York DNP024, DNP030, DNP036, DNP042, DNP048 User Manual

...

036-21366-007-A-1205

®

TECHNICAL GUIDE

AFFINITY™ SERIES

SINGLE PACKAGE GAS/ELECTRIC AIR COOLED AIR CONDITIONERS 2 THRU 5 NOMINAL TON

DNP024, 030, 036, 042, 048 AND 060 13 SEER

DESCRIPTION

York® Affinity™ Series packaged cooling/heating air conditioners are designed for outdoor installation. Only utility and duct connections are required at the point of installation.

The gas-fired heaters have aluminized steel tubular heat exchangers and hot surface to pilot ignition. They are available in natural gas with field conversion to propane.

FEATURING

•FACTORY MOUNTED TXV

•COOLING/GAS HEATING UNITS (NATURAL GAS OR PROPANE)

•LOW PROFILE

•QUIET OPERATION

•COMMON FOOTPRINT

•OPTIONAL SLIDE IN MOTORIZED DAMPERS

•OPTIONAL SLIDE IN ECONOMIZERS

•OPTIONAL PROPANE CONVERSION KIT

•OPTIONAL HIGH ALTITUDE CONVERSION KIT (NATURAL GAS/PROPANE)

•OPTIONAL LOW NOx KIT

•FULL PERIMETER BASE RAILS

•BOTTOM AND SIDE UTILITY CONNECTIONS

•1” OR 2” CLEANABLE FILTERS STANDARD ON ALL

3 PHASE MODELS. OPTIONAL ON 1 PHASE MODELS

•WARRANTY - 1 PHASE

•10 year compressor

•20 year heat exchanger

•5 year other parts

•WARRANTY - 3 PHASE

•5 year compressor

•10 year heat exchanger

•1 year other parts

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

036-21366-007-A-1205

TABLE OF CONTENTS

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 STANDARD FEATURES/BENEFITS . . . . . . . . . . . . 3 FIELD-INSTALLED ACCESSORIES . . . . . . . . . . . . 4 TYPICAL WIRING DIAGRAM NOTES . . . . . . . . . . 32 MECHANICAL SPECIFICATIONS . . . . . . . . . . . . . 33

|

LIST OF FIGURES |

|

Fig# |

|

Pg# |

1 |

PRODUCT NOMENCLATURE . . . . . . . . . . . . . . . . |

. . 2 |

2 |

UNIT COMPONENT LOCATION . . . . . . . . . . . . . . . |

. . 6 |

3 |

FIELD WIRING DIAGRAM CONTROL WIRING . . . . 18 |

|

4 |

POWER WIRING FIELD DIAGRAM . . . . . . . . . . . . |

. 19 |

5 |

UNIT DIMENSIONS - FRONT . . . . . . . . . . . . . . . . . |

. 20 |

6 |

UNIT DIMENSIONS - FRONT & BOTTOM . . . . . . . |

. 21 |

7 |

UNIT DIMENSIONS - BACK & BOTTOM . . . . . . . . |

. 21 |

8 |

TYPICAL SLAB ON GROUND INSTALLATION . . . . 22 |

|

9 |

TYPICAL ROOF CURB INSTALLATION . . . . . . . . . |

. 22 |

10 |

TYPICAL DUCT APPLICATIONS . . . . . . . . . . . . . . |

. 23 |

11 |

UNIT CENTER OF GRAVITY . . . . . . . . . . . . . . . . . |

. 23 |

12 |

ROOF CURB DIMENSIONS . . . . . . . . . . . . . . . . . . |

. 24 |

13 |

ROOF CURB CROSS SECTION . . . . . . . . . . . . . . . |

. 24 |

14 |

TYPICAL WIRING DIAGRAM D*NP 024 (208/230-1-60 |

|

|

POWER SUPPLY) . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 25 |

15 |

TYPICAL WIRING DIAGRAM D*NP 030-048 (208/230- |

|

|

1-60 POWER SUPPLY) . . . . . . . . . . . . . . . . . . . . . . |

. 26 |

16 |

TYPICAL WIRING DIAGRAM D*NP 060 (208/230-1-60 |

|

|

POWER SUPPLY) . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 27 |

17 |

TYPICAL WIRING DIAGRAM D*NP 030-048 (208/230- |

|

|

3-60 POWER SUPPLY) . . . . . . . . . . . . . . . . . . . . . . |

. 28 |

18 |

TYPICAL WIRING DIAGRAM D*NP 060 (208/230-3-60 |

|

|

POWER SUPPLY) . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 29 |

19 TYPICAL WIRING DIAGRAM D*NP 030-048 (460/575-3-60 POWER SUPPLY) . . . . . . . . . . . . . . . 30

20 TYPICAL WIRING DIAGRAM D*NP 060 (460/575-3-60 POWER SUPPLY) . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

21 TYPICAL WIRING DIAGRAM LEGEND . . . . . . . . . . 32

|

LIST OF TABLES |

|

Tbl# |

|

Pg# |

1 |

PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 6 |

2 |

RATINGS COOLING/GAS HEATING . . . . . . . |

. . . . . . 7 |

3 |

DNP024 COOLING CAPACITIES - 2 TON . . . |

. . . . . . 8 |

4 |

DNP030 COOLING CAPACITIES - 2-1/2 TON |

. . . . . 10 |

5 |

DNP036 COOLING CAPACITIES - 3 TON . . . |

. . . . . 11 |

6 |

DNP042 COOLING CAPACITIES - 3-1/2 TON |

. . . . . 12 |

7 |

DNP048 COOLING CAPACITIES - 4 TON . . . |

. . . . . 13 |

8 |

DNP060 COOLING CAPACITIES - 5 TON . . . |

. . . . . 14 |

9 |

TWO TON AIR PERFORMANCE . . . . . . . . . . |

. . . . . 15 |

10 |

SIDE SUPPLY AIR BLOWER PERFORMANCE - |

|

|

208/230 VOLTS . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 16 |

11 |

BOTTOM SUPPLY AIR BLOWER PERFORMANCE - |

|

|

208/230 VOLTS . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 17 |

12 |

ADDITIONAL STATIC PRESSURE RESISTANCE - |

|

|

2, 2-1/2, 3 TON . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . 18 |

13 |

ADDITIONAL STATIC PRESSURE RESISTANCE - |

|

|

3-1/2, 4 AND 5 TON . . . . . . . . . . . . . . . . . . . . . |

. . . . . 18 |

14 |

ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . |

. . . . . 19 |

15 |

UNIT DIMENSIONS FRONT . . . . . . . . . . . . . . |

. . . . . 20 |

16 |

UNIT MINIMUM CLEARANCES . . . . . . . . . . . |

. . . . . 20 |

17 |

UNIT WEIGHTS AND CENTER OF GRAVITY |

. . . . . 23 |

|

|

|

|

|

|

|

' |

|

|

|

1 |

3 |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

352'8&7 &$7(*25< |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

92/7$*( &2'( |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

' 6LQJOH 3DFNDJH $LU &RQGLWLRQHU |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

352'8&7 *(1(5$7,21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VW *HQHUDWLRQ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

QG *HQHUDWLRQ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

120,1$/ *$6 +($7,1* |

|

||||||

352'8&7 ,'(17,),(5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

287387 &$3$&,7< |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

13 6((5 *DV +HDW (OHFWULF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

%78+ |

|

||||||

|

120,1$/ &22/,1* |

|

)$&725< |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

%78+ |

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

&$3$&,7< 0%+ |

|

|

,167$//(' *$6 +($7 |

|

|

|

|

%78+ |

|

|||||||||||||||||||||||||||

|

|

|

|

%78+ |

|

|

1 1DWXUDO *DV +HDW ,QVWDOOHG |

|

|

|

%78+ |

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

%78+ |

|

||||||||||||||||||||||||||||||

|

|

|

|

%78+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

%78+ |

|

|||||||||||||||

|

|

|

|

%78+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

%78+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

%78+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

%78+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FIGURE 1 - PRODUCT NOMENCLATURE

2 |

Unitary Products Group |

036-21366-007-A-1205

STANDARD FEATURES/BENEFITS

OPERATING EFFICIENCY - All units provide high operating efficiencies and have a minimum AFUE of 80% and SEER of 13.0. All efficiencies exceed legislated minimum levels.

