Page 1

Series 47 and 247

Mechanical Water Feeders

Series 47-2 and 247-2

Combination Mechanical

INSTRUCTION MANUAL

MM-316E

Water Feeder/Low Water

Cut-Off

Applications:

For steam and hot water boilers with cold

water feed, to maintain a minimum safe

water level independent of electrical service.

• Before using this product read and understand instructions.

CAUTION

WARNING

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be

0 psi (0 bar) before servicing.

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• The low water cut-off switch must be installed in series with all other limit and operating

controls installed on the boiler. After installation, check for proper operation of all of the

limit and operating controls, before leaving the site.

• We recommend that secondary (redundant) Low Water Cut-Off controls be installed on all

steam boilers with heat input greater than 400,000 BTU/hour or operating above 15 psi

steam pressure. At least two controls should be connected in series with the burner

control circuit to provide safety redundancy protection should the boiler experience a

low-water condition. Moreover, at each annual outage, the low water cutoffs should be

dismantled, inspected, cleaned, and checked for proper calibration and performance.

• Boiler manufacturer schematics should always be followed. In the event that the boiler

manufacturer's schematic does not exist, or is not available from the boiler manufacturer,

refer to the schematics provided in this document.

• To prevent a fire, do not use this low water cut-off to switch currents over 10.2A, 1/2 HP at

120 VAC or 5.1A, 1/2 HP at 240 VAC, unless a starter or relay is used in conjunction with it.

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Series 47-2 Combination

Water Feeder Low Water

WARNING

!

!

Series 47

Water Feeder

Cut-Off

Series 247

Water Feeder

Series 247-2 Combination

Water Feeder Low Water

Cut-Off

Page 2

Water Feeder

Closing Level

Low

Water Cut-Off

Burner Starts

2

1

/4" (57mm)

37/16" (87mm)

23/4" (70mm)

Feeder keeps water

level 37/16" (87mm)

above center of lower

gauge glass tapping

If extreme priming or

foaming causes water

line to fall 13/16" (30mm)

below feeder closing

level, cut-off switch

stops the burner

When water level is

restored 1/2" (13mm)

above emergency.

Cut-off switch starts

burner and the water

feeder resumes

control

Motor Switch Rating (Amperes)

Voltage Full Load Locked Rotor Pilot Duty

120 VAC 10.2 61.2

125 VA at 120

240 VAC 5.1 30.6

or 240 VAC, 60 Hz

OPERATION

Series 47/47-2 Operating Levels

All Models

• Maximum Water Pressure: 150 psi (10.5 kg/cm2)

• Maximum Water Temp: 120˚F (49˚C)

• Water Connection Size:

1

/2” NPT

47/47-2

• Maximum Boiler Pressure: 25 psi (1.76 kg/cm2)

247/247-2

• Maximum Boiler Pressure: 30 psi (2.1 kg/cm

2

)

Electrical Ratings

Series 47 Water Feeders and Series 47-2

Combination Water Feeder/Low Water Cut-Off

maintain minimum water level in the boiler during

normal operation.

Series 47-2 Combination Water Feeder/Low

Water Cut-Off allows the burner to operate on

demand as the water level is restored to its

proper level.

Series 47-2 Combination Water Feeder/Low

Water Cut-Off shuts off the burner if the boiler

water level drops 1 3/16” (30mm) below the water

feeder’s closing level.

2

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

&

'

