Page 1

INSTRUCTION MANUAL

IM186

Battery Backup

Sump Pump

INSTALLATION, OPERATION AND PARTS MANUAL

Page 2

Table of Contents

SUBJECT PAGE

Safety Instructions .........................................................................................................................................................2

Basic Tools and Materials Needed .................................................................................................................................2

General Information ......................................................................................................................................................2

Charger Operation ........................................................................................................................................................2

Battery Requirements ....................................................................................................................................................3

Pump Installation and Operation ...................................................................................................................................3

Electrical Connections ...................................................................................................................................................4

Charger/Battery Installation ...........................................................................................................................................4

Battery Maintenance .....................................................................................................................................................4

Repair Parts ...................................................................................................................................................................5

Troubleshooting ............................................................................................................................................................6

Limited Warranty ..........................................................................................................................................................8

Owner’s Information

Pump Model Number:

Pump Serial Number:

Control Model Number:

Dealer:

Dealer Phone No.

Date of Purchase: Installation:

2

Page 3

RULES FOR SAFE INSTALLATION AND OPERATION

DANGER

WARNING

CAUTION

WARNING

DANGER

Carefully read and follow all safety instructions in this

manual or on system.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on your

pump or in this manual, look for one of

the following signal words and be alert

to the potential for personal injury!

Warns about hazards that WILL cause

serious personal injury, death or major

property damage if ignored.

Warns about hazards that CAN cause

serious personal injury or major

property damage if ignored.

Warns about hazards that WILL or

CAN cause minor personal injury or

property damage if ignored.

The word NOTICE indicates special instructions

which are important but not related to hazards.

1. To avoid risk of serious bodily injury and property

damage, read safety instruction carefully before

installing pump.

2. Follow local and/or national plumbing and electrical

codes when installing pump. A ground fault circuit

interruptor (GFCI) is recommended for use on any

electrical appliance submerged in water.

3. Use this pump only for backup sump pump duty in

a residential application. It is not designed as a

primary sump pump.

Hazardous Voltage. Can cause severe or

fatal electrical shock.

4. Do not plug in or unplug battery charger while

standing on a wet floor or in water. Be sure one hand

is free when plugging in or unplugging charger. If

basement floor is wet, disconnect power to basement

before walking on floor.

5. Do not lift pump by electrical cord.

6. Pump water only with this pump.

7. Pump is permanently lubricated at the factory.

Do not try to lubricate it!

8. Keep battery charger and battery box in a dry, cool,

well ventilated area.

9. To avoid danger of fire or explosion, keep sparks and

flame away from battery.

Battery acid is corrosive.

10. Do not spill on skin, clothing or battery charger.

Wear eye protection when working on battery.

11. Maximum vertical pumping distance is

15 feet (4.6 M).

12. Make sure pump is clear of debris.

BASIC TOOLS AND MATERIALS NEEDED

Pipe wrenches, screwdriver, hacksaw, adjustable wrench,

Teflon tape, knife, 12-volt battery, PVC cement, primary

pump check valve (if not installed)

GENERAL INFORMATION

The battery back-up sump system is not a substitute for

your primary sump pump. It is designed as a backup

pump to pinch-hit for your primary sump pump during

a power outage or other problem which prevents normal

operation. Do not use it to pump flammable liquids or

chemicals.

Keep battery charger dry and protected from damage.

In an emergency (such as an extended power outage)

which depletes the system battery, your automobile battery may be temporarily substituted. Be sure to replace

the system battery as soon as possible.

CHARGER OPERATION

Backup pump will start automatically when sump water

level rises far enough to trip float switch. After a delay

of about 4 seconds, alarm will sound. Silence alarm by

pushing ALARM TEST/RESET button. In normal (switch

actuated) operation, alarm is locked out until about 4

seconds after float switch has dropped to OFF position,

cycle can then begin again.

Test alarm by pushing ALARM TEST/RESET button

when alarm is not sounding. Alarm will then sound as

long as button is held down.

If alarm sounds, check operation of primary pump,

which may need service. If battery backup operation is

due to a power outage, alarm will sound, but no service

is likely to be required to primary pump.

Battery charger has capacity to run pump and charge

battery at the same time as long as power to the charger

is not interrupted. If power to charger circuit is interrupted, the length of time that the backup pump will run

depends on the ampere-hour capacity of the battery used.

Extended periods of operation (for example, during an

extended power outage) may exhaust the battery. However, once the load is removed, usually it will self-regenerate far enough to allow the charger to start. The battery

charger will begin charging the battery as long as the

battery has a charge of at least 1/2 volt.

After power is restored, charger will automatically recharge battery fully in about six hours.

NOTICE: If battery has not reached a satisfactory

voltage after 24 hours of charging, alarm will

sound. In this case alarm cannot be reset.

Possible causes are:

PROBLEM ACTION

Back-up pump has run Push ‘Reset’. Check main pump

Power out more than Disconnect charger from battery.

24 hours Call power company.

Continuous charging Disconnect charger from battery.

more than 24 hours Check for defective battery.

Loose connection or Disconnect charger from battery.

no power to charger Check plug, receptacle, power

at main breaker.

After restoring power or replacing battery, alarm can be reset.

3

Page 4

BATTERY REQUIREMENTS

WARNING

CAUTION

Hazardous electrical current.

