York B3CH 048, B3CH060 User Manual

GENERAL

YORK Model BCH units are single package heat pumps

designed for outdoor installation on a rooftop or a slab.

Supplemental electric heaters are available as field-installed

accessories. The units are manufactured under ISO 9002

Quality System Certification.

Units are completely assembled on rigid, permanently

attachedbaserails.Allpiping,refrigerant charge, andelectrical

wiring is factory-installed and tested. The units require only

electricpowerandductconnectionsatthe point of installation.

The supplemental electric heaters have nickel-chrome

elements and utilize single point power connection.

INSPECTION

Assoonasaunit is received, itshouldbeinspectedforpossible

damage during transit. If damage is evident, the extent of the

damageshould be noted on thecarrier's freight bill. Aseparate

request for inspection by the carrier's agent should be made in

writing. See local distributor for additional information.

REFERENCE

Additional information on the design, installation, operation

and service of this equipment is available in the following

reference forms:

•

55.70-N1 -General Installation

•

55.70-N2 -Pre-start & Post-start Check List

•

530.18-N1.2V -Economizer Accessory

•

530.18-N1.4V -Fixed Outdoor Air Damper Accessory

•

530.18-N1.6V -Motorized Outdoor Air Damper Accy.

•

530.18-N7.1V -Electric Heater Accessory

• 530.18-N7.2V -Fuse Block Accessory

Renewal Parts:

•

Refer to Parts Manual for complete listing of replacement

parts on this equipment.

All forms referenced in this instruction may be ordered from:

Standard Register

Toll Free Tel: (405) 691-1126

Toll Free Fax: (405) 799-7746

APPROVALS

These units are designed and manufactured as follows:

1. For use as a heat pump only unit or a heat pump unit with

supplemental electric heat.

2. For outdoor installation only.

®

SUNLINE 2000

SINGLE PACKAGE HEAT PUMPS

INSTALLATION INSTRUCTION

Supersedes: 511.13-N1YI (900)/035-12984-000

035-12984-001-A-0204

Installershouldpay particular attentionto thewords: NOTE, CAUTIONand WARNING.Notes

areintended to clarifyor makethe

installation easier. Cautions

are given to prevent equipment damage. Warnings are given to alert installer that personal injury

and/or equipment damage may result if installation procedure is not handled properly.

MODELS B3CH 048 AND 060

(WORLD 50 HZ)

CAUTION

THE ENCLOSED INSTALLATION INSTRUCTIONS AND ANY APPLICABLE

LOCAL, STATE, AND NATIONAL CODES INCLUDING, BUT NOT LIMITED

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

TH IS P RO DU CT MU ST BE INS TAL LED IN STR IC T C O M P LIANCE W ITH

WARNING

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAMAGE.

INCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

035-12984-001-A-0204

2 Unitary Products Group

General

................................................................................

1

Inspection

............................................................................

1

Reference

............................................................................

1

Approvals

............................................................................

1

Nomenclature

......................................................................

2

INSTALLATION

Limitations

...........................................................................

3

Location

...............................................................................

3

Condensate Drainage Precaution

.......................................

3

Rigging and Handling

..........................................................

3

Clearances

..........................................................................

3

Ductwork

.............................................................................

3

Filters

...................................................................................

4

Condensate Drain

...............................................................

4

Service Access

....................................................................

4

Blower Speed Selection

......................................................

4

Disconnect Switch Bracket For Optional Belt-Drive

............

4

Compressors

.......................................................................

4

Thermostat

..........................................................................

4

Power and Control Wiring

...................................................

4

Electric Heaters...................................................................4

Optional Economizer Rain Hood.........................................6

OPERATION

Cooling System .................................................................12

Preliminary Operation Cooling ..........................................12

Cooling Sequence of Operation ........................................12

Heating Sequence of Operation........................................12

Defrost Sequence of Operation.........................................12

Lockout Control

.................................................................

13

Checking Supply Airflow

....................................................

13

Secure Owner's Approval

..................................................

14

MAINTENANCE

Normal Maintenance

.........................................................

