York CZH024 THRU 060 User Manual

TECHNICAL GUIDE

AFFINITY

R-410A SPLIT-SYSTEM AIR CONDITIONERS

18 SEER

MODELS: CZH024 THRU 060

(2 THRU 5 NOMINAL TONS)

ISO 9001

LISTED

Due to continuous product improvement, specific a t ion s

are subject to change without notice.

Visit us on the web at www.york.com for the most

up-to-date technical information.

Additional rating information can be foun d at

www.ariprimenet.org.

Certified Quality

Management System

350154-YTG-B-0408

DESCRIPTION

The CZH Series condensing unit is the outdoor part of a versatile

air conditioning system. It is designed to be custom matched with

one of our complete line of evaporator sections, each designed to

serve a specific function. Matching air handlers are available for

upflow, downflow, and horizontal lef t or right applic ation to provi de a

complete system. Electric heaters are available if required. Add-on

coils are available for use with upflow, downflow, or horizontal furnaces. Field installed accessories are available as needed.

WARRANTY

5-year limited parts warranty.

10-year limited compressor warranty.

Premium System Warranty - Limited lifetime compressor and 10year parts when matched with an approved York Affinity furnace or

UPG air handler and coil.

FEATURES

• Superior Coil Protection – A stamped decorative metal coil

guard completely protects coil from debris and other large damaging material while a polymer mesh further protects the coil

against smaller particles.

• Isolated Compressor Compartment – A molded composite

bulkhead isolates the compressor from the rest of the u nit red ucing sound and vibration.

• Protected Compressors – Each compressor is protected

against abnormal pressures by an internal pressure relief valve

and factory installed high and low pressure controls. Additional

protection against moisture and debris is provided by factory

installed liquid line filter driers.

• Environmentally Friendly Refrigerant – Next generation

refrigerant R-410A delivers environmentally friendly performance with zero ozone depletion.

• Durable Finish – Automotive quality finish provides the ultimate

protection from harmful U.V. rays and rust creep ensuring longlasting high quality appearance. A powder-paint topcoat is

applied over a baked-on primer, using a galvanized, zinc coated

steel base material. The result is a finish that has been p roven in

testing to provide 33% greater durability than conventional powder-coat finishes.

• Lower Installed Cost – Designed to provide enhanced installability by featuring a slide-down control compartment and angled

service valves to reduce overall install ation time and cost.

• Low Operating Sound Levels – A fan design boasting technology adapted from aeronautic and defense engineering provides

for whisper quiet operation by allowing airflow to flow smoothly

and efficiently across the fan tips.

• Filter-Drier – A factory installed, solid core liquid line filter-drier

filters harmful debris and moisture from the system.

• Easy Service Access – A full end, full service, access panel

with handle makes for easy entry to internal components.

• Composite Base - Strong and durable composite base pan

resists rust and corrosion while it helps reduce vibrations and

noise.

•

Quiet drive system - Features combination of swept-wing fan,

composite base pan, isolated compressor compartment and

two-stage compressor to reduce overall sound to a mere whisper.

• Low RPM fan motor - Helps to reduce airflow noise.

Certified in accordance with the Unitary Small Equipment certification program, which is based on ARI Standard 210/240.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

