York ARC 045, ARC 060, ARG 060, ARC 075, ARC 090 Installation Manual

...

ACTIVA SERIES ROOF TOP Air

Conditioners

Installation manual

Ref.: N-40XXX

Index

1 Installation manual.................................................................................................................. 1

1.1 Safety instructions.................................................................................................................. 2

1.2 Icons used in this document................................................................................................... 2

1.3 Instructions for storage, transport, loading and unloading of the unit.................................... 3

1.3.1 Disposal of packaging............................................................................................................ 3

1.3.2 Lifting points........................................................................................................................... 3

1.4 Technical data........................................................................................................................ 4

1.4.1 Technical and physical data for ARC (cool only) and ARG (cool only + gas heat)................ 4

1.4.2 ARH technical and physical data (heat pump) and ARD (heat pump + gas heat)................. 5

1.4.3 Weight options and accessories............................................................................................. 7

1.5 ARC units with electric heater................................................................................................ 7

1.6 ARH units with electric heater................................................................................................ 7

1.7 Limits of use........................................................................................................................... 8

1.8 Power and application data for gas ARG / ARD.................................................................... 8

1.9 Hot water coil, optional in ARC/ARH...................................................................................... 9

1.10 Measurements, clearances and accesses........................................................................... 10

1.10.1 Connections for supply and return side ducts...................................................................... 10

1.10.2 General dimensions and accesses (models 045/060)......................................................... 11

1.10.3 General dimensions and accesses (models 075/090)......................................................... 12

1.11 ARC/ARG Performance....................................................................................................... 13

1.11.1 ARC/ARG 045 Cooling capacities........................................................................................ 13

1.11.2 ARC/ARG 060 Cooling capacities........................................................................................ 13

1.11.3 ARC/ARG 075 Cooling capacities........................................................................................ 14

1.11.4 ARC/ARG 090 Cooling capacities........................................................................................ 14

1.12 ARH/ARD Output................................................................................................................. 15

1.12.1 ARH/ARD 045 Cooling capacities........................................................................................ 15

1.12.2 ARH/ARD 060 Cooling capacities........................................................................................ 15

1.12.3 ARH/ARD 075 Cooling capacities........................................................................................ 16

1.12.4 ARH/ARD 090 Cooling capacities........................................................................................ 16

1.12.5 ARH/ARD 045 Thermodynamic heat capacity..................................................................... 16

1.12.6 ARH/ARD 060 Thermodynamic heat capacity..................................................................... 17

1.12.7 ARH/ARD 075 Thermodynamic heat capacity..................................................................... 17

1.12.8 ARH/ARD 090 Thermodynamic heat capacity..................................................................... 18

1.13 Indoor fan............................................................................................................................. 18

1.13.1 Features table...................................................................................................................... 18

1.13.2 Considerations when consulting the output tables............................................................... 18

1.13.3 Output table for indoor fan, model ARC-045, applications with side ducts, standard drive motor

3 kW..................................................................................................................................... 19

1.13.4 Performance table for inside fan, model ARC-045, applications with side ducts, optional

operation HPD motor 4 kW.................................................................................................. 19

1.13.5 Output table for indoor fan, model ARC-060, applications with side ducts, standard drive motor

4 kW..................................................................................................................................... 19

Index

i

1.13.6 Output table for indoor fan, model ARC-060, applications with side ducts, optional HPD drive

motor 5.5 kW........................................................................................................................ 20

1.13.7 Output table for indoor fan, model ARC-075, applications with side ducts, standard drive motor

5.5 kW.................................................................................................................................. 20

1.13.8 Performance table for inside fan, model ARC/ARH-075, applications with side ducts, optional

operation HPD motor 7.5 kW............................................................................................... 20

1.13.9 Output table for indoor fan, model ARC/ARH-090, applications with side ducts, standard drive

motor 7.5 kW and optional HPD motor 9.2 kW.................................................................... 21

1.13.10 Output table for indoor fan, model ARC/ARH-090, applications with side ducts, optional HPD

drive motor 11 kW................................................................................................................ 21

1.14 Pressure drop of options/accessories, gas heating and vertical ducts................................ 21

1.15 Instructions for installation and connection of the unit......................................................... 22

1.15.1 Characteristics of the placement.......................................................................................... 22

1.15.2 Characteristics of the facility where the unit will be installed................................................ 22

1.15.3 Specifications for the foundation or anchoring of the unit.................................................... 23

1.15.4 Characteristics of utility provider connections...................................................................... 23

1.15.5 Preparation and connecting to the various utilities............................................................... 23

1.16 Instructions for starting up the unit....................................................................................... 29

1.16.1 Electrical checks................................................................................................................... 29

1.16.2 Starting the gas heating, ARG/ARD..................................................................................... 30

1.17 Unblocking the unit safely in case of breakdown................................................................. 33

1.18 Regular maintenance tasks performed by specialised personnel........................................ 34

1.18.1 Planned Maintenance Schedule........................................................................................... 34

1.18.2 Maintenance tasks performed by specialised personnel...................................................... 35

1.18.3 Gas heating (ARG/ARD Models).......................................................................................... 38

1.19 Unit sound pressure data..................................................................................................... 40

2 Unit installation data.............................................................................................................. 43

2.1 List of tests for unit start-up.................................................................................................. 44

2.2 Start-up Data........................................................................................................................ 45

Index

ii

1

Installation manual

1.1 Safety instructions

This document contains the necessary information for the safe and efficient transportation, assembly

and installation of the air conditioning unit. This guarantees the condition of the unit and its operating

safety.