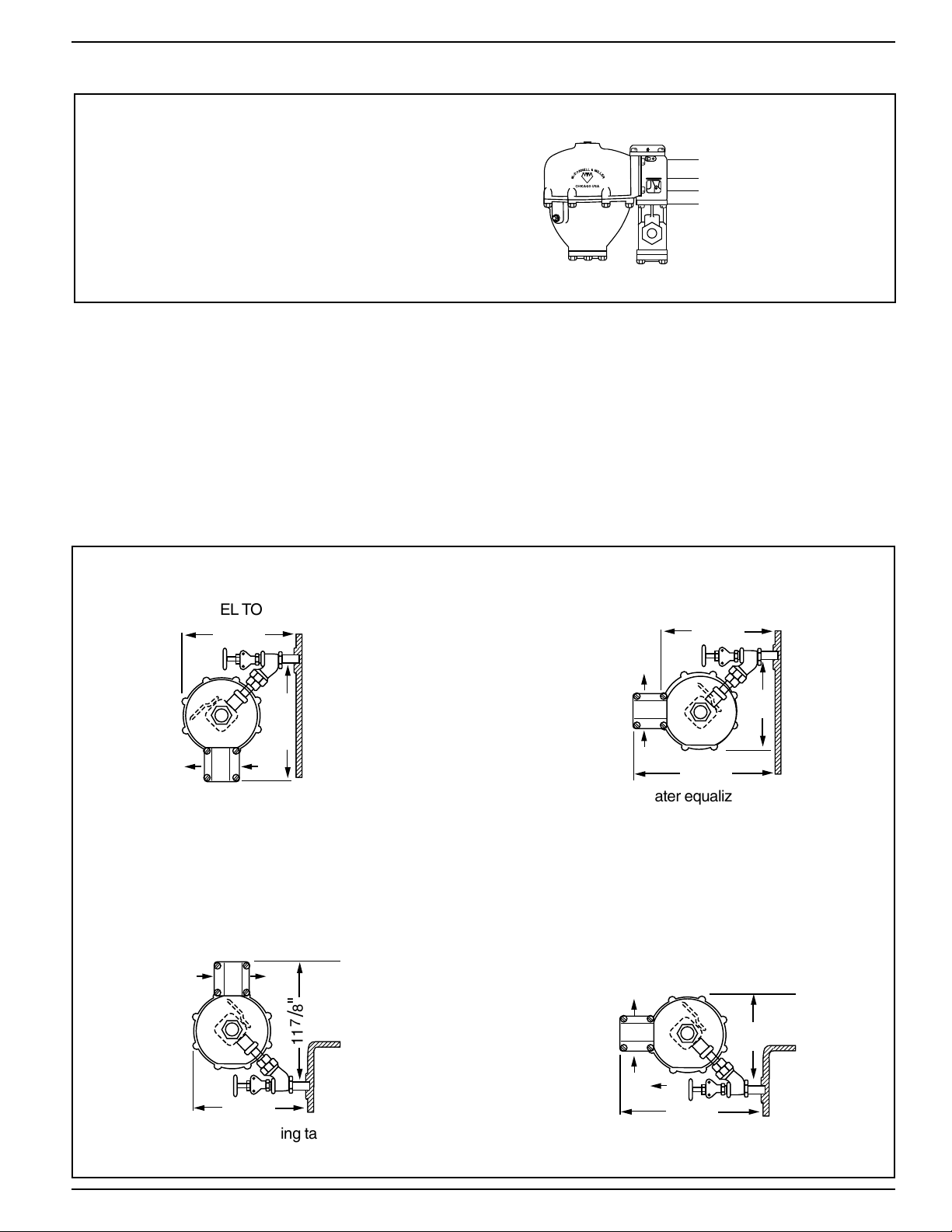

Page 3

11

7

/8"

PARALLEL TO BOILER

OUT

IN

11

7

/8"

10

5

/8"

OUT

IN

(alternate water equalizing tapping used)

OUT

IN

10

5

/8"

13

5

/8"

9"

9"

13

5

/8"

(alternate water equalizing tapping used)

IN OUT

10

5

/8"

RIGHT ANGLED TO BOILER

RIGHT ANGLED TO BOILER

WITH TURNED Y FITTINGS

PARALLEL TO BOILER

WITH TURNED Y FITTINGS

3

STEP 1 - Determine Best Position to Install the Water Feeder

(to clear obstructions that may be encountered on the side of the boiler).

INSTALLATION –

TOOLS NEEDED:

Two (2) pipe wrenches, and one (1) flathead screwdriver.

