Page 1

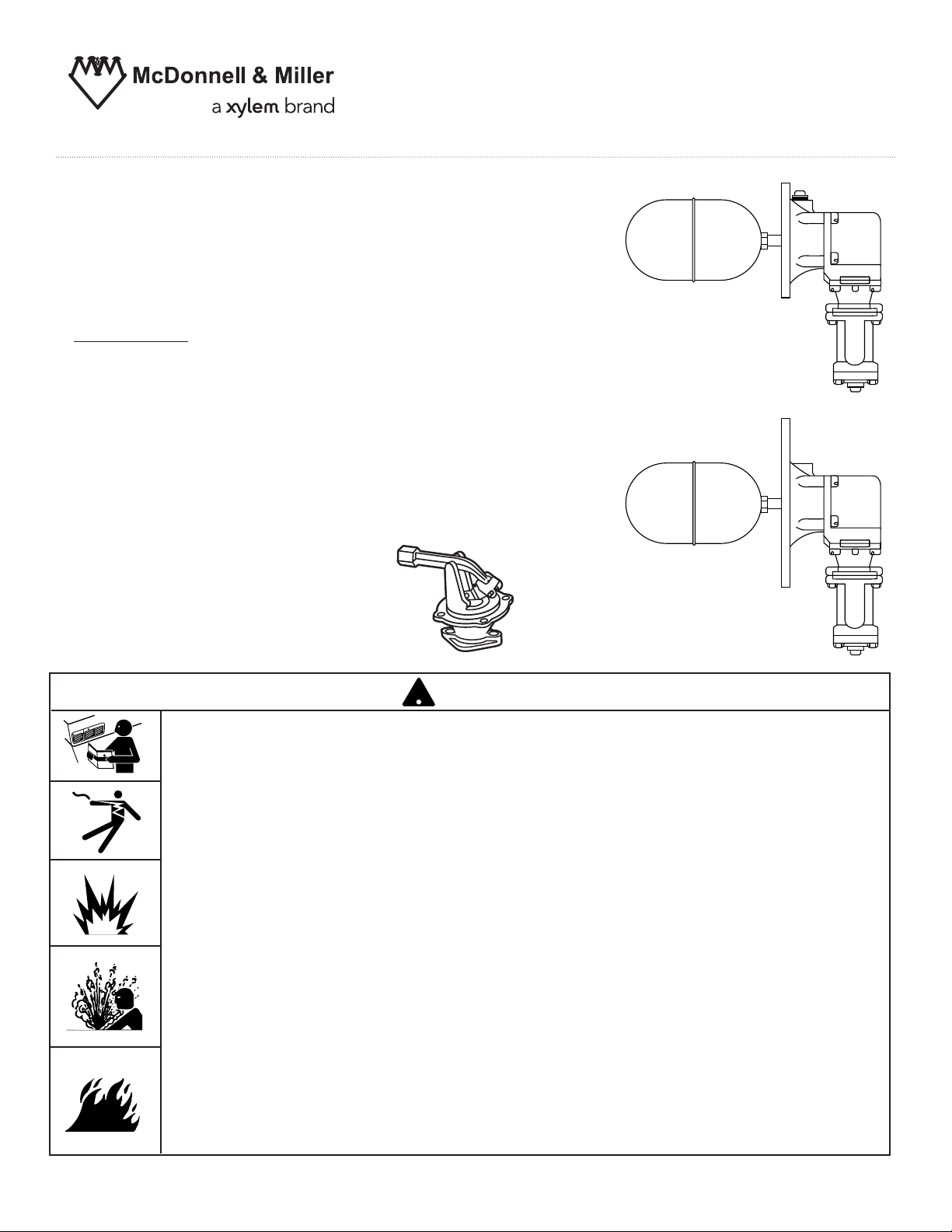

Model 21 and 221

Mechanical Water Feeders

And Replacement Valve Assembly SA21-6

Applications:

For receiver tanks in industrial or

commercial applications.

Maximum water supply pressure: 150 PSIG (10.55 kg/cm2)

2

Maximum vessel pressure: 35 PSIG (2.46 kg/cm

Maximum fluid temperature: 120°F (49°C)

)

INSTRUCTION MANUAL

MM-317C

Model 21

SA21-6

WARNING

!

TION

CAU

ING

WARN

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• Drain water level down below feeder and let cool to 80° (27°C) before servicing.

• If tank or receiver is pressurized relieve pressure to 0 psi (0 Bar) before servicing.

• To prevent water damage check to make sure there is adequate floor drainage capacity.

Check all components in the system to insure they will not leak in the event of an

overfeed condition.

