York DM072 User Manual

®

TECHNICAL GUIDE

SINGLE PACKAGE GAS/ELECTRIC UNITS AND SINGLE PACKAGE

AIR CONDITIONERS

DM072

6 NOMINAL TONS

9.0 EER

392856-YTG-B-0708

DESCRIPTION

YORK Sunline 2000™ units are convertible single package air conditioners. The units were designed for light commercial and commercial applications. They can easily be installed on a roof curb, slab, roof jack or frame.

All units include:

•Powder Paint finish that meets ASTM-B-117 1000 hour salt spray standards

•Permanently lubricated motors

•Direct Drive or Belt Drive Blower with high static drive option

•Bottom or side air discharge configuration capability (field convertible)

•Manufactured under the quality standards of ISO9001

•Simplicity® Control Board

•Copper tube/aluminum fin coils

•Easy access to all components

•Rigging holes in base rails for lifting

•Fork lift slots on three sides

•Single point power connection

•Complete factory package - tested, charged and wired

•CSA agency listing on all units

WARRANTY

•Factory Limited Parts Warranty

•One-year parts warranty

•A Five-year parts warranty on the compressor and electric heat elements.

•Ten-year parts warranty on the gas-fired heat exchangers.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

392856-YTG-B-0708

TABLE OF CONTENTS

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 PRODUCT NOMENCLATURE . . . . . . . . . . . . . . . . . 3 FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 FACTORY-INSTALLED OPTIONS . . . . . . . . . . . . . . 6 FIELD-INSTALLED ACCESSORIES . . . . . . . . . . . . 7 GUIDE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . 24

LIST OF FIGURES

Fig. # |

Pg. # |

1 UNIT CUTAWAY GAS/ELECTRIC . . . . . . . . . . . . . . . . . 5 2 UNIT CUTAWAY ELECTRIC/ELECTRIC . . . . . . . . . . . 5

3TYPICAL FIELD POWER & CONTROL WIRING . . . . 17

4UNIT DIMENSIONS (6 TON COOLING ONLY/

ELECTRIC HEAT) FRONT VIEW . . . . . . . . . . . . . . . . 18

5 UNIT DIMENSIONS (6 TON COOLING/GAS HEAT) FRONT VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6 UNIT WITH ECONOMIZER RAINHOOD . . . . . . . . . . . 19

7 UNIT WITH FIXED OUTDOOR AIR/MOTORIZED DAMPER RAINHOOD . . . . . . . . . . . . . . . . . . . . . . . . . 19

8 UNIT DIMENSIONS (REAR VIEW) . . . . . . . . . . . . . . . 20 9 DISCONNECT/BLOWER ACCESS LOCATION . . . . . 20 10 TYPICAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . 21 11 FOUR AND SIX POINT LOADING . . . . . . . . . . . . . . . . 22 12 ROOF CURB DIMENSIONS . . . . . . . . . . . . . . . . . . . . 23

LIST OF TABLES

Tbl. # |

Pg. # |

1 SOUND POWER RATING . . . . . . . . . . . . . . . . . . . . . . . 8 2 CAPACITY RATINGS - (ARI 210/240) . . . . . . . . . . . . . . 8 3 GAS HEAT RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . 8 4 2 STAGE GAS HEAT RATINGS . . . . . . . . . . . . . . . . . . 8 5 DM072 COOLING CAPACITIES (6 TON) . . . . . . . . . . . 9

Tbl. # |

Pg. # |

6 SUPPLY AIR BLOWER PERFORMANCE (DM072 BELT DRIVE) - SIDE DUCT APPLICATION . . . . . . . . . . . . . 10

7 SUPPLY AIR BLOWER PERFORMANCE (DM072 BELT DRIVE) - BOTTOM DUCT APPLICATION . . . . . . . . . 10

8 SUPPLY AIR BLOWER PERFORMANCE (DM072 DIRECT DRIVE) SIDE DUCT APPLICATION . . . . . . . 10

9SUPPLY AIR BLOWER PERFORMANCE (DM072 DIRECT DRIVE) BOTTOM DUCT APPLICATION . . . 10

10 BELT DRIVE RPM SELECTION . . . . . . . . . . . . . . . . . 10 11 BELT DRIVE BLOWER MOTOR AND DRIVE DATA . 11 12 STATIC RESISTANCES . . . . . . . . . . . . . . . . . . . . . . . 11 13 ELECTRIC HEATER CFM LIMITATIONS . . . . . . . . . . 12

14 ELECTRICAL DATA - DM072 DIRECT DRIVE W/O POWERED CONV. OUTLET . . . . . . . . . . . . . . . . . . . . 13

15 ELECTRICAL DATA - DM072 BELT DRIVE W/O POWERED CONV. OUTLET . . . . . . . . . . . . . . . . . . . . 13

16 ELECTRICAL DATA - DM072 BELT DRIVE HIGH STATIC W/O POWERED CONV. OUTLET . . . . . . . . . 14

17 ELECTRICAL DATA - DM072 DIRECT DRIVE W/ POWERED CONV. OUTLET . . . . . . . . . . . . . . . . . . . . 14

18 ELECTRICAL DATA - DM072 BELT DRIVE W/ POWERED CONV. OUTLET . . . . . . . . . . . . . . . . . . . . 15

19 ELECTRICAL DATA - DM072 BELT DRIVE HIGH STATIC W/POWERED CONV. OUTLET . . . . . . . . . . . 15

20 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 21 ELECTRIC HEAT CORRECTION FACTORS . . . . . . . 16 22 VOLTAGE LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . 16 23 UTILITIES ENTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 24 MINIMUM CLEARANCES . . . . . . . . . . . . . . . . . . . . . . 20

