BOSCH GDR10 8V-LI User Manual

OBJ_BUCH-241-002.book Page 1 Thursday, December 14, 2006 8:52 AM

GDR 10,8 V-LI

PROFESSIONAL

Operating Instructions

Petunjuk-Petunjuk untuk Penggunaan

Hõëng dÿn s¥ dông

Instructions d’emploi

ÁU~²Ýœ ÈULM¼«—

OBJ_BUCH-241-002.book Page 2 Thursday, December 14, 2006 8:52 AM

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Bahasa Indonesia . . . . . . . . . . . . . . . . . Halaman 33

Tiøng Vi·t . . . . . . . . . . . . . . . . . . . . . . .Trang 39

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

ΔΤϔλ 51 |

vÝ—U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

ϪΤϔλ 56 |

2 |

|

|

|

2 609 140 432 • 14.12.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

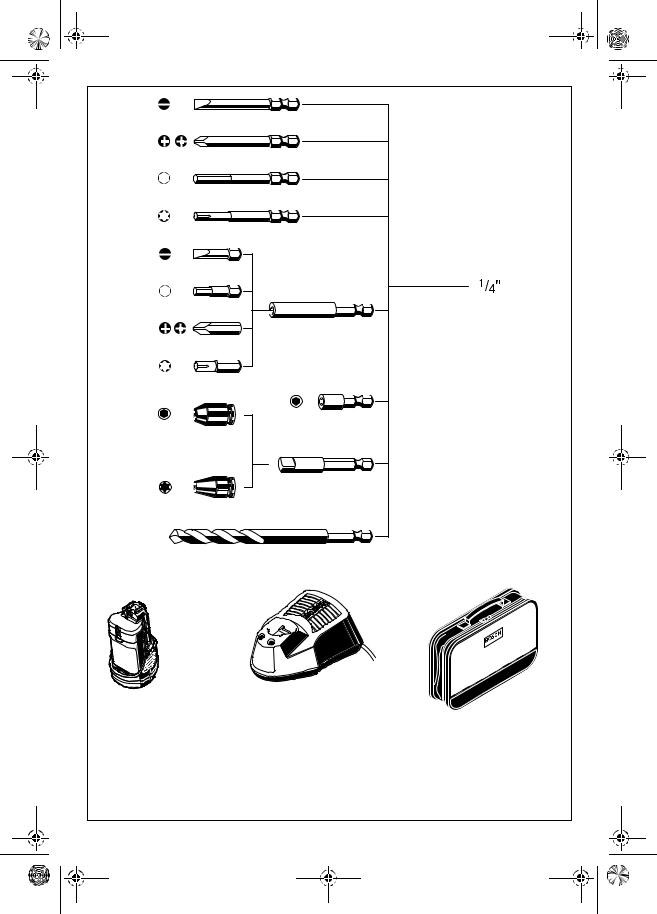

OBJ_BUCH-241-002.book Page 3 Thursday, December 14, 2006 8:52 AM |

|

||

|

AL 1130 CV |

|

|

10,8 V |

(10,8 V) |

|

|

2 607 336 028 |

2 607 225 134 |

(MY/SG/HK) |

6 035 960 844 |

|

2 607 225 136 |

(Far East) |

|

|

2 607 225 138 |

(AU) |

|

|

2 607 225 142 |

(TW) |

|

|

2 607 225 146 |

(KR) |

|

|

2 607 225 304 (CN) |

|

|

3 |

|

|

2 609 140 432 • 14.12.06 |

OBJ_BUCH-241-002.book Page 4 Thursday, December 14, 2006 8:52 AM |

|

4 |

|

3 |

|

2 |

|

1 |

|

|

5 |

9 |

|

8 |

|

|

6 |

|

7 |

GDR 10,8 V-LI |

|

PROFESSIONAL |

|

4 |

2 609 140 432 • 14.12.06 |

OBJ_BUCH-241-002.book Page 5 Thursday, December 14, 2006 8:52 AM

A

6 |

7 |

C |

8 |

8 |

5 |

B |

3 |

2 |

1 |

10 |

1 |

2 609 140 432 • 14.12.06

OBJ_BUCH-241-002.book Page 6 Thursday, December 14, 2006 8:52 AM

General Power Tool Safety

Warnings

|

Read all safety warnings and all |

|

WARNING |

||

instructions. Failure to follow the |

||

|

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-oper- ated (cordless) power tool.

1)Work area safety

a)Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b)Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

c)Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2)Electrical safety

a)Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

b)Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c)Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d)Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e)When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f)If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) or an earth leakage circuit breaker (ELCB). Use of a GFCI or an ELCB reduces the risk of electric shock.