Only an authorised company may assemble the air conditioning unit.

A T T E N T I O N

Only authorised companies with the appropriate technical resources and suitably trained personnel may

install the air conditioning unit.

C A U T I O N

The specialists responsible for installing the air conditioning unit must make sure they have all of the

information and knowledge required to correctly install, test and deliver the unit. Johnson Controls Inc.

shall not be considered responsible for any damage caused by installation of the unit that is no consistent

with that described in this document or others specifically provided with the unit.

During regular unit installations, the fitter must pay special attention to certain situations in order to pre‐

vent injuries or damage to the unit.

Situations that could jeopardise the safety of the fitter or that of others nearby or that could put the unit

itself at risk are clearly indicated in this manual.

A series of special symbols are used to clearly identify these situations.

Pay careful attention to these symbols and to the messages following them, as your safety and the safety

of others depends on it.

1.2 Icons used in this document

D A N G E R

• The text following this symbol contains information and instructions relating directly to your safety

and physical wellbeing.

• Not taking these instructions into account could lead to serious, very serious or even fatal injuries to

you and others in the proximities of the unit.

Information can also be found on safe procedures during unit handling. This will help reduce the risk of

accidents.

C AU T I O N

• The text following this symbol contains information and instructions relating directly to your safety

and physical wellbeing.

• Not taking these instructions into account could lead to minor injuries to you and others in the prox‐

imities of the unit.

• Not taking these instructions into account could lead to unit damage.

Information can also be found on safe procedures during unit handling. This will help reduce the risk of

accidents.

N OT E

• The text following this symbol contains information or instructions that may be of use or that is worthy

of a more thorough explanation.

• Instructions regarding inspections to be made on unit parts or systems may also be included.

1

Installation manual

1.1 Safety instructions

2

1.3 Instructions for storage, transport, loading and unloading of

the unit

Delivery inspection

The unit should be carefully inspected for visible damage or abnormalities as soon as it is received.

Any abnormalities or damage to the unit should be communicated to both the transportation and insur‐

ance company in writing.

Storage instructions

The unit should be stored in a place suitable to the purpose (warehouse or similar), protected from the

weather, water, humidity and dust.

Cover the unit with a canvas of a suitable size.

The unit should be appropriately protected from knocks and dust, ensuring the protective parts it was

supplied with remain in place. Where these are not in place, establish the necessary protection and

barriers to keep vehicles or fork-lift trucks away.

Transport, loading and unloading of the unit

The units should only be handled by personnel from the company responsible for their installation.

Transport of the unit should be in such a manner that no damage is caused by faulty or inadequate

mooring to the bed or body of the vehicle.

Where necessary, protect all of the edges of the unit against knocks and scratches and moor it to the

bed or body of the vehicle using suitable textile belts or slings to keep it perfectly still.

Loading and unloading the unit from a truck or trailer should be on flat, solid ground using an appropriate

crane with sufficient capacity.

C AU T I O N

It is strictly prohibited to use fork lifts to load, unload, or handle the unit.

1.3.1 Disposal of packaging

The packaging is recyclable. Dispose of it in the appropriate place or take it to an appropriate collection

centre. Respect the regulations in force for this type of waste in the country where the unit is being

installed.

Packaging remains must be correctly disposed of. Improper disposal of packaging generates environ‐

mental problems that affect human life.

