York STYLE A YCWS User Manual

YCWS

WATER COOLED LIQUID CHILLER

FORM 201.24-EG1 (701)

91 TONS THROUGH 216 TONS

320 kW THROUGH 760 kW

60Hz

STYLE A

Table of Contents

Introduction .............................................................................................................................................................. 3

Specifications .......................................................................................................................................................... 4

Accessories & Options ............................................................................................................................................ 7

Design Parameters .................................................................................................................................................. 8

Pressure Drops ...................................................................................................................................................... 10

Selection Data ....................................................................................................................................................... 12

Ratings (R-22 English) ........................................................................................................................................... 14

Ratings (R-22 SI).................................................................................................................................................... 16

Ratings- Brine (30 % Ethylene Glycol) (R-22 English) ............................................................................................ 18

Ratings- Brine (30 % Ethylene Glycol) (R-22 SI) ................................................................................ .................... 20

Ratings- Brine (30 % Propylene Glycol) (R-22 English) .......................................................................................... 22

Ratings- Brine (30 % Propylene Glycol) (R-22 SI)................................................................................................... 24

Part Load Ratings .................................................................................................................................................. 26

Physical Data ........................................................................................................................................................ 28

Isolator Selection Data ........................................................................................................................................... 29

Isolator Details ....................................................................................................................................................... 30

Sound Data ............................................................................................................................................................ 31

Dimensions (English) ............................................................................................................................................. 32

Electrical Data ....................................................................................................................................................... 36

Incoming Wire Range Selections............................................................................................................................ 39

Customer Wiring Data............................................................................................................................................ 42

Typical Control Panel Wiring .................................................................................................................................. 44

Application Data..................................................................................................................................................... 46

Guide Specifications .............................................................................................................................................. 47

YC W S 0140 S C 46 Y A

YC= York Chiller

W= Water cooled

S= Screw Compressor

Nominal Capacity in Tons

2

Nomenclature

S= Standard Efficiency

Design Series: A

Type Start: Y = Star-Delta

Voltage Code:

Refrigerant C = R-22

17 = 200-3-60

28 = 230-3-60

40 = 380-3-60

46 = 460-3-60

58 = 575-3-60

YORK INTERNATIONAL

Introduction

York YCWS W ater Cooled Screw Chillers

FORM 201.24-EG1

YORK YCWS Water-Cooled models provide chilled water for all air conditioning applications that

use central station air handling or terminal units. They are completely self-contained and are

designed for indoor (new or retrofit) installation. Each unit includes accessible semi-hermetic

screw compressors, a liquid cooler, water cooled condenser, and a user-friendly, diagnostic

Microcomputer Control Center all mounted on a rugged steel base. The units are produced at an

ISO 9001 registered facility. The YCWS chillers have certified ratings in accordance with ARI

Standard 550/590.

YORK INTERNATIONAL

3

Specifications

GENERAL

The Liquid Chiller will be completely assembled with all

interconnecting refrigerant piping and internal wiring,

ready for field installation.

• Each compressor will be mounted on isolator pads to

reduce transmission of vibration to the rest of the unit.

COOLER

The unit will be pressure-tested, evacuated, and charged

with Refrigerant-22, and York ‘L’ (POE) synthetic oil.

There will be an operational test, with water flowing

through the cooler, to check that each control device

operates correctly.

The unit will be covered with a coat of Caribbean Blue

enamel. Units are designed in accordance with NFPA

70 (National Electric Code), U.L. and cU.L. Standards,

ASHRAE/ANSI 15 Safety Code for Mechanical Refrigeration. All units are produced at an ISO 9001 registered facility. All YCWS chillers are rated and certified in

accordance with ARI Standard 550/590 at ARI conditions.

SEMI-HERMETIC YORK SCREW COMPRESSORS

• Continuous function, microprocessor controlled, 3- way

proportional Capacity Control Valve provides regulated

output pressure independent of valve input pressure

for a stable, smooth, and precise match of compressor capacity to cooling load to 10% of chiller capacity.

• Automatic spring return of capacity control valve to

minimum load position ensures compressor starting

at minimum motor load. Internal discharge check to

prevent rotor backspin upon shutdown.

• Acoustically tuned, internal discharge gas path elimi-

nates objectionable noise at the source, while optimizing flow for maximum performance.

• Reliable suction gas cooled, high efficiency, acces-

sible hermetic motor with APT2000 type magnet wire

and redundant overload protection using both thermistor and current overload protection.

• Suction gas screen and serviceable, 0.5 micron full

flow oil filter within the compressor housing.

The dual-circuit cooler will be the direct-expansion type,

with refrigerant in the tubes and chilled liquid flowing

through the baffled shell. The design working pressure

of the shell (liquid) side will be 150 PSIG (10.3 bar), and

300 PSIG (26.7 bar) for the tube (refrigerant) side.

The cooler will be constructed and tested in accordance

with the applicable sections of the ASME Pressure Vessel Code, Section VlII, Division (1). The water side will

be exempt per paragraph U-1, (c)(6).

The water baffles will be constructed of galvanized steel

to resist corrosion. The removable heads will allow access to the internally enhanced, seamless, copper tubes.

Vent and drain connections will be included.

The cooler will be covered with 3/4" (19.1 mm ) flexible,

closed-cell, foam insulation (K = 0.25).

CONDENSER

The condenser is a cleanable thru-tube type with steel

shell, copper tubes, removable water heads, and includes

integral subcooling. Refer to PHYSICAL DATA for design working pressures. The shell will be constructed

and tested in accordance with section Vll, division 1 of

the ASME pressure-vessel code. The water side is exempt per paragraph U-1 (c) of section VlII, division 1 of

the ASME pressure-vessel code. The condenser is

equipped with relief valves and will hold the full refrigerant charge for pumpdown.

REFRIGERANT CIRCUIT

Two independent refrigerant circuits will be furnished on

each unit. All piping will be copper with brazed joints.

The liquid line will include: a shutoff valve with charging

port; sightglass with moisture indicator; thermal expansion valve; solenoid valve; and high-absorption removable-core filter drier. The entire suction line and the liquid line between the expansion valve and the cooler will

be insulated with flexible, closed-cell, foam insulation.

• Cast iron compressor housing precisely machined for

optimal clearances and superb efficiency. Entire compressor, from suction to discharge has a Design Working Pressure of 450psig (31 bar).

• 350W compressor body cartridge heater.

4

POWER AND CONTROL PANELS

All controls and motor starting equipment necessary for

unit operation shall be factory wired and function tested.

The panel enclosures shall be designed to NEMA 1 (IP

32) and manufactured from powder-painted galvanized

steel.

YORK INTERNATIONAL

FORM 201.24-EG1

The Power and Control Panel shall be divided into a power

section for each electrical system, a common input section and a control section.

Each power panel shall contain:

Compressor starting contactors, control circuit

serving compressor capacity control, compressor

contactor coils and compressor motor overloads. The

compressor motor overloads contain current transformers which sense each phase, as an input to the

microprocessor, to protect the compressor motors

from damage due to: low input current, high input current, unbalanced current, single phasing, phase

reversal, and compressor locked rotor.

The common input section shall contain:

The control supply transformer providing 115V, customer relay board and control circuit switch disconnect/emergency stop device.

The control section shall contain:

On/Off rocker switch, microcomputer keypad and display, microprocessor board, I/O expansion board,

relay boards, and 24V fused power supply board.

MICROPROCESSOR CONTROLS

Fuzzy Logic control will be incorporated in the YCWS

range of chillers. Fuzzy Logic allows the control system

to monitor several key variables to provide tighter, more

stable chilled water temperature control. The control system monitors the leaving chilled water temperature to

track where it has been, where it is now, how fast it is

moving, and accurately adjusts the chiller operation in

anticipation of expected performance to minimize hunting and save energy.

The microprocessor shall have the following functions

and displays:

• A liquid crystal 40 character display with text provided

on two lines and light emitting diode backlighting for

outdoor viewing.

• A color-coded, 35 button, sealed keypad with sections for Display, Entry, Setpoints, Clock, Print, Program, and Unit On/Off Switch.

reset after power failure, automatic system optimization

to match operating conditions, software stored in nonvolatile memory (EPROM) to eliminate chiller failure due

to AC power failure.

