Page 1

E

Page 2

2

Determine which situation applies:

a. For models 51-2, 51-S-2 or 53-2 on steam boilers:

Always set the control to shut off the burner while

there is water visible in the gauge glass. This applies

when the gauge glass is directly mounted in the boiler

or on a water column.

b. For models 51, 51-S or 53 on steam boilers:

Set the line on the casting 3

1

/8" below the boiler

manufacturer’s normal water level.

c. For all models on steam process boilers when no

condensate is returned to the boiler: Set the line

on the casting 11/8" below the boiler manufacturer’s

normal water level.

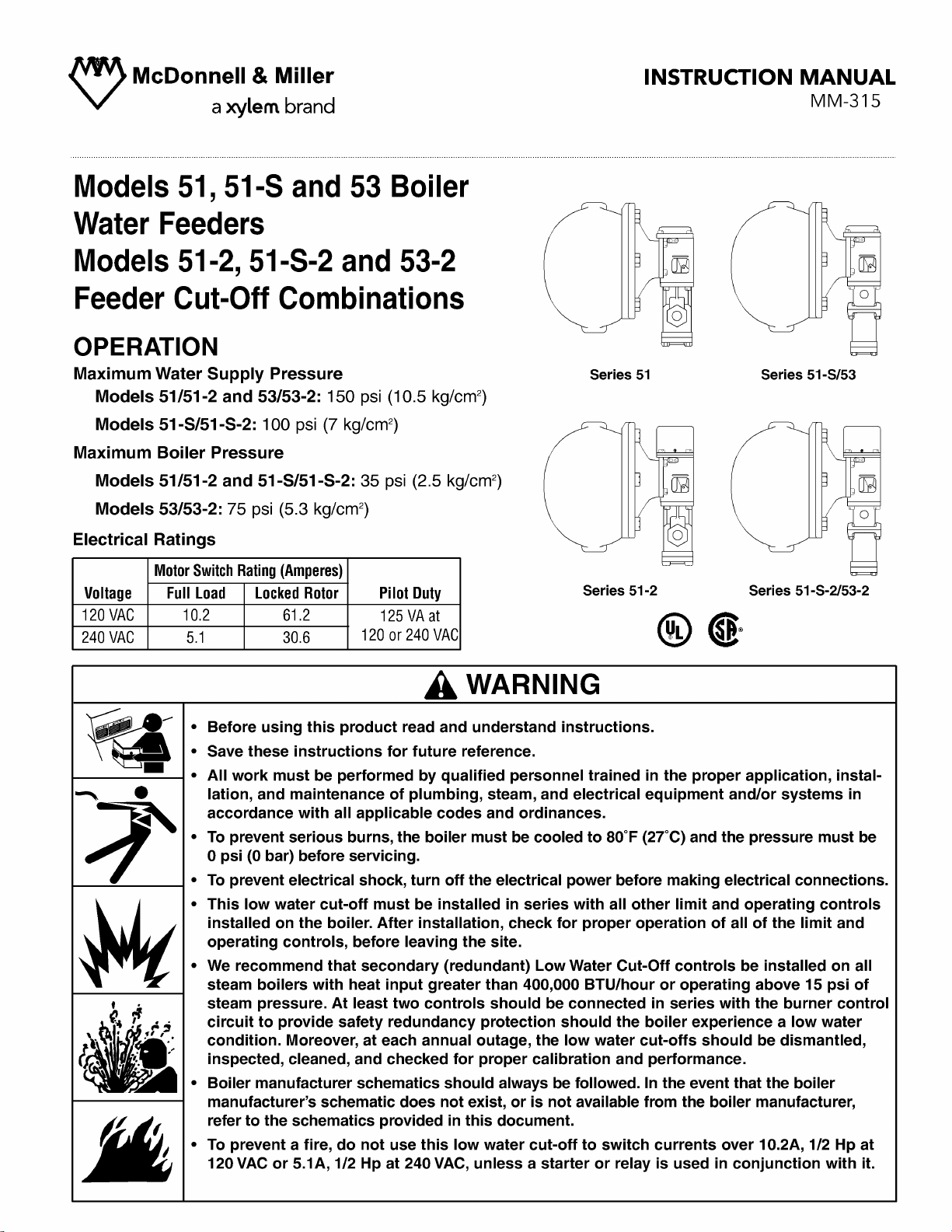

Models 51 / 51-2, Models 51-S / 51-S-2 and Models 53 / 53-2 –

For Steam Boilers with 1” (25mm) Equalizing Lines

INSTALLATION –

TOOLS NEEDED:

One (1) flathead screwdriver and two (2) pipe wrenches.