14

TABLES

No. Description Page

1 Unit Application Data

..................................

3

2 Air Flow Limitations

....................................

5

3 Physical Data

.............................................

7

4 Supply Air Perferformance — BCH048

......

10

5 Supply Air Performance — BCH060

..........

10

6 Motor and Drive Data - Belt-Drive Blower

..

10

7 Static Resistances

......................................

10

8 Electrical Data — Basic Unit

......................

11

9 Electrical Data — Heat Pump

....................

11

10 Belt-Drive Supply Air Motor Pulley Adj.

.......

13

FIGURES

No. Description Page

1 Center of Gravity........................................ 3

2 Recommended Drain Piping...................... 4

3 Typical Field Wiring.................................... 5

4 Economizer Rain Hood Assembly.............. 6

5 Adjusting Enthalpy Setpoint....................... 7

6 Dimensions and Clearances...................... 8 & 9

7 Defrost Initiation Times .............................. 12

8 Ambient Modified Time/Temp. Control....... 12

9 Belt Adjusment

...........................................

13

10 Hole Loc. for Press. Drop Readings

...........

13

11 Press. Drop versus Supply Airflow

.............

13

TABLE OF CONTENTS

B 3 C H A

PRODUCT NOMENCLATURE

PRODUCT GENERATION

3 = Third Generation

PRODUCT CATEGORY

B = Single Package Heat Pump

(Air Cooled)

PRODUCT IDENTIFIER

CH = Heat Pump

VOLTAGE CODE

50 = 380/415-3+N-50

048 = 4 Ton

060 = 5 Ton

40 8 5 0

FACTORYINSTALLED HEAT

A = No Supplemental Heat

NOMINAL COOLING CAPACITY

LIMITATIONS

These units must be installed in accordance with national and

local or municiple safety codes: Refer to Table 1 for Unit

Application Data.

If components are to be added to a unit to meet local codes, they

aretobeinstalledatthedealer'sand / or the customer'sexpense.

LOCATION

Use the following guidelines to select a suitable location for

these units.

1. Unit is designed for outdoor installation only.

2. Outdoor coil must have an unlimited supply of air.

3. For ground level installation, use a level concrete slab with

a minimum thickness of 102mm (4 in.). The length and

widthshould be at least 152mm (6 in.) greater than the unit

base rails. Do not tie slab to the building foundation.

4. Roof structures must be able to support the weight of the unit

and its options and / or accessories. Unit must be installed on

a solid level roof curb or appropriate angle iron frame.

CAUTION: If a unit is to be installed on a roof curb or special frame

other than a YORK roof curb, gasketing must be applied

toallsurfacesthatcomeincontactwith the unit underside.

5. Maintain level tolerance to 13mm (

1

2

in.) maximum across

the entire length or width of the unit.

6. Elevate the unit sufficiently to prevent any blockage of the

airentrances by snowin areas wherethere will besnow ac

-

cumulation. Check the local weather bureau for the ex

-

pected snow accumulation in your area.

OUTDOORCOIL CONDENSATEDRAINAGE PRECAUTION

Condensatedrainsfromtheoutdoorcoil during theheatingand

defrost cycles. Normally this condensate may be allowed to

drain directly onto the ground/roof. A gravel bed is

recommended to prevent mud splashing.

WARNING:Theunit should notbe installed in an area wheremud

or ice could cause personal injury. Remember that

condensate drips from the outdoor coil during heat

and defrost cycles and that this condensate freezes

when the temperature of the outdoor air is below 0°C

(32

°

F).

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaginguntil the unitis near the place of installation. Rig the

unit by attaching chain or cable slings to the lifting holes

provided in the base rails. Spreaders, whose length exceeds

the largest dimension across the unit, MUST be used across

the top of the unit.

BEFORE LIFTING AUNIT,MAKE SURE THATITS WEIGHT

IS DISTRIBUTED EQUALLY ON THE CABLES SO THAT IT

WILL LIFT EVENLY.

Units may also be moved or lifted with a forklift. Slotted

openings in the base rails are provided for this purpose.