The microprocessor can be directly connected to a YORK

ISN Building Automation System via the standard onboard RS485 communications port. This option also provides open system compatibility with other communications networks.

Programmed Setpoints shall be retained in a lithium battery backed RTC with a memory of five years.

Display - In Imperial (°F and PSIG) or SI (°C and BAR)

units, and for each circuit:

• Return and leaving chilled liquid

• Day, date and time. Daily start/stop times. Holiday

and Manual Override status.

• Compressor operating hours and starts. Automatic

or manual lead/lag. Lead compressor identification.

• Run permissive status. No cooling load condition.

Compressor run status.

• Anti-recycle timer and anti-coincident start timer status per compressor.

• Suction (and suction superheat), discharge, and oil

pressures and temperatures per System.

• Percent full load compressor motor current per phase

and average per phase. Compressor capacity control valve input steps.

• Cutout status and setpoints for: supply fluid temperature, low suction pressure, high discharge pressure

and temperature, high oil temperature, low and high

current, phase rotation safety, and low leaving liquid

temperature.

• Unloading limit setpoints for high discharge pressure

and compressor motor current.

• Liquid pull-down rate sensitivity (0.5°F to 5°F [0.3°C

to 3.0°C]/minute in 0.1°F [0.05°C] increments).

• Status of: evaporator heater, load and unload timers,

chilled water pump.

• Out of range message.

• Up to 6 fault shut down conditions.

• Standard Display Language is English, with an Option for Spanish.

The standard controls shall include: brine chilling or thermal storage, automatic pumpdown, run signal contacts,

demand load limit from external building automation system input, remote reset liquid temperature reset input,

unit alarm contacts, chilled liquid pump control, automatic

YORK INTERNATIONAL

Entry - Enter set point changes, cancel inputs, advance

day, change AM/PM.

Set Points - Chilled liquid temperature, chilled liquid

range, remote reset temperature range.

Clock - Time, daily or holiday start/stop schedule, manual

5

Specifications (Continued)

override for servicing.

Print - Operating data or system fault shutdown history

for last six faults. Printouts through an RS-232 port via a

separate printer (by others).

Program -

• Low leaving liquid temperature cutout, 300 to 600

second anti-recycle timer, lag compressor start time

delay, and average motor current unload point. Liquid temperature setpoint reset signal from YORK ISN

or building automation system (by others) via:

• Pulse width modulated (PWM) input for up to 40°F

(22°C) total reset as standard.

• Optional Building Automation System interface input

card for up to 20°F (11.1°C) reset using a: 4 to 20

mA, 0 to 10 Vdc input, or discrete reset input.

• NOTE: The Standard MicroPanel can be directly connected to a YORK ISN Building Automation System

via the standard onboard RS485 communication port.

This Option also provides open system compatibility

with other communications networks (BACnet™ &

LONMARK™ via interface through standard onboard

485 or 232 port and an external YorkTalk Translator.

• Additional functions (password protected) for programming by a qualified service technician:

Cutouts for low suction pressure, high discharge

pressure, high oil temperature.

Refrigerant type.

High discharge pressure unload setpoint.

Compressor motor current percent limit.

6

YORK INTERNATIONAL

Accessories & Options

FORM 201.24-EG1

ALTERNA TIVE REFRIGERANTS - Contact your nearest YORK of-

fice for information and availability on alternative HFC refrigerants.

ELECTRICAL OPTIONS:

MULTIPLE POINT POWER SUPPL Y CONNECTION -

Standard field power wiring connection on all models is Multiple

Point Power Connection to factory provided T erminal Blocks. T wo

field supplied electrical power circuits with appropriate branch circuit protection provide power to each of two motor control center

cabinets, located on either side of the Control panel on the front of

the chiller. Each cabinet contains starter elements for one compressor.

Optional to the Terminal Blocks for field power connection are

Non-Fused Disconnects or Circuit Breaker Switches with external,

lockable handles.

SINGLE POINT POWER CONNECTION - (Factory Mounted) An

optional configuration for field connection of a single electrical circuit to: either T erminal Block or Non-Fused Disconnect Switch with

lockable external handle (in compliance with Article 440 of N.E.C.,

to isolate unit power supply for service). Factory wiring is provided from the Terminal Block or Disconnect Switch to Factory

supplied individual system Circuit Breakers, Non-Fused Disconnect

switch with external, lockable handle or J Class Fuses/Fuse Block

in each of the two compressor motor control centers. (Note: Single

Point Non-Fused Disconnect Switch will not be supplied with individual system Non Fused Disconnect Switches with external, lockable handles in each of the two compressor motor control centers).

65 Ka HIGH VOL T AGE PROTECTION - Non-Fused Disconnect

Switch with fuses (200 & 575V) or Circuit Breakers (230, 380, &

460V) are used for applications where customers have a requirement for single point wiring with high “fault current” withstanding

capability. This option provides between 50Ka and 65Ka withstand

protection to the equipment.

BUILDING AUTOMATION SYSTEM INTERFACE (Factory

Mounted) – Provides means to reset the leaving chilled liquid

temperature or percent full load amps (current limiting) from the

BAS (Factory Mounted):

• Printed circuit board to accept 4 to 20 milliamp, 0 to 10 VDC,

or dry contact closure input from the BAS.

• A YORK ISN Building Automation System can provide a Pulse

Width Modulated (PWM) signal direct to the standard control

panel via the standard onboard RS485 port.

FLOW SWITCH – The flow switch or its equivalent must be furnished with each unit. 150 PSIG (10.5 bar) DWP – For standard

units. Johnson Controls model F61MG-1C Vapor-proof SPDT, NEMA

4X switch (150 PSIG [10.5 bar] DWP), -20°F to 250°F- (29°C to

121°C), with 1" NPT connection for upright mounting in horizontal

pipe. (Field mounted)

DIFFERENTIAL PRESSURE SWITCH - Alternative to the above mentioned Flow Switch. Pretemco Model DPS 300A-P4OPF-82582-S

(20.7bar max working pressure). SPDT 5 amp 125/250 V AC switch.

Range: 0 - 2.8bar, deadband: 0.003 - 0.005bar , with 1/4 NPTE pressure connections.

LANGUAGE LCD AND KEYP AD - Standard display language and

keypad is in English. Spanish is available as an option.

PRINTER KIT - Printer for obtaining printout of unit operating and

history data. (Field Mounted)

MULTIPLE UNIT SEQUENCE CONTROL (Field Mounted) - Sequencing Control with automatic unit sequencing. Necessary items

for operation and control of up to eight units with parallel water

circuits. Includes software and mixed liquid temperature sensor

(interconnecting wiring by others).

PRESSURE VESSEL CODES - Coolers and condensers can be

supplied in conformance with the following pressure codes:

A.S.M.E. (Standard)

CHICAGO CODE RELIEF V ALVES (Factory Mounted) - Unit will be

provided with relief valves to meet Chicago Code requirements.

ACCESSORIES:

FLANGES (Weld T ype) – Consists of 150 PSI (10.5 bar ) standard

cooler (150 lb) R.F . flanges to convert to flanged cooler-connections and includes companion flanges. (Field mounted)

FLANGES (Victaulic T ype) – Consists of (2) Flange adapter for

grooved end pipe (standard 150 PSI [10.5 bar] cooler). Includes

companion flanges. (Field mounted)

VIBRATION ISOLA TION:

• Neoprene Isolators – Recommended for normal installations.

Provides very good performance in most applications for the

least cost. (Field mounted)

• 1" Spring Isolators – Level adjustable, spring and cage type

isolators for mounting under the unit base rails. 1" nominal deflection may vary slightly by application. (Field mounted)

• 2" Seismic Spring Isolators – Restrained Spring-Flex Mountings

incorporate a rugged welded steel housing with vertical and

horizontal limit stops. Housings designed to withstand a minimum 1.0g accelerated force in all directions to 2". Level adjustable, deflection may vary slightly by application. (Field-mounted)

ALTERNA TIVE CHILLED FLUID APPLICA TIONS:

Standard water chilling application range is 40°F to 50°F (4.4°C to

10°C) Leaving Chilled Water T emperature. To protect against nuisance safety trips below 40°F (4.4°C) and reduce the possibility of

cooler damage due to freezing during chiller operation, the unit

microprocessor automatically unloads the compressors at abnormally low suction temperature (pressure) conditions , prior to safety

shutdown.

