Yamaha YZF-R1 2004 User Manual [ru]

EAS00010

YZF-R1S/YZF-R1SC

SERVICE MANUAL2003 by Yamaha Motor

Corporation, U.S.A. First edition, December 2003

All rights reserved. Any reproduction or unauthorized use without the written permission of Yamaha Motor Corporation, U.S.A. is expressly prohibited.

Printed in U.S.A.

P/N LIT-11616-17-55

EAS00030

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles should have a basic understanding of mechanics and the techniques to repair these types of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

This model has been designed and manufactured to perform within certain specifications in regard to performance and emissions. Proper service with the correct tools is necessary to ensure that the vehicle will operate as designed. If there is any question about a service procedure, it is imperative that you contact a Yamaha dealer for any service information changes that apply to this model. This policy is intended to provide the customer with the most satisfaction from his vehicle and to conform to federal environmental quality objectives.

Yamaha Motor Company, Ltd. is continually striving to improve all of its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

SThis Service Manual contains information regarding periodic maintenance to the emission control system. Please read this material carefully.

SDesigns and specifications are subject to change without notice.

EAS00040

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

WARNING

CAUTION:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death to the motorcycle operator, a bystander or a person checking or repairing the motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage to the motorcycle.

NOTE: A NOTE provides key information to make procedures easier or clearer.

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order.

1The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each page indicate the current chapter.

Refer to “SYMBOLS”.

2Each chapter is divided into sections. The current section title is shown at the top of each page, except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section title(s) appears.

3Sub-section titles appear in smaller print than the section title.

4To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section.

5Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a disassembly step.

6Symbols indicate parts to be lubricated or replaced.

Refer to “SYMBOLS”.

7A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of parts, notes in jobs, etc.

8Jobs requiring more information (such as special tools and technical data) are described sequentially.

2 |

1 |

|

3 |

4 |

|

5 |

|

6 |

|

|

8 |

7 |

|

1 |

2 |

GEN |

SPEC |

|

INFO |

||

|

||

3 |

4 |

|

CHK |

CHAS |

|

ADJ |

||

|

||

5 |

6 |

|

ENG |

COOL |

|

7 |

8 |

|

|

ELEC |

|

9 |

10 |

|

TRBL |

|

|

SHTG |

|

|

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

EAS00008

SYMBOLS

The following symbols are not relevant to every vehicle.

Symbols 1 to 9 indicate the subject of each chapter.

1General information

2Specifications

3Periodic checks and adjustments

4Chassis

5Engine

6Cooling system

7Fuel injection system

8Electrical system

9Troubleshooting

Symbols 10 to 17 indicate the following.

10Serviceable with engine mounted

11Filling fluid

12Lubricant

13Special tool

14Tightening torque

15Wear limit, clearance

16Engine speed

17Electrical data

Symbols 18 to 23 in the exploded diagrams indicate the types of lubricants and lubrication points.

18Engine oil

19Gear oil

20Molybdenum-disulfide oil

21Wheel-bearing grease

22Lithium-soap- based grease

23Molybdenum-disulfide grease

Symbols 24 to 25 in the exploded diagrams indicate the following.

24Apply locking agent (LOCTITE )

25Replace the part

EAS00012

TABLE OF CONTENTS

GENERAL INFORMATION |

|

|

|

GEN |

1 |

||

|

INFO |

||

|

|

|

|

SPECIFICATIONS |

|

|

|

SPEC |

2 |

||

|

|||

|

|

|

|

PERIODIC CHECKS AND |

|

|

|

CHK |

3 |

||

ADJUSTMENTS |

|||

ADJ |

|||

|

|

|

|

CHASSIS |

|

|

|

CHAS |

4 |

||

|

|||

|

|

|

|

ENGINE |

|

|

|

ENG |

5 |

||

|

|||

|

|

|

|

COOLING SYSTEM |

|

|

|

COOL |

6 |

||

|

|||

|

|

|

|

FUEL INJECTION SYSTEM |

|

|

|

FI |

7 |

||

|

|||

|

|

|

|

ELECTRICAL SYSTEM |

|

|

|

ELEC |

8 |

||

|

|||

|

|

|

|

TROUBLESHOOTING |

|

|

|

TRBL |

9 |

||

|

SHTG |

CHAPTER 1

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

VEHICLE IDENTIFICATION NUMBER . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

MODEL LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

INSTRUMENT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

PREPARATION FOR REMOVAL AND DISASSEMBLY . . . . . . . . . |

1-6 |

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

GASKETS, OIL SEALS AND O-RINGS . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

LOCK WASHERS/PLATES AND COTTER PINS . . . . . . . . . . . . . . |

1-7 |

BEARINGS AND OIL SEALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

CIRCLIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

CHECKING THE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-8 |

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

ENGINE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

CHASSIS SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-11 |

ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-15 |

CONVERSION TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-18 |

GENERAL TIGHTENING TORQUE SPECIFICATIONS . . . . . . . . . . . . |

2-18 |

TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-19 |

ENGINE TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-19 |

CHASSIS TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-23 |

LUBRICATION POINTS AND LUBRICANT TYPES . . . . . . . . . . . . . . . |

2-25 |

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-25 |

CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-26 |

COOLING SYSTEM DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-27 |

ENGINE OIL LUBRICATION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

LUBRICATION DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-30 |

CABLE ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-35 |

CHAPTER 3

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

PERIODIC MAINTENANCE CHART FOR THE EMISSION |

|

CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

GENERAL MAINTENANCE AND LUBRICATION CHART . . . . . . . . . |

3-1 |

SEATS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-3 |

FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

REMOVING THE FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-5 |

REMOVING THE FUEL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-5 |

INSTALLING THE FUEL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-6 |

INSTALLING THE FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-6 |

COWLINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-7 |

FRONT COWLING AND SIDE COWLINGS . . . . . . . . . . . . . . . . . . . |

3-7 |

REAR COWLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-8 |

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-9 |

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-9 |

AIR FILTER CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-10 |

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-11 |

ADJUSTING THE VALVE CLEARANCE . . . . . . . . . . . . . . . . . . . . . . |

3-11 |

SYNCHRONIZING THE THROTTLE BODIES . . . . . . . . . . . . . . . . . |

3-17 |

ADJUSTING THE EXHAUST GAS VOLUME . . . . . . . . . . . . . . . . . . |

3-19 |

ADJUSTING THE ENGINE IDLING SPEED . . . . . . . . . . . . . . . . . . . |

3-21 |

ADJUSTING THE THROTTLE CABLE FREE PLAY . . . . . . . . . . . . |

3-22 |

CHECKING THE SPARK PLUGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-23 |

