Yamaha YZF-R1 2000 User Manual [ru]

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the YZF-R1 2000. For complete service information procedures it is necessary to use this Supplementary Service Manual together with the following manual.

YZF-R1 SERVICE MANUAL: 4XV1-AE1

YZF-R1 2000

SUPPLEMENTARY

SERVICE MANUAL1999 by Yamaha Motor Co., Ltd.

First Edition, December 1999 Any reproduction or unauthorized use

without the written permission of Yamaha Motor Co., Ltd. is expressly prohibited.

EB001000

NOTICE

This manual was produced by the Yamaha Motor Company, Ltd. primarily for use by Yamaha dealers and their qualified mechanics. it is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles should have a basic understanding of mechanics and the techniques to repair these types of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

Yamaha Motor Company, Ltd. is continually striving to improve all of its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

EB002000

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

|

|

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR |

||

|

|

SAFETY IS INVOLVED! |

||

WARNING |

Failure to follow WARNING instructions could result in severe injury or death to |

|||

|

|

the motorcycle operator, a bystander or |

|

|

|

|

a person checking or repairing the mo- |

||

|

|

torcycle. |

||

|

|

|

|

|

CAUTION: |

|

A CAUTION indicates special precautions that must be taken to avoid damage |

||

NOTE: |

to the motorcycle. |

|||

A NOTE provides key information to make procedures easier or clearer. |

||||

EB003000

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order.

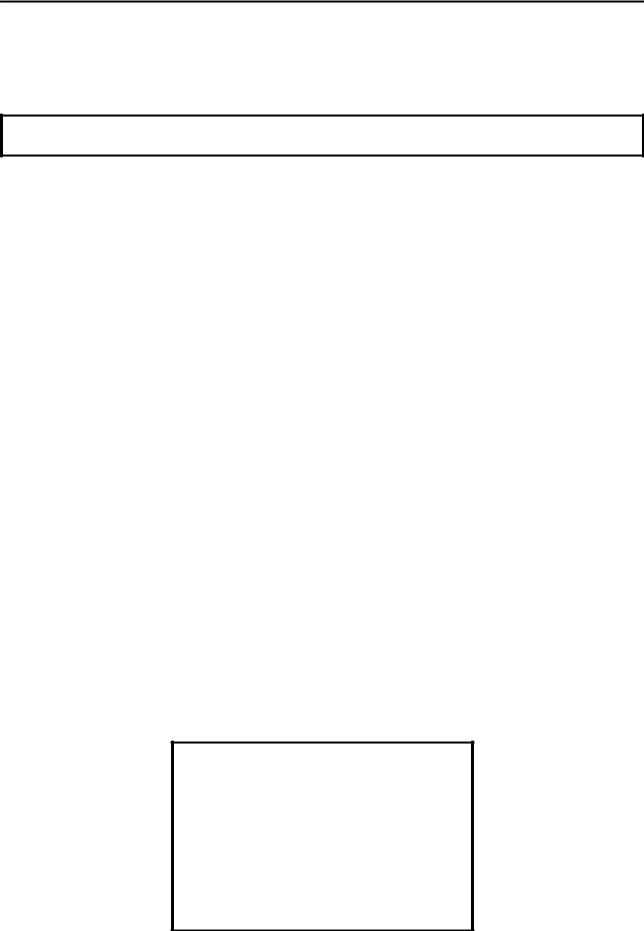

1The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each page indicate the current chapter.

Refer to ªSYMBOLSº.

2Each chapter is divided into sections. The current section title is shown at the top of each page, except in Chapter 3 (ªPERIODIC CHECKS AND ADJUSTMENTSº), where the sub-section title(-s) appears.

3Sub-section titles appear in smaller print than the section title.

4To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section.

5Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a disassembly step.

6Symbols indicate parts to be lubricated or replaced.

Refer to ªSYMBOLSº.

7A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of parts, notes in jobs, etc.

8Jobs requiring more information (such as special tools and technical data) are described sequentially.

6 2 1

3

4

5

8

7

1 |

2 |

GEN |

SPEC |

|

INFO |

||

|

||

3 |

4 |

|

CHK |

ENG |

|

ADJ |

||

|

||

5 |

6 |

|

COOL |

CARB |

|

7 |

8 |

|

CHAS |

ELEC |

|

9 |

10 |

|

TRBL |

|

|

SHTG |

|

|

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

EB004000

SYMBOLS

The following symbols are not relevant to every vehicle.

Symbols 1 to 9 indicate the subject of each chapter.

1General information

2Specifications

3Periodic checks and adjustments

4Engine

5Cooling system

6Carburetor(-s)

7Chassis

8Electrical system

9Troubleshooting

Symbols 10 to 17 indicate the following.

10Serviceable with engine mounted

11Filling fluid

12Lubricant

13Special tool

14Tightening torque

15Wear limit, clearance

16Engine speed

17Electrical data

Symbols 18 to 23 in the exploded diagrams indicate the types of lubricants and lubrication points.

18Engine oil

19Gear oil

20Molybdenum disulfide oil

21Wheel bearing grease

22Lithium soap base grease

23Molybdenum disulfide grease

Symbols 24 to 25 in the exploded diagrams indicate the following.