25 DM 4 AND 6 POINT LOADS WEIGHT |

|

DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

26 CENTER OF GRAVITY . . . . . . . . . . . . . . . . . . . . . . . . 22 27 OPERATING WEIGHTS (LBS.) . . . . . . . . . . . . . . . . . . 23

2 |

Johnson Controls Unitary Products |

392856-YTG-B-0708

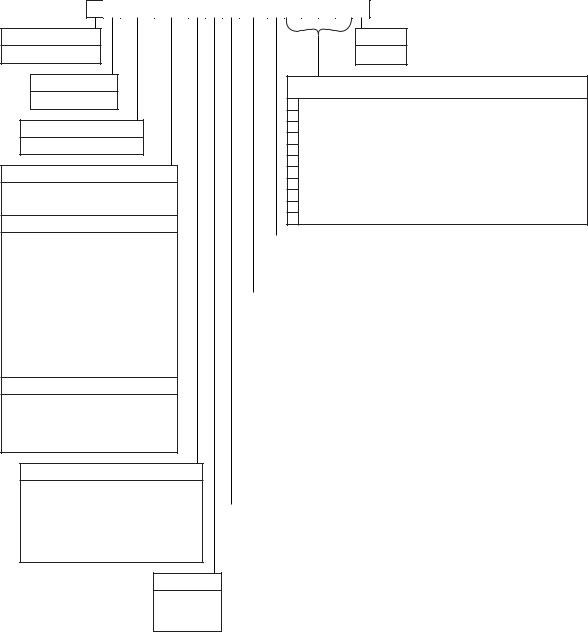

PRODUCT NOMENCLATURE

6 Ton Sunline Model Number Nomenclature

D M 072 N04 A 2 A AA 1 0 1 2 4 A

Product Category

D = A/C, Single Pkg., R-22

Product Identifier

M = 9.0 EER A/C

Nominal Cooling Capacity

072 = 6.0 Ton

Heat Type and Nominal Heat Capacity

C00 = Cooling Only. Suitable for Field

Installed Electric Heat

Gas Heat Options

N08 = 80 MBH Output Aluminized Steel, 1 Stage

(072)

N10 = 100 MBH Output Aluminized Steel, 1 Stage

(072)

D06 = 60 MBH Output Aluminized Steel, 2 Stage

(072)

D10 = 100 MBH Output Aluminized Steel, 2 Stage

(072)

S08 = 80 MBH Output Stainless Steel, 1 Stage

(072)

S10 = 100 MBH Output Stainless Steel, 1 Stage

(072)

T06 = 60 MBH Output Stainless Steel, 2 Stage

(072)

T10 = 100 MBH Output Stainless Steel, 2 Stage

(072)

Electric Heat Options

E05 = 5 KW

E07 = 7 KW

E10 = 10 KW

E15 = 15 KW

E20 = 20 KW

E30 = 30 KW

Airflow

A = Direct Drive

B = Direct Drive/Single Input Economizer

D = Direct Drive/Motorized Damper

N = Belt Drive

P = Belt Drive/Single Input Economizer

R = Belt Drive/Motorized Damper

T = Belt Drive High Static

U = Belt Drive High Static/Single Input Economizer

V = Belt Drive High Static/Motorized Damper

Voltage

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

7 = 380/415-3-50

Product Style

A = Style A

Configuration Options (not required for all units)

These four digits will not be assigned until a quote is requested, or an order placed.

SS Drain Pan

CPC Controller, DFS, APS

Johnson Controller UNT 1126 (N2 protocol), DFS, APS

Honeywell Controller, DFS, APS

Novar Controller, DFS, APS

Simplicity IntelliComfort Controller

Simplicity IntelliComfort Controller w/ModLinc

York Commercial Comfort System (YCCS) Rtu Controller

2" Pleated filters

BAS Ready Economizer (2-10 V. D. C. Actuator without a Controller)

Any Combination of Additional Options that Don’t Have an Option Code Pre-assigned

|

|

Product Generation |

|

|

|

|

|

|

|

|

|

|

|

1 = First Generation |

|

|

|

|

|

2 = Second Generation |

|

|

|

|

|

3 = Third Generation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Additional Options |

|

|

|

|

|

||

|

|

Standard Cabinet |

Hinged Filter Door & Toolless Access Cabinet |

||

|

|

|

|||

|

AA = None |

BA = Hinged Filter Door & Toolless Access Panels |

|||

|

AB = Phase Monitor |

BA = Hinged Filter Door & Toolless Access Panels |

|||

|

AC = Coil Guard |

BB = Phase Monitor, Hinged Filter Door & Toolless |

|||

|

AD = Dirty Filter Switch |

Access Panels |

|||

|

AE = Phase Monitor & Coil Guard |

BC = Coil Guard, Hinged Filter Door & Toolless |

|||

|

AF = Phase Monitor & Dirty Filter Switch |

Access Panels |

|||

|

AG = Coil Guard & Dirty Filter Switch |

BD = Dirty Filter Switch, Hinged Filter Door & |

|||

|

AH = Phase Monitor, Coil Guard & Dirty Filter Switch |

Toolless Access Panels |

|||

|

AS = Bottom Drain Connection |

BE = Phase Monitor & Coil Guard, Hinged Filter |

|||

|

RC = Coil Guard & American Flag |

Door & Toolless Access Panels |

|||

|

TA = Technicoat Condenser Coil |

BF = Phase Monitor & Dirty Filter Switch, Hinged |

|||

|

TJ = Technicoat Evaporator Coil |

Filter Door & Toolless Access Panels |

|||

|

TS = Technicoat Evaporator and Condenser Coil |

BG = Coil Guard & Dirty Filter Switch, Hinged Filter |

|||

|

|

|

|

|

Door & Toolless Access Panels |

|

|

|

|

|

BH = Phase Monitor, Coil Guard & Dirty Filter Switch, |

|

|

|

|

|

Hinged Filter Door & Toolless Access Panels |

|

|

|

|||

|

ZZ = If desired option combination is not listed above, ZZ will be assigned and configuration options will be |