350154-YTG-B-0408

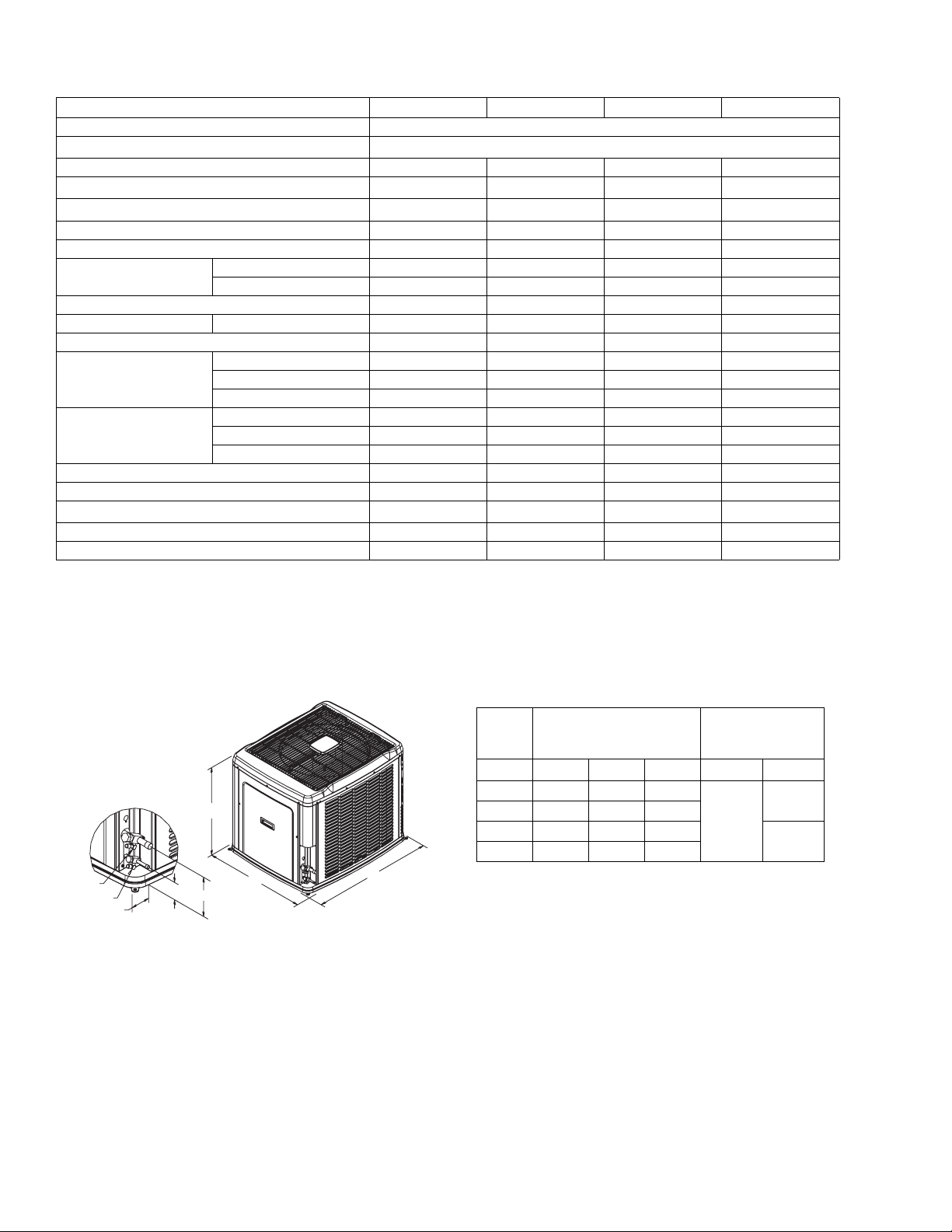

Physical and Electrical Data

MODEL

CZH02411 CZH03611 CZH04811 CZH06011

Unit Supply Voltage 208-230V, 1φ, 60Hz

Normal Voltage Range

1

187 to 252

Minimum Circuit Ampacity 15.6 23.6 29.2 34.8

Max. Overcurrent Device Amps

Min. Overcurrent Device Amps

2

3

25 40 50 60

20 25 30 35

Multi-stage Compressor Yes Yes Yes Yes

Compressor Type Scroll Scroll Scroll Scroll

Compressor Amps

Rated Load 10.3 16.7 21.2 25.6

Locked Rotor 52 82 96 118

Crankcase Heater No No No No

Fan Motor Amps Rated Load 2.8 2.8 2.8 2.8

Fan Diameter Inches 24 24 24 24

Rated HP 1/3 1/3 1/3 1/3

Fan Motor

Nominal RPM 685 685 685 685

Nominal CFM 2900 3200 3100 3150

Face Area Sq. Ft. 23.58 23.58 23.58 23.58

Coil

Rows Deep 2 2 2 2

Fins / Inch 16 16 14 14

Liquid Line Set OD (Field Installed) 3/8 3/8 3/8 3/8

Vapor Line Set OD (Field Installed) 3/4 3/4 7/8 7/8

Unit Charge (Lbs. - Oz.)

4

15 - 1 13 - 7 12 - 9 13 - 5

Charge Per Foot, Oz. 0.62 0.62 0.67 0.67

Operating Weight Lbs. 305 305 310 330

1 Rated in accordance with ARI Standard 110, utilization range “A”.

2 Dual element fuses or HACR circuit breaker. Maximum allowable overcurrent protection.

3 Dual element fuses or HACR circuit breaker. Minimum recommended overcurrent protection.

4 The Unit Charge is correct for the outdoor unit, matched indoor coil and 15 feet of refrigerant tubing. For tubing lengths other than 15

feet, add or subtract the amount of refrigerant, using the difference in length multiplied by the per foot value.