24Apply locking agent (LOCTITE )

25Replace the part

CONTENTS

SPECIFICATIONS

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 ENGINE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 CHASSIS SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ENGINE TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . 11 CHASSIS TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . 12

LUBRICATION POINTS AND LUBRICANT TYPES . . . . . . . . . . . . . 13 ENGINE LUBRICATION POINTS AND LUBRICANT TYPES . . 13 OIL FLOW DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 COOLANT FLOW DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 CABLE ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PERIODIC CHECKS AND ADJUSTMENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

PERIODIC MAINTENANCE AND LUBRICATION INTERVALS . . . 33

COWLINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

AIR FILTER CASE AND IGNITION COIL PLATE . . . . . . . . . . . . . . . 36

OVERHAULING THE ENGINE

AIR INDUCTION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 INSTALLING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 CRANKCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 ASSEMBLING THE CRANKCASE . . . . . . . . . . . . . . . . . . . . . . . . . 43

COOLING SYSTEM

RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

CARBURETORS

AIR INDUCTION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 AIR INJECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 AIR CUTOFF VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 AIR INDUCTION SYSTEM DIAGRAMS . . . . . . . . . . . . . . . . . . . . . 48 CHECKING THE AIR INDUCTION SYSTEM . . . . . . . . . . . . . . . . 49

CHASSIS

FRONT WHEEL AND BRAKE DISCS . . . . . . . . . . . . . . . . . . . . . . . . . 50 INSTALLING THE FRONT WHEEL . . . . . . . . . . . . . . . . . . . . . . . . 51 FRONT AND REAR BRAKES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

REAR BRAKE MASTER CYLINDER AND BRAKE

FLUID RESERVOIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

ELECTRICAL

INSTRUMENT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 INDICATOR LIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 COOLANT TEMPERATURE WARNING LIGHT . . . . . . . . . . . . . . 54 SPEEDOMETER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 ELECTRIC STARTING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 STARTER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 SELF-DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

YZF-R1 WIRING DIAGRAM (For EUR)

YZF-R1 WIRING DIAGRAM (For OCE)