ON SITE FLEXIBILITY - All model sizes share a common, compact design cabinet in a single footprint. The installer has the flexibility of setting one curb and placing the proper tonnage unit on that curb after the internal load has been determined. Field convertible duct connections from side shot to down shot allows the installer to have greater flexibility with less inventory.

LOWER INSTALLATION COST - Installation time and costs are reduced by easy power and control wiring connections. The small base dimension means less space is required on the ground or roof, plus, the installer can fit this unit between the wheel wells of full size pick-up truck. All models are well under 500 pounds.

All units are completely wired, charged with R-22 and tested prior to shipment. Unique test stations using a new state of the art computerized process system are used to insure product quality. Refrigerant charge and component part numbers are verified via computers at assembly. Vital run test statistics such as system pressure, motor currents, air velocity and temperature, unit vibration, and gas system safeties are monitored and recorded by the system to insure unit performance.

Equal size, side supply and return duct connections allows easy hook-up of ducts to match low crawl spaces without transition pieces.

UTILITY CONNECTIONS MADE EASY - Gas and electric utility knockouts are provided through the bottom as well as the side of the unit. Utility connections can be made quickly and with a minimum amount of field labor. A field supplied and field installed electrical disconnect switch must be installed.

CONVERTIBLE AIRFLOW DESIGN - The bottom duct openings are covered when they leave the factory ready to be used for a side supply / side return application. If a bottom supply / bottom return application is desired, you simply remove the two panels from the bottom of the unit and place them in the side supply / side return duct openings. No panel cutting is required and no accessory panel is necessary. Convertible airflow design allows maximum field flexibility and minimum inventory.

CONDENSATE PAN - A non-corrosive, long-lasting, watertight pan is positioned below the evaporator coil to collect and drain all condensate. Less collection of stagnate condensate

will build-up. The condensate pan conforms to ASHRAE 6289 standards (Ventilation for Acceptable Indoor Air Quality).

CONDENSATE DRAIN - The heavy duty, 3/4 inch NPTI copper connection is more durable over time. The connection is rigidly mounted to assure proper fit and leak tight seal.

DURABLE FINISH - With a heavy duty cabinet made of pow- der-painted, galvanized steel the neutral color blends into surrounding areas. The powdered paint provides a better paint to steel bond, which resists corrosion and rust creep. The special primer formulas and glossy finish insures less fading when exposed to sunlight and offers a more attractive on site appearance. This paint finish meets ASTM-B117 standards for 1000 hours salt spray rating. The highest in the industry.

FULL PERIMETER BASE RAILS - The easily removable base rails provide a solid foundation for the entire unit and protects the unit during shipment. The rails provide fork lift access from all sides, and rigging holes are also provided so that an overhead crane can be used to place the units on a roof. On applications where the unit is placed on a pad, the base will keep the unit off the pad to deter corrosion. On applications where height is limited, the inch high base rails may be removed on location.

MORE ATTRACTIVE APPEARANCE - A single piece Water Shed top cover containing a top discharge condenser fan arrangement requires less square footage on installation and provides a wider variety of installations. The one piece design adds greater water integrity. Rounded corners with water drip edges add to the attractive appearance. The cabinet panels have a non-fibrous insulation that will not release insulation fibers into conditioned area.

TOP DISCHARGE - The top discharge condenser fan does not disrupt neighboring areas or dry-out vegetation surrounding the unit. The warm air from the top mounted fan is blown up away from the structure and any landscaping. This allows compact location on multi-unit applications.

CONDENSER COIL GRILLE - A multi-piece totally enclosed, rigidly mounted condenser coil grille provides protection from objects after installation and provides protection during transit.

LOW OPERATING SOUND LEVEL - The upward air flow carries the normal operating noise up and away from the living area. The rigid top panel effectively isolates any motor sound. Isolator mounted compressor and the rippled fins of the condenser coil muffle the normal fan motor and compressor operating sounds. The unique formed base pan also aids in sound alterations with it's Super-Structure design. This design strategically places embossments in the pan for optimum strength and rigidity.

Unitary Products Group |

3 |

FAN SYSTEM - All 2-1/2, 3, 3-1/2 and 4 ton models operate over a wide range of design conditions with a constant CFM, electrically commutated (ECM) fan motor. These units easily match all types of applications and provide greater on site flexibility to match comfort requirement. These models have 2 cooling speeds and a single heating speed. The cooling speed is factory set and can be field adjusted to a second speed. The heating speed is factory set to maintain mid point rise at the units heating input. It cannot be field adjusted. This allows maximum comfort conditions.

Two ton models operate over a wide range of design conditions with a 3-speed direct-drive fan motor. These single phase models have the Comfort-Match system that allows different speed taps for heating or cooling operations.

SIMPLE CONTROL CIRCUIT - A low voltage printed circuit board contains a diagnostic indicator light and a low voltage terminal strip. An additional set of pin connectors is also provided to simplify the field interface of external controls. Mate- n-lock plug connectors are used. The electrical control box is not located in the compressor compartment. The controls are mounted on a Control-Tilt control panel to allow the access cover to be removed for trouble shooting and maintenance without affecting the normal system operating pressures. All wiring internal to the unit is color/number coded.

PROTECTED COMPRESSOR - The compressor is internally protected against high pressure and temperature. This is accomplished by the simultaneous operation of high pressure relief valve and a temperature sensor which protect the compressor if undesirable operating conditions occur.

EXCLUSIVE COIL DESIGN - Grooved copper tubes and enhanced aluminum fin construction improves heat transfer for maximum efficiency and durability.

HEAT EXCHANGERS - Are corrosion-resistant, aluminizedsteel tubular construction to provide long-life, trouble-free operation. The unique blow-through design also assures that condensate does not collect in humid areas when in the cooling cycle. This adds to longer heat exchanger life and higher long term efficiencies.

POST PURGE INDUCED DRAFT COMBUSTION - Exhausts combustion products from the heat exchanger upon completion of the heating cycle to prolong the heat exchanger life.

SELF DIAGNOSTIC FAN CONTROL MODULE - Due to this self diagnostic control, less on site time is required to trouble shoot these units.

HOT SURFACE TO PILOT IGNITION - Provides faster heat delivery. This ignition is highly reliable, durable and eliminates nuisance lockouts. Also assures starts in damp conditions.

MULTI PORT IN-SHOT BURNERS - No field adjustment is required to mix the air and gas. These burners are constructed of high-grade corrosion-resistant, aluminized-steel.

036-21366-007-A-1205

LOW MAINTENANCE - Long life, permanently lubricated condenser and evaporator fan motor bearings need no annual maintenance adding greater reliability to the unit. Blower assembly can be easily cleaned by the unique SlipTrack slide-out blower assembly.

SECURED SERVICE ACCESS PORTS - Protected, externally mounted, re-usable service access ports are provided on both the high and low lines for ease of evacuating and charging the system. No final field mounting required.

EASY SERVICE ACCESS - A large, single panel covers the electrical and gas controls makes servicing easy. The blower compartment has an additional large panel with a built-in handle tab. Removing this panel will allow the blower assembly to slide-out for easy removal for maintenance and ease of trouble shooting.

REPLACEMENT PARTS - The installer requires no special training to replace any of the components of these units and does not need to maintain an inventory of unique parts.

SYSTEM INTEGRATION - Each unit has the internal ability to integrate an electronic air cleaner or humidifier to work in conjunction with the base unit.