VAPOR

LIQUID

2-3/8

3-1/8

6-1/2

All dimensions are in inches. They are subject to change without

notice. Certified dimensions will be provided upon request.

Unit

Model

Dimensions

(Inches)

Refrigerant

Connection

Service Valve Size

A B C Liquid Vapor

24 39-1/2 42 34

A

36 39-1/2 42 34

48 39-1/2 42 34

3/8”

60 39-1/2 42 34

C

B

3/4”

7/8”

2 Johnson Controls Unitary Products

350154-YTG-B-0408

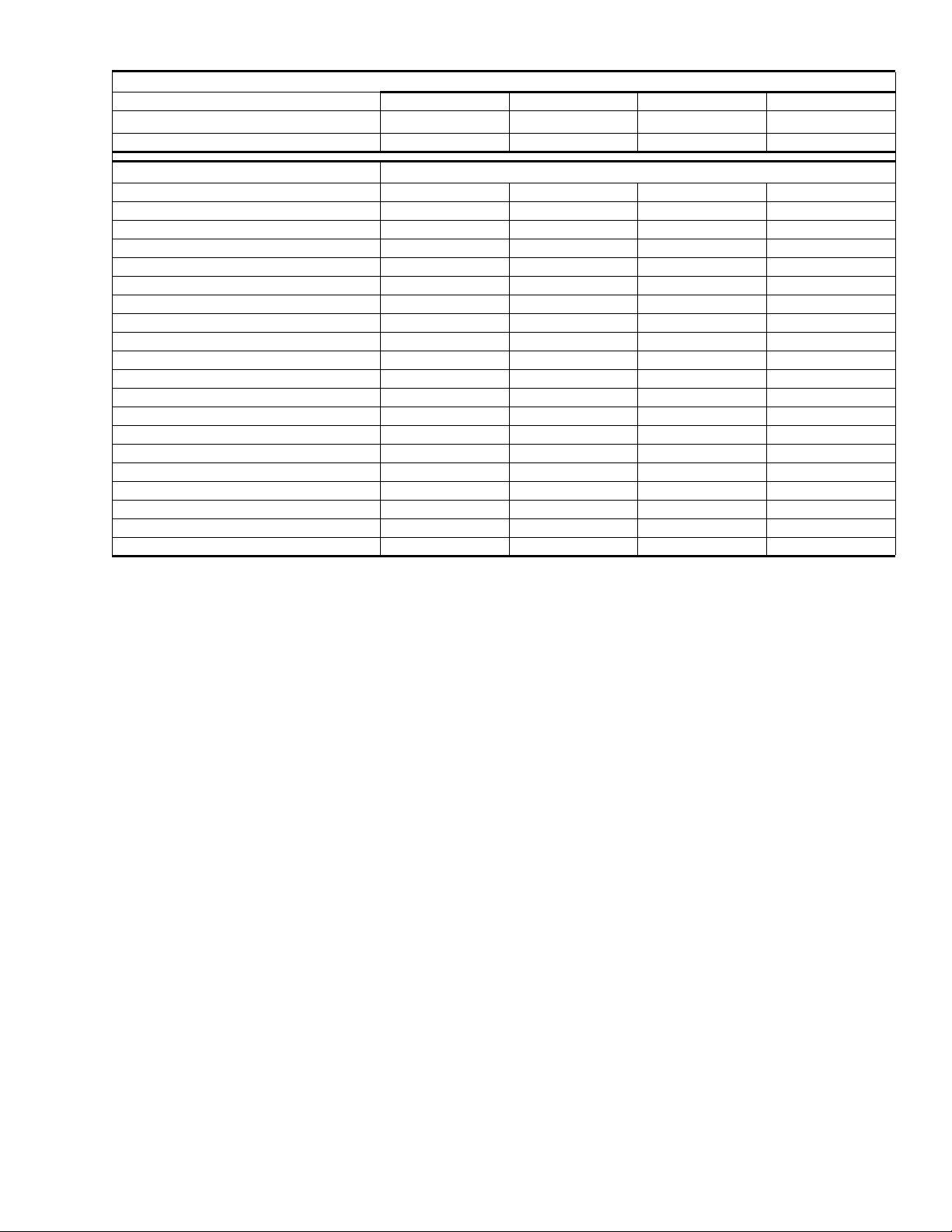

Additional R-410A Charge / TXV Size for Various Matched Systems

Outdoor Unit CZH02411 CZH03611 CZH04811 CZH06011

Approved System Thermal Expansion Valve

Factory R-410A Charge, lbs-oz 16 - 2 15 - 14 13 - 8 14 - 1

Indoor Coil

FC/MC/PC32A 1 – – –

FC/MC/PC35B 0 – – –

FC/MC/PC35C 0 – – –

FC/MC/PC37A 7 24 – –

FC/MC/PC43B 7 24 – –

FC/MC/PC43C 7 24 – –

FC/MC/PC48C 17 7 10 –

FC/MC/PC48D 17 7 10 –

FC/PC60C –––0

FC/MC/PC60D –––0

FC/MC62D – 39 15 12

HC36B 0 – – –

HC42C – 24 – –

HC60D – – 1 0

UC48D 17 7 10 –

UC60D –––0

AV36C 7 0 – –

AV/SV48D – – 1 –

AV/SV60D – – 0 0

F4FV060D – – 1 0

FOOTNOTES:

PROCEDURES:

2

1 Systems matched with furnace or air handlers not equipped with blower-off delays may require blower Time Delay Kit 2FD06700224.

2 PC coils cannot be used in downflow or horizontal applications. FC coils cannot be used in horizontal applications.

3 A TXV kit must be used with these coils to obtain system performance.

Note: If a TXV is factory installed on the coil, it must be replaced with the listed TXV.

1. Unit factory charge listed on the unit nameplate includes refrigerant for the condenser, the smallest evaporator and 15 feet of interconnecting line tubing.

2. Verify the TXV and additional charge required for specific evaporator coil in the system using the above table.

3. Additional charge for the amount of interconnecting line tubing greater than 15 feet at the rate specified on the previous page.

4. Permanently mark the unit nameplate with the total system charge. Total System Charge = Base Charge (as shipped) + adder for

evaporator + adder for line set.