GENERAL SPECIFICATIONS |

|

SPEC |

|

||

SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

||

GENERAL SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

Item |

Standard |

|

|

Limit |

|

|

|

|

|

|

|

Dimensions |

|

|

|

|

|

Overall length |

2,035 mm |

|

|

|

|

|

2,095 mm (for AUS) |

|

|

|

|

Overall width |

695 mm |

|

|

|

|

Overall height |

1,105 mm |

|

|

|

|

Seat height |

815 mm |

|

|

|

|

Wheelbase |

1,395 mm |

|

|

|

|

Minimum ground clearance |

140 mm |

|

|

|

|

Minimum turning radius |

3,400 mm |

|

|

|

|

|

|

|

|

|

|

Weight |

|

|

|

|

|

Wet (with oil and a full fuel tank) |

194 kg |

|

|

|

|

Dry (without oil and fuel) |

175 kg |

|

|

|

|

Maximum load (total of cargo, rider, |

201 kg |

|

|

|

|

passenger, and accessories) |

|

|

|

|

|

|

|

|

|

|

|

±1±

|

ENGINE SPECIFICATIONS |

|

SPEC |

|

|

ENGINE SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

Standard |

|

|

Limit |

|

|

|

|

|

|

|

Engine |

|

|

|

|

|

Engine type |

Liquid-cooled, 4-stroke, DOHC |

|

|

|

|

Displacement |

998 cm3 |

|

|

|

|

Cylinder arrangement |

Forward-inclined parallel 4-cylinder |

|

|

|

|

Bore stroke |

74 58 mm |

|

|

|

|

Compression ratio |

11.8 : 1 |

|

|

|

|

Engine idling speed |

1,000 1,100 r/min |

|

|

|

|

Vacuum pressure at engine idling |

29.3 kPa (220 mm Hg) |

|

|

|

|

speed |

1,450 kPa (14.5 kgf/cm2) at 400 r/min |

|

|

||

Standard compression pressure |

|

|

|||

(at sea level) |

|

|

|

|

|

|

|

|

|

|

|

Fuel |

|

|

|

|

|

Recommended fuel |

Regular unleaded gasoline |

|

|

|

|

|

Unleaded fuel (for AUS) |

|

|

|

|

Fuel tank capacity |

|

|

|

|

|

Total (including reserve) |

18 L |

|

|

|

|

Reserve only |

3.8 L |

|

|

|

|

|

|

|

|

|

|

Engine oil |

|

|

|

|

|

Lubrication system |

Wet sump |

|

|

|

|

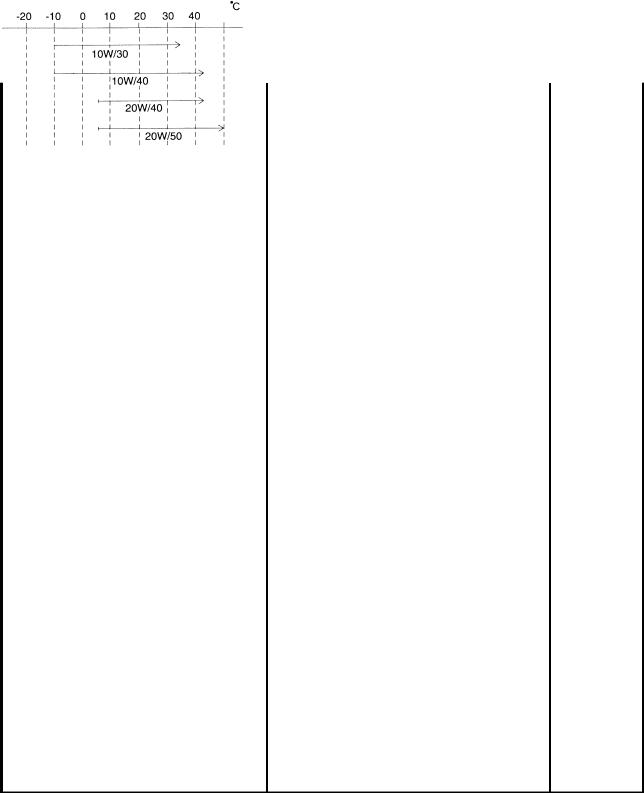

Recommended oil |

|

|

|

|

|

Temp. |

|

|

|

|

|

|

SAE20W40SE or SAE10W30SE |

|

|

|

|

Quantity |

|

|

Total amount |

3.6 L |

|

Without oil filter cartridge |

2.7 L |

|

replacement |

|

|

With oil filter cartridge replacement |

2.9 L |

|

Oil pressure (hot) |

45 kPa at 1,100 r/min |

|

|

(0.45 kgf/cm2 at 1,100 r/min) |

|

Relief valve opening pressure |

490 570 kPa (4.9 5.7 kgf/cm2) |

|

±2±

|

ENGINE SPECIFICATIONS |

|

SPEC |

|

|

|

|

|

|

|

|

|

|

|

Item |

Standard |

|

Limit |

|

|

|

|

|

|

Camshafts |

|

|

|

|

Drive system |

Chain drive (right) |

|

|

|

Camshaft cap inside diameter |

24.500 X 24.521 mm |

|

|

|

Camshaft journal diameter |

24.459 X 24.472 mm |

|

|

|

Camshaft-journal-to-camshaft- |

0.028 X 0.062 mm |

|

|

|

cap clearance |

|

|

|

|

Intake camshaft lobe dimensions |

|

|

|

|

Measurement A |

32.5 X 32.6 mm |

32.4 mm |

Measurement B |

24.95 X 25.05 mm |

24.85 mm |

Measurement C |

7.45 X 7.65 mm |

|

Exhaust camshaft lobe dimensions

Measurement A |

32.95 X 33.05 mm |

32.85 mm |

Measurement B |

24.95 X 25.05 mm |

24.85 mm |

Measurement C |

7.75 X 7.95 mm |

|

Max. camshaft runout |

|

0.03 mm |

±3±

|

ENGINE SPECIFICATIONS |

|

SPEC |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

Standard |

|

|

Limit |

|

|

|

|

|

|

|

|

Valves, valve seats, valve guides |

|

|

|

|

|

|

Valve clearance (cold) |

|

|

|

|

|

|

Intake |

|

0.11 X 0.20 mm |

|

|

|

|

Exhaust |

|

0.21 X 0.25 mm |

|

|

|

|

Valve dimensions |

|

|

|

|

|

|

|

|

|

|

|

|

|

Head Diameter |

Face Width |

Seat Width |

Margin Thickness |

Valve head diameter A |

|

|

|

Intake |

|

22.9 X 23.1 mm |

|

Exhaust |

|

24.4 X 24.6 mm |

|

Valve face width B |

|

|

|

Intake |

|

1.76 X 2.90 mm |

|

Exhaust |

|

1.76 X 2.90 mm |

|

Valve seat width C |

|

|

|

Intake |

|

0.9 X 1.1 mm |

|

Exhaust |

|

0.9 X 1.1 mm |

|

Valve margin thickness D |

|

|

|

Intake |

|

