York DM120, DM150, DM090 User Manual

INSTALLATION

MANUAL - 50 Hz

CONTENTS

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 SAFETY CONSIDERATIONS. . . . . . . . . . . . . . . . . . . 5 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 START-UP (COOLING) . . . . . . . . . . . . . . . . . . . . . . 45 START-UP (GAS HEAT) . . . . . . . . . . . . . . . . . . . . . 45 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . 50

See the following pages for a complete Table of Contents.

NOTES, CAUTIONS AND WARNINGS

The installer should pay particular attention to the words: NOTE, CAUTION, and WARNING. Notes are intended to clarify or make the installation easier. Cautions are given to prevent equipment damage. Warnings are given to alert installer that personal injury and/or equipment damage may result if installation procedure is not handled properly.

CAUTION: READ ALL SAFETY GUIDES BEFORE YOU

BEGIN TO INSTALL YOUR UNIT.

SAVE THIS MANUAL

SINGLE PACKAGE AIR CONDITIONERS AND SINGLE PACKAGE GAS/ELECTRIC UNITS DM090, 120 AND 150

7-1/2, 10 AND 12-1/2 TON

(9.0 TO 10.0 EER) 50 Hz

127408-YIM-B-0606

127408-YIM-B-0606

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . 5 INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 REFERENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION SAFETY INFORMATION . . . . . . . . . . . . 8 PRECEDING INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 8 LIMITATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 LOCATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 RIGGING AND HANDLING . . . . . . . . . . . . . . . . . . . . . . . 10 CLEARANCES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 DUCT COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 CONDENSATE DRAIN . . . . . . . . . . . . . . . . . . . . . . . . . . 15 COMPRESSORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 THERMOSTAT WIRING . . . . . . . . . . . . . . . . . . . . . . . . . 16 POWER AND CONTROL WIRING . . . . . . . . . . . . . . . . . 16 POWER WIRING DETAIL . . . . . . . . . . . . . . . . . . . . . . . . 16 OPTIONAL ELECTRIC HEAT . . . . . . . . . . . . . . . . . . . . . 21 OPTIONAL GAS HEAT . . . . . . . . . . . . . . . . . . . . . . . . . . 21

GAS PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 GAS CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 LP UNITS, TANKS AND PIPING . . . . . . . . . . . . . . . . . . . . . . . 23 VENT AND COMBUSTION AIR . . . . . . . . . . . . . . . . . . . . . . . . 23

OPTIONS/ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . 23

ELECTRIC HEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 MOTORIZED OUTDOOR DAMPER . . . . . . . . . . . . . . . . . . . . 23 ECONOMIZER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 POWER EXHAUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 RAIN HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ECONOMIZER AND POWER EXHAUST

SET POINT ADJUSTMENTS AND INFORMATION . . . . 24

MINIMUM POSITION ADJUSTMENT . . . . . . . . . . . . . . . . . . . 24 ENTHALPY SET POINT ADJUSTMENT . . . . . . . . . . . . . . . . . 24 POWER EXHAUST DAMPER SET POINT

(WITH OR WITHOUT POWER EXHAUST) . . . . . . . . . . . . . . . 24 INDOOR AIR QUALITY AQ . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PHASING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 BLOWER ROTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

AIR BALANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

CHECKING AIR QUANTITY . . . . . . . . . . . . . . . . . . . . . . 34

METHOD ONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 METHOD TWO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SUPPLY AIR DRIVE ADJUSTMENT. . . . . . . . . . . . . . . . 36

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SEQUENCE OF OPERATIONS OVERVIEW . . . . . . . . . 40 COOLING SEQUENCE OF OPERATION . . . . . . . . . . . . 40

CONTINUOUS BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 INTERMITTENT BLOWER. . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 NO OUTDOOR AIR OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . 40 ECONOMIZER WITH SINGLE ENTHALPY SENSOR. . . . . . . 40 ECONOMIZER WITH DUAL ENTHALPY SENSORS . . . . . . . 40

ECONOMIZER WITH POWER EXHAUST . . . . . . . . . . . . . . . .41 MOTORIZED OUTDOOR AIR DAMPERS . . . . . . . . . . . . . . . .41 COOLING OPERATION ERRORS . . . . . . . . . . . . . . . . . . . . . .41 HIGH-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . . . . . . . . .41 LOW-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . . . . . . . . .41 FREEZESTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 LOW AMBIENT COOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 COMPRESSOR PROTECTION . . . . . . . . . . . . . . . . . . . 42

FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

ELECTRIC HEATING SEQUENCE OF OPERATIONS . 42 ELECTRIC HEAT OPERATION ERRORS . . . . . . . . . . . 42

TEMPERATURE LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 LIMIT SWITCH (LS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

ELECTRIC HEAT ANTICIPATOR SETPOINTS . . . . . . . 42 GAS HEATING SEQUENCE OF OPERATIONS . . . . . . 43 IGNITION CONTROL BOARD . . . . . . . . . . . . . . . . . . . . 43

FIRST STAGE OF HEATING . . . . . . . . . . . . . . . . . . . . . . . . . .43 SECOND STAGE OF HEATING. . . . . . . . . . . . . . . . . . . . . . . .43 RETRY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43 RECYCLE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

GAS HEATING OPERATION ERRORS . . . . . . . . . . . . . 43

LOCK-OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43 TEMPERATURE LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43 FLAME SENSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43 GAS VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43 SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44 LIMIT SWITCH (LS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44 AUXILIARY LIMIT SWITCH (ALS) . . . . . . . . . . . . . . . . . . . . . .44 PRESSURE SWITCH (PS) . . . . . . . . . . . . . . . . . . . . . . . . . . . .44 ROLLOUT SWITCH (ROS) . . . . . . . . . . . . . . . . . . . . . . . . . . . .44 INTERNAL MICROPROCESSOR FAILURE . . . . . . . . . . . . . .44 FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44 RESETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

GAS HEAT ANTICIPATOR SETPOINTS . . . . . . . . . . . . 44

START-UP (COOLING) . . . . . . . . . . . . . . . . . . . . . . . . 45

PRESTART CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . 45 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . 45 POST START CHECK LIST . . . . . . . . . . . . . . . . . . . . . . 45

START-UP (GAS HEAT) . . . . . . . . . . . . . . . . . . . . . . . 45

PRE-START CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . 45 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . 45

LIGHTING THE MAIN BURNERS. . . . . . . . . . . . . . . . . . . . . . .45

POST START CHECKLIST. . . . . . . . . . . . . . . . . . . . . . . 45 SHUT DOWN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 MANIFOLD GAS PRESSURE ADJUSTMENT . . . . . . . . 46 CHECKING GAS INPUT . . . . . . . . . . . . . . . . . . . . . . . . . 46

NATURAL GAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

ADJUSTMENT OF TEMPERATURE RISE . . . . . . . . . . . 47 BURNERS/ORIFICES INSPECTION/SERVICING . . . . . 47 CHARGING THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . 48

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . 50

PREDATOR® FLASH CODES . . . . . . . . . . . . . . . . . . . . 50 COOLING TROUBLESHOOTING GUIDE. . . . . . . . . . . . 54 GAS HEAT TROUBLESHOOTING GUIDE. . . . . . . . . . . 57