MEASURING THE COMPRESSION PRESSURE . . . . . . . . . . . . . . |

3-24 |

CHECKING THE ENGINE OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . |

3-26 |

CHANGING THE ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-28 |

MEASURING THE ENGINE OIL PRESSURE . . . . . . . . . . . . . . . . . |

3-29 |

ADJUSTING THE CLUTCH CABLE FREE PLAY . . . . . . . . . . . . . . . |

3-31 |

REPLACING THE AIR FILTER ELEMENT . . . . . . . . . . . . . . . . . . . . |

3-32 |

CHECKING THE FUEL AND BREATHER HOSES . . . . . . . . . . . . . |

3-33 |

CHECKING THE CRANKCASE BREATHER HOSE . . . . . . . . . . . . |

3-34 |

CHECKING THE EXHAUST SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . |

3-35 |

ADJUSTING THE EXUP CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-36 |

CHECKING THE COOLANT LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-37 |

CHECKING THE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . |

3-38 |

CHANGING THE COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-39 |

CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42 ADJUSTING THE FRONT BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42 ADJUSTING THE REAR BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43 CHECKING THE BRAKE FLUID LEVEL . . . . . . . . . . . . . . . . . . . . . . 3-44 ADJUSTING THE REAR BRAKE LIGHT SWITCH . . . . . . . . . . . . . 3-45 CHECKING THE FRONT AND REAR BRAKE PADS . . . . . . . . . . . 3-45 CHECKING THE FRONT AND REAR BRAKE HOSES . . . . . . . . . 3-46 BLEEDING THE HYDRAULIC BRAKE SYSTEM . . . . . . . . . . . . . . . 3-47 ADJUSTING THE SHIFT PEDAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48 ADJUSTING THE DRIVE CHAIN SLACK . . . . . . . . . . . . . . . . . . . . . 3-49 LUBRICATING THE DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50 CHECKING AND ADJUSTING THE STEERING HEAD . . . . . . . . . 3-51 CHECKING THE FRONT FORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53 ADJUSTING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . . 3-54 ADJUSTING THE REAR SHOCK ABSORBER ASSEMBLY . . . . . 3-56 CHECKING THE TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58 CHECKING THE WHEELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60 CHECKING AND LUBRICATING THE CABLES . . . . . . . . . . . . . . . 3-61 LUBRICATING THE LEVERS AND PEDALS . . . . . . . . . . . . . . . . . . 3-61 LUBRICATING THE SIDESTAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61 LUBRICATING THE REAR SUSPENSION . . . . . . . . . . . . . . . . . . . . 3-61

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62 CHECKING AND CHARGING THE BATTERY . . . . . . . . . . . . . . . . . 3-62 CHECKING THE FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67 REPLACING THE HEADLIGHT BULBS . . . . . . . . . . . . . . . . . . . . . . 3-69 ADJUSTING THE HEADLIGHT BEAMS . . . . . . . . . . . . . . . . . . . . . . 3-70

CHAPTER 4

CHASSIS

FRONT WHEEL AND BRAKE DISCS . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 REMOVING THE FRONT WHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 CHECKING THE FRONT WHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 CHECKING THE BRAKE DISCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 INSTALLING THE FRONT WHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6 ADJUSTING THE FRONT WHEEL STATIC BALANCE . . . . . . . . . 4-7

REAR WHEEL AND BRAKE DISC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9 REAR WHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9 REAR BRAKE DISC AND REAR WHEEL SPROCKET . . . . . . . . . 4-10 REMOVING THE REAR WHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12 CHECKING THE REAR WHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13 CHECKING THE REAR WHEEL DRIVE HUB . . . . . . . . . . . . . . . . . 4-13 CHECKING AND REPLACING THE REAR WHEEL

SPROCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13 INSTALLING THE REAR WHEEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14 ADJUSTING THE REAR WHEEL STATIC BALANCE . . . . . . . . . . . 4-14

FRONT AND REAR BRAKES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15 FRONT BRAKE PADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15 REAR BRAKE PADS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16 REPLACING THE FRONT BRAKE PADS . . . . . . . . . . . . . . . . . . . . . 4-18 REPLACING THE REAR BRAKE PADS . . . . . . . . . . . . . . . . . . . . . . 4-20 FRONT BRAKE MASTER CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . 4-22 REAR BRAKE MASTER CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . 4-25 DISASSEMBLING THE FRONT BRAKE MASTER

CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27 DISASSEMBLING THE REAR BRAKE MASTER

CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27 CHECKING THE FRONT AND REAR BRAKE MASTER

CYLINDERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28 ASSEMBLING AND INSTALLING THE FRONT BRAKE

MASTER CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29 ASSEMBLING THE REAR BRAKE MASTER CYLINDER . . . . . . . 4-31 FRONT BRAKE CALIPERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33 REAR BRAKE CALIPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35 DISASSEMBLING THE FRONT BRAKE CALIPERS . . . . . . . . . . . 4-37 DISASSEMBLING THE REAR BRAKE CALIPER . . . . . . . . . . . . . . 4-38 CHECKING THE FRONT AND REAR BRAKE CALIPERS . . . . . . 4-39 ASSEMBLING AND INSTALLING THE FRONT BRAKE

CALIPERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40 ASSEMBLING AND INSTALLING THE REAR

BRAKE CALIPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

FRONT FORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44 FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44 REMOVING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . . . 4-47 DISASSEMBLING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . . 4-48 CHECKING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . . . 4-49 ASSEMBLING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . 4-50 INSTALLING THE FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . . 4-55

HANDLEBARS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56 REMOVING THE HANDLEBARS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58 CHECKING THE HANDLEBARS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58 INSTALLING THE HANDLEBARS . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58 CHECKING THE STEERING DAMPER . . . . . . . . . . . . . . . . . . . . . . . 4-60

STEERING HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61 UNDER BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61 REMOVING THE UNDER BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . 4-63 CHECKING THE STEERING HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63 INSTALLING THE STEERING HEAD . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

REAR SHOCK ABSORBER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 4-65 HANDLING THE REAR SHOCK ABSORBER AND

GAS CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66 DISPOSING OF A REAR SHOCK ABSORBER AND

GAS CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66 REMOVING THE REAR SHOCK ABSORBER ASSEMBLY . . . . . 4-67 CHECKING THE REAR SHOCK ABSORBER ASSEMBLY . . . . . . 4-68 INSTALLING THE REAR SHOCK ABSORBER ASSEMBLY . . . . . 4-68

SWINGARM AND DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-69 REMOVING THE SWINGARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71 REMOVING THE DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72 CHECKING THE SWINGARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72 CHECKING THE DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-73 INSTALLING THE SWINGARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-75

CHAPTER 5

ENGINE

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 DRIVE SPROCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 EXHAUST PIPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 LEADS AND HOSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7 INSTALLING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

CAMSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11 CYLINDER HEAD COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11 CAMSHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13 REMOVING THE CAMSHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14 CHECKING THE CAMSHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15 CHECKING THE TIMING CHAIN, CAMSHAFT SPROCKETS,

AND TIMING CHAIN GUIDES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17 CHECKING THE TIMING CHAIN TENSIONER . . . . . . . . . . . . . . . . 5-17 INSTALLING THE CAMSHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22 REMOVING THE CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23 CHECKING THE CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23 INSTALLING THE CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

VALVES AND VALVE SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25 REMOVING THE VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27 CHECKING THE VALVES AND VALVE GUIDES . . . . . . . . . . . . . . . 5-28 CHECKING THE VALVE SEATS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30 CHECKING THE VALVE SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31 CHECKING THE VALVE LIFTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32 INSTALLING THE VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

STARTER CLUTCH AND GENERATOR . . . . . . . . . . . . . . . . . . . . . . . . . 5-35 STATOR COIL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35 STARTER CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37 REMOVING THE GENERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38 REMOVING THE STARTER CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . 5-39 CHECKING THE DAMPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39 CHECKING THE STARTER CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . 5-40 INSTALLING THE STARTER CLUTCH . . . . . . . . . . . . . . . . . . . . . . . 5-41 INSTALLING THE GENERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41

CRANKSHAFT POSITION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43 REMOVING THE CRANKSHAFT POSITION SENSOR . . . . . . . . . 5-44 INSTALLING THE CRANKSHAFT POSITION SENSOR . . . . . . . . 5-44