LENGTH OF FORKS MUST BE A MINIMUM OF 1067mm

(42 in.).

Remove the nesting brackets from the four corners on top of

the unit. All screws that are removed when taking these

brackets off must be replaced on the unit.

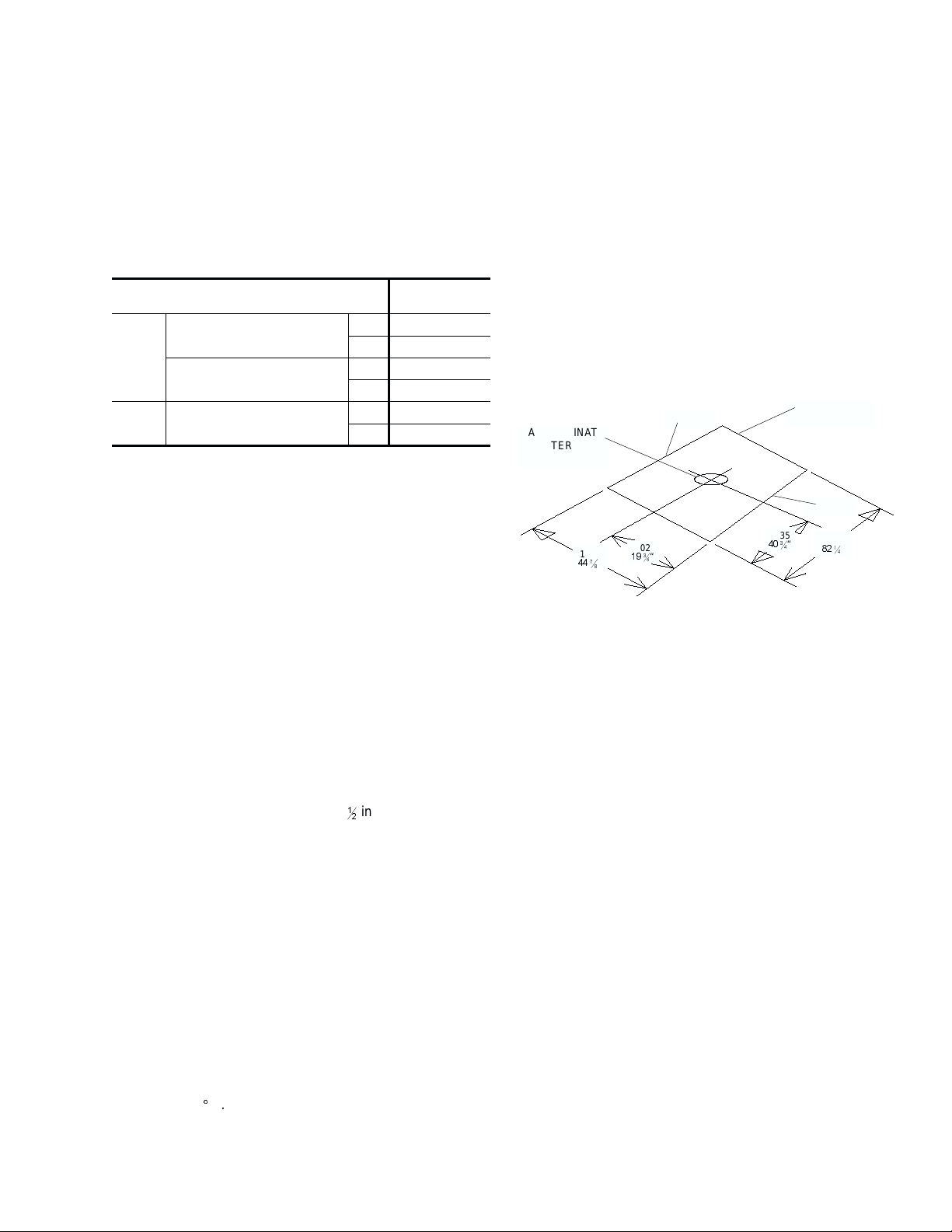

RefertoTable3forunitweightsandtoFigure 1 for approximate

center of gravity.

