Page 1

SETUP SEQUENCE

Q 1

MIN MAX

ACTIVE ACTIVE

Q 3

MIN MAX

ACTIVE ACTIVE

Q 5

ACTIVE ACTIVE

Q 2

MIN MAX

Q 4

MIN MAX

Q 6

F 1F 2F 3F 4F 5F 6

F 1 F 2 F 3 F 4 F 5 F 6

PAD BANK

BC

A

A

BCDEFGH

Q-LINK

SEQUENCE

&

PAD

ASSIGN

#

FULL

LEVEL

16

LEVELS

!

ERASE

(

NOTE

REPEAT

)

PAD 13 PA D 14 PAD 15 PAD 16

PAD 9 PAD 10 PAD 11 PAD 12

PAD 5 PAD 6 PAD 7 PAD 8

PAD 1 PAD 2 PAD 3 PAD 4

D

P LOOP PTO P FROM

DRUMS

F

E

NEXT

SEQUENCE

CONTRAST

REC GAIN

MAIN VOLUME

GAIN

HIGH

LOW

MAX

MINMIN MAX

R

L

SAMPLE

MULTI

SAVE LOAD

SONG MISC.

MAIN

SEQ EDIT

JOG

START END

PROGRAM

MIXER

EFFECT

GLOBAL

MIDI

STEP EDIT

BLOCK

CURSOR

BAR

PLAY

PLAY

START

RECORD

STEP

EVENT

OVER

DUB

IJK

LMN

OPQ

RST

UVW

CURSOR

LOCATE

GO TO

PLAY/ REC

STOP

TRACK

MUTE

PLAY

789

456

123

TIMING CORRECT

X

MASTER TEMPO

Y

UNDO SEQ

Z

TAP TEMPO

0 ENTER

WINDOW

SHIFT

REC

Music production Center

SERVICE MANUAL

1

Page 2

##

# SAFETY INSTRUCTIONS

##

##

# INFORMATIONS

##

1. Parts identified by the } symbol are critical for safety.

Replace them only with the parts number specified.

2. In addition to safety, other parts and assemblies are

specified for conformance with such regulations as those

applying to spurious radiation.

These must also be replaced only with the specified

replacements.

Examples : Noise blocking capacitors, noise blocking filters,

etc.

3. Use specified internal wiring. Note especially :

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

4. Use specified insulating materials for hazardous live parts.

Note especially :

1) Insulation Tape

2) PVC tubing

3) Spacers (insulating barriers)

4) Insulation sheets for transistors

5) Plastic screws for fixing micro switches

5. When replacing AC primary side components (transformers, power cords, noise blocking capacitors, etc.),

wrap the ends of the wires securely around the terminals

before soldering.

SYMBOLS FOR PRIMARY DESTINATION

Unit destinations are indicated with letters as shown below.

Symbols Principal Destinations

A U.S.A

B England

E Europe

J Japan

V

X1

X4

MAKE YOUR CONTRIBUTION TO PROTECT THE

ENVIRONMENT

Used batteries with the ISO symbol for recycling as

well as small accumulators (rechargeable batteries),

mini-batteries (cells) and starter batteries should not

be thrown into the garbage can.

Please leave them at an appropriate depot.

PRECAUTIONS FOR LITHIUM BATTERY

The lithium battery may explode when

[OBSERVE THE FOLLOEING WHEN REPLACING]

Germany

Japan

Universal Area

incorrectly replaced.

6. Make sure that wires do not contact heat producing parts

(heat sinks, oxide metal film resistors, fusible resistors,

etc.).

7. Check that replaced wires do not contact sharp edged or

pointed parts.

8. Also check areas surrounding repaired locations.

9. Make sure that foreign objects (screws, solder droplets,

etc.) do not remain inside the set.

SAFETY CHECK AFTER SERVICING

After servicing, make measurements of leakage-current or

resistance in order to determine that exposed parts are

acceptably insulated from the supply circuit. The leakagecurrent measurement should be done between accessible

metal parts (such as chassis, ground terminal, microphone

jacks, signal input/output connectors, etc.) and the earth ground

through a resistor of 1500 ohms paralleled with a 0.15 µF

capacitor, under the unit’s normal working conditions.

The leakage-current should be less than 0.5 mA rms AC. The

resistance measurement should be done between accessible

exposed metal parts and power cord plug prongs with the

power switch (if included) “ON”. The resistance should be

more than 2.2 M ohms.

• Replace with the same make and type or equivalent recom

mended by manufacturer.

• Place battery in correct polarity.

• Do not short the terminals.

• Do not charge battery.

• Do not dispose of battery in fire.

SERVICE MANUAL

2

Page 3

I. SPECIFICATIONS

General Power supply 100-240V AC 50/60Hz 70W (27W without options)

Dimensions 526 (W) x 170 (H) x 453 (D) mm (with LCD tilted down)

Weight 10.5kg (without options)

Display 320 x 240 dots grey-scale graphical LCD w/back light

Sound Generator Sampling rate 44.1kHz, 48kHz, 96kHz

Data format 24/16 bit linear

Sampling time 180/120 (16/24 bit) seconds mono FS=44.1kHz

(unexpanded memory) 166/110 (16/24 bit) seconds mono FS=48kHz

82/53 (16/24 bit) seconds mono FS=96kHz

90/60 (16/24 bit) seconds stereo FS=44.1kHz

83/55 (16/24 bit) seconds stereo FS=48kHz

40/26 (16/24 bit) seconds stereo FS=96kHz

Memory 16MB standard, expandable to 512MB

168-pin DIMM (PC133/PC100, CL2) slot x 2

Polyphony 64 voices

Filter 2-pole x 3 with resonance

Envelope generators 3 x Envelope generators (2 multi-stage)

LFO 2 x Multi-wave

Sequencer Maximum events 300,000 notes (equivalent)

Resolution 960 parts per 1/4-note (ppq)

Sequences 128

Tracks per sequence 128

MIDI output channels 64 (16 channels x 4 output ports)

Song mode 128 songs, 250 steps per song

Drum pads 16 (velocity and pressure sensitive)

Drum pads banks 6

Sync modes MTC, MIDI clock, SMPTE

Inputs/Outputs Rec In LINE/MIC L/R 1/4-inch stereo phone/XLR Combo jack, balanced,

1/4-inch phone, Imp. 18kΩ, 24dBu max./XLR, Imp. 6kΩ, 22dBu max.

Rec In PHONO L/R RCA phono x 2 with RIAA EQ, -24dBu max. (1kHz)

Main Out L/R 1/4-inch stereo phone/XLR Combo jack, balanced,

1/4-inch phone, Imp. 1.7kΩ, 24dBu max./XLR, Imp. 200Ω, 18dBu max.

Assignable Outs (IB-48P

required) 1/4-inch stereo phone x 8, balanced, Imp. 1.7kΩ, 18dBu max.

Headphone 1/4-inch stereo phone, 60mW (32Ω)

Digital Input (IB-4D required) RCA phono x 1, SPDIF

Digital Main Output

(IB-4D required) RCA phono x 1, SPDIF

Word Clock Input

(IB-4D required) BNC x 1 (w/75Ω terminator On/Off)

SMPTE In 1/4-inch stereo phone, balanced

SMPTE Out 1/4-inch stereo phone, balanced

Footswitch 1/4-inch phone x 2

MIDI Input 5-pin DIN x 2

MIDI Output 5-pin DIN x 4

SCSI 50-pin high-pitch SCSI connector x 1

USB Host x 1, Slave x 1 (V1.1)

Options IB-4D Digital Audio (SPDIF) I/O board

IB-4ADT Adat Interface board (2-in/8-out)

IB-48P Assignable 8-channel Output Board

Standard accessory Power Cable x 1

CD-ROM disc x 1

Drive Mounting Kit x 1

User Guide x 1

* The specifications are subject to change without the prior notice.