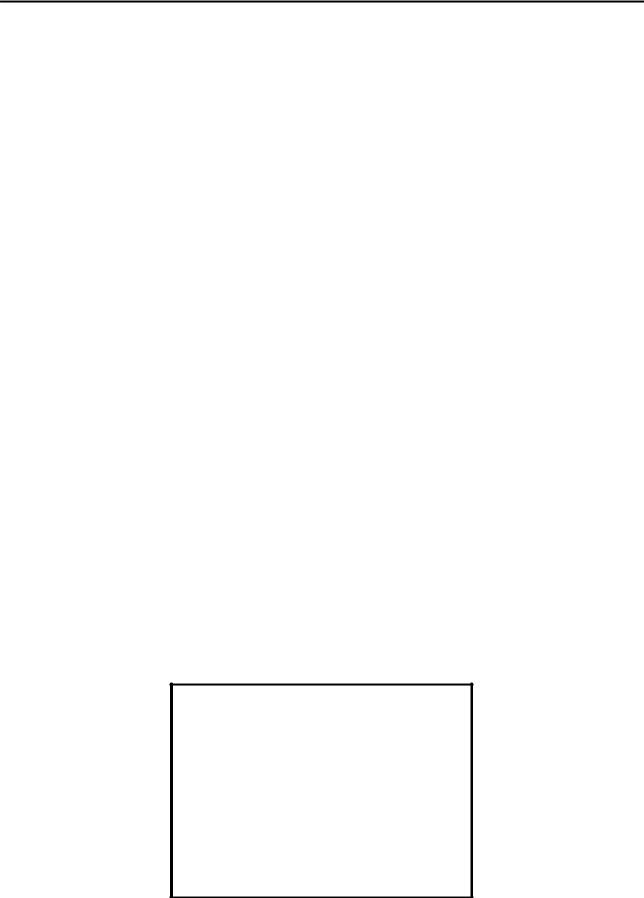

CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46 CLUTCH COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46 PULL LEVER SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47 CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48 REMOVING THE CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50 CHECKING THE FRICTION PLATES . . . . . . . . . . . . . . . . . . . . . . . . . 5-52 CHECKING THE CLUTCH PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . 5-52 CHECKING THE CLUTCH SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . 5-53 CHECKING THE CLUTCH HOUSING . . . . . . . . . . . . . . . . . . . . . . . . 5-53 CHECKING THE CLUTCH BOSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53 CHECKING THE PRESSURE PLATE . . . . . . . . . . . . . . . . . . . . . . . . 5-54 CHECKING THE PULL LEVER SHAFT AND PULL ROD . . . . . . . 5-54 INSTALLING THE CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

SHIFT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-58 SHIFT SHAFT AND STOPPER LEVER . . . . . . . . . . . . . . . . . . . . . . . 5-58 REMOVING THE SHIFT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-60 CHECKING THE SHIFT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61 CHECKING THE STOPPER LEVER . . . . . . . . . . . . . . . . . . . . . . . . . 5-61 INSTALLING THE SHIFT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-61

OIL PAN AND OIL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-63 REMOVING THE OIL PAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-66 CHECKING THE SPROCKET AND CHAIN . . . . . . . . . . . . . . . . . . . . 5-66 CHECKING THE OIL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67 CHECKING THE RELIEF VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-67 CHECKING THE OIL DELIVERY PIPE AND OIL PIPE . . . . . . . . . 5-68 CHECKING THE OIL STRAINER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68 CHECKING THE OIL NOZZLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68 ASSEMBLING THE OIL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-68 INSTALLING THE OIL/WATER PUMP ASSEMBLY . . . . . . . . . . . . 5-69 INSTALLING THE OIL PAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-71

CRANKCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72 DISASSEMBLING THE CRANKCASE . . . . . . . . . . . . . . . . . . . . . . . . 5-74 CHECKING THE CRANKCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75 CHECKING THE BEARINGS AND OIL SEALS . . . . . . . . . . . . . . . . 5-75 ASSEMBLING THE CRANKCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-75

CONNECTING RODS AND PISTONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-77 REMOVING THE CONNECTING RODS AND PISTONS . . . . . . . . 5-78 REMOVING THE CRANKSHAFT ASSEMBLY . . . . . . . . . . . . . . . . . 5-79 CHECKING THE CYLINDER AND PISTON . . . . . . . . . . . . . . . . . . . 5-79 CHECKING THE PISTON RINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-80 CHECKING THE PISTON PINS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-81 CHECKING THE BIG END BEARINGS . . . . . . . . . . . . . . . . . . . . . . . 5-82 INSTALLING THE CONNECTING ROD AND PISTON . . . . . . . . . . 5-86

CRANKSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-92 CHECKING THE CRANKSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93 CHECKING THE CRANKSHAFT DRIVE SPROCKET . . . . . . . . . . 5-93 CHECKING THE CRANKSHAFT JOURNAL BEARINGS . . . . . . . . 5-93 INSTALLING THE CRANKSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-96

TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-97 TRANSMISSION, SHIFT DRUM ASSEMBLY AND

SHIFT FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-97 REMOVING THE TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-103 CHECKING THE SHIFT FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-103 CHECKING THE SHIFT DRUM ASSEMBLY . . . . . . . . . . . . . . . . . . . 5-104 CHECKING THE TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-104 INSTALLING THE TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . 5-105

CHAPTER 6

COOLING SYSTEM

RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 CHECKING THE RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 INSTALLING THE RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

OIL COOLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5 CHECKING THE OIL COOLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7 INSTALLING THE OIL COOLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8 CHECKING THE THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10 ASSEMBLING THE THERMOSTAT ASSEMBLY . . . . . . . . . . . . . . . 6-11 INSTALLING THE THERMOSTAT ASSEMBLY . . . . . . . . . . . . . . . . 6-11

WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12 IMPELLER SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12 DISASSEMBLING THE WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . 6-14

CHECKING THE WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14 ASSEMBLING THE WATER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

CHAPTER 7

FUEL INJECTION SYSTEM

FUEL INJECTION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 ECU’S SELF-DIAGNOSTIC FUNCTION . . . . . . . . . . . . . . . . . . . . . . 7-4 SUBSTITUTE CHARACTERISTICS OPERATION CONTROL (FAIL-SAFE ACTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5 FAIL-SAFE ACTIONS TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5 TROUBLESHOOTING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7 DIAGNOSTIC MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8 TROUBLESHOOTING DETAILS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

THROTTLE BODIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35 INJECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37 CHECKING THE INJECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39 CHECKING THE THROTTLE BODIES . . . . . . . . . . . . . . . . . . . . . . . 7-39 CHECKING THE THROTTLE BODY JOINTS . . . . . . . . . . . . . . . . . . 7-39 CHECKING THE PRESSURE REGULATOR . . . . . . . . . . . . . . . . . . 7-40 CHECKING THE FUEL PUMP AND PRESSURE REGULATOR OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40 CHECKING AND ADJUSTING THE THROTTLE POSITION

SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41 CHECKING AND ADJUSTING THE SUB-THROTTLE POSITION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43 CHECKING AND ADJUSTING THE THERMO WAX . . . . . . . . . . . . 7-45

AIR INDUCTION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46 AIR INJECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46 AIR CUT-OFF VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46 AIR INDUCTION SYSTEM DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . 7-47 CHECKING THE AIR INDUCTION SYSTEM . . . . . . . . . . . . . . . . . . 7-48

CHAPTER 8

ELECTRICAL SYSTEM

ELECTRICAL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

CHECKING SWITCH CONTINUITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

CHECKING THE SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8-4 |

CHECKING THE BULBS AND BULB SOCKETS . . . . . . . . . . . . . . . . . 8-5 TYPES OF BULBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5 CHECKING THE CONDITION OF THE BULBS . . . . . . . . . . . . . . . . 8-5

CHECKING THE CONDITION OF THE BULB SOCKETS . . . . . . . 8-6 CHECKING THE LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

IGNITION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

ELECTRIC STARTING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14 STARTING CIRCUIT CUT-OFF SYSTEM OPERATION . . . . . . . . . 8-15 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19 CHECKING THE STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . 8-21 ASSEMBLING THE STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . 8-22

CHARGING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

LIGHTING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29 CHECKING THE LIGHTING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . 8-31

SIGNALING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36 CHECKING THE SIGNALING SYSTEM . . . . . . . . . . . . . . . . . . . . . . 8-36

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-45

FUEL PUMP SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-48 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-48 FUEL PUMP SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-49 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-50 CHECKING THE FUEL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-52