• Process Brine Option – Process or other applications requir-

ing chilled fluid below 40°F (4.4°C) risk water freezing in the

evaporator, typically overcome by using antifreeze. For these

applications, the chiller system incorporates brine (ethylene or

propylene glycol solution), and the system design Leaving Chilled

Fluid T emperature must be provided on the order form to ensure

proper factory configuration.

• Thermal Storage Option – Thermal Storage equires special

capabilities from a chiller, including the ability to ‘charge’ an ice

storage tank, then possibly automatically reset for operation at

elevated Leaving Chilled Fluid T emperatures as required by automatic building controls. The Thermal Storage Option provides

Ice Storage duty Leaving Chilled Fluid setpoints from 25°F to

15°F( -4°C to -10°C) minimum during charge cycle, with a Reset

range of 36°F (20°C) supply fluid temperature.

YORK INTERNATIONAL

7

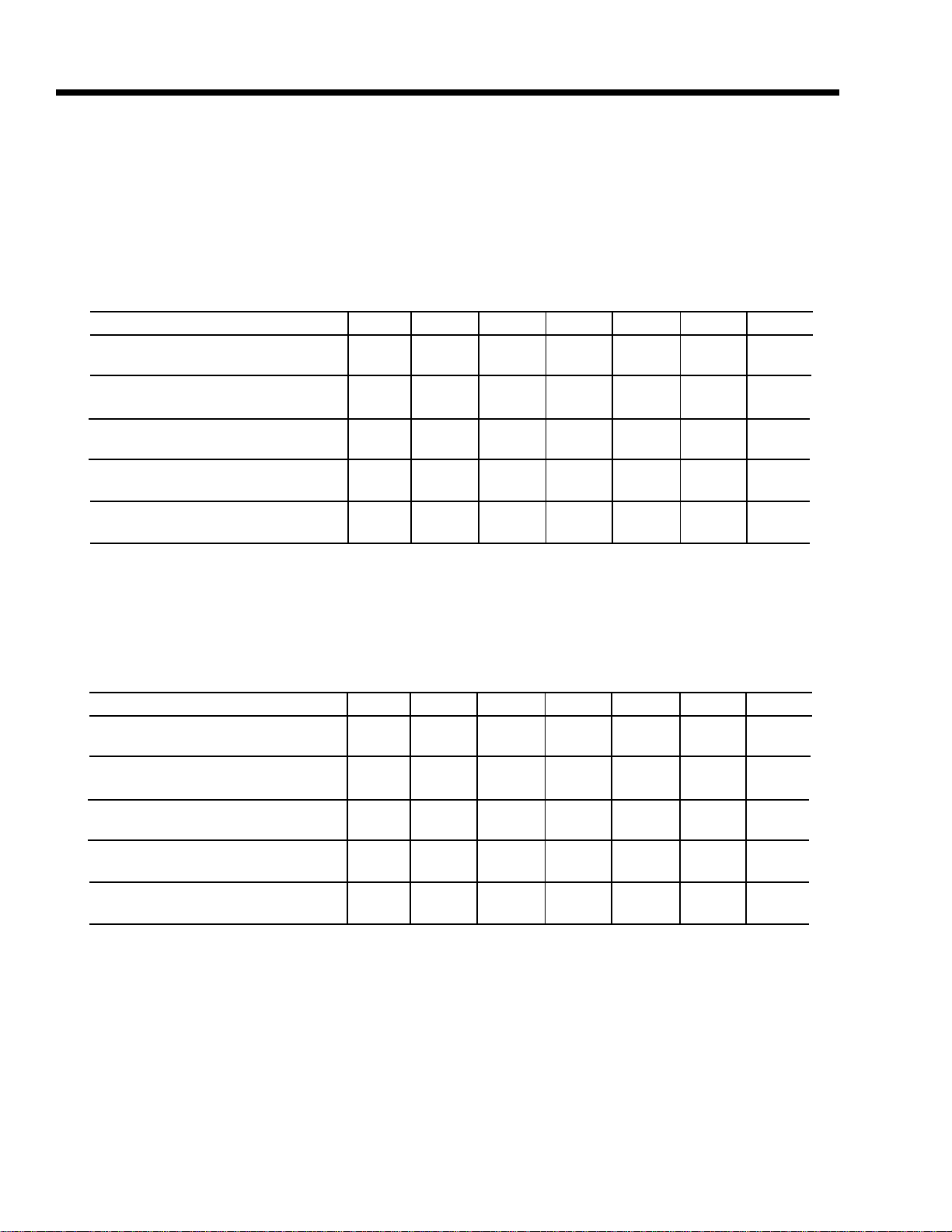

Design Parameters

English

YCWS 0100SC 0120SC 0140SC 0180SC 0200SC 0220SC 0240SC

Min. Cooler Water Flow - GPM 200 200 200 260 260 300 300

Max. Cooler Water Flow - GPM 506 506 506 695 695 830 830

Min. Cond. Water Flow - GPM 193 193 193 330 330 330 330

Max. Cond. Water Flow - GPM 645 645 64 5 1050 1050 1050 1050

Min. Lvg. Liquid Temp. - °F 40 40 40 40 40 40 40

Max. Lvg. Liquid Temp. - °F 50 50 50 50 50 50 50

Min. Ent. Cond. Water Temp - °F 75 75 75 75 75 75 75

Max. Ent. Cond. Water Temp - °F 95 95 95 95 95 95 95

Min. Equipment Room Temp. - °F 40 40 40 40 40 40 40

Max. Equipment Room Temp. - °F 115 115 115 115 115 115 115

SI

YCWS 0100SC 0120SC 0140SC 0180SC 0200SC 0220SC 0240SC

Min. Cooler Water Flow - l/sec 12.6 12.6 12.6 16.4 16.4 18.9 18.9

Max. Cooler Water Flow - l/sec 31.9 31.9 31.9 43.8 43.8 52.4 52.4

Min. Cond. Water Flow - l/sec 12.2 12.2 12.2 20.8 20.8 20.8 20.8

Max. Cond. Water Flow - l/sec 40.7 40.7 40.7 66.2 66.2 66.2 66.2

Min. Lvg. Liquid Temp. - °C 4.4 4.4 4.4 4.4 4.4 4.4 4.4

Max. Lvg. Liquid Temp. - °C 10.0 10.0 10.0 10.0 10.0 10.0 10.0

Min. Ent. Cond. Water Temp - °C 23.8 23.8 23.8 23.8 23.8 23.8 23.8

Max. Ent. Cond. Water Temp - °C 35..0 35..0 35..0 35..0 35..0 35..0 35..0

Min. Equipment Room Temp. - °C 4.4 4.4 4.4 4.4 4.4 4.4 4.4

Max. Equipment Room Temp. - °C 46.1 46.1 46.1 46.1 46.1 46.1 46.1

8

YORK INTERNATIONAL

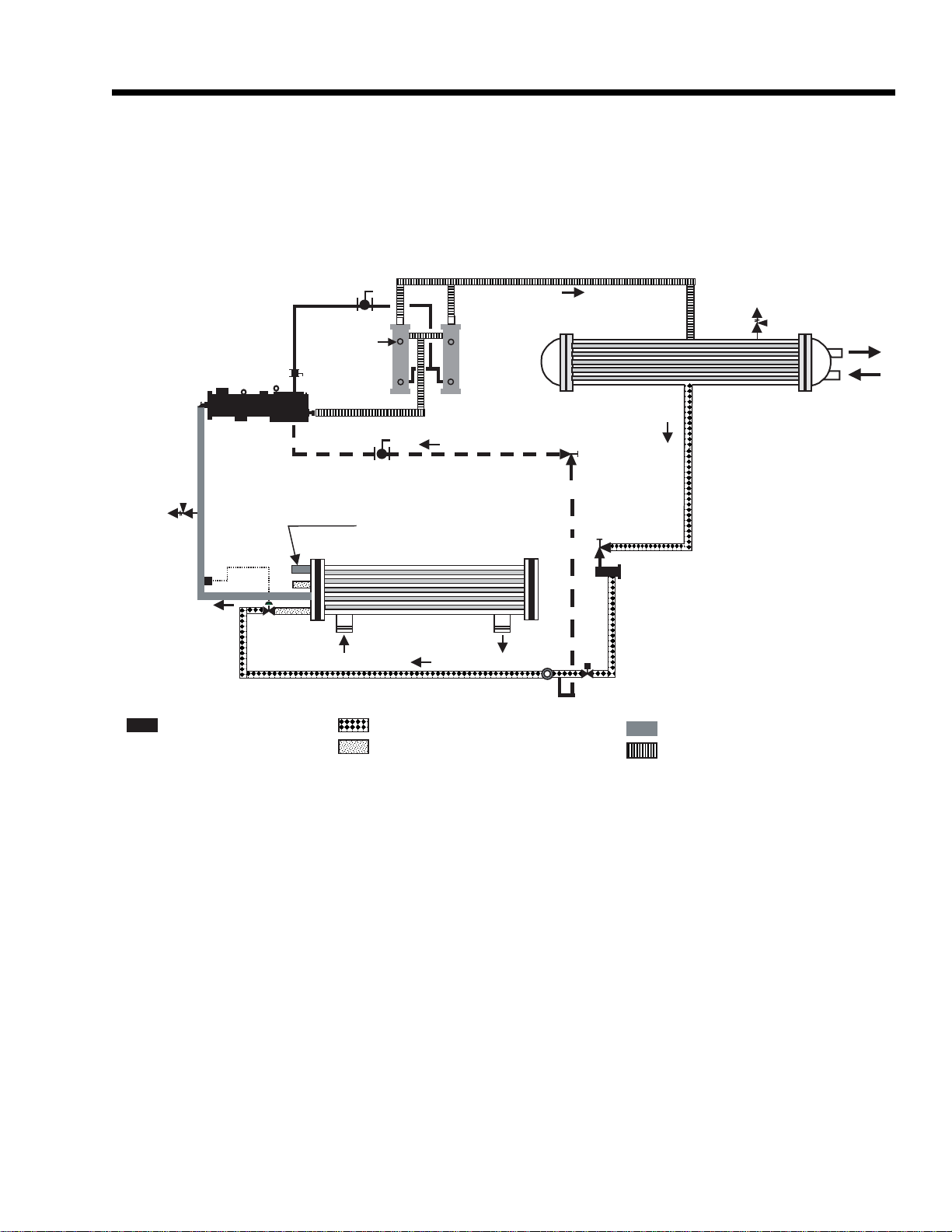

Relief

Valve

FORM 201.24-EG1

Relief

Val ve

Oil

SV = Solenoid Valve

Compressor

TEV

SG = Sight Glass

SG

Refrigerant Circuit No 2

Cooler

High Pressure Subcooled Liquid

Low Pressure Liquid

TEV = Thermostatic Expansion Valve

Oil

Separators

Oil Cooling

Liquid Injection

Condenser

SG

SV

Low Pressure Superheated Vapour

High Pressure Superheated Vapour

Low-pressure liquid refrigerant enters the cooler tubes and is evaporated and superheated by the heat energy absorbed

from the chilled liquid passing through the cooler shell. Low-pressure vapor enters the compressor where pressure and

superheat are increased. High-pressure vapor is passed through the oil separator where heat is rejected to the condenser water passing through the tubes. The fully condensed and subcooled liquid leaves the condenser and enters the

expansion valve, where pressure reduction and further cooling take place. The low pressure liquid refrigerant then

returns to the cooler. Each refrigerant circuit utilizes liquid injection, maintaining efficient oil temperature operation

within the compressor.