SERVICE MANUAL

3

Page 4

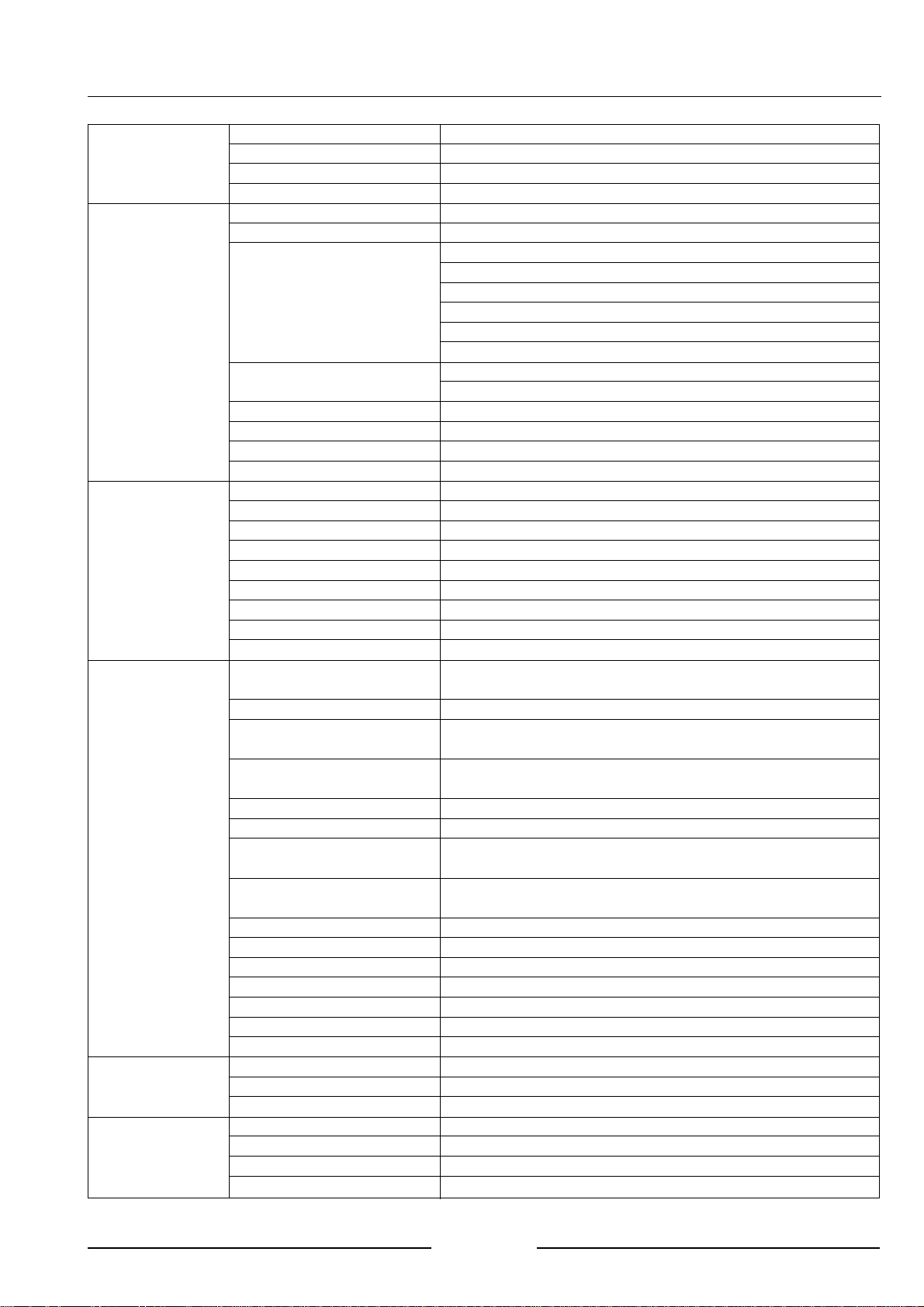

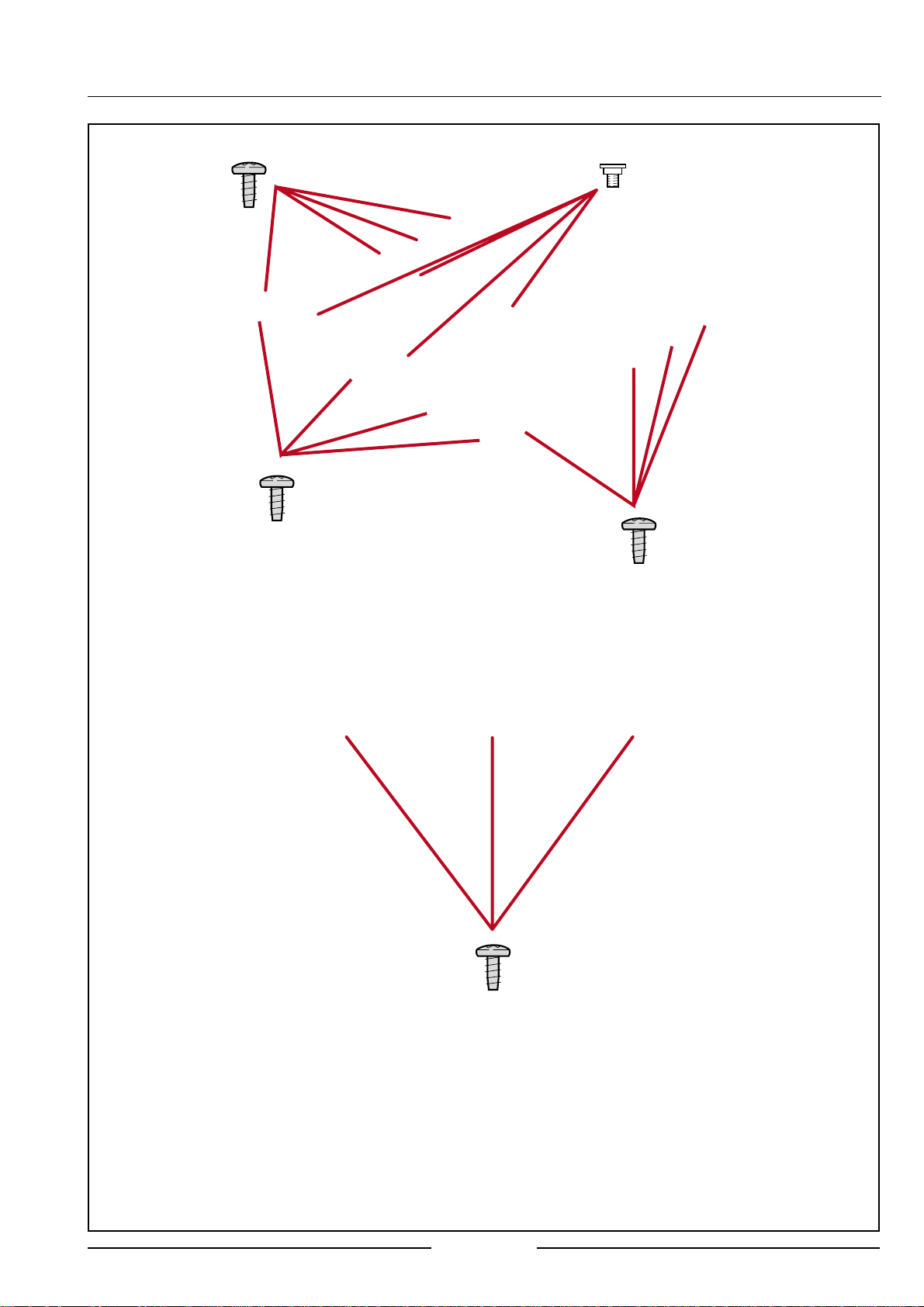

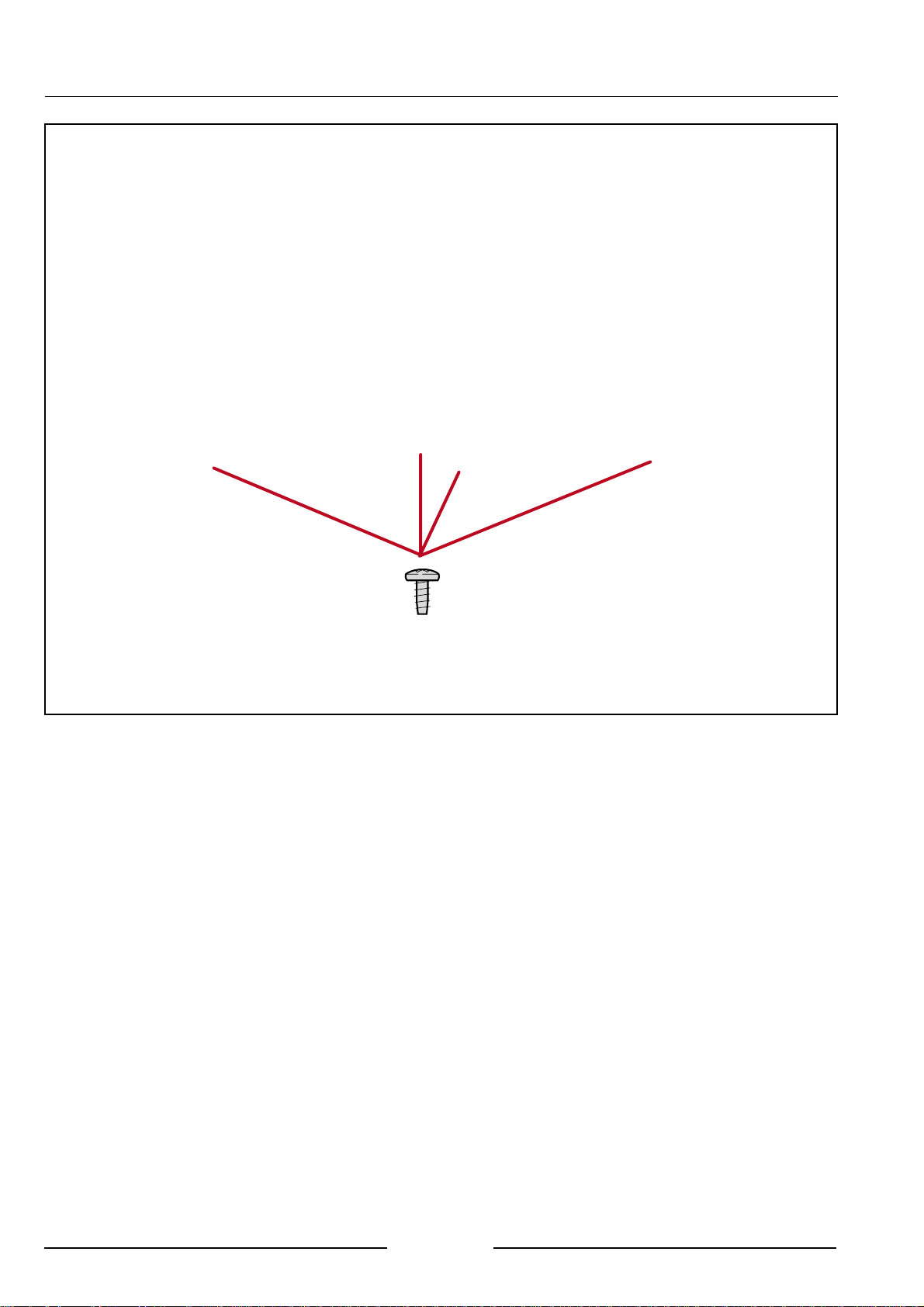

II. DISASSEMBLY

In case of trouble, etc., necessitating dismantling, please dismantle in the order shown in the illustrations. Reassemble in the

reverse order.

1. Removal of the OPERATION BLOCK

ZS-322570

ST BID40X08STL NI3

ZS-331182

BT BID30X08STL BNI

SERVICE MANUAL

4

Page 5

ZS-331182

BT BID30X08 STL BNI

ZS-821548X SCREW TOP COVER NI

ZS-331182

BT BID30X08 STL BNI

SERVICE MANUAL

5

Page 6

ZS-331182

BT BID30X08 STL BNI

SERVICE MANUAL

6

Page 7

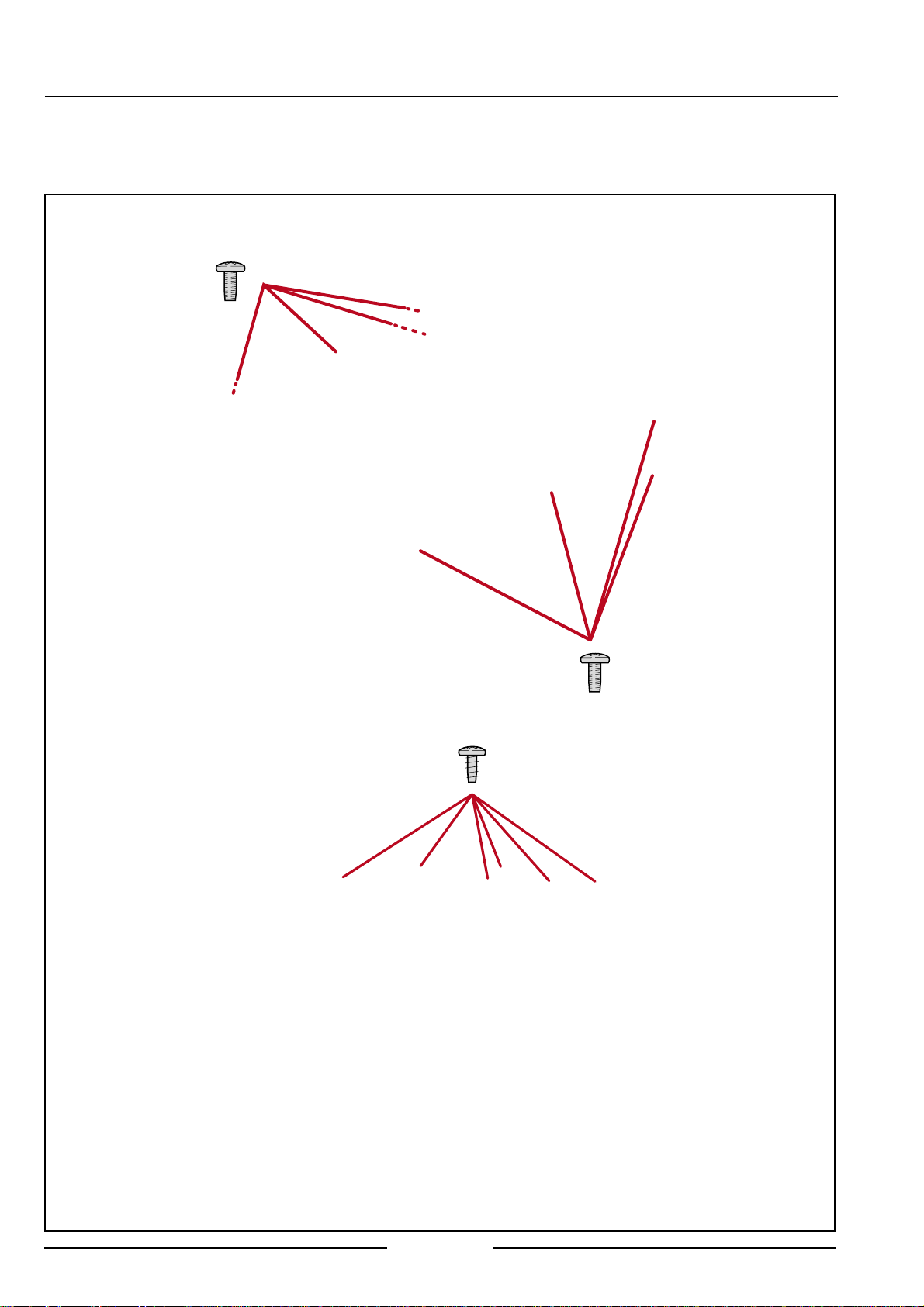

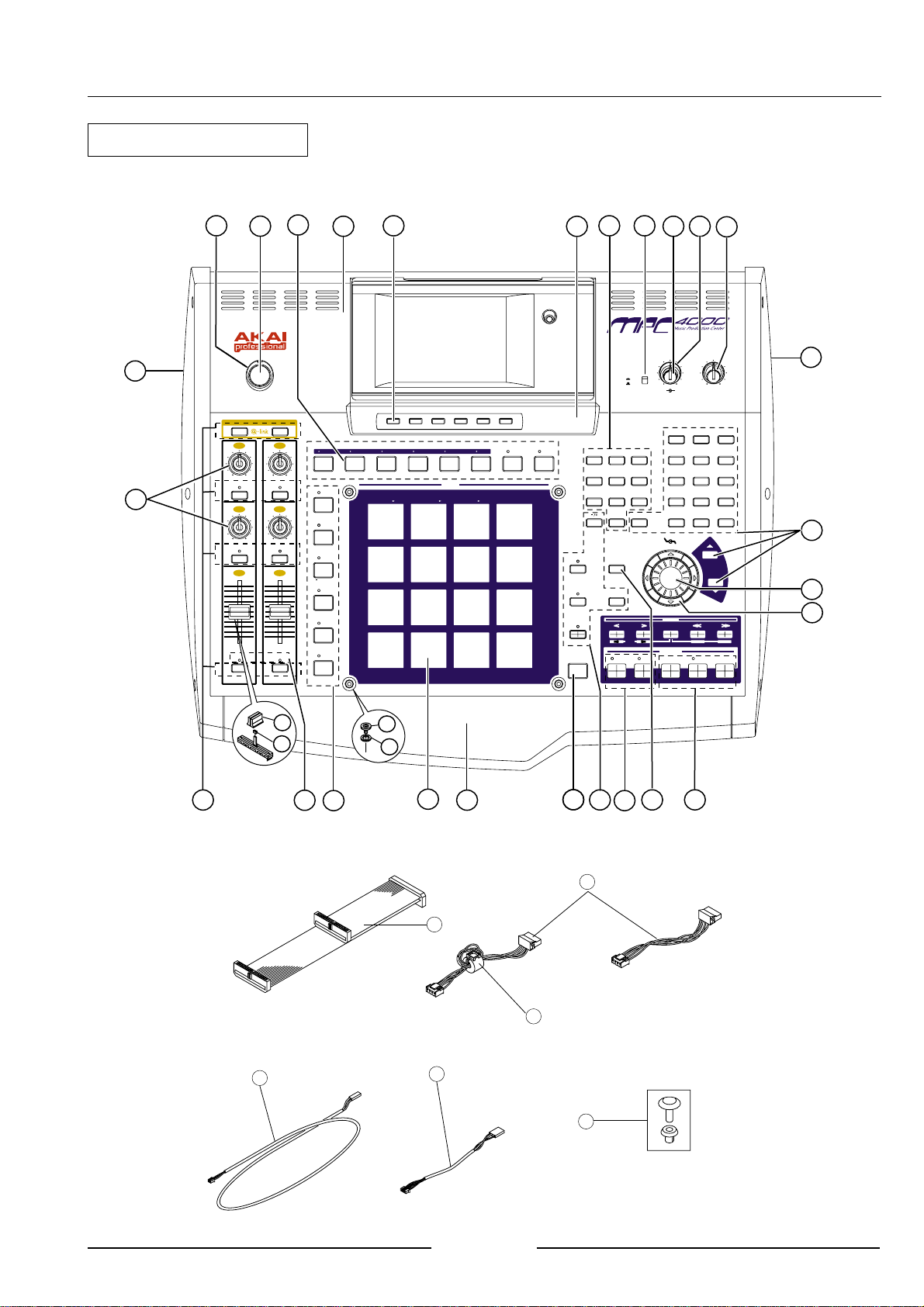

III. PRINCIPAL PARTS LOCATION

EM-812761J

IND LCD

BA-L4016A504F

PC POWER SW BLK

BA-L4016A504C

PC LCD BLK

BA-L4016A502C

PC IO VR BLK

BA-L4016A504B

PC FUNCTION BLK

BA-L4016A504A

PC JOG BLK

BA-L4016A030A

PC OPERATION BLK

BA-L4016A504E

PC FILTER BLK

BA-L4016A502A

PC IO BLK

BA-L4016A502B

PC IO ADDA BLK

BA-L6052A020A

PC CPU BLK Z8

BA-LJ038A020A

PC POWER BLK SPS-80

BA-L4016A504D

PC HEAD PHONE & USB BLK

SERVICE MANUAL

EB4JS

7

Page 8

IV. OS Update Procedure

OS Update Procedure

[OS Update procedure from USB]

The OS update can be made from the PC via the USB port.

You must have the “OS loader software for MPC4000” besides the OS .bin file.

The OS loader software includes the OS Loader.exe file, USB driver.inf file, and USB Driver.sys file.

1. Install USB Driver to your PC

After all files are un-Zipped, place the USB Driver.inf and USB Driver.sys files into the same folder, e.g. Driver.

Boot up the PC and MPC4000 complete and then connect the sampler to the PC using the USB cable.

This prompts that the PC found the new device an d the new driver is required.

Refer it to the Driver folder you just created.

The Driver software will be placed correctly and the MPC4000 is recognized properly.