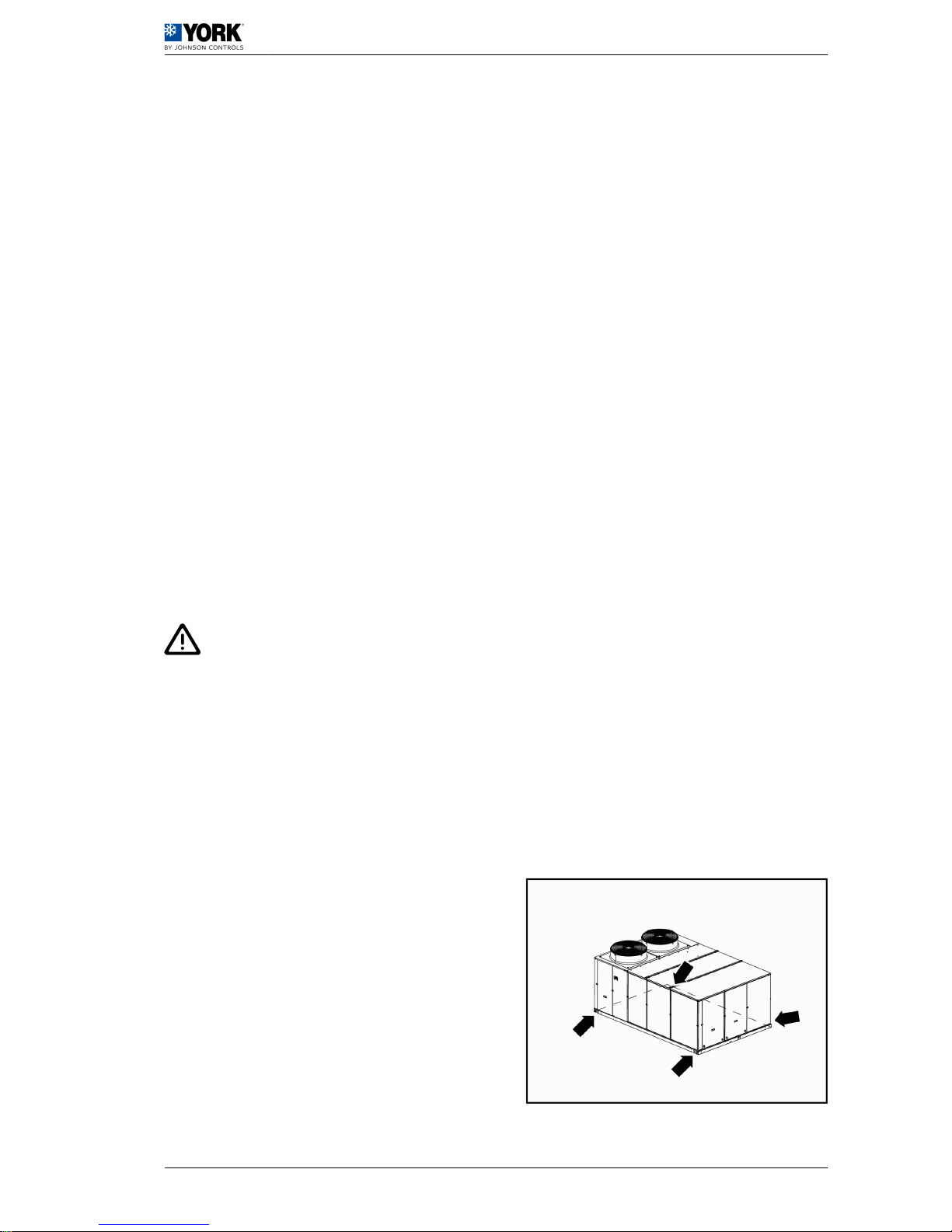

1.3.2 Lifting points

The points designed for lifting the unit are situated in

the beams at its base. -arrows-.

Before hoisting the unit, check that the cables or

slings are firmly hooked to these points and make

sure the crane and the cables or slings are capable of

lifting the weight.

Installation manual 1

Instructions for storage, transport, loading and unloading of the unit 1.3

3

Place separators -1- above the unit to prevent the ca‐

bles or slings from touching it.

Attach guide ropes so that that the unit does not rotate

freely.

The cables or slings should be long enough to form

an angle of over 45º to the horizontal plane. Hoist the

unit keeping it in a horizontal position.

D AN G E R

There should not be onlookers within a radius of 10

m of the unit when it is being hoisted.

Centre of gravity of the unit

Models 045 060 075 090

A 1180 1180 1135 1080

B 1390 1425 1480 1540

C 3180 3180 3495 3495

D 2337 2337 2337 2337

All measurements in mm.