Can cause severe burns and start a fire if battery terminals are short circuited. Install battery in box. To prevent

accidental shorting across battery terminals, strap cover

securely on battery box. Do not leave battery uncovered.

Do not allow children to play around sump pump

installation.

Your backup sump pump depends on the battery used

with it for power. The better the battery, the better the

performance of the pump.

We recommend the use of a 105 Amp Deep Cycle

Marine Battery.

This battery will perform well for many hours and stands

up well to long periods of little or no use.

Use of a standard automobile or marine

battery with this charger is not recommended. An automobile battery may

require charging after only 1-2 hours of

continuous use, and the repeated charging cycles may cause early plate failure

in the battery.

Use only a new, fully charged battery

that will fit in the battery box (maximum size 125⁄8" long, 7" wide and 93⁄8"

high (320.7 mm x 177.8 mm x 238 mm)

including terminals).

PUMP INSTALLATION AND OPERATION

NOTICE: We recommend a trial fitting of all

components before gluing anything. This

will allow you to check pump mounting

height, float switch clearance, etc., while

adjustments can still be easily made.

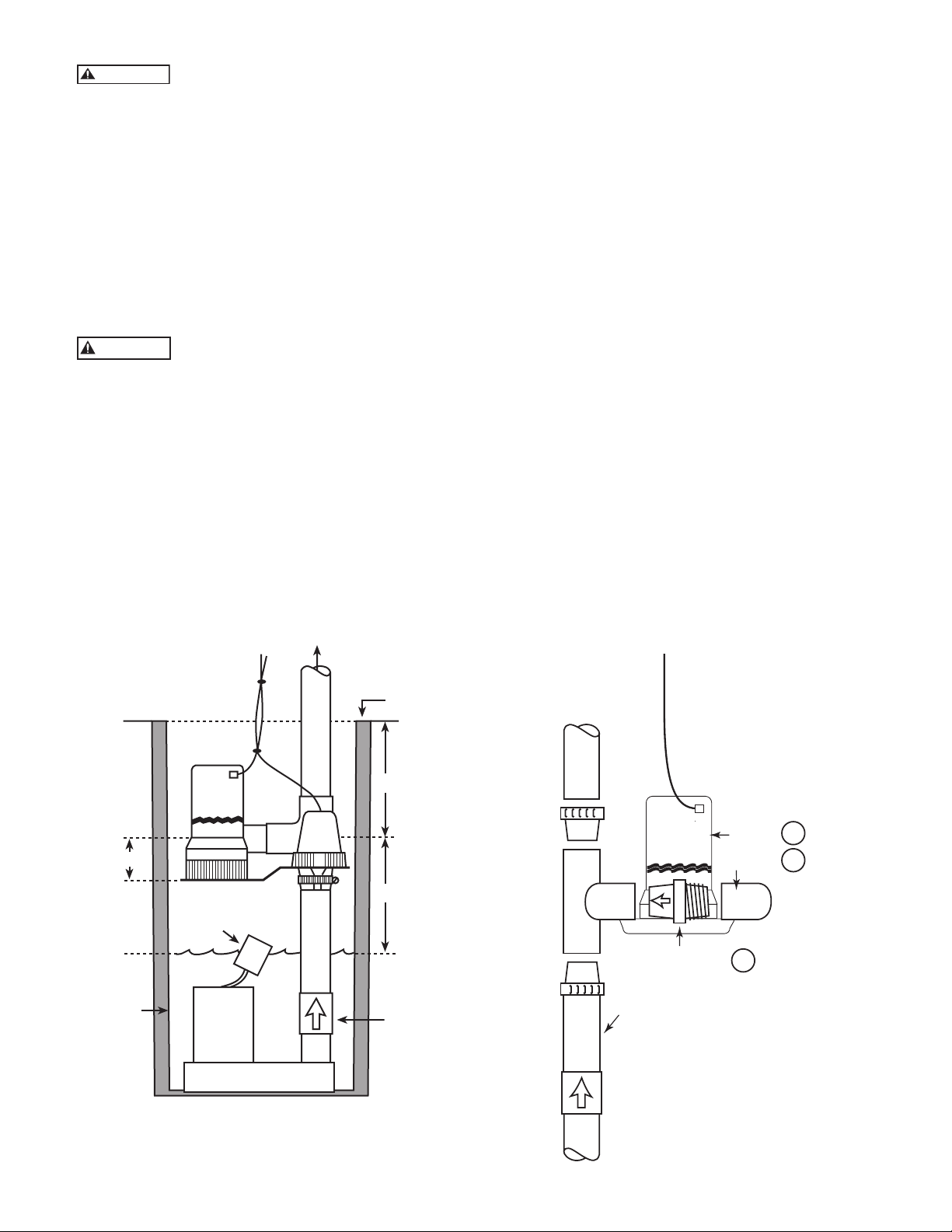

1. Fill sump until primary pump turns on. Mark this

level as “Normal High Water”.

2. When installing the pump, mount the centerline of

the tee inlet at least 2 inches above the normal high

water level.

3. Check that the location of the tee is at least 2 inches

below the top of the sump.

4. Make sure the installation will not interfere with the

primary sump pump operation as follows:

(A) Back up pump must not interfere with primary

pump float switch swing.

(B) Normal high water level must not be high

enough to start the back-up pump.

(C) Install a check valve in the main sump pump

discharge pipe below the back-up pump tee.

Flow in this pipe must be away from the primary

pump. DO NOT INSTALL IT BACKWARDS!