3)Personal safety

a)Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

b)Use personal protective equipment. Always wear eye protection. Protective equipment such as dusk mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

c)Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

d)Remove any adjusting key or wrench before turning the power tool on. A wrench or a key that is left attached to a rotating part of the power tool may result in personal injury.

e)Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f)Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

g)If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dustrelated hazards.

4)Power tool use and care

a)Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it is designed.

b)Do not use the power tool if the switch does not turn it on or off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c)Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

|

6 | English |

|

|

2 609 140 432 • 14.12.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 7 Thursday, December 14, 2006 8:52 AM

d)Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e)Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f)Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g)Use the power tool, accessories, tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

5)Battery tool use and care

a)Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

b)Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

c)When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another.

Shorting the battery terminals together may cause burns or a fire.

d)Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. In liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

6)Service

a)Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Power Tool-specific Safety

Warnings

f Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

fAlways wait until the power tool has come to a complete stop before placing it down. The tool insert can jam and lead to loss of control over the power tool.

fBefore any work on the power tool (e. g., maintenance, tool change, etc.) as well as during transport and storage, set the rotational direction switch to the center position.

Unintentional actuation of the On/Off switch can lead to injuries.

fAvoid unintentional switching on. Ensure the On/Off switch is in the off position before inserting battery pack. Carrying the power tool with your finger on the On/Off switch or inserting the battery pack into power tools that have the switch on invites accidents.

fDo not open the battery. Danger of short-circuit- ing.

fProtect the battery against heat, e.g., also against continuous sun irradiation and fire.

There is danger of explosion.

fDo not short-circuit the battery. There is danger of explosion.

fIn case of damage and improper use of the battery, vapors may be emitted. Provide for fresh air and seek medical help in case of complaints. The vapors can irritate the respiratory system.

Functional Description

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

While reading the operating instructions, unfold the graphics page for the tool and leave it open.

Intended Use

The machine is intended for driving in and loosening screws and bolts as well as for tightening and loosening nuts within the respective range of dimension.

|

2 609 140 432 • 14.12.06 |

|

|

English | 7 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 8 Thursday, December 14, 2006 8:52 AM