||||

|

|

located in digits 15-18. |

|

||

|

|

|

|||

|

|

|

|

|

|

Installation Options |

|

|

|

||

|

|

|

|

||

A = No Options Installed |

|

|

|

||

B = Option 1 |

|

|

|||

C = Option 2 |

|

|

|||

D = Options 1 & 2 |

|

|

|||

E = Option 3 |

|

|

|||

F = Option 4 |

|

|

|||

G = Options 1 & 3 |

|

|

|||

H = Options 1 & 4 |

|

|

|||

J = Options 1, 2 & 3 |

|

|

|||

K = Options 1, 2, & 4 |

|

|

|||

L = Options 1,3 & 4 |

|

|

|||

M = Options 1, 2, 3, & 4 |

|

|

|||

N = Options 2 & 3 |

|

|

|||

P = Options 2 & 4 |

|

|

|||

Q = Options 2, 3, & 4 |

|

|

|||

R = Options 3 & 4 |

|

|

|||

S = Option 5 |

|

|

|||

T = Options 1 & 5 |

|

|

|||

U = Options 1, 3, & 5 |

|

|

|||

V = Options 1, 4, & 5 |

|

|

|||

W = Options 1, 3, 4, & 5 |

|

|

|||

X = Options 3 & 5 |

|

|

|||

Y = Options 4 & 5 |

|

|

|||

Z = Options 3, 4 & 5 |

|

|

|||

|

|

|

|

||

|

Options |

|

|

|

|

|

|

|

|

||

1 = Disconnect |

|

|

|

||

2 = Non-Pwr'd Conv. Outlet |

|

|

|||

3 = Smoke Detector S.A. |

|

|

|||

4 = Smoke Detector R.A. |

|

|

|||

5 = Pwr'd Conv. Outlet |

|

|

|||

|

|

|

|

|

|

Johnson Controls Unitary Products |

3 |

392856-YTG-B-0708

FEATURES

All models are available with a wide variety of factorymounted options such as stainless steel heat exchangers, electric heaters, phase monitor, convenience outlet, dirty filter switch, disconnect switch, smoke detectors, and coil guard to make them suitable for almost every application.

All units are self-contained and assembled on full perimeter base rails with forklift holes on three sides and holes for overhead rigging. Every unit is completely piped, wired, charged and tested at the factory to simplify the field installation and to provide years of dependable operation.

All models (including those with an economizer) are suitable for either bottom or horizontal duct connections. For bottom duct, remove the sheet metal panels from the supply and return air openings through the base of the unit. For horizontal duct, remove the supply and return air panels on the rear of the unit.

All models are available with these “factory mounted” outdoor air damper options:

•Single enthalpy economizer

•Motorized outdoor air damper

Supply air blowers are equipped with either a direct drive or a belt drive that can be adjusted to meet the exact requirements of the job.

All compressors are equipped with internal pressure relief. Every refrigerant circuit includes a liquid line filter-drier, a high pressure switch and a suction line with a freezestat and low pressure/loss of charge switch to protect all system components.

•Simplicity® Controls - Simplicity® control boards have standardized a number of features previously available only as options or by utilizing additional controls.

•Low Ambient - An integrated low-ambient control allows all units to operate in the cooling mode down to 0ºF outdoor ambient without additional assistance. Optionally, the control board can be programmed to lockout the compressors when the outdoor air temperature is low or when free cooling is available.

•Anti-Short Cycle Protection - To aid compressor life, an anti-short cycle delay is incorporated into the standard controls. Compressor reliability is further ensured by programmable minimum run times. For testing, the anti short cycle delay can be temporarily overridden with the push of a button.

•Fan Delays - Fan on and fan off delays are fully programmable and are independent of one another. All units are programmed with default values based upon their configuration of cooling and heat.

•Safety Monitoring - The control board monitors the high and low-pressure switches, the freezestats, the gas valve, if applicable, and the temperature limit switch on gas heat units. The unit control board will

alarm on ignition failures, compressor lockouts and repeated limit switch trips.

•Nuisance Trip Protection- To prevent nuisance trouble calls, the control board uses a “three strikes, you’re out” philosophy. The high and low-pressure switches and the freezestats must trip three times within two hours before the unit control board will lock out the compressor.

•On Board Diagnostics - Each alarm will energize a trouble light on the thermostat, if so equipped, and flash an alarm code on the control board LED. Each high and low-pressure switch alarm as well as each freezestat alarm has its own flash code. The control board saves the five most recent alarms in memory, and these alarms can be reviewed at any time. Alarms and programmed values are retained through the loss of power.

All units have long lasting powder paint cabinets with 1000 hour salt spray test approval under ASTM-B117 procedures.

All models are CSA listed.

