Page 1

Series FS4-3T

®

General Purpose

Liquid Flow Switch

INSTRUCTION MANUAL

MM-613F

Page 2

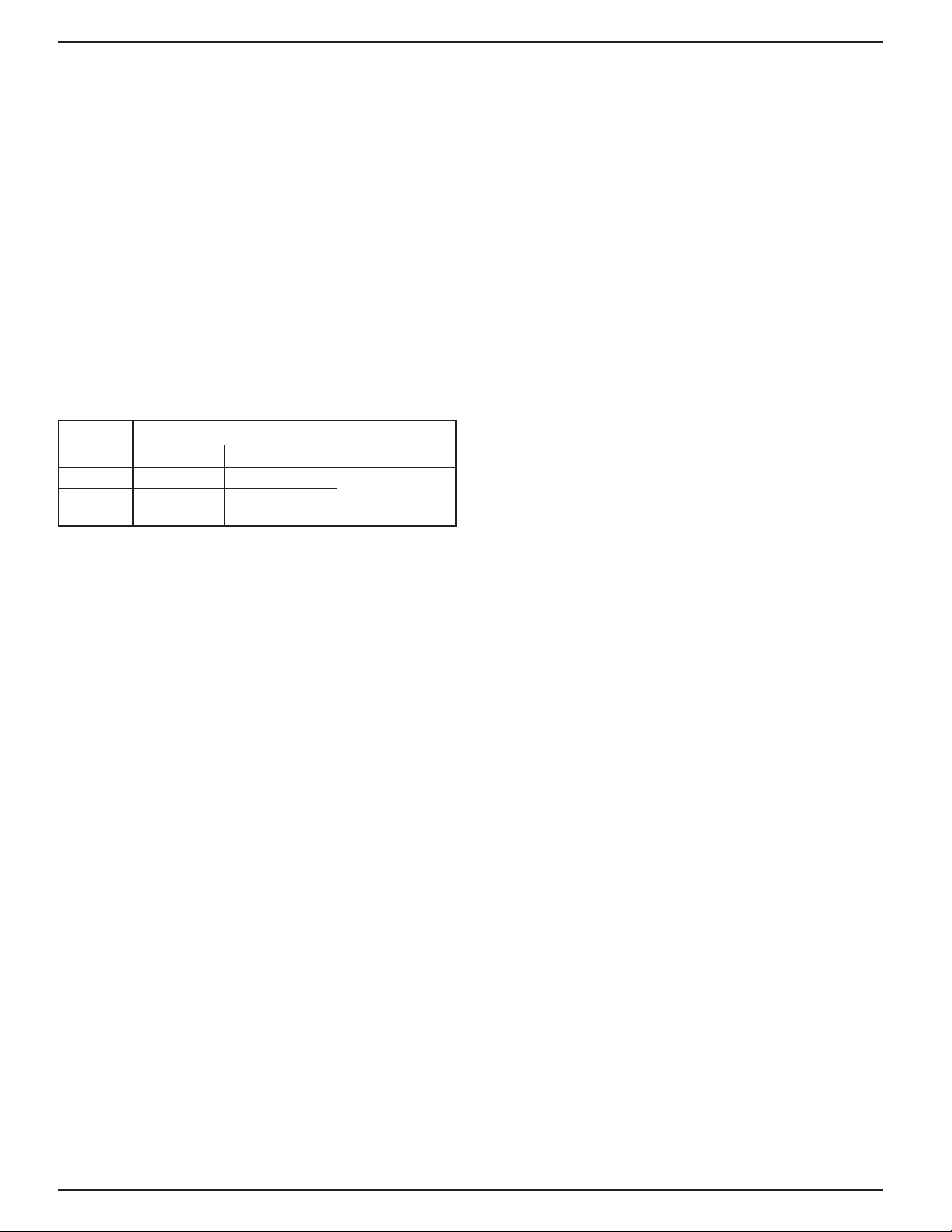

SPECIFICATIONS

Maxim

Liquid

Ambient Temperature Range (T

um Liquid Pressure: 160 psi (11.3 kg/cm

Temperature Range (T

): 32

L

- 300°F (0 - 149°C)