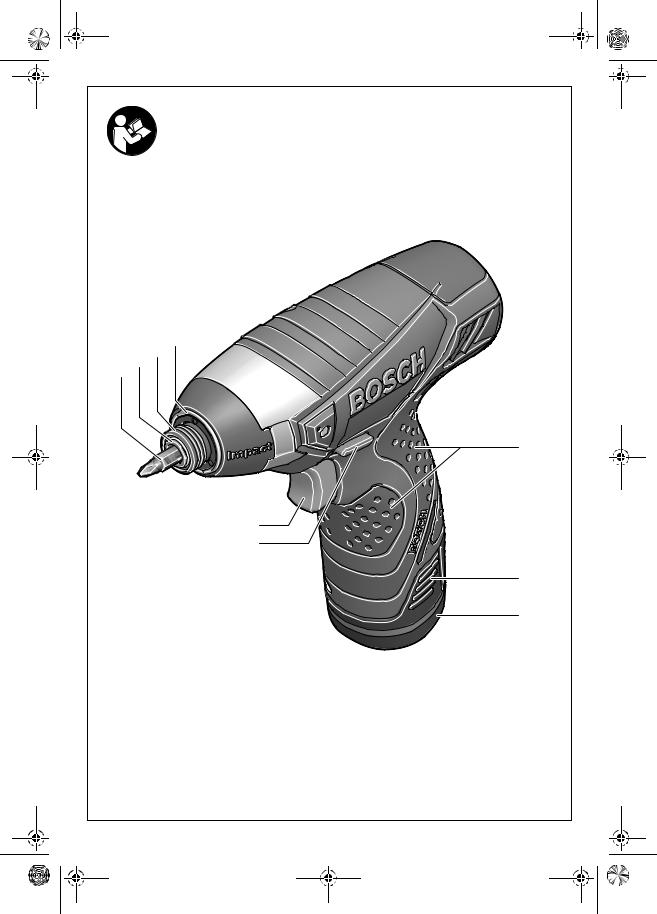

Product Features

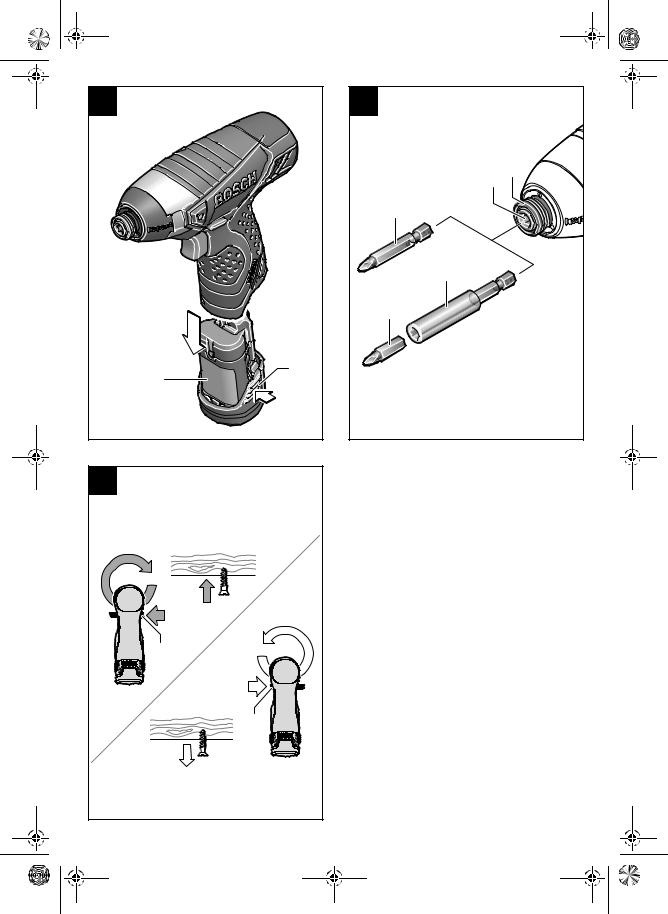

The numbering of the product features refers to the illustration of the power tool on the graphics page.

1 Screwdriver bit*

2 Tool holder

3 Locking sleeve

4 “Power Light”

5 Soft grip

6 Battery release button

7 Battery*

8 Rotational direction switch

9 On/Off switch

10 Universal bit holder*

*The accessories illustrated or described are not included as standard delivery.

WARNING Do not continue to press the On/Off switch after the machine

has been automatically switched off. The battery can be damaged.

The battery is supplied partially charged. Completely charge the battery before using your power tool for the first time. The lithium ion battery can be charged at any time without reducing its service life. Interrupting the charging procedure does not damage the battery.

To remove the battery 7, press the unlocking buttons 6 and pull out the battery downwards. Do not exert any force.

The battery is equipped with an NTC temperature control which allows charging only within a temperature range of between 0 °C and 45 °C. A long battery service life is achieved in this manner.

Observe the notes for disposal.

Technical Data

Cordless Impact Screwdriver |

GDR 10,8 V-LI |

|

|

|

PROFESSIONAL |

Article number |

|

3 601 J09 0.. |

Rated voltage |

V= |

10.8 |

No-load speed |

rpm |

0 –1800 |

Impact rate |

bpm |

0 –3000 |

Maximum torque, hard |

|

|

screwdriving application |

|

|

according to ISO 5393 |

Nm |

100 |

Bolt size |

|

M4 – M12 |

Max. screw dia. |

mm |

8 |

Tool holder |

|

¼" hexagon socket |

Weight according to |

|

|

EPTA-Procedure |

|

|

01/2003 |

kg |

1.0 |

Please observe the article number on the type plate of your power tool. The trade names of individual tools may vary.