This valve will prevent flow from the back-up

pump back to the sump during battery powered

operation.

5. Cut rigid discharge pipe from primary sump pump

to length, use PVC piping. Tee supplied is 1½" slip

fit; if necessary use 1¼" bushings supplied. Do not

glue the tee until all parts have been trial

fitted and aligned.

1.6 REF.

SUMP

BACK UP

PUMP

FLOAT

SW

*PRIMARY

PUMP

FIGURE 1

Standard Installation

1½

MAX.

SW

1½

MAX.

TOP OF SUMP

2" MIN.

C

L

2" MIN.

“ON”

POSITION

(Primary pump

normal high

water level)

CHECK VALVE

Must be

installed

to prevent

recirculation

into sump.

TEE

PUMP

TEE

CHECK

pump

CHECK

VALV E

PRIMARY

DISCHARGE

PIPE

VALV E

FIGURE 2

Assembly Details

PUMP

ELBOW

11

3

12

4

Page 5

WARNING

CAUTION

WARNING

6. Thread check valve tightly into the elbow provided

and plug the pump discharge into the other end of

the elbow. Secure with hose clamp. Slip the plain end

of the check valve into the side socket of the tee.

7. Install the float switch on the stainless steel bracket

provided and attach the bracket as shown.

Adjust bracket to support pump/switch assembly to

approximately level position.

8. Check for clearance to all working parts of the

primary and back-up pump systems.

9. Remove pump assembly from tee. Remove tee

from pump.

10. Using PVC cement, permanently install the tee on

the discharge pipe, according to the PVC cement

instructions.

Hazardous Fumes. Follow cement

manufacturer’s instructions. Use PVC

cement only in a well ventilated area

away from fire or flame.

11. Reinstall switch/bracket assembly.

12. Using PVC cement, permanently install the pump

assembly by cementing the check valve in the tee side

socket, with the pump base approximately level.

13. Adjust the switch/bracket assembly to support the

pump. Tighten the clamp.

14. Make sure battery is fully charged: then check

operation by disconnecting power to the primary

sump pump and filling sump until the battery

operated pump starts. Run pump through one

complete cycle.

15. Operation may be checked at any time by rotating

the float switch knob or ribbed wheel (4) pivots to

turn on the pump.

The liquid sound you hear in the float

portion of the switch is mercury, not

water, and should be disposed of properly. If you cannot arrange for proper

disposal, the product may be returned

for disposal to place of purchase.

ELECTRICAL CONNECTIONS

Hazardous Voltage. Can cause serious

or fatal electrical shock. Review safety

instructions before operating charger.

Do not modify cord or plug.

CHARGER/BATTERY INSTALLATION

NOTICE: Alarm will sound when charger is first

connected to battery. Press ALARM TEST/

RESET button on charger. If alarm continues

to sound, disconnect one charger lead from

the battery and reconnect it. Press ALARM

TEST/RESET again; alarm will stop

sounding.