FIELD-INSTALLED ACCESSORIES

LOW NOx KIT - Kit includes all the necessary hardware and instructions to field convert units to reduce emissions to less than 40 nanogram per Joule. California requirement on single phase models only.

PROPANE CONVERSION KIT - Kit includes burner orifices, gas valve conversion and installation instructions necessary to field convert unit from natural gas to propane.

HIGH ALTITUDE CONVERSION KIT (Natural Gas/Propane) - Kit includes all necessary labels and instructions to field alter units with natural gas/propane for installations above 2000 feet. Burner orifices must be obtained from Source 1 Parts. Propane Conversion Kit must be obtained separately.

ECONOMIZER DOWN DISCHARGE / SUPPLY KIT - Modulating integrated economizer provides simultaneous operation between the mechanical cooling and economizer operation. Independent blade design insures proper control and less than 1% leak rate. Includes hood and mesh bird screen filter integrated into the hood, dry bulb sensor and relief damper. Separate field accessories of single enthalpy and dual enthalpy are also available. A built-in barometric relief of 25% is provided.

SINGLE ENTHALPY SENSOR - Sensor replaces dry bulb sensor standard in economizer kit. Provides improved economizer operation by sensing the dry bulb temperature from outdoors plus the enthalpy content of the outdoor air.

DUAL ENTHALPY SENSOR - Additional sensor to single enthalpy sensor. Sensor senses both the return air temperature dry bulb and humidity in conjunction with the single

4 |

Unitary Products Group |

036-21366-007-A-1205

enthalpy to determine the most economical mix. Single Enthalpy sensor also required.

PRESSURE SWITCH UPGRADE KIT - Contains screw in type High pressure, Low Pressure/Loss of Charge switch, freeze protection switch and lockout relay. Switches are placed onto existing scharder ports located in the unit by furnished adapters. When abnormal conditions are sensed through the pressure switches, the unit will lock out preventing any further operation until reset or problem is corrected. Package agency approved.

HAIL GUARD KIT - Kit contains protective grilles made of expanded aluminum with full perimeter frame. Sloped hoods are also included to assure maximum protection.

ANTI SHORT CYCLE TIMER - Automatically prevents the compressor from restarting for 5 minutes after cycled off.Not required if Thermostat 2ET07700224 and 2ET04700224 are used.

FILTER / FRAME KIT (Single Phase only) - Kit contains the necessary hardware to field install return air filters into the base unit. Pre-cut filter racks and appropriate cleanable standard size filters are shipped in one kit. The filter rack is suitable for either 1" or 2" filters. (1" filter is supplied) This kit is available for single phase horizontal or vertical duct application only. Standard in all 3 Phase models.

MOTORIZED FRESH AIR DAMPER - Designed for duct mounted side supply/return and unit mounted down supply/ return applications. Damper capable of providing 0% through

50% of outdoor air (field supplied). Closes on power loss, includes hood and screen assembly.

RECTANGLE TO ROUND ADAPTERS - Kit includes one supply and one return air rectangle to round duct adapter. Adapters are preformed and designed to fit over current duct openings on the base unit. Transition is from side square duct opening to 14" round duct opening.

ROOF CURBS - NRCA approved curbs provide proper fit to base unit for rooftop installations. Curbs are designed to be assembled through hinge pins in each corner. Kit also provides seal strip to assure a water tight seal. 8 and 14 inch high roof curbs are available.

MANUAL OUTDOOR DAMPER - Provides 0% through 50% outdoor air capability (field adjustable). Designed for duct mounted side supply/return applications. Includes hood and screen assembly.

WALL THERMOSTAT - The units are designed to operate with 24-volt electronic and electro-mechanical thermostats. All units can operate with single stage heat / single stage cool thermostats - with or without the economizer.

LOW AMBIENT KIT - Kit provides necessary hardware to convert unit to operate in cooling cycle down to 0º F. Standard unit operation 45º F.

TRANSFORMER KIT - Kit provides necessary hardware to provide single phase models from factory furnished 40 VA transformer capability to 75 VA transformer capability.

(Required on installations with economizer or motorized damper.)