1. Centre of gravity

2. End of the outdoor coil

1.4 Technical data

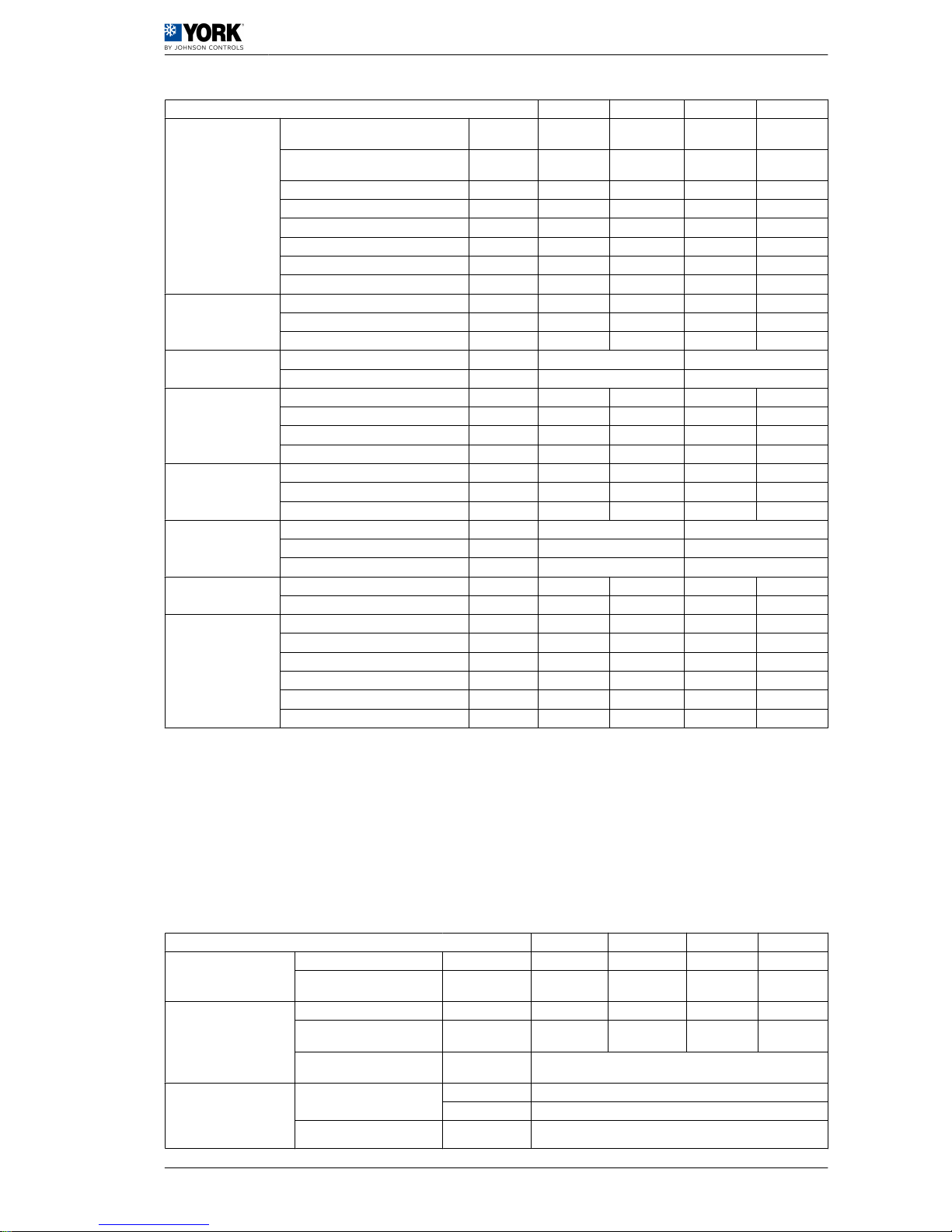

1.4.1 Technical and physical data for ARC (cool only) and ARG (cool only

+ gas heat)

Models ARC/ARG 045 060 075 090

Cooling capacity(1)

Net cooling capacity kW 45,1 61 71,5 84

Rated absorbed power in cool mode kW 16 23 30 36

Heating (ARC)

Optional electric heating capacity (400

V) (2)

kW 12-25-37-50

Gas Heating (ARG)

Heat capacity at 100% power (standard)

(LHV) Total

kW

85

Net (2) kW 76

Heat capacity at 100% power, high ca‐

pacity (optional)

Total kW 100

Net (2) kW 90

100% gas consumption (2ND-H natural

gas, G20 at 20 mbar and 15ºC) (stand‐

ard)

m3/h 8,6

100% gas consumption (2ND-H natural

gas, G20 at 20 mbar and 15ºC) high ca‐

pacity (optional)

m3/h 9,8

Stages No. 2

Compressors

Rated/start-up current A 2x12/95 2x15/118 2x20/140 2x25/198

Type and quantity SCROLL, 1 (TANDEM 50% + 50%)

Degree of protection IP21

Refrigerant (R-410A) kg 10,5 18,2 20,5 29

Electric power supply V / ph / Hz 400/3+N/50

Indoor fan (3)

Rated air flow m3/h 8500 11500 13500 16000

1 Installation manual

1.4 Technical data

4

Models ARC/ARG 045 060 075 090

Maximum static pressure with rated flow

(standard)

Pa 182 270 240 368

Maximum static pressure with rated flow

(optional HPD drive)

Pa 368 430 >500 >500

Maximum flow m3/h 10000 13500 16000 18000

Minimum flow m3/h 7000 9500 11500 13000

IP55 Motor (standard) kW 3 4 5,5 7,5

Rated current A 5,5 5,7 7,6 11,7

IP55 Motor (HPD optional) kW 4 5,5 7,5 9,2/11

Rated current A 5,7 7,6 11,7 14/17,4

Indoor coil (evaporator)

Number of elements No. 2 3 3 4

Distance between fins mm 1,81 1,81 1,81 1,81

Front surface m

2

1,44 1,58 1,95 1,06 (x 2)

Air filters (G4)

Quantity per unit No. 6 6

Dimensions mm 470x550x48 565x594x48

Outdoor fan

Diameter / number mm 800/1 800/2 800/2 800/2

Total rated flow m3/h 15000 23000 27000 27000

Motor (IP54) kW 1,9 1,9 1,9 1,9

Rated current A 3,5 2x3,5 2x3,5 2x3,5

Outdoor coil (condens‐

er)

Number of elements No. 2 3 2 3

Distance between fins mm 1,81 1,81 1,81 1,81

Front area m

2

2,27 2,49 2.31 (x2) 2.31 (x2)

Net dimensions (4)

Height mm 1316 1367

Length mm 3180 3495

Width mm 2337 2337

Net weight (basic unit

without accessories) (4)

ARC kg 900 945 1118 1142

ARG kg 1010 1055 1228 1252

Electrical features of

the unit

Total rated power kW 16 23 30 36

Total rated current A 32 42 54 70

Total maximum power kW 23 31 38 45

Total maximum current A 42 56 70 83

Circuit breaker (K Curve (5) A 50 63 80 100

Minimum cable section (6) mm

2

10 16 25 35

(1) Data comply with Eurovent conditions, summer: indoor 27 °C TS / 19 °C TH - outdoor TS 35 °C (TS Dry-bulb Thermometer; TH Wet-bulb thermometer).

(2) Add the inside motor consumption to find the total calorific capacity.

(3) See

Indoor fan , see on page 18

.

(4) Consider the additional weight of options and accessories. To do so, see

Weight options and accessories , see on page 7

.