•Warranty - All models include a one-year limited parts warranty on the complete unit. Compressors and electric heater elements carry a five-year warranty. Gas heat exchangers carry a 10-year parts warranty.

•Gas Heat Operation - All single phase models with gas heat have minimum annual fuel utilization efficiency (AFUE) of 80%. All three phase models with gas heat have minimum steady state efficiency of 80%. Each section includes a durable heat exchanger with aluminized steel or optional stainless steel tubes, a redundant gas valve, spark ignition, power venting, an ignition module for 100% shut-off and all of the safety controls required to meet the latest ANSI standards.

The gas supply piping can be routed into the heating compartment through a hole in the base pan of the unit or through a knockout in the piping panel on the front of the unit.

•Electric Heat Operation - All electric heat models are wired for a single power source and include a bank of nickel chromium elements mounted at the discharge of the supply air blower to provide a high velocity and uniform distribution of air across the heating elements. Every element is fully protected against excessive temperature by thermal limit switches.

The power supply wiring can be routed into the control box through a threaded pipe connection (field supplied) in the base pan of the unit or through a knockout in the wiring panel on the side of the unit.

•BAS Controls - York’s Sunline™ series units offer factory mounted BAS controls such as Simplicity® INTELLI-Com- fort™, Novar, Honeywell, Johnson, York Commercial Comfort System (YCCS) and CPC.

4 |

Johnson Controls Unitary Products |

392856-YTG-B-0708

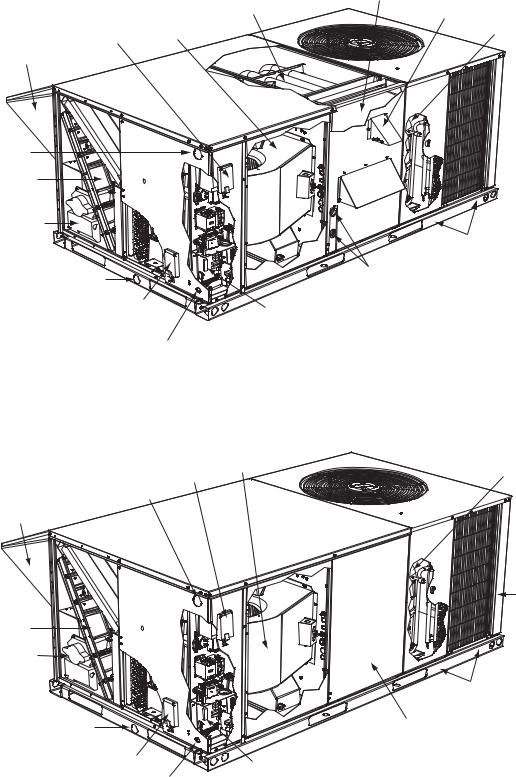

|

|

|

Electric heat |

|

|

20 Gauge aluminized |

accessory location |

|

|

Power ventor motor with |

|

|

|

steel tubular heat exchanger |

|

|

Belt drive or |

post purge cycle |

|

|

|

||

HACR |

Direct drive |

|

High efficiency |

blower |

|

compressor |

|

breaker |

|

||

|

|

|

Economizer

hood

Copper tube/  aluminum fin condensing coil

aluminum fin condensing coil

Knockout for side power entry

Slide-in economizer

Smoke detector

Full perimeter baserails with forklift slots and lifting holes

3/4" PVC female |

Knockout for side |

condensate drain |

gas supply entry |

GFCI |

Simplicity® Lite™ |

convenience outlet |

control board |

Knockout |

|

for side |

|

control entry |

|

FIGURE 1 - UNIT CUTAWAY GAS/ELECTRIC

|

|

Belt drive or |

|

HACR |

Direct drive |

|

blower |

|

Knockout |

breaker |

High efficiency |

for side |

|

|

|

compressor |

|

power entry |

|

|

|

|

Economizer

hood

Copper tube/ aluminum fin condensing coil

Slide-in economizer

Smoke detector

Full perimeter baserails with forklift slots and lifting holes

3/4" PVC female |

Electric Heat |

|

condensate drain |

||

accessory location |

||

|

GFCI convenience outlet

Simplicity® Lite™

control board

Knockout for side control entry

FIGURE 2 - UNIT CUTAWAY ELECTRIC/ELECTRIC

Johnson Controls Unitary Products |

5 |

392856-YTG-B-0708

FACTORY-INSTALLED OPTIONS

•SINGLE INPUT ELECTRONIC ENTHALPY ECONOMIZERS - Includes a slide-in / plug-in damper assembly with fully modulating spring-return motor actuator capable of introducing up to 100% outdoor air with nominal 1% leakage type dampers.

The enthalpy system contains one sensor that monitors the outdoor air and determines when the air is cool enough and dry enough to provide free cooling.

The rainhood is painted to match the basic unit and must be field-assembled before installing.

•MOTORIZED OUTDOOR AIR INTAKE DAMPER - Includes a slide-in / plug-in damper assembly with a 2-posi- tion, spring return motor actuator which opens to a pre-set position whenever the supply air blower is operating and will drive fully closed when the blower unit shuts down.

The rain hood is painted to match the basic unit and must be field assembled before installing.

•PHENOLIC COATED EVAPORATOR AND CONDENSER COILS - Special coating process that utilizes Technicoat 10-1™ processes. Coating is applied by total immersion of the complete coil for maximum protection.

•ELECTRIC HEATERS - Wired for single point power supply. These nickel chromium heater elements are provided with limit and automatic reset capability to prevent operation at excessive temperatures.