STEP 1 - Determine the Location of the Feeder and/or Low Water Cut-Off

Operating Levels of 51/51-2,

51-S/51-S-2 or 53/53-2

Drip tight valve off – 11/8"

Casting line – 0”

Burner on –1/8" (±1/4")

Burner off –7/8" (±1/4")

Series 51 and 53 Operating Level

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to fo

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell & Miller's warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

llow this warning could cause property damage, personal injury or death.

Casting

Line

Valve Off -11/8"

Casting Line - 0"

Burner On - 1/8" (± 1/4")

Burner Off -

7

/8" (± 1/4")

Page 3

a. Using the criteria in Step 1,

determine the location of the

51/51-2, 51-S/51-S-2 or 53/53-2.

This applies when the gauge

glass is directly mounted in the

boiler or on a water column.

b. Use Figure 1 or Figure 2 as a

general guide.

c. Connect steam equalizing lines

to any available opening other

than steam flow line.

(Take off line).

d. Test the Model 51/51-2, 51-S/51-S-2 and 53/53-2 Before Turning it Over to the Owner

Open the blow-down valve while burner is operating. As the water level drops the feeder will begin to

add water. As the water continues to drop the burner will shut off (on the 51-2, 51-S-2 and 53-2 only).

STEP 2 - Installation of the Models 51/51-2, 51-S/51-S-2 and 53/53-2

3

Lower

Gauge

Glass

Connect to Return

Header on Boiler

Side of all Valves

1" Crosses

Gauge Glass

Level

Mark

1" Steam Equalizing Line

(Short as Possible)

1" Minimum Blow-down

Valve for Feeder

Float Chamber

1" Water

Equalizing Line

(Short as Possible)

Cold City Supply

Normal Water Line

Swing Check Valve

By-Pass

Feeder Casting Mark

(See Installation Location)

1" Crosses

Level

Mark

Water

Column

1" Steam Equalizing Line (Short as Possible)

1" Minimum Blow-down Valve

for Feeder Float Chamber

Normal Water Line

Feeder Casting Mark

(See Installation Location)

Connect to Return

Header on Boiler

Side of all Valves

Swing Check Valve

Cold City Supply

By-Pass

1" Water Equalizing Line (Short as Possible)

1" Minimum Blow-down Valve

Figure 1

Gauge Glass Mounted in the Boiler

Figure 2

Gauge Glass Mounted on a Water Column

Page 4

4

Strainer

Basket

Assembly

Swing Check Valve

By-pass

Hand By-Pass Valve

Connect to return

header on boiler

side of all valves

City Water

Supply

Supply To

Feeder

CAUTION

Before turning

on city water

pressure be

sure to open

this valve

a. Follow the drawing to the right for piping the

valve to boiler and city water supply. When

piping the valve remember to leave room for

servicing the valve.

Models 51 / 51-2, Models 51-S / 51-S-2 and Models 53 / 53-2

For Steam or Hot Water Boilers

INSTRUCTIONS FOR PIPING THE WATER FEEDER VALVE

TOOLS NEEDED:

Two (2) pipe wrenches.

STEP 1 - Piping the Valve on Models 51/51-2

Swing Check Valve

By-pass

Hand By-Pass

Valve

Connect to return

header on boiler

side of all valves

CAUTION

Before turning

on city water

pressure be

sure to open

this valve

City Water

Supply

Supply

Valve

Strainer

Basket

Assembly

a. Follow the drawing to the right for piping the

valve to the boiler and city water supply.

When piping the valve remember to leave

room for servicing the valve.

STEP 2 -

Piping the Valve on Models 51-S/51-S-2, 53/53-2

Page 5

5

Models 51-2, 51-S-2 and 53-2

ELECTRICAL WIRING

TOOLS NEEDED:

One (1) flathead screwdriver.