LHV: Lower heating value.

(5) and (6) Circuit breaker with K curve, according to DIN, VDE 0660-104. Section of cables for the power supply line based on copper conductors, 105 ºC. The indicated

circuit breaker and the section of power supply cables are guidelines. They should be adjusted based on the requirements of each installation, distance between units, fall

in planned voltage and on the application of the current regulations with respect to the country where the unit is being installed.

1.4.2 ARH technical and physical data (heat pump) and ARD (heat pump

+ gas heat)

Models ARH/ARD 045 060 075 090

Cooling capacity(1)

Net cooling capacity kW 47,6 61,9 71,4 83,4

Rated absorbed power in cool

mode

kW 17 20 28 36

Heat capacity

Heating capacity (2) kW 45,2 58 71,7 86,5

Rated power absorbed in heat

mode

kW 16 19 27 33

Optional electric heating ca‐

pacity (400 V) (ARH) (2)

kW 12-25-37-50

Gas Heating (ARG)

Heat capacity at 100% power

(standard)

(LHV) Total kW 85

Net (2) kW 76

Heat capacity at 100% power,

high capacity (optional)

Total kW 100

Installation manual 1

Technical data 1.4

5

Models ARH/ARD 045 060 075 090

Net (2) kW 90

100% gas consumption (2NDH natural gas, G20 at 20 mbar

and 15ºC) (standard)

m3/h 8,6

100% gas consumption (2NDH natural gas, G20 at 20 mbar

and 15ºC) high capacity (op‐

tional)

m3/h 9,8

Stages No. 2

Compressors

Rated/start-up current A 2x12/95 2x15/118 2x20/140 2x25/198

Type and quantity SCROLL, 1 (TANDEM 50 % + 50 %)

Degree of protection IP21

Refrigerant

(R-410A)

kg 14,5 19 20,5 29

Electric power supply V / ph / Hz 400/3+N/50

Indoor fan (3)

Rated air flow m3/h 8500 11500 13500 16000

Maximum static pressure with

rated flow (standard drive)

Pa 168 242 240 368

Maximum static pressure with

rated flow (optional HPD drive)

Pa 335 402 >500 >500

Maximum flow m3/h 10000 13500 16000 18000

Minimum flow m3/h 7000 9500 11500 13000

IP55 Motor (standard) kW 3 4 5,5 7,5

Rated current A 5,5 5,7 7,6 11,7

IP55 Motor (HPD optional) kW 4 5,5 7,5 9,2/11

Rated current A 5,7 7,6 11,7 14/17,4

Indoor coil (evaporator)

Number of elements No. 3 4 3 4

Distance between fins mm 2,11 2,11 1,81 1,81

Front surface m

2

1,44 1,58 1,95 1,06 (x 2)

Air filters (G4)

Quantity per unit No. 6 6

Dimensions mm 470x550x48 565x594x48

Outdoor fan

Diameter / number mm 800/1 800/2 800/2 800/2

Total rated flow m3/h 15000 23000 27000 27000

Motor (IP54) kW 1,9 1,9 1,9 1,9

Rated current A 3,5 2x3,5 2x3,5 2x3,5

Outdoor coil (condenser)

Number of elements No. 3 4 2 3

Distance between fins mm 2,11 2,54 1,81 1,81

Front area m

2

2,27 2,49 2.31 (x2) 2.31 (x2)

Net dimensions (4)

Height mm 1316 1367

Length mm 3180 3495

Width mm 2337 2337

Net weight (basic unit with‐

out accessories) (4)

ARH kg 930 985 1145 1220

ARD kg 1040 1095 1255 1330

Electrical features of the

unit

Total rated power kW 17 22 28 36

Total rated current A 32 42 54 70

Total maximum power kW 23 31 38 45

Total maximum current A 42 56 70 83

Circuit breaker (K Curve (5) A 50 63 80 100

Minimum cable section (6) mm

2

10 16 25 35

(1) Data comply with Eurovent conditions, summer: indoor 27 °C TS / 19 °C TH - outdoor TS 35 °C. Winter: Indoor TS 20 °C, outdoor TS 7 °C / TH 6 °C (TS Dry-bulb

thermometer; TH Wet-bulb thermometer).

(2) Add the inside motor consumption to find the total calorific capacity.

(3) See

Indoor fan , see on page 18

(4) Consider the additional weight of options and accessories. To do so, see

Weight options and accessories , see on page 7

.

LHV: Lower heating value.

(5) and (6) Circuit breaker with K curve, according to DIN, VDE 0660-104. Section of cables for the power supply line based on copper conductors, 105 ºC. The indicated

circuit breaker and the section of power supply cables are guidelines. They should be adjusted based on the requirements of each installation, distance between units, fall

in planned voltage and on the application of the current regulations with respect to the country where the unit is being installed.