YORK INTERNATIONAL

9

Pressure Drops

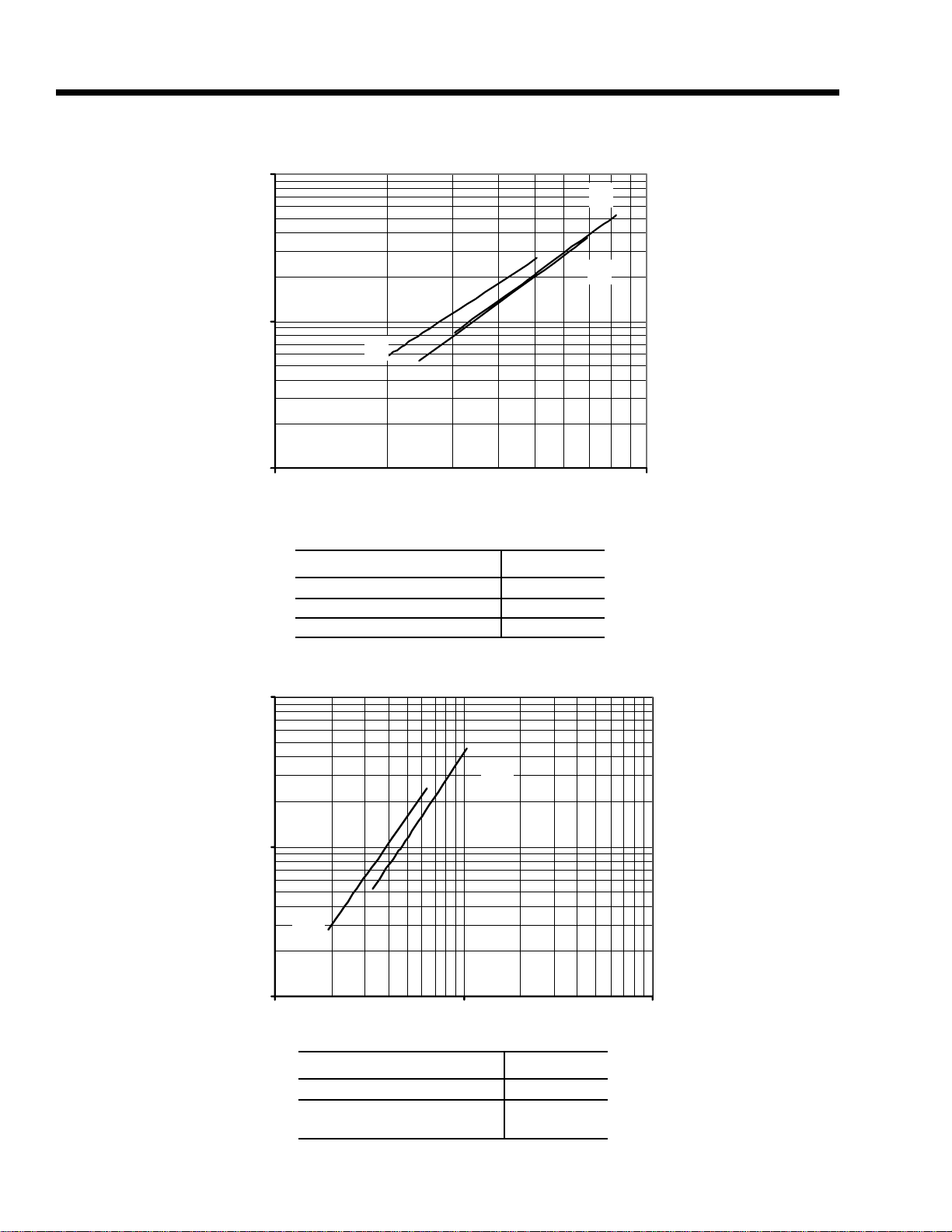

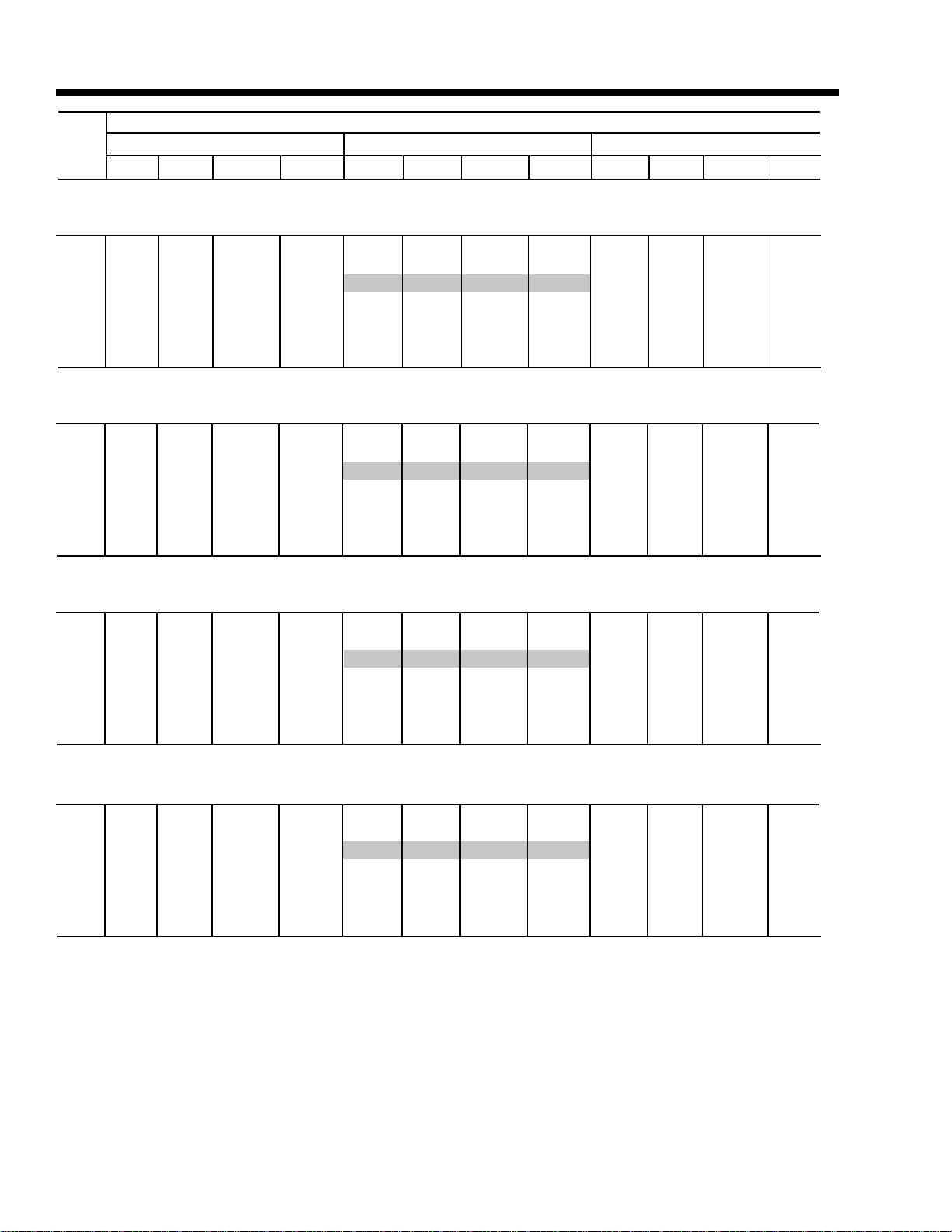

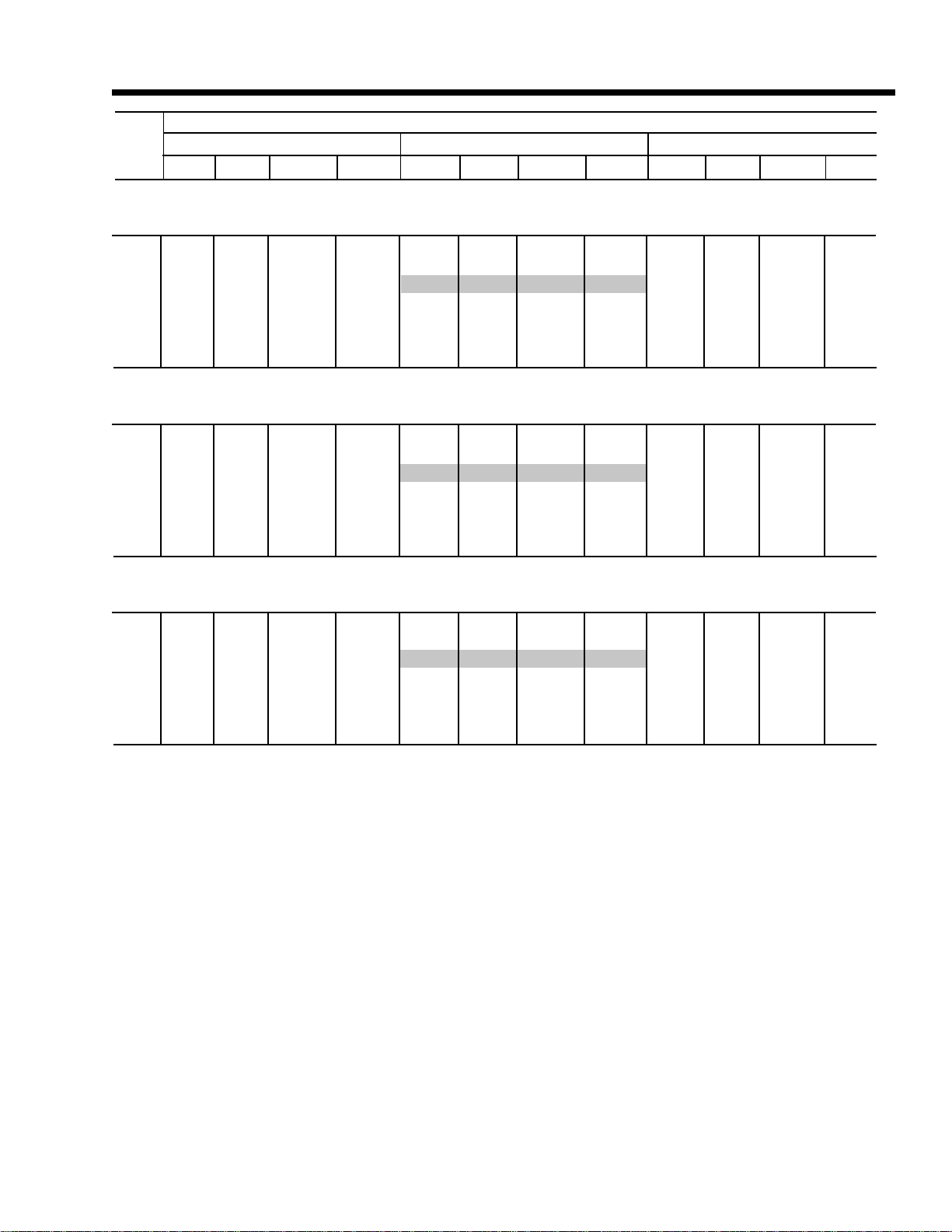

FIGURE 1 - COOLER WA TER PRESSURE DROP CURVES (ENGLISH)

100

O)

2

10

Pressure Drop (H

1

100 1000

Q

P

O

Flow (GPM)

YCWS Model Number Cooler

0100SC, 0120SC, 0140SC

0180SC, 0200SC

0220SC, 0240SC

O

P

Q

FIGURE 3 - CONDENSER WA TER PRESSURE DROP CURVES (ENGLISH)

100

O)

2

10

U

Pressure Drop (H

S

10

1

100 1000 10000

Flow (GPM)