•FILTER OPTIONS - Standard units are shipped with 1” throw-away filters installed. 2” pleated filters are offered as a factory installed option.

•CONVENIENCE OUTLET - This 110 volt outlet can be “powered” by the unit with a stepdown transformer or the unit may be ordered with a “non-powered” convenience outlet that can be wired in the field.

•DISCONNECT SWITCH - For gas heat units and cooling units with electric heat, a HACR breaker sized to the unit is provided. For cooling only units, a switch sized to the largest electric heat available for the particular unit is provided. Factory installed option only.

•BAS - Building Automation System Controls Simplicity® INTELLI-Comfort™ CONTROL - The York®

Simplicity® INTELLI-Comfort™ control is factory installed. It includes a supply air sensor, a return air sensor, and an outside air sensor. There are provisions for a field installed dirty filter indicator switch, an air-proving switch, an Outside Air Humidity sensor, a Return Air Humidity sensor, an Inside IAQ sensor, and an Outside Air IAQ sensor. Construction mode operation, 365-day real time clock with 7

day programming plus holiday scheduling is built-in. Two different modes of demand ventilation are achieved through the INTELLI-Comfort™using CO2 sensors. It uses an inside CO2 sensor to perform Demand Ventilation. It can also use an Outside CO2 sensor to perform Differential Demand Ventilation. It uses a Patented Comfort Ventilation algorithm to provide comfortable ventilation air temperature. The patented economizer-loading algorithm will protect the equipment when harsh operating conditions exist. Humidity in the occupied space or return duct can be monitored and controlled via humidity sensors and the on-board connection for hot gas re-heat system. It uses the INTELLI-Start™ algorithm to maximize energy savings by recovering the building from the Unoccupied Setpoints to the Occupied Setpoints just in time for the Occupied Time Period to begin. The Simplicity® INTELLIComfort™ balances space temperature, ventilation air temperature, CO2 and humidity for ultimate comfort.

•Simplicity® INTELLI-Comfort™ with MOD LINK CONTROL - The York® Simplicity® INTELLI-Comfort™ with Mod Link control is factory installed. It includes all the features of the INTELLI-Comfort™ control with an additional control to translate communications from MODBUS to the BACnet MSTP protocol.

•Novar® BAS CONTROL - The Novar® ETC-3 building automation system controller is factory installed. Includes supply air sensor, return air sensor, dirty filter indicator switch, and air proving switch.

•JOHNSON CONTROLS BAS CONTROL - The Johnson Control YK-UNT-1126 building automation system controller is factory installed. Includes supply air sensor, return air sensor, dirty filter indicator switch, and air proving switch.

•CPC BAS CONTROL - The Computer Process Controls Model 810-3060 ARTC Advanced Rooftop building automation system controller is factory installed. Includes supply air sensor, return air sensor, dirty filter indicator switch and air proving switch.

•HONEYWELL BAS CONTROL - The Honeywell W7750C building automation system controller is factory installed. Includes air supply sensor, return air sensor, dirty filter indicator switch, and air proving switch.

•YORK COMMERCIAL COMFORT SYSTEM (YCCS) - Provides rooftop system integration for YCCS single zone and change-over bypass systems.

•SMOKE DETECTORS - (supply air & return air) The smoke detectors stop operation of the unit by interrupting power to the control board if smoke is detected within the air compartment.

6 |

Johnson Controls Unitary Products |

Factory installed Smoke Detectors in the return air, may be subjected to freezing temperatures during “off” times due to outside air infiltration. These smoke detectors have an operational limit of 32°F to 131°F. Smoke detectors installed in areas that could be outside those limitations will have to be moved to prevent having false alarms.

•COIL GUARD - Customers can purchase a coil guard kit to protect the condenser coil from damage. This is not a hail guard kit.

•STAINLESS STEEL HEAT EXCHANGER - For applications in corrosive environments, this option provides a full stainless steel heat exchanger assembly.

•STAINLESS STEEL DRAIN PAN - An optional rustproof stainless steel drain pan is available to provide years of trouble-free operation in corrosive environments.

•BOTTOM DRAIN CONNECTION - An optional bottom drain connection is available for inside the curb connections for applications in cold environments to reduce freezing drain lines.

•PHASE MONITORS - Designed to prevent unit damage. The phase monitor will shut the unit down in an out-of- phase condition.

•DIRTY FILTER SWITCH - This kit includes a differential pressure switch that energizes the fault light on the unit thermostat, indicating that there is an abnormally high pressure drop across the filters. Factory installed option or field installed accessory.

•HINGED FILTER DOOR/“TOOLLESS” BLOWER AND ACCESS PANELS (not hinged) - This option allows for easy access and maintenance.

NOTE:Knobs are shipped inside the unit to prevent shipping damage. These must be field installed for tool-less operation.

•HIGH STATIC DRIVE OPTION - May include a belt, blower pulley, motor pulley or a motor change to enhance blower performance.

FIELD-INSTALLED ACCESSORIES

•SINGLE INPUT ELECTRONIC ENTHALPY ECONOMIZERS - Includes a slide-in / plug-in damper assembly with fully modulating spring-return motor actuator capable of introducing up to 100% outdoor air with nominal 1% leakage type dampers.

392856-YTG-B-0708

The enthalpy system contains one sensor that monitors the outdoor air and determines when the air is cool enough and dry enough to provide free cooling.

The rainhood is painted to match the basic unit and must be field-assembled before installing.