1 Installation manual

1.4 Technical data

6

1.4.3 Weight options and accessories

Models 045 060 075 090

Economiser kg 65 65 73 73

Extraction fan (axial) kg 54 54 63 63

Return fan (centrifuge) kg

Roof-curb mounting base (fixed/adjustable) kg 81/157 81/157 85/165 85/165

ERP adaptor for Roof Curb kg 177 177 190 190

Electric resistor kg 20 20 20 20

Hot water coil kg 60 60 60 60

Fixed outdoor air intake kg 9 9 9 9

Barometric damper kg 20 20 20 20

Copper fin coil

ARC/ARG

indoor 19 31 44 64

outdoor 30 49 70 104

ARH/ARD

indoor 29 48 44 64

outdoor 44 64 70 104

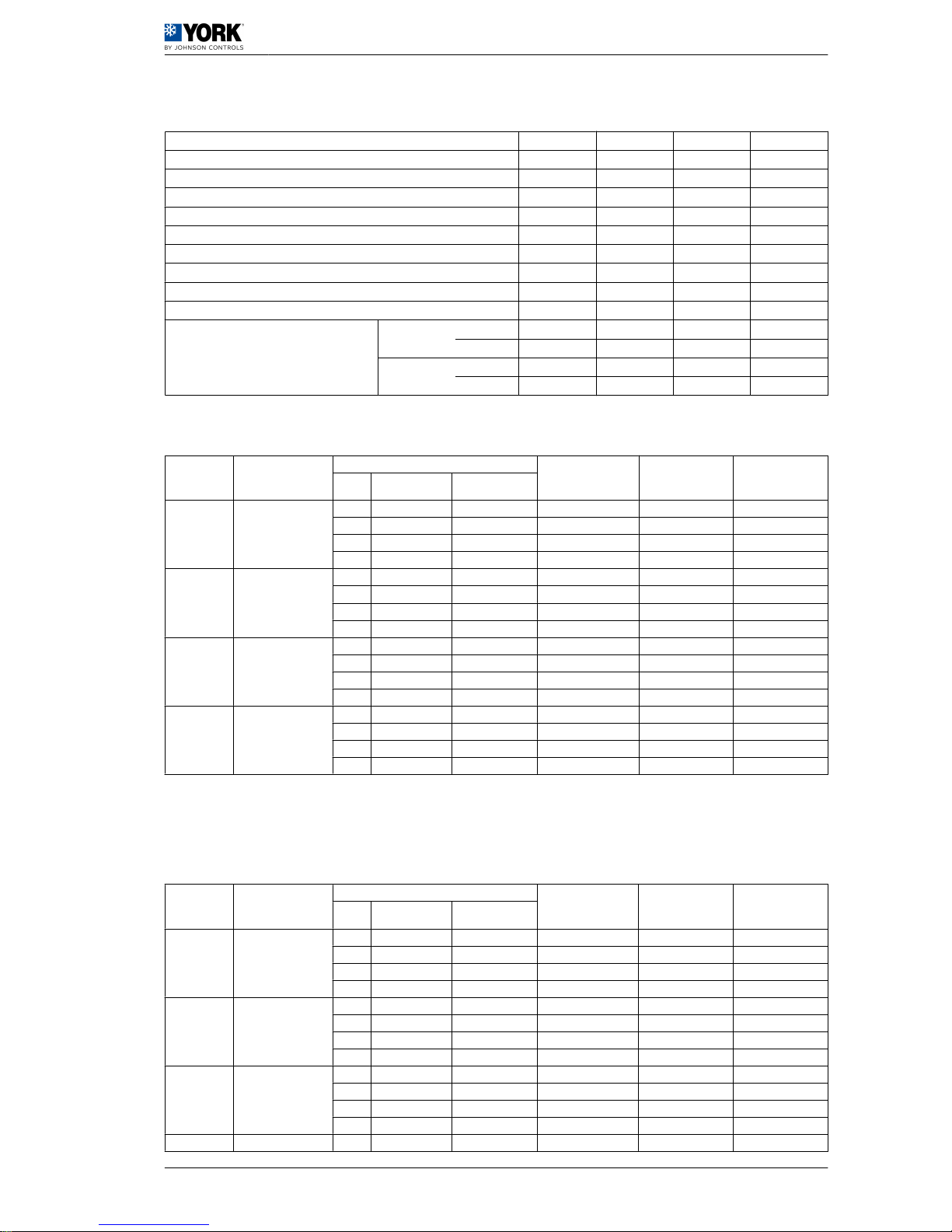

1.5 ARC units with electric heater

ARC Model

Electric power sup‐

ply V/Ph/Hz

Electric resistor

Maximum total current

of the unit (A)

Maximum circuit

breaker (K Curve) (1)

Minimum cable cross-

section (mm2) (2)

Power

(kW)

Stages (No.) Current (A)

045 400/3/50

12 1 18 32 50 10

25 2 36 38 50 10

37 2 54 60 80 25

50 2 72 78 100 35

060 400/3/50

12 1 18 42 50 10

25 2 36 42 50 10

37 2 54 60 80 25

50 2 72 78 100 35

075 400/3/50

12 1 18 54 63 16

25 2 36 54 63 16

37 2 54 62 80 25

50 2 72 80 100 35

090 400/3/50

12 1 18 70 80 25

25 2 36 70 80 25

37 2 54 70 80 25

50 2 72 84 100 35

(1) K Curve (DIN, VDE 0660-104).

(2) Based on copper conductors 105 °C.