Series 247 and 247-2 Operating Level

Water feeder figures are +/- 1/4" (6.4mm)

Burner figures are +/- 1/8" (3.2mm)

TOP VIEWS

Valve Off -7/16" (11.1mm)

Casting Line - 0"

Burner On - 1/4" (6.4mm)

Burner Off - 3/4" (19mm)

Page 4

E

F

D

10-5/8"

(270mm)

G

d. Determine the position of the black "Y" casting (F).

If gauge glass tappings (D) and (E) are less

than 10

5

⁄8" (270 mm) apart, install the black

"Y" casting (F) as depicted in the diagram to the

top right.

OR

If gauge glass tappings (D) and (E) are

greater than 10

5

⁄8" (270 mm) apart, invert

the black "Y" casting (F) as depicted in the

diagram to the bottom right.

OR

If gauge glass tappings (D) and (E) are

greater than 14" (356 mm) apart, invert the

black "Y" casting (F) as depicted in the diagram

to the bottom right and install a longer nipple (G).

4

STEP 2 - Preparation (Installing Quick Hook-up Fittings to Water Feeder)

a. Turn the boiler off.

A

b. Drain the water in the boiler until the level falls below the lower

gauge glass connection (A). Allow the boiler to cool to 80˚F

(27 ˚C) and allow the pressure to release to 0 psi (0 bar).

B

C

c. Remove the water glass (B) and gauge glass connections (C)

from the boiler.

OFF

ON

INVERTED “Y” CASTING

Note:

F

Reverse union

nuts, packing

and plug.

G

Tighten top

nut securely.

Page 5

F

G

g. Slide the black "Y" (F) casting over the nipple (G)

in accordance with Step 2d, but do not tighten.

L

F

M

N

L

P

U

U

K

Q

Q

h. 1). Apply sealant to the external threads of the nipple (L)

of the upper "Y" connection. Using a pipe wrench,

tighten the nipple (L) into the 1/2" (15 mm) NPT

tapping (M) of the black "Y" casting (F). Slide union

nut (U) over nipple (L). Using a pipe wrench tighten

the upper “Y” connection (N) to nipple (L). Tighten to

54 ft

•lb (74 N•m).

2). Apply sealant to the external threads of the tailpiece (P)

of the lower "Y" connection. Slide union nut (U) over

tailpiece (P). Using a pipe wrench, tighten the tailpiece

(P) into the 1/2” (15 mm) NPT tapping (Q) in the lower

half of body (K). Tighten to 54 ft

•lb (74 N•m).

5

J

H

K

e. Remove the plug (H) from the 1/2" (15 mm) NPT

tapping (J) in the top of the feeder body (K).

J

G

K

No Threads

f. Apply thread sealant to the external threads. Using

a pipe wrench, tighten the 1/2" (15 mm) NPT nipple

(G) into the tapping (J) on the top of the feeder (K)

to approximately 54 ft

•lb (74 N•m).

Note: Nipple (G) is only threaded on one end.

Upper “Y”

Lower “Y”

When using pipe or tape sealant on the external threads of pipes or fittings, follow the manufacturers

instructions. Use sparingly and do not place on the first thread.

!

IMPORTANT

Page 6

6

STEP 3 - Installing Series 47 Water Feeder or Series 47-2 Combination Water

Feeder/Low Water Cut-Off with Quick Hook-Up Fittings to Boiler

a. Apply thread sealant to the external threads

of the "Y" fittings (T). Using the pipe wrench,

install them in the boiler gauge glass tappings (S),

and tighten to approximately 54 ft

•lb (74 N•m).

Tighten both union nuts (U).

b. Reinstall water glass and gauge connections to “Y”

fittings (T).

When using pipe or tape sealant on the external threads of pipes or fittings, follow the manufacturers

instructions. Use sparingly and do not place on the first thread.

!

IMPORTANT

U

N

L

U

U

T

S

R

i. Using the pipe wrench, tighten the furnished pipe

plug into the open tapping (R) on the lower half of

the feeder float body in accordance with the

position diagrams in Step 1. Tighten the plug to

approximately 20 ft

•lb (27.3 N•m).