0.5 X 0.9 mm |

|

Exhaust |

|

0.5 X 0.9 mm |

|

Valve stem diameter |

|

|

|

Intake |

|

3.975 X 3.990 mm |

3.945 mm |

Exhaust |

|

4.465 X 4.480 mm |

4.43 mm |

Valve guide inside diameter |

|

|

|

Intake |

|

4.000 X 4.012 mm |

4.05 mm |

Exhaust |

|

4.500 X 4.512 mm |

4.55 mm |

Valve-stem-to-valve-guide clearance |

|

|

|

Intake |

|

0.010 X 0.037 mm |

0.08 mm |

Exhaust |

|

0.020 X 0.047 mm |

0.1 mm |

Valve stem runout |

|

|

0.01 mm |

Valve seat width |

|

|

Intake |

0.9 X 1.1 mm |

|

Exhaust |

0.9 X 1.1 mm |

|

|

|

|

Connecting rods |

|

|

Crankshaft-pin-to-big-end-bearing |

0.031 X 0.055 mm |

|

clearance |

|

|

Bearing color code |

±1 = Violet 0 = White 1 = Blue 2 = Black |

|

±4±

|

ENGINE SPECIFICATIONS |

|

SPEC |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

Standard |

|

|

Limit |

|

|

|

|

|

|

|

|

Transmission |

|

|

|

|

|

|

Transmission type |

|

Constant mesh, 6-speed |

|

|

|

|

Primary reduction system |

|

Spur gear |

|

|

|

|

Primary reduction ratio |

|

68/43 (1.581) |

|

|

|

|

Secondary reduction system |

|

Chain drive |

|

|

|

|

Secondary reduction ratio |

|

43/16 (2.688) |

|

|

|

|

Operation |

|

Left-foot operation |

|

|

|

|

Gear ratios |

|

|

|

|

|

|

1st gear |

|

35/14 (2.500) |

|

|

|

|

2nd gear |

|

35/19 (1.842) |

|

|

|

|

3rd gear |

|

30/20 (1.500) |

|

|

|

|

4nd gear |

|

28/21 (1.333) |

|

|

|

|

5th gear |

|

30/25 (1.200) |

|

|

|

|

6th gear |

|

29/26 (1.115) |

|

|

|

|

Max. main axle runout |

|

|

|

|

0.08 mm |

|

Max. drive axle runout |

|

|

|

|

0.08 mm |

|

|

|

|

|

|

|

|

Carburetors |

|

|

|

|

|

|

Model (manufacturer) quantity |

|

BDSR40 (MIKUNI) 4 |

|

|

|

|

Throttle cable free play (at the |

|

3 5 mm |

|

|

|

|

flange of the throttle grip) |

|

|

|

|

|

|

ID mark |

|

5JJ1 00 |

|

|

|

|

Main jet |

|

#130 |

|

|

|

|

Main air jet |

|

Carburetors 1 and 4: #60 |

|

|

|

|

|

|

Carburetors 2 and 3: #65 |

|

|

|

|

Jet needle |

|

6DEY5-53-3 |

|

|

|

|

Needle jet |

|

P-OM |

|

|

|

|

Pilot air jet |

|

#120 |

|

|

|

|

Pilot outlet |

|

1.0 |

|

|

|

|

Pilot jet |

|

#15 |

|

|

|

|

Bypass 1 |

|

0.8 |

|

|

|

|

Bypass 2 |

|

0.9 |

|

|

|

|

Bypass 3 |

|

0.8 |

|

|

|

|

Pilot screw turns out |

|

3.125 |

|

|

|

|

Valve seat size |

|

1.5 |

|

|

|

|

±5±

|

CHASSIS SPECIFICATIONS |

|

SPEC |

|

CHASSIS SPECIFICATIONS |

|

|

|

|

|

|

|

||

|

|

|

|

|

Item |

Standard |

|

Limit |

|

|

|

|

|

|

Front tire |

|

|

|

|

Tire type |

Tubeless |

|

|

|

Size |

120/70 ZR17 (58W) |

|

|

|

Model (manufacturer) |

MEZ3Y FRONT (METZELER) |

|

|

|

|

D207FQ (DUNLOP) |

|

|

|

Tire pressure (cold) |

250 kPa (2.5 kg/cm2, 2.5 bar) |

|

|

|

0 90 kg |

|

|

||

90 197 kg |

250 kPa (2.5 kg/cm2, 2.5 bar) |

|

|

|

High-speed riding |

250 kPa (2.5 kg/cm2, 2.5 bar) |

|

|

|

Min. tire tread depth |

|

|

1.6 mm |

|

|

|

|

|

|

Rear tire |

|

|

|

|

Tire type |

Tubeless |

|

|

|

Size |

190/50 ZR17 (73W) |

|

|

|

Model (manufacturer) |

MEZ3Y (METZELER)/D207N (DUNLOP) |

|||

Tire pressure (cold) |

250 kPa (2.5 kg/cm2, 2.5 bar) |

|

|

|

0 90 kg |

|

|

||

90 197 kg |

290 kPa (2.9 kg/cm2, 2.9 bar) |

|

|

|

High-speed riding |

250 kPa (2.5 kg/cm2, 2.5 bar) |

|

|

|

Min. tire tread depth |

|

|

1.6 mm |

|

|

|

|

|

|

Rear brake |

|

|

|

|

Brake type |

Single-disc brake |

|

|

|

Operation |

Right-foot operation |

|

|

|

Brake pedal position (from the top |

35 40 mm |

|

|

|

of the brake pedal to the bottom of |

|

|

|

|

the rider footrest bracket) |

|

|

|

|

Recommended fluid |

DOT 4 |

|

|

|

Brake discs |

|

|

|

|

Diameter thickness |

245 5 mm |

|

|

|

Min. thickness |

|

|

4.5 mm |

|

Max. deflection |

|

|

0.1 mm |

|

Brake pad lining thickness |

5.5 mm |

|

0.5 mm |

|