1.6 ARH units with electric heater

ARC Model

Electric power sup‐

ply V/Ph/Hz

Electric resistor

Maximum total current

of the unit (A)

Maximum circuit

breaker (K Curve) (1)

Minimum cable cross-

section (mm2) (2)

Power

(kW)

Stages (No.) Current (A)

045 400/3/50

12 1 18 50 63 16

25 2 36 68 80 25

37 2 54 86 100 35

50 2 72 104 125 50

060 400/3/50

12 1 18 60 80 25

25 2 36 78 100 35

37 2 54 96 125 50

50 2 72 114 125 50

075 400/3/50

12 1 18 72 80 25

25 2 36 90 100 35

37 2 54 108 125 50

50 2 72 126 160 70

090 400/3/50

12 1 18 88 100 35

Installation manual 1

ARC units with electric heater 1.5

7

ARC Model

Electric power sup‐

ply V/Ph/Hz

Electric resistor

Maximum total current

of the unit (A)

Maximum circuit

breaker (K Curve) (1)

Minimum cable cross-

section (mm2) (2)

Power

(kW)

Stages (No.) Current (A)

25 2 36 106 125 50

37 2 54 124 160 70

50 2 72 142 160 70

(1) K Curve (DIN, VDE 0660-104).

(2) Based on copper conductors 105 °C.

1.7 Limits of use

Model 045 060 075 090

Voltage limits Min./Max V 342/457

ARC/ARG

Temperature of air input in indoor coil

TH °C Min./Max. 15/23 15/23 15/23 15/23

DB °C Min./Max. 20/32 20/32 20/32 20/32

Outdoor temperature (without condensa‐

tion control)

TS °C Min. 7 7 7 7

Maximum outdoor tempera‐

ture (1)

At full

load

TS °C 46 46 46 46

At partial

load

TS °C 52 52 52 52

ARH/ARD

Summer cycle

Temperature of air input in indoor coil

WB °C Min./Max. 15/23 15/23 15/23 14/23

DB °C Min./Max. 20/32 20/32 20/32 20/32

Outdoor temperature (without condensa‐

tion control)

TS °C Min. 7 7 7 7

Maximum outdoor tempera‐

ture (1)

At full

load

TS °C 46 46 46 46

At partial

load

TS °C 52 52 52 52

Winter cycle

Temperature of air input in indoor coil DB °C Min./Max. 10/25 10/25 10/25 10/25

Outdoor temperature DB °C Min./Max. -10/20 -10/20 -10/20 -10/20

ARG/ARD (2) Gas heating

Indoor temperature TS °C Max 30 30 30 30

Outdoor temperature DB °C Min./Max. -15/25 -15/25 -15/25 -15/25

1. Direct sunlight on the unit should be prevented when temperatures are higher than 43ºC. If placed under some kind of protective cover, the cover should not interfere

with the flow of outdoor ventilation.

2. The gas heating units (ARG/ARD) are only appropriate for use with gas. In LPG (Liquefied Petroleum Gas, propane) installations, it must be ensured that in no case

should gasoline in liquid form reach the gas group.

DB: Dry-bulb Thermometer; TH: Wet-bulb thermometer.

1.8 Power and application data for gas ARG / ARD

Model

Heat capacity Gas consumption m3/h

Temperature rise in ºC at full

power (4)

Total (LHV) (1) kW Net kW

Natural gas (2) L.P.G. pro‐

pane (3)

Standard High power Standard High power Standard High power

Optional (on‐

ly standard)

Min. Max.

045 85 100 76 90 8,6 9,8 3,6 17 33

060 85 100 76 90 8,6 9,8 3,6 17 33

075 85 100 76 90 8,6 9,8 3,6 17 33

090 85 100 76 90 8,6 9,8 3,6 17 33

(1) LHV: Lower heating value.

(2) Natural gas 2ND-H, G20, at 20 mbar and 15 ºC

(3) Propane gas, G31, at 37 mbar and 15 ºC.

(4) The air flow should be regulated so as to increase temperature within the specified limits. Units with optional high power burners should have a minimum air flow of

10000 m3/h.

Note: The gas units are shipped ready to operate with natural gas. A conversion kit can be used to convert them to propane gas (L.P.G.).

1 Installation manual

1.7 Limits of use

8

1.9 Hot water coil, optional in ARC/ARH

ARC/ARH

Data with water, without glycol

090

075

060

045

Water temperature ºC 90 ÷ 70

Air flow m37000 8500 10000 11500 13500 15000 16000 17000 18000

Heat capacity kW 71,1 79,5 87,0 93,7 101,7 107,3 111 114,2 117,4

Water flow m3/h 3 3,3 3,7 4 4,3 4,5 4,7 4,8 5

Pressure drop kPa 9,5 11 14 16 19 21 22 23 25

Air temperature rise K 30 27 25 24 22 21 20 19 18

Water temperature ºC 80 ÷ 60

Air flow m37000 8500 10000 11500 13500 15000 16000 17000 18000

Heat capacity kW 58,6 65,4 71,5 77 83,5 88,1 90,8 93,7 96,3

Water flow m3/h 2,5 2,8 3 3,3 3,5 3,7 3,9 4 4,1

Pressure drop kPa 7,5 9 9,5 11 13 14 16 16 18

Air temperature rise K 24 22 21 20 18 17 17 16 15

Water temperature ºC 70 ÷ 50

Air flow m37000 8500 10000 11500 13500 15000 16000 17000 18000

Heat capacity kW 46,0 51,2 55,8 61,1 65,1 68,7 71 73 75

Water flow m3/h 1,9 2,2 2,4 2,6 2,8 2,9 3 3,1 3,2

Pressure drop kPa 4,5 6 6,5 7,5 9 9,5 10,5 11 11

Air temperature rise K 19 18 16 15 14 13 13 12 12

- Pressure drop of coil + 3-way valve.