Page 7

STEP 4 - Installing Series 247/247-2 Water Feeder to Boiler

Burner

Boiler

City Water Supply

Return

Header

Series 247

Water

Feeder

Casting

Line

ByPass

Valve

Pipe the Series 247/247-2 water feeder so that

the line on the casting is 3" (76mm) above the

minimum safe operating level as specified by

the boiler manufacturer.

Recommended Piping

STEP 5 - Piping the valve on the Models 47/47-2 and 247/247-2

TO BOILER

By-Pass

Valve

Swing Check

STEP 6 - Electrical Wiring (Only for Series 47-2 & 247-2)

AA

a. Using the flathead screwdriver, loosen the two

(2) screws that secure the switch cover (AA).

Remove cover.

7

!

IMPORTANT

Boiler manufacturer schematics should always be followed. In the event that the boiler manufacturer's schematic

does not exist, or is not available from the boiler manufacturer, refer to the schematics provided in this document.

a. Follow the drawing to the right for piping the valve

to the boiler and city water supply. When piping the

valve, remember to leave room for servicing the

valve.

b. Piping the valve this way will aid in troubleshooting

the valve and piping in the future.

Page 8

8

STEP 7 - Testing and Inspection

V

CLOSING

LEVEL

INSTALLATION COMPLETE

C.

Line

Load

N.

N.C.

O.

C.

Load

or

Burner

Circuit

Low

Water

Alarm

N.

N.C.

Neutral

120 V.A.C.

or 24 V.A.C.

Supply

HOT

O.

b. Based on the mode of operation required for

your application, complete the appropriate

corresponding step.

When the water feeder is used as a low water

cut-off switch and/or a low water alarm

, connect

the "Hot" wire to the "Common" contact. Using a

flat head screw driver, tighten the screw. Connect

the low water alarm to the “Normally Open” contact

and tighten the screw. Connect the burner or load

circuit wire to the “Normally Closed” contact and

tighten the screw.

OR

When the water feeder is used as a pilot switch

to a holding coil of a motor starter or relay,

connect as shown in the diagram to the right.

Low water cut-off switch and/or low water alarm

Pilot switch for motor starter or relay

The feeder should be blown down after initial installation

before leaving site. It should also be blown down as

recommended in the Maintenance section of these

instructions.

• Burner should be on and water level above 'closing

level' of feeder.

• Slowly open the water feeder blow down valve 'V'

which will lower the water level in the float chamber.

As water flows out the blow down pipe, you should

begin to hear the feeder valve open.

• If the feeder has a #2 switch, the burner should stop.

• Close the water feeder blow down valve 'V'. The water

level should return to a safe operating level and the

burner should turn on.

To prevent serious personal injury from steam pipe

blow down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

Failure to follow this caution could cause personal

injury.

!

CAUTION

Blow Down of Feeder

Page 9

9

X

Z

TO BOILER

Feed

Valve

By-Pass

Valve

Check Valve

WATER

SUPPLY

Make sure that the water level in the boiler is above the

closing level of the feeder.

Close valve 'X' and slowly open union 'Z' to determine if

valve is leaking.

• If water is leaking from the union, the valve needs to

be serviced.

• If no water leaks from the union, the feeder operation

is not the cause of the flooding.

Broken Union Test

E

D

B

H

x 4

A. Using a 1/2" socket wrench, unscrew the four (4) hex-head

bolts (B) that secure the strainer basket (H) to the valve

assembly (E).

B. Using a 13/16" socket wrench, unscrew the cartridge (D)

and remove.

C. Clean any debris (scale, rust, etc.) from strainer and cartridge.

Poppet inside cartridge must move freely. Replace if debris

cannot be removed or poppet does not move freely.

D. Lubricate cartridge o-rings using silicone type lubricant and

re-install.

E. Re-install strainer basket.

Removal of cartridge and strainer for inspection and cleaning

Page 10

10

TROUBLESHOOTING

The following is intended as a guide to determine why the feeder may not be operating as intended. Please note that

there can be system and installation issues that can affect the operation of the feeder. This includes but is not limited to

the following:

• Piping not installed properly • Priming and foaming of boiler water

• Faulty check valve in return header • Delay in condensate returning to boiler

• Tankless coil leaking

Boiler is getting too much water.

a) Cause: There is something preventing the valve

(cartridge poppet) from completely closing.