2. OS update

Double click on the OS Loader.exe icon and specify the OS .bin file. It will send the OS to the MPC4000.

[Caution]

After the update, be sure to initialize the MPC4000 by pressing the GLOBAL key, and then [F6] (INITIAL)

and [F5] (DO IT) keys, before turning it off.

[OS update procedure from CD-R]

To update the OS from the CD-ROM, it requires the OS version later than V1.02 software installed on the MPC4000.

You can update the OS from the CD-ROM drive. Be sure to use the CD-ROM that contains the OS for the MPC

4000. You can create the OS disc by using your PC’s CD-R/W function to write the “MPC4000.bin” file on to an

ISO9660 CD-ROM disc.

1. Turn the MPC4000 on and insert the OS disc.

2. Press the LOAD key and select the MPC4000 OS file (.bin file).

3. Press the [F6] (DO IT) key and then the [F6] (INSTALL) key.

4. The OS Update progress appears, i.e. the messages “Please wait ??.” and then “Upgrading of the Flash

ROM was successful.” appear accordingly.

5. Press the [F6] (Restart) key. Be sure to initialize the MPC4000 by pressing the GLOBAL key, and then the

[F6] (INITIAL) and [F5] (DO IT) keys, before turning it off.

Writing Panel OS Program

Change the position of the Short Pin P15 on the IO PCB to PROG side.

The OS is automatically written to the Panel CPU RAM when the MPC4000 is switched on.

Switch the unit off when the “Process completed!” prompt message appeared and then replace the Short Pin to the

original position.

SERVICE MANUAL

8

Page 9

V. TEST MODE

Panel Test Mode

To enter the Panel Test Mode, press the GLOBAL key while holding down the SHIFT key in the GLOBAL page [F1] of the

GLOBAL Mode.

• Moving the Q-link knobs changes the graphics accordingly.

• Tapping the PAD shows the amount of pressure applied on the bar graph.

• Switching the FOOT Pedal on/off changes the graphics accordingly.

• Turning the JOG wheel increases/decreases the value in the Data field.

• Pressing the key shows its name at the bottom of the screen. For those keys with the LED, the LED is turned

on/off.

• Pressing the [F1] key stops the key test.

• After stopping the key test, pressing the mode key will abort the test mode.

• While the key test is stopped, pressing the SHIFT key and [F6] key shows the A/D converted value of the

Q-link/ PAD.

CPU Board Test Mode

The Test Mode of the MPC4000 CPU Board is performed while the CPU board is mounted on the Z4/Z8 Sampler.

When the Z4/Z8 is switched on after the MPC4000 CPU Board is mounted on the Z4/Z8 Sampler, the sampler

is turned on with the MPC4000 screen.

Install the Z4/Z8 OS using the “OS Loader” of “Boot Overwrite” type via the USB port.

Similarly, when the CPU Board is mounted back on the MPC4000 after the Z4/Z8 OS is installed for the test,

it boots up with the Z4/Z8 screen. Reinstall the MPC4000 OS using the “OS Loader” of “Boot Overwrite” type.

Refer to the Z4/Z8 Service Manual for the operation details of the Test Mode for the CPU Board.

SERVICE MANUAL

9

Page 10

VI. PARTS LIST

ATTENTION

1. When placing an order for parts, be sure to list the Part No., Model No. and the description of each part.

Otherwise, the non-delivery of the part or the delivery of a wrong part may result.

2. Please make sure that Part No. is correct when ordering.

If not, a part different from the one you ordered may be delivered.

3. Since the parts shown in Parts List or Preliminary Service Manual may have been the subject of changes,

please use this Parts List for all future reference.

HOW TO USE THIS PARTS LIST

1. This Parts List lists those parts which are considered necessary for repairs.

2. Parts not shown in the Parts List will not in principle be supplied.

3. How to read the Parts List.

1. PC MAIN BOARD BLK

Ref. No. Part No. Description

D5 ED-431276C D SCHOT 1S30-J T05

D110 ED-431276C D SCHOT 1S30-J T05

:

:

IC5 EI-811073J ICTRC-6593

IC10 EI-811068J IC HD74HC157FP

Service parts classification

These reference symbols correspond with component

symbols in the Schematic Diagrams.

2. FINAL ASSEMBLY BLK

Ref. No. Part No. Description

1. SA-349332 FOOT

2. ZS-344754C ST PAN30x06STL CMT

:

:

44. SP-417333J COVER TOP

45. ZS-418385J BT BID30X06STL BNI EATRH LOCK

46-A } EW-380905J AC CORD 250S KP300 KS16A

H B J [J]

46-B } EW-368420J1 AC CORD 200SKP30KS B AC [A]

46-C } EW-410608J AC CORD 250 KP4819D KS31A B E

[E,V]

Symbols for primary destination

[A] U.S.A. [J] Japan

[B] England [V] Germany

[E] Europe [x1] Japan

[X4] Universal Area

Safety critical component

This number corresponds with the individual parts index number

in the figure.

WARNING

}}

} INDICATES SAFETY CRITICAL COMPONENTS. FOR CONTINUED SAFETY, REPLACE SAFETY CRITICAL

}}

COMPONENTS ONLY WITH MANUFACTURER'S RECOMMENDED PARTS.

AVERTISSEMENT

}}

} IL INDIQUE LES COMPOSANTS CRITIQUES DE SÉCURITÉ. POUR MAINTENIR LE DEGRÉ DE SÉCURITÉDE

}}

L'APPAREIL, NE REMPLACER QUE DES PIÉCES RECOMMANDEES PAR LÉ FABRICANT.

SERVICE MANUAL

10

Page 11

PC BOARD BLK

The PC Board Block may contain several PC Boards. They appear

under its block name with their individual part number.

1. P.C. BOARD BLOCK

Ref.No. Part No. Description

1 BA-L6052A020A PC CPU BLK Z8

2 BA-L4016A020A PC (#) IO BLK MPC4000

3 BA-L4016A030A PC OPERATION BLK MPC4000

4 BA-L4016A040A PC (#) OTHER BLK MPC4000

PC (#) IO BLK CONSISTS OF FOLLOWING P.C. BOARDS.

✽ BA-L4016A502A PC IO BLK

✽ BA-L4016A502B PC IO ADDA BLK

✽ BA-L4016A502C PC IO VR BLK

PC (#) OTHER BLK CONSISTS OF FOLLOWING P.C. BOARDS.

✽ BA-L4016A504A PC JOG BLK

✽ BA-L4016A504B PC FUNCTION KEYS BLK

✽ BA-L4016A504C PC LCD BLK

✽ BA-L4016A504D PC HEAD PHONE & USB BLK

✽ BA-L4016A504E PC FILTER BLK

✽ BA-L4016A504F PC POWER SW BLK

2. P.C. CPU BLOCK

Ref.No. Part No. Description

IC1 EI-820788X IC GDS1110BD-206MHZ MBGA

[ unavailable ]