CLEARANCES

All units require certain clearances for proper operation and

service. Refer to Figure 6 for the clearances required for

combustibleconstruction,servicing,andproperunitoperation.

WARNING:Do not permit overhanging structures or shrubs to

obstruct outdoor air discharge outlet.

DUCTWORK

A closed return duct system shall be used. This does not

preclude use of economizers or outdoor fresh air intake. The

supply and return air duct connections at the unit should be

madewithflexiblejointstominimizethetransmission of noise.

Thesupply and return air duct systems should be designed for

theairflowandstatic requirements of thejob.Theyshould NOT

be sized to match the dimensions of the duct connections on

the unit.

CAUTION: When fastening ductwork to the side duct flanges

on the unit, insert the screws through the duct

flanges only. DO NOT insert the screws through

the casing.

Outdoor ductwork must be insulated and water

-

proofed.

Refer to Figure 6 for information concerning side and bottom

supply and return air duct openings.

FILTERS

Each unit is supplied with 25mm (1 in.) filters . Replacement

51mm (2 in.) filters may be used without modification to the

filter racks. Filters must always be installed ahead of the

evaporator coil and must be kept clean or replaced with same

035-12984-001-A-0204

Unitary Products Group 3

INSTALLATION

FIG. 1 - CENTER OF GRAVITY

2089

82

1

4

“

1035

40

3

4

“

1140

44

7

8

“

502

19

3

4

“

APPROXINATE

CENTER OF

GRAVITY

FRONT

BACK

CONDENSER

COIL END

Voltage Variation

Min. / Max.

342 / 457

Cooling

Wet Bulb Temperature of Air

on Indoor Coil, Min./Max.

°C 14 / 22

°F 57 / 72

Dry Bulb Temperature of Air

on Outdoor Coil, Min./Max.

°C 7 / 49

°F 45 / 120

Heating

Minimum Dry Bulb Temperature

of Air on Outdoor Coil

°C -23

°F -10

TABLE 1 - UNIT APPLICATION DATA

size and type. Dirty filters reduce the capacity of the unit and

result in frosted coils or safety shutdown. Minimum filter area

and required sizes are shown in Table 3.

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing

compound on male pipe threads. Install a condensate drain

linefromthe19mm(

3

4

in.)PVCfemaleconnectionon the unit to

spill into an open drain.

NOTE: The condensate drain line MUST be trapped to pro

-

vide proper drainage. See Figure 2.

SERVICE ACCESS

Access to all serviceable components is provided by the

following removable panels:

•

Compressor compartment

•

Heater compartment

•

Blower compartment

•

Main control box

•

Filter compartment

•

Motor Access (on units w/belt-drive option)

Refer to Figure 6 for location of these access panels.

BLOWER SPEED SELECTION

Threeblowermotor speeds areavailable on theBCH048 units.

The speed selection is determined by the airflow and ESP

requirements of the applications. BCH060 units have an

adjustable motor pulley to achieve the above conditions.

BCH048 units are shipped with the black wire (labeled #8)

connectedto the high speed tapon the blower motor.If a lower

blower speed is desired, this wire should be moved to the

medium or low speed tap on the motor.

DISCONNECT SWITCH BRACKET FOR UNITS

WITH OPTIONAL BELT-DRIVE BRACKET

A special bracket for mounting a field-supplied disconnect

switch is provided in each BCH060. The bracket is shipped

inside the blower compartment taped to the top of the blower

housing. Install the bracket on the left hand side of the unit as

shownin Figure6. Severalexisting screws at the top of the unit

and one approximately midway down from the top will be used

for mounting the bracket. Screws should be loosened only -

NOT REMOVED. Mounting holes in the bracket have

elongated keyways allowing easy installation. Re-tighten

screws after bracket is in place to ensure panels will remain

leak tight.

COMPRESSORS

On some units the compressor is mounted on springs which

have been tightened down for shipment only.

After this unit is installed, back out the compressor bolts until

the sleeve clears the top grommet.