): 32

S

- 120°F (0 - 49°C)

Electrical Enclosure Rating: NEMA Type 1 (IP 21)

Maximum Velocity: 10ft/sec (3M/sec)

3

Pipe Connection Thread Size:

ELECTRICAL

Motor Switch Rating (Amperes)

Voltage

120 VAC 7.4 44.4

240 VAC 3.7 22.2

Full Load Locked Rotor Pilot Duty

RATINGS

/4” or

1” NPT

125 VA at

120 or 240 VAC

50 or 60 cycles

2

)

2

Page 3

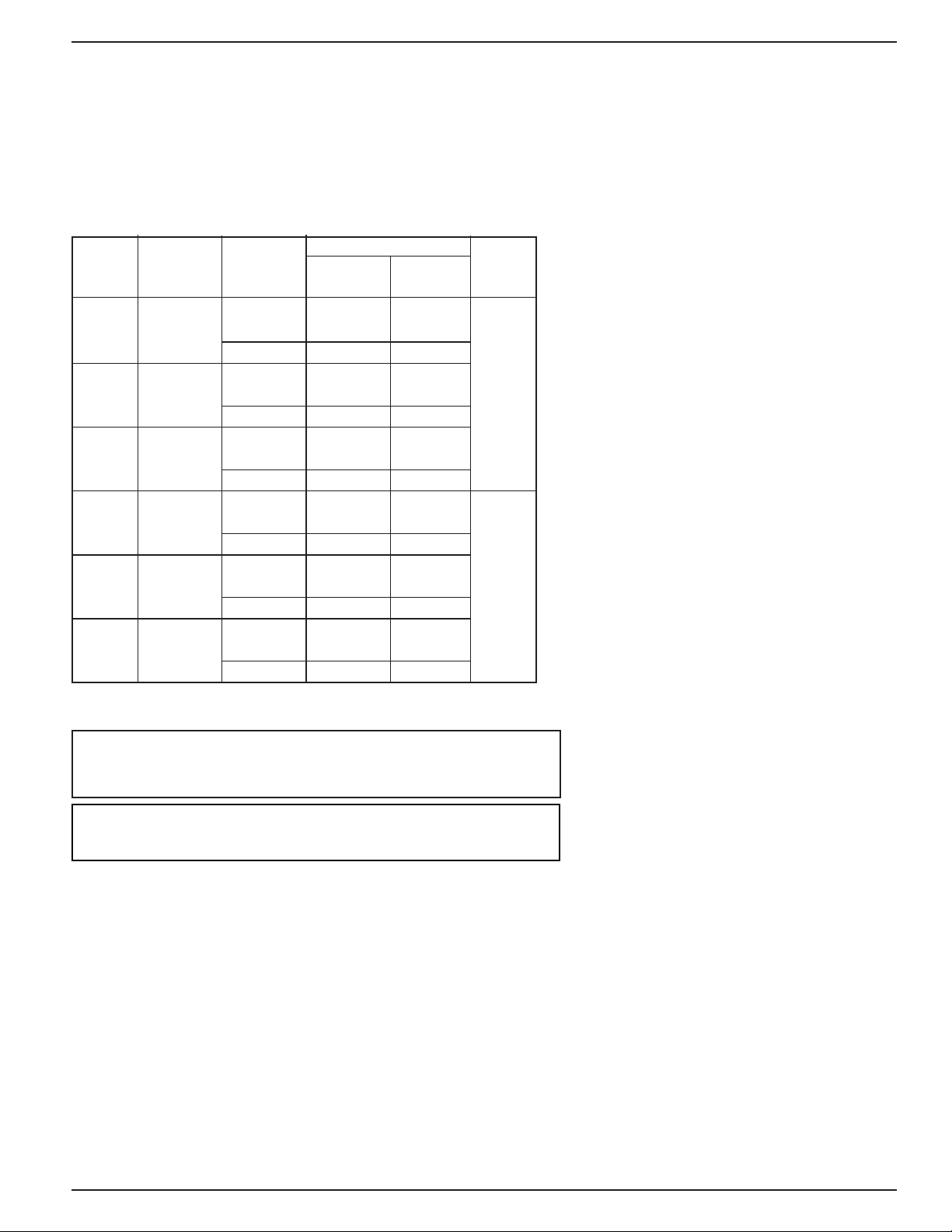

FLOW RATES

Flow rates required to activate the flow switch

are shown in chart below.These values were

calculated using clean water in a horizontal pipe.

Flow Rates

Pipe

Model Size NPT Flow No Flow

Number in. (mm) Settings gpm (lpm) gpm (lpm)

FS4-3T1-

FS4-3T2-

FS4-3T3-

FS4-3T1-1 1 (25) Minimum 5 (18.9) 3.2 (12.1)

⁄

4

3

4

⁄

3

⁄

4

(20) Minimum 4.4 (16.7) 2.6 (9.8)

⁄

4

3

4

(20) Minimum 3.7 (14) 2.2 (8.3) 16.62

⁄

3

⁄

4

(20) Minimum 2 (7.6) 1.2 (4.5)

3

3

Factory or

Maximum 10.5 (39.7) 9.8 (37.1)

Factory or

Maximum 8.9 (33.7) 8.3 (31.4) (63)

Factory or

Maximum 4.5 (17) 4.1 (15.5)

Factory or

Maximum 11.5 (43.5) 11 (41.6)

Mode of Operation

Settings will vary when used to sense flow of other

fluids.

Max. Flow

Rate gpm

(lpm) w/o

Paddle Damage

Factory or

FS4-3T2-1 1 (25) Minimum 4.8 (18.1) 2.9 (11) 27

Maximum 10.1 (38.2) 9.4 (35.6) (102)

Factory or

FS4-3T3-1 1 (25) Minimum 2 (7.6) 1.2 (4.5)

Maximum 4.5 (17) 4.1 (15.5)

Values are ± 10%

NOTE: DO NOT USE LIQUID FLOW SWITCHES ON SYSTEMS

WITH FLOW VELOCITY GREATER THAN 10 FEET (3M)

PER SECOND.