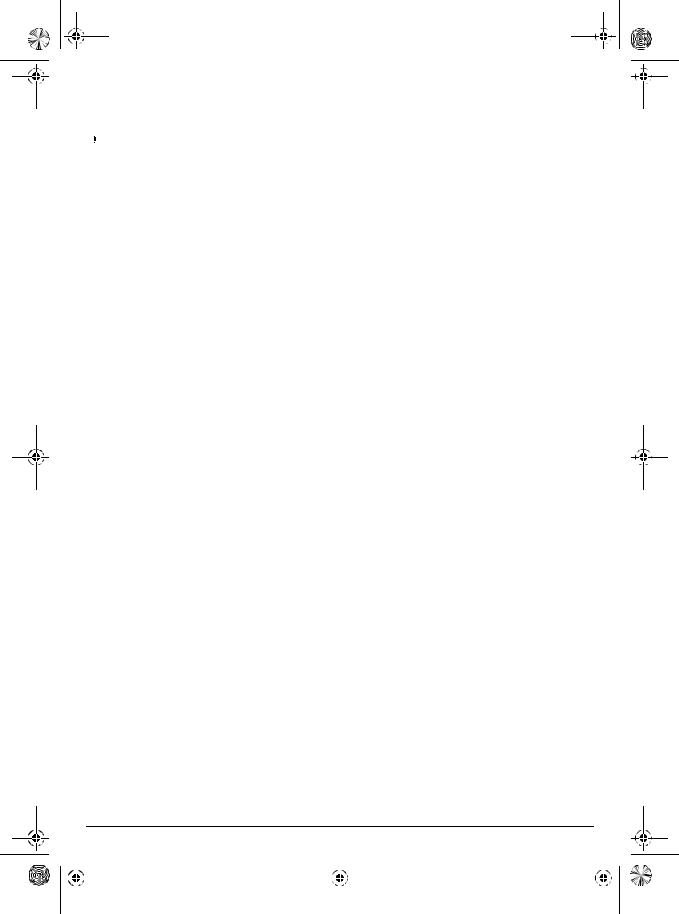

Changing the Tool (see figure B)

f Before any work on the power tool (e. g., maintenance, tool change, etc.) as well as during transport and storage, set the rotational direction switch to the center position.

Unintentional actuation of the On/Off switch can lead to injuries.

Inserting

Pull the locking sleeve 3 forward, push the insert tool to the stop into the tool holder 2 and release the locking sleeve 3 to lock the insert tool.

For quick changing of bits, it is recommended to use a universal bit holder 10.

Removing

Pull the locking sleeve 3 forward and remove the insert tool.

Assembly

Battery Charging (see figure A)

f Use only the battery chargers listed on the accessories page. Only these battery chargers are matched to the lithium ion battery of your power tool.

The lithium ion battery is protected against deep discharging by the “Electronic Cell Protection (ECP)”. When the battery is empty, the machine is switched off by means of a protective circuit: The inserted tool no longer rotates.

Operation

Method of Operation

The tool holder 2 with the tool is driven by an electric motor via a gear and impact mechanism.

The working procedure is divided into two phases: Screwing in and tightening (impact mechanism in action).

The impact mechanism is activated as soon as the screwed connection runs tight and thus load is put on the motor. In this instance, the impact mechanism converts the power of the motor to steady rotary impacts. When loosening screws or nuts, the process is reversed.

|

8 | English |

|

|

2 609 140 432 • 14.12.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 9 Thursday, December 14, 2006 8:52 AM

Starting Operation

Inserting the Battery

fUse only original Bosch lithium ion batteries with the voltage listed on the nameplate of your power tool. Using other batteries can lead to injuries and pose a fire hazard.

Note: Use of batteries not suitable for the machine can lead to malfunctions of or cause damage to the power tool.

Set the rotational direction switch 8 to the center position in order to avoid unintentional starting. Insert the charged battery 7 into the handle so that it can be felt to engage and faces flush against the handle.

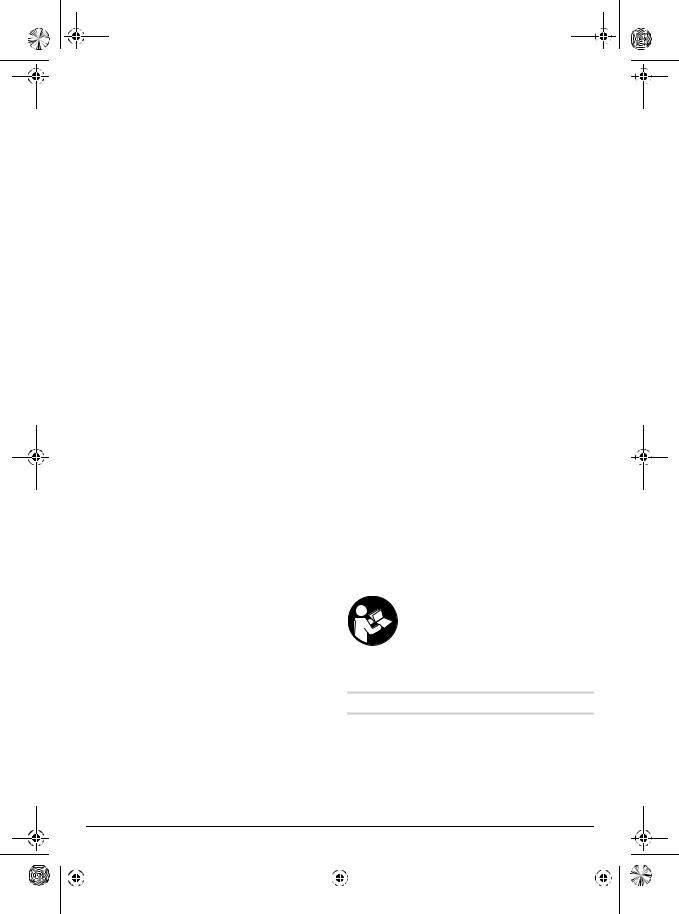

Reversing the Rotational Direction (see figure C)

The rotational direction switch 8 is used to reverse the rotational direction of the machine. However, this is not possible with the On/Off switch 9 actuated.