CAUTION: Do Not

loosen compressor mounting bolts.

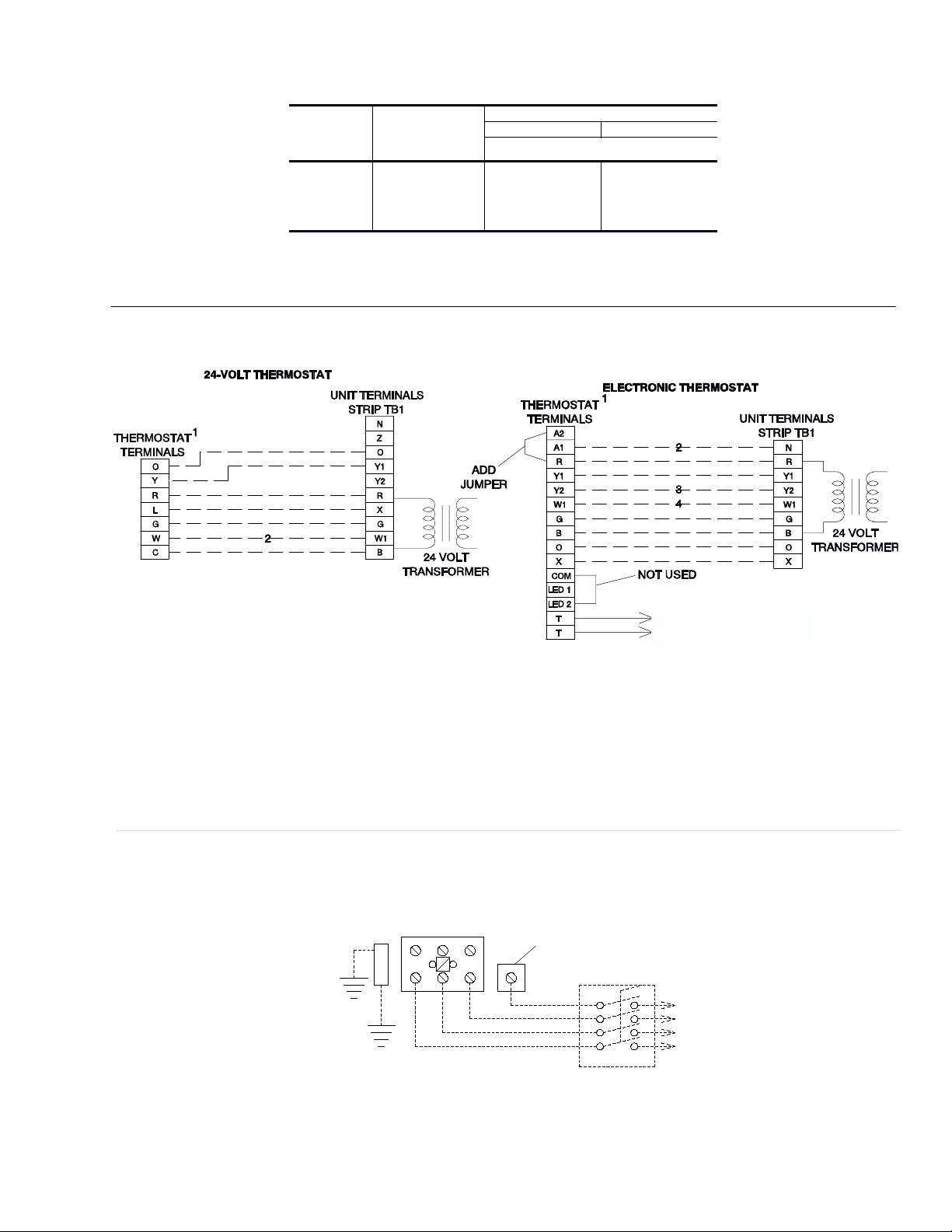

THERMOSTAT

The room thermostat should be located on an inside wall

approximately 1422mm (56 in.) above the floor where it is not

subjected to drafts, sun exposure, or heat from electrical

fixtures or appliances. Follow manufacturer's instructions

enclosed with thermostat for general installation procedure.