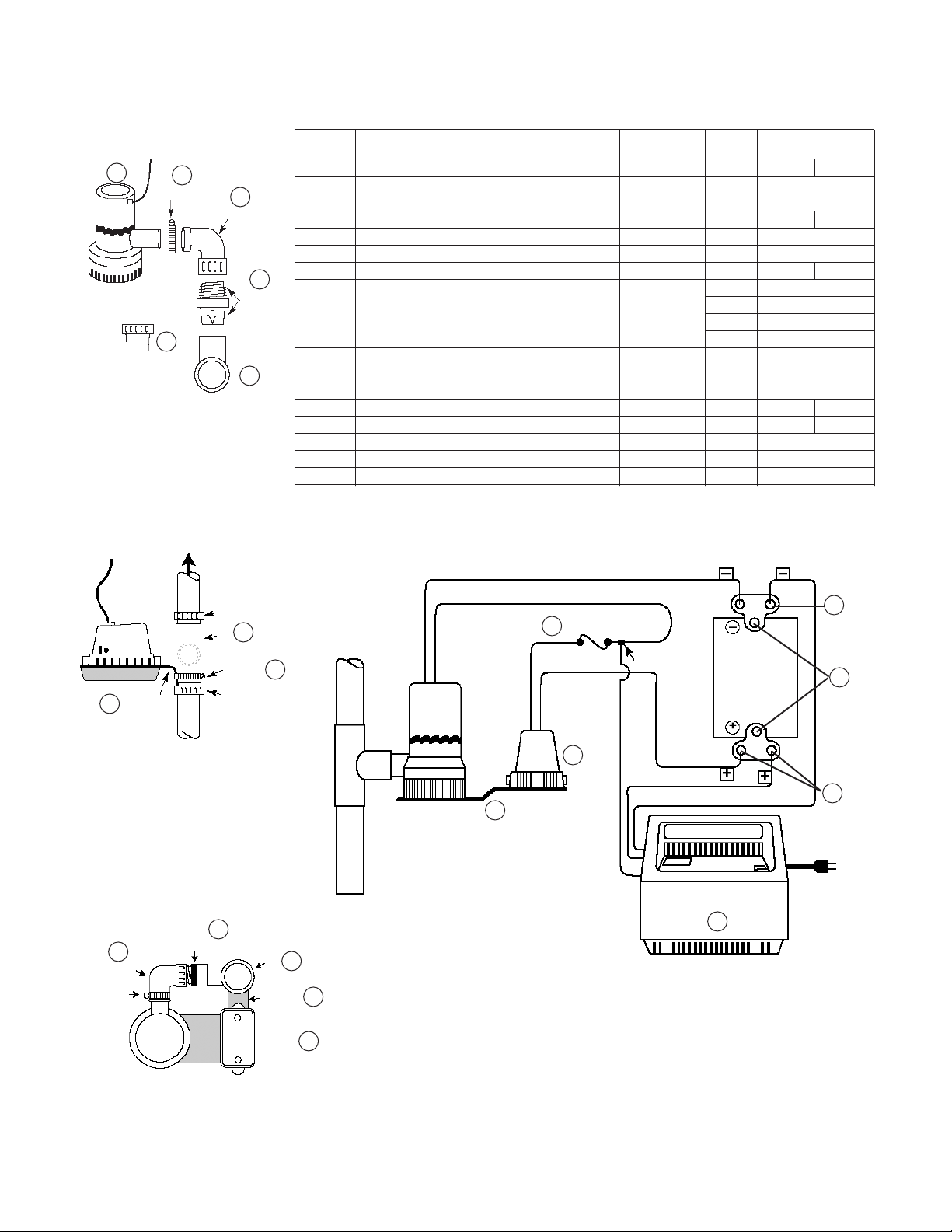

1. Connect charger as shown in Figure 3.

A. Connect Positive (+) lead from charger to

positive battery terminal.

B. Connect (–) lead from charger to negative

battery terminal.

C. Connect the third (blue) lead from the charger to

the blue tap on the brown pump wire just before

the fuse holder.

D. Put the 15 Amp fuse into ½ of the fuse holder

and connect the second half of the fuse holder.

E. Connect the black pump wire to the Negative

battery terminal.

F. Connect the gray switch wire marked + to the

Positive battery terminal.

2. Plug in power cord to a 115-125 Volt AC outlet

delivering at least 2 amps. Do not use a switch

controlled outlet. Mark circuit in main power panel

“Backup sump pump power supply; do not turn off”.