SELF-DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-53 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-54

CHAPTER 9

TROUBLESHOOTING

STARTING FAILURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

ELECTRICAL SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

INCORRECT ENGINE IDLING SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2 FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2 ELECTRICAL SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

POOR MEDIUM-AND-HIGH-SPEED PERFORMANCE . . . . . . . . . . . . . 9-2 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2 FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

FAULTY GEAR SHIFTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3 SHIFTING IS DIFFICULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3 SHIFT PEDAL DOES NOT MOVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3 JUMPS OUT OF GEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

FAULTY CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3 CLUTCH SLIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3 CLUTCH DRAGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

OVERHEATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4 COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4 FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4 CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4 ELECTRICAL SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

OVERCOOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4 COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

POOR BRAKING PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

FAULTY FRONT FORK LEGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5 LEAKING OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5 MALFUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

UNSTABLE HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

FAULTY LIGHTING OR SIGNALING SYSTEM . . . . . . . . . . . . . . . . . . . . 9-6 HEADLIGHT DOES NOT COME ON . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6 HEADLIGHT BULB BURNT OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6 TAIL/BRAKE LIGHT DOES NOT COME ON . . . . . . . . . . . . . . . . . . . 9-6 TAIL/BRAKE LIGHT BULB BURNT OUT . . . . . . . . . . . . . . . . . . . . . . 9-6 TURN SIGNAL DOES NOT COME ON . . . . . . . . . . . . . . . . . . . . . . . . 9-6 TURN SIGNAL BLINKS SLOWLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6 TURN SIGNAL REMAINS LIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6 TURN SIGNAL BLINKS QUICKLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6 HORN DOES NOT SOUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

MOTORCYCLE IDENTIFICATION

EAS00014

GEN INFO

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION

EAS00017

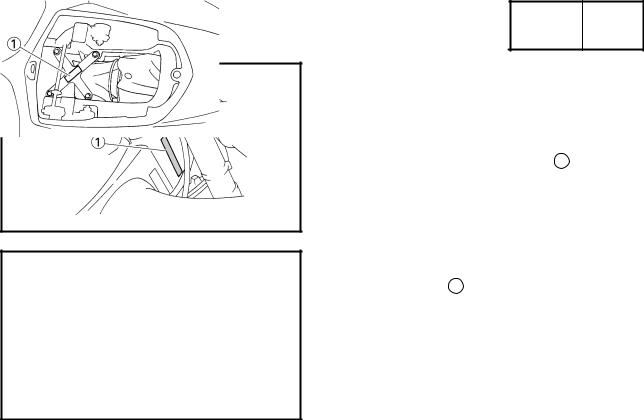

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is stamped into the right side of the steering head pipe.

EAS00018

MODEL LABEL

The model label 1 is affixed to the frame. This information will be needed to order spare parts.

1-1

FEATURES

EAS00019

GEN INFO

FEATURES

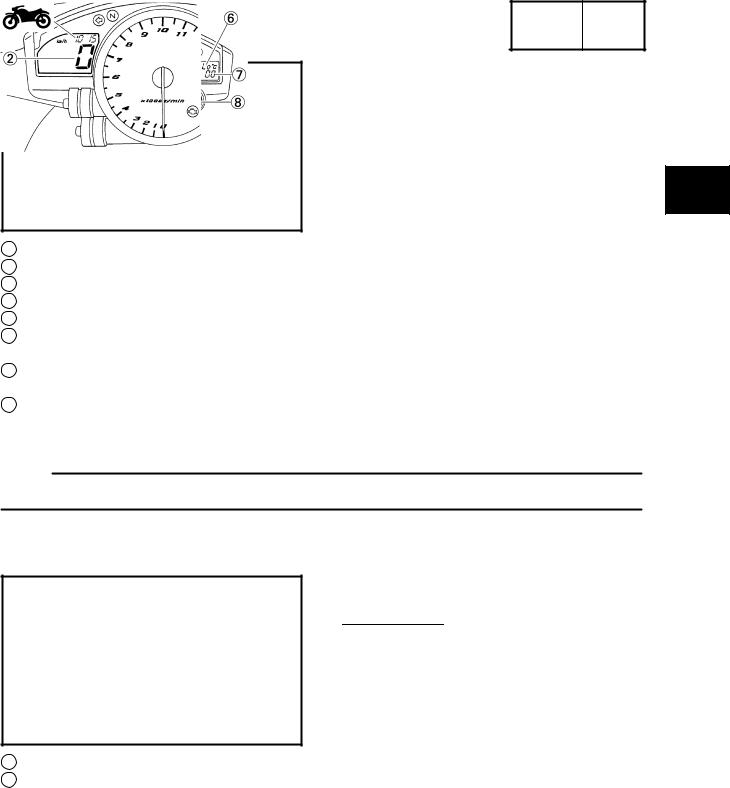

1Clock

2Speedometer

3“SELECT” button

4“RESET” button

5Tachometer

6Coolant temperature display/air intake temperature display

7Odometer/tripmeters/fuel reserve tripmeter/stopwatch

8Shift timing indicator light

NOTE:

INSTRUMENT FUNCTIONS |

|

Multi-function display |

|

The multi-function meter unit is equipped with |

|

the following: |

1 |

S a speedometer (which shows the riding |

|

speed) |

|

S a tachometer (witch shows engine speed) |

S an odometer (which shows the total distance traveled)

S two tripmeters (which show the distance traveled since they were last set to zero)

S a fuel reserve tripmeter (which shows the distance traveled since the fuel level warning light came on)

S a stopwatch S a clock

S a coolant temperature display

S an air intake temperature display S a self-diagnosis device

S a display brightness and shift timing indicator light control mode

S Be sure to turn the key to “ON” before using the “SELECT” and “RESET” buttons.

1Clock

2Speedometer

Clock mode

Turn the key to “ON”.

To set the clock

1.Push the “SELECT” button and “RESET” button together for at least two seconds.

2.When the hour digits start flashing, push the “RESET” button to set the hours.

3.Push the “SELECT” button, and the minute digits will start flashing.

4.Push the “RESET” button to set the minutes.

5.Push the “SELECT” button and then release it to start the clock.

1-2

GEN

FEATURES INFO

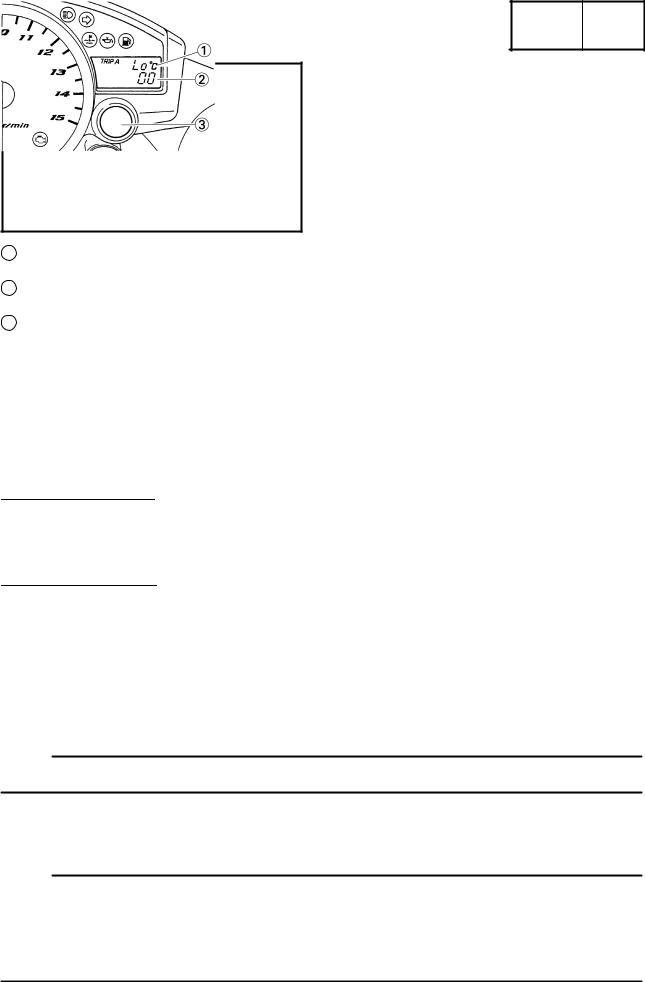

1 Coolant temperature display/air intake temperature display

2Odometer/tripmeters/fuel reserve tripmeter/stopwatch

3Shift timing indicator light

Odometer, tripmeter, and stopwatch modes

Push the “SELECT” button to switch the display between the odometer mode “ODO”, the tripmeter modes “TRIP A” and “TRIP B” and the stopwatch mode in the following order:

TRIP A ! TRIP B ! ODO ! Stopwatch ! TRIP A

If the fuel level warning light comes on, the odometer display will automatically change to the fuel reserve tripmeter mode ”F-TRIP” and start counting the distance traveled from that point. In that case, push the ”SELECT” button to switch the display between the various tripmeter, odometer, and stopwatch modes in the following order:

F-TRIP ! Stopwatch ! TRIP A ! TRIP B ! ODO ! F-TRIP

To reset a tripmeter, select it by pushing the “SELECT” button, and then push the “RESET” button for at least one second. If you do not reset the fuel reserve tripmeter manually, it will reset itself automatically and the display will return to the prior mode after refueling and traveling 5 km (3 mi).

Stopwatch mode

Standard measurement

1.Push the “RESET” button to start the stopwatch.

2.Push the “SELECT” button to stop the stopwatch.

3.Push the “SELECT” button again to reset the stopwatch.

Split-time measurement

1.Push the “RESET” button to start the stopwatch.

2.Push the “RESET” button to measure split-times. (The colon “:” will start flashing.)

3.Push the “RESET” button to display the final split-time or push the “SELECT” button to stop the stopwatch and display total elapsed time.

4.Push the “SELECT” button to reset the stopwatch.

Coolant temperature display

The coolant temperature display indicates the temperature of the coolant. Push the “RESET” button to switch the coolant temperature display to the air intake temperature display.

NOTE:

When the coolant temperature display is selected, “C” is displayed before the coolant temperature.

Air intake temperature display

The air intake temperature display indicates the temperature of the air drawn into the air filter case. Push the “RESET” button to switch the coolant temperature display to the air intake temperature display.

NOTE:

SEven if the air intake temperature is set to be displayed, the coolant temperature warning light comes on when the engine overheats.

SWhen the key is turned to “ON”, the coolant temperature is automatically displayed, even if the air intake temperature was displayed prior to turning the key to “OFF”.

SWhen the air intake temperature display is selected, “A” is displayed before thetemperature.

1-3

GEN

FEATURES INFO

Self-diagnosis devices

The model is equipped with a self-diagnosis device for various electrical circuits. If any of those circuits are defective, the engine trouble warning light will come on, and then the right display will indicate a two-digit error code (e.g.,11,12,13).

Display brightness and shift timing indicator light control mode

This mode cycles through five control functions, allowing you to make the following settings in the order listed below.

SDisplay brightness:

This function allows you to adjust the brightness of the displays and tachometer to suit the outside lighting conditions.

SShift timing indicator light activity:

This function allows you to choose whether or not the indicator light should be activated and whether it should flash or stay on when activated.

SShift timing indicator light activation:

This function allows you to select the engine speed at which the indicator light will be activated.

SShift timing indicator light deactivation:

This function allows you to select the engine speed at which the indicator light will be deactivated.

SShift timing indicator light brightness:

This function allows you to adjust the brightness of the indicator light to suit your preference.

NOTE:

STo make any settings in this mode, you have to cycle through all of its functions. However, if the key is turned to “OFF” or the engine is started before completing the procedure, only the settings made before the “SELECT” button was last pushed will be applied.

SIn this mode, the right display shows the current setting for each function (except the shift timing indicator light activity function).

To adjust the brightness of the multifunction meter displays and tachometer

1.Turn the key to “OFF”.

2.Push and hold the “SELECT” button.

3.Turn the key to “ON”, and then release the “SELECT” button after five seconds.

4.Push the “RESET” button to select the desired brightness level.

5.Push the “SELECT” button to confirm the selected brightness level. The control mode changes to the shift timing indicator light activity function.

To set the shift timing indicator light activity function

1. Push the “RESET” button to select one of the following indicator light activity settings:

SThe indicator light will stay on when activated. (This setting is selected when the indicator light stays on.)

SThe indicator light will flash when activated. (This setting is selected when the indicator light flashes four times per second.)

SThe indicator light is deactivated; in other words, it will not come on or flash. (This setting is selected when the indicator light flashes once every two seconds.)

2.Push the ”SELECT” button to confirm the selected indicator light activity. The control mode changes to the shift timing indicator light activation function.

1-4

FEATURES

To set the shift timing indicator light activation function

NOTE:

GEN INFO

The shift timing indicator light activation function can be set between 7000 r/min and 15000 r/m. From 7000 r/min to 12000 r/min, the indicator light can be set in increments of 500 r/min. From 12000 r/min to 15000 r/min, the indicator light can be set in increments of 200 r/min.

1.Push the “RESET” button to select the desired engine speed for activating the indicator light.

2.Push the “SELECT” button to confirm the selected engine speed. The control mode changes to the shift timing indicator light deactivation function.

To set the shift timing indicator light deactivation function

NOTE:

SThe shift timing indicator light activation function can be set between 7000 r/min and 15000 r/min. From 7000 r/min to 12000 r/min, the indicator light can be set in increments of 500 r/min. From 12000 r/min to 15000 r/min, the indicator light can be set in increments of 200 r/min.

SBe sure to set the deactivation function to a higher engine speed than for the activation function, otherwise the shift timing indicator light will remain deactivated.

1.Push the “RESET” button to select the desired engine speed for deactivating the indicator light.

2.Push the “SELECT” button to confirm the selected engine speed. The control mode changes to the shift timing indicator light brightness function.

To adjust the shift timing indicator light brightness

1.Push the “RESET” button to select the desired indicator light brightness level.

2.Push the “SELECT” button to confirm the selected indicator light brightness level. The right display will return to the odometer or tripmeter mode

1-5

lip

lip spring

oil

GEN

IMPORTANT INFORMATION INFO

EAS00020

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND

DISASSEMBLY

1.Before removal and disassembly, eliminate all dirt, mud, dust and foreign material.

2.Use only the proper tools and cleaning equipment.

Refer to the “SPECIAL TOOLS”.

3.When disassembling, always keep mated parts together. This includes gears, cylinders, pistons and other parts that have been “mated” through normal wear. Mated parts must always be reused or replaced as an assembly.

4.During disassembly, clean all of the parts and place them in trays in the order of disassembly. This will speed up assembly and allow for the correct installation of all parts.

5.Keep all parts away from any source of fire.

EAS00021

REPLACEMENT PARTS

Use only genuine Yamaha parts for all replacements. Use oil and grease recommended by Yamaha for all lubrication jobs. Other brands may be similar in function and appearance, but inferior in quality.

EAS00022

GASKETS, OIL SEALS AND O-RINGS

1.When overhauling the engine, replace all gaskets, seals and O-rings. All gasket surfaces, oil seal lips and O-rings must be cleaned.

2.During reassembly, properly oil all mating

grease |

parts and bearings and lubricate the oil seal |

|

|

|

lips with grease. |

1-6

IMPORTANT INFORMATION

EAS00023

GEN INFO

LOCK WASHERS/PLATES AND COTTER PINS

After removal, replace all lock washers/plates 1 and cotter pins. After the bolt or nut has been tightened to specification, bend the lock tabs along a flat of the bolt or nut.