Master cylinder inside diameter |

12.7 mm |

|

Caliper cylinder inside diameter |

38.2 mm |

|

±6±

|

CHASSIS SPECIFICATIONS |

|

SPEC |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

Standard |

|

|

Limit |

|

|

|

|

|

|

|

|

Front suspension |

|

|

|

|

|

|

Suspension type |

|

Telescopic fork |

|

|

|

|

Front fork type |

|

Coil spring/oil damper |

|

|

|

|

Front fork travel |

|

135 mm |

|

|

|

|

Spring |

|

|

|

|

|

|

Free length |

|

255 mm |

|

|

|

|

Spacer length |

|

85 mm |

|

|

|

|

Installed length |

|

242.4 mm |

|

|

|

|

Spring rate (K1) |

|

7.35 N/mm (0.75 kgf/mm) |

|

|

|

|

Spring stroke (K1) |

|

0 X 135 mm |

|

|

|

|

Optional spring available |

|

No |

|

|

|

|

Fork oil |

|

|

|

|

|

|

Recommended oil |

|

Suspension oil ª01º or equivalent |

|

|

|

|

Quantity (each front fork leg) |

|

482 cm3 |

|

|

|

|

Level (from the top of the inner |

|

74 mm |

|

|

|

|

tube, with the inner tube fully |

|

|

|

|

|

|

compressed, and without the |

|

|

|

|

|

|

fork spring) |

|

|

|

|

|

|

Damper adjusting rod locknut |

|

11 mm |

|

|

|

|

distance |

|

|

|

|

|

|

Spring preload adjusting positions |

|

|

|

|

|

|

Minimum |

|

8 |

|

|

|

|

Standard |

|

6 |

|

|

|

|

Maximum |

|

1 |

|

|

|

|

Rebound damping adjusting |

|

|

|

|

|

|

positions |

|

|

|

|

|

|

Minimum* |

|

11 |

|

|

|

|

Standard* |

|

5 |

|

|

|

|

Maximum* |

|

1 |

|

|

|

|

Compression damping adjusting |

|

|

|

|

|

|

positions |

|

|

|

|

|

|

Minimum* |

|

9 |

|

|

|

|

Standard* |

|

5 |

|

|

|

|

Maximum* |

|

1 |

|

|

|

|

*with the adjusting screw fully turned |

|

|

|

|

|

|

in position |

|

|

|

|

|

|

|

|

|

|

|

|

|

±7±

|

CHASSIS SPECIFICATIONS |

|

SPEC |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

Standard |

|

|

Limit |

|

|

|

|

|

|

|

|

Rear suspension |

|

|

|

|

|

|

Suspension type |

|

Swingarm (link suspension) |

|

|

|

|

Rear shock absorber assembly |

|

Coil spring/gas-oil damper |

|

|

|

|

type |

|

|

|

|

|

|

Rear shock absorber assembly |

|

65 mm |

|

|

|

|

travel |

|

|

|

|

|

|

Spring |

|

|

|

|

|

|

Free length |

|

176 mm |

|

|

|

|

Installed length |

|

162.5 mm |

|

|

|

|

Spring rate (K1) |

|

78.4 N/mm (7.84 kgf/mm) |

|

|

|

|

Spring stroke (K1) |

|

0 X 65 mm |

|

|

|

|

Optional spring available |

|

No |

|

|

|

|

Standard spring preload gas/air |

|

1,200 kPa (12 kgf/cm2) |

|

|

|

|

pressure |

|

|

|

|

|

|

Spring preload adjusting positions |

|

|

|

|

|

|

Minimum |

|

1 |

|

|

|

|

Standard |

|

4 |

|

|

|

|

Maximum |

|

9 |

|

|

|

|

Rebound damping adjusting |

|

|

|

|

|

|

positions |

|

|

|

|

|

|

Minimum* |

|

11 |

|

|

|

|

Standard* |

|

7 |

|

|

|

|

Maximum* |

|

1 |

|

|

|

|

Compression damping adjusting |

|

|

|

|

|

|

positions |

|

|

|

|

|

|

Minimum* |

|

11 |

|

|

|

|

Standard* |

|

9 |

|

|

|

|

Maximum* |

|

1 |

|

|

|

|

*with the adjusting screw fully turned |

|

|

|

|

|

|

in position |

|

|

|

|

|

|

|

|

|

|

|

|

|

±8±

ELECTRICAL SPECIFICATIONS |

|

SPEC |

|

|||

|

|

|

|

|

|

|

ELECTRICAL SPECIFICATIONS |

|

|

|

|||

|

|

|

|

|||

Item |

Standard |

|

Limit |

|||

|

|

|

|

|||

System voltage |

12 V |

|

|

|||

|

|

|

|

|

|

|

Ignition system |

|

|

|

|

|

|

Ignition system type |

Transistorized coil ignition |

|

|

|||

Ignition timing |

5_ BTDC at 1,050 r/min |

|

|

|||

Advanced timing |

55_ BTDC at 5,000 r/min |

|

|

|||

Advancer type |

Throttle position sensor and electrical |

|

|

|||

Pickup coil resistance/color |

248 372 W/Gy-B |

|

|

|||

Transistorized coil ignition unit |

TNDF54 (DENSO) |

|

|

|||

model (manufacturer) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Voltage regulator |