IC2 EI-821551X IC MB87L1852PFVS-G-BND JSL

IC3 EI-821594X IC HM5264165FTT-75

IC4 EI-821594X IC HM5264165FTT-75

IC5 EI-821424X IC HY57V281620AT-7 FPTY

IC6 EI-821424X IC HY57V281620AT-7 FPTY

IC7 EI-821211X IC MBM29DL322TE90TN

IC8 EI-820962X IC XC95144XL-7TQ100C

IC9 EI-820961X IC XC2S100-5TQ144C

IC10 EI-820959X1 IC SL811HST V1.5

IC11 EI-812785J IC FAS236U PQFP

IC12 EI-820949X IC HD74ALVCH16245TEL

IC13 EI-820948X IC HD74ALVCH16244TE

IC14 EI-820948X IC HD74ALVCH16244TE

IC15 EI-820948X IC HD74ALVCH16244TE

IC16 EI-820949X IC HD74ALVCH16245TEL

IC17 EI-820951X IC HD74LVC244AT FPELT16E

IC18 EI-820951X IC HD74LVC244AT FPELT16E

IC19 EI-812979J IC HD74LVC245ATELL FPELT16E

IC20 EI-810574J IC M51957BFP FP73AT12

IC21 EI-820957X IC NJM317DL1 FPTE1T16E

IC22 EI-820957X IC NJM317DL1 FPTE1T16E

IC23 EI-820955X IC NET2890

J1 EJ-820938X SOCKET SMD XH4A-8035-A 80P

J2 EJ-820938X SOCKET SMD XH4A-8035-A 80P

J3 EJ-820937X SOCKET SMD XH4A-4035-A 40P

J4 EJ-820937X SOCKET SMD XH4A-4035-A 40P

J5 EJ-820990X SOCKET DMM-168F-111B1 168P

J6 EJ-820990X SOCKET DMM-168F-111B1 168P

J7 EJ-419246J SOCKET 128A-050S2A-S14A 50P

P2 EJ-810581J PLUG SCP40GS3 40P

P2 EJ-810581J PLUG SCP40GS3 40P

P4 EJ-432670J PLUG C.S6B-PH-SM3-TB 6P T24E

P5 EJ-821159X PLUG C.S5B-PH-SM3-TB 5P T24E

P6 EJ-820998X PLUG C.S4B-PH-SM3-TB 4P T24E

TR1 ET-430868J TR C.DTC114EKA T146T08E

TR2 ET-430868J TR C.DTC114EKA T146T08E

TR3 ET-430868J TR C.DTC114EKA T146T08E

UN1 EI-820944X DC-DC CONVERTER HGS15-3R3

Ref.No. Part No. Description

X1 EI-820769X OSC X'TAL C.SMD-49 3.6864MHZ

X2 EI-820994X OSC X'TAL C.DS0751SV 18.4320MHZ

X3 EI-820993X OSC X'TAL C.DS0751SV 16.9344MHZ

X4 EI-820991X OSC X'TAL C.SMD-49 12.0000MHZ

X5 EI-820995X OSC X'TAL C.DS0751SB 40.0000MHZ

X6 EI-820989X OSC X'TAL C.DS0751SV 48.0000MHZ

3. P.C. IO BLOCK

Ref.No. Part No. Description

100 EZ-811066J BATTERY LITHIUM CR2025

400 ES-429984J SOCKET IC113-0444-004 44P

D1 ED-811455J D SILICON H 1SS133T-77 T26

D2 ED-811455J D SILICON H 1SS133T-77 T26

D3 ED-428162J D SCHOTTKY 1S30-E T26

D4 ED-428162J D SCHOTTKY 1S30-E T26

D5 ED-820774X D SCHOT.H EK16 V0 T26 60/1.5A

D6 ED-811455J D SILICON H 1SS133T-77 T26

D7 ED-811455J D SILICON H 1SS133T-77 T26

D8 ED-811455J D SILICON H 1SS133T-77 T26

D9 ED-811455J D SILICON H 1SS133T-77 T26

D30 ED-811455J D SILICON H 1SS133T-77 T26

D31 ED-811455J D SILICON H 1SS133T-77 T26

D32 ED-811455J D SILICON H 1SS133T-77 T26

D33 ED-811455J D SILICON H 1SS133T-77 T26

FS1

IC1 EI-821048X IC UPC29M33AT-E2 FPE2T16E

IC2 EI-811073J IC RTC-6593

IC3 EI-396659J IC NJM2360D

IC4 EI-820062J IC HD74HCT541FP FPELT24

IC5 EI-821116X IC HD74HCT04AFP FPELT16E

IC6 EI-810828J IC MCCS142236DWR2 18B

IC7 EI-812979J IC HD74LVC245ATELL FPELT16E

IC8 EI-812979J IC HD74LVC245ATELL FPELT16E

IC9 EI-812977J IC HD74LVC08TELL FPELT16E

IC10 EI-431113J IC M51953BFP-73A FP73AT12E

IC11 EI-821593X IC ICS2008BV

IC12 EI-380145J IC LF353

IC13 EI-821344X IC TC74HCT32AF-EL FPELT16

IC14 EI-812980J IC HD74LVC32TELL FPELT16E

IC15 EI-812979J IC HD74LVC245ATELL FPELT16E

IC16 EI-812980J IC HD74LVC32TELL FPELT16E

IP1 EF-373285 FUSE ICP-N25 T05 50V 1.0A

J1 EJ-430956J DIN J YKF51-5058 2X5P

J2 EJ-430956J DIN J YKF51-5058 2X5P

J3 EJ-430956J DIN J YKF51-5058 2X5P

J5 EJ-820493X SOCKET BATTERY BH25TN

J6 EJ-820316X SOCKET CONNECTER YKF45-

J8 EJ-820939X SOCKET XH4A-8031-A 80P

J9 EJ-820939X SOCKET XH4A-8031-A 80P

J10 EJ-821219X PHONE J YKB22-5244 NUT 6.3

J11 EJ-821219X PHONE J YKB22-5244 NUT 6.3

J12 EJ-812347J SOCKET FCN-235D050-G/J 50P

J13 EJ-821386X PHONE J YKB22-5264 NUT 6.3

J14 EJ-821386X PHONE J YKB22-5264 NUT 6.3

L1 EO-812743J COIL FIX 1 LHL10NB 821K

P14 EJ-810270J PLUG SCP50GS3 50P

P2 EJ-810271J PLUG SCP26GS3 26P

P3 EJ-810581J PLUG SCP40GS3 40P

P3 EJ-810581J PLUG SCP40GS3 40P

P4 EJ-810270J PLUG SCP50GS3 50P

P9 EJ-810271J PLUG SCP26GS3 26P

PH1 EJ-431258J DETECTOR C.PC400T T12E

PH2 EJ-431258J DETECTOR C.PC400T T12E

EF-811786J FUSE RUE110 30V 1.10A

FPR2T24E

0001 4P

SERVICE MANUAL

11

Page 12

Ref.No. Part No. Description

R23

R77

TR1 ET-429896J TR C.DTA144EKA T146T08E

TR2 ET-429897J TR C.DTC144EKA T146T08E

TR3 ET-434246J TR 2SB1326 Q,R T05

TR4 ET-362209 TR 2SC3330 S,T,U T05

TR5 ET-430868J TR C.DTC114EKA T146T08E

TR6 ET-429898J TR C.DTA114EKA T146T08E

P.C. IO ADD BLOCK

X1 EI-410263J OSC X'TAL HC-49/U 14.318180MHZ

D10 ED-811455J D SILICON H 1SS133T-77 T26

D11 ED-811455J D SILICON H 1SS133T-77 T26

D12 ED-811455J D SILICON H 1SS133T-77 T26

D13 ED-811455J D SILICON H 1SS133T-77 T26

D14 ED-811455J D SILICON H 1SS133T-77 T26

D15 ED-811455J D SILICON H 1SS133T-77 T26

D16 ED-811455J D SILICON H 1SS133T-77 T26

D17 ED-811455J D SILICON H 1SS133T-77 T26

D18 ED-811455J D SILICON H 1SS133T-77 T26

D19 ED-811455J D SILICON H 1SS133T-77 T26

D20 ED-811455J D SILICON H 1SS133T-77 T26

D21 ED-811455J D SILICON H 1SS133T-77 T26

D22 ED-811455J D SILICON H 1SS133T-77 T26

D23 ED-811455J D SILICON H 1SS133T-77 T26

D24 ED-811455J D SILICON H 1SS133T-77 T26

IC21 EI-348785 IC M5220L

IC22 EI-348785 IC M5220L

IC23 EI-348785 IC M5220L

IC24 EI-397407J IC NJM7812FA

IC25 EI-348785 IC M5220L

IC26 EI-348785 IC M5220L

IC27 EI-810591J IC NJM5532L

IC28 EI-348785 IC M5220L

IC29 EI-810591J IC NJM5532L

IC30 EI-812781J IC AK5383VS FPE2T24E

IC31 EI-820696X IC ICS570A-01CS08 FP T12E

IC32 EI-821120X IC HD74LVC02TELL FPELT12E

IC33 EI-810574J IC M51957BFP FP73AT12

IC34 EI-336995 IC NJM78L05A

IC35 EI-810574J IC M51957BFP FP73AT12

IC36 EI-821442X IC PCM1730E FPT16E

IC37 EI-821226X IC OPA2134UA FPT12E

IC38 EI-821226X IC OPA2134UA FPT12E

IC39 EI-810591J IC NJM5532L

IC40 EI-377191 IC NJM5532D-D

IC41 EI-377191 IC NJM5532D-D

IC42 EI-377191 IC NJM5532D-D

IC43 EI-377191 IC NJM5532D-D

IC44 EI-348785 IC M5220L

IC45 EI-410281J IC NJM7912FA

IC46 EI-821118X IC NJM78M08FA

IC47 EI-400856J IC NJM78M05FA

IC48 EI-400856J IC NJM78M05FA

IC49 EI-821118X IC NJM78M08FA

IC50 EI-821048X IC UPC29M33AT-E2 FPE2T16E

IC51 EI-812977J IC HD74LVC08TELL FPELT16E

IC52 EI-820951X IC HD74LVC244AT FPELT16E

IC53 EI-810588J IC SSM-2404P

J21 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J22 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