2 |

Unitary Products Group |

127408-YIM-B-0606

LIST OF FIGURES

Fig. # |

Pg. # |

|

1 |

UNIT SHIPPING BRACKET . . . . . . . . . . . . . . . . . . |

. . . 8 |

2 |

CONDENSER COVERING . . . . . . . . . . . . . . . . . . . |

. . . 8 |

3 |

COMPRESSOR SECTION . . . . . . . . . . . . . . . . . . . |

. . . 8 |

4 |

PREDATOR® COMPONENT LOCATION . . . . . . . |

. . . 9 |

5 |

UNIT 4 POINT LOAD . . . . . . . . . . . . . . . . . . . . . . . |

. . 10 |

6 |

UNIT 6 POINT LOAD . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

7 |

UNIT CENTER OF GRAVITY . . . . . . . . . . . . . . . . . |

. . 11 |

8 |

UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . |

. . 12 |

9 |

BOTTOM DUCT OPENINGS (FROM ABOVE). . . . |

. . 13 |

10 |

REAR DUCT DIMENSIONS . . . . . . . . . . . . . . . . . . |

. . 13 |

11 |

PREDATOR® ROOF CURB DIMENSIONS . . . . . . |

. . 14 |

12 |

SUNLINE™ TO PREDATOR® TRANSITION |

|

|

ROOF CURBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 14 |

13 |

SIDE PANELS WITH HOLE PLUGS. . . . . . . . . . . . |

. . 15 |

14 |

RETURN DOWNFLOW PLENUM WITH PANEL . . |

. . 15 |

15 |

DISCHARGE PANEL IN PLACE. . . . . . . . . . . . . . . |

. . 15 |

16 |

CONDENSATE DRAIN . . . . . . . . . . . . . . . . . . . . . . |

. . 15 |

17 |

ELECTRONIC THERMOSTAT FIELD WIRING . . . |

. . 17 |

Fig. # |

Pg. # |

|

18 |

FIELD WIRING 24 VOLT THERMOSTAT . . . . . . . |

. . 17 |

19 |

FIELD WIRING DISCONNECT - COOLING UNIT |

|

|

WITH OR WITHOUT ELECTRIC HEAT . . . . . . . . . . |

. 18 |

20 |

FIELD WIRING DISCONNECT - COOLING UNIT |

|

|

WITH GAS HEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 18 |

21 |

SIDE ENTRY GAS PIPING. . . . . . . . . . . . . . . . . . . . |

. 21 |

22 |

BOTTOM ENTRY GAS PIPING . . . . . . . . . . . . . . . . |

. 21 |

23 |

ENTHALPY SET POINT CHART . . . . . . . . . . . . . . . |

. 25 |

24 |

HONEYWELL ECONOMIZER CONTROL W7212 . . |

. 25 |

25 |

BELT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . |

. 26 |

26 |

DRY COIL DELTA P 50" CABINET . . . . . . . . . . . . . |

. 35 |

27 |

DRY COIL DELTA P 42" CABINET . . . . . . . . . . . . . |

. 35 |

28 |

TYPICAL FLAME . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 44 |

29 |

TYPICAL GAS VALVE . . . . . . . . . . . . . . . . . . . . . . . |

. 48 |

30 |

UNIT CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . |

. 51 |

31 |

BASIC TROUBLESHOOTING FLOWCHART . . . . . |

. 52 |

32 |

POWER ON FLOW CHART . . . . . . . . . . . . . . . . . . . |

. 52 |

33 |

TRIP FAILURE FLOW CHART. . . . . . . . . . . . . . . . . |

. 53 |

Unitary Products Group |

3 |

127408-YIM-B-0606

LIST OF TABLES

Tbl. # |

Pg. # |

|

1 |

UNIT VOLTAGE LIMITATIONS . . . . . . . . . . . . . . . . |

. . 10 |

2 |

UNIT TEMPERATURE LIMITATIONS . . . . . . . . . . . |

. . 10 |

3 |

UNIT WEIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

4 |

4 POINT LOAD WEIGHT . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

5 |

6 POINT LOAD WEIGHT . . . . . . . . . . . . . . . . . . . . . |

. . 11 |

6 |

UNIT HEIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 12 |

7 |

UNIT CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . |

. . 12 |

8 |

REAR DUCT DIMENSIONS. . . . . . . . . . . . . . . . . . . |

. . 13 |

9 |

CONTROL WIRE SIZES . . . . . . . . . . . . . . . . . . . . . |

. . 16 |

10 |

ELECTRICAL DATA 7-1/2 TON. . . . . . . . . . . . . . . . |

. . 19 |

11 |

ELECTRICAL DATA 10 TON . . . . . . . . . . . . . . . . . . |

. . 19 |

12 |

ELECTRICAL DATA 12-1/2 TON. . . . . . . . . . . . . . . |

. . 20 |

13 |

PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 20 |

14 |

ELECTRIC HEAT MINIMUM SUPPLY AIR CFM. . . |

. . 21 |

15 |

GAS APPLICATION DATA . . . . . . . . . . . . . . . . . . . |

. . 21 |

16 |

GAS PIPE SIZING - CAPACITY OF PIPE . . . . . . . . |

. . 22 |

17 |

SUPPLY AIR LIMITATIONS. . . . . . . . . . . . . . . . . . . |

. . 26 |

18 |

BLOWER PERFORMANCE 7-1/2 TON |

|

|

STANDARD MOTOR - SIDE DUCT (IMPERIAL) . . |

. . 27 |

19 |

BLOWER PERFORMANCE 7-1/2 TON |

|

|

STANDARD MOTOR - SIDE DUCT (METRIC) . . . . |

. . 27 |

20 |

BLOWER PERFORMANCE 7-1/2 TON |

|

|

OPTIONAL MOTOR - SIDE DUCT (IMPERIAL) . . . |

. . 27 |

21 |

BLOWER PERFORMANCE 7-1/2 TON |

|

|

OPTIONAL MOTOR - SIDE DUCT (METRIC) . . . . . |

. . 27 |

22 |

BLOWER PERFORMANCE 10 TON |

|

|

STANDARD MOTOR - SIDE DUCT (IMPERIAL) . . |

. . 28 |

23 |

BLOWER PERFORMANCE 10 TON |

|

|

STANDARD MOTOR - SIDE DUCT (METRIC) . . . . |

. . 28 |

24 |

BLOWER PERFORMANCE 10 TON |

|

|

OPTIONAL MOTOR - SIDE DUCT (IMPERIAL) . . . |

. . 28 |

25 |

BLOWER PERFORMANCE 10 TON |

|

|

OPTIONAL MOTOR - SIDE DUCT (METRIC) . . . . . |

. . 29 |

26 |

BLOWER PERFORMANCE 12-1/2 TON - |

|

|

SIDE DUCT (IMPERIAL) . . . . . . . . . . . . . . . . . . . . . |

. . 29 |

27 |

BLOWER PERFORMANCE 12-1/2 TON - |

|

|

SIDE DUCT (METRIC). . . . . . . . . . . . . . . . . . . . . . . |

. . 29 |

28 |

BLOWER PERFORMANCE 7-1/2 TON |

|

|

STANDARD MOTOR - DOWNSHOT (IMPERIAL) . |

. . 30 |

Tbl. # |

Pg. # |

|

29 |

BLOWER PERFORMANCE 7-1/2 TON |

|

|

STANDARD MOTOR - DOWNSHOT (METRIC) . . |

. . 30 |

30 |

BLOWER PERFORMANCE 7-1/2 TON |

|

|

OPTIONAL MOTOR - DOWNSHOT (IMPERIAL) . . |

. . 30 |

31 |

BLOWER PERFORMANCE 7-1/2 TON |

|

|

OPTIONAL MOTOR - DOWNSHOT (METRIC). . . . |

. . 31 |

32 |

BLOWER PERFORMANCE 10 TON |

|

|

STANDARD MOTOR - DOWNSHOT (IMPERIAL) . |

. . 31 |

33 |

BLOWER PERFORMANCE 10 TON |

|

|

STANDARD MOTOR - DOWNSHOT (METRIC) . . |

. . 31 |

34 |

BLOWER PERFORMANCE 10 TON |

|

|

OPTIONAL MOTOR - DOWNSHOT (IMPERIAL) . . |

. . 32 |

35 |

BLOWER PERFORMANCE 10 TON |

|

|

OPTIONAL MOTOR - DOWNSHOT (METRIC). . . . |

. . 32 |

36 |

BLOWER PERFORMANCE 12-1/2 TON - |

|

|

DOWNSHOT (IMPERIAL) . . . . . . . . . . . . . . . . . . . . |

. . 33 |

37 |

BLOWER PERFORMANCE 12-1/2 TON - |

|

|