1

1TVM902 1TVM904 1TVM905 1TVM906

TXV Kit3 - Additional Charge, Oz

Johnson Controls Unitary Products 3

350154-YTG-B-0408

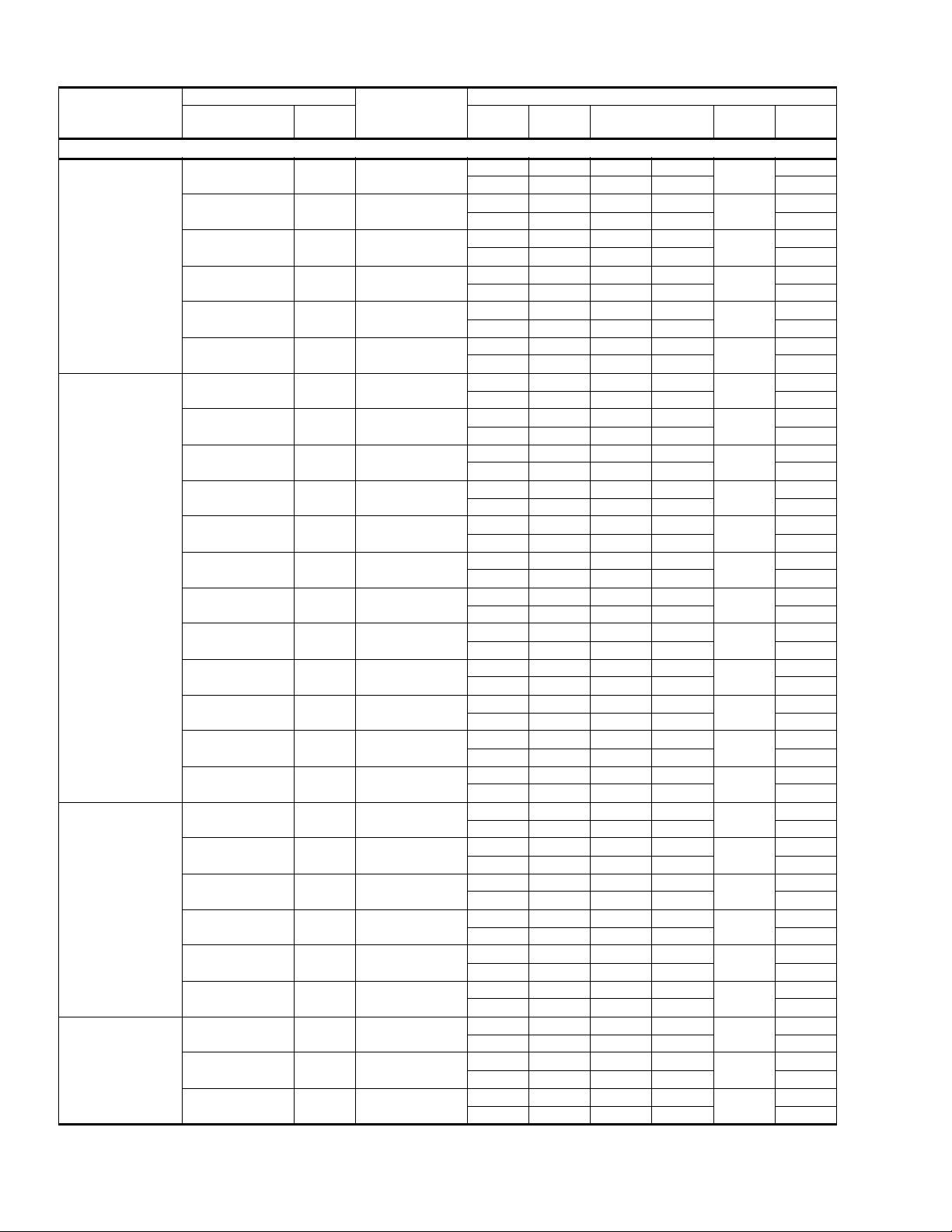

COOLING CAPACITY - With Air Handler Coils

UNIT

MODEL

CZH02411

CZH03611

CZH04811

CZH06011

For notes see Page 5.