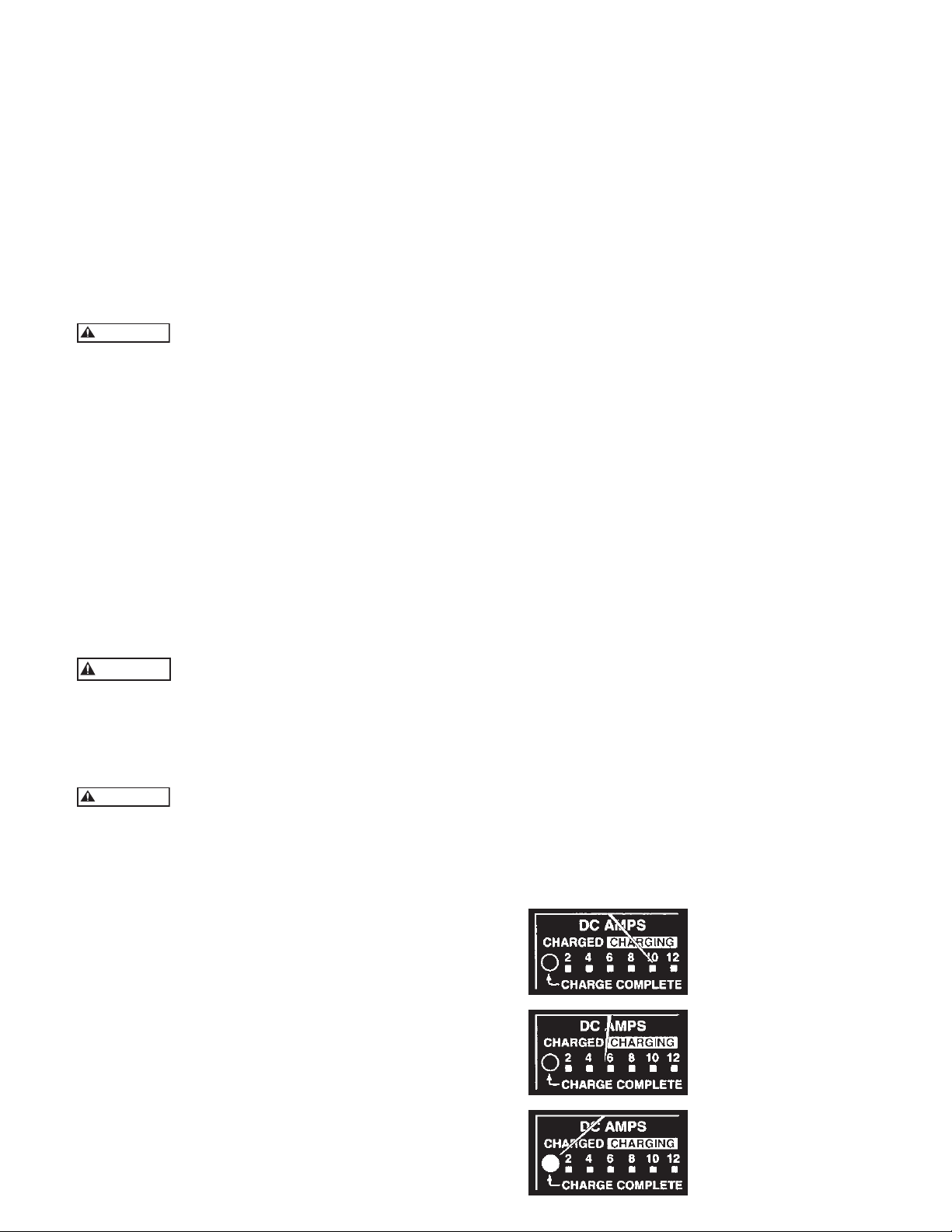

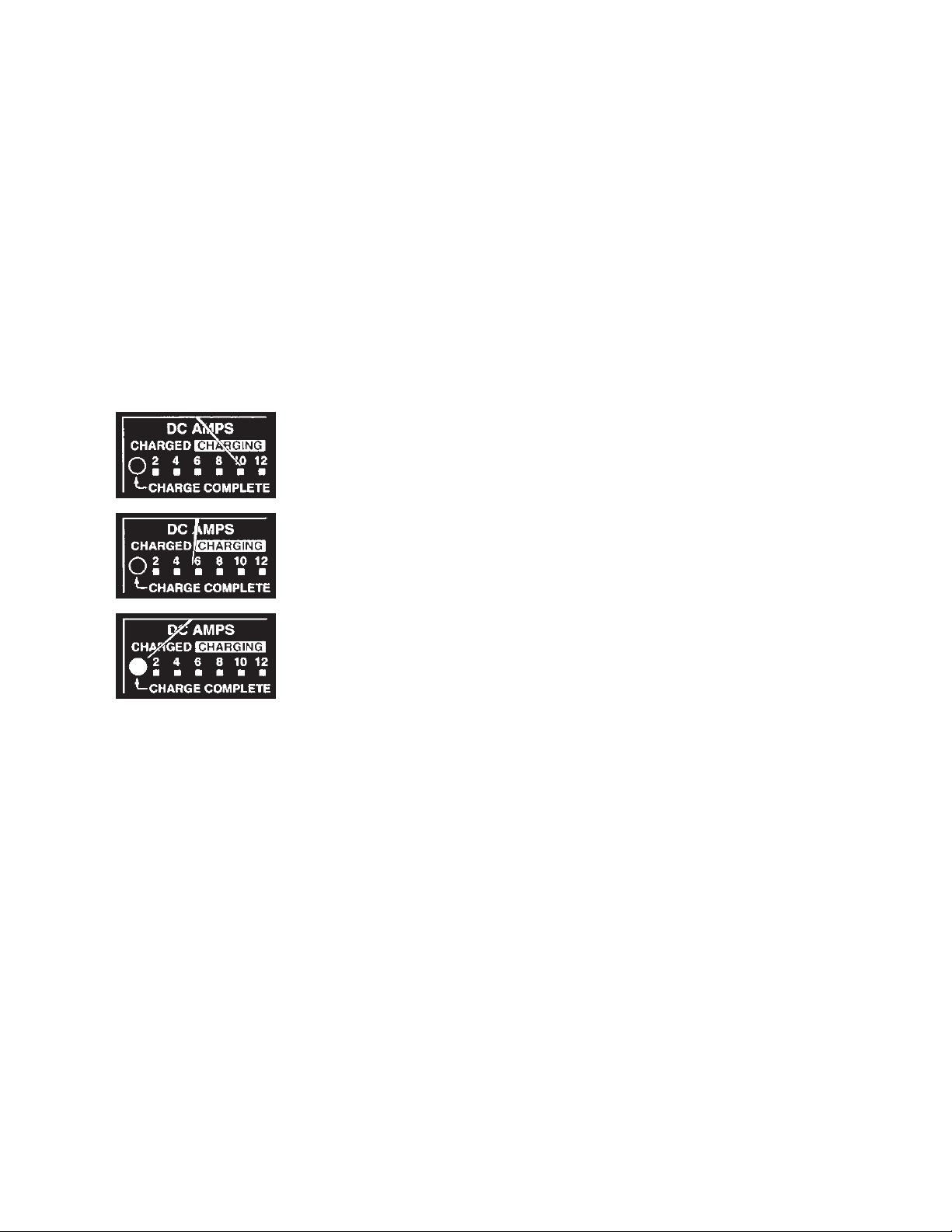

3. With charger properly connected and plugged in, the

panel on the front of the charger will appear as in

one of the following:

A. If battery is dead, charger will supply about

10 amps power (see Figure 3A).

B. If battery is near full charge, charger will deliver

about 5 amps power (see figure 3B).

C. If battery is fully charged, charging current will

be 0 amps and green LED lamp will be lighted

(see figure 3C).

4. The charger is equipped with a self-resetting circuit

breaker which protects it from temporary overloads.

In case of an overload, the circuit breaker will open.

It automatically resets after a short cool-down

period. In some conditions where the overload is

extended the breaker will cycle, repeating the open/

reset process indefinitely. When this happens,

normally the charger will emit a clicking sound as

the breaker opens and resets.

NOTICE: If the clicking sound continues for more

than 30 minutes or so, check for reversed

charger connections to the battery and for

shorted cells in the battery.

BATTERY MAINTENANCE

NOTICE: To protect battery case from chipping and

gouging, do not let battery sit on concrete

floor (plywood, 2x4’s, etc.). Always install

battery in a dry location that is protected

from flooding.

1. Unplug battery charger.

2. On batteries with removable top caps, measure

specific gravity of electrolyte. Use a hydrometer

(available at auto parts stores). If the specific gravity

of any cell is less than 1.225 or if there is more than

.050 variation between cells, replace the battery.