Color coded insulated wires (#18 AWG) should be used to

connect thermostat to unit. See Figure 3 for wiring details.

NOTE: On units with economizer, remove jumper “J1" from

terminals 8 and 10 on plug connector J3/P7 on the re

-

layboardin the unitcontrolbox. Refer totheunitwiring

labels located on the inside of the control box access

panel.

An “Emergency Heat” position is provided with the

thermostat.In the “Emergency Heat” position, the thermostat

allowselectricresistanceheatonly.The compressorislocked

out. Apilot light on the thermostat indicates that the switch is

on “EM HT”.

POWER AND CONTROL WIRING

Voltagetolerances which must be maintained at the compressor

terminals during starting and running conditions are indicated on

the unit Rating Plate and Table 1.

The wiring harness furnished with this unit is an integral partof

the unit. Field alteration to comply with electrical codes should

not be required.

A disconnect switch should be field provided for the unit. The

switch must be separate from all other circuits. Refer to Figure

6forinstallationlocation.If any of thewiresuppliedwith the unit

mustbe replaced, replacement wire must be of the typeshown

on the wiring diagram.

Electrical lines must be sized properly to carry the load. USE

COPPERCONDUCTORSONLY.Eachunit must bewired with

a separate branch circuit fed directly from the meter panel and

properly protected.

CAUTION: When connecting electrical power and control wir

-

ing to the unit, waterproof type connectors MUST

BE USED so that water or moisture cannot be

drawn into the unit during normal operation. The

above waterproofing conditions also apply when

installing a field-supplied disconnect switch.

Refer to Figure 3 for typical field wiring and to the appropriate

unit wiring diagram for control circuit and power wiring

information. Refer to Tables 8 and 9 for electrical data.

ELECTRIC HEATERS

Supplemental electric heaters may be ordered as a field-

installed accessory. Refer to Form 530.18-N7.1V for

installation instruction. These approved heaters are located

within the central compartment of the unit (see Figure 6 for

access panel) with the heating elements extending into the

supply air chamber.

Fuses are supplied, where required, by the factory. Some kW

sizes require fuses and others do not. Refer to the electric

035-12984-001-A-0204

4 Unitary Products Group

FIG. 2 - RECOMMENDED DRAIN PIPING

76

3"

51

2"

035-12984-001-A-0204

Unitary Products Group 5

FIG. 3 - TYPICAL FIELD WIRING

CONTROL WIRING

POWER WIRING

NOMINAL

HEATER

SIZE

KW

VOLTAGE

UNIT MODEL SIZE, NOMINAL TONS

45

MINIMUM SUPPLYAIR CFM

7

10

15

20

30

380/415-3+N-50

1,300

1,300

1,300

1,300

–

1,600

1,600

1,600

1,600

1,600

TABLE 2 - AIR FLOW LIMITATIONS

TO REMOTE SENSOR

2ET04701324 IF USED

1 Typical 24-volt thermostat with subbase

-2ET03700424 for manual changeover.

2

Only required on units with supplemental electric heat.

1 Typical Electronic programmable thermostat 2ET04701124 with subbase for

either manual or automatic changeover.

2

Only required on units with economizer. Remove jumper L2 from terminals

4 and 9 on jumper plug P7. The outdoor air intake dampers will return to their

fully closed position when the thermostat switches to the “unoccupied” mode.

3

Second stage cooling may be used on units with economizer. Remove jumper

J1 from terminals 8 and 10 on jumper plug connector P7.

4

Only required on units with supplemental electric heat.

REFER TO ELECTRICAL DATA

TABLES TO SIZE THE DISCONNECT

SWITCH, THE WIRING AND THE

OVERCURRENT PROTECTION.

GROUND

LUG

NEUTRAL

TERMINAL

BLOCK

CONTACTOR

FIELD-SUPPLIED

DISCONNECT

Note: The thermostat terminals shown

above are typical. Check thermostat

and unit wiring diagrams for correct

wiring connections.

Loading...

Loading...