DOWNSHOT (METRIC) . . . . . . . . . . . . . . . . . . . . . |

. . 33 |

38 |

INDOOR BLOWER SPECIFICATIONS . . . . . . . . . . |

. . 33 |

39 |

ADDITIONAL STATIC RESISTANCE 50” CABINET |

|

|

(IMPERIAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 37 |

40 |

ADDITIONAL STATIC RESISTANCE 42” CABINET |

|

|

(IMPERIAL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 37 |

41 |

ADDITIONAL STATIC RESISTANCE 50” CABINET |

|

|

(METRIC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 38 |

42 |

ADDITIONAL STATIC RESISTANCE 42” CABINET |

|

|

(METRIC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 38 |

43 |

MOTOR SHEAVE DATUM . . . . . . . . . . . . . . . . . . . |

. . 39 |

44 |

ELECTRIC HEAT LIMIT SETTING . . . . . . . . . . . . . |

. . 42 |

45 |

ELECTRIC HEAT ANTICIPATOR SETPOINTS . . . |

. . 42 |

46 |

GAS HEAT LIMIT SETTINGS . . . . . . . . . . . . . . . . . |

. . 44 |

47 |

GAS HEAT ANTICIPATOR SETPOINTS . . . . . . . . |

. . 44 |

48 |

GAS HEAT STAGES . . . . . . . . . . . . . . . . . . . . . . . . |

. . 46 |

49 |

GAS RATE CUBIC FEET PER HOUR . . . . . . . . . . |

. . 47 |

50 |

7.5 TON SUPERHEAT CHARGING . . . . . . . . . . . . |

. . 48 |

51 |

10 TON SUPERHEAT CHARGING . . . . . . . . . . . . . |

. . 49 |

52 |

UNIT CONTROL BOARD FLASH CODES . . . . . . . |

. . 50 |

53 |

IGNITION CONTROL FLASH CODES . . . . . . . . . . |

. . 51 |

4 |

Unitary Products Group |

127408-YIM-B-0606

GENERAL

YORK® Predator® units are single package air conditioners with optional gas heating designed for outdoor installation on a rooftop or slab and for non-residential use. These units can be equipped with factory or field installed electric heaters for heating applications.

These units are completely assembled on rigid, permanently attached base rails. All piping, refrigerant charge, and electrical wiring is factory installed and tested. The units require electric power, gas supply (where applicable), and duct connections. The electric heaters have nickel-chrome elements and utilize single-point power connection.

SAFETY CONSIDERATIONS

Should overheating occur, or the gas supply fail to shut off, shut off the manual gas valve to the furnace before shutting off the electrical supply.

Do not use this furnace if any part has been under water. Immediately call a qualified service technician to inspect the furnace and to replace any part of the control system and any gas control which has been under water.

Due to system pressure, moving parts, and electrical components, installation and servicing of air conditioning equipment can be hazardous. Only qualified, trained service personnel should install, repair, or service this equipment. Untrained personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters.

Observe all precautions in the literature, labels, and tags accompanying the equipment whenever working on air conditioning equipment. Be sure to follow all other applicable safety precautions and codes including ANSI Z223.1 or CSAB149.1- latest edition.

Wear safety glasses and work gloves. Use quenching cloth and have a fire extinguisher available during brazing operations.

If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

a.Do not try to light any appliance.

b.Do not touch any electrical switch; do not use any phone in your building.

c.Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

d.If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

INSPECTION

As soon as a unit is received, it should be inspected for possible damage during transit. If damage is evident, the extent of the damage should be noted on the carrier’s freight bill. A separate request for inspection by the carrier’s agent should be made in writing.

This furnace is not to be used for temporary heating of buildings or structures under construction.

Before performing service or maintenance operations on unit, turn off main power switch to unit. Electrical shock could cause personal injury. Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual. For assistance or additional information consult a qualified installer, service agency or the gas supplier.

Unitary Products Group |

5 |

127408-YIM-B-0606

REFERENCE

Additional information is available in the following reference forms:

•Technical Guide - DM090-150, 259335

•General Installation - DM090 - 150, 127408

•Pre-start & Post-start Check List

•Economizer Accessory -

Downflow Factory Installed

Downflow Field Installed

Horizontal Field Installed

•Motorized Outdoor Air Damper

•Manual Outdoor Air Damper (0-100%)

•Manual Outdoor Air Damper (0-35%)

•Gas Heat Propane Conversion Kit

•Gas Heat High Altitude Kit (Natural Gas)

•Gas Heat High Altitude Kit (Propane)

•–60°F Gas Heat Kit

•Electric Heater Accessory

APPROVALS

Design certified by CSA as follows:

1.For use as a cooling only unit, cooling unit with supplemental electric heat or a forced air furnace.

2.For outdoor installation only.

3.For installation on combustible material and may be installed directly on combustible flooring or, in the U.S., on wood flooring or Class A, Class B or Class C roof covering materials.

4.For use with natural gas (convertible to LP with kit).

This product must be installed in strict compliance with the enclosed installation instructions and any applicable local, state, and national codes including, but not limited to, building, electrical, and mechanical codes.

RENEWAL PARTS

Contact your local York® parts distribution center for authorized replacement parts.

Incorrect installation may create a condition where the operation of the product could cause personal injury or property damage.

The installer should pay particular attention to the words: NOTE, CAUTION, and WARNING. NOTES are intended to clarify or make the installation easier. CAUTIONS are given to prevent equipment damage. WARNINGS are given to alert installer that personal injury and/or equipment damage may result if installation procedure is not handled properly.