3. Check electrolyte level and refill as needed.

4. Check battery terminals and clamps for tightness and

corrosion. Clean and tighten as needed.

5. Plug in battery charger.

FIGURE 3 –

Battery Backup

3A.

3B.

Control Panel

A. Battery depleted –

charging current

10 Amps.

B. Battery nearly

charged – current

about 5 Amps.

C. Charge complete –

current 0 amps,

LED lights up.

3C.

5

Page 6

REPAIR PARTS

3

pump

1¼"

REDUCING

BUSHINGS

(2) if required

SWITCH

14

HOSE CLAMP

1½"

BRACKET

13

2

12

ELBOW

11

CHECK

VALVE

1½

TEE

1

IF REQUIRED

1

TEE

(opening on other side)

CLAMP

IF REQUIRED

Item

Number Required SPBB SPBB2

1 Tee, 1½" Socket Thermoplastic 1 6K146

2 Reducing Bushing, 1½" x 1¼" Thermoplastic 2 4K499

3 Pump – 2000GPH or 3700GPH Varies 1 9K318 9K499

4 Float Switch Assembly — 1 9K319

5 Fuse Holder — 1 9K320

6 Fuse - 15 Amps/25 Amps — 1 9K321 9K565

1 9K322

2 9K324

3 9K325

8 Terminals - Top Post Battery — 2 9K326

9 Battery Case Thermoplastic 1 9K327

10 Charger Assembly — 1 9K328

11 Check Valve - 1" MPT Thermoplastic 1 6K147 6K174

12 Elbow - 1" FPT Thermoplastic 1 6K148 6K175

13 Hose Clamp — 1 4K497

14 Pump / Switch Bracket — 1 9K329

15 Hose Clamp — 1 4K498

15

Part Description Material

7 Wire Terminals —

BLACK

BROWN

FUSE HOLDER

5

GRAY

pump

FUSE

BLUE

Quantity Repair Part Repair Part

1 9K323

NEGATIVE

CONNECTORS

BATTERY

105 AMP

MIN.

POSITIVE

7

8

6

ELBOW

HOSE

CLAMP

12

pump

11

CHECK VALVE

TEE

BRACKET

SWITCH

4

SWITCH

14

1

14

4

FIGURE 4

GRAY

BLACK/WHITE

BLACK

CHARGER

10

7

Page 7

TROUBLESHOOTING

Pump won’t run:

1. Check all connections.

2. Check for low or defective battery.

3. Check that automatic switch is operating properly.

4. Blown fuse in switch circuit. Unplug pump and re

move the strainer. Check to see if impeller is free

to turn. If impeller is locked remove the obstruction.

Replace strainer and fuse.

Motor hums but pump won’t run:

1. Check for low or defective battery.

Pump runs but pumps very little or no water:

1. Make sure a check valve is installed and

functioning between primary pump discharge and

backup sump pump tee.

2. Check for obstruction in discharge pipe.

3. Discharge pipe length and/or height exceeds capacity

of pump. See Table 1 for pump capacity.

4. Check for low or defective battery.

5. Drill a 1⁄16 to 1⁄8 inch diameter vent hole between

pump discharge and check valve.

Pump cycles too frequently:

1. Main check valve located between discharge of

primary pump and the backup sump pump tee or

check valve not installed or working properly. Install

or repair as required.

NOTE:

“Deep Cycle Marine” batteries are different

than marine and automotive batteries!

7

Page 8

This warranty applies to all water systems pumps manufactured by Red Jacket Water Products.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The war-

ranty period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever

period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Red Jacket Water Products distributor from whom the pump was

purchased and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Red Jacket Water

Products Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Red Jacket Water Products

and the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing

pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corpora-

tion, limited liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

RED JACKET WATER PRODUCTS LIMITED WARRANTY

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. IM186 Revision Number 3 July 2012

Page 9

MANUAL DE INSTRUCCIÓN

IM186

Bomba de sumidero

de reserva a batería

MANUAL DE INSTALACIÓN, OPERACIÓN Y PARTES

Page 10

Índice

TEMA PÁGINA

Instrucciones de seguridad ...........................................................................................................................................11

Herramientas y materiales básicos necesarios ...............................................................................................................11

Información general ....................................................................................................................................................11

Funcionamiento del cargador ......................................................................................................................................11

Requisitos para la batería .............................................................................................................................................12

Instalación y funcionamiento de la bomba ...................................................................................................................12

Conexiones eléctricas ..................................................................................................................................................13

Instalación de cargador/batería ....................................................................................................................................13

Mantenimiento de la batería ........................................................................................................................................14

Localización de fallas ...................................................................................................................................................14

Partes de reparación ....................................................................................................................................................15

Garantía limitada .........................................................................................................................................................16

Información para el propietario

Número de modelo de la bomba:

Número de serie de la bomba:

Número de modelo de control:

Representante:

Número telefónico del representante:

Fecha de compra: Instalación:

10

Page 11

NORMAS PARA UNA INSTALACIÓN Y OPERACIÓN SEGURAS

Lea y siga atentamente todas las instrucciones de seguridad de este manual o del sistema.

Éste es un símbolo de alerta de seguridad. Cuando vea este símbolo sobre la

bomba o en este manual, localice una

de las siguientes palabras y esté alerta

ante posibles lesiones personales.