Unitary Products Group |

5 |

036-21366-007-A-1205

|

|

|

|

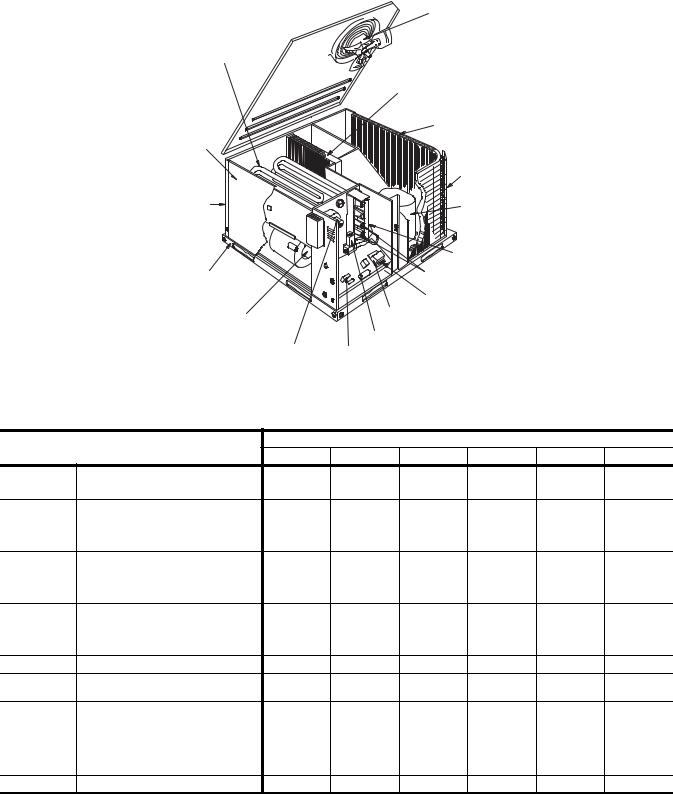

DIRECT DRIVE |

|

|

||

|

|

|

|

CONDENSER |

|

|

||

|

|

|

|

FAN MOTOR |

|

|

||

|

BLOW-THROUGH DESIGN |

|

|

|

|

|

|

|

|

WITH RELIABLE ALUMINIZED |

|

|

|

|

|

|

|

|

STEEL TUBULAR HEAT EXCHANGERS |

|

|

|

|

|

||

|

|

|

HIGHLY EFFICIENT ENHANCED |

|

|

|||

|

|

|

COPPER TUBE/ALUMINUM FIN |

|

|

|||

|

|

|

|

EVAPORATOR COIL |

|

|

|

|

|

|

|

|

HIGHLY EFFICIENT |

|

|

||

|

|

|

|

ENHANCED COPPER |

|

|

||

|

|

|

|

TUBE/ALUMINUM FIN |

|

|

||

|

LONG LASTING |

|

|

CONDENSER COIL |

|

|

||

|

POWDER PAINT |

|

|

|

|

|

|

|

|

FINISH |

|

|

|

|

|

|

|

|

|

|

|

DECORATIVE |

|

|

||

|

|

|

|

|

PROTECTIVE |

|

|

|

|

|

|

|

|

COIL GAURD |

|

|

|

|

REAR AND BOTTOM |

|

|

HIGH EFFICIENCY |

|

|

||

|

RETURN AIR |

|

|

|

|

|||

|

|

|

|

COMPRESSOR |

|

|

||

|

AND SUPPLY AIR |

|

|

|

|

|

||

|

|

|

|

RIGIDLY |

|

|

||

|

DUCT OPENINGS |

|

|

|

|

|

||

|

|

|

|

MOUNTED |

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

HOT SURFACE PILOT |

|

|

||

|

|

|

|

|

ASSEMBLY |

|

|

|

|

HEAVY GAUGE |

|

|

HIGH GRADE ALUMINIZED |

|

|

||

|

|

|

IN-SHOT BURNERS |

|

|

|||

|

REMOVABLE |

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

BASE RAILS |

|

|

LOW VOLTAGE |

|

|

||

|

|

|

|

|

|

|||

|

|

|

|

TERMINAL BLOCK |

|

|

||

|

|

|

SELF-DIAGNOSTIC CONTROLS WITH |

|

|

|||

|

DIRECT DRIVE |

|

"COMFORT-MATCH" SPEED CONTROL |

|

|

|||

|

BLOWER MOTOR WITH |

|

|

|

|

|

|

|

|

SLIDE-OUT BLOWER ASSEMBLY |

|

AUTOMATIC GAS VALVE (1/2" - 14 NPTI) |

|

|

|||

|

|

|

|

|

||||

|

POWER VENTER MOTOR |

HIGH VOLTAGE |

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

TERMINAL BLOCK |

|

|

|

|

|

FIGURE 2 - UNIT COMPONENT LOCATION |

|

|

|

|

|

|||

TABLE 1: PHYSICAL DATA |

|

|

|

|

|

|

||

|

MODEL |

|

|

DNP |

|

|

||

|

024 |

030 |

036 |

042 |

048 |

060 |

||

|

|

|||||||

EVAPORATOR |

CENTRIFUGAL BLOWER (Dia. x W. in.) |

10 x 8 |

10 x 8 |

11 x 10 |

12 x 11 |

12 x 11 |

12 x 11 |

|

BLOWER |

FAN MOTOR HP |

1/2 |

3/4 |

3/4 |

1 |

1 |

1 |

|

|

||||||||

EVAPORATOR |

ROWS DEEP |

2 |

3 |

3 |

3 |

3 |

3 |

|

FINS PER INCH |

15 |

13 |

13 |

13 |

16 |

16 |

||

COIL |

FACE AREA (Sq. Ft.) |

3.5 |

3.5 |

3.5 |

4.5 |

4.5 |

4.5 |

|

|

||||||||

CONDENSER |

PROPELLER DIA. (in.) |

22 |

22 |

22 |

22 |

22 |

22 |

|

FAN MOTOR HP |

1/4 |

1/4 |

1/4 |

1/4 |

1/3 |

1/3 |

||

FAN |

||||||||

NOM. CFM TOTAL |

2,200 |

2,400 |

2,400 |

2,400 |

3,000 |

3,500 |

||

|

||||||||

CONDENSER |

ROWS DEEP |

2 |

1 |

2 |

2 |

2 |

2 |

|

FINS PER INCH |

20 |

20 |

20 |

20 |

20 |

20 |

||

COIL |

||||||||

FACE AREA (Sq. Ft.) |

11.7 |

11.7 |

11.7 |

14.7 |

14.7 |

14.7 |

||

|

||||||||

CHARGE |

REFRIGERANT 22 (lbs./oz.) |

6 / 4 |

4 / 9 |

6 / 12 |

9 / 6 |

8 / 4 |

8 / 8 |

|

FILTER |

FACE AREA (Sq. Ft.) Size (Actual) |

2.6 / 19 x 19.5 |

2.6 / 19 x 19.5 |

2.6 / 19 x 19.5 |

3.1 / 19.5 x 11.5 3.1 / 19.5 x 11.5 3.1 / 19.5 x11.5 |

|||

|

|

|

|

|

(2 Reqd.) |

(2 Reqd.) |

(2 Reqd.) |

|

|

NATURAL GAS BURNER ORIFICE NO. |

43 |

43 |

43 |

40 |

40 |

40 |

|

|

(Drill Size) |

|||||||

|

|

|

|

|

|

|

||

FURNACE |

PROPANE BURNER ORIFICE NO. |

55 |

55 |

55 |

53 |

53 |

53 |

|

SECTION |

||||||||

(Drill Size) |

||||||||

|

|

|

|

|

|

|

||

|

GAS CONNECTION SIZE |

1/2 NPTI |

1/2 NPTI |

1/2 NPTI |

1/2 NPTI |

1/2 NPTI |

1/2 NPTI |

|

COMPRESSOR |

HERMETIC TYPE, (Qty. = 1) |

Recip |

Scroll |

Scroll |

Scroll |

Scroll |

Scroll |

|

6 |

Unitary Products Group |

036-21366-007-A-1205

TABLE 2: RATINGS COOLING/GAS HEATING

MODEL |

NET COOLING CAPACITY1 |

SOUND |

|

GAS HEAT CAPACITY / EFFICIENCIES |

|

|||||

|

|

|

RATING |

INPUT |

OUTPUT |

AFUE5 |

NUMBER OF |

TEMP. |

||

DNP |

MBH |

SEER3 |

EER4 |

RISE |

||||||

(dbels)2 |

(MBH) |

(MBH) |

(%) |

BURNERS |

||||||

|

|

|

|

|

|

|

|

|

(°F) RANGE |

|

024N03606 |

25.4 |

13.3 |

11.6 |

81 |

45 |

36 |

80.2 |

2 |

25 - 55 |

|

024N05606 |

25.4 |

13.3 |

11.6 |

81 |

70 |

56 |

80.2 |

3 |

30 - 60 |

|

030N03606 |

30.6 |

13.4 |

11.75 |

80 |

45 |

36 |

80.2 |

2 |

25 - 55 |

|

030N03625 |

30.6 |

13.4 |

11.75 |

80 |

45 |

36 |

80.2 |

2 |

25 - 55 |

|

030N03646 |