YCWS Model Number Cooler

0100SC, 0120SC, 0140SC

S

0180SC, 0200SC

0220SC, 0240SC

U

YORK INTERNATIONAL

100

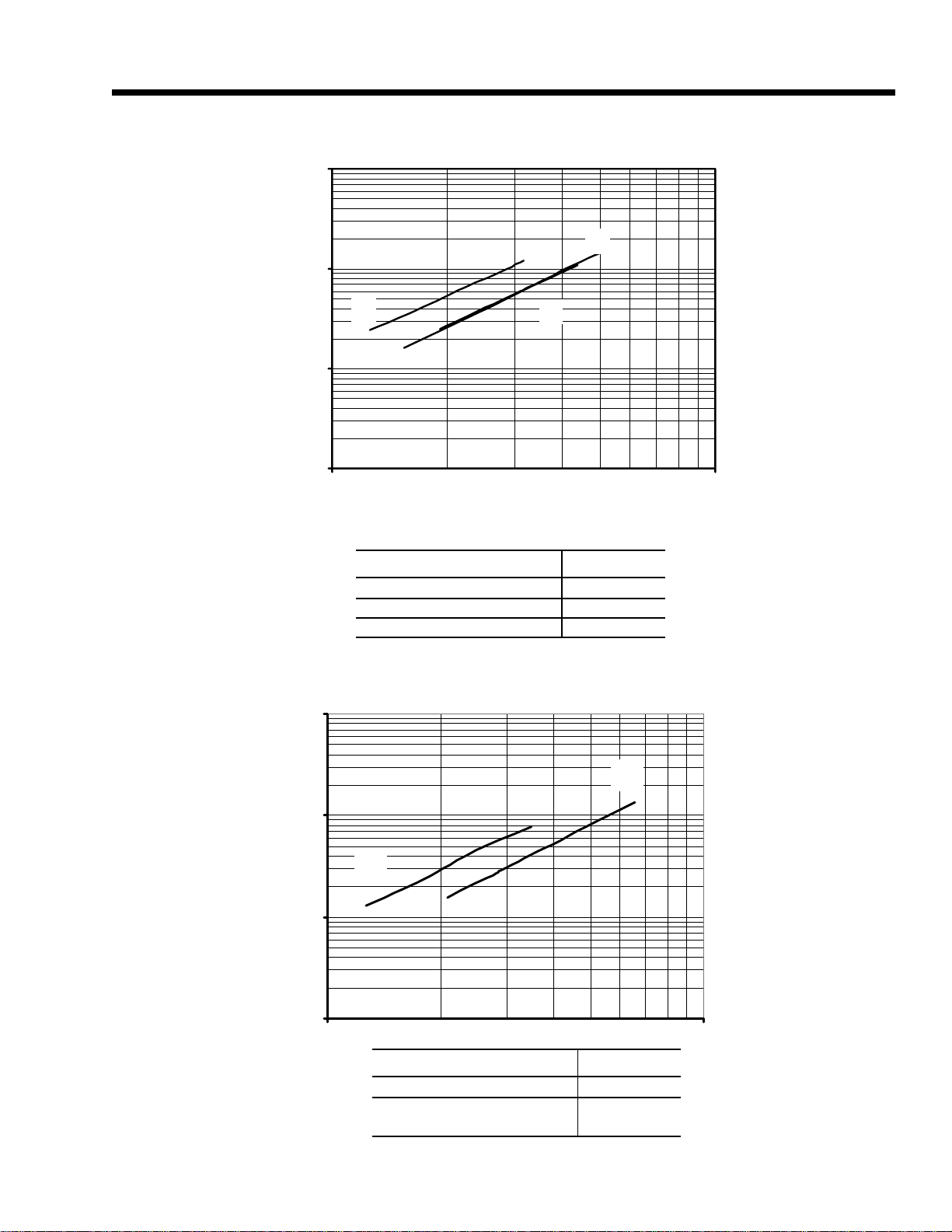

FIGURE 2 - COOLER WA TER PRESSURE DROP CURVES (SI)

1000

Q

100

FORM 201.24-EG1

O

10

P

Pressure Drop (kPa)

1

10

Flow (l/s)

YCWS Model Number Cooler

0100SC, 0120SC, 0140SC

0180SC, 0200SC

0220SC, 0240SC

O

P

Q

FIGURE 4 - CONDENSER WA TER PRESSURE DROP CURVES (SI)

1000

YORK INTERNATIONAL

100

S

Pressure Drop (kPa)

10

1

10 100

0100SC, 0120SC, 0140SC

Flow (l/s)

0180SC, 0200SC

0220SC, 0240SC

U

S

U

11

Selection Data

GUIDE TO SELECTION

Complete water chilling capacity ratings for YORK YCWS

chillers are shown on the following pages to cover the

majority of job requirements. For any application beyond the scope of this Engineering Guide, consult your

nearest YORK Office.

SELECTION RULES

1. RATINGS - YCWS 200, 230 380, 460 & 575-3-60 rating are certified in accordance with ARI standard 550/

590, at the ARI standard condition. Rating not at standard ARI conditions are rated in accordance with ARI

rating procedures. These ratings may be interpolated

but should not be extrapolated.

2. COOLING WATER QUANTITY - Ratings are based

on 10ºF chilled water range. Use the chilled water

correction factors (below) for other ranges except as

limited by water pressure drop, minimum or maximum

water flows for the cooler.

3. CONDENSER WATER QUANTITY – Rating are applicable from 2 to 4 gpm/ton as limited by water pressure drop or minimum or maximum water flows for

the condenser. Using the tabulated MBH, the Cond.

GPM is calculated as follows:

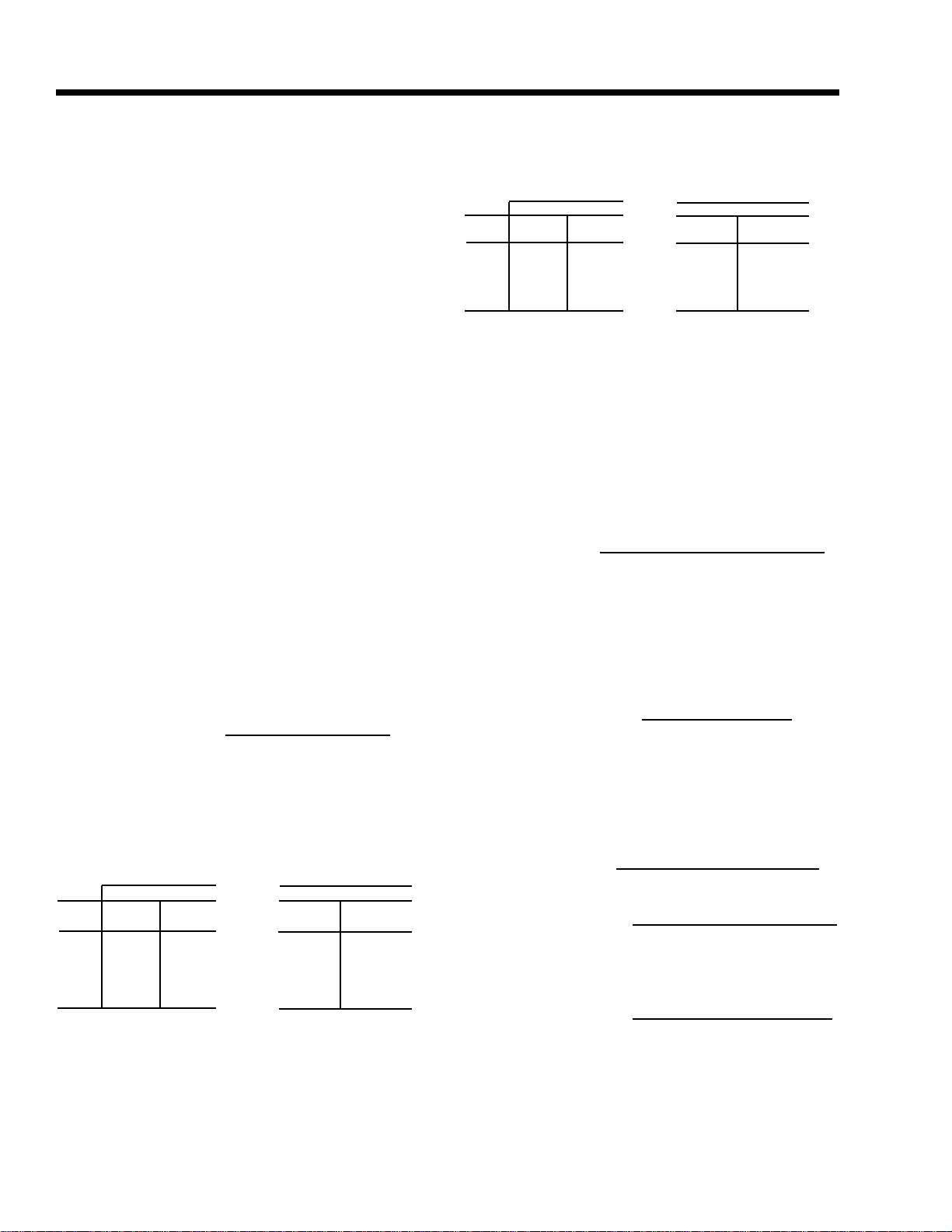

COND FOULING FACTORS

T emp

Split

8 0.9998 1.0004 0.9957 1.0072

10 1.0000 1.0000 0.9959 1.0068

12 1.0001 0.9998 0.9961 1.0065

14 1.0001 0.9998 0.9965 1.0060

Note: Temperature split factors @ 95ºF Leaving Condenser Water

Temp (LCWT).