AIR HANDLER

MODEL W STAGE

1 PH 18 SEER AC WITH MV

MV12B 17 FC/MC/PC35B

MV12B 17 FC/MC/PC35C

MV12B 17 FC/MC/PC43B

MV12B 17 FC/MC/PC43C

MV12D 24 FC/MC/PC48D

MV12D 24 UC48D

MV12B 17 FC/MC/PC43B

MV12B 17 FC/MC/PC43C

MV16C 21 FC/MC/PC43C

MV12D 24 FC/MC/PC48D

MV12D 24 UC48D

MV16C 21 FC/MC/PC48C

MV16C 21 FC/MC/PC48D

MV16C 21 UC48D

MV20D 24 FC/MC/PC48D

MV20D 24 UC48D

MV12D 24 FC/MC62D

MV20D 24 FC/MC62D

MV16C 21 FC/MC/PC48C

MV16C 21 FC/MC/PC48D

MV16C 21 UC48D

MV20D 24 FC/MC/PC48D

MV20D 24 UC48D

MV20D 24 FC/MC62D

MV20D 24 FC/MC/PC60D

MV20D 24 UC60D

MV20D 24 FC/MC62D

COIL

MODEL

COOLING

1

RATED

CFM

1 620 18.2 13.8

2 800 23.6 17.2 13.80

1 620 18.2 13.8

2 800 23.6 17.2 13.80

1 620 18.5 14.0

2 800 24.0 17.5 14.00

1 620 18.5 14.0

2 800 24.0 17.5 14.00

1 645 18.9 14.3

2 835 24.6 17.9 14.45

1 645 18.9 14.3

2 835 24.6 17.9 14.45

1 775 25.6 18.0

2 1200 36.0 25.2 13.55

1 775 25.6 18.0

2 1200 36.0 25.2 13.55

1 775 25.7 18.1

2 1200 36.2 25.3 14.00

1 735 25.6 18.0

2 1135 36.0 25.2 13.95

1 735 25.6 18.0

2 1135 36.0 25.2 13.95

1 775 25.9 18.2

2 1200 36.4 25.4 14.15

1 775 25.9 18.2

2 1200 36.4 25.4 14.15

1 775 25.9 18.2

2 1200 36.4 25.4 14.15

1 770 25.8 18.1

2 1200 36.6 25.6 14.20

1 770 25.8 18.1

2 1200 36.6 25.6 14.20

1 735 25.7 18.1

2 1135 36.6 25.6 14.25

1 770 25.9 18.2

2 1200 37.0 25.9 14.35

1 1000 34.0 25.1

2 1600 46.0 35.1 12.45

1 1000 34.0 25.1

2 1600 46.0 35.1 12.45

1 1000 34.0 25.1

2 1600 46.0 35.1 12.45

1 1020 34.0 25.1

2 1600 46.0 35.1 12.35

1 1020 34.0 25.1