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

!

&

'

Model 221

Page 2

2

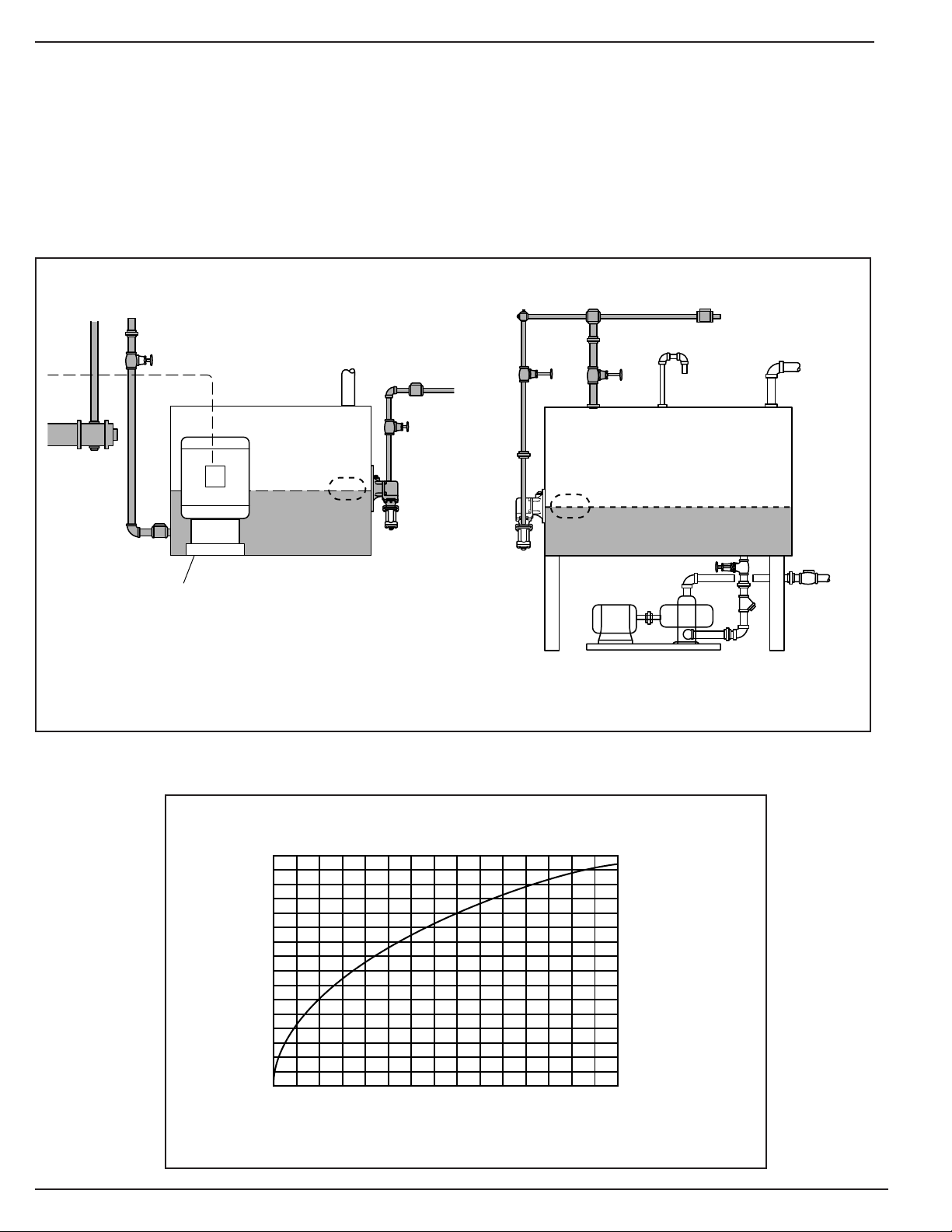

OPERATION

Capacities

WATER SUPPLY PRESSURE IN LBS. PER SQ. IN.

CAPACITY CURVE

lbs./hr.

psi

(kg/hr.)