NOTE: THIS PRODUCT IS NOT INTENDED FOR USE IN

POTABLE WATER APPLICATIONS.

3

Page 4

INSTALLATION –

STEP 1 - Determine the Location of the Flow Switch

• The flow switch should be located in a horizontal

section of pipe where there is a straight horizontal run

of at least 5 pipe diameters on each side of the flo w

switch. The flow switch may be installed in a vertical

pipe if the flow is in the upward direction.

• The flow switch must be installed in the upright

position as shown with arrow mark on side of casting

in the same direction as fluid will flow.

• Some system conditions that require more than 5 pipe

diameters are high viscosity fluid and high fluid v elocity.

• The flow switch should be installed in the pump suction

piping when spring-loaded check valves and/or other

closed coupled accessories are installed in the pump

discharge piping.

STEP 2 - Connecting the Flow Switch to Pipe

a. Apply pipe sealing compound or PTFE tape to the

pipe threads.

NOTE: Do not apply sealant to first threads as this

switch is grounded (earthed) via the pipe mounting.

3/4" or 1"

PIPE

5 x D

MINIMUM

FLOW

D= PIPE DIAMETER

PTFE

D

5 x D

MINIMUM

b. Insert pipe threads into flow switch and turn 2

or 3 times until tight.

• Place one pipe wrench on base of flow

switch and one wrench on connecting piping.

Tighten to following torque values.

- 47 ft•lb (64 N•m) for 3/4” pipe

- 63 ft•lb (85 N•m) for 1” pipe

• Repeat to connect pipe to opposite side of

flow switch.