Right rotation: For driving in screws and tightening nuts, press the rotational direction switch 8 through to the left stop.

Left Rotation: For loosening and unscrewing screws and nuts, press the rotational direction switch 8 through to the right stop.

Switching On and Off

To start the power tool, press the On/Off switch 9 and keep it pressed.

The power light 4 lights up when the On/Off switch 9 is slightly pressed, and enables illumination of the screwing location in unfavorable light conditions.

To switch off the power tool, release the On/Off switch 9.

Adjusting the Speed

The speed of the switched on power tool can be variably adjusted, depending on how far the On/Off switch 9 is pressed.

Light pressure on the On/Off switch 9 results in a low rotational speed. Further pressure on the switch results in an increase in speed.

Temperature Dependent Overload Protection

When using as intended for, the power tool cannot be subject to overload. When the load is too high or the allowable battery temperature of 70 °C is exceeded, the speed is reduced. The power tool will not run at full capacity until after cooling down.

Protection Against Deep Discharging

The lithium ion battery is protected against deep discharging by the “Electronic Cell Protection (ECP)”. When the battery is empty, the machine is switched off by means of a protective circuit: The inserted tool no longer rotates.

Working Instructions

f Apply the power tool to the screw/nut only when it is switched off. Rotating tool inserts can slip off.

The torque depends on the impact duration. The maximum achieved torque results from the sum of all individual torques achieved through impact. The maximum torque is achieved after an impact duration of 6– 10 seconds. After this duration, the tightening torque is increased only minimally.

The impact duration is to be determined for each required tightening torque. The actually achieved tightening torque is always to be checked with a torque wrench.

Screw Applications with Hard, Spring-loaded or Soft Seat

When in a test, the achieved torques in an impact series are measured and transferred into a diagram, the result is the curve of a torque characteristic. The height of the curve corresponds with the maximum reachable torque, and the steepness indicates the duration in which this is achieved.

A torque gradient depends on the following factors:

•Strength properties of the screws/nuts

•Type of backing (washer, disc spring, seal)

•Strength properties of the material being screwed/bolted together

•Lubrication conditions at the screw/bolt connection

The following application cases result accordingly:

•A hard seat is given for metal-to-metal screw applications with the use of washers. After a relatively short impact duration, the maximum torque is reached (steep characteristic curve). Unnecessary long impact duration only causes damage to the machine.

•A spring-loaded seat is given for metal-to-metal screw applications, however with the use of spring washers, disc springs, studs or screws/nuts with conical seat as well as when using extensions.

•A soft seat is given for screw applications, e. g., metal on wood or when using lead washers or fiber washers as backing.

For a spring-loaded seat as well as for a soft seat, the maximum tightening torque is lower than for a hard seat. Also, a clearly longer impact duration is required.

|

2 609 140 432 • 14.12.06 |

|

|

English | 9 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 10 Thursday, December 14, 2006 8:52 AM

Reference Values for Maximum Screw/Bolt Tightening Torques |

|

|

|

|

|

|

|||||

Calculated from the tensional cross-section; utilization |

of the yield |

point |

90 % |

(with |

friction coefficient |

||||||

µtotal = 0.12). As a control measure, always check the tightening torque with a torque wrench. |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Property Classes according to |

Standard Screws/Bolts |

|

|

|

|

High-strength |

|||||

DIN 267 |

|

|

|

|

|

|

|

|

Bolts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.6 |

4.6 |

5.6 |

4.8 |

6.6 |

5.8 |

6.8 |

6.9 |

8.8 |

10.9 |

12.9 |

|

|

|

|

|

|

|

|

|

|

|

|

M 6 |

2.71 |

3.61 |

4.52 |

4.8 |

5.42 |

6.02 |

7.22 |

8.13 |

9.7 |

13.6 |

16.2 |

|

|

|

|

|

|

|

|

|

|

|

|

M 8 |

6.57 |

8.7 |

11 |

11.6 |

13.1 |

14.6 |

17.5 |

19.7 |

23 |

33 |

39 |

|

|

|

|

|

|

|

|

|

|

|

|

M 10 |

13 |

17.5 |

22 |

23 |

26 |

29 |

35 |

39 |

47 |

65 |

78 |

|

|

|

|

|

|

|

|

|

|

|

|

M 12 |

22.6 |

30 |

37.6 |

40 |

45 |

50 |

60 |

67 |

80 |

113 |

135 |

|

|

|

|

|

|

|

|

|

|

|

|

Tips

Before screwing larger, longer screws into hard materials, it is advisable to predrill a pilot hole with the core diameter of the thread to approx. 2/3 of the screw length.