13 012 011010 09080706050403010

16,000

15,000

14,000

13,000

12,000

11,000

10,000

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

(7258)

(6804)

(6350)

(5897)

(5443)

(4990)

(4536)

(4082)

(3629)

(3175)

(2722)

(2268)

(1814)

(1361)

(907)

(454)

(0)

(0.7) (1.4) (2.1)(2.8) (3.5) (4.2) (4.9) (5.6)(6.3) (7.0) (7.7) (8.4) (9.1)(9.8) (10.5)

200

(0)

14 0 15 0

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

(121.12)

(113.55)

(105.98)

(98.41)

(90.84)

(83.27)

(75.70)

(68.13)

(60.56)

(52.99)

(45.42)

(37.85)

(30.28)

(22.71)

(15.14)

(7.57)

(0)

(kg/cm

2

)

gpm

(lpm)

464

435

406

377

348

319

290

261

232

203

174

145

116

87

58

29

0

(4549)

(4264)

(3980)

(3696)

(3411)

(3127)

(2843)

(2559)

(2274)

(1990)

(1706)

(1421)

(1137)

(853)

(569)

(284)

(0)

Boiler Hp

(kilowatts)

The Series 21 make-up water feeder provides

dependable, float-operated automatic water filling

service to tanks used as condensate receivers in

boiler systems. The valve components are of brass,

an elastomer sealing disc and stainless steel materials, and a 4-3/4” diameter copper float providing

closure against supply pressure up to 150 PSI. An

integral strainer and housing with removable drainage

plug precede the valve for regular servicing. The control is a direct-feeding unit (feeds through the flange

connection) available in two flange sizes.

TYPICAL INSTALLATIONS

Boiler

Feed

Tank

MODEL 221

City Water Supply

Check Valve

Bypass

Condensate Receiver Tank

MODEL 21

Feed Pump

Pump

Discharge

Feed Pump

Page 3

3

INSTALLATION

TOOLS NEEDED:

One (1) adjustable wrench, socket wrenches, two (2)

pipe wrenches, pipe dope, assorted fittings and lengths

of 3/4” pipe.

STEP 1 - Preparation

This Water Feeder mounts directly on the

tank or vessel. The tank or vessel is to be

manufactured with a mating flange (A)

and opening large enough for the float.

The flange can be either welded flush on

the side or head and have pre-tapped

mounting holes (preferred), or a necked

or nozzle flange with plain mounting

holes. Either must have a 1-3/8” maximum

distance from the outer flange face to the

interior wall surface to allow the float to

fully drop to get maximum valve capacity.

City Water Supply

Check Valve

Bypass

Condensate Receiver Tank

Pump

Discharge

Feed Pump

MODEL 21

The feeder is usually mounted one-third

(1/3) of the way up from the bottom of the

tank. This provides two-thirds (2/3) of the

tank for return condensate.

Follow the diagram for piping the feeder

to the tank and water supply. Remember

to leave room for the servicing the water

feeder. At all right angle turns in the

equalizing piping, crosses should be used

to facilitate inspection and cleaning.

STEP 2 - Install the Piping

Flange Dimension Details

e

Tank w/

Flange

1-3/8”

MAX.

1-3/8”

MAX.

Bulk

Head

Flang

NO. 21

NO. 221

Page 4

INSTALLATION (cont.)

21 Series - Replacement Valve Assembly (SA21-6)

a. Remove Feeder from Tank. Turn off the water

supply and drain the tank below the level of the

feeder flange. If fluid is heated, allow system to

cool to 80°F (27°C) before disassembly.

Disconnect the piping above the strainer assembly. Remove the six (6) mounting bolts and lift off

the feeder from the tank.

b. Remove Valve Assembly. Remove float and

rod from the float arm of the valve linkage.

Unscrew the two (2) bolts from the strainer body

at the bottom of the valve assembly. Unscrew

the four (4) bolts from the valve body at the bottom of the valve housing bracket. Pull the valve

assembly from the housing in an arcing movement to clear the float arm from the interior.

c. Reassemble with new Valve Assembly.

Position the new valve assembly with new

gasket, float arm first, into the housing. Hand

secure the four (4) bolts and tighten to 16 ft/lbs.

Replace the strainer body and new gasket using

the two (2) bolts. Tighten to 16 ft/lbs. Reattach

the float and rod onto the float arm and hand

tighten.

d. Replace Feeder on Tank. Replace the assem-

bly and new gasket onto the tank flange. Tighten

the six (6) bolts to 16 ft/lbs. Reconnect the

piping and restore water supply. Check for proper closing level and leakage before leaving the

jobsite.

Note: Use new gaskets; make sure all gasket

surfaces are clean.

Housing Gasket

SA21-6

Replacement

Valve

Housing

Strainer

Assembly

MAINTENANCE:

• Blow down tank weekly during heating season.

Blow down may have to be more frequent

depending on local water conditions and the

amount of make-up water.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-317C July 2013 Part No. 246731

• Clean strainer at least twice during heating

season. Cleaning may have to be more frequent

depending on local water conditions and the

amount of make-up water.

• Replace control every 15 years.

Loading...

Loading...