6 |

Unitary Products Group |

127408-YIM-B-0606

NOMENCLATURE

7.5-12.5 Ton York® Model Number Nomenclature

D M 090 N10 A 7 A AA 3 0 1 2 4 A

Product Category

D = A/C, Single Pkg., R-22

Product Identifier

M = 9.0 EER A/C

Nominal Cooling Capacity

090 = 7.5 Ton

120 = 10.0 Ton

150 = 12.5 Ton

Heat Type and Nominal Heat Capacity

C00 = Cooling Only. No heat installed

Gas Heat Options

N10 = 100 MBH Output Aluminized Steel

N15 = 150 MBH Output Aluminized Steel

S10 = 100 MBH Output Stainless Steel

S15 = 150 MBH Output Stainless Steel

Electric Heat Options

E09 = 9 KW

E18 = 18 KW

E24 = 24 KW

E36 = 36 KW

E54 = 54 KW

Airflow

A = Std. Motor

B = Std. Motor/Econo./Barometric Relief (Downflow

Only)

C = Std. Motor/Econo./Power Exhaust (Downflow Only)

D = Std. Motor/Motorized Damper (Downflow Only)

E = Std. Motor/Horizontal Economizer (No Baro.)

F = Std. Motor/Slab Econo./Power Exhaust

(Downflow Only)

G = Std. Motor/Slab Econo./Barometric Relief

(Downflow Only)

N = Hi Static Mtr.

P = Hi Static Mtr./Econo./Barometric Relief

(Downflow Only)

Q = Hi Static Mtr./Econo./Power Exhaust

(Downflow Only)

R = Hi Static Mtr./Motorized Damper (Downflow Only)

S = Hi Static Mtr./Horizontal Economizer (No Baro.)

T = Hi Static Mtr./Slab Econo./Power Exhaust

(Downflow Only)

U = Hi Static Mtr./Slab Econo./Barometric Relief

(Downflow only)

Voltage

7 = 380/415-3-50

Product Style

A = Style A

B = Style B

C = Style C

Configuration Options (not required for all units)

These four digits will not be assigned until a quote is requested, or an order placed.

SS Drain Pan

Honeywell Controller, DFS, APS

Simplicity IntelliComfort Controller

Simplicity IntelliComfort Controller w/ModLinc

2" Pleated filters

BAS Ready Unit with Belimo Economizer

Shipping Bag

Any Combination of Additional Options that Don’t Have an Option Code Pre-assigned

|

|

Product Generation |

|

|

|

|

|

|

3 |

= Third Generation |

|

|

4 |

= Fourth Generation |

|

|

|

|

|

|

|

|

|

|

|

|

Additional Options |

AA = None |

RC = Coil Guard, Shipping Bag & American Flag |

AB = Phase Monitor |

TA = Technicoat Condenser Coil |

AC = Coil Guard |

TJ = Technicoat Evaporator Coil |

AD = Dirty Filter Switch |

TS = Technicoat Evaporator & Condenser Coils |

AE = Phase Monitor & Coil Guard |

|

AF = Phase Monitor & Dirty Filter Switch |

|

AG = Coil Guard & Dirty Filter Switch |

|

AH = Phase Monitor, Coil Guard & Dirty Filter Switch |

|

|

|

ZZ= If desired option combination is not listed above, ZZ will be assigned and configuration options will be located in digits 15-18.

Installation Options

A = No Options Installed

B = Option 1

C = Option 2

D = Options 1 & 2

E = Option 3

F = Option 4

G = Options 1 & 3

H = Options 1 & 4

J = Options 1, 2 & 3

K = Options 1, 2, & 4

L = Options 1,3 & 4

M = Options 1, 2, 3, & 4

N = Options 2 & 3

P = Options 2 & 4

Q = Options 2, 3, & 4

R = Options 3 & 4

S = Option 5

T = Options 1 & 5

U = Options 1, 3, & 5

V = Options 1, 4, & 5

W = Options 1, 3, 4, & 5

X = Options 3 & 5

Y = Options 4 & 5

Z = Options 3, 4 & 5

Options

1 = Disconnect

2 = Non-Pwr'd Conv. Outlet

3 = Smoke Detector S.A.

4 = Smoke Detector R.A.

5 = Pwr'd Conv. Outlet

Unitary Products Group |

7 |

127408-YIM-B-0606

INSTALLATION

INSTALLATION SAFETY INFORMATION

Read these instructions before continuing this appliance installation. This is an outdoor combination heating and cooling unit. The installer must assure that these instructions are made available to the consumer and with instructions to retain them for future reference.

1.Refer to the furnace rating plate for the approved type of gas for this furnace.

2.Install this furnace only in a location and position as specified on Page 10 of these instructions.

3.Never test for gas leaks with an open flame. Use commercially available soap solution made specifically for the detection of leaks when checking all connections, as specified on Pages 8, 22, 23 and 45 of these instructions.

4.Always install furnace to operate within the furnace's intended temperature-rise range with the duct system and within the allowable external static pressure range, as specified on the unit name/rating plate, specified on Page 47 of these instructions.

5.This equipment is not to be used for temporary heating of buildings or structures under construction.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warning exactly could result in serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially available soap solution made specifically for the detection of leaks to check all connections. A fire or explosion may result causing property damage, personal injury or loss of life.

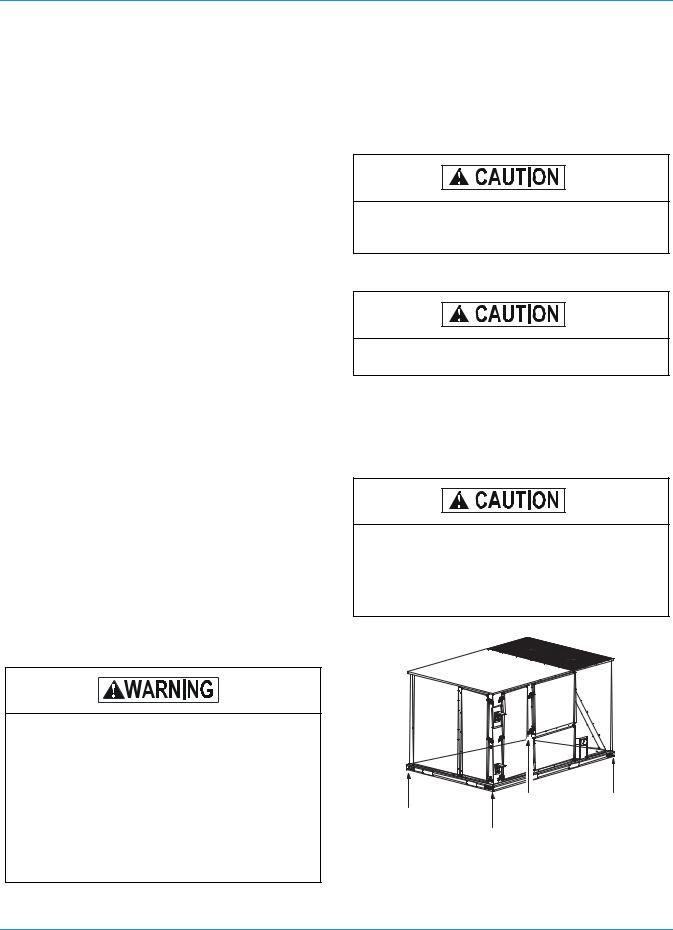

PRECEDING INSTALLATION

1.Remove the two screws holding the brackets in the front, rear and compressor side fork-lift slots.