Soft Grip

The gripping surface (soft grip) 5 reduces the danger of slipping and thereby improves the grip on the machine and the handling.

At the same time, the rubber coating achieves a vibra- tion-reducing effect.

Maintenance and Service

Maintenance and Cleaning

f Before any work on the power tool (e. g., maintenance, tool change, etc.) as well as during transport and storage, set the rotational direction switch to the center position.

Unintentional actuation of the On/Off switch can lead to injuries.

fFor safe and proper working, always keep the power tool and the ventilation slots clean.

When the battery is no longer operative, please refer to an authorized after-sales service agent for Bosch power tools.

If the power tool should fail despite the care taken in manufacturing and testing procedures, repair should be carried out by an after-sales service center for Bosch power tools.

In all correspondence and spare parts orders, please always include the 10-digit article number given on the type plate of the power tool.

Service and Customer Assistance

Exploded views and information on spare parts can be found under:

www.bosch-pt.com

In case of a claim, repair or purchase of replacement parts or in case of queries or other problems, please contact your local dealer or Bosch representative.

People’s Republic of China

Website: www.bosch-pt.com.cn

China Mainland

Bosch Power Tools (China) Co., Ltd. 567, Bin Kang Road

Bin Jiang District 310052 Hangzhou, P.R.China

Service Hotline: . . . . . . . . . . . . . . . . . . 800 8 20 84 84. . . . . . . . . . . . . . . . . . . . . . . . +86 571 87 77 43 38 Fax . . . . . . . . . . . . . . . . . . . . . . . . +86 571 87 77 45 02

HK and Macau Special Administrative Regions

Melchers (H.K.) Ltd, Room 1210 Shun Tak Centre, West-Tower

168 – 200 Connaught Road, Central Hong Kong Customer Service Hotline: . . . . . . . +852 25 89 15 61 Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . +852 25 48 79 14 E-Mail: bosch@melchers.com.hk

Indonesia

P. T. Multi Tehaka

Karang Anyar Permai Block B-24 Jl. Karang Anyar No. 55

Jakarta Pusat 10740 Indonesia

. . . . . . . . . . . . . . . . . . . +62 21 6 59 52 22 (5 lines) Fax . . . . . . . . . . . . . . . . . . . . . . . +62 21 6 59 52 52 – 3 sales@bosch.co.id

www.bosch.co.id

|

10 | English |

|

|

2 609 140 432 • 14.12.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 11 Thursday, December 14, 2006 8:52 AM

OBJ_BUCH-241-002.book Page 11 Thursday, December 14, 2006 8:52 AM

Phillippines

Robert Bosch, Inc. Zuellig Building

Sen. Gil Puyat Avenue

Makati City 1200, Metro Manila Philippines

. . . . . . . . . . . . . . . . . . . . . . . . . . . +63 2 8 17 32 31 www.bosch.com.ph

Malaysia

Robert Bosch (SEA.) Pte. Ltd. No. 8a, Jalan 13/6

Selangor Darul Ehsan

Petaling Jaya 46200 Malaysia

. . . . . . . . . . . . . . . . . . . . . . . . . . +60 3 79 58 30 00 Fax (EW Dept.) . . . . . . . . . . . . . . . +60 3 79 58 38 38 www.bosch.com.sg

Thailand

Robert Bosch Ltd. Liberty Square Building No. 287, 11 Floor Silom Road, Bangrak Bangkok 10500

. . . . . . . . . . . . +66 2 6 31 18 79 – 18 88 (10 lines) Fax. . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 38 47 83 Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501, Thailand

Bosch Service – Training Centre 2869-2869/1 Soi Ban Kluay

Rama IV Road (near old Paknam Railway) Prakanong District

10110 Bangkok Thailand

. . . . . . . . . . . . . . . . . . . . . . . . +66 26 71 78 00 – 4 Fax . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 49 42 96 Fax . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 49 52 99

Singapore

Robert Bosch (SEA.) Pte. Ltd. 38 C Jalan Pemimpin Singapore 915701

Republic of Singapore

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +65 3 50 54 94 Fax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +65 3 50 53 27 www.bosch.com.sg