30.6 |

13.4 |

11.75 |

80 |

45 |

36 |

80.2 |

2 |

25 - 55 |

|

030N05606 |

30.6 |

13.4 |

11.75 |

80 |

70 |

56 |

80.2 |

3 |

30 - 60 |

|

030N05625 |

30.6 |

13.4 |

11.75 |

80 |

70 |

56 |

80.2 |

3 |

30 - 60 |

|

030N05646 |

30.6 |

13.4 |

11.75 |

80 |

70 |

56 |

80.2 |

3 |

30 - 60 |

|

036N03606 |

37.4 |

13.65 |

11.75 |

81 |

45 |

36 |

80.4 |

2 |

25 - 55 |

|

036N03625 |

37.4 |

13.65 |

11.75 |

81 |

45 |

36 |

80.4 |

2 |

25 - 55 |

|

036N03646 |

37.4 |

13.65 |

11.75 |

81 |

45 |

36 |

80.4 |

2 |

25 - 55 |

|

036N03658 |

37.4 |

13.65 |

11.75 |

81 |

45 |

36 |

80.4 |

2 |

25 - 55 |

|

036N05606 |

37.4 |

13.65 |

11.75 |

81 |

70 |

56 |

80.2 |

3 |

25 - 55 |

|

036N05625 |

37.4 |

13.65 |

11.75 |

81 |

70 |

56 |

80.2 |

3 |

25 - 55 |

|

036N05646 |

37.4 |

13.65 |

11.75 |

81 |

70 |

56 |

80.2 |

3 |

25 - 55 |

|

036N05658 |

37.4 |

13.65 |

11.75 |

81 |

70 |

56 |

80.2 |

3 |

25 - 55 |

|

036N07206 |

37.4 |

13.65 |

11.75 |

81 |

90 |

72 |

80.1 |

4 |

30 - 60 |

|

036N07225 |

37.4 |

13.65 |

11.75 |

81 |

90 |

72 |

80.1 |

4 |

30 - 60 |

|

036N07246 |

37.4 |

13.65 |

11.75 |

81 |

90 |

72 |

80.1 |

4 |

30 - 60 |

|

036N07258 |

37.4 |

13.65 |

11.75 |

81 |

90 |

72 |

80.1 |

4 |

30 - 60 |

|

042N06506 |

44 |

13.7 |

10.65 |

80 |

80 |

64 |

80.6 |

3 |

25 - 55 |

|

042N06525 |

44 |

13.7 |

10.65 |

80 |

80 |

64 |

80.6 |

3 |

25 - 55 |

|

042N06546 |

44 |

13.7 |

10.65 |

80 |

80 |

64 |

80.6 |

3 |

25 - 55 |

|

042N06558 |

44 |

13.7 |

10.65 |

80 |

80 |

64 |

80.6 |

3 |

25 - 55 |

|

042N09006 |

44 |

13.7 |

10.65 |

80 |

108 |

86 |

80.8 |

4 |

45 - 75 |

|

042N09025 |

44 |

13.7 |

10.65 |

80 |

108 |

86 |

80.8 |

4 |

45 - 75 |

|

042N09046 |

44 |

13.7 |

10.65 |

80 |

108 |

86 |

80.8 |

4 |

45 - 75 |

|

042N09058 |

44 |

13.7 |

10.65 |

80 |

108 |

86 |

80.8 |

4 |

45 - 75 |

|

048N06506 |

48 |

13.2 |

11.7 |

84 |

80 |

64 |

80.8 |

3 |

25 - 55 |

|

048N06525 |

48 |

13.2 |

11.7 |

84 |

80 |

64 |

80.8 |

3 |

25 - 55 |

|

048N06546 |

48 |

13.2 |

11.7 |

84 |

80 |

64 |

80.8 |

3 |

25 - 55 |

|

048N06558 |

48 |

13.2 |

11.7 |

84 |

80 |

64 |

80.8 |

3 |

25 - 55 |

|

048N09006 |

48 |

13.2 |

11.7 |

84 |

108 |

86 |

80.6 |

4 |

35 - 65 |

|

048N09025 |

48 |

13.2 |

11.7 |

84 |

108 |

86 |

80.6 |

4 |

35 - 65 |

|

048N09046 |

48 |

13.2 |

11.7 |

84 |

108 |

86 |

80.6 |

4 |

35 - 65 |

|

048N09058 |

48 |

13.2 |

11.7 |

84 |

108 |

86 |

80.6 |

4 |

35 - 65 |

|

048N11006 |

48 |

13.2 |

11.7 |

84 |

135 |

107 |

80.5 |

5 |

45 - 75 |

|

048N11025 |

48 |

13.2 |

11.7 |

84 |

135 |

107 |

80.5 |

5 |

45 - 75 |

|

048N11046 |

48 |

13.2 |

11.7 |

84 |

135 |

107 |

80.5 |

5 |

45 - 75 |

|

048N11058 |

48 |

13.2 |

11.7 |

84 |

135 |

107 |

80.5 |

5 |

45 - 75 |

|

060N06506 |

55.5 |

13.0 |

11.2 |

84 |

80 |

64 |

80.8 |

3 |

25 - 55 |

|

060N06525 |

55.5 |

13.0 |

11.2 |

84 |

80 |

64 |

80.8 |

3 |

25 - 55 |

|

060N06546 |

55.5 |

13.0 |

11.2 |

84 |

80 |

64 |

80.8 |

3 |

25 - 55 |

|

060N06558 |

55.5 |

13.0 |

11.2 |

84 |

80 |

64 |

80.8 |

3 |

25 - 55 |

|

060N09006 |

55.5 |

13.0 |

11.2 |

84 |

108 |

86 |

80.6 |

4 |

35 - 65 |

|

060N09025 |

55.5 |

13.0 |

11.2 |

84 |

108 |

86 |

80.6 |

4 |

35 - 65 |

|

060N09046 |

55.5 |

13.0 |

11.2 |

84 |

108 |

86 |

80.6 |

4 |

35 - 65 |

|

060N09058 |

55.5 |

13.0 |

11.2 |

84 |

108 |

86 |

80.6 |

4 |

35 - 65 |

|

060N11006 |

55.5 |

13.0 |

11.2 |

84 |

135 |

107 |

80.5 |

5 |

45 - 75 |

|

060N11025 |

55.5 |

13.0 |

11.2 |

84 |

135 |

107 |

80.5 |

5 |

45 - 75 |

|

060N11046 |

55.5 |

13.0 |

11.2 |

84 |

135 |

107 |

80.5 |

5 |

45 - 75 |

|

060N11058 |

55.5 |

13.0 |

11.2 |

84 |

135 |

107 |

80.5 |

5 |

45 - 75 |

|

1.Net Cooling Capacity = ARI 210 standard rating conditions.

2.(dbels) = ARI 270-95

3.Seasonal Energy Efficiency Ratio - the total cooling output in BTU’s during a normal annual usage period for cooling divided by the total electric power input in watt-hours during the same period.

4.Tested in accordance with ARI 210 Standard Rating Conditions.

5.AFUE = Annual Fuel Utilization Efficiency.

Unitary Products Group |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

036-21366-007-A-1205 |

||||

TABLE 3: DNP024 COOLING CAPACITIES - 2 TON |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