2.Turn each bracket toward the ground and the protective plywood covering will drop to the ground.

3.Remove the condenser coil external protective covering prior to operation.

Bracket |

Turn down |

|

Screws |

||

|

FIGURE 1 - UNIT SHIPPING BRACKET

4.Remove the toolless doorknobs and instruction packet prior to installation.

Condenser

Coil External

Protective

Covering

Barometric Relief Hood in Shipping Location (if included)

FIGURE 2 - CONDENSER COVERING

Toolless

Doorknobs

Installation

Instruction

Packet

FIGURE 3 - COMPRESSOR SECTION

8 |

Unitary Products Group |

127408-YIM-B-0606

This product must be installed in strict compliance with the enclosed installation instructions and any applicable local, state and national codes including, but not limited to, building, electrical, and mechanical codes.

The furnace and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure testing at pressures in excess of 1/2 PSIG.

Pressures greater than 1/2 PSIG will cause gas valve damage resulting in a hazardous condition. If it is subjected to a pressure greater than 1/2 PSIG, the gas valve must be replaced.

The furnace must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 PSIG.

LIMITATIONS

These units must be installed in accordance with the following:

1.Local building codes, and

2.Local gas utility requirements

3.Local plumbing and waste water codes, and

4.Other applicable local codes.

Refer to Tables 1 & 2 for unit application data.

After installation, gas fired units must be adjusted to obtain a temperature rise within the range specified on the unit rating plate.

If components are to be added to a unit to meet local codes, they are to be installed at the dealer’s and/or customer’s expense.

Size of unit for proposed installation should be based on heat loss/heat gain calculation made according to the methods of Air Conditioning Contractors of America (ACCA).

This furnace is not to be used for temporary heating of buildings or structures under construction.

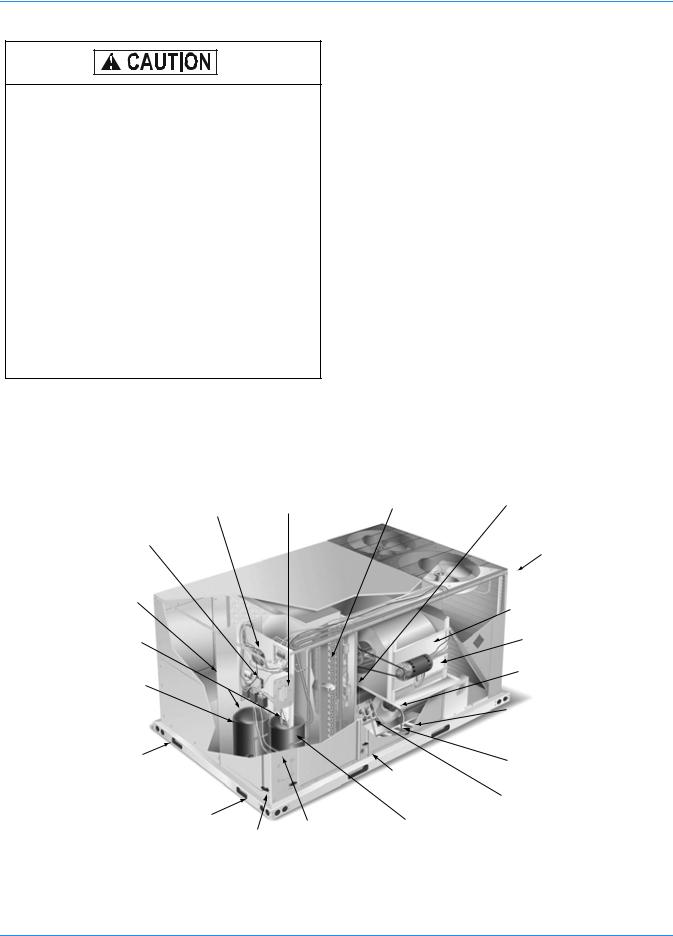

3FJMIF@FQV FRQWURO ERDUG Z VFUHZ FRQQHFWRU IRU 7 VWDW ZLULQJ DQG QHWZRUN FRQQHFWLRQV

7HUPLQDO EORFN IRU KL YROWDJH FRQQHFWLRQ

6HFRQG PRGHO QDPHSODWH LQVLGH KLQJHG DFFHVV SDQHO

'LVFRQQHFW ORFDWLRQ )LOWHU DFFHVVRSWLRQDO GLVFRQQHFW VZLWFK ´ WKURZ DZD\

)LOWHU GULHUVROLG FRUH

'XDO VWDJH FRROLQJ IRU PD[LPXP FRPIRUW

&RPSUHVVRU DFFHVV KLJK HIILFLHQF\ FRPSUHVVRU Z FUDQNFDVH KHDWHU

%DVH UDLOV Z IRUNOLIW VORWV WKUHH VLGHV DQG OLIWLQJ KROHV

5RRI FXUEV LQ HLJKW DQG IRXUWHHQ LQFK KHLJKWV 5RRI FXUEV IRU WUDQVLWLRQLQJ IURP <RUN 6XQOLQH IRRWSULQW WR WKH =+ 6HULHV IRRWSULQWV DUH DOVR DYDLODEOH ILHOG LQVWDOOHG DFFHVVRU\

7RROOHVV GRRU ODWFK

6OLGH RXW GUDLQ SDQ ZLWK VWHHO ´137 IHPDOH FRQQHFWLRQ

6LGH HQWU\ SRZHU &RPSUHVVRU DFFHVV DQG FRQWURO ZLULQJ KLJK HIILFLHQF\ FRPSUHVVRU NQRFNRXWV Z FUDQNFDVH KHDWHU

FIGURE 4 - PREDATOR® COMPONENT LOCATION

Unitary Products Group |

9 |

127408-YIM-B-0606

TABLE 1: UNIT VOLTAGE LIMITATIONS

Power Rating* |

|

Minimum |

Maximum |

|||

380/415-3-50 |

|

342 |

|

|

456 |

|

|

|

|

|

|

||

*. Utilization range “A” in accordance with ARI Standard |

||||||

110. |

|

|

|

|

|

|

TABLE 2: UNIT TEMPERATURE LIMITATIONS |

||||||

|

|

|

|

|

|

|

Temperature |

|

|

Min. |

|

Max. |

|

|

|

|

|

|

||

Wet Bulb Temperature °F(°C) of Air |

|

57(14) |

|

72(22) |

||

on Evaporator Coil |

|

|

||||

|

|

|

|

|||

|

|

|

|

|

||

Dry Bulb Temperature °F(°C) of Air |

|

0(-18) |

|

125(52) |

||

on Condenser Coil |

|

|

||||

|

|

|

|

|||

|

|

|

|

|

|

|

LOCATION |

|

|

|

|

|

|

Use the following guidelines to select a suitable location for these units:

1.Unit is designed for outdoor installation only.