Vietnam

Saigon Trade Center

37 Ton Duc Thang St Ben Nghe Ward

Dist 1

HCMC

Vietnam

. . . . . . . . . . . . . . . . +84 8 9 11 13 74 – 9 11 13 75 Fax. . . . . . . . . . . . . . . . . . . . . . . . . . . +84 8 9 11 13 76

Australia and New Zealand

Robert Bosch Australia Pty. Ltd. RBAU/SPT

1555 Centre Road P.O. Box 66

3168 Clayton/Victoria

. . . . . . . . . . . . . . . . . . . . . +61 (0)1 / 3 00 30 70 44 Fax . . . . . . . . . . . . . . . . . . . . . +61 (0)1 / 3 00 30 70 45 www.bosch.com.au

Transport

The battery is tested according to UN document ST/SG/AC.10/11/Rev.3 Part III, subsection 38.3. It has effective protection against internal overpressure and short circuiting as well as devices for the prevention of violent rupture and dangerous reverse current flow.

The lithium-equivalent content in the battery is below applicable limit values. Therefore, the battery is not subject to national or international regulations pertaining to dangerous mediums, neither as an individual component nor when inserted into a machine. However, the regulations governing dangerous goods may be relevant when transporting several batteries. In this case, it can be necessary to comply with special conditions (e.g., concerning the packaging). For more information, please refer to the instruction sheet (in English) under the following Internet address: http://purchasing. bosch.com/en/start/Allgemeines/Download/index.htm.

Disposal

Power tools, accessories and packaging should be sorted for environmental-friendly recycling.

Battery packs/batteries:

Lithium ion:

Please observe the information under “Transport”.

Do not dispose of battery packs/batteries into household waste, fire or water. Battery packs/batteries should be collected, recycled or disposed of in an envi- ronmental-friendly manner.

Subject to change without notice.

|

2 609 140 432 • 14.12.06 |

|

|

English | 11 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 12 Thursday, December 14, 2006 8:52 AM

/

" "

a) 昏暗的工作场所容易导致意外。

易引燃尘埃或易燃蒸汽。

b) 害的发生机率。

c)/

d) 整工具/ ,

e) 助您在突发状况下及时控制住电动工具。

f) 首饰容易被捲入转动的机件中。

2) |

g) |

|

b) 容易遭受电击。

高操作者遭受电击的危险。

e) 低操作者遭受电击的危险。

f) 流保护开关可以预防遭受电击。

a) 用电动工具时只要稍微分心便可能发生后果严重 的意外。

b) 将故障的机器送修。

c) 必须先从插座上拔出插头并且/

d) 动工具容易发生意外。

e) 彻底执行机器的维护工作容易导致工作意外。

f) 操作。

|

12 | |

|

|

2 609 140 432 • 14.12.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 13 Thursday, December 14, 2006 8:52 AM

b) 的蓄电池可能发生工作意外並引起火灾。

並且/

d) 电池流出的液体会刺激或灼伤皮肤。

a) 器的安全性能。

1 *

2

3

4 " "

5

6

7 *

8

9

f 用手持握工件更牢固。

f 具。

f 爆炸的危险。

f 的蒸汽会刺激呼吸道。

10 *

*

/ |

|

GDR 10,8 V-LI |

|

|

PROFESSIONAL |

|

|

3 601 J09 0.. |

|

V= |

10,8 |

|

/ |

0 – 1800 |

|

/ |

0 – 3000 |

ISO 5393 |

|

|

|

|

100 |

Ø |

|

M4 – M12 |

|

|

8 |

|

|

¼" |

EPTA- |

|

|

Procedure 01/2003 |

|

1,0 |

|

2 609 140 432 • 14.12.06 |

|

|

| 13 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 14 Thursday, December 14, 2006 8:52 AM

A

f 具上的锂离子蓄电池的专用充电器。

" (ECP)"

关。

67

NTC045

B

3 23

10

先向前抽拉锁定套筒3

2

8 7

C

89

8

/ 8

/

9

9 4

9

9

9

70

" (ECP)"

|

14 | |

|

|

2 609 140 432 • 14.12.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 15 Thursday, December 14, 2006 8:52 AM