Conduit opening facing

toward float chamber

Conduit opening facing

away from float chamber

Manual reset button

on No. 2m Switch

a. The No. 2 switch can be positioned with the

conduit opening facing toward or away from

the float chamber. These are the only positions

in which the switch will function properly.

See drawing at right.

b. On initial fill-up, push the 2M manual reset

button after the proper water level is reached

to energize the burner. If a low water condition

occurs and the water level has been restored,

push the reset button to energize the burner.

c. Follow the wiring diagrams below to wire the

No. 2 Switch. Terminals C and NC are the low

water cut-off switch. Terminals C and NO are

alarm switch. If the electrical load exceeds the

rating of the switch, use an auxiliary relay or

motor starter.

USED AS A MAIN LINE SWITCH

AND/OR LOW WATER ALARM

USED AS A PILOT SWITCH TO COIL

OF RELAY OR MOTOR STARTER

N.

O.

N.C.

C.

N. O.

N.C.

C.

Neutral

120 V.A.C.

Supply Hot

Low

Water

Alarm

Burner

Circuit

Line

Load

SCHEMATIC OF SWITCH OPERATION

Water Level Normal

Burner On

Alarm Off

Low

Water

Alarm

Terminals

Low Water

Cut-Off

Terminals

C.

N.O.

N.C.

Water Level Low

Burner Off

Alarm On

C.

N.O.

N.C.

N.

O.

N.C.

C.

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls installed on the

boiler. After installation, check for proper operation of all of the limit and operating controls, before leaving

the site.

Failure to follow this warning could cause electrical shock, an explosion and/or a fire, which could result in

property damage, personal injury or death.

!

WARNING

Page 6

6

STEP 3 - Testing and Inspection

Blow-Down

Valve

Feeder

Valve

Closing

Level

The feeder should be blown down after initial installation, before leaving site. It should also be blown down

as recommended in the Maintenance section of these

instructions.

• Burner should be on and water level above 'closing

level' of feeder.

• Slowly open the water feeder blow down valve, which

will lower the water level in the float chamber. As

water flows out the blow down pipe, you should begin

to hear the feeder valve open.

• If the feeder has a #2 switch, the burner should stop.

• Close the water feeder blow down valve. The water

level should return to a safe operating level and the

burner should turn on.

To prevent serious personal injury from steam pipe

blow down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

Failure to follow this caution could cause personal

injury.

!

CAUTION

Swing check

TO BOILER

By-pass

valve

A

B

Make sure that the water level in the boiler is above the

closing level of the feeder.

Close valve 'A' and slowly open union 'B' to determine if

valve is leaking.

• If water is leaking from the union, the valve needs to

be serviced.

• If no water leaks from the union, the feeder operation

is not the cause of the flooding.