2.Condenser coils must have an unlimited supply of air. Where a choice of location is possible, position the unit on either north or east side of building.

3.Suitable for mounting on roof curb.

4.For ground level installation, use a level concrete slab with a minimum thickness of 4 inches (102 mm). The length and width should be at least 6 inches (152 mm) greater than the unit base rails. Do not tie slab to the building foundation.

5.Roof structures must be able to support the weight of the unit and its options/accessories. Unit must be installed on a solid, level roof curb or appropriate angle iron frame.

6.Maintain level tolerance to 1/2” (13 mm) across the entire width and length of unit.

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any packaging until the unit is near the place of installation. Rig the unit by attaching chain or cable slings to the lifting holes provided in the base rails. Spreader bars, whose length exceeds the largest dimension across the unit, MUST be used across the top of the unit.

If a unit is to be installed on a roof curb other than a YORK roof curb, gasketing must be applied to all surfaces that come in contact with the unit underside.

Before lifting, make sure the unit weight is distributed equally on the rigging cables so it will lift evenly.

Units may be moved or lifted with a forklift. Slotted openings in the base rails are provided for this purpose.

LENGTH OF FORKS MUST BE A MINIMUM OF 60 INCHES (1524 mm.).

All panels must be secured in place when the unit is lifted.

The condenser coils should be protected from rigging cable damage with plywood or other suitable material.

Excessive exposure of this furnace to contaminated combustion air may result in equipment damage or personal injury. Typical contaminates include: permanent wave solution, chlorinated waxes and cleaners, chlorine based swimming pool chemicals, water softening chemicals, carbon tetrachloride, Halogen type refrigerants, cleaning solvents (e.g. perchloroethylene), printing inks, paint removers, varnishes, hydrochloric acid, cements and glues, antistatic fabric softeners for clothes dryers, masonry acid washing materials.

A

FIGURE 5 -

|

|

FRONT |

LEFT |

B |

C |

|

D

UNIT 4 POINT LOAD

10 |

Unitary Products Group |

127408-YIM-B-0606

TABLE 3: UNIT WEIGHT

Model |

Shipping Weight |

Operating Weight |

|

lbs. (kg) |

lbs. (kg) |

||

|

|||

090 |

865 (392.4) |

860 (390.1) |

|

120 |

1143 (518.6) |

1138 (516.3) |

|

150 |

1202 (545.3) |

1197 (543.1) |

TABLE 4: 4 POINT LOAD WEIGHT

Model |

|

Location (lbs. (kg.)) |

|

||

|

|

|

|

||

A |

B |

C |

D |

||

|

|||||

|

|

|

|

|

|

090 |

192 |

143 |

224 |

301 |

|

(87.1) |

(64.9) |

(101.6) |

(136.5) |

||

|

|||||

|

|

|

|

|

|

120 |

245 |

209 |

305 |

357 |

|

(111) |

(94) |

(138) |

(162) |

||

|

|||||

150 |

262 |

224 |

327 |

382 |

|

(118) |

(101) |

(148) |

(173) |

||

|

|||||

TABLE 5: 6 POINT LOAD WEIGHT

Model |

|

Locations (lbs. (kg.)) |

|

||||

|

|

|

|

|

|

||

A |

B |

C |

D |

E |

F |

||

|

|||||||

|

|

|

|

|

|

|

|

090 |

135 |

110 |

91 |

142 |

172 |

211 |

|

(61.2) |

(49.9) |

(41.3) |

(64.4) |

(78.0) |

(95.71) |

||

|

|||||||

120 |

168 |

151 |

136 |

198 |

219 |

244 |

|

(76.2) |

(68.4) |

(61.7) |

(89.8) |

(99.3) |

(110.7) |

||

|

|||||||

|

|

|

|

|

|

|

|

150 |

180 |

161 |

145 |

212 |

235 |

262 |

|

(81.6) |

(73) |

(65.8) |

(96.2) |

(107) |

(118.8) |

||

|

|||||||

A

FIGURE 6 -

|

FRONT |

LEFT |

D |

C |

B

E

F

UNIT 6 POINT LOAD

X |

Y |

|

|

|

|

|

|

|

FRONT |

|

|

LEFT |

|

|

|

|

|

|

|

Unit Model Number |

X |

|

Y |

DM090 |

38 (965.2) |

|

23 (584.2) |

DM120 |

47 1/2 (1206.5) |

|

25 1/2 (647.7) |

DM150 |

47 1/2 (1206.5) |

|

25 1/2 (647.7) |

FIGURE 7 - UNIT CENTER OF GRAVITY

CLEARANCES

All units require particular clearances for proper operation and service. Installer must make provisions for adequate combustion and ventilation air in accordance with section 5.3 of Air for Combustion and Ventilation of the National Fuel Gas Code, ANSI Z223.1 – Latest Edition (in U.S.A.), or Sections 7.2, 7.3, or 7.4 of Gas Installation Codes, CSA-B149.1 (in Canada) - Latest Edition, and/or applicable provisions of the local building codes. Refer to Table 7 for clearances required for combustible construction, servicing, and proper unit operation.

Do not permit overhanging structures or shrubs to obstruct condenser air discharge outlet, combustion air inlet or vent outlets.

Excessive exposure to contaminated combustion air will result in safety and performance related problems. To maintain combustion air quality, the recommended source of combustion air is the outdoor air supply. The outdoor air supplied for combustion should be free from contaminants due to chemical exposure that may be present from the following sources.

•Commercial buildings

•Indoor pools

•Laundry rooms

•Hobby or craft rooms

•Chemical storage areas

The following substances should be avoided to maintain outdoor combustion air quality.

•Permanent wave solutions

•Chlorinated waxes and cleaners

•Chlorine based swimming pool cleaners

•Water softening chemicals

•De-icing salts or chemicals

•Carbon tetrachloride

•Halogen type refrigerants

•Cleaning solvents (such as perchloroethylene)

•Printing inks, paint removers, varnishes, etc.