4

FLOW

Page 5

STEP 3 - Electrical Installation

!

WARNING

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• To prevent an electrical fire or equipment damage, electrical wiring insulation must have a rating of

167°F (75°C) if the liquid’s temperature exceeds 180°F (82°C).

• To prevent electrocution, when the electrical power is connected to the flow switch, do not touch the

terminals.

• Make sure flow switch electrical cover is secured before turning on electric power.

Failure to follow this warning could cause property damage, personal injury or death.

a. Cover Removal and Installation Procedure

• Using a flathead screwdriver, loosen but do not remove

the two cover screws and remove the cover (A).

• Place the cover on the flow switch sliding the slots

behind the two loose cover screws. Push the cover

down into the flow switch and using a flat blade screwdriver, tighten the cover screws to a torque of 10 lb•in

(1.13 N•m).

A

b. Electrical Conduit Connection

• Connect electric conduit to flow switch electrical enclosure.

•Follow accepted electrical practices when installing fittings

and making connections.

• Refer to and follow local codes and standards when

selecting the types of electrical fittings and conduit to

connect to flow switch.

5

Page 6

c. Determine which switch action is required for the

flow switch.

• “Flow” means that the switch will close circuit

C.-N.O. and open circuit C.-N.C. when flow rate

is increased above setpoint of flow switch.

• “No Flow” means that the switch will open circuit

C.-N.O. and close circuit C.-N.C. when flow rate

is decreased below setpoint of flow switch.

d. Based upon the mode of operation (“Flow” or “No-

Flow”) required, complete the appropriate steps to

connect wires to flow switch. Use a phillip’s head

screwdriver to loosen and tighten switch terminal

screws when attaching wires.

For “Flow” Mode of Operation (Fig. 1)

If the flow switch will be used to actuate a signal,

alarm or other device when flow occurs, connect

the wire from that device to the “N.O.” contact.

Connect the “Hot” power supply wire to “C” terminal.

For “No Flow” Mode of Operation (Fig. 2)

If the flow switch will be used to actuate a signal,

alarm or other device when no flow occurs, connect

the wire from that device to the “N.C.” contact.

Connect the “Hot” power supply wire to “C” terminal.

COMMON

FLOW

1

CLOSES

FLOW

CIRCUIT

OPENS

2

CIRCUIT

3

Flow

Opens

Flow

Common

(

Common

1

(

Normally

(

Closes

Circuit

open

Circuit

(

(

Normally

closed

3

(

2

FS4-3

31

2

Fig. 1

HOT

LINE

LOAD

FS4-3

31

2

Fig. 2

LINE

HOT

LOAD

6

Page 7

STEP 4 - Testing

a. Place cover on flow switch and turn on power. Initiate fluid

flow through the system. Observe the device being

activated by the flow switch to determine if device is

operating as required.

b. Tu rn off fluid flow to determine if device is operating

as required.

c. Repeat initiating and turning off fluid flow several times to

test flow switch and device for proper operation.

- If operating as required, put system into service.

- If not operating as required, flow switch may need

to be adjusted.

SECTION 5 - Adjustment

ON

OFF

Adjustment is necessary only if required flow/no

flow setpoints are above factory set minimum.

a. Tu rn off power. Remove electric enclosure

cover.

b. Tu rn adjusting screw clockwise (1/8 turn) to

increase setpoint.

IMPORTANT: Do not attempt to lower flow switch

setpoint from original factory minimum setting.

Lowering (turning adjusting screw counterclockwise) the setpoint from original factory setting

may cause erratic flow switch operation.

c. Place the cover on the flow switch and turn on

power.

d. Test the operation of the flow switch after

each adjustment.

COMMON

FLOW

1

CLOSES

FLOW

CIRCUIT

OPENS

2

CIRCUIT

3

ADJUSTING SCREW

7

Page 8

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.mcdonnellmiller.com

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2014 Xylem Inc. MM-613F March 2014 Part No. 246714

Loading...

Loading...