0.00025 x 0.0005

Tons

Compr

kW

Tons

Compr

kW

METHOD OF SELECTION

If the duty requires a 10ºF range on both the cooler and

condenser, see “Ratings”. For water ranges other than

10ºF, use the following procedure.

1. Determine capacity required from the following formula

Capacity (tons) =

GPM x Chilled Water Range (ºF)

24

2. After applying any fouling factor corrections, the actual condenser heat rejection may be determined as

follows:

Heat Rejection (Btuh) = (Tons x 12,000) + (kW x 3415)

Cond. GPM =

Cond. Water Range (ºF)

MBH x 2

4. FOULING FACTORS – Rating are based on 0.0001

evaporator and 0.00025 condenser fouling factor. For

other fouling factors, consult the table below or contact your YORK representative.

EVAP FOULING FACTORS

0.0001 x 0.00025

T emp

Split

10 1.0000 1.0000 0.9982 1.0001

12 1.0133 0.9993 0.9978 1.0001

14 1.0248 0.9986 0.9979 1.0001

Note: Temperature split factors @ 44ºF Leaving Chilled Liquid Temp

(LCLT)

Tons

6 0.9692 1.0015 0.9972 1.0001

8 0.9849 1.0008 0.9980 1.0001

Compr

kW

Tons

Compr

kW

Heat Rejection (MBH) =

Heat Rejection (Btuh)

1000

= (Tons x 12) = (kW x 3.415)

3. Determine condensing water requirements for water

cooled models as follows:

Condenser Tons =

Cond. Water GPM =

Heat Rejection (MBH) x 1000

15,000

Condenser Tons x 30

Condenser Water Range (ºF)

Or combine the two formulas:

Cond. Water GPM =

Condenser Water Range (ºF)

MBH x 2

12

YORK INTERNATIONAL

FORM 201.24-EG1

SAMPLE SELECTION

Water Cooled Condenser (YCWS)

GIVEN – Chill 200 GPM of water from 56ºF to 44ºF and

0.0001 evaporator fouling factor with 85ºF to 95ºF condensing water available. Fouling factor of 0.0005 special field for the condenser.

FIND – The required unit size capacity, kW, EER, and

water pressure drop.

SOLUTION:

1. Chilled water range = 56ºF - 44ºF = 12ºF and correction factors are 1.0133 for Tons and 0.9993 for kW for

the cooler.

2. Capacity (tons) =

= 200 x 12

24

GPM x Chilled Water Range

24

= 100TR

2. From the rating, a model YCWS0120SC has a capacity range required. For the cooler leaving water

temperature of 44ºF and a condenser leaving water

temperature of 95ºF, the unit capacity rating table indicates:

EER =

Tons x 12 = 95.0 X 12 = 15.4

Kw 74

4. Determine the cond. Heat rejection as follows:

Heat Rejection (MBH) = (Tons x 12) + (kW x 3.415)

= (95.0 x 12) + (74 x 3.415)

= 1140 + 253

= 1393

5. Determine GPM condensing water as follows:

GPM Condenser Water =

Cond Water Range

MBH x2

6. From curves on pages 10 and 11, the pressure drops

with 200GPM through the cooler and 288 through the

condenser of the Model YCWS120SC

Cooler Pressure Drop at 200 GPM = 2.9ft

Condenser Pressure Drop at 288 GPM = 5.5ft

Tons = 110.3

KW = 86.2

EER = 15.4

Correcting for the 12ºF chilled water range and the 0.0005

condenser-fouling factor:

Tons = 110.3 x 1.0133 x 0.9961 = 111.3TR

KW = 86.2 x 0.9993 x 1.0065 = 86.7

The unit is suitable.

3. Determine the average full load kW and EER at 95.0

Tons

95.0

X (86.7) = 74KW

111.3

YORK INTERNATIONAL

13

Ratings (R-22 English)

LEA VING CONDENSER WA TER TEMPERA TURE (°F)

LCWT 85.0 95.0 105.0

(°F) TONS KW MBH EER TONS KW MBH EER TONS K W MBH EER

YCWS0100SC

40.0 89.4 63.3 1288.0 17.0 84.1 71.5 1253.0 14.1 78.7 80.7 1219.0 11.7

42.0 93.1 63.4 1333.0 17.6 87.7 71.8 1297.0 14.7 82.1 80.9 1260.0 12.2

44.0 96.9 63.5 1379.0 18.3 91.3 72.0 1341.0 15.2 85.6 81.1 1304.0 12.7

45.0 98.8 63.6 1402.0 18.7 93.2 72.2 1364.0 15.5 87.4 81.2 1325.0 12.9

46.0 100.7 63.6 1426.0 19.0 95.0 72.3 1387.0 15.8 89.2 81.4 1348.0 13.2

48.0 104.7 63.5 1473.0 19.8 98.9 72.5 1434.0 16.4 92.9 81.7 1393.0 13.7

50.0 108.8 63.4 1522.0 20.6 102.8 72.7 1482.0 17.0 96.7 81.9 1439.0 14.2

YCWS0120SC

40.0 108.0 75.6 1553.0 17.1 101.7 85.6 1512.0 14.3 95.3 96.6 1473.0 11.8

42.0 1 12.3 75.8 1607.0 17.8 105.9 85.9 1564.0 14.8 99.3 96.9 1522.0 12.3

44.0 1 16.8 76.0 1661.0 18.5 110.3 86.2 1617.0 15.4 103.5 97.2 1573.0 12.8

45.0 1 19.1 76.0 1689.0 18.8 112.5 86.3 1644.0 15.6 105.6 97.3 1599.0 13.0

46.0 121.5 76.0 1717.0 19.2 114.7 86.5 1671.0 15.9 107.8 97.5 1626.0 13.3

48.0 126.2 76.0 1774.0 19.9 119.3 86.7 1727.0 16.5 112.2 97.8 1680.0 13.8

50.0 131.1 75.9 1832.0 20.7 124.0 86.9 1784.0 17.1 116.7 98.1 1735.0 14.3

YCWS0140SC

40.0 127.8 88.1 1834.0 17.4 120.4 99.8 1786.0 14.5 112.9 112.9 1740.0 12.0

42.0 132.9 88.3 1896.0 18.1 125.4 100.2 1847.0 15.0 1 17.7 1 13.1 1798.0 12.5

44.0 138.2 88.5 1960.0 18.7 130.5 100.5 1909.0 15.6 122.6 113.4 1858.0 13.0

45.0 140.9 88.5 1993.0 19.1 133.1 100.7 1940.0 15.9 125.1 113.6 1889.0 13.2

46.0 143.6 88.6 2025.0 19.5 135.7 100.8 1973.0 16.2 127.7 113.7 1920.0 13.5

48.0 149.2 88.6 2093.0 20.2 141.1 101.1 2038.0 16.7 132.8 114.1 1983.0 14.0

50.0 154.9 88.6 2161.0 21.0 146.6 101.3 2105.0 17.4 138.1 114.4 2047.0 14.5

IPLV = 18.8

IPLV = 18.2

IPLV = 19.3

YCWS0180SC

40.0 156.6 97.9 2213.0 19.2 147.7 1 11.5 2153.0 15.9 138.5 126.2 2093.0 13.2

42.0 163.2 98.0 2292.0 20.0 153.9 1 11.8 2229.0 16.5 144.5 126.5 2166.0 13.7

44.0 169.6 97.9 2369.0 20.8 160.3 112.0 2306.0 17.2 150.6 126.8 2240.0 14.3

45.0 172.9 97.9 2409.0 21.2 163.6 112.1 2345.0 17.5 153.7 126.9 2278.0 14.5

46.0 176.5 97.8 2452.0 21.7 166.5 112.2 2380.0 17.8 156.9 127.1 2317.0 14.8

48.0 183.5 97.5 2535.0 22.6 173.6 112.4 2466.0 18.5 163.4 127.4 2395.0 15.4

50.0 190.9 97.2 2622.0 23.6 180.5 112.5 2549.0 19.3 170.0 127.7 2476.0 16.0

NOTES:

1. Tons = Unit Cooling Capacity Output

2. kW = Compressor Input Power

3. MBH = Condenser heat rejection

4. EER = Chiller Energy Efficiency Ratio (Capacity [Tons x 12] ÷ kW)

5. LCWT = Leaving Chilled Water Temperature

6. Ratings based on 2.4 GPM cooler water per ton

7. Ratings certified in accordance with ARI Standard 550/590-98 up to 200 tons.

14

IPLV = 20.9

YORK INTERNATIONAL

FORM 201.24-EG1

LEA VING CONDENSER WA TER TEMPERA TURE (°F)

LCWT 85.0 95.0 105.0

(°F) TONS KW MBH EER TONS KW MBH EER TONS KW MBH EER

YCWS0200SC

IPLV = 21.8

40.0 179.1 110.1 2525.0 19.5 168.8 125.4 2454.0 16.2 158.3 142.0 2384.0 13.4

42.0 186.3 110.2 2611.0 20.3 175.7 125.7 2538.0 16.8 165.1 142.3 2467.0 13.9

44.0 194.0 110.1 2703.0 21.1 183.2 126.0 2629.0 17.4 171.9 142.6 2549.0 14.5

45.0 197.8 110.1 2749.0 21.6 186.7 126.1 2671.0 17.8 175.6 142.8 2594.0 14.8

46.0 201.7 110.0 2796.0 22.0 190.6 126.2 2717.0 18.1 179.1 143.0 2637.0 15.0

48.0 209.6 109.8 2890.0 22.9 198.3 126.4 2811.0 18.8 186.6 143.3 2729.0 15.6

50.0 217.7 109.4 2986.0 23.9 206.2 126.5 2906.0 19.6 194.3 143.7 2821.0 16.2

YCWS0220SC

IPLV = 20.8

40.0 195.2 121.3 2756.0 19.3 183.8 138.1 2677.0 16.0 172.5 156.2 2603.0 13.3

42.0 203.1 121.4 2851.0 20.1 191.7 138.5 2773.0 16.6 179.7 156.6 2691.0 13.8

44.0 211.2 121.4 2948.0 20.9 199.6 138.8 2869.0 17.3 187.5 157.0 2786.0 14.3

45.0 215.3 121.4 2997.0 21.3 203.7 138.9 2918.0 17.6 191.2 157.2 2831.0 14.6

46.0 219.5 121.3 3047.0 21.7 207.6 139.1 2966.0 17.9 195.4 157.4 2882.0 14.9

48.0 228.4 121.1 3154.0 22.6 215.4 139.3 3060.0 18.6 203.4 157.8 2980.0 15.5

50.0 237.3 120.7 3260.0 23.6 224.7 139.4 3171.0 19.3 21 1.5 158.2 3078.0 16.0

YCWS0240SC

IPLV = 21.2

40.0 210.6 132.7 2981.0 19.0 198.0 151.0 2891.0 15.7 185.9 170.7 2814.0 13.1

42.0 219.2 132.9 3084.0 19.8 205.9 151.4 2988.0 16.3 193.9 171.2 2911.0 13.6

44.0 228.1 133.0 3191.0 20.6 215.4 151.8 3102.0 17.0 202.3 171.6 3014.0 14.1

45.0 232.6 132.9 3245.0 21.0 219.7 152.0 3155.0 17.3 206.5 171.9 3065.0 14.4

46.0 237.2 132.9 3299.0 21.4 224.1 152.2 3208.0 17.7 210.8 172.1 31 16.0 14.7

48.0 246.5 132.7 3411.0 22.3 233.1 152.4 3317.0 18.4 219.4 172.6 3222.0 15.3

50.0 256.1 132.4 3524.0 23.2 242.3 152.6 3429.0 19.1 228.3 173.1 3330.0 15.8

NOTES:

1. Tons = Unit Cooling Capacity Output

2. kW = Compressor Input Power

3. MBH = Condenser heat rejection

4. EER = Chiller Energy Efficiency Ratio (Capacity [Tons x 12] ÷ kW)

5. LCWT = Leaving Chilled Water Temperature

6. Ratings based on 2.4 GPM cooler water per ton

7. Ratings certified in accordance with ARI Standard 550/590-98 up to 200 tons.

YORK INTERNATIONAL

15

Ratings (R-22 SI)

LEAVING CONDENSER W A TER TEMPERA TURE (°C)

LCWT 30.0 35.0 40.0

(°C) KWo KWi KW COP KWo KWi KW COP KWo KWi KW COP

YCWS0100SC

5.0 316.4 64.1 380.0 4.9 299.5 71.6 371.0 4.2 282.3 79.8 362.0 3.5

6.0 328.1 64.3 392.0 5.1 310.8 71.8 382.0 4.3 293.2 80.0 373.0 3.7

7.0 340.1 64.4 404.0 5.3 322.4 72.1 394.0 4.5 304.3 80.2 384.0 3.8

8.0 352.4 64.5 416.0 5.5 334.4 72.3 406.0 4.6 315.7 80.4 396.0 3.9

9.0 365.1 64.5 429.0 5.7 346.5 72.5 419.0 4.8 327.6 80.7 408.0 4.1

10.0 377.9 64.4 442.0 5.9 359.0 72.7 431.0 4.9 339.5 81.0 420.0 4.2

YCWS0120SC

5.0 382.2 76.7 458.0 5.0 362.1 85.7 447.0 4.2 341.6 95.6 437.0 3.6

6.0 396.1 76.9 473.0 5.2 375.6 86.0 461.0 4.4 354.6 95.8 450.0 3.7

7.0 410.5 77.0 487.0 5.3 389.5 86.3 475.0 4.5 368.0 96.1 464.0 3.8

8.0 425.1 77.1 502.0 5.5 403.6 86.5 490.0 4.7 381.7 96.4 478.0 4.0

9.0 440.1 77.1 517.0 5.7 418.2 86.7 504.0 4.8 395.7 96.7 492.0 4.1

10.0 455.5 77.1 532.0 5.9 432.9 86.9 519.0 5.0 410.0 96.9 507.0 4.2

YCWS0140SC

5.0 452.5 89.3 541.0 5.1 428.9 100.0 528.0 4.3 405.4 111.6 517.0 3.6

6.0 468.9 89.5 558.0 5.2 444.9 100.3 545.0 4.4 420.5 111.8 532.0 3.8

7.0 485.7 89.7 575.0 5.4 461.2 100.6 561.0 4.6 436.0 112.1 548.0 3.9

8.0 502.9 89.8 592.0 5.6 477.8 100.8 578.0 4.7 452.3 112.4 564.0 4.0

9.0 520.5 89.9 610.0 5.8 494.9 101.1 596.0 4.9 468.6 112.8 581.0 4.2

10.0 538.6 89.9 628.0 6.0 511.9 101.3 613.0 5.1 485.6 113.1 598.0 4.3

YCWS0180SC

5.0 554.1 99.4 653.0 5.6 525.2 111.7 636.0 4.7 496.0 124.8 620.0 4.0

6.0 574.6 99.4 674.0 5.8 545.2 111.9 657.0 4.9 515.0 125.1 640.0 4.1

7.0 594.4 99.4 693.0 6.0 565.5 112.1 677.0 5.0 534.1 125.4 659.0 4.3

8.0 616.7 99.3 716.0 6.2 586.3 112.3 698.0 5.2 554.7 125.7 680.0 4.4

9.0 638.9 99.2 738.0 6.4 608.8 112.5 721.0 5.4 575.7 125.9 701.0 4.6

10.0 661.6 98.9 760.0 6.7 629.2 112.5 741.0 5.6 596.4 126.2 722.0 4.7

NOTES:

1. KWo = Unit kW Cooling Capacity Output

2. KWi = Compressor kW Input

3. COP = Coefficient of Performance

4. LCWT= Leaving Chilled Water Temperature

5. Ratings based on 0.047 l/s cooler water per kW.

16

YORK INTERNATIONAL

Loading...

Loading...