•Hydrochloric acid

•Cements and glues

•Anti-static fabric softeners for clothes dryers

•Masonry acid washing materials

Unitary Products Group |

11 |

127408-YIM-B-0606

|

|

|

|

|

6HH 'HWDLO |

|

|

|

|

|

|

|

|

8 |

|

|

3RZHU |

&RQWURO |

|

% |

|

|

|

(QWU\ |

|

|

|

|

|

|

(QWU\ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3RZHU |

|

|

|

|

|

|

|

|

|

|

|

|

(QWU\ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

&RQYHQLHQFH |

|

|

|

|

|

|

3RZHU |

|

|

|

|

|

|

2XWOHW |

|

)RU %DVHUDLO |

|

|

|

|

(QWU\ |

)5217 |

|

|

|

|

|

'LPHQVLRQV |

||

|

|

)RU 'UDLQ |

6HH 'HWDLO & |

|||

|

|

|

|

|

|

|

|

|

|

|

'LPHQVLRQV |

|

|

|

|

|

|

|

6HH 'HWDLO ' |

|

/()7 |

|

|

|

|

|

|

|

|

|

|

127( [[[ LQGLFDWHV GLPHQVLRQV

JLYHQ LQ PLOOLPHWHUV

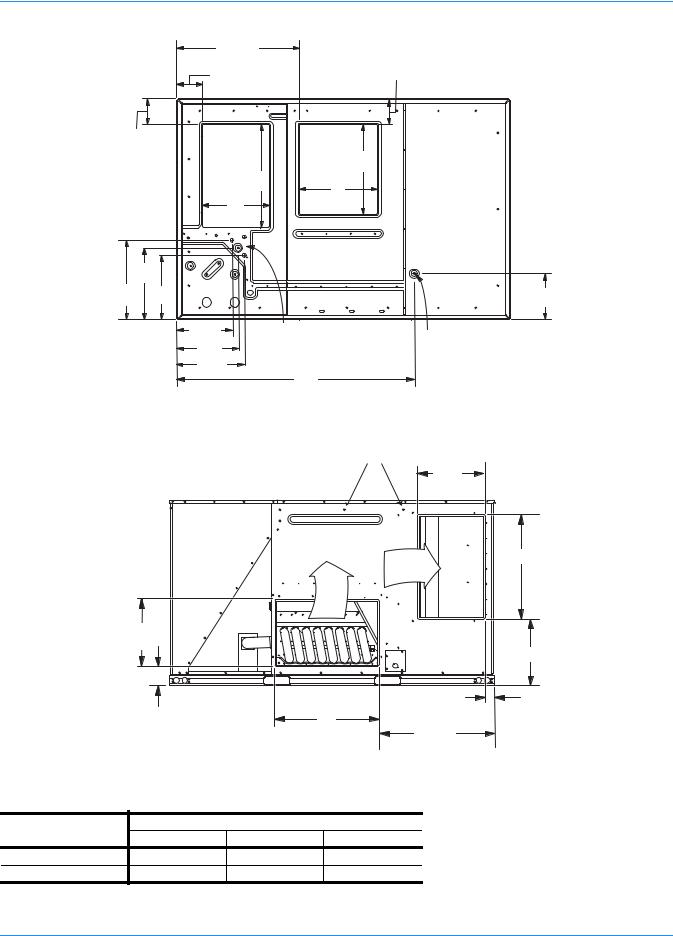

FIGURE 8 - UNIT DIMENSIONS

TABLE 6: UNIT HEIGHT

Unit Model Number |

X |

|

|

DM090 |

42 (1067) |

DM120 |

50 3/4 (1289) |

DM150 |

50 3/4 (1289) |

DETAIL B |

GasPipeInlet |

|

5-1/4

(135)Base

17-13/16 |

Pan |

|

(450) |

||

|

||

ViewofWalAcrossfromCoil |

|

|

TABLE 7: UNIT CLEARANCES * |

|

Top† |

72(1830) |

Right |

12(305) |

Front |

36(915) |

Left |

36(915) |

Rear‡ |

36(915) |

Bottom** |

0(0) |

*. In inches and millimeters, in.(mm).

†.Units must be installed outdoors. Overhanging structure or shrubs should not obstruct condenser air discharge outlet.

‡.To remove the slide-out drain pan, a rear clearance of 60” (1525 mm) is required. If space is unavailable, the drain pan can be removed through the front by separating the corner wall.

**. Units may be installed on combustible floors.

NOTE: A one-inch clearance must be provided between any combustible material and the supply ductwork for a distance of 3 feet from the unit.

DETAIL C |

2-3/8 |

(60) |

3-3/4

(95)

3-9/16

(90)

DETAIL D

5-3/8

(135)

NOTE: If the unit includes gas heating, locate the unit so the flue exhaust is at least:

•Three (3) feet above any forced air inlet located within 10 horizontal feet (excluding those integral to the unit).

•Four (4) feet below, four (4) horizontal feet from, or one

(1) foot above any door or gravity air inlet into the building.

•Four (4) feet from electric meters, gas meters, regulators, and relief equipment.

12 |

Unitary Products Group |

127408-YIM-B-0606

.

32-11/16 |

(830) |

6-13/16 |

(175) |

NOTE:(XXX)INDICATES

6-13/16 DIMENSIONSIN

(175) MILLIMETERS

6-13/16

(175)

24

(610)

27-1/2

(700) 21

LEFT |

(535) |

18

(455)

19-3/16

(485)

21-3/16 17-3/16

(540) (435)

14-23/32 |

BotomPower, |

|

|

|

(375) |

Controland |

FRONT |

Botomgas |

|

16-3/8 |

supplyentry |

|||

Convenience |

|

(415)OutletWiring

18-1/16 |

Entry |

|

(460) |

||

|

63-1/2

(1610)

FIGURE 9 - BOTTOM DUCT OPENINGS (FROM ABOVE)

DOT PLUGS

18-1/4 (465)

|

|

|

Return |

|

|

|

|

Air |

|

|

|

|

Supply |

|

|

|

|

Air |

|

|

18-1/4 |

|

|

|

|

(465) |

|

|

|

|

|

|

|

2-31/32 |

|

5-5/32 |

|

|

(75) |

|

|

C |

|

|

|

(130) |

|

|

|

|

|

|

|

|

|

NOTE: (XXX) indicates millimeters |

31-11/16 |

||

|

(805) |

|||

FIGURE 10 - REAR DUCT DIMENSIONS |

|

|

||

TABLE 8: REAR DUCT DIMENSIONS |

|

|

|

|

Cabinet Size |

|

Dimensions |

|

|

“A” |

“B” |

“C” |

|

|

|

|

|||

50 3/4 (1289) |

28 1/4 (717) |

18 1/16 (459) |

28 1/4 (717 |

|

42 (1067) |

27 3/4 (705) |

12 1/16 (308) |

27 1/2 (699) |

|

12-5/16

(315)

A

B

Unitary Products Group |

13 |

127408-YIM-B-0606

DUCTWORK

Ductwork should be designed and sized according to the methods in Manual D of the Air Conditioning Contractors of America (ACCA) or as recommended by any other recognized authority such as ASHRAE or SMACNA.

A closed return duct system should be used. This will not preclude use of economizers or outdoor fresh air intake. The supply and return air duct connections at the unit should be made with flexible joints to minimize noise.

The supply and return air duct systems should be designed for the CFM and static pressure requirements of the job. They should NOT be sized to match the dimensions of the duct connections on the unit.

Refer to Figure 9 for bottom air duct openings. Refer to Figure 10 for rear air duct openings.

DUCT COVERS

Units are shipped with the side duct openings covered and a covering over the bottom of the unit. For bottom duct application, no duct cover changes are necessary. For side duct application, remove the side duct covers and install over the bottom duct openings. The panels removed from the side duct connections are designed to be reused by securing each panel to its respective downflow opening. But keep in mind that the supply panel is installed with the painted surface UP, facing the heat exchanger, while the return panel is installed with the painted surface DOWN, facing the downflow duct opening. The supply panel is secured with the bracket (already in place from the factory) and two screws. It’s a snug fit for the panel when sliding it between the heat exchanger and unit bottom, but there is room. The return panel is secured with four screws.