|

|

|

|

|

|

Regulator type |

Semiconductor short circuit |

|

|

|||

Model |

SH650A-12 |

|

|

|||

No-load regulated voltage |

14.1 14.9 V |

|

|

|||

|

|

|

|

|

|

|

Bulbs (voltage/wattage quantity) |

|

|

|

|

|

|

Headlight |

12 V 60 W/55 W 2 |

|

|

|||

Auxiliary light |

12 V 5 W 2 |

|

|

|||

Tail/brake light |

12 V 5 W/21 W 2 |

|

|

|||

Turn signal light |

12 V 21 W 4 |

|

|

|||

Meter light |

LED |

|

|

|||

|

|

|

|

|

|

|

Electric starting system |

|

|

|

|

|

|

System type |

Constant mesh |

|

|

|||

Starter motor |

|

|

|

|

|

|

Model (manufacturer) |

5JJ (YAMAHA) |

|

|

|||

Power output |

0.75 kW |

|

|

|||

Brushes |

|

|

|

|

|

|

Overall length |

9.8 mm |

|

3.65 mm |

|||

Spring force |

4.88 7.32 N (488 732 gf) |

|

|

|||

Commutator resistance |

0.009 0.011 Ω |

|

|

|||

Commutator diameter |

24.5 mm |

|

23.5 mm |

|||

Mica undercut |

1.5 mm |

|

|

|||

|

|

|

|

|

|

|

Turn signal relay |

|

|

|

|

|

|

Relay type |

Full-transistor |

|

|

|||

Model (manufacturer) |

FE246BH (DENSO) |

|

|

|||

Self-cancelling device built-in |

No |

|

|

|||

Turn signal blinking frequency |

75 95 cycles/min. |

|

|

|||

Wattage |

21 W 2 |

|

|

|||

|

|

|

|

|||

Oil level switch model |

4XV (DENSO) |

|

|

|||

(manufacturer) |

|

|

|

|

|

|

|

|

|

|

|||

Fuel pump relay model |

G8R-30Y-M (OMRON) |

|

|

|||

(manufacturer) |

|

|

|

|

|

|

±9±

|

ELECTRICAL SPECIFICATIONS |

|

SPEC |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

Standard |

|

|

Limit |

|

|

|

|

|

|

|

|

Thermo unit |

|

|

|

|

|

|

Model (manufacturer) |

|

5JJ (NIPPON THERMOSTAT) |

|

|

|

|

|

|

|

|

|

|

|

Fuses (amperage quantity) |

|

|

|

|

|

|

Main fuse |

|

30 A 1 |

|

|

|

|

Headlight fuse |

|

20 A 1 |

|

|

|

|

Signaling system fuse |

|

20 A 1 |

|

|

|

|

Ignition fuse |

|

15 A 1 |

|

|

|

|

Radiator fan fuse |

|

10 A 1 |

|

|

|

|

Backup fuse (odometer) |

|

10 A 1 |

|

|

|

|

Reserve fuse |

|

30 A 1 |

|

|

|

|

|

|

20 A 1 |

|

|

|

|

|

|

15 A 1 |

|

|

|

|

|

|

10 A 1 |

|

|

|

|

|

|

|

|

|

|

|

±10±

|

TIGHTENING TORQUES |

|

|

SPEC |

|

||||||

TIGHTENING TORQUES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENGINE TIGHTENING TORQUES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Thread |