Broken Union Test

Blow Down of Feeder

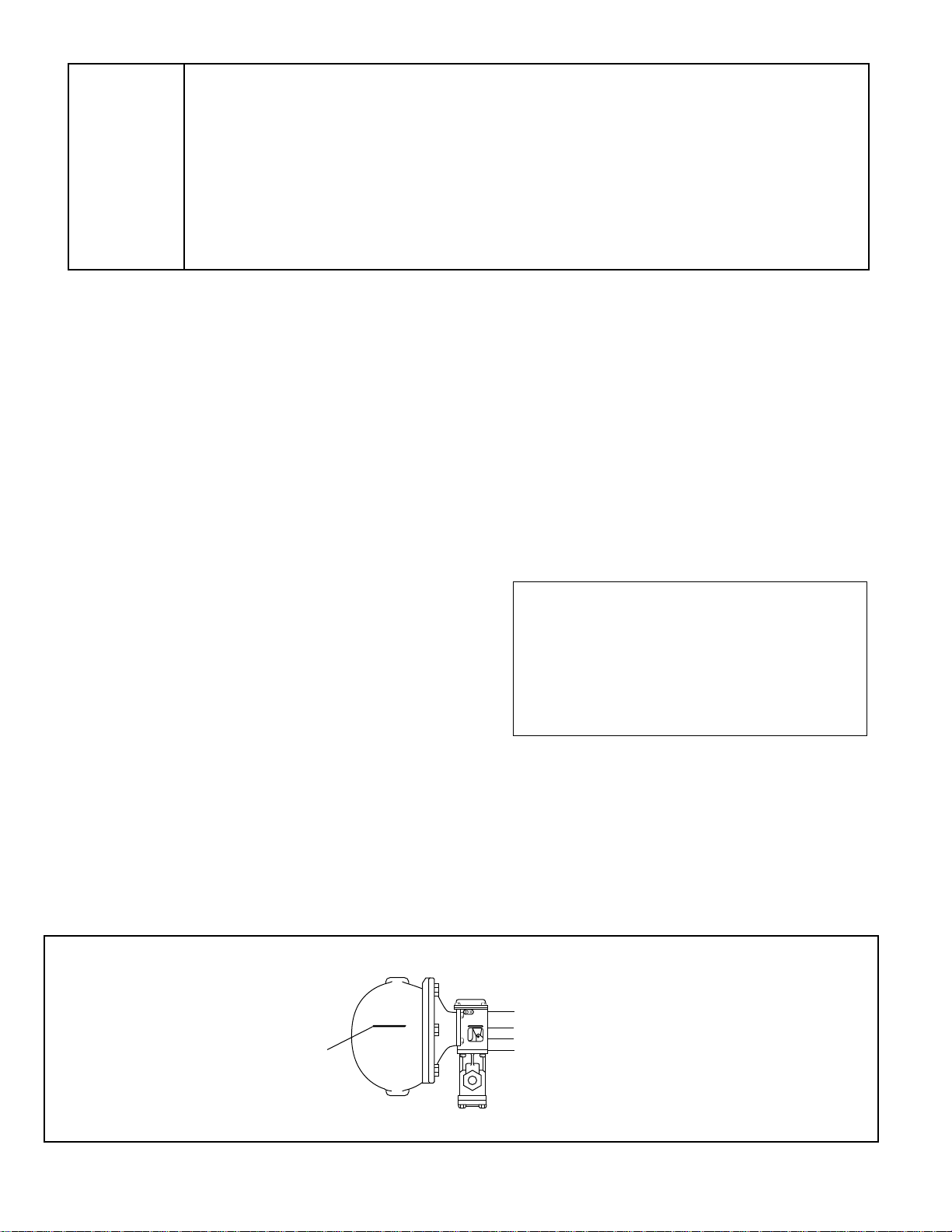

E

D

B

H

x 4

A. Using a 1/2" socket wrench, unscrew the four (4) hex-head

bolts (B) that secure the strainer basket (H) to the valve

assembly (E).

B. Using a 13/16" socket wrench, unscrew the cartridge (D)

and remove.

C. Clean any debris (scale, rust, etc.) from strainer and cartridge.

Poppet inside cartridge must move freely. Replace if debris

cannot be removed or poppet does not move freely.

D. Lubricate cartridge o-rings using silicone type lubricant and

re-install.

E. Re-install strainer basket.

Series 51

Removal of cartridge and strainer for inspection and cleaning

Page 7

7

The following is intended as a guide to determine why the feeder may not be operating as intended. Please note that

there can be system and installation issues that can affect the operation of the feeder. This includes but is not limited to

the following:

• Piping not installed properly • Priming and foaming of boiler water

• Faulty check valve in return header • Delay in condensate returning to boiler

• Tankless coil leaking

TROUBLESHOOTING

B

A. Using a 1/2" wrench, unscrew the four (4) hex-head

bolts (B) that secure the strainer.

B. Clean any debris (scale, rust, etc.) from strainer.

Replace if debris cannot be removed.

C. Re-install strainer.

Series 51-S/53

Removal of strainer for inspection and cleaning

Boiler is getting too much water.

a) Cause: The valve is not shutting off.

Test: Perform broken union test.

Solution:

• Series 51 Feeders Only: Remove and inspect

cartridge. Clean or replace as necessary.

• Series 51-S and 53 Feeders Only: There may be

debris lodged in the valve preventing it from closing

completely. Remove and clean valve assembly.

Replace if necessary.

b) Cause: By-pass valve is leaking.