PELIGRO

Advierte sobre los peligros que, si se

ignoran, PROVOCARÁN lesiones

graves, muerte o daños significativos a

la propiedad.

ADVERTENCIA

Advierte sobre los peligros que, si

se ignoran, PUEDEN PROVOCAR

lesiones graves o daños significativos a

la propiedad.

PRECAUCIÓN

Advierte sobre los peligros que, si se

ignoran, PROVOCARÁN o PUEDEN

PROVOCAR lesiones menores o daños

a la propiedad.

La palabra AVISO indica que existen instrucciones

especiales e importantes pero que no están relacionadas

con el peligro.

1. Para evitar lesiones físicas de gravedad y daños a

la propiedad, lea atentamente las instrucciones de

seguridad antes de instalar la bomba.

2. Cuando instale una bomba, ajústese a las normas

locales y/o nacionales relacionadas con la plomería y

la electricidad. Se recomienda el uso de un

interruptor de circuito con cable a tierra (del inglés,

GFCI) para todos los aparatos eléctricos sumergibles.

3. Utilice esta bomba de sumidero sólo de reserva para

aplicarla en residencias. No está diseñada para su uso

como bomba de sumidero principal.

ADVERTENCIA

Voltaje peligroso. Puede provocar una

descarga eléctrica importante o fatal.

4. No conecte o desconecte un cargador de batería

cuando se encuentre parado sobre un piso húmedo

o sobre agua. Asegúrese de que una de sus manos

esté libre cuando conecte o desconecte el cargador.

Si el piso del sótano está mojado, desconecte la

energía eléctrica que se dirige al sótano antes de

caminar por esa superficie.

5. No levante la bomba con un cable eléctrico.

6. Bombee agua sólo con esta bomba.

7. La bomba se encuentra lubricada de fábrica. No

intente lubricarla.

8. Mantenga el cargador de la batería y su gabinete en

un lugar seco, fresco y bien ventilado.

9. Para evitar el peligro de incendio o explosión, man

tenga las chispas y llamas lejos de la batería.

ADVERTENCIA

El ácido de la batería es corrosivo.

10. No derrame el ácido sobre la piel, ropa o sobre el

cargador de la batería. Utilice un protector para sus

ojos cuando trabaje con la batería.

11. La distancia máxima de bombeo vertical es de

15 pies (4,6 m.).

12. Asegúrese que la bomba esté libre de suciedad.

HERRAMIENTAS Y MATERIALES BÁSICOS

NECESARIOS

Llaves para tubos, destornillador, sierra para metales,

llave inglesa ajustable, cinta Teflón, cuchillo, batería de

12 voltios, cemento PVC, válvula de retención de la

bomba principal (si no está instalada).

INFORMACIÓN GENERAL

El sistema de sumidero de reserva a batería no reemplaza

a la bomba de sumidero principal. Está diseñada como

una bomba de reserva para sustituir a la bomba principal

en caso de emergencia durante un corte de energía o en

otros casos que impiden su funcionamiento normal. No

la utilice para bombear líquidos o productos químicos

inflamables.

Mantenga seco el cargador de batería y protéjalo de

daños. Si se agota la batería del sistema (por ejemplo, durante un corte de energía prolongado), podrá utilizar, en

caso de emergencia, la batería de su auto provisoriamente

para sustituirla. Asegúrese de reemplazar el sistema de

batería lo antes posible.

FUNCIONAMIENTO DEL CARGADOR

La bomba de reserva comenzará a funcionar automáticamente cuando el nivel de agua del sumidero se eleve

lo suficiente como para disparar el interruptor de flotador. Luego de un retraso de alrededor de 4 segundos,

sonará una alarma. Apague la alarma presionando el

botón ALARM TEST/RESET (PRUEBA DE ALARMA/

REINICIO). Si la operación es normal (cuando actúa el

interruptor), la alarma permanecerá bloqueada hasta 4

segundos luego de que el interruptor del flotador haya

descendido hasta la posición OFF. Posteriormente, el

ciclo comenzará de nuevo.

Cuando no suene la alarma, puede controlarla presionando el botón ALARM TEST/RESET. En ese caso, la alarma

sonará mientras el botón permanezca hacia abajo.

Si suena la alarma, controle el funcionamiento de la

bomba principal, ya que es posible que necesite servicio.

Si la operación de reserva de batería se debe a una descarga eléctrica, la alarma sonará. No obstante, es posible

que la bomba principal no requiera de servicio.

El cargador de la batería puede mantener la bomba en

funcionamiento y cargar la batería al mismo tiempo

mientras no se interrumpa la energía que se dirige al

cargador. Si se interrumpe el paso de energía al cargador,

el tiempo de operación de la bomba de reserva dependerá de la capacidad de amperes por hora de la batería

utilizada.

Los períodos de operación prolongados (por ejemplo,

durante un corte de energía prolongado) pueden agotar

la batería. No obstante, una vez que la carga se agote,

generalmente se recargará por sí sola y durará el tiempo

suficiente para que el cargador arranque. El cargador de

la batería comenzará a recargar la batería nuevamente

siempre que ésta cuente con una carga de por lo menos

½ voltios.

Cuando retorne la energía, el cargador automáticamente

recargará la batería en forma completa en alrededor de

dos horas.