|

|

Tightening |

|

|

||||

Item |

Fastener |

Q'ty |

|

torque |

Remarks |

||||||

size |

|

||||||||||

|

|

|

|

Nm |

m kgf |

|

|

||||

|

|

|

|

|

|

|

|||||

Cylinder head |

Nut |

M10 |

8 |

50 |

5.0 |

|

|

|

|||

Cylinder head |

Cap nut |

M10 |

2 |

65 |

6.5 |

|

|

|

|||

Generator rotor |

Bolt |

M10 |

1 |

65 |

6.5 |

|

|

|

|||

Oil/water pump assembly driven |

Bolt |

M6 |

1 |

12 |

1.2 |

|

|

|

|||

sprocket cover |

|

|

|

|

|

|

|

|

|

|

|

Air induction system hose |

Clamp |

M7 |

4 |

4 |

0.4 |

|

|

|

|||

Crankcase |

Bolt |

M9 |

10 |

|

See NOTE |

|

|

|

|||

Crankcase |

Bolt |

M6 |

2 |

|

|

|

|

|

|

||

14 |

1.4 |

|

|

||||||||

Crankcase |

Bolt |

M6 |

14 |

12 |

1.2 |

|

|

|

|||

Crankcase |

Bolt |

M8 |

2 |

24 |

2.4 |

|

|

|

|||

Ignitor unit |

Screw |

M5 |

2 |

7 |

0.7 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

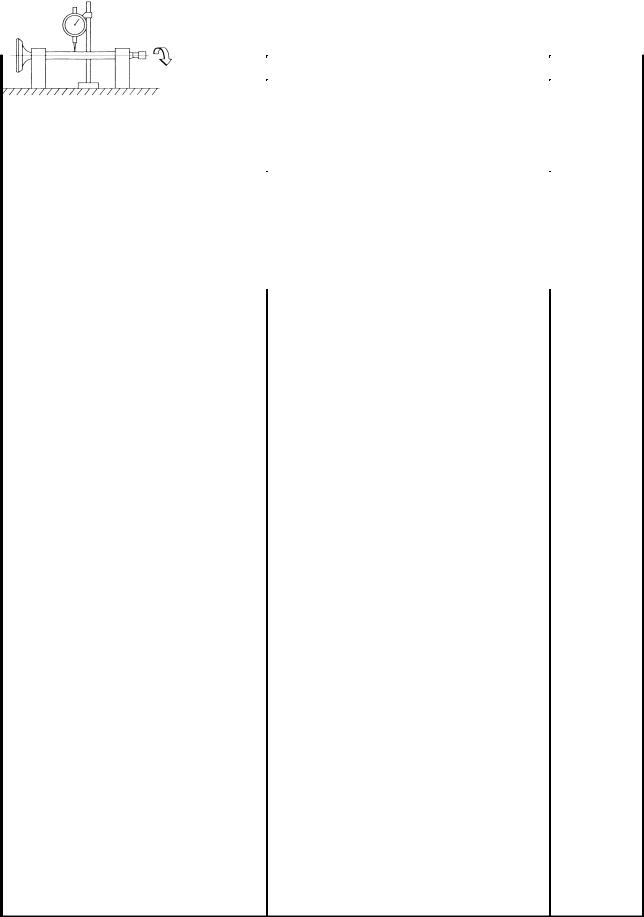

NOTE:

After tightening to 15 Nm (1.5 m kg), tighten another 45_ X 50_

±11±

|

TIGHTENING TORQUES |

|

|

SPEC |

|

|||

CHASSIS TIGHTENING TORQUES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Item |

|

Thread size |

Tightening |

Remarks |

||||

|

|

|

|

|

||||

|

Nm |

m kgf |

||||||

|

|

|

|

|

||||

Lower ring nut |

|

M30 |

9 |

0.9 |

See NOTE. |

|||

Engine mounting |

|

|

|

|

|

|

|

|

Front mounting bolts |

|

M10 |

40 |

4.0 |

|

|

||

Rear upper mounting bolt |

|

M10 |

55 |

5.5 |

|

|

||

Rear under mounting bolts |

|

M10 |

55 |

5.5 |

|

|

||

Pinch bolts |

|

M8 |

24 |

2.4 |

|

|

||

Exhaust pipe bracket |

|

M8 |

24 |

2.4 |

|

|

||

Rear master cylinder |

|

M8 |

18 |

1.8 |

|

|

||

|

|

|

|

|

|

|

|

|

NOTE:

1.First, tighten the ring nut to approximately 18 Nm (1.8 m kg) with a torque wrench, then loosen the ring nut completely.

2.Retighten the ring nut to specification.