f/

击所产生的单一扭力的总和。在冲击约6 –10

可以得到扭力变化的曲线。曲线的最高点是最大扭力。 上升的线段则代表到达最大扭力所须的时间。

•/

• 会损坏机器。

• 栓、带圆锥座的螺丝/

• 垫片。

90 % µ = 0,12

DIN 267 |

|

|

|

|

|

|

|

|

|

||

|

3.6 |

4.6 |

5.6 |

4.8 |

6.6 |

5.8 |

6.8 |

6.9 |

8.8 |

10.9 |

12.9 |

|

|

|

|

|

|

|

|

|

|

|

|

M 6 |

2.71 |

3.61 |

4.52 |

4.8 |

5.42 |

6.02 |

7.22 |

8.13 |

9.7 |

13.6 |

16.2 |

|

|

|

|

|

|

|

|

|

|

|

|

M 8 |

6.57 |

8.7 |

11 |

11.6 |

13.1 |

14.6 |

17.5 |

19.7 |

23 |

33 |

39 |

|

|

|

|

|

|

|

|

|

|

|

|

M 10 |

13 |

17.5 |

22 |

23 |

26 |

29 |

35 |

39 |

47 |

65 |

78 |

|

|

|

|

|

|

|

|

|

|

|

|

M 12 |

22.6 |

30 |

37.6 |

40 |

45 |

50 |

60 |

67 |

80 |

113 |

135 |

|

|

|

|

|

|

|

|

|

|

|

|

的2/3

5

f 高工作品质和安全性。

户服务中心求援。

的顾客服务处修理。

10

|

2 609 140 432 • 14.12.06 |

|

|

| 15 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 16 Thursday, December 14, 2006 8:52 AM

OBJ_BUCH-241-002.book Page 16 Thursday, December 14, 2006 8:52 AM

|

|

|

www.bosch-pt.com

询。

www.bosch-pt.com.cn

567

310052 . . . . . . . . . . . . . . . . . . . . . . 800 8 20 84 84

. . . . . . . . . . . . . . . . . . . . . . . . +86 571 87 77 43 38. . . . . . . . . . . . . . . . . . . . . . . . +86 571 87 77 45 02

香港上环干诺道中168 – 2001210

. . . . . . . . . . . . . . . . . . . +852 25 89 15 61. . . . . . . . . . . . . . . . . . . . . . . . . . . +852 25 48 79 14bosch@melchers.com.hk

UN

ST/SG/AC.10/11/Rev.3 38.3http://purchasing. bosch.com/en/start/Allgemeines/Download/index.htm.

和废弃的包装材料。

/

请注意" "

中。请收集损坏的充电电池//

|

16 | |

|

|

2 609 140 432 • 14.12.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 17 Thursday, December 14, 2006 8:52 AM

/

" "

a) 昏暗的工作場所容易導致意外。

易引燃塵埃或易燃蒸汽。

合適的插座可以降低遭受電擊的危險。

b) 容易遭受電擊。

高操作者遭受電擊的危險。

e) 低操作者遭受電擊的危險。

f) 流保護開關可以預防遭受電擊。

a) 用電動工具時只要稍微分心便可能發生後果嚴重 的意外。

b) 害的發生機率。

c)/

d) 整工具/ ,

e) 助您在突發狀況下及時控制住電動工具。

f) 首飾容易被捲入轉動的機件中。

g) 體。

b) 將故障的機器送修。

c) 必須先從插座上拔出插頭并且/

d) 動工具容易發生意外。

e) 徹底執行機器的維護工作容易導致工作意外。

f) 操作。

|

2 609 140 432 • 14.12.06 |

|

|

| 17 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 18 Thursday, December 14, 2006 8:52 AM

b) 的蓄電池可能發生工作意外並引起火災。

並且/

翻開折疊

d) 電池流出的液體會刺激或灼傷皮膚。

a) 器的安全性能。

1 *

2

3

4 " "

5

6

7 *

8

9

f 比用手持握工件更牢固。

f 具。

f 爆炸的危險。

f 的蒸汽會刺激呼吸道。

10 *

*

/ |

|

GDR 10,8 V-LI |

|

|

PROFESSIONAL |

|

|

3 601 J09 0.. |

|

V= |

10,8 |

|

/ |

0 – 1800 |

|

/ |

0 – 3000 |

ISO 5393 |

|

|

|

|

100 |

Ø |

|

M4 – M12 |

|

|

8 |

|

|

¼" |

EPTA- |

|

|

Procedure 01/2003 |

|

1,0 |

有

|

18 | |

|

|

2 609 140 432 • 14.12.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-241-002.book Page 19 Thursday, December 14, 2006 8:52 AM

A

f 具上的鋰離子蓄電池的專用充電器。

" (ECP)":

關。

67

NTC- 0 45

B

3 23

10

3

2

:

行。

8 7

C

89

8

/ 8

/

9

9 4

9

9

9

70

" (ECP)":

|

2 609 140 432 • 14.12.06 |

|

|

| 19 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...