TEMPERATURE OF AIR ON CONDENSER COIL |

|

|

TEMPERATURE OF AIR ON CONDENSER COIL |

|

|

||||||||||||||

AIR ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

85°F |

|

|

|

|

|

|

|

95°F |

|

|

|

|

|

||||||

EVAPORATOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

COIL |

|

NET |

POWER |

|

|

SENSIBLE CAPACITY1 |

|

NET |

POWER |

|

|

SENSIBLE CAPACITY1 |

|

|

|||||||||

|

|

|

|

ENTERING DRY BULB, °F |

|

|

ENTERING DRY BULB, °F |

|

|

||||||||||||||

|

|

|

CAP. |

INPUT |

|

|

CAP. |

INPUT |

|

|

|

||||||||||||

CFM |

|

WB |

MBH |

KW |

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

MBH |

KW |

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

|

|

°F |

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

72 |

24.7 |

1.90 |

15.0 |

13.3 |

|

11.6 |

9.9 |

8.1 |

#N/A |

#N/A |

23.1 |

2.03 |

15.0 |

13.3 |

|

11.6 |

9.9 |

8.1 |

#N/A |

#N/A |

|

600 |

|

67 |

22.6 |

1.91 |

18.4 |

16.7 |

|

14.9 |

13.2 |

11.5 |

9.8 |

8.1 |

21.0 |

2.03 |

18.1 |

16.4 |

|

14.7 |

13.0 |

11.3 |

9.5 |

7.8 |

|

|

62 |

20.9 |

1.89 |

20.9 |

19.5 |

|

17.8 |

16.1 |

14.4 |

12.7 |

11.0 |

19.5 |

2.00 |

19.5 |

19.4 |

|

17.7 |

16.0 |

14.3 |

12.5 |

10.8 |

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

20.6 |

1.88 |

20.6 |

20.2 |

|

18.5 |

16.8 |

15.1 |

13.4 |

11.7 |

19.5 |

1.99 |

19.5 |

19.5 |

|

17.9 |

16.2 |

14.5 |

12.7 |

11.0 |

|

|

|

72 |

26.4 |

1.94 |

17.0 |

14.9 |

|

12.9 |

10.9 |

8.9 |

#N/A |

#N/A |

24.6 |

2.08 |

16.7 |

14.7 |

|

12.7 |

10.7 |

8.6 |

#N/A |

#N/A |

|

700 |

|

67 |

24.1 |

1.94 |

20.7 |

18.7 |

|

16.7 |

14.7 |

12.7 |

10.6 |

8.6 |

22.3 |

2.08 |

20.1 |

18.1 |

|

16.1 |

14.1 |

12.1 |

10.0 |

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

62 |

22.3 |

1.93 |

22.3 |

21.6 |

|

19.9 |

17.9 |

15.9 |

13.9 |

11.8 |

20.7 |

2.05 |

20.7 |

20.7 |

|

19.4 |

17.4 |

15.3 |

13.3 |

11.3 |

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

22.0 |

1.92 |

22.0 |

21.8 |

|

20.7 |

18.7 |

16.7 |

14.6 |

12.6 |

20.7 |

2.04 |

20.7 |

20.7 |

|

19.6 |

17.6 |

15.6 |

13.5 |

11.5 |

|

|

|

72 |

28.0 |

1.97 |

19.0 |

16.6 |

|

14.3 |

12.0 |

9.6 |

#N/A |

#N/A |

26.0 |

2.13 |

18.5 |

16.1 |

|

13.8 |

11.5 |

9.1 |

#N/A |

#N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

|

67 |

25.6 |

1.98 |

23.1 |

20.8 |

|

18.5 |

16.1 |

13.8 |

11.5 |

9.1 |

23.7 |

2.13 |

22.2 |

19.8 |

|

17.5 |

15.2 |

12.8 |

10.5 |

8.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

62 |

23.7 |

1.96 |

23.7 |

23.7 |

|

22.0 |

19.7 |

17.4 |

15.0 |

12.7 |

22.0 |

2.09 |

22.0 |

22.0 |

|

21.1 |

18.8 |

16.4 |

14.1 |

11.8 |

|

|

|

57 |

23.3 |

1.95 |

23.3 |

23.3 |

|

22.9 |

20.5 |

18.2 |

15.9 |

13.5 |

22.0 |

2.09 |

22.0 |

22.0 |

|

21.3 |

19.0 |

16.7 |

14.3 |

12.0 |

|

|

|

72 |

28.2 |

2.01 |

20.4 |

17.7 |

|

15.1 |

12.4 |

9.8 |

#N/A |

#N/A |

26.2 |

2.15 |

19.9 |

17.2 |

|

14.6 |

11.9 |

9.3 |

#N/A |

#N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

|

67 |

25.8 |

2.01 |

24.5 |

22.1 |

|

19.5 |

16.8 |

14.2 |

11.5 |

8.8 |

23.9 |

2.15 |

23.1 |

21.2 |

|

18.5 |

15.8 |

13.2 |

10.5 |

7.9 |

|

|

|

62 |

23.8 |

1.99 |

23.8 |

23.8 |

|

23.0 |

20.3 |

17.7 |

15.0 |

12.4 |

22.1 |

2.12 |

22.1 |

22.1 |

|

21.7 |

19.1 |

16.4 |

13.7 |

11.1 |

|

|

|

57 |

23.5 |

1.98 |

23.5 |

23.5 |

|

23.2 |

20.6 |

17.9 |

15.3 |

12.6 |

22.2 |

2.11 |

22.2 |

22.2 |

|

21.8 |

19.2 |

16.5 |

13.9 |

11.2 |

|

|

|

72 |

28.3 |

2.04 |

21.8 |

18.8 |

|

15.9 |

12.9 |

9.9 |

#N/A |

#N/A |

26.5 |

2.18 |

21.3 |

18.3 |

|

15.4 |

12.4 |

9.4 |

#N/A |

#N/A |

|

1000 |

|

67 |

25.9 |

2.04 |

25.9 |

23.5 |

|

20.5 |

17.5 |

14.5 |

11.5 |

8.6 |

24.1 |

2.18 |

24.1 |

22.5 |

|

19.5 |

16.5 |

13.5 |

10.5 |

7.6 |

|

|

62 |

24.0 |

2.02 |

24.0 |

24.0 |

|

24.0 |

21.0 |

18.0 |

15.0 |

12.0 |

22.3 |

2.14 |

22.3 |

22.3 |

|

22.3 |

19.3 |

16.4 |

13.4 |

10.4 |

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

23.6 |

2.01 |

23.6 |

23.6 |

|

23.6 |

20.6 |

17.6 |

14.7 |

11.7 |

22.3 |

2.14 |

22.3 |

22.3 |

|

22.3 |

19.4 |

16.4 |

13.4 |

10.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

TEMPERATURE OF AIR ON CONDENSER COIL |

|

|

TEMPERATURE OF AIR ON CONDENSER COIL |

|

|

||||||||||||||

AIR ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

105°F |

|

|

|

|

|

|

|

115°F |

|

|

|

|

|

|||||||

EVAPORATOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

COIL |

|

NET |

POWER |

|

|

SENSIBLE CAPACITY1 |

|

NET |

POWER |

|

|

SENSIBLE CAPACITY1 |

|

|

|||||||||

|

|

|

|

ENTERING DRY BULB, °F |

|

|

ENTERING DRY BULB, °F |

|

|

||||||||||||||

|

|

|

CAP. |

INPUT |

|

|

CAP. |

INPUT |

|

|

|

||||||||||||

CFM |

|

WB |

MBH |

KW |

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

MBH |

KW |

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

|

|

°F |

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

72 |

21.5 |

2.20 |

14.4 |

12.7 |

|

10.9 |

9.2 |

7.5 |

#N/A |

#N/A |

20.0 |

2.36 |

13.7 |

12.0 |

|

10.3 |

8.6 |

6.9 |

#N/A |

#N/A |

|

600 |

|

67 |

19.5 |

2.17 |

17.6 |

15.9 |

|

14.2 |

12.5 |

10.8 |

9.1 |

7.4 |

18.1 |

2.30 |

17.2 |

15.4 |

|

13.7 |

12.0 |

10.3 |

8.6 |

6.9 |

|

|

|

62 |

18.4 |

2.15 |

18.4 |

18.3 |

|

16.7 |

15.0 |

13.3 |

11.6 |

9.9 |

17.3 |

2.30 |

17.3 |

17.3 |

|

15.7 |

14.0 |

12.3 |

10.6 |

8.9 |

|

|

|

57 |

18.5 |

2.15 |

18.5 |