•MOTORIZED OUTDOOR AIR INTAKE DAMPER - Includes a slide-in / plug-in damper assembly with a 2- position, spring return motor actuator which opens to some pre-set position whenever the supply air blower is operating and will drive fully closed when the blower unit shuts down.

The rain hood is painted to match the basic unit and must be field assembled before installing.

•ELECTRIC HEATERS wired for single point power supply. These nickel chromium heater elements are provided with limit and automatic reset capability to prevent operation at excessive temperatures.

•ROOF CURBS - Eight and fourteen-inch high roof curbs provide a water-tight seal between the unit and the finished roof. These full perimeter curbs meet the requirements of the National Roofing Contractors Association (NRCA) and are shipped knocked-down for field assembly.

Roof curbs are designed to fit inside the base rails of the unit and include both a wood nailing strip and duct hanger supports.

•HIGH ALTITUDE NATURAL GAS - Burner orifices and pilot orifices are provided for proper furnace operation at altitudes up to 6,000 feet.

•PROPANE - Burner orifices, pilot orifices and gas valve parts are provided to convert a natural gas furnace to propane.

•HIGH ALTITUDE PROPANE - Burner orifices and pilot orifices are provided for proper furnace operation at altitudes up to 6,000 feet. This accessory supplements the basic propane conversion kit.

•LOW NOX KIT- Required to reduce the emission of nitrogen oxides below 40 nanograms per joule.

•POWER EXHAUST - Our single input economizer options are available with power exhaust. Whenever the outdoor air intake dampers are opened for free cooling, the exhaust fan will be energized to prevent the conditioned space from being over-pressurized during economizer operation.

The power exhaust option can only be used on bottom duct configurations.

•BAROMETRIC RELIEF DAMPER - This damper accessory can be used to relieve internal building air pressure on units with an economizer without power exhaust. This accessory includes a rain hood, a bird screen and a fully assembled damper. With bottom duct connections, the damper should be mounted over the opening in the

Johnson Controls Unitary Products |

7 |

392856-YTG-B-0708

return air panel. With horizontal ductwork, the accessory should be mounted on the return air duct.

•ENTHALPY ACCESSORY CONTROL KIT - This kit contains the required components to convert a single enthalpy economizer to dual enthalpy.

•BURGLAR BARS - Mount in the supply and return openings to prevent entry into the duct work.

•FLUE EXHAUST EXTENSION KIT - In locations with wind or weather conditions which may interfere with proper exhausting of furnace combustion products, this kit can be installed to prevent the flue exhaust from entering nearby fresh air intakes.

TABLE 1: SOUND POWER RATING1

•CO2 SENSOR - Senses CO2 levels and automatically overrides the economizer when levels rise above the present limits.

•COIL GUARD - Customers can purchase a coil guard kit to protect the condenser coil from damage. This is not a hail guard kit.

•HAIL GUARD -Hail Guard Kit is available to protect coils from damage. This is a sloped hood that fits above the outdoor coil.

•GAS PIPING KIT - This kit supplies all necessary fittings and shut off valve.

|

|

ESP |

BLOWER |

|

|

|

|

SOUND POWER (db 10-12 |

Watts) |

|

|

|

||||

UNIT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

CFM |

|

|

|

|

|

Octave Band Centerline Frequency (Hz) |

|

SWL |

dB(A) |

|||||||

SIZE |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

@ |

||

|

|

IWG |

SPEED |

KW |

63 |

125 |

|

250 |

500 |

1,000 |

2,000 |

|

4,000 |

8,000 |

dB(A) |

|

|

|

|

|

10Ft.2 |

||||||||||||

|

|

|

|

|

||||||||||||

072 |

2,200 |

0.3 |

HIGH |

1.35 |

87 |

87 |

|

77 |

70 |

72 |

65 |

|

60 |

55 |

77 |

44 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.These values have been accessed using a model of sound propagation from a point source into the hemispheric\free field. The dBA values provided are to be used for reference only. Calculation of dBA values cover matters of system design and the fan manufacture has no way of knowing the details of each system. This constitutes and expectation to any specification or guarantee requiring a dBA value or sound data in any other form than sound power level ratings.

2.At a distance of 10 feet from the blower.

TABLE 2: CAPACITY RATINGS - (ARI 210/240)1

MODEL |

MBH |

EER2 |

DM072 |

72.0 |

9.0 |

1.80/67°F Indoor and 95°F outdoor.

2.EER = Energy Efficiency Ratio at full load - the cooling capacity in Btu’s per hour (Btuh) divided by the power input in watts, expressed in Btuh per watt (Btuh/watt).

TABLE 3: GAS HEAT RATINGS1

MODEL |

MBH |

MBH |

AFUE |

TEMP |

|

INPUT |

OUTPUT |

(%) |

RISE ºF |

||

|

|||||

DM072N08 |

100 |

80 |

80.5 |

25 - 55 |

|

DM072N10 |

125 |

100 |

80.3 |

30 - 75 |

1. All units are single-stage heating.

TABLE 4: 2 STAGE GAS HEAT RATINGS

MODEL1 |

MBH INPUT |

MBH OUTPUT |

STEADY STATE EFFICIENCY |

RISE |

MINIMUM HEATING |

|||||

1ST STAGE |

2ND STAGE |

1ST STAGE |

2ND STAGE |

1ST STAGE |

2ND STAGE |

MIN. |

MAX. |

AIRFLOW (CFM) |

||

|

||||||||||

DM072D06 |

45 |

75 |

35.8 |

60.8 |

79.4 |

81.1 |

15 |

45 |

1230 |

|

DM072D10 |

75 |

125 |

60.4 |

100.6 |

80.5 |

80.5 |

30 |

75 |

1230 |

|

|

|

|

|

|

|

|

|

|

|

|

1. Models are 3Ø only.

8 |

Johnson Controls Unitary Products |

392856-YTG-B-0708

TABLE 5: DM072 COOLING CAPACITIES (6 TON)