EAS00024

BEARINGS AND OIL SEALS

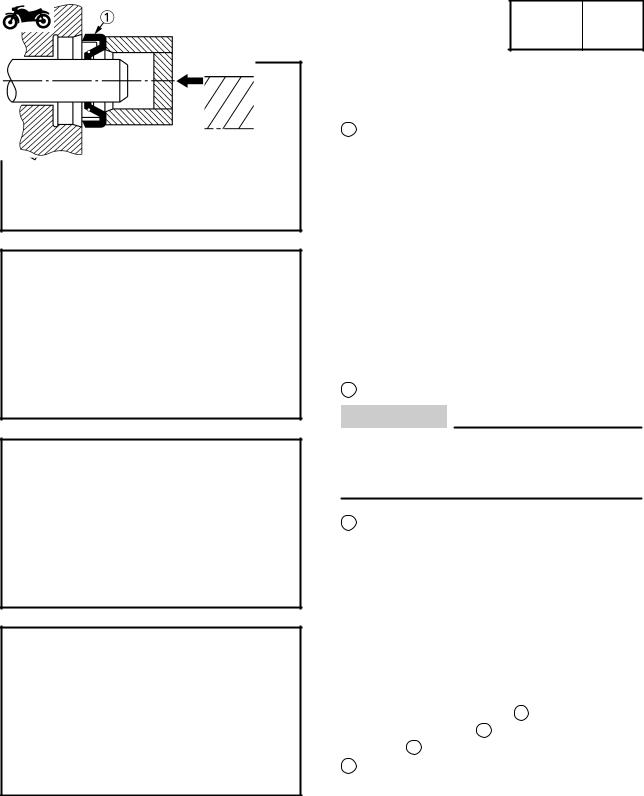

Install bearings and oil seals so that the manufacturer’s marks or numbers are visible. When installing oil seals, lubricate the oil seal lips with a light coat of lithium-soap-based grease. Oil bearings liberally when installing, if appropriate.

1 Oil seal

CAUTION:

Do not spin the bearing with compressed air because this will damage the bearing surfaces.

1 Bearing

EAS00025

CIRCLIPS

Before reassembly, check all circlips carefully and replace damaged or distorted circlips. Always replace piston pin clips after one use. When installing a circlip 1 , make sure the sharp-edged corner 2 is positioned opposite the thrust 3 that the circlip receives.

4 Shaft

1-7

GEN

CHECKING THE CONNECTIONS INFO

EAS00026

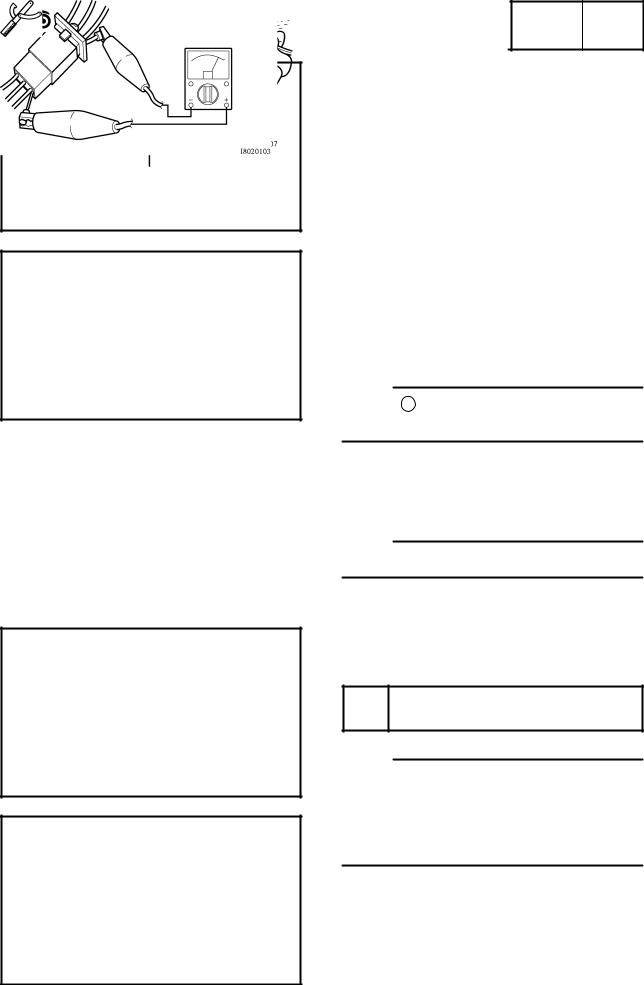

CHECKING THE CONNECTIONS

Check the leads, couplers, and connectors for stains, rust, moisture, etc.

1.Disconnect: S lead

S coupler

S connector

2.Check:

Slead

Scoupler

Sconnector

Moisture ! Dry with an air blower. Rust/stains ! Connect and disconnect several times.

3.Check:

Sall connections

Loose connection ! Connect properly.

NOTE:

If the pin 1 on the terminal is flattened, bend it up.

4. Connect:

Slead

Scoupler

Sconnector

NOTE:

Make sure all connections are tight.

5. Check:

Scontinuity

(with the pocket tester)

Pocket tester 90890-03112, YU-3112

NOTE:

SIf there is no continuity, clean the terminals.

SWhen checking the wire harness, perform steps (1) to (3).

SAs a quick remedy, use a contact revitalizer available at most part stores.

1-8

SPECIAL TOOLS

EAS00027

GEN INFO

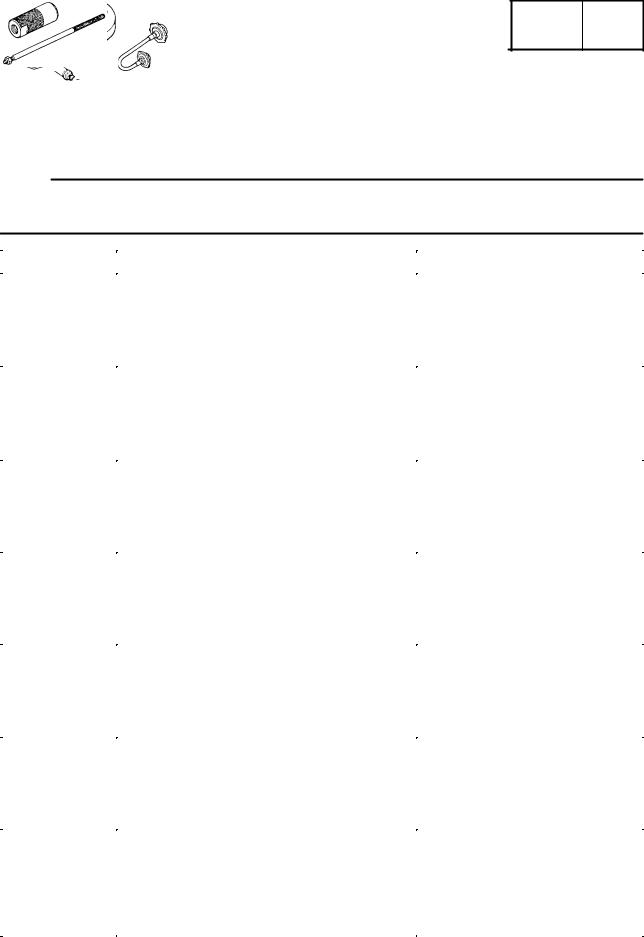

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools, part numbers or both may differ depending on the country. When placing an order, refer to the list provided below to avoid any mistakes.

NOTE:

SFor U.S.A. and Canada, use part number starting with “YM-”, “YU-”, or “ACC-”.

SFor others, use part number starting with “90890-”.