RIGHT

80-5/8

(2050) INSULATEDDECKUNDER CONDENSERSECTION

20

(510)

|

SUPPLY |

|

20 |

6 |

|

(510)(150) |

||

2TYP. |

RETURN |

|

(50) |

||

|

||

30 |

|

(760) |

|

|

INSULATEDDECKUNDER |

50-1/2 |

COMPRESSORSECTION |

(1285) |

|

8 OR 14 |

FRONT |

|

(205) |

(355) |

|

NOTE:(XXX)INDICATES

DIMENSIONSIN

MILLIMETERS

FIGURE 11 - PREDATOR® ROOF CURB DIMENSIONS

|

2TYP |

|

|

|

(50) |

|

|

|

30-1/2 |

23 |

|

50-1/2 |

(775) |

(585) |

|

(1285) |

|

4 |

|

|

|

(100) |

|

|

RETURN |

26 |

80-5/8 |

|

(660) |

(2050) |

|

|

|

SUPPLY

10  (255

(255

76-5/8

(1945)

59-1/4 FRONT 94 (1505)

(2390)

RIGHT

64-1/4 (1630)

FIGURE 12 - SUNLINE™ TO PREDATOR® TRANSITION ROOF CURBS

14 |

Unitary Products Group |

127408-YIM-B-0606

When fastening ductwork to side duct flanges on unit, insert screws through duct flanges only. DO NOT insert screws through casing. Outdoor ductwork must be insulated and water-proofed.

FIGURE 13 - SIDE PANELS WITH HOLE PLUGS

Note orientation. Panel is “insulation” side up.

FIGURE 14 - RETURN DOWNFLOW PLENUM WITH PANEL

FIGURE 15 - DISCHARGE PANEL IN PLACE

CONDENSATE DRAIN

The side condensate drain is reversible and maybe re-ori- ented to the rear of the cabinet to facilitate condensate piping. A condensate drain connection is available through the base pan for piping inside the roof curb. Trap the connection per Figure 16: Condensate Drain. The trap and drain lines should be protected from freezing.

Plumbing must conform to local codes. Use a sealing compound on male pipe threads. Install condensate drain line from the 3/4 inch (19 mm) NPT female connection on the unit to an open drain.

3"Minimum (76.2mm)

FIGURE 16 - CONDENSATE DRAIN

COMPRESSORS

The compressors are mounted on elastomer insulators. The mounting bolts have been fully tightened for shipping.

Do not loosen the compressor mounting bolts.

FILTERS

Two-inch filters are supplied with each unit. One-inch filters may be used with no modification to the filter racks. Filters must always be installed ahead of evaporator coil and must be kept clean or replaced with same size and type. Dirty filters reduce the capacity of the unit and result in frosted coils or safety shutdown. All units use four (4) 20”x25”x2” filters. The unit should not be operated without filters properly installed.

Make sure that panel latches are properly positioned on the unit to maintain an airtight seal.

Unitary Products Group |

15 |

127408-YIM-B-0606

THERMOSTAT WIRING

The thermostat should be located on an inside wall approximately 56 inches (1422 mm) above the floor where it will not be subject to drafts, sun exposure or heat from electrical fixtures or appliances. Follow the manufacturer's instructions enclosed with thermostat for general installation procedure. Seven (7) color-coded, insulated wires should be used to connect the thermostat to the unit. Refer to Table 9 for control wire sizing and maximum length.

TABLE 9: CONTROL WIRE SIZES

Wire Size |

Maximum Length |

|

|

18 AWG |

150 Feet (45.72 meters) |

|

|

POWER AND CONTROL WIRING

Field wiring to the unit, fuses, and disconnects must conform to provisions of National Electrical Code (NEC), ANSI/NFPA No. 70 – Latest Edition (in U.S.A.), current Canadian Electrical Code C221, and/or local ordinances. The unit must be electrically grounded in accordance with NEC and CEC as specified above and/or local codes.

Voltage tolerances which must be maintained at the compressor terminals during starting and running conditions are indicated on the unit Rating Plate and Table 1.

The internal wiring harnesses furnished with this unit are an integral part of the design certified unit. Field alteration to comply with electrical codes should not be required. If any of the wire supplied with the unit must be replaced, replacement wire must be of the type shown on the wiring diagram and the same minimum gauge as the replaced wire.

A disconnect must be utilized for these units. When installing a disconnect, refer to Figure 4 for the recommended mounting location.

Avoid damage to internal components if drilling holes for disconnect mounting.

NOTE: Since not all local codes allow the mounting of a disconnect on the unit, please confirm compliance with local code before mounting a disconnect on the unit.

Electrical line must be sized properly to carry the load. USE COPPER CONDUCTORS ONLY. Each unit must be wired with a separate branch circuit fed directly from the meter panel and properly fused.

Refer to Figures 17, 18 and 19 for typical field wiring and to the appropriate unit wiring diagram mounted inside control doors for control circuit and power wiring information.

When connecting electrical power and control wiring to the unit, water-proof connectors must be used so that water or moisture cannot be drawn into the unit during normal operation. The above water-proofing conditions will also apply when installing a field supplied disconnect switch.

POWER WIRING DETAIL

Units are factory wired for the voltage shown on the unit nameplate. Refer to Electrical Data Tables 10 through 12 size power wiring, fuses, and disconnect switch.

Power wiring is brought into the unit through the side of the unit or the basepan inside the curb.

16 |

Unitary Products Group |

127408-YIM-B-0606

THERMOSTAT |

|

|

|

1 |

|

|

|

TERMINALS |

|

UNITTERMINALS |

|

|

|

||

RC |

|

STRIPTB1 |

|

RH |

|

R |

|

Y1 |

|

Y1 |

|

Y2 |

|

Y2 |

|

W1 |

|

W1 |

|

W2 |

|

W2 |

|

G |

|

G |

|

C |

|

C |

24Volt |

|

|

|

|

X1 |

|

X |

Transformer |

|

|

||

X3 |

2 |

OCC |

|

X4

A1

A2

T

T

TOREMOTESENSOR 2ET04701324IFUSED

1ElectronicprogrammableThermostat2ET0770010024(includessubbase). 2TerminalsA1andA2providearelayoutputtoclosetheoutdoor

economizerdamperswhenthethermostatswitchestotheset-backposition.

FIGURE 17 - ELECTRONIC THERMOSTAT FIELD WIRING

T-STAT

W1

W2

Y1

G

Y2

C

RH

RC

W1

W2

Y1

G

OCC

REMOTEMIN POS

Y2

X

UNITCONTROL

BOARD

R

SD

C

FIGURE 18 - FIELD WIRING 24 VOLT THERMOSTAT

Unitary Products Group |

17 |

127408-YIM-B-0606

TERMINAL BLOCK TB1

FIELD SUPPLIED

DISCONNECT

GROUND

LUG

THREE

PHASE

POWER

SUPPLY

FIGURE 19 - FIELD WIRING DISCONNECT - COOLING UNIT WITH OR WITHOUT ELECTRIC HEAT

CONTACTOR 1M

T1 |

T2 |

T3 |

L1 |

L2 |

L3 |

|

|

FIELD SUPPLIED |

GROUND |

|

DISCONNECT |

LUG |

|

|

THREE

PHASE

POWER

SUPPLY

FIGURE 20 - FIELD WIRING DISCONNECT - COOLING UNIT WITH GAS HEAT

18 |

Unitary Products Group |

Loading...

Loading...