J23 EJ-821443X PIN J YKC21-3079 P2P

J24 EJ-386340J SOCKET RECEPTACLE XLB3-

J25 EJ-386340J SOCKET RECEPTACLE XLB3-

J26 EJ-821386X PHONE J YKB22-5264 NUT 6.3

ER-812771J R OMF V T05FS ERX12SE1/2W 1R0J

ER-821483X R OMF H S15 FS ERG2SH 2W 820J

32PCVM1

32PCVM1

Ref.No. Part No. Description

J27 EJ-821386X PHONE J YKB22-5264 NUT 6.3

R361 ER-422512J R OMF H S15 FS ERG2SH 2W 151J

RL1 EQ-348929 RELAY SIG G5A-237P 2TR 12V

RL2 EQ-348929 RELAY SIG G5A-237P 2TR 12V

SW1 ES-821121X SW SLIDE SSSF142-S09N0 4-02N

TR10 ET-821232X TR 2SC3329 GR,BL T05

TR11 ET-821232X TR 2SC3329 GR,BL T05

TR12 ET-821232X TR 2SC3329 GR,BL T05

TR13 ET-821232X TR 2SC3329 GR,BL T05

TR14 ET-821232X TR 2SC3329 GR,BL T05

TR15 ET-821232X TR 2SC3329 GR,BL T05

TR16 ET-821232X TR 2SC3329 GR,BL T05

TR17 ET-821232X TR 2SC3329 GR,BL T05

TR19 ET-362847 TR 2SA1317 S,T,U T05

TR20 ET-430868J TR C.DTC114EKA T146T08E

TR21 ET-410280J TR 2SC3327 A T05

TR22 ET-410280J TR 2SC3327 A T05

TR23 ET-410280J TR 2SC3327 A T05

TR24 ET-410280J TR 2SC3327 A T05

P.C. IO VR BLOCK

IC60 EI-810591J IC NJM5532L

IC61 EI-812479J IC NJM5532M FPT1T32P

IC62 EI-812479J IC NJM5532M FPT1T32P

SW3 ES-821122X SW PUSH SPUJ19B-2N-✽W

2-02-02N

VR1 EV-821124X VR ROTARY RK1612220 L25RD203X2

VR2 EV-821123X VR ROTARY RK16312A0 L25 B103X2

4. P.C. OPERATION BLOCK

Ref.No. Part No. Description

D100 ED-811455J D SILICON H 1SS133T-77 T26

D101 ED-811455J D SILICON H 1SS133T-77 T26

D102 ED-811455J D SILICON H 1SS133T-77 T26

D103 ED-811455J D SILICON H 1SS133T-77 T26

D104 ED-811455J D SILICON H 1SS133T-77 T26

D105 ED-811455J D SILICON H 1SS133T-77 T26

D106 ED-811455J D SILICON H 1SS133T-77 T26

D107 ED-811455J D SILICON H 1SS133T-77 T26

D108 ED-811455J D SILICON H 1SS133T-77 T26

D109 ED-811455J D SILICON H 1SS133T-77 T26

D110 ED-811455J D SILICON H 1SS133T-77 T26

D111 ED-811455J D SILICON H 1SS133T-77 T26

D112 ED-811455J D SILICON H 1SS133T-77 T26

D113 ED-811455J D SILICON H 1SS133T-77 T26

D114 ED-811455J D SILICON H 1SS133T-77 T26

D115 ED-811455J D SILICON H 1SS133T-77 T26

D116 ED-811455J D SILICON H 1SS133T-77 T26

D117 ED-811455J D SILICON H 1SS133T-77 T26

D118 ED-811455J D SILICON H 1SS133T-77 T26

D119 ED-811455J D SILICON H 1SS133T-77 T26

D120 ED-811455J D SILICON H 1SS133T-77 T26

D121 ED-811455J D SILICON H 1SS133T-77 T26

D122 ED-811455J D SILICON H 1SS133T-77 T26

D123 ED-811455J D SILICON H 1SS133T-77 T26

D124 ED-811455J D SILICON H 1SS133T-77 T26

D125 ED-811455J D SILICON H 1SS133T-77 T26

D126 ED-811455J D SILICON H 1SS133T-77 T26

D127 ED-811455J D SILICON H 1SS133T-77 T26

D128 ED-811455J D SILICON H 1SS133T-77 T26

D129 ED-811455J D SILICON H 1SS133T-77 T26

D130 ED-811455J D SILICON H 1SS133T-77 T26

D131 ED-811455J D SILICON H 1SS133T-77 T26

D132 ED-811455J D SILICON H 1SS133T-77 T26

D133 ED-811455J D SILICON H 1SS133T-77 T26

D134 ED-811455J D SILICON H 1SS133T-77 T26

12

SERVICE MANUAL

Page 13

Ref.No. Part No. Description

D135 ED-811455J D SILICON H 1SS133T-77 T26

D136 ED-811455J D SILICON H 1SS133T-77 T26

D137 ED-811455J D SILICON H 1SS133T-77 T26

D138 ED-811455J D SILICON H 1SS133T-77 T26

D139 ED-811455J D SILICON H 1SS133T-77 T26

D140 ED-811455J D SILICON H 1SS133T-77 T26

D141 ED-811455J D SILICON H 1SS133T-77 T26

D142 ED-811455J D SILICON H 1SS133T-77 T26

D143 ED-811455J D SILICON H 1SS133T-77 T26

D144 ED-811455J D SILICON H 1SS133T-77 T26

D145 ED-811455J D SILICON H 1SS133T-77 T26

D146 ED-811455J D SILICON H 1SS133T-77 T26

D147 ED-811455J D SILICON H 1SS133T-77 T26

D148 ED-811455J D SILICON H 1SS133T-77 T26

D149 ED-811455J D SILICON H 1SS133T-77 T26

D150 ED-811455J D SILICON H 1SS133T-77 T26

D151 ED-811455J D SILICON H 1SS133T-77 T26

D152 ED-811455J D SILICON H 1SS133T-77 T26

D153 ED-811455J D SILICON H 1SS133T-77 T26

D154 ED-811455J D SILICON H 1SS133T-77 T26

D155 ED-811455J D SILICON H 1SS133T-77 T26

D156 ED-811455J D SILICON H 1SS133T-77 T26

D157 ED-811455J D SILICON H 1SS133T-77 T26

D158 ED-811455J D SILICON H 1SS133T-77 T26

D159 ED-811455J D SILICON H 1SS133T-77 T26

D160 ED-811455J D SILICON H 1SS133T-77 T26

D161 ED-811455J D SILICON H 1SS133T-77 T26

D162 ED-811455J D SILICON H 1SS133T-77 T26

D163 ED-811455J D SILICON H 1SS133T-77 T26

D164 ED-811455J D SILICON H 1SS133T-77 T26

D165 ED-811455J D SILICON H 1SS133T-77 T26

D166 ED-811455J D SILICON H 1SS133T-77 T26

D167 ED-811455J D SILICON H 1SS133T-77 T26

D168 ED-811455J D SILICON H 1SS133T-77 T26

D169 ED-811455J D SILICON H 1SS133T-77 T26

D170 ED-811455J D SILICON H 1SS133T-77 T26

D200 ED-388539J D LED GL-3HD43

D201 ED-388539J D LED GL-3HD43

D202 ED-388539J D LED GL-3HD43

D203 ED-812086J D LED L-934SGD GREEN

D204 ED-812086J D LED L-934SGD GREEN

D205 ED-810393J D LED GL-3KG8

D206 ED-810393J D LED GL-3KG8

D208 ED-812086J D LED L-934SGD GREEN

D209 ED-812086J D LED L-934SGD GREEN

D210 ED-810393J D LED GL-3KG8

D211 ED-810393J D LED GL-3KG8

D212 ED-810393J D LED GL-3KG8

D213 ED-810393J D LED GL-3KG8

D214 ED-812086J D LED L-934SGD GREEN

D215 ED-810393J D LED GL-3KG8

D216 ED-810393J D LED GL-3KG8

D217 ED-810393J D LED GL-3KG8

D218 ED-810393J D LED GL-3KG8

D219 ED-810393J D LED GL-3KG8

D220 ED-812086J D LED L-934SGD GREEN

D221 ED-810393J D LED GL-3KG8

D222 ED-810393J D LED GL-3KG8

D224 ED-810393J D LED GL-3KG8

D225 ED-810393J D LED GL-3KG8

D226 ED-810393J D LED GL-3KG8

D227 ED-810393J D LED GL-3KG8

D300 ED-811455J D SILICON H 1SS133T-77 T26

D301 ED-811455J D SILICON H 1SS133T-77 T26

D302 ED-811455J D SILICON H 1SS133T-77 T26

D303 ED-811455J D SILICON H 1SS133T-77 T26

D304 ED-811455J D SILICON H 1SS133T-77 T26

Ref.No. Part No. Description

D305 ED-811455J D SILICON H 1SS133T-77 T26

D310 ED-811455J D SILICON H 1SS133T-77 T26

D311 ED-811455J D SILICON H 1SS133T-77 T26

D312 ED-811455J D SILICON H 1SS133T-77 T26

D313 ED-811455J D SILICON H 1SS133T-77 T26

D314 ED-811455J D SILICON H 1SS133T-77 T26

D315 ED-811455J D SILICON H 1SS133T-77 T26

D320 ED-811455J D SILICON H 1SS133T-77 T26

D321 ED-811455J D SILICON H 1SS133T-77 T26

D322 ED-811455J D SILICON H 1SS133T-77 T26

D323 ED-811455J D SILICON H 1SS133T-77 T26

D324 ED-811455J D SILICON H 1SS133T-77 T26

D325 ED-811455J D SILICON H 1SS133T-77 T26

D330 ED-811455J D SILICON H 1SS133T-77 T26

D331 ED-811455J D SILICON H 1SS133T-77 T26

D332 ED-811455J D SILICON H 1SS133T-77 T26

D333 ED-811455J D SILICON H 1SS133T-77 T26

D334 ED-811455J D SILICON H 1SS133T-77 T26

D335 ED-811455J D SILICON H 1SS133T-77 T26

D350 ED-393487J D ZENER H HZS7A1L T26

D351 ED-393487J D ZENER H HZS7A1L T26

D352 ED-393487J D ZENER H HZS7A1L T26

D353 ED-393487J D ZENER H HZS7A1L T26

D354 ED-393487J D ZENER H HZS7A1L T26

IC22 EI-820947X IC HD64F2132RFA20

IC24 EI-375185 IC M51953BL

IC300 EI-362588J1 IC M5238AP

IC320 EI-362588J1 IC M5238AP

IC350 EI-387934J IC HD74HC04P

P20 EJ-361777 PLUG S6B-PH-K WHT 6P

P30 EJ-367245 PLUG S4B-PH-K WHT 4P

P300 EJ-821080X SOCKET 5229-20APB 20P

SW100 ES-415015J SW TACT SKQEAD

SW101 ES-415015J SW TACT SKQEAD

SW102 ES-415015J SW TACT SKQEAD

SW103 ES-415015J SW TACT SKQEAD

SW104 ES-415015J SW TACT SKQEAD

SW105 ES-415015J SW TACT SKQEAD

SW106 ES-349474 SW TACT SKHHAM004A

SW107 ES-349474 SW TACT SKHHAM004A

SW108 ES-349474 SW TACT SKHHAM004A

SW109 ES-349474 SW TACT SKHHAM004A

SW110 ES-349474 SW TACT SKHHAM004A

SW111 ES-349474 SW TACT SKHHAM004A

SW112 ES-349474 SW TACT SKHHAM004A

SW113 ES-415015J SW TACT SKQEAD

SW114 ES-349474 SW TACT SKHHAM004A

SW115 ES-349474 SW TACT SKHHAM004A

SW116 ES-349474 SW TACT SKHHAM004A

SW117 ES-349474 SW TACT SKHHAM004A

SW118 ES-349474 SW TACT SKHHAM004A

SW119 ES-349474 SW TACT SKHHAM004A

SW120 ES-349474 SW TACT SKHHAM004A

SW121 ES-349474 SW TACT SKHHAM004A

SW122 ES-349474 SW TACT SKHHAM004A

SW123 ES-349474 SW TACT SKHHAM004A

SW124 ES-349474 SW TACT SKHHAM004A

SW125 ES-349474 SW TACT SKHHAM004A

SW126 ES-349474 SW TACT SKHHAM004A

SW127 ES-349474 SW TACT SKHHAM004A

SW128 ES-349474 SW TACT SKHHAM004A

SW129 ES-349474 SW TACT SKHHAM004A

SW130 ES-349474 SW TACT SKHHAM004A

SW131 ES-349474 SW TACT SKHHAM004A

SW132 ES-349474 SW TACT SKHHAM004A

SW133 ES-349474 SW TACT SKHHAM004A

SW134 ES-349474 SW TACT SKHHAM004A

SERVICE MANUAL

13

Page 14

Ref.No. Part No. Description

SW135 ES-349474 SW TACT SKHHAM004A

SW136 ES-349474 SW TACT SKHHAM004A

SW137 ES-349474 SW TACT SKHHAM004A

SW138 ES-349474 SW TACT SKHHAM004A

SW139 ES-349474 SW TACT SKHHAM004A

SW140 ES-349474 SW TACT SKHHAM004A

SW141 ES-349474 SW TACT SKHHAM004A

SW142 ES-349474 SW TACT SKHHAM004A

SW143 ES-349474 SW TACT SKHHAM004A

SW144 ES-349474 SW TACT SKHHAM004A

SW145 ES-349474 SW TACT SKHHAM004A

SW146 ES-349474 SW TACT SKHHAM004A

SW147 ES-349474 SW TACT SKHHAM004A

SW148 ES-349474 SW TACT SKHHAM004A

SW149 ES-337521 SW TACT SKHHAL

SW150 ES-337521 SW TACT SKHHAL

SW151 ES-337521 SW TACT SKHHAL

SW152 ES-337521 SW TACT SKHHAL

SW153 ES-337521 SW TACT SKHHAL

SW154 ES-337521 SW TACT SKHHAL

SW155 ES-337521 SW TACT SKHHAL

SW156 ES-337521 SW TACT SKHHAL

SW157 ES-337521 SW TACT SKHHAL

SW158 ES-337521 SW TACT SKHHAL

SW159 ES-337521 SW TACT SKHHAL

SW160 ES-337521 SW TACT SKHHAL

SW161 ES-337521 SW TACT SKHHAL

SW162 ES-337521 SW TACT SKHHAL

SW163 ES-349474 SW TACT SKHHAM004A

SW164 ES-349474 SW TACT SKHHAM004A

SW165 ES-349474 SW TACT SKHHAM004A

SW166 ES-349474 SW TACT SKHHAM004A

SW167 ES-349474 SW TACT SKHHAM004A

SW168 ES-349474 SW TACT SKHHAM004A

SW169 ES-349474 SW TACT SKHHAM004A

SW170 ES-349474 SW TACT SKHHAM004A

TR200 ET-364023 TR DTC114ES T05

TR201 ET-364023 TR DTC114ES T05

TR202 ET-364023 TR DTC114ES T05

TR203 ET-364023 TR DTC114ES T05

TR204 ET-364023 TR DTC114ES T05

TR205 ET-366753 TR DTA114ES T05

TR206 ET-366753 TR DTA114ES T05

TR207 ET-366753 TR DTA114ES T05

TR208 ET-366753 TR DTA114ES T05

TR209 ET-366753 TR DTA114ES T05

TR210 ET-366753 TR DTA114ES T05

VR200 EV-812350J VR SLIDE RS45112 L15 B103X2 SP

VR202 EV-812350J VR SLIDE RS45112 L15 B103X2 SP

VR204 EV-812348J VR ROTARY RK14K124 L20 B103X2

VR206 EV-812348J VR ROTARY RK14K124 L20 B103X2

VR208 EV-812348J VR ROTARY RK14K124 L20 B103X2

VR210 EV-812348J VR ROTARY RK14K124 L20 B103X2

X20 EI-820996X OSC X'TAL C.SMD-49 14.7456MHZ

Ref.No. Part No. Description

D175 ED-811455J D SILICON H 1SS133T-77 T26

D176 ED-811455J D SILICON H 1SS133T-77 T26

SW171 ES-349474 SW TACT SKHHAM004A

SW172 ES-349474 SW TACT SKHHAM004A

SW173 ES-349474 SW TACT SKHHAM004A

SW174 ES-349474 SW TACT SKHHAM004A

SW175 ES-349474 SW TACT SKHHAM004A

SW176 ES-349474 SW TACT SKHHAM004A

W170 EW-821085X WIRE ASSY L4016(3) JB-PH 6P

P.C. HEADPHONE & USB BLOCK

IC200 EI-353227 IC M5216L

J200 EJ-821000X PHONE J YKB26-5264 S.NUT 6.3

J250 EJ-820970X SOCKET CONNECTER YKF45-

0001 4P

PS200

R210

R211

TR200 ET-410280J TR 2SC3327 A T05

TR201 ET-410280J TR 2SC3327 A T05

TR202 ET-410280J TR 2SC3327 A T05

TR203 ET-410280J TR 2SC3327 A T05

VR200 EV-821235X VR ROTARY RK0971220 L15 B103X2

W200 EW-821086X WIRE ASSY L4016(4) JC-PH 8P

W250 EW-821088X WIRE ASSY L4016(6) JB-PH 4P

P.C. JOG BLOCK

RE300 ES-821084X ROTARY ENCORDER REC16B25-

W300 EW-821087X WIRE ASSY L4016(5) JB-PH 4P

P.C. LCD BLOCK

J400 EJ-812770J SOCKET 14FE-ST-VK-N 14P

VR400 EV-820602X VR ROTARY RK09K113AF25B14 B103

W400 EW-812756J WIRE ASSY L3055 W12 JB-51021 5

W401 EW-812757J WIRE ASSY L3055 W16 JB-EH 14P

W402 EW-813024J WIRE AWG24 TCT BLK L=60

P.C. POWER SW BLOCK

P3 EJ-359621 PLUG B2P-3-VH P7.92 2P

P4 EJ-375206 PLUG B2P3VH RED P7.92 2P

SW1 ES-430685J1 SW PUSH SDDF3A 02-1

EF-811786J FUSE RUE110 30V 1.10A