Tool No. |

Tool name/Function |

Illustration |

|

|

|

|

Piston pin puller |

|

90890-01304 |

|

|

YU-01304 |

|

|

|

This tool is used to remove the piston pins. |

|

|

|

|

Radiator cap tester |

Radiator cap tester |

|

90890-01325 |

Radiator cap tester adapter |

|

YU-24460-01 |

|

|

Adapter |

These tools are used to check the cooling |

|

90890-01352 |

|

|

system. |

|

|

YU-33984 |

|

|

|

|

|

|

Steering nut wrench |

|

90890-01403 |

|

|

YU-33975 |

This tool is used to loosen or tighten the |

|

|

|

|

|

steering stem ring nuts. |

|

|

|

|

|

Damper rod holder |

|

90890-01423 |

This tool is used to hold the damper rod as- |

|

YM-01423 |

|

|

sembly when loosening or tightening the |

|

|

|

|

|

|

damper rod assembly bolt. |

|

|

|

|

|

Oil filter wrench |

|

90890-01426 |

|

|

YU-38411 |

This tool is needed to loosen or tighten the |

|

|

|

|

|

oil filter cartridge. |

|

|

|

|

|

Rod holder |

|

90890-01434 |

|

|

YM-01434 |

This tool is used to support the damper ad- |

|

|

|

|

|

justing rod. |

|

|

|

|

Rod puller |

Rod puller |

|

90890-01437 |

|

|

Rod puller attachment |

|

|

YM-01437 |

|

|

Rod puller |

|

|

attachment |

These tools are used to pull up the front |

|

90890-01436 |

fork damper rod. |

|

YM-01436 |

|

|

1-9

|

SPECIAL TOOLS |

|

|

GEN |

|

|

|

|

|

INFO |

|

||

|

|

|

|

|||

Tool No. |

Tool name/Function |

|

Illustration |

|||

|

|

|

|

|

|

|

|

Fork spring compressor |

|

|

|

|

|

90890-01441 |

|

|

|

|

|

|

YM-01441 |

This tool is used to disassemble or |

|

|

|

|

|

|

|

|

|

|

|

|

|

assemble the front fork legs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fork seal driver |

|

|

|

|

|

90890-01442 |

|

|

|

|

|

|

YM-01442 |

This tool is used to install the front fork’s oil |

|

|

|

|

|

|

|

|

|

|

|

|

|

seal and dust seal. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Vacuum gauge |

|

|

|

|

|

90890-03094 |

|

|

|

|

|

|

YU-08030 |

This guide is used to synchronize the car- |

|

|

|

|

|

|

|

|

|

|

|

|

|

buretors. |

|

|

|

|

|

|

|

|

|

|

|

|

Compression |

Compression gauge |

|

|

|

|

|

gauge |

Compression gauge adapter |

|

|

|

|

|

90890-03081 |

|

|

|

|

|

|

YU-33223 |

These tools are used to measure engine |

|

|

|

|

|

Adapter |

|

|

|

|

|

|

compression. |

|

|

|

|

|

|

90890-04136 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Valve spring compressor |

Valve spring compressor |

|

|

|

|

|

90890-04019 |

Valve spring compressor attachment |

|

|

|

|

|

YM-04019 |

|

|

|

|

|

|

Attachment |

|

|

|

|

|

|

90890-04108 |

These tools are used to remove or install |

|

|

|

|

|

YM-01253 |

|

|

|

|

|

|

90890-04114 |

|

|

|

|

|

|

the valve assemblies. |

|

|

|

|

|

|

YM-4114 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Middle driven shaft |

Middle driven shaft bearing driver |

|

|

|

|

|

bearing driver |

Mechanical seal installer |

|

|

|

|

|

90890-04058 |

|

|

|

|

|

|

YM-4058 |

|

|

|

|

|

|

Mechanical seal |

These tools are used to install the water |

|

|

|

|

|

installer |

|

|

|

|

|

|

90890-04078 |

pump seal. |

|

|

|

|

|

YM-33221 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clutch holding tool |

|

|

|

|

|

90890-04086 |

This tool is used to hold the clutch boss |

|

|

|

|

|

YM-91042 |

|

|

|

|

|

|

when removing or installing the clutch boss |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

nut. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Valve guide remover |

|

|

|

|

|

90890-04111 |

|

|

|

|

|

|

90890-04116 |

|

|

|

|

|

|

YM-4116 |

This tool is used to remove or install the |

|

|

|

|

|

|

valve guides. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Valve guide installer |

|

|

|

|

|

90890-04112 |

|

|

|

|

|

|

90890-04117 |

|

|

|

|

|

|

YM-4117 |

|

|

|

|

|

|

|

This tool is used to install the valve guides. |

|

|

|

|

|

|

|

|

|

|

|

|

1-10

|

SPECIAL TOOLS |

|

|

GEN |

|

|

|

|

|

INFO |

|

||

|

|

|

|

|||

Tool No. |

Tool name/Function |

|

Illustration |

|||

|

|

|

|

|

|

|

90890-04113 |

Valve guide reamer |

|

|

|

|

|

|

|

|

|

|

|

|

YM-04113 |

|

|

|

|

|

|

90890-04118 |

This tool is used to rebore the new valve |

|

|

|

|

|

YM-4118 |

|

|

|

|

|

|

guides. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ignition checker |

|

|

|

|

|

90890-06754 |

|

|

|

|

|

|

YM-34487 |

This tool is used to check the ignition sys- |

|

|

|

|

|

|

|

|

|

|

|

|

|

tem components. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Yamaha bond No. 1215 |

|

|

|

|

|

90890-85505 |

|

|

|

|

|

|

ACC-1109-0501 |

This bond is used to seal two mating sur- |

|

|

|

|

|

|

faces (e.g., crankcase mating surfaces). |

|

|

|

|

|

|

|

|

|

|

|

|

|

Digital circuit tester |

|

|

|

|

|

90890-03174 |

|

|

|

|

|

|

|

This tool is used to check the electrical sys- |

|

|

|

|

|

|

tem. |

|

|

|

|

|

|

|

|

|

|

|

|

Pivot shaft wrench |

Pivot shaft wrench |

|

|

|

|

|

90890-01471 |

Pivot shaft wrench adapter |

|

|

|

|

|

YM-01471 |

|

|

|

|

|

|

Pivot shaft wrench |

This tool is need to loosen or tighten the |

|

|

|

|

|

adapter |

|

|

|

|

|

|

90890-01476 |

spacer bolt. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pocket tester |

|

|

|

|

|

90890-03132 |

|

|

|

|

|

|

YU-3112 |

This instrument is needed for checking the |

|

|

|

|

|

|

|

|

|

|

|

|

|

engine oil temperature. |

|

|

|

|

|

|

|

|

|

|

|

|

Oil pressure |

Oil pressure gauge |

|

|

|

|

|

gauge |

Adapter |

|

|

|

|

|

90890-03153 |

|

|

|

|

|

|

YU-03153 |

These tools are used to measure engine oil |

|

|

|

|

|

Adapter |

|

|

|

|

|

|

90890-03139 |

pressure. |

|

|

|

|

|

|

Vacuum/pressure pump gauge set |

|

|

|

|

|

90890-06756 |

|

|

|

|

|

|

|

This tool used to measure the vacuum pres- |

|

|

|

|

|

|

sure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine tachometer |

|

|

|

|

|

90793-80009 |

|

|

|

|

|

|

|

This tool is needed for observing engine |

|

|

|

|

|

|

rpm. |

|

|

|

|

|

|

|

|

|

|

|

|

1-11

|

SPECIAL TOOLS |

|

|

GEN |

|

|

|

|

|

INFO |

|

||

|

|

|

|

|||

Tool No. |

Tool name/Function |

|

Illustration |

|||

|

|

|

|

|

|

|

|

Valve lapper |

|

|

|

|

|

90890-04101 |

|

|

|

|

|

|

|

This tool is needed to remove and install |

|

|

|

|

|

|

the valve lifter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel pressure adapter |

