atmospheric tank (minimum, normal and maximum);

-assures the filtering of water.

Construction

The construction is compact, simple and easy to use. The pipes are corrosion protected through galvanic treatment both on the inside and on the outside. The components selection (size and type) is made using a calculation method developed by Schmidt-Bretten Technology, member of Danfoss Group.

Specific advantages

-protection of the heating circuit at overpressure

-automatic control of pressure in heating circuit

-monitoring and remote control

-a unitary system, ready to be mounted in site, easy to install for a minimal location site

-very good performances when coupling with Schmidt heating substations

DH-SMT/PL |

VD.EH.D1.02 © Danfoss 02/2009 |

1 |

Data sheet |

MAKE-UP LINE Substations |

|

|

Ordering |

The Make Up substation is made up of the pump group (see Table 1) and of the Storage tank (see |

|

Table 2) that are ordered separately. |

Table 1

Pump group range and their ordering codes

Type |

Code no |

|

|

EXP 203 |

004F4094 |

|

|

EXP 204 |

004F4095 |

EXP 205 |

004F4096 |

|

|

EXP 206 |

004F4097 |

|

|

EXP 403 |

004F4098 |

EXP 404 |

004F4099 |

|

|

EXP 405 |

004F4100 |

|

|

EXP 406 |

004F4101 |

EXP 802 |

004F4102 |

|

|

EXP 803 |

004F4103 |

|

|

EXP 804 |

004F4104 |

EXP 805 |

004F4105 |

|

|

Table 2

Atmospheric storage tank range and their ordering codes

Storage tank volume |

Code no |

[liters] |

|

|

|

200 |

CTK0101 |

|

|

300 |

CTK0102 |

400 |

CTK0103 |

|

|

500 |

CTK0104 |

|

|

800 |

CTK0105 |

1000 |

CTK0106 |

|

|

1200 |

CTK0107 |

|

|

1500 |

CTK0108 |

2000 |

CTK0109 |

|

|

2500 |

CTK0110 |

|

|

3000 |

CTK0111 |

3500 |

CTK0112 |

|

|

4000 |

CTK0113 |

|

|

Technical parameters: |

WORKING MEDIUM (heating circuit) |

|

|

|

|||

|

Maximum temperature |

T |

|

= 115oC |

|

|

|

|

Nominal pressure |

max |

|

|

|

||

|

PN 6 / PN 10 |

|

|

||||

|

MAKE UP SOURCE |

|

|

|

|

|

|

|

Maximum temperature |

T |

|

= 80oC |

|

|

|

|

Nominal pressure |

max |

|

|

|

||

|

PN 6 / PN 10 |

|

|

||||

|

Electrical supply |

3~ 400 V / 50 Hz |

|

|

|||

Table 3 Low power Make up substations characteristics |

|

|

|

|

|

||

|

|

|

|

|

|

||

Type |

EXP 203 |

|

EXP 204 |

EXP 205 |

EXP 206 |

||

Pressure relief controller - range |

1 ÷ 4.5 bar |

|

1 ÷ 4.5 bar |

3 ÷ 11 bar |

3 ÷ 11 bar |

||

|

|

|

|

|

|

||

Electrical power [kW] |

2 x 0.55 |

|

2 x 0.55 |

2 x 0.75 |

2 x 1.1 |

||

|

|

|

|

|

|

|

|

DN collectors |

DN 40 |

|

|

DN 40 |

DN 40 |

DN 40 |

|

Table 4 Medium power Make up substations characteristics |

|

|

|

|

|

||

|

|

|

|

|

|

||

Type |