ER-430691J R OMF H S12 FS 1W 101J

ER-430691J R OMF H S12 FS 1W 101J

201-C

6. P.C. EFFECT BLOCK (Z8)

Ref.No. Part No. Description

IC1 EI-812794J IC XCB56362PV100 TQFP

IC2 EI-820459X IC GM71VS65163CLT-5

IC3 EI-820459X IC GM71VS65163CLT-5

IC4 EI-812841J IC HM62W16255HJP-15

IC5 EI-812841J IC HM62W16255HJP-15

IC6 EI-812977J IC HD74LVC08TELL FPELT16E

J1 EJ-820937X SOCKET SMD XH4A-4035-A 40P

J2 EJ-820937X SOCKET SMD XH4A-4035-A 40P

5. P.C. FILTER BLOCK

Ref.No. Part No. Description

L1 EO-427223J COIL LF HR-24-562

P1 EJ-397230J PLUG B2P3VH BLACK P7.92 2P

P2 EJ-359621 PLUG B2P-3-VH P7.92 2P

P.C. FUNCTION KEYS BLOCK

D171 ED-811455J D SILICON H 1SS133T-77 T26

D172 ED-811455J D SILICON H 1SS133T-77 T26

D173 ED-811455J D SILICON H 1SS133T-77 T26

D174 ED-811455J D SILICON H 1SS133T-77 T26

SERVICE MANUAL

14

7. IB-48P

Ref.No. Part No. Description

IC1 EI-397407J IC NJM7812FA

IC2 EI-410281J IC NJM7912FA

IC3 EI-812978J IC HD74LVC541ATELL FPELT16E

IC4 EI-427221J IC NJM7808FA

IC5 EI-400856J IC NJM78M05FA

IC6 EI-821048X IC UPC29M33AT-E2 FPE2T16E

IC7 EI-336995 IC NJM78L05A

IC8 EI-810574J IC M51957BFP FP73AT12

IC9 EI-821442X IC PCM1730E FPT16E

IC10 EI-821226X IC OPA2134UA FPT12E

Page 15

Ref.No. Part No. Description

IC11 EI-810591J IC NJM5532L

IC12 EI-821226X IC OPA2134UA FPT12E

IC13 EI-810591J IC NJM5532L

IC14 EI-821442X IC PCM1730E FPT16E

IC15 EI-821226X IC OPA2134UA FPT12E

IC16 EI-810591J IC NJM5532L

IC17 EI-821226X IC OPA2134UA FPT12E

IC18 EI-810591J IC NJM5532L

IC19 EI-821442X IC PCM1730E FPT16E

IC20 EI-821226X IC OPA2134UA FPT12E

IC21 EI-810591J IC NJM5532L

IC22 EI-821226X IC OPA2134UA FPT12E

IC23 EI-810591J IC NJM5532L

IC24 EI-821442X IC PCM1730E FPT16E

IC25 EI-821226X IC OPA2134UA FPT12E

IC26 EI-810591J IC NJM5532L

IC27 EI-821226X IC OPA2134UA FPT12E

IC28 EI-810591J IC NJM5532L

IC30 EI-812977J IC HD74LVC08TELL FPELT16E

J1 EJ-413165J PHONE J 3P YKB21-5009 NI 6.3

J2 EJ-821387X PHONE J YKB21-5264 6.3

J3 EJ-821387X PHONE J YKB21-5264 6.3

J4 EJ-413165J PHONE J 3P YKB21-5009 NI 6.3

J5 EJ-821387X PHONE J YKB21-5264 6.3

J6 EJ-821387X PHONE J YKB21-5264 6.3

J7 EJ-413165J PHONE J 3P YKB21-5009 NI 6.3

J8 EJ-821387X PHONE J YKB21-5264 6.3

TR1 ET-410280J TR 2SC3327 A T05

TR2 ET-410280J TR 2SC3327 A T05

TR3 ET-410280J TR 2SC3327 A T05

TR4 ET-410280J TR 2SC3327 A T05

TR5 ET-410280J TR 2SC3327 A T05

TR6 ET-410280J TR 2SC3327 A T05

TR7 ET-410280J TR 2SC3327 A T05

TR8 ET-410280J TR 2SC3327 A T05

TR9 ET-410280J TR 2SC3327 A T05

TR10 ET-410280J TR 2SC3327 A T05

TR11 ET-410280J TR 2SC3327 A T05

TR12 ET-410280J TR 2SC3327 A T05

TR13 ET-410280J TR 2SC3327 A T05

TR14 ET-410280J TR 2SC3327 A T05

TR15 ET-410280J TR 2SC3327 A T05

TR16 ET-410280J TR 2SC3327 A T05

TR17 ET-364023 TR DTC114ES T05

TR18 ET-362847 TR 2SA1317 S,T,U T05

W1 EW-820969X WIRE ASSY L5261(1) RA-RC 26P

Ref.No. Part No. Description

X1 EI-820992X OSC X'TAL C.DS0751SV 25.0000MHZ

9. IB-4D

Ref.No. Part No. Description

100 EZ-811066J BATTERY LITHIUM CR2025

110 EJ-378916J SOCKET JM-2W-96 2P

IC1 EI-813234J IC CS8414-CS FPT1T24E

IC2 EI-813233J IC CS8404A-CS FPT1T24E

IC3 EI-821412X IC SM5849BF

IC4 EI-821412X IC SM5849BF

IC5 EI-810887J IC AV9173-01CS08 FP T12E

IC6 EI-810887J IC AV9173-01CS08 FP T12E

IC7 EI-821022X IC XC9572XL-7TQ100C

IC8 EI-811576J IC DS34C86TM FP T16E

IC9 EI-811205J IC MC74HCU04AF FPELT16E

IC10 EI-811125J IC UPC2933T

J1 EJ-820754X PIN J YKC21-3079 P2P

J2 EJ-820150J SOCKET COAX. BNC-LNRD-BPAA

SW1 ES-428287J SW SLIDE SSSF112-S06N1 1-02N

T1 BT-810651J TRANS PULSE CIT0705S-35101TFP

TR1 ET-391712J TR 2SA1317 S,T T05

W1 EW-821006X WIRE ASSY L5262(1) RA-RC 40P

X1 EI-821023X OSC X'TAL C.DS0751SV 6.144MHZ

10. LCD BLOCK

Ref.No. Part No. Description

1 SP-812808X2 PANEL LCD

2 SP-821150X WINDOW LCD

3 EM-812761J IND LCD G321EV5R001

4 MB-820395X SHIELD LCD 110

5 MB-820396X SHIELD LCD 90

6 EM-812795J INVERTER CXA-K0505-VJL

7 ZS-811805J BT BID30X10STL BNI

8 EW-821444X CORD FFC P1.25 L480 14P

9 ZS-331182 BT BID30X08STL BNI

10 MS-812805J SHAFT (1)

11 ZW-270101 RING E 300SUP CMT

12 MS-812806J SHAFT (2)

13 SP-812809J BOTTOM LCD

14 SK-821433X KNOB LCD (2)

14 EV-820602X VR ROTARY RK09K113AF25B14 B103

15 BA-L4016A504C PC LCD BLK

16 EL-820373X FL UNIT 001

8. IB-4ADT

Ref.No. Part No. Description

IC1 EI-821412X IC SM5849BF

IC2 EI-821412X IC SM5849BF

IC3 EI-821412X IC SM5849BF

IC4 EI-821412X IC SM5849BF

IC5 EI-821412X IC SM5849BF

IC6 EI-820941X IC XC2S50-5TQ144C

IC7 EI-820957X IC NJM317DL1 FPTE1T16E

IC8 EI-810887J IC AV9173-01CS08 FP T12E

IC9 EI-810887J IC AV9173-01CS08 FP T12E

IC10 EI-812977J IC HD74LVC08TELL FPELT16E

IC11 EI-821160X IC BA033FP E2 FPE2T16E

IC13 EI-812978J IC HD74LVC541ATELL FPELT16E

IC14 EI-812978J IC HD74LVC541ATELL FPELT16E

J1 EJ-394459J SOCKET OPTICAL GP1F32R

J2 EJ-394490J SOCKET OPTICAL GP1F32T

J3 EJ-820965X WIRE ASSY L5263(1) RA-RC 50P

P1 EJ-364356 PLUG B8B-PH-K WHT 8P

SERVICE MANUAL

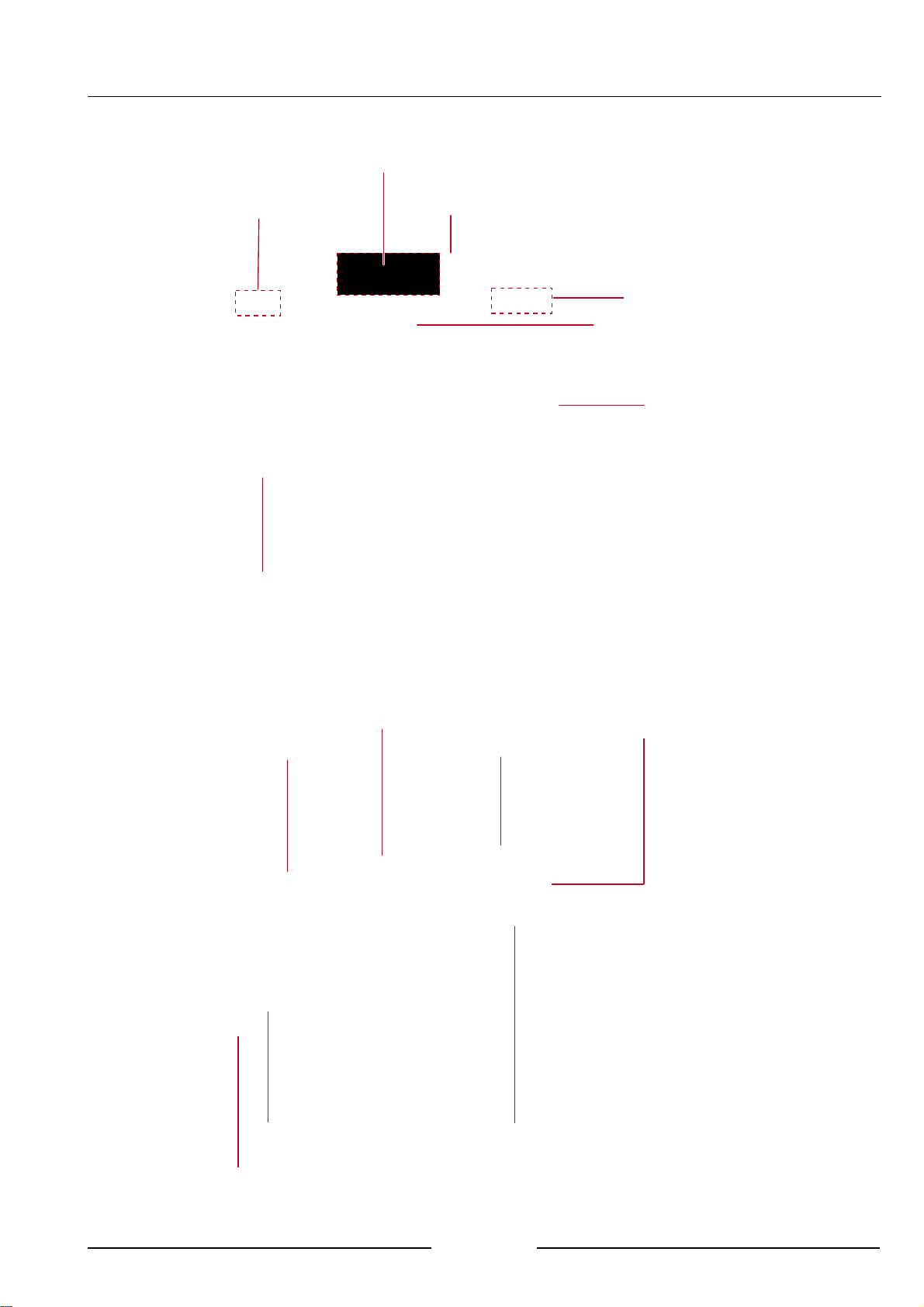

11. FINAL ASSEMBLY BLOCK

Ref.No. Part No. Description

1 SP-821144X1 PANEL TOP

2 SE-820647X1 ESCUTCHEON POWER

3 SE-810353J LENS LED

4 SE-821149X ESCUTCHEON PANEL

5 SP-821147X PANEL FRONT

6 BUTTON SB-820646X BUTTON POWER [ Pow SW ]

6 SW ES-430685J1 SW PUSH SDDF3A 02-1

7 BUTTON SB-821492X BUTTON PUSH (A) [ White ]

7 SW ES-349474 SW TACT SKHHAM004A

8 BUTTON SB-821549X BUTTON PUSH C-7 [ White ]

8 SW ES-349474 SW TACT SKHHAM004A

9 BUTTON SB-430328J BUTTON PUSH C [ Black ]

9 SW ES-349474 SW TACT SKHHAM004A

10 BUTTON SB-812379J BUTTON PUSH C-4 [ Yellow ]

10 SW ES-349474 SW TACT SKHHAM004A

11 BUTTON SB-821429X BUTTON PUSH C-6 [ Purple ]

11 SW ES-349474 SW TACT SKHHAM004A

12 BUTTON SB-430327J BUTTON PUSH B(2) [ Red ]

15

Page 16

Ref.No. Part No. Description

12 SW ES-415015J SW TACT SKQEAD

13 BUTTON SB-821550X BUTTON PUSH B(5) [ White ]

13 SW ES-415015J SW TACT SKQEAD

[ TAP TEMPO ONLY ]

13 SW ES-337521 SW TACT SKHHAL

[ PADBANK,NEXT,etc ]

14 BUTTON SB-820334X BUTTON PUSH B(4) [ Black ]

14 SW ES-415015J SW TACT SKQEAD

[ PLAY,STOP,PLAY ST. ]

14 SW ES-337521 SW TACT SKHHAL

[ Q-LINK SEQ, PAD ASSING,etc ]

15 PAD SE-820582X PAD CH-SE3 [ Black ]

15 SENSOR BA-379695J1 PC PAD SENSOR

16 KNOB SK-821427X KNOB VOL LOWER PART (2)

[ REC LOWER]

17 KNOB SK-821426X KNOB VOL UPPER PART (2)

[ REC UPPER ]

17 VOL EV-821124X VR ROTARY RK1612220

L25RD203X2

18 KNOB SK-821438X KNOB VOL PART(12) [ MAIN ]

18 VOL EV-821123X VR ROTARY RK16312A0 L25

B103X2

19 KNOB SK-821152X KNOB JOG [ JOG ]

19 VOL ES-821084X ROTARY ENCORDER REC16B25-

201-C

20 KNOB SK-821430X KNOB SLIDE (C) [ Q-LINK ]

20 VOL EV-812350J VR SLIDE RS45112 L15 B103X2 SP

21 KNOB SK-821439X KNOB VOL PART(13) [ Q-LINK ]

21 VOL EV-812348J VR ROTARY RK14K124 L20 B103X2

22 SP-821145X PANEL SIDE(L)

23 SP-821146X PANEL SIDE(R)

24 ZS-821548X SCREW TOP COVER NI

25 ZS-821678X WASHER TOP

26 SK-821679X SPACER SLIDE

27 BUTTON SB-821151X BUTTON CURSOR [ CURSOR ]

27 SW ES-349474 SW TACT SKHHAM004A

28 EJ-358632J2 SOCKET INLET SOT-16 3P

[ AC INLET]

29 BM-821374X MOTOR FAN 109R0612F402 L=230

[ MOTOR FAN ]

30 SA-311742 FOOT ROUND SHAPED [ FOOT ]

31 EJ-329610 TERMINAL W/SCREW UB-0067 L 1P

[ Signal GND ]

32 SP-821155X PANEL REAR

33 ZS-331182 BT BID30X08STL BNI

34 ZS-396044 BID30X08STL BNI

35 EJ-430956J DIN J YKF51-5058 2X5P [ MIDI I/O ]

36 EJ-812347J SOCKET FCN-235D050-G/J 50P

[ SCSI I/O ]

37 EJ-821386X PHONE J YKB22-5264 NUT 6.3

[ MAIN OUT ]

38 EJ-820762X SOCKET RECEPTACLE NCJ9FI-H-0

[ XLR IN ]

39 EJ-386340J SOCKET RECEPTACLE XLB3-

32PCVM1 [ XLR OUT ]

40 EJ-821219X PHONE J YKB22-5244 NUT 6.3

[ FOOT SW ]

41 EJ-820316X SOCKET CONNECTER YKF45-0001

4P [ USB-B ]

42 EJ-821443X PIN J YKC21-4042 P2P [ PHONO IN ]

43 ES-821121X SW SLIDE SSSF142-S09N0 4-02N

[ INPUT SEL ]

44 ZS-820481X BT PAN30X08STL BZN C080

[ AC INLET ]

45 ZS-388940J BID40X35STL BNI

46 EJ-820150J SOCKET COAX. BNC-LNRD-BPAA

[ Word Clock ]

Ref.No. Part No. Description

47 ES-428287J SW SLIDE SSSF112-S06N1 1-02N

[ Termineter ]

48 EJ-820754X PIN J YKC21-3079 P2P

[ DIGITAL I/O ]

49 ZS-322570 ST BID40X08STL NI3

50 ZW-413267 N FRANGE 40STL CMT

51 ZS-812613J PAN25X06STL NI3 [ SCSI JACK ]

52

53A

53B EW-368420J1 AC CORD200SKP30KS16 B AC [ A ]

53C

53D EW-419170J AC CORD200S KP610 KS31A B [ B ]

54 EW-821111X WIRE ASSY L4016(12) AMP 40P

55 ZS-418538J PAN N06-32UNCX5MM STL CMT

56 ZS-417137 BID30X04STL CMT [ for ZIP ]

57 EW-821112X WIRE ASSY L4016(13) AMP-AMP 4P

58 ZW-302909 RV NYL30X035 BL

59 EW-821537X WIRE ASSY L4016(19) JST-MLX 2P

60 EW-821536X WIRE ASSY L4016(18) JST-MLX 4P

61 EH-821634X FILTER EMI TFC-16-8-13F WO/OP

62 BA-LJ038A020A PC POWER BLK SPS-80

63 KNOB SK-821432X KNOB VOL(F) [ Head Phone ]

63 VOL EV-821235X VR ROTARY RK0971220 L15

64 ZW-273914 SW40

65 ZW-413188 N40STL CMT 1

66 EJ-821000X PHONE J YKB26-5264 S.NUT 6.3

67 EJ-820970X SOCKET CONNECTER YKF45-0001

68 ES821122X SW PUSH SPUJ19B-2N-*W 2-02-

EJ-405424J PLUG ADAPTOR KPR-25 J

EW-380905J AC CORD 250S KP300 KS16A H B J

[ J ]

EW-403993J AC CORD200SKP4819DKS31A B E

[ E ]

[ ATA-40pin ]

[ for HD ]

[ Power Cable ]

[ Digital Cable ]

[ Analog Cable ]

[ for HD Power Cable ]

[ Power BLK ]

B103X2

4P [ USB-A ]

02N [ REC GAIN ]

16

SERVICE MANUAL

Page 17

FINAL ASSEMBLY BLOCK

22

21

2

SETUP SEQUENCE

MIN MAX

ACTIVE ACTIVE

MIN MAX

ACTIVE ACTIVE

ACTIVE ACTIVE

13

6

Q 2

Q 1

MIN MAX

Q 4

Q 3

MIN MAX

Q 6

Q 5

1

A

A

Q-LINK

SEQUENCE

&

PAD

ASSIGN

#

FULL

LEVEL

16

LEVELS

!

ERASE

(

NOTE

REPEAT

)

7

CONTRAST

F 1 F 2 F 3 F 4 F 5 F 6

F 1 F 2 F 3 F 4 F 5 F 6

PAD BANK

B

BCDEFGH

PAD 13 PA D 14 PAD 15 PAD 16

PAD 9 PAD 10 PAD 11 PAD 12

PAD 5 PAD 6 PAD 7 PAD 8

PAD 1 PAD 2 PAD 3 PAD 4

D

C

P LOOP PTO P FROM

E

DRUMS

NEXT

SEQUENCE

TRACK

MUTE

PLAY

F

4

TIMING CORRECT

X

MASTER TEMPO

Y

UNDO SEQ

Z

TAP TEMPO

68 17

11

GAIN

HIGH

LOW

789

456

123

0 ENTER

WINDOW

SHIFT

STEP

EVENT START END

OVER

REC

DUB

16

REC GAIN

MAIN VOLUME

MAX

MINMIN MAX

R

L

RECORD

SAMPLE

IJK

MULTI

MIXER

LMN

SAVE LOAD

OPQ

SONG MISC.

RST

MAIN

SEQ EDIT

UVW

CURSOR

JOG

BLOCK

CURSOR

LOCATE

GO TO

BAR

PLAY/ REC

STOP

PLAY

18

PROGRAM

EFFECT

GLOBAL

MIDI

STEP EDIT

PLAY

START

23

8

19

27

20

26

8

3

14

14

24

25

15

5

13

13

8

12

10

14

57

54

61

60

59

58

SERVICE MANUAL

17

Page 18

FINAL ASSEMBL Y BLOCK

43

42

31

38 39

37

33

32

45 29

52

5353

35

34

51

3641

40

37

48

46

4447

28

30

50

49

5655

54

ZS-418538J

ZS-417137

18

SERVICE MANUAL

Page 19

LCD BLOCK

3

◎ ◎

○

5

○

◎

4

2

11

1

3

9

16

7

6

14

15

8

13

12

10

SERVICE MANUAL

19

Page 20

VII. INFORMATION OF ICs

1. IC Explanation.

1-1 IC1 SA1110B (Intel CPU)

206MHz version chip.

CPU clock : 176.9MHz.

SDRAM (CPU work memory) : 88.45MHz (=176.9MHz/2)

1-1-2 Pin Descriptions

Signal name Dir Explanation

D[31:0] i/o Data-bus

A[25:0] out Address-bus

SDCKE1 out SDRAM clock enable for CPU’s work memory

SDCLK1 out SDRAM clock for CPU’s work memory.(88.45MHz)

SDCLK2 out Not used though this is connected.(44.225MHz)

/SDRAS out SDRAM RAS for CPU’s work memory

/SDCAS out SDRAM CAS for CPU’s work memory

/SDCS0 out SDRAM CS for CPU’s work memory

DQM[3:0] out SDRAM data out mask enable for CPU’s work memory

/OE out Output enable (/RD)

/WE out Write enable

/Cs[5:0] out Chip select

RDY in Data ready signal for /CS[5:3]

RD/nWR out Read/write direction control

/RESET in Hard reset. Active low.