Test: Perform broken union test.

Solution: Remove and inspect cartridge. Clean or

replace as necessary.

b) Cause: By-pass valve is leaking.

Test: Perform broken union test.

Solution: Repair or replace valve.

c) Cause: Float chamber clogged with sediment.

Test: Open blow-down valve. If there is little or no

water flow, the chamber may be clogged with sediment.

Solution: Remove bottom of float chamber. Clean

sediment from chamber, float and bellows mechanism.

Replace control if necessary.

d) Cause: Float has filled with water.

Solution: Replace float.

e) Cause: Equalizing piping is plugged.

Solution: Clean or replace piping.

f) Cause: Water supply is above 150 psi.

Solution: Install pressure reducing valve to reduce

water pressure.

Boiler is not getting enough water.

a) Cause: There is something preventing the valve

(cartridge poppet) from fully opening.

Test: Perform broken union test.

Solution: Remove and inspect cartridge. Clean or

replace as necessary.

b) Cause: Strainer clogged with sediment.

Test: Perform broken union test.

Solution: Remove and inspect strainer. Clean or

replace as necessary.

c) Cause: Float chamber clogged with sediment.

Test: Open blow-down valve. If there is little or no

water flow, the chamber may be clogged with sediment.

Solution: Remove bottom of float chamber and clean

sediment from chamber, float and bellows mechanism.

Replace control if necessary.

d) Cause: Feed line between valve and boiler is partially

plugged.

Test: Perform broken union test. With union broken,

there should be water flowing through the piping from

the boiler.

Solution: Clean or replace piping.

e) Cause: Feed line between valve and city water supply

is plugged.

Solution: Clean or replace piping.

f) Cause: Water supply pressure is less than boiler

pressure.

Solution: Reduce boiler pressure or convert to pumped

return.

Page 11

11

MAINTENANCE

SCHEDULE:

Weekly

• Blow down when boiler is in operation.

Annually

• Disassemble and inspect/clean strainer screen.

Replace if screen is torn or not able to be cleaned.

• Remove and inspect/clean cartridge. Replace if

poppet does not move freely or debris cannot be

removed.

• Remove lower float chamber and inspect internal

parts. Clean out all mud, silt, sediment and debris from

chamber, float mechanism and other waterside

components.

• Inspect equalizing piping. Clean or replace as

required.

• Check all wires for brittle or worn insulation.

• Check for leaks at gasket surfaces and solder joints.

Replace entire unit including equalizing piping every

10 years.

More frequent cleaning or replacement may be

required if used in locations where water treatment is

required or in applications with high make-up water

requirements.

NOTE

Use clean water to rinse components and surfaces. DO

NOT use sharp objects to scrape off any accumulations

of sediment or debris.

Unit is making noise.

a) Cause: Under certain system conditions, there may be

a vibration when the valve mechanism (cartridge poppet)

is slightly open.

Solution: Install a pressure reducing valve, such as the

Bell & Gossett B-38, in the inlet water line before the

feeder valve.

Burner switch not working.

a) Cause: Cam worn or broken.

Solution: Replace cam assembly (CO-106/302900).

b) Cause: Linkages not transferring float movement

to switch.

Solution:

• Linkage pins may be worn or broken which would

require purchasing a new valve assembly

(SA47-101-102/341600).

• Float may be damaged, sediment may have

accumulated in chamber or equalizing piping may be

plugged. Perform testing to determine what the

problem may be and correct.

Water leaking from bellows

a) Cause: Continuous exposure to chemicals or water with

pH higher than 9.0 can cause the solder to deteriorate.

Solution: Remove source of chemicals or consider

replacing control with one that is suitable for the

application.

TROUBLESHOOTING (cont'd)

Page 12

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,000 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-316E July 2013 Part No. 210386

Loading...

Loading...