2 1600 46.0 35.1 12.35

1 1020 34.1 25.2

2 1600 46.5 35.5 12.50

1 1030 40.2 27.3

2 1800 55.5 40.5 11.55

1 1030 40.2 27.3

2 1800 55.5 40.5 11.55

1 1030 42.1 28.6

2 1800 58.0 42.3 12.00

NET MBH SEER EER

17.05

17.05

17.20

17.20

18.00

18.00

17.70

17.70

18.00

18.40

18.40

18.40

18.40

18.40

18.30

18.30

18.50

18.30

17.30

17.30

17.30

17.00

17.00

17.00

15.30

15.30

16.00

14.50

14.50

14.65

14.65

15.25

15.25

14.90

14.90

15.00

15.40

15.40

15.40

15.40

15.40

15.30

15.30

15.40

15.30

14

.20

14.20

14.20

14.00

14.00

14.05

12.55

12.55

13.20

4 Johnson Controls Unitary Products

350154-YTG-B-0408

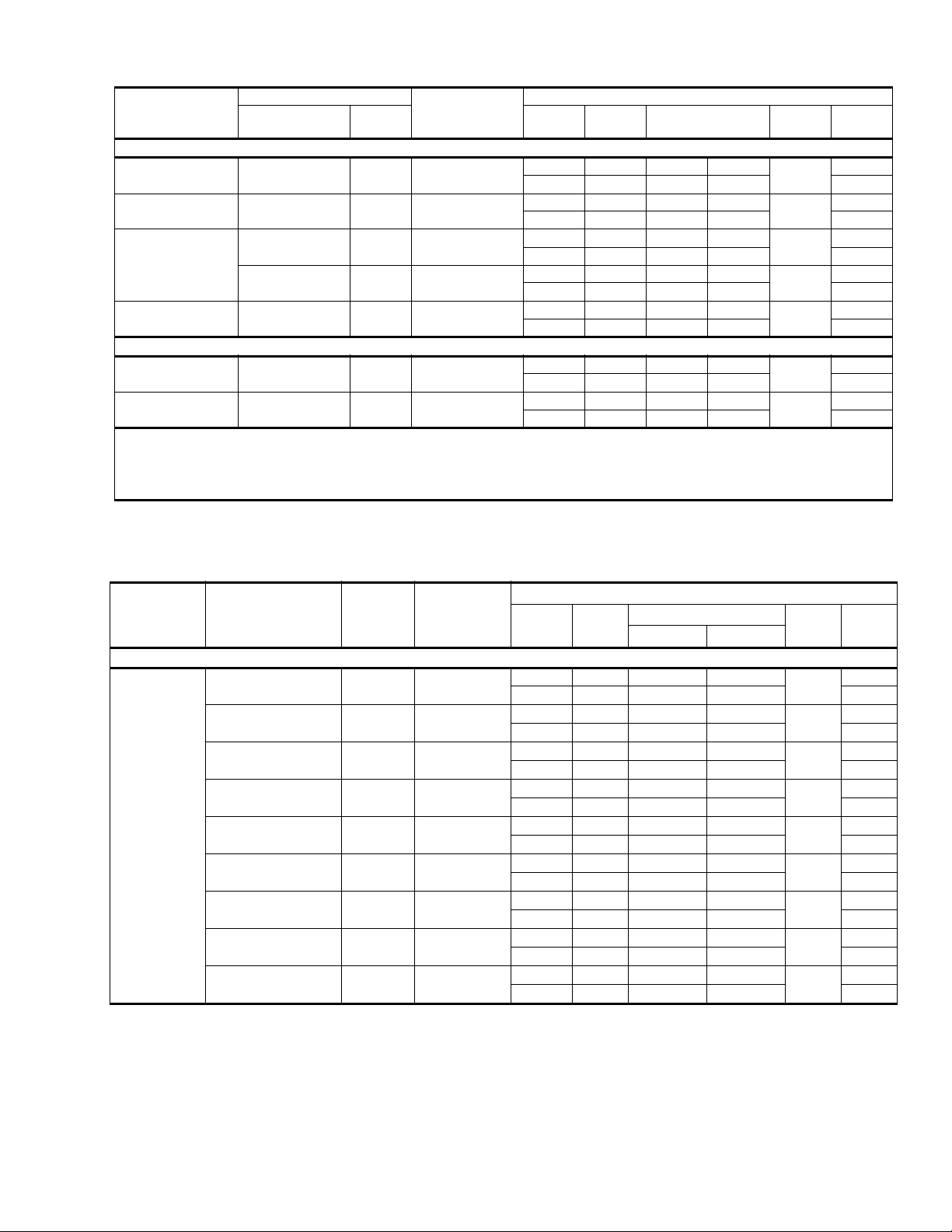

COOLING CAPACITY - With Air Handler Coils (Continued)

UNIT

MODEL

AIR HANDLER

MODEL W STAGE

COIL

MODEL

1

RATED

CFM

1 PH 18 SEER AC WITH AV/SV

CZH02411 AV36C 21 N / A

CZH03611 AV36C 21 N / A

AV/SV48D 24 N / A

CZH04811

AV/SV60D 24 N / A

CZH06011 AV/SV60D 24 N / A

1 600 18.4 13.9

2 765 23.8 17.3 14.10

1 830 25.7 18.1

2 1270 35.6 24.9 13.45

1 1135 33.1 24.4

2 1610 44.5 34.0 12.10

1 1085 33.0 24.4

2 1655 44.5 34.0 12.10

1 1145 41.5 28.2

2 1765 55.5 40.5 11.65

1 PH 18 SEER AC WITH F*F*

CZH04811 F4FV060 24 N / A

CZH06011 F4FV060 24 N / A

Rated in accordance with DOE test procedures (Federal Register 12-27-79 and 3-18-88) and ARI Standards 210.

Cooling MBH based on 80°F entering air temperature, 50% RH, and rated air flow.

EER (Energy Efficiency Ratio) is the total cooling output in BTU’s at 95°F outdoor ambient divided by the total electric power in watt-hours at those conditions.