PXTAL in Input for 3.686MHz crystal (non-CMOS threshold)

PEXTAL out Output for 3.686MHz crystal (non-CMOS level)

GP0 in Interrupt from Voice-LSI

GP1 in Interrupt from SCSI controller (FAS236U)

GP2 in Interrupt from IDE

GP3 in Interrupt from USB-host controller (SL811HST)

GP4 in Interrupt from effect board

GP5 in Interrupt from MIDI (Voice-LSI)

GP6 in Interrupt from USB-function controller (NET2890)

GP7 in Interrupt from SMPTE option (MPC only)

GP8 in Interrupt from FPGA

GP9 in Interrupt from Voice-LSI

GP11 out Initialize FPGA. active high.

GP13 out DIMM SPDA for reading information.

GP14 out DIMM SPCL for reading information.

GP15 out LCD DISP off. Active low.(MPC only)

GP16 in SCSI jack board recognition. Low=connected.

GP17 out Control /PROGRAM pin of FPGA during configuration

GP18 in effect board recognition. Low=connected.

GP19 in FPGA /INIT. used during configuration.

GP20 out D/A converter CDTI (control data input)

GP21 in FPGA done. used during configuration.

GP22 out Used for ROM emulator.

GP23 out CPLD TDI. used during configuration in factory.

GP24 out CPLD TMS. used during configuration in factory.

GP25 out CPLD TCK. used during configuration in factory.

GP26 in 8 Para board recognition. Low=connected.

GP27 in CPLD TDO. used during configuration in factory.

RxD_1 in DIO board recognition. Low=connected.

TxD_1 in SMPTE board recognition. Low=connected.

RxD_2 in RxD. from panel(remocon) 230.4kbps.

TxD_2 out TxD. to panel(remocon). 230.4kbps.

RxD_3 in ADAT board recognition. Low=connected.

TxD_3 in for future. (Low When ADAT board is exist now)

RxD_C in CD analog recognition. Low=connected.(MPC only)

20

SERVICE MANUAL

Page 21

Signal name Dir Explanation

TxD_C in CD digital recognition. Low=connected.(MPC only)

SCLK_C in BM1. Machine recognition. Low=Z4/8. High=MPC.

SFRM_C in BM0. Connected GND now. for future.

LDD[7:0] out LCD controller display data.

L_BIAS out LCD ac bias drive.

L_PCLK out LCD pixel clock.

L_LCLK out LCD line clock.

L_FCLK out LCD frame clock.

TXTAL in Not used.(Clock for CPU’s real-time clock)

ROM_SEL in ROM bus width select. Low=16bits.

SMROM_EN in SMROM enable. Low= disable.

/PIOR,/PIOW out PCMCIA I/o read/write for ROM Emulator

/IOIS16 in PCMCIA 16-bit I/O data transfers for ROM Emulator

TCK_BYP

TESTCLK in Test pin

GP10,/PCE1

/PWAIT

BATT_FAULT

VDD_FAULT out # Not used though this is connected #

VDD - Positive supply for the core. +1.75V

VDDX - Positive supply for the pins. +3.3V

VSS - Ground supply.

VSSX - Ground supply for the I/O pins.

1-3. IC3,4 HM5264165FTT (64Mbit SDRAM (4Mword x16bit))

Wave RAM for Voice LSI

The clock changes by the value of sampling frequency.

44.1kHz: 33.869MHz (= fsx768)

48kHz : 36.864MHz (= fsx768)

96kHz : 36.864MHz (= fsx384)

If there is no DIMM, SDRAM is placed in zero address.

If there is DIMM(s), SDRAM is placed in last address.

1-4. IC5,6 HY57V281620AT-P (128Mbit SDRAM (8Mword x16bit))

CPU work RAM

This clock is set to half of CPU core clock by software.

(“88.45MHz” When CPU clock is 176.9MHz.)

1-5. IC7 MBM29DL322TE90TN (32Mbit Flash ROM (2M word x16bits))

CPU Boot ROM

(If ROM-card is inserted in J7, system boot up from ROM card.)

SERVICE MANUAL

21

Page 22

1-6. IC8 XC95144XL-7TQ100C (Complex programable logic (CPLD).

Address decoder.

Expansion port by using data-latch.

Communication logic for RTC.

Selector.

1-6-2. Pin Descriptions

Signal name Dir Explanation

D[7:0] i/o Connected with CPU data bus for communication.

A[24:21] in Connected with CPU address bus for communication.

/CS[5:0] in Chip select for other device.

/RD in Data output enable of CPU data bus.

/WR in Data strobe of CPU data bus.

/RESET in For initializing logic. Active low.

/GWR,/FWR out buffered /WR. (= /WR)

/GDB out Gate of buffer for logic on CPU board.

/GDB2 out Gate of buffer for logic except for CPU board.

ROMCARD in ROM card. L: not inserted (normal), H: inserted.

/FLASH_CS out Chip select for Flash-ROM. /CS0 OR (A24 XOR ROMCARD).

/ROM_CS out Chip select for ROM-card. /CS0 OR (/A24 XOR ROMCARD).

/SCSI_CS out Chip select for SCSI controller. /CS5 OR A24.

/USBF_CS out Chip select for USB host controller. /CS5 OR /A24.

FPCCLK out FPGA configuration clock on CPU PCB.

/EB_CS out Chip select for DSP on effect PCB.

FP2_CCLK out FPGA configuration clock on ADAT PCB.

/ADAT_CS out Chip select for FPGA on ADAT PCB.

/SMPTE_CS out Chip select for controller on SMPTE PCB.

/DIO_CS out Chip select for CPLD on DIO PIB.

/LSI_RESET out Reset Voice-LSI. Active low.

/VO_PLLRST out Reset PLL of Voice-LSI. Active low.

/IDE_RESET out Reset IDE.

/ADAT_INIT out Initialize FPGA and IC on ADAT PCB. Active low.

/EB_RESET out Reset DSP on effect PCB. Active low.

VO_SIN[1:0] out Audio serial data to Voice-LSI’s SIN[1:0]

AD_DATA in Analog-in audio data from CODEC (A/D at MPC).

DIO_RCVD in Digital-in audio data from DIO PCB.

ADAT_RCVD in ADAT-in audio data from ADAT PCB.

EB_RTN[3:2] out Effect return.

/SCSI_TERM out SCSI termination. H:off, L:on.

/ADA_CS out Chip select for CODEC (A/D conv. at MPC).

/ADA_PD out /PD of CODEC and A/D on MPC.

AD_DFS out DFS of a/d converter on MPC.

DA_CCLK out Control clock for CODEC (D/A conv. at MPC).

/DA_CS out Chip select for dD/A converter at MPC.

/DA_PD out /PD of D/a converter’s on MPC and DIO.

/AD_CDSEL out Select analog-out of CD player at MPC.

MUTE out For mute circuit. H: mute on, L: mute off.

LSI_MCLK in MCLK of Voice-LSI. Make synchronous reset for Voice LSI.

RTC_D[7:0] i/o RTC data bus.

RTC_AS

RTC_DS

RTC_RW out Control for RTC

/RTC_SEL

/RTC_XALM

WCKE[1:0] out Clock enable of wave SDRAM and DIMM.

SEL_XTAL0 out X2 output enable. H: enable, L: disable.

SEL_XTAL1 out X3 output enable. H: enable, L: disable.

MOTOR_ON out Control fan on MPC.

22

SERVICE MANUAL

Page 23

Signal name Dir Explanation

/FP2_PROG out For configuration to FPGA on ADAT PCB.

PLD2_TMS

PLD2_TDI

out For configuration to CPLD on DIO.

PLD2_TDO in For configuration to CPLD on DIO.

TCK,TMS,TDI in For configuration.(TCK is also used for CPLD on DIO)

TDO out For configuration.

VCCINT - Positive supply for internal logic. +3.3V

VccIO - Positive supply for output driver. +3.3V

GND - Ground supply.

1-7. IC9 XC2S100-5TQ144C (Field Programmable Gate Arrays (FPGA))

IDE controller.

DMA controller between Voice-LSI and IDE/SCSI.

MIDI interface.

1-7-2. Pin Descriptions

Signal name Dir Explanation

CD[15:0] i/o Connected with CPU bus for communication.

A[5:0] in Connected with CPU address bus for communication.

/IDE_CS in Chip select for this FPGA.

/CPU_RD in Data output enable of CPU bus.

/CPU_WR in Data strobe of CPU bus.

RESET in Initialize FPGA logic. Active high.

LSI_D[15:0] i/o Connected with DMA data bus of Voice-LSI.

IDE_D[15:0] i/o Connected with data bus of IDE.

IDE_DA[2:0] out Connected with DA[2:0] of IDE I/F

/IDE_CS1,0 out Connected with CS[1:0] of IDE I/F.

/IDE_IORD Out Connected with /DIOR_HD of IDE I/F.

/IDE_DIOW Out Connected with /DIOW_STOP of IDE I/F.

IORDY in Connected with IORDY of IDE I/F.

/IDE_DMACK out Connected with /DMACK of IDE I/F.

IDE_DMARQ in Connected with DMARQ of IDE I/F.

CPU_RDY out Connected with CPU RDY.

SCSI_DMAREQ

/SCSI_DMACK out Connected with SCSI controller. DMA control.

LSI_DMAREQ out Connected with Voice-LSI. DMA control.

/LSI_DMAACK in Connected with Voice-LSI. DMA control.

/LSI_DMARD in Connected with Voice-LSI. DMA control.

/LSI_DMAWR in Connected with Voice-LSI. DMA control.

/INT_DMA out Interrupt request output of DMA to CPU. Active low.

LRCK in Word clock of system. Connected with Voice-LSI.

SFrame out Pin No.133. Frequency= Fs/256. duty cycle= 255:1.

MIDI_IN1,2 in MIDI 2 input.

MIDI_OUT1-4 out MIDI 4 output.

/INT_MIDI out Interrupt request output of Midi to CPU. Active low.

MCLK in Master clock of FPGA logic.

CCLK in Configuration clock I/O pin.

/INIT i/o For configuration. Active Low.

/PROGRAM in Initiates a configuration sequence when asserted Low.

DONE i/o Indicates that configuration is complete. open drain.

M0,M1,M2 in configuration mode pin.

TCK,TMS,TDI in # Not used though this is connected #

VCCINT - Power supply for internal core logic. +2.5V

VccO - Power supply for output driver. +3.3V

GND - Ground supply.

in Connected with SCSI controller. DMA control.

SERVICE MANUAL

23

Page 24

1-8. IC10 SL811HST (USB Host/Slave Controllers).

1-8-2. Pin Descriptions

Pin No. Signal name Dir Explanation

3 /WR in Write Strobe. Active low.

4 /CS in Chip select. Active low.

5 CM in Clock mode. H: at 12MHz. L: at 48MHz clock source.

6 USBVDD - Power for USB Transceivers.

7 DATA+ i/o USB Differential Data Signal High Side.

8 DATA- i/o USB Differential Data Signal Low Side.

9 USBGND - Ground Connection for USB.

16 CLK/X1 in Clock or External Crystal X1 connection.

17 X2 out External Crystal X2 connection.

18 /RST in SL811HST Device reset. Active low.

19 INTRQ out Interrupt Request output. Active high.

21,39

27-29 D[7:0] i/o Connected with CPU bus for communication.

31-33

40 M/S in Master/Slave Mode select. H: Slave. L: Master.

42 A0 in L:Addr.Pointer.Register. H:Data Buffer or Register.

43 /DACK in DMA Acknowledge. Active low.

44 /DRQ Out DMA Request. Active low.

45 /RD in Read Strobe Input. Active low.

15,41 VDD - Device VDD Power.

9,20

30

GND - Device Ground.

24

SERVICE MANUAL

Page 25

1-9. IC11 FAS236U (SCSI Controller)

1-9-2. Pin Descriptions

Pin No. Signal name Dir Explanation

100 DREQ out DMA request. H: ready to transfer data.

1 /DACK in DMA acknowledge.

2 /DBWR in Data-bus write control.

4 IGS out Indicates that chip is acting in initiator mode.

5 DIFFSENS in H: differential mode.

6 TGS out Indicates that chip is acting in target mode.

7 EDIFFS in H: Enable “DIFFSENS” function.

8-15

19-26

16,27 DBP[1:0] i/o DMA data-bus parity.

29-36 /SDI[7:0] in SCSI data bus.

37 /SDIP in SCSI data parity.

42-45

48-51

52 /SDOP out SCSI data parity.

56 /SELO out SCSI bus select.

57 /BSYO out SCSI bus busy.

58 /REQO out SCSI bus request.

59 /ACKO out SCSI bus acknowledge.

62 /MSG i/o SCSI bus message phase.

63 /CD i/o SCSI bus control and data phase.

64 /IO i/o SCSI bus I/O phase.

65 /ATN i/o SCSI bus attention.

66 /RSTO out SCSI bus reset.

69 /SELI in SCSI bus select.

70 /BSYI in SCSI bus busy.

71 /REQI in SCSI bus request.

72 /ACKI in SCSI bus acknowledge.

73 /RSTI in SCSI bus reset.

74,75 MODE[1:0] in Bus configuration mode select.

76 /INT out Interrupt output.

77 RESET in Power reset.

79 /WR in Write control.

80 /RD in Read control.

81 /CS in Chip select.

82-85 A[3:0] in Address bus.

86 CLK in Internal chip timing clock.

87 /DIFFM in H: single-endes mode. L: differential mode.

90-93

96-99

38,88 VDD - +5V DC power input.

17,18,40

41,46,47

54,55,60

61,67,68

94,95

DB[15:0] i/o DMA data-bus.

/SDO[7:0] out SCSI data bus.

PAD[7:0] i/o PAD bus. Connected with CPU for communication.

Vss - GROUND. 0V DC power return.

SERVICE MANUAL

25

Page 26

1-10 IC12, 16 ALVCH16245 (16 bit Bus bidirectional transceivers)

1-11 IC13-15 ALVCH16244 (16 bit Bus Buffers)

1-12 IC17, 18 LVC244 (8 bit Bus Buffers)

1-13 IC19 LVC245 (8 bit Bus bidirectional transceivers)

In particular, this is used for changing 5V into 3.3V.

1-14 IC20 M51957B (System Reset IC. Delay time is about 0.34 sec)

1-15 IC21, 22 NJM317 (Regulator IC)

IC21: regulate +2.5V for FPGA.