±12±

LUBRICATION POINTS AND LUBRICANT TYPES SPEC

E202000

LUBRICATION POINTS AND LUBRICANT TYPES

ENGINE LUBRICATION POINTS AND LUBRICANT TYPES

Lubrication point |

Lubricant |

Connecting rod bolts and nuts

±13±

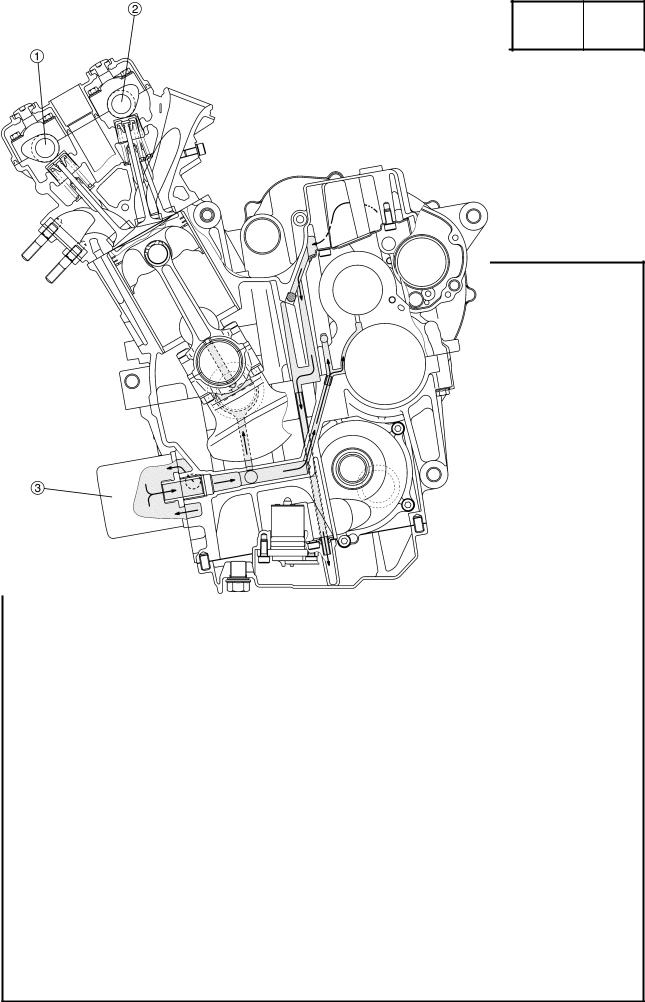

OIL FLOW DIAGRAMS SPEC

EB203000

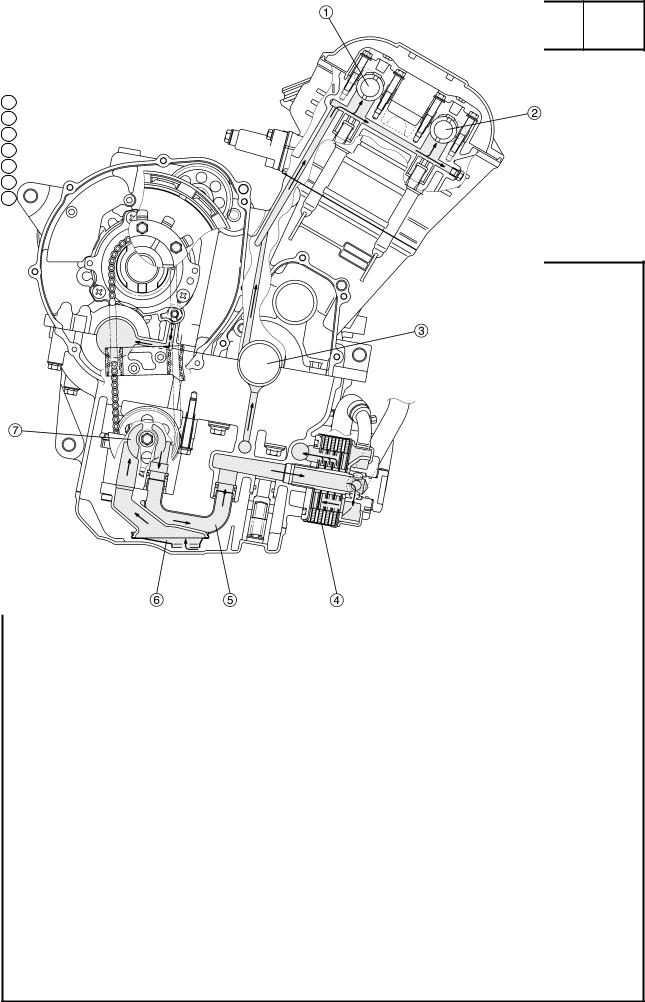

OIL FLOW DIAGRAMS

1Intake camshaft

2Exhaust camshaft

3Crankshaft

4Oil cooler

5Oil pipe

6Oil strainer

7Oil pump

±14±

OIL FLOW DIAGRAMS SPEC

1Exhaust camshaft

2Intake camshaft

3Oil filter

±15±

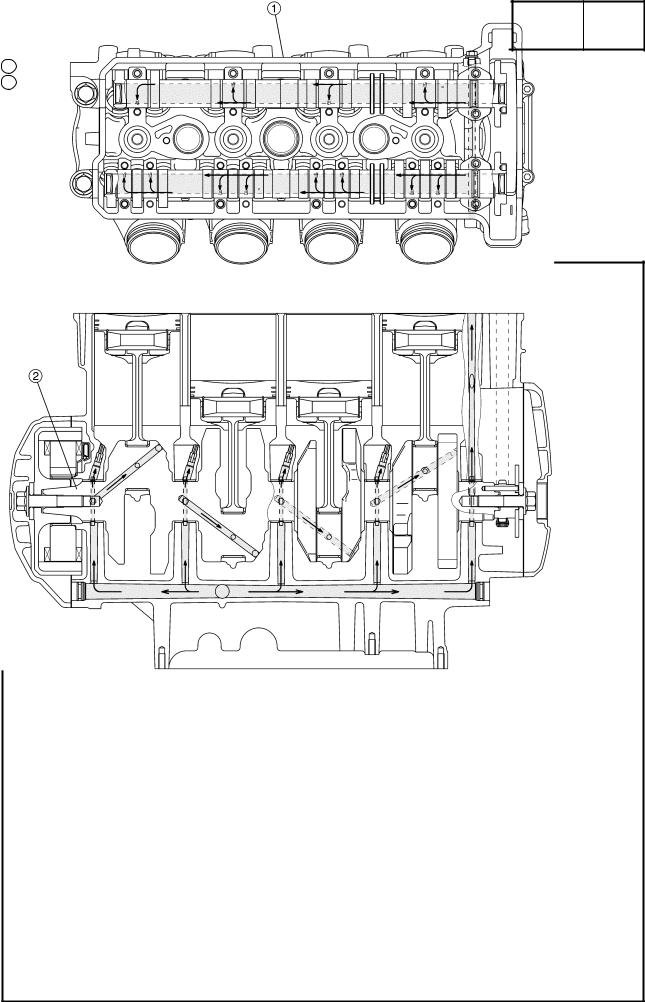

OIL FLOW DIAGRAMS SPEC

1Cylinder head

2Crankshaft

±16±

Loading...

Loading...