SEER (Seasonal Energy Efficiency Ratio) is the total cooling output in BTU’s during a normal annual usage period for cooling divided by the total electric power

input in watt-hours during the same period.

1 1200 33.6 24.8

2 1600 44.5 34.0 12.15

1 1200 41.8 28.4

2 1780 55.5 40.5 11.60

COOLING

NET MBH SEER EER

17.60

18.00

16.60

16.50

15.70

16.85

15.55

14.95

15.25

13.60

13.60

13.00

13.75

12.80

1 MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

COOLING CAPACITY - With Variable Speed Furnaces

UNIT MODEL

VARIABLE SPEED

FURNACE MODEL

CZH02411

For notes see Page 8.

PV8*A12 14 FC/MC/PC32A

PV9*A12 14 FC/MC/PC32A

P(C,V)9*B12 17 FC/MC/PC35B

P(C,V)9*B12 17 FC/MC/PC35C

PV8*A12 14 FC/MC/PC37A

PV9*A12 14 FC/MC/PC37A

P(C,V)9*B12 17 FC/MC/PC43B

P(C,V)9*B12 17 FC/MC/PC43C

P(C,V)9*B12 17 HC36B

COIL

MODEL

1

W

STAGE

RATED

CFM

TOTAL SENSIBLE

1 PH 18 SEER AC WITH VARIABLE SPEED FURNACES

1 470 17.2 13.0

2 750 23.2 16.9 13.55

1 625 18.1 13.7

2 800 23.2 16.9 13.05

1 560 17.9 13.6

2 820 23.4 17.0 13.45

1 560 17.9 13.6

2 820 23.4 17.0 13.45

1 470 17.4 13.2

2 750 23.6 17.2 13.75

1 625 18.6 14.1

2 800 23.6 17.2 13.30

1 560 18.1 13.7

2 820 24.0 17.5 13.70

1 560 18.1 13.7

2 820 24.0 17.5 13.70

1 560 17.9 13.6

2 820 23.4 17.0 13.55

COOLING

NET MBH

SEER EER

16.70

16.60

17.05

17.05

17.00

17.00

17.35

17.35

17.10

14.15

14.25

14.55

14.55

14.35

14.60

14.70

14.70

14.55

Johnson Controls Unitary Products 5

Loading...

Loading...