- Coil input air: 18 ℃.

- Total volume of water in circuit 10 l.

- See air pressure drop,

Pressure drop of options/accessories, gas heating and vertical ducts. , see on page 21

.

ARC/ARH

Data with a mix of water and 35% glycol

090

075

060

045

Water temperature ºC 90 ÷ 70

Air flow m37000 8500 10000 11500 13500 15000 16000 17000 18000

Heat capacity kW 68,5 76,3 83,6 89,8 97,5 102,8 106,3 109,4 112,4

Water flow m3/h 3,2 3,6 4 4,2 4,6 4,8 5 5,1 5,3

Pressure drop kPa 12 15 17 20 23 25 27 28 30

Air temperature rise K 28 26 24 22 21 20 19 18 17

Water temperature ºC 80 ÷ 60

Air flow m37000 8500 10000 11500 13500 15000 16000 17000 18000

Heat capacity kW 55,6 62 67,7 72,8 79 83,3 85,9 88,5 91

Water flow m3/h 2,6 2,9 3,2 3,5 3,7 4 4,1 4,2 4,3

Pressure drop kPa 9 10 12 14 16 18 19 20 21

Air temperature rise K 23 21 20 18 17 16 16 15 14

Water temperature ºC 70 ÷ 50

Air flow m37000 8500 10000 11500 13500 15000 16000 1700 18000

Heat capacity kW 41,4 46 50,7 54,8 59,6 63,1 65,3 67,3 69,2

Water flow m3/h 2 2,2 2,4 2,6 2,8 3 3,1 3,2 3,3

Pressure drop kPa 6 6,5 7 8,5 10 11 12 13 14

Air temperature rise K 17 16 15 14 13 12 12 11 11

- Pressure drop of coil + 3-way valve.

- Coil input air: 18 ℃.

- Total volume of water in circuit 10 l.

- See air pressure drop,

Pressure drop of options/accessories, gas heating and vertical ducts. , see on page 21

.

Installation manual 1

Hot water coil, optional in ARC/ARH 1.9

9

1.10 Measurements, clearances and accesses

1.10.1 Connections for supply and re‐

turn side ducts

Minimum clearance

A. Minimum clearance: 900 mm

B. Minimum clearance: 600 mm (without economiser), 1,200 mm (with economiser)

C. Minimum clearance: 600 mm (without economiser), 1245 mm (with economiser)

D. Outdoor coil

1. Return air

2. Supply air

Units are shipped with the lower duct openings covered.

For applications with downward airflow ducts:

1 In order to access the covers of the lower supply and return air ducts, remove the side panels of the

supply and return air compartments.

2 Remove and discard the lower duct covers.

3 Replace the side panels of the supply and return air compartments. Make sure that the seal is com‐

pletely air-tight and check that the screws that fasten the panel have their corresponding o-rings.

For applications with sideways airflow ducts:

Flanges for connecting the side ducts are included in an accessory kit.

1 Replace the side panels of the supply and return air compartments with the set of accessory panels.

Make sure that the seal is air-tight.

1 Installation manual

1.10 Measurements, clearances and accesses

10

2 Connect the duct system to the panel flanges.

Minimum clearance above the unit

The unit is designed to be installed outdoors.

In ground level installations, the building eaves should be at a vertical distance of at least 1830 mm from

the top of the unit and should not overhang the unit more than 915 mm.

There are no restrictions regarding the overhang if the eaves are 3000 mm or more above the unit.

1.10.2 General dimensions and ac‐

cesses (models 045/060)

A. Combustion exhaust hood

B. Combustion air input hood

C. Access to gas heating system

D. Gas supply intake (∅ 58 mm), with rubber grommet

E. RAG/RAD unit details

F. Access to motor, fan and pulleys

G. Access to heating options

H. Access to control system

I. Control cable intake (∅ 23 mm) (side)

J. Power cable intake (∅ 38 + 29 mm) (side)

K. Opening for connection of lower supply and return air ducts.

L. Control cable intake (PG 21 mm) (lower)

M. Power cable intake (PG 48 mm) (lower)

Installation manual 1

Measurements, clearances and accesses 1.10

11

N. Close-up of the base, shown separately to be more easily seen

O. Access to filters and indoor coil

P. Condensate drain connection (1” BSP Female)

Q. Access to the outdoor air compartment

R.

Supply and return air compartment side panels See

Connections for supply and return side

ducts , ver pág. 10

S. Compressor access

T. Pressure reading connection

1. Return air

2. Supply air

3. Condensate air

1.10.3 General dimensions and ac‐

cesses (models 075/090)

A. Combustion exhaust hood

B. Combustion air input hood

C. Access to gas heating system

D. Gas supply intake (∅ 58 mm), with rubber grommet

E. RAG/RAD unit details

F. Access to motor, fan and pulleys

G. Access to heating options

H. Access to control system

I. Control cable intake (∅ 23 mm) (side)

1 Installation manual

1.10 Measurements, clearances and accesses

12

Loading...

Loading...