|

|

|

|

|

|

|

|

|

TEMPERATURE OF AIR ON CONDENSER COIL |

|

|

|

|

|

|

|

|

||||||

AIR ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

85°F |

|

|

|

|

|

|

|

|

|

95°F |

|

|

|

|

|

|||||

EVAPORATOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

TOTAL |

|

|

SENSIBLE CAPACITY1 |

|

TOTAL |

|

|

|

SENSIBLE CAPACITY1 |

|

|||||||||||||

|

COIL |

POWER |

|

|

POWER |

|

|

|

|||||||||||||||

|

|

|

1 |

|

ENTERING DRY BULB, °F |

|

1 |

|

|

ENTERING DRY BULB, °F |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

CAP. |

INPUT2 kW |

|

|

CAP. |

INPUT2 kW |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

CFM |

|

WB °F |

MBH |

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

MBH |

|

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

||

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

72 |

80 |

5.7 |

63 |

55 |

|

47 |

40 |

32 |

- |

- |

77 |

6.3 |

|

63 |

55 |

|

47 |

40 |

32 |

- |

- |

2700 |

|

67 |

80 |

5.7 |

76 |

68 |

|

60 |

53 |

45 |

37 |

30 |

77 |

6.3 |

|

75 |

68 |

|

60 |

53 |

45 |

37 |

30 |

|

62 |

70 |

5.5 |

70 |

70 |

|

70 |

62 |

55 |

47 |

39 |

71 |

6.3 |

|

71 |

71 |

|

71 |

63 |

56 |

48 |

40 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

68 |

5.6 |

68 |

68 |

|

68 |

60 |

52 |

45 |

37 |

71 |

6.3 |

|

71 |

71 |

|

71 |

63 |

56 |

48 |

40 |

|

|

72 |

82 |

5.7 |

60 |

53 |

|

46 |

38 |

31 |

- |

- |

76 |

6.3 |

|

60 |

53 |

|

46 |

39 |

31 |

- |

- |

2550 |

|

67 |

82 |

5.7 |

73 |

65 |

|

58 |

51 |

43 |

36 |

29 |

76 |

6.3 |

|

73 |

66 |

|

58 |

51 |

44 |

36 |

29 |

|

62 |

71 |

5.5 |

71 |

71 |

|

70 |

62 |

55 |

48 |

41 |

70 |

6.3 |

|

70 |

70 |

|

69 |

62 |

55 |

48 |

40 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

69 |

5.6 |

69 |

69 |

|

69 |

62 |

55 |

47 |

40 |

70 |

6.3 |

|

70 |

70 |

|

70 |

62 |

55 |

48 |

40 |

|

|

72 |

83 |

5.7 |

58 |

51 |

|

44 |

37 |

30 |

- |

- |

75 |

6.3 |

|

58 |

51 |

|

44 |

37 |

30 |

- |

- |

2400 |

|

67 |

83 |

5.7 |

70 |

63 |

|

56 |

49 |

42 |

35 |

28 |

75 |

6.3 |

|

70 |

64 |

|

57 |

50 |

43 |

36 |

29 |

|

62 |

73 |

5.5 |

73 |

73 |

|

70 |

63 |

56 |

49 |

42 |

69 |

6.3 |

|

69 |

69 |

|

68 |

61 |

54 |

47 |

40 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

71 |

5.6 |

71 |

71 |

|

71 |

64 |

57 |

50 |

43 |

69 |

6.3 |

|

69 |

69 |

|

68 |

61 |

54 |

47 |

40 |

|

|

72 |

79 |

5.7 |

54 |

48 |

|

41 |

35 |

29 |

- |

- |

73 |

6.3 |

|

53 |

47 |

|

41 |

35 |

29 |

- |

- |

2100 |

|

67 |

79 |

5.7 |

65 |

59 |

|

53 |

47 |

40 |

34 |

28 |

73 |

6.3 |

|

65 |

59 |

|

52 |

46 |

40 |

34 |

28 |

|

62 |

69 |

5.5 |

69 |

69 |

|

66 |

60 |

54 |

47 |

41 |

67 |

6.3 |

|

67 |

66 |

|

63 |

57 |

51 |

45 |

38 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

67 |

5.6 |

67 |

67 |

|

67 |

61 |

54 |

48 |

42 |

67 |

6.3 |

|

67 |

66 |

|

63 |

57 |

51 |

45 |

39 |

|

|

72 |

74 |

5.6 |

50 |

44 |

|

39 |

34 |

28 |

- |

- |

71 |

6.3 |

|

49 |

43 |

|

38 |

33 |

27 |

- |

- |

1800 |

|

67 |

74 |

5.6 |

60 |

55 |

|

50 |

44 |

39 |

34 |

28 |

71 |

6.3 |

|

59 |

54 |

|

48 |

43 |

38 |

32 |

27 |

|

62 |

65 |

5.4 |

65 |

65 |

|

62 |

57 |

51 |

46 |

41 |

65 |

6.2 |

|

65 |

63 |

|

58 |

53 |

47 |

42 |

37 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

63 |

5.5 |

63 |

63 |

|

63 |

58 |

52 |

47 |

42 |

65 |

6.3 |

|

65 |

63 |

|

58 |

53 |

47 |

42 |

37 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

TEMPERATURE OF AIR ON CONDENSER COIL |

|