18.5 |

|

16.9 |

15.2 |

13.5 |

11.8 |

10.0 |

17.5 |

2.31 |

17.5 |

17.5 |

|

15.9 |

14.2 |

12.5 |

10.8 |

9.1 |

|

|

|

72 |

22.8 |

2.24 |

16.0 |

14.0 |

|

12.0 |

9.9 |

7.9 |

#N/A |

#N/A |

21.0 |

2.40 |

15.3 |

13.3 |

|

11.2 |

9.2 |

7.2 |

#N/A |

#N/A |

|

700 |

|

67 |

20.7 |

2.21 |

19.4 |

17.6 |

|

15.5 |

13.5 |

11.5 |

9.5 |

7.4 |

19.0 |

2.34 |

18.6 |

17.0 |

|

15.0 |

12.9 |

10.9 |

8.9 |

6.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

62 |

19.5 |

2.19 |

19.5 |

19.4 |

|

18.3 |

16.2 |

14.2 |

12.2 |

10.2 |

18.2 |

2.34 |

18.2 |

18.2 |

|

17.2 |

15.1 |

13.1 |

11.1 |

9.1 |

|

|

|

57 |

19.6 |

2.19 |

19.6 |

19.6 |

|

18.5 |

16.4 |

14.4 |

12.4 |

10.4 |

18.4 |

2.35 |

18.4 |

18.4 |

|

17.3 |

15.3 |

13.3 |

11.3 |

9.2 |

|

|

|

72 |

24.1 |

2.28 |

17.6 |

15.3 |

|

13.0 |

10.6 |

8.3 |

#N/A |

#N/A |

22.1 |

2.43 |

16.8 |

14.5 |

|

12.2 |

9.8 |

7.5 |

#N/A |

#N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

|

67 |

21.8 |

2.25 |

21.1 |

19.2 |

|

16.9 |

14.5 |

12.2 |

9.9 |

7.5 |

20.0 |

2.38 |

20.0 |

18.5 |

|

16.2 |

13.9 |

11.5 |

9.2 |

6.9 |

|

|

62 |

20.5 |

2.24 |

20.5 |

20.5 |

|

19.8 |

17.5 |

15.2 |

12.8 |

10.5 |

19.1 |

2.38 |

19.1 |

19.1 |

|

18.6 |

16.2 |

13.9 |

11.6 |

9.2 |

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

20.7 |

2.24 |

20.7 |

20.7 |

|

20.0 |

17.7 |

15.4 |

13.0 |

10.7 |

19.3 |

2.38 |

19.3 |

19.3 |

|

18.7 |

16.4 |

14.1 |

11.7 |

9.4 |

|

|

|

72 |

24.3 |

2.32 |

19.0 |

16.3 |

|

13.7 |

11.0 |

8.3 |

#N/A |

#N/A |

22.3 |

2.48 |

18.1 |

15.4 |

|

12.7 |

10.1 |

7.4 |

#N/A |

#N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

|

67 |

22.0 |

2.29 |

21.6 |

20.3 |

|

17.7 |

15.1 |

12.4 |

9.8 |

7.1 |

20.2 |

2.43 |

20.2 |

19.5 |

|

17.0 |

14.3 |

11.6 |

9.0 |

6.3 |

|

|

|

62 |

20.7 |

2.27 |

20.7 |

20.7 |

|

20.4 |

17.7 |

15.1 |

12.4 |

9.7 |

19.3 |

2.43 |

19.3 |

19.3 |

|

19.0 |

16.4 |

13.7 |

11.1 |

8.4 |

|

|

|

57 |

20.8 |

2.27 |

20.8 |

20.8 |

|

20.5 |

17.9 |

15.2 |

12.6 |

9.9 |

19.5 |

2.43 |

19.5 |

19.5 |

|

19.2 |

16.6 |

13.9 |

11.3 |

8.6 |

|

|

|

72 |

24.5 |

2.36 |

20.3 |

17.3 |

|

14.3 |

11.4 |

8.4 |

#N/A |

#N/A |

22.5 |

2.53 |

19.3 |

16.3 |

|

13.3 |

10.3 |

7.4 |

#N/A |

#N/A |

|

1000 |

|

67 |

22.2 |

2.33 |

22.2 |

21.4 |

|

18.6 |

15.6 |

12.6 |

9.7 |

6.7 |

20.4 |

2.47 |

20.4 |

20.4 |

|

17.7 |

14.8 |

11.8 |

8.8 |

5.8 |

|

|

62 |

20.9 |

2.31 |

20.9 |

20.9 |

|

20.9 |

17.9 |

15.0 |

12.0 |

9.0 |

19.5 |

2.47 |

19.5 |

19.5 |

|

19.5 |

16.5 |

13.5 |

10.6 |

7.6 |

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

21.0 |

2.31 |

21.0 |

21.0 |

|

21.0 |

18.0 |

15.1 |

12.1 |

9.1 |

19.7 |

2.48 |

19.7 |

19.7 |

|

19.7 |

16.7 |

13.7 |

10.8 |

7.8 |

|

1. These capacities are net capacities (the indoor fan heat is deducted).

ALL SENSIBLE CAPACITY

8 |

Unitary Products Group |

036-21366-007-A-1205

TABLE 3: DNP024 COOLING CAPACITIES - 2 TON (CONT’D)

|

AIR ON |

|

|

TEMPERATURE OF AIR ON CONDENSER COIL |

|

|

||||||

|

|

|

|

|

125°F |

|

|

|

|

|||

EVAPORATOR |

|

|

|

|

|

|

|

|

|

|

||

|

COIL |

NET |

POWER |

|

|

|

SENSIBLE CAPACITY1 |

|

|

|||

|

|

|

|

|

|

ENTERING DRY BULB, °F |

|

|

||||

|

|

|

CAP. |

INPUT |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

CFM |

|

WB |

MBH |

KW |

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

|

°F |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

72 |

18.4 |

2.5 |

13.1 |

11.4 |

|

9.7 |

8.0 |

6.3 |

#N/A |

#N/A |

600 |

|

67 |

16.6 |

2.4 |

16.7 |

15.0 |

|

13.3 |

11.5 |

9.8 |

8.1 |

6.4 |

|

62 |

16.2 |

2.5 |

16.2 |

16.2 |

|

14.8 |

13.1 |

11.4 |

9.6 |

7.9 |

|

|

|

|

||||||||||

|

|

57 |

16.5 |

2.5 |

16.5 |

16.5 |

|

14.9 |

13.2 |

11.5 |

9.8 |

8.1 |

|

|

72 |

19.3 |

2.6 |

14.6 |

12.5 |

|

10.5 |

8.5 |

6.5 |

#N/A |

#N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

700 |

|

67 |

17.4 |

2.5 |

17.8 |

16.4 |

|

14.4 |

12.4 |

10.3 |

8.3 |

6.3 |

|

62 |

17.0 |

2.5 |

17.0 |

17.0 |

|

16.0 |

14.0 |

12.0 |

10.0 |

7.9 |

|

|

|

|

||||||||||

|

|

57 |

17.2 |

2.5 |

17.2 |

17.2 |

|

16.2 |

14.2 |

12.1 |

10.1 |

8.1 |

|

|

72 |

20.1 |

2.6 |

16.0 |

13.7 |

|

11.3 |

9.0 |

6.7 |

#N/A |

#N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

800 |

|

67 |

18.1 |

2.5 |

18.9 |

17.9 |

|

15.5 |

13.2 |

10.9 |

8.5 |

6.2 |

|

62 |

17.7 |

2.5 |

17.7 |

17.7 |

|

17.3 |

15.0 |

12.6 |

10.3 |

8.0 |

|

|

|

|

||||||||||

|

|

57 |

18.0 |

2.5 |

18.0 |

18.0 |

|

17.5 |

15.1 |

12.8 |

10.5 |

8.1 |

|

|

72 |

20.4 |

2.6 |

17.1 |

14.5 |

|

11.8 |

9.2 |

6.5 |

#N/A |

#N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

900 |

|

67 |

18.3 |

2.6 |

18.7 |

18.6 |

|

16.2 |

13.5 |

10.9 |

8.2 |

5.6 |

|

62 |

17.9 |

2.6 |

17.9 |

17.9 |

|

17.7 |

15.0 |

12.4 |

9.7 |

7.1 |

|

|

|

|

||||||||||

|

|

57 |

18.2 |

2.6 |

18.2 |

18.2 |

|

17.9 |

15.3 |

12.6 |

9.9 |

7.3 |

|

|

72 |

20.6 |

2.7 |

18.3 |

15.3 |

|

12.3 |

9.3 |

6.3 |

#N/A |

#N/A |

|

|

|

|

|

|

|

|

|

|

|

|

|

1000 |

|

67 |

18.5 |

2.6 |

18.5 |

19.3 |

|

16.9 |

13.9 |

10.9 |

7.9 |

4.9 |

|

62 |

18.1 |

2.6 |

18.1 |

18.1 |

|

18.1 |

15.1 |

12.1 |

9.2 |

6.2 |

|

|

|

|

||||||||||

|

|

57 |

18.4 |

2.7 |

18.4 |

18.4 |

|

18.4 |

15.4 |

12.4 |

9.4 |

6.5 |

1.These capacities are net capacities (the indoor fan heat is deducted).