|

|

|

|

|

90890-03176 |

|

|

|

|

|

|

YM-03176 |

This tool is needed to measure fuel pres- |

|

|

|

|

|

|

|

|

|

|

|

|

|

sure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure gauge |

|

|

|

|

|

90890-03153 |

|

|

|

|

|

|

YU-03153 |

|

|

|

|

|

|

|

This tool is used to measure fuel pressure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Camshaft wrench |

|

|

|

|

|

90890-04143 |

|

|

|

|

|

|

YM-04143 |

|

|

|

|

|

|

|

This tool is used to hold and rotate the cam- |

|

|

|

|

|

|

shaft sprocket. |

|

|

|

|

|

|

|

|

|

|

|

|

1-12

|

GENERAL SPECIFICATIONS |

|

SPEC |

|

||

SPECIFICATIONS |

|

|

|

|

||

|

|

|

|

|||

GENERAL SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

Standard |

|

|

Limit |

|

|

|

|

|

|

|

|

Model code |

|

5VY4 (USA), 5VY5 (CAL) |

|

|

SSS |

|

|

|

|

|

|

|

|

Dimensions |

|

|

|

|

|

|

Overall length |

|

2,065 mm (8.13 in) |

|

|

SSS |

|

Overall width |

|

720 mm (28.3 in) |

|

|

SSS |

|

Overall height |

|

1,105 mm (43.5 in) |

|

|

SSS |

|

Seat height |

|

835 mm (32.9 in) |

|

|

SSS |

|

Wheelbase |

|

1,395 mm (54.9 in) |

|

|

SSS |

|

Minimum ground clearance |

|

135 mm (5.31 in) |

|

|

SSS |

|

Minimum turning radius |

|

3,400 mm (133.9 in) |

|

|

SSS |

|

|

|

|

|

|

|

|

Weight |

|

|

|

|

|

|

Wet (with oil and a full fuel tank) |

|

193 kg (425 lb) (USA) |

|

|

SSS |

|

|

|

194 kg (428 lb) (CAL) |

|

|

|

|

Maximum load (except motorcycle) |

|

202 kg (445 lb) (USA) |

|

|

SSS |

|

|

|

201 kg (443 lb) (CAL) |

|

|

|

|

|

|

|

|

|

|

|

2-1

|

ENGINE SPECIFICATIONS |

|

SPEC |

|

|

|

|

||

ENGINE SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Item |

Standard |

|

|

Limit |

|

||||

|

|

|

|

|

|

|

|

|

|

Engine |

|

|

|

|

|

|

|

|

|

Engine type |

Liquid-cooled, 4-stroke, DOHC |

|

SSS |

|

|

|

|

||

Displacement |

998 cm3 (60.90 cu.in) |

|

SSS |

|

|

|

|

||

Cylinder arrangement |

Forward-inclined parallel 4-cylinder |

|

SSS |

|

|

|

|

||

Bore stroke |

77.0 53.6 mm (3.03 2.11 in) |

|

SSS |

|

|

|

|

||

Compression ratio |

12.4 : 1 |

|

|

|

SSS |

|

|

|

|

Engine idling speed |

1,150 X 1,250 r/min |

|

SSS |

|

|

|

|

||

Vacuum pressure at engine idling |

22 kPa (165 mmHg, 6.5 inHg) |

|

SSS |

|

|

|

|

||

speed |

|

|

|

|

|

|

|

|

|

1,480 kPa (14.80 kg/cm2,14.80 bar, |

|

|

|

|

|

2 |

|||

Standard compression pressure |

|

SSS |

|

|

|

||||

(at sea level) |

210.5 psi) at 350 r/min |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Fuel |

|

|

|

|

|

|

|

|

|

Recommended fuel |

Premium unleaded gasoline only |

|

SSS |

|

|

|

|

||

Fuel tank capacity |

|

|

|

|

|

|

|

|

|

Total (including reserve) |

18 L (3.96 Imp gal, 4.76 US gal) |

|

SSS |

|

|

|

|

||

Reserve only |

3.4 L (0.75 Imp gal, 0.90 US gal) |

|

SSS |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Engine oil |

|

|

|

|

|

|

|

|

|

Lubrication system |

Wet sump |

|

SSS |

|

|

|

|

||

Recommended oil |

|

|

|

|

|

|

|

|

|

|

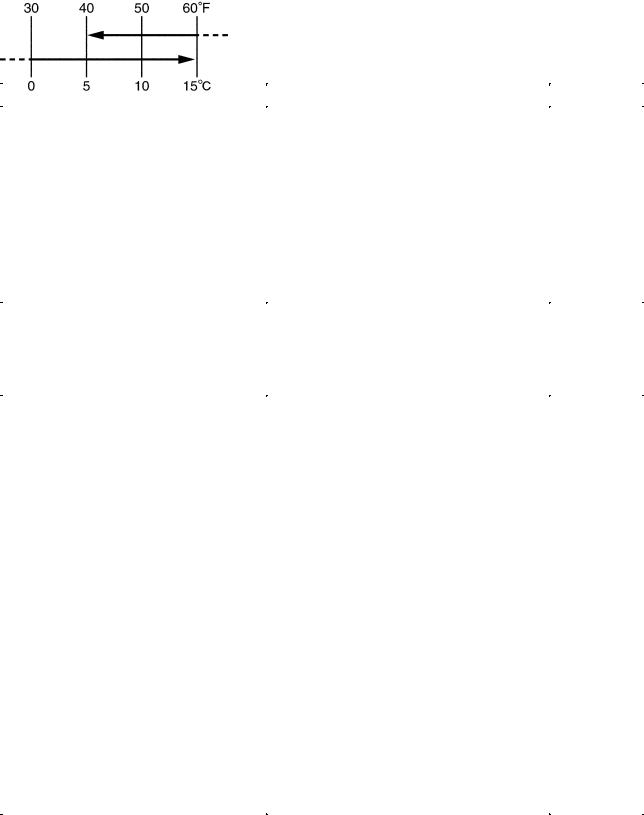

At 5_C (40_F) or higher |

|

|

|

|

|

|

||

|

Yamalube 4 (20W40) or SAE 20W40 |

|

|

|

|

|

|

||

|

type SE motor oil |

|

|

|

|

|

|

||

|

At 15_C (60_F) or lower |

|

|

|

|

|

|

||

|

Yamalube 4 (10W30) or SAE 10W30 |

|

|

|

|

|

|

||

|

type SE motor oil |

|

|

|

|

|

|

||

Quantity |

|

|

|

|

|

|

|

|

|

Total amount |

3.8 L (3.35 Imp qt, 4.02 US qt) |

|

SSS |

|

|

|

|

||

Without oil filter cartridge |

2.9 L (2.55 Imp qt, 3.07 US qt) |

|

SSS |

|

|

|

|

||

replacement |

|

|

|

|

|

|

|

|

|

With oil filter cartridge replacement |

3.1 L (2.73 Imp qt, 3.28 US qt) |

|

SSS |

|

|

|

|

||

Oil pressure |

230 kPa at 5,000 r/min |

|

SSS |

|

|

|

|

||

|

(2.3 kg/cm2 at 5,000 r/min) |

|

|

|

|

|

|

||

|

(2.3 bar at 5,000 r/min) |

|

|

|

|

|

|

||

|

(32.7 psi at 5,000 r/min) |

|

SSS |

|

|

|

|

||

Engine oil temperature |

100_C (212_F) |

|

|

|

|

|

|

||

Relief valve opening pressure |

600 X 680 kPa (6.0 X 6.8 kg/cm2, |

|

|

|

|

|

|

||

|

6.0 X 6.8 bar, 87.0 X 98.6 psi) |

|

|

|

|

|

|

||

2-2

Loading...

Loading...