|

|

|

|

|

|

|

||||||

AIR ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

105°F |

|

|

|

|

|

|

|

|

|

115°F |

|

|

|

|

|

|||||

EVAPORATOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

COIL |

TOTAL |

POWER |

|

SENSIBLE CAPACITY1 |

|

TOTAL |

POWER |

|

|

SENSIBLE CAPACITY1 |

|

|||||||||||

|

|

|

1 |

|

ENTERING DRY BULB, °F |

|

1 |

|

|

ENTERING DRY BULB, °F |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

CAP. |

INPUT2 kW |

|

|

CAP. |

INPUT2 kW |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

CFM |

|

WB °F |

MBH |

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

MBH |

|

86 |

83 |

|

80 |

77 |

74 |

71 |

68 |

||

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

72 |

76 |

7.1 |

61 |

53 |

|

45 |

38 |

30 |

- |

- |

75 |

7.9 |

|

59 |

51 |

|

43 |

36 |

28 |

- |

- |

2700 |

|

67 |

71 |

7.1 |

70 |

66 |

|

58 |

50 |

43 |

35 |

27 |

65 |

7.8 |

|

65 |

64 |

|

56 |

48 |

41 |

33 |

25 |

|

62 |

64 |

7.0 |

64 |

64 |

|

64 |

56 |

49 |

41 |

34 |

57 |

7.8 |

|

57 |

57 |

|

57 |

50 |

42 |

34 |

27 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

64 |

7.0 |

64 |

64 |

|

64 |

56 |

49 |

41 |

34 |

57 |

7.7 |

|

57 |

57 |

|

57 |

50 |

42 |

34 |

27 |

|

|

72 |

76 |

7.1 |

59 |

51 |

|

44 |

37 |

29 |

- |

- |

76 |

7.9 |

|

57 |

49 |

|

42 |

35 |

27 |

- |

- |

2550 |

|

67 |

71 |

7.1 |

69 |

64 |

|

56 |

49 |

42 |

34 |

27 |

66 |

7.9 |

|

66 |

61 |

|

54 |

47 |

40 |

32 |

25 |

|

62 |

64 |

7.0 |

64 |

64 |

|

64 |

56 |

49 |

42 |

35 |

58 |

7.8 |

|

58 |

58 |

|

58 |

51 |

43 |

36 |

29 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

64 |

7.0 |

64 |

64 |

|

64 |

56 |

49 |

42 |

34 |

58 |

7.7 |

|

58 |

58 |

|

58 |

50 |

43 |

36 |

29 |

|

|

72 |

75 |

7.1 |

56 |

49 |

|

43 |

36 |

29 |

- |

- |

76 |

8.0 |

|

55 |

48 |

|

41 |

34 |

27 |

- |

- |

2400 |

|

67 |

70 |

7.1 |

68 |

61 |

|

54 |

48 |

41 |

34 |

27 |

66 |

7.9 |

|

66 |

59 |

|

52 |

45 |

38 |

32 |

25 |

|

62 |

64 |

7.0 |

64 |

64 |

|

63 |

56 |

49 |

42 |

35 |

59 |

7.8 |

|

59 |

59 |

|

59 |

52 |

45 |

38 |

31 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

64 |

7.0 |

64 |

64 |

|

63 |

56 |

49 |

42 |

35 |

59 |

7.7 |

|

59 |

59 |

|

58 |

51 |

44 |

37 |

30 |

|

|

72 |

73 |

7.1 |

52 |

45 |

|

39 |

33 |

27 |

- |

- |

73 |

7.9 |

|

50 |

44 |

|

37 |

31 |

25 |

- |

- |

2100 |

|

67 |

68 |

7.1 |

63 |

56 |

|

50 |

44 |

38 |

32 |

26 |

63 |

7.8 |

|

61 |

54 |

|

48 |

42 |

36 |

30 |

24 |

|

62 |

61 |

7.0 |

61 |

61 |

|

58 |

52 |

46 |

40 |

34 |

56 |

7.7 |

|

56 |

56 |

|

54 |

48 |

42 |

35 |

29 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

61 |

7.0 |

61 |

61 |

|

58 |

52 |

46 |

40 |

34 |

56 |

7.7 |

|

56 |

56 |

|

53 |

47 |

41 |

35 |

29 |

|

|

72 |

70 |

7.1 |

47 |

41 |

|

36 |

31 |

25 |

- |

- |

69 |

7.8 |

|

45 |

40 |

|

34 |

29 |

23 |

- |

- |

1800 |

|

67 |

65 |

7.0 |

57 |

51 |

|

46 |

41 |

35 |

30 |

25 |

60 |

7.8 |

|

55 |

49 |

|

44 |

39 |

33 |

28 |

23 |

|

62 |

59 |

7.0 |

59 |

58 |

|

54 |

48 |

43 |

38 |

32 |

53 |

7.7 |

|

53 |

53 |

|

49 |

44 |

39 |

33 |

28 |

|

|

|

|

|

|

|||||||||||||||||||

|

|

57 |

59 |

6.9 |

59 |

58 |

|

53 |

48 |

43 |

37 |

32 |

53 |

7.6 |

|

53 |

53 |

|

49 |

44 |

38 |

33 |

27 |

1.These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2.These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

NOMINAL RATING

NOMINAL RATING

Johnson Controls Unitary Products |

9 |

Loading...

Loading...