IC22: regulate +1.75V for CPU.

1-16. IC23 NET2890 (USB function controllers)

1-16-2. Pin Descriptions (PU:pull-up, PD:pull-down)

Pin No. Signal name Dir Explanation

2 /SOF out Start of Frame. Active low.

3,4 DP,DM i/o USB data port. differential data.

5-11 bi-directional 8-bit data bus.

14

15 /CS in Chip select. Active low. (PU)

16 LCLK out buffered clock output.

17 /IOR in I/O read strobe. Active low. (PU)

18 /IOW in I/O write strobe. Active low. (PU)

19 DRQ out DMA request.

20 /DACK in DMA acknowledge. Active low. (PU)

21 /EOT in End of transfer. Active low. (PU)

22 /BUSPWR

23 /PWRGOOD in

26 /IRQ out Interrupt Request. Active low.

27 /USBOE i/o USB port output enable. Active low. (PU)

28 /DEVCFG out Device config. Alternatively general output. (PD)

30 TEST in Test. Connect this pin to ground. (PD)

32 /LRESET out Local reset. Active low. (PU)

33 /SUSP out Device suspended. Active low. (PU)

34 /WAKEUP in USB remote wakeup. Active low. (PU)

35 /RESET in External reset. (PU)

38-42 A[4:0] in Address bus.

44 CLKIN in 48 MHz Oscillator input.

45 CLKOUT out 48 MHz Oscillator output.

47 TESTOUT out Test output. Used for manufacturing test.

31 VDD_LOCAL - +3.3V or +5V DC power input for CPU I/F.

1,13,25

37,43

12,24,36

46,48

D[7:0] i/o

in

Connected with CPU for communication.

Indicates that external logic is powered by USB bus.

Alternatively general input.

Indicates that external power supply used for self-powered mode is operational.

Alternatively general input.

VDD - +3.3V DC power input for the core and USB I/F.

Vss - GROUND. 0V DC power return.

26

SERVICE MANUAL

Page 27

Appendix: Installing storage devices (for service engineers)

This appendix explains how to install storage devices (ATA hard disk, CD-ROM drive, Zip drive, etc.) in the MPC4000.

Check the included items

The following items are included with the MPC4000 for use when installing storage devices. Check to make sure that no

items are missing.

■ Cables

• Flat cable for ATA drive

• Power cable for drive (without ferrite core)

• Power cable for drive (with ferrite core)

• Analog audio cable for CD-ROM

• Digital audio cable for CD-ROM

• Drive Mount Bracket (S)

• Drive Mount Bracket (L)

■ Other items

• Screws (inch) for attaching hard disk (4 pcs.)

• Screws (metric) for attaching hard disk (4 pcs.)

• Screw hole plugs (4 pcs.)

• Screws (metric) for attaching Drive Mount Bracket (8 pcs.)

Opening the top panel

When installing a storage device, use the following procedure to open the top panel of the MPC4000.

1. Loosen the screws that fasten the side panels (four on each side, left and right), and remove the side panels.

2. Remove the screws (five on each side, left and right) that fasten each side of the top panel to the chassis.

SERVICE MANUAL

27

Page 28

3. Remove the screw (located in the center of the front panel) that fastens the top panel from the lower front side.

4. Remove the screw (located in the center of rear panel) that fastens the top panel from the rear side.

5. Use both hands to lift the protrusion on the front of the top panel, and open the top panel.

SERVICE MANUAL

28

Page 29

6. Use a metal rod or similar object as a prop inside the chassis to hold up the top panel.

The side panels and screws you removed must be kept in a safe place.

To close the top panel, re-tighten the screws in the opposite order to which they were removed.

Installing a drive

1. If you are installing a removable-media drive such as a CD-ROM drive or Zip drive, remove the blank panel from the

front panel.

2. Use the hard disk attachment screws (included with the MPC4000) to attach the drive to the bracket, and attach the

bracket to the bottom panel of the chassis. Use the bracket in the correct direction (as illustrated or on reverse side)

according to the drive mounted.

When installing a drive in the 3.5 inch bay

P7

P8

PC IO

SERVICE MANUAL

Bracket (S)

PC IO AD_DA

PC CPU

29

Page 30

When installing a drive in the 5 inch bay

1

Bracket (L)

PC IO

P7

P8

P2

PC CPU

PC IO AD_DA

Cable connections

Connecting the flat cable

1. Remove two screws from the cover that conceals the PC CPU board.

When you remove the cover, you will see the P2 connector for the ATA drive.

P23

Bracket (S)

PC IO AD_DA

P7

P8

PC IO

P2

PC CPU

Step

2. 3Insert the blue connector of the included flat cable into the P2 connector of the PC CPU board.

3. Reattach the cover that you removed.

4. Connect the other end of the flat cable to the drive.

SERVICE MANUAL

30

Page 31

Connecting the power cable

1. Insert the connector of the included power cable into the P7 connector or P8 connector of the PC I/O board.

Use the power cable with the ferrite core if you are installing a hard disk. Use the power cable without a ferrite

core if you are installing a Zip drive or CD-ROM drive.

2. Connect the other end of the power cable to the drive.

Connecting the CD-ROM analog audio cable

If the CD-ROM drive has an analog audio output connector, connect it to the MPC4000’s circuit board as follows.

1. Insert the connector of the included CD-ROM analog audio cable into the P23 connector of the PC I/O ADDA

board.

2. Insert the other end of the CD-ROM analog audio cable into the analog audio output connector of the CD-ROM

drive.

Make connections so that the red cable goes to R (right channel) and the white cable to L (left channel).

3. On the PC I/O ADDA board, plug in the P22 jumper (located in front of P23) at the “SET” position.

Connecting the CD-ROM digital audio cable

If the IB-4D digital I/O option is installed in the MPC4000, connect the digital audio output connector of the CD-ROM

drive to the IB-4D as follows.

1. Insert the connector of the included CD-ROM digital audio cable into the digital audio output connector of the CDROM drive.

Make connections so that the black cable is the ground.

2. Insert the other end of the CD-ROM digital audio cable into the P1 connector of the IB-4D digital I/O option.

3. On the IB-4D circuit board, plug in the JP1 jumper in the 1-2 (SHORT) position.

* If you connect the analog/digital audio cable and make the correct jumper setting, you will be able to select the

CD-ROM playback as the recording source in RECORD mode.

Master/slave settings for ATA drives

If you install two drives, you must set one as the master and the other as the slave. (If a hard disk is installed, set the

hard disk as the master.)

For details on how to make master/slave settings, refer to the manual that came with your drive.

Installing Memory Board

The memory slots are on the CPU board and their 2 long DIMM sockets are located on the right-hand side of the unit towards

the rear.

Insert the memory board securely in the correct direction. When only one memory board is installed, it can be installed on either

slot.

The required memory board is 168-pin DIMM (PC133/PC100, CL2).

* 256Mbit x 8 ICs type 256Mbyte DIMM is not supported. 128Mbit x 16 ICs type is recommended.

SERVICE MANUAL

31

Page 32

! Installation - MPC4000

1. Remove the fixing screws of the MPC4000 Side Panels (4pcs. on each side) and remove Side Panels. Next,

remove the screws (5pcs. on each side) hidden by the Side Panels and then remov e the center screws (2pcs.)

located underneath the Armrest and the topmost of Rear Panel. The Top Panel Block can be swing-opened by

lifting the Armrest from the front. Save the removed screws.

2. Remove the fixing screws (4pcs.) for the Mask Plate (lower slot) on the Rear Panel and remove the Mask Plate.

Save the screws for later use. The Mask Plate is not used.

3. Referring to the illustration, remove the fixing screw (1pc.) on the I/O board and install the Mounting Post (S) in

its place. Save the screw for later use.

4. Set the IB-48P on the Rear Panel and Mounting Posts and fix it securely with the screws removed in earlier

steps and the Fixing Screw (gold) included.

5. Connect the cable from the IB-48P board to the connector (P2) on the I/O board.

6. Replace and fix the Top Panel Block and Side Panels in the opposite order to which they were removed.

✽ Be sure to fix the screws and connectors securely to avoid malfunctioning.

MPC4000

IB-48P

PC IO

P2

P4

32

SERVICE MANUAL

Page 33

! Installation - MPC4000

1. Remove the fixing screws of the MPC4000 Side Panels (4pcs. on each side) and remove Side Panels. Next,

remove the screws (5pcs. on each side) hidden by the Side Panels and then remove the center screws (2pcs.)

located underneath the Armrest and the to pmost of Rear Panel. The Top Panel Block can be swing-opened by

lifting the Armrest from the front. Save the removed screws.

2. Remove the fixing screws (2pcs.) for the Mask Plate on the Rear Panel and remove the Mask Plate. Save the

screws for later use. The Mask Plate is not used.

3. Referring to the illustration, set the IB-4D on the Rear Panel and Mounting Post and fix it securely with the screws

removed in earlier step and the Fixing Screw included.

4. Connect the cable from IB-4D board to the connector (P3) on the I/O board.

5. Replace and fix the Top Panel Block and Side Panels in the opposite order to which they were removed.

✽ Be sure to fix the screws and connectors securely to avoid malfunctioning.

MPC4000

IB-4D

P3

PC IO

SERVICE MANUAL

33

Page 34

! Installation – MPC4000

1. Remove the fixing screws of the MPC4000 Side Panels (4pcs. on each side) and remove Side Panels. Next,

remove the screws (5pcs. on each side) hidden by the Side Panels and then remove the center screws (2pcs.)

located underneath the Armrest and the topmost of Rear Panel. The Top Panel Block can be swing-opened by

lifting the Armrest from the front. Save the removed screws.

2. Remove the fixing screws (4pcs.) for the Mask Plate (upper slot) on the Rear Panel and remove the Mask Plate.

Save the screws for later use. The Mask Plate is not used.

3. Referring to the illustration, remove the fixing screw (1pc.) on the I/O board and install the Mounting Post (S) in

its place. Then extend the 2 Mounting Posts with the 2 Mounting Posts (L) included.

4. Set the IB-48P on the Rear Panel and Mounting Posts and fix it securely with the screws removed in earlier

step and the Fixing Screws (gold, 2pcs.) included.

5. Connect the cable from the IB-4ADT board to the connector (P4) on the I/O board.

6. Replace and fix the Top Panel Block and Side Panels in the opposite order to which they were removed.

Note 1: When the IB-48P 8-Individual Output board is installed at the lower slot, remove the fixing screws (2pcs.) of the

Mounting Posts for the IB-48P and re place them with the 2 Mounting Posts (L) included and mount the IB-4ADT on them.

Note 2: On the MPC4000 with IB-4D SP-DIF Digital Interface Board installed, Connect the 8-pin Connecting Cable

included between the IB-4D (P2) and IB-4ADT (P1) boards.

✽ Be sure to fix the screws and connectors securely to avoid malfunctioning.

MPC4000

PC IO

IB-4ADT

P2

P4

34

SERVICE MANUAL

Page 35

1-3, Hiranuma 1-Chome, Nishi-Ku, Yokohama, Japan

SERVICE SECT. PHONE : +81-45-412-2373 FAX : +81-45-412-2372

SERVICE MANUAL

35

Page 36

MPC4000

OPERATION

BLOCK DIAGRAM

Page 37

MPC4000

PC IO

BLOCK DIAGRAM

Page 38

MPC4000

AD DA

BLOCK DIAGRAM

Page 39

5

SW171

LED

RED

3pcs

GREEN

23pcs

D D

SW163

RET0

1 2

Q-LINK SETUP Q-LINK ASSIGN

D163

GMA01

SEND5

VR208

RK14K124

VR204

RK14K124

C C

SEND5

SEND3

B B

+5V

6

B(MAX)

5

A(MAX)

B(TAP)

A(TAP)

AB(MIN)

DUMMY

SW165

1 2

Q-LINK Q5 Q-LINK Q6

D165

GMA01

B(MAX)

A(MAX)

B(TAP)

A(TAP)

AB(MIN)

DUMMY

GREEN GREEN

D213 D206

SW167

1 2

Q-LINK Q3 Q-LINK Q4

D167

GMA01

2MAX

2TAP

2MIN

D217 D211

SW169

1 2

AN8 AN9

4

3

2

C208

C209

1

473

473

GND

RET2

+5V

6

5

AN6

4

3

2

C204

C205

1

473

473

GND

RET4

+5V

C201

473

1MAX

12

VR200

C200

473

1MIN

1TAP

AN4

GND

RET14

Q-LINK Q1 Q-LINK Q2

D169

GMA01

L4016A503A

RET1

SW164

1 2

D164

GMA01

VR210

RK14K124

D225D219

VR206

RK14K124

GREENGREEN

SW166

1 2

D166

GMA01

SW168

1 2

D168

GMA01

SW170

1 2

GREENGREEN

D170

GMA01

B(MAX)

A(MAX)

B(TAP)

A(TAP)

AB(MIN)

DUMMY

B(MAX)

A(MAX)

B(TAP)

A(TAP)

AB(MIN)

DUMMY

RET5

RET3

RET15

6

5

4

3

2

1

GND

6

5

4

3

2

1

GND

+5V

1MAX

2MAX

12

1TAP

2TAP

2MIN

GND

SEND2

+5V

C210

C211

473

473

GREEN

D222

SW157

1 2

NEXT SEQUENCE

D157

GMA01

+5V

AN7

C206

C207

473

473

C203

473

VR202

C202

473

1MIN

AN5

D216

D210

D205

GREEN

SW158

1 2

TRACK MUTE

D158

GMA01

GREEN

SW159

1 2

FULL LEVEL

D159

GMA01

GREEN

SW160

1 2

16 LEVELS

D160

GMA01

GREEN

SW161

1 2

ERASE

D161

GMA01

GREEN

SW162

1 2

NOTE REPEAT

D162

GMA01

1 2

L4016A504B

D203 D208 D214 D220 D204 D209 D215 D221

SEND0

PAD BANK A PAD BANK B PAD BANK C PAD BANK D PAD PLAY A PAD PLAY B PAD PLAY C PAD PLAY D

SW149

1 2

D149

GMA01

RET12

RET13

RET14

RET15

D226

RET12

D227

RET13

SW172

1 2

F1 F2 F3 F4 F5 F6

D171

GMA01

D172

GMA01

B-SEND4

SW150

1 2

D150

GMA01

RET12

+5V +5V +5V +5V +5V

AN0

AN1

AN2

AN3

TR205

DTA114ESA

D220

GREEN

D214

GREEN

D208