EXP 403 |

|

EXP 404 |

EXP 405 |

EXP 406 |

||

|

|

|

|

|

|

||

Pressure relief controller - range |

1 ÷ 4.5 bar |

|

1 ÷ 4.5 bar |

3 ÷ 11 bar |

3 ÷ 11 bar |

||

Electrical power [kW] |

2 x 0.55 |

|

2 x 0.75 |

2 x 1.1 |

2 x 1.5 |

||

|

|

|

|

|

|

||

DN collectors |

DN 50 |

|

DN 50 |

DN 50 |

DN 50 |

||

|

|

|

|

|

|

|

|

Table 5 High power Make up substations characteristics |

|

|

|

|

|

||

Type |

EXP 802 |

|

EXP 803 |

EXP 804 |

EXP 805 |

||

|

|

|

|

|

|

||

Pressure relief controller - range |

1 ÷ 4.5 bar |

|

1 ÷ 4.5 bar |

1 ÷ 4.5 bar |

3 ÷ 11 bar |

||

|

|

|

|

|

|

|

|

Electrical power [kW] |

2 x 0.75 |

|

|

2 x 1.1 |

2 x 1.5 |

2 x 1.85 |

|

DN collectors |

DN 65 |

|

|

DN 65 |

DN 65 |

DN 65 |

|

|

|

|

|

|

|

|

|

2 |

VD.EH.D1.02 © Danfoss 02/2009 |

DH-SMT/PL |

Data sheet |

MAKE-UP LINE Substations |

|

|

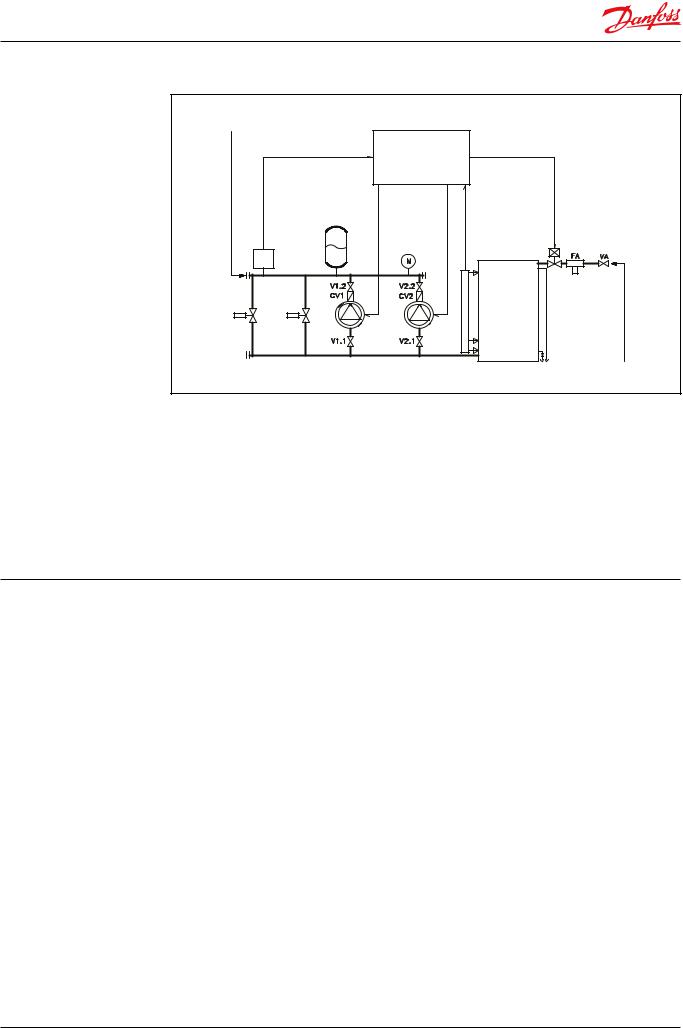

Design: |

R1 (R2): heating |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

installation connection |

|

|

|

|

|

|

|

|

|

|

ELP |

|

|

|

|

|

P |

VTM |

|

|

EVM |

|

|

|

|

M |

|

FA |

VA |

|

|

|

|

|

|

|

||

|

|

|

V1.2 |

V2.2 |

|

|

|

|

|

|

CV1 |

CV2 |

|

|

|

|

VD1 |

VD2 |

PA1 |

PA2 |

L |

WT |

|

|

|

|

V1.1 |

V2.1 |

|

|

|

|

|

|

|

|

|

|

R3: soft water |

|

|

|

|

|

|

|

connection |

|

Components: |

|

|

|

|

|

|

|

PA1 (PA2) |

Make up pump – one or two pieces |

V1 (V2) |

Shut off valve – pump circuit |

|||

|

VD1 (VD2) |

Excess pressure valve |

|

VA |

Shut off valve – fill up circuit |

||

|

|

(pressure relief controller) |

|

CV1 (CV2) |

Check valve |

|

|

|

|

– one or two pieces |

|

FA |

Strainer |

|

|

|

EVM |

Solenoid valve |

|

M |

Manometer |

|

|

|

P |

Pressure sensor |

|

WT |

Atmospheric water tank |

||

|

L |

Level switches |

|

VTM |

Closed pressure vessel |

||

|

ELP |

Electric and control panel |

|

|

(against pressure shocks) |

||

Main functions: |

- Maintains heating system pressure in very strict |

|

limits; |

-Protects the heating circuit against overpressure;

-Fills up and makes up the heating circuit;

-Recovers the discharged soft water from the heating system;

-Monitors the water leakage and, in case of pipe breaking, stops the pumps;

-Monitors the water level in atmospheric tank (minimum, normal and maximum);

-Fills up water tank;

-Protects pump in case of water lack;

-Communicates via standardized RS485 optional modules

Specific restriction

- The soft water available flow should be larger than the necessary make up flow for heating circuit.

DH-SMT/PL |

VD.EH.D1.02 © Danfoss 02/2009 |

3 |

Loading...

Loading...