ALL SENSIBLE CAPACITY

ALL SENSIBLE CAPACITY

Unitary Products Group |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

036-21366-007-A-1205 |

||

TABLE 4: DNP030 COOLING CAPACITIES - 2-1/2 TON |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEMPERATURE |

|

|

|

|

|

AIR ON EVAPORATOR COIL |

|

|

|

|

||||||

|

|

1,000 CFM |

|

|

|

1,250 CFM |

|

|||||||||

|

OF AIR ON |

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

WB °F |

|

|

|

|

WB °F |

|

|||||

CONDENSER COIL |

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

72 |

67 |

|

62 |

57 |

72 |

|

67 |

|

62 |

57 |

|

|

NET CAP.MBH |

|

33.6 |

31.6 |

|

30.3 |

30.2 |

34.5 |

|

32.4 |

|

31.1 |

31.0 |

||

|

TOTAL POWER INPUT kW |

2.4 |

2.4 |

|

2.3 |

2.3 |

2.6 |

|

2.6 |

|

2.5 |

2.5 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

86 |

23.6 |

29.2 |

|

30.3 |

30.2 |

27.2 |

|

32.4 |

|

31.1 |

31.0 |

|

SensibleCapacity |

MBH |

|

EnteringDry Bulb°F |

71 |

N/A |

14.6 |

|

19.7 |

20.8 |

N/A |

|

14.8 |

|

19.9 |

19.8 |

|

|

|

|

|

83 |

20.7 |

26.3 |

|

30.3 |

30.2 |

23.5 |

|

29.7 |

|

31.1 |

31.0 |

85 °F |

|

1 |

|

|

80 |

17.8 |

23.4 |

|

28.4 |

29.6 |

19.7 |

|

25.9 |

|

31.1 |

31.0 |

|

|

|

|

|

77 |

14.9 |

20.5 |

|

25.5 |

26.7 |

16.0 |

|

22.2 |

|

27.3 |

27.3 |

|

|

|

|

|

74 |

12.0 |

17.5 |

|

22.6 |

23.8 |

12.3 |

|

18.5 |

|

23.6 |

23.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

68 |

N/A |

11.7 |

|

16.8 |

17.9 |

N/A |

|

11.0 |

|

16.2 |

16.1 |

|

|

NET |

CAP. MBH |

|

32.7 |

30.5 |

|

28.8 |

28.9 |

33.5 |

|

31.3 |

|

29.6 |

29.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

TOTAL POWER INPUT kW |

2.6 |

2.6 |

|

2.6 |

2.5 |

2.8 |

|

2.8 |

|

2.8 |

2.7 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

86 |

23.1 |

29.0 |

|

28.8 |

28.9 |

26.9 |

|

31.3 |

|

29.6 |

29.7 |

|

SensibleCapacity |

MBH |

|

EnteringDry Bulb°F |

71 |

N/A |

14.4 |

|

19.2 |

19.6 |

N/A |

|

14.8 |

|

18.4 |

18.5 |

|

|

|

|

|

83 |

20.2 |

26.1 |

|

28.8 |

28.9 |

23.1 |

|

29.7 |

|

29.6 |

29.7 |

95 °F |

|

1 |

|

|

80 |

17.3 |

23.2 |

|

27.9 |

28.4 |

19.4 |

|

26.0 |

|

29.6 |

29.7 |

|

|

|

|

|

77 |

14.4 |

20.3 |

|

25.0 |

25.4 |

15.7 |

|

22.3 |

|

25.9 |

26.0 |

|

|

|

|

|

74 |

11.5 |

17.3 |

|

22.1 |

22.5 |

12.0 |

|

18.5 |

|

22.1 |

22.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

68 |

N/A |

11.5 |

|

16.3 |

16.7 |

N/A |

|

11.1 |

|

14.7 |

14.8 |

|

|

NET |

CAP.MBH |

|

31.0 |

28.3 |

|

27.3 |

27.3 |

32.2 |

|

29.4 |

|

28.3 |

28.3 |

|

|

TOTAL POWERINPUT kW |

2.9 |

2.9 |

|

2.9 |

2.9 |

3.1 |

|

3.1 |

|

3.0 |

3.0 |

||||

|

|

|

|

|

86 |

22.6 |

27.6 |

|

27.3 |

27.3 |

26.4 |

|

29.4 |

|

28.3 |

28.3 |

|

SensibleCapacity |

MBH |

|

EnteringDry Bulb°F |

71 |

N/A |

13.5 |

|

17.7 |

18.0 |

N/A |

|

13.9 |

|

17.1 |

17.2 |

|

|

|

|

|

83 |

19.6 |

25.1 |

|

27.3 |

27.3 |

22.6 |

|

28.6 |

|

28.3 |

28.3 |

105 °F |

|

1 |

|

|

80 |

16.7 |

22.2 |

|

26.4 |

26.8 |

18.9 |

|

25.1 |

|

28.3 |

28.3 |

|

|

|

|

|

77 |

13.8 |

19.3 |

|

23.5 |

23.8 |

15.2 |

|

21.4 |

|

24.6 |

24.6 |

|

|

|

|

|

74 |

10.9 |

16.4 |

|

20.6 |

20.9 |

11.5 |

|

17.6 |

|

20.8 |

20.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

68 |

N/A |

10.5 |

|

14.8 |

15.1 |

N/A |

|

10.2 |

|

13.4 |

13.4 |

|

|

NET |

CAP.MBH |

|

29.3 |

26.2 |

|

25.7 |

25.7 |

30.8 |

|

27.5 |

|

27.0 |

27.0 |

|

|

TOTAL POWER NPUT kW |

3.2 |

3.3 |

|

3.2 |

3.2 |

3.4 |

|

3.4 |

|

3.3 |

3.3 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

86 |

22.0 |

26.2 |

|

25.7 |

25.7 |

25.8 |

|

27.5 |

|

27.0 |

27.0 |

|

SensibleCapacity |

MBH |

|

EnteringDry Bulb°F |

71 |

N/A |

12.5 |

|

16.2 |

16.4 |

N/A |

|

13.0 |

|

15.8 |

15.8 |

|

|

|

|

|

83 |

19.0 |

24.1 |

|

25.7 |

25.7 |

22.1 |

|

27.5 |

|

27.0 |

27.0 |

115 °F |

|

1 |

|

|

80 |

16.1 |

21.2 |

|

24.9 |

25.2 |

18.4 |

|

24.2 |

|

27.0 |

27.0 |

|

|

|

|

|

77 |

13.2 |

18.3 |

|

22.0 |

22.2 |

14.7 |

|

20.5 |

|

23.3 |

23.2 |

|

|

|

|

|

74 |

10.3 |

15.4 |

|

19.1 |

19.3 |

10.9 |

|

16.8 |

|

19.5 |

19.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

68 |

N/A |

9.6 |

|

13.3 |

13.5 |

N/A |

|

9.3 |

|

12.1 |

12.1 |

|

|

NET |

CAP. MBH |

|

27.6 |

24.1 |

|

24.2 |

24.0 |

29.4 |

|

25.6 |

|

25.7 |

25.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

TOTAL POWER INPUT kW |

3.5 |

3.6 |

|

3.5 |

3.5 |

3.6 |

|

3.7 |

|

3.6 |

3.6 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

86 |

21.4 |

24.8 |

|

24.2 |

24.0 |

25.3 |

|

25.6 |

|

25.7 |

25.6 |

|

SensibleCapacity |

MBH |

|

EnteringDry Bulb°F |

71 |

N/A |

11.5 |

|

14.7 |

14.8 |

N/A |

|

12.1 |

|

14.5 |

14.4 |

|

|

|

|

|

83 |

18.4 |

23.2 |

|

24.2 |

24.0 |

21.6 |

|

26.4 |

|

25.7 |

25.6 |

125 °F |

|

1 |

|

|

80 |

15.5 |

20.2 |

|

23.4 |

23.6 |

17.9 |

|

23.3 |

|

25.7 |

25.6 |

|

|

|

|

|

77 |

12.6 |

17.3 |

|

20.5 |

20.7 |

14.2 |

|

19.6 |

|

22.0 |

21.9 |

|

|

|

|

|

74 |

9.7 |

14.4 |

|

17.6 |

17.7 |

10.4 |

|

15.9 |

|

18.3 |

18.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

68 |

N/A |

8.6 |

|

11.8 |

11.9 |

N/A |

|

8.4 |

|

10.8 |

10.7 |