Test: Perform broken union test.

Solution: Repair or replace valve.

c) Cause: Float chamber clogged with sediment.

Test: Open blow-down valve. If there is little or no

water flow, the chamber may be clogged with sediment.

Solution: Remove head assembly from float chamber

and clean sediment from chamber, float and bellows

mechanism. Replace head mechanism if necessary.

d) Cause: Float has filled with water.

Solution: Replace float.

e) Cause: Equalizing piping is plugged.

Solution: Clean or replace piping.

f) Cause: City water supply is above 150 psi (51, 53

Feeders) or 100 psi (51-S Feeder).

Solution: Install pressure reducing valve to reduce

water pressure.

Boiler is not getting enough water.

a) Cause: There is something preventing the valve from

fully opening.

Test: Perform broken union test.

Solution:

• Series 51 Feeders Only: Remove and inspect

cartridge. Clean or replace as necessary.

• Series 51-S and 53 Feeders Only: There may be

debris lodged in the valve preventing it from closing

completely. Remove and clean valve assembly.

Replace if necessary.

b) Cause: Strainer clogged with sediment.

Test: Perform broken union test.

Solution: Remove and inspect strainer. Clean or

replace as necessary.

c) Cause: Float chamber clogged with sediment.

Test: Open blow-down valve. If there is little or no

water flow, the chamber may be clogged with sediment.

Solution: Remove head assembly from float chamber

and clean sediment from chamber, float and bellows

mechanism. Replace head mechanism if necessary.

d) Cause: Feed line between valve and boiler is partially

plugged.

Test: Perform broken union test. With union broken,

there should be water flowing through the piping from

the boiler.

Solution: Clean or replace piping.

e) Cause: Feed line between valve and city water supply

is plugged.

Solution: Clean or replace piping.

f) Cause: Water supply pressure less than boiler

pressure.

Solution: Reduce boiler pressure or convert to pumped

return.

Page 8

TROUBLESHOOTING (cont'd)

Unit is making noise.

(Series 51 Feeders Only)

a) Cause: Under certain system conditions, there may be

a vibration when the valve mechanism (cartridge poppet)

is slightly open.

Solution: Install a pressure reducing valve such as the

Bell & Gossett B-38 in the inlet water line before the

feeder valve.

Burner switch not working.

a) Cause: Cam worn or broken.

Solution: Replace cam assembly (CO-106/302900).

b) Cause: Linkages not transferring float movement to

switch.

Solution:

• Linkage pins may be worn or broken which would

require purchasing a new valve assembly:

-for 51/51-2: SA51-101-102/342500

-for 53/53-2: SA53-6/342800

-for 51-S/51-S-2: SA515-6/342100

• Float may be damaged, sediment may have

accumulated in chamber or equalizing piping may be

plugged. Perform testing to determine what the

problem may be and correct.

Water leaking from bellows

a) Cause: Continuous exposure to chemicals with pH

higher than 9.0 will cause the solder to deteriorate.

Solution: Remove source of chemicals or consider

replacing control with one that is suitable for the

application.

MAINTENANCE

SCHEDULE:

Daily

• Blow down when boiler is in operation if boiler operating

pressure is above 15 psi.

Weekly

• Blow down when boiler is in operation if boiler operating

pressure is below 15 psi.

Annually

• Disassemble and inspect/clean strainer screen.

Replace if screen is torn or not able to be cleaned.

• Remove and inspect/clean cartridge. (For Series 51

Feeders Only). Replace if poppet does not move freely

or debris cannot be removed.

• Remove head and inspect internal parts. Clean out all

mud, silt, sediment and debris from chamber, float

mechanism and other waterside components.

• Inspect equalizing piping. Clean or replace as

required.

• Check all wires for brittle or worn insulation.

• Check for leaks at gasket surfaces and solder joints.

NOTE

Use clean water to rinse components and surfaces. DO

NOT use sharp objects to scrape off any accumulations

of sediment or debris.

Replace entire unit including equalizing piping every

10 years.

More frequent cleaning or replacement may be

required if used in locations where water treatment is

required or in applications with high make-up water

requirements.

Xylem, Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-315E July 2013 Part No. 210424

Loading...

Loading...