AVISO: Si la batería no ha alcanzado un voltaje satis factorio luego de 24 horas de carga, sonará la

alarma. En este caso la alarma no podrá reinici arse. Las posibles causas de este problema son:

11

Page 12

PROBLEMA ACCIÓN

Opera la bomba de reserva Push ‘Reset’. Check main pump

Corte de energía de Desconecte el cargador de la

más de 24 hs batería. Comuníquese con la

empresa de energía.

Carga continua por más Desconecte el cargador de la

de 24 hs. batería. Controle si la batería

presenta un desperfecto.

Conexión floja o cargador Desconecte el cargador de la

sin energía batería. Controle el enchufe,

receptáculo y energía en el

interruptor principal.

La alarma puede reiniciarse cuando se restaura la energía o se cambia

la batería.

REQUISITOS PARA LA BATERÍA

ADVERTENCIA

Corriente eléctrica peligrosa.

Si las terminales de la batería se encuentran en cortocircuito pueden provocar quemaduras de gravedad e iniciar

un incendio. Instale la batería en el gabinete. Para evitar

un cortocircuito accidental en las terminales de la batería,

sujete la tapa firmemente sobre el gabinete de la batería.

No deje la batería descubierta. No permita que los niños

jueguen cerca del sector donde se encuentra la bomba de

sumidero.

La bomba de sumidero de reserva depende de la energía

de la batería utilizada. Cuanto mejor sea la condición de

la batería, mejor será el rendimiento de la bomba.

Recomendamos el uso de una Batería Marina de ciclo

profundo de 105 amperes.

Esta batería funciona durante muchas horas y se mantiene en buenas condiciones durante largos períodos de

poco uso o uso nulo.

PRECAUCIÓN

No se recomienda el uso de una batería

estándar marina o de automóvil. Una

batería de automóvil puede requerir

una recarga luego de sólo 1 o 2 horas

de uso continuo, y los ciclos reiterados

de recarga pueden provocar una falla

temprana en la placa de la batería.

Utilice sólo una batería nueva con carga

completa del tamaño correcto para su

gabinete (tamaño máximo de 125⁄8"

de largo, 7" de ancho y 93⁄8" de altura

(320,7 mm x 177,8 mm x 238 mm)

incluidas las terminales).

INSTALACIÓN Y FUNCIONAMIENTO DE LA BOMBA

AVISO Recomendamos una prueba de ajuste de todos

los componentes antes de fijar cualquiera de

ellos. Esto le permitirá controlar la distancia de

la altura de montaje del interruptor flotante de

la bomba, etc., mientras aún se pueden realizar

ajustes fácilmente

1. Cargue el sumidero hasta que arranque la bomba

principal. Marque este nivel como la “altura normal

de agua”.

2. Cuando instale la bomba, monte la línea central de

la boca de entrada en T por lo menos a 2 pulgadas

por encima del nivel normal de agua.

3. Verifique que la ubicación de la entrada en T se

encuentre por lo menos a 2 pulgadas por debajo de

la parte superior del sumidero.

REF. 1,6

BOMBA

BOMBA DE

RESERVA

INTERR.

FLOTANTE

*BOMBA

PRINCIPAL

FIGURA 1

Instalación estándar

MÁX.

1 ½

INTERR.

MÁX.

1 ½

PARTE SUP.

DE LA BOMBA

MIN. 2"

C

T

L

MIN. 2"

POSICIÓN

“ON” (Nivel de agua

normal de la bomba

principal)

VÁLVULA DE

RETENCIÓN

Debe instalarse

para evitar la

recirculación al

sumidero.

BOCA DE

PUMP

ENTRADA

EN T

bomba

VÁLVULA DE

RETENCIÓN

TUBO DE

DESCARGA

PRINCIPAL

VÁLVULA DE

RETENCIÓN

BOMBA

CODILLO

11

3

12

12

FIGURA 2

Detalles de montaje

Page 13

4. Asegúrese de que la instalación no interfiera con el

funcionamiento de la bomba de sumidero principal

mediante los siguientes pasos:

(A) La bomba de reserva no debe interferir con

la oscilación del interruptor flotante de la

bomba principal.

(B) El nivel normal de agua no debe ser tan alto

como para iniciar el funcionamiento de la

bomba de reserva.

(C) Instale una válvula de retención en el tubo de

descarga de la bomba de sumidero debajo de

la entrada en T de la bomba de reserva. El

flujo en este tubo debe estar lejos de la bomba

principal. ¡NO LA INSTALE EN FORMA

INVERSA! Esta válvula evitará que el flujo de

la bomba de reserva vuelva al del sumidero

durante la operación de recarga de la batería.

5. Corte a lo largo el tubo rígido de descarga de la

bomba de sumidero principal. Utilice tubos de

PVC. La boca de entrada en T suministrada es de

1½ pulgada con ajuste deslizante. Si es necesario

utilice las boquillas de (1)¼" que se suministran. No

pegue la entrada en T hasta que se haya probado el

ajuste y alineación de todas las partes.

6. Enrosque la válvula de retención bien ajustada

dentro del codillo que se suministra y conecte la

descarga de la bomba dentro del otro extremo del

mismo. Asegure con abrazadera de manguera.

Deslice el extremo plano de la válvula de retención

dentro del enchufe lateral de la entrada en T.

7. Instale el interruptor flotante sobre el soporte de

acero inoxidable que se suministra y sujete el soporte

como se muestra más abajo: Ajuste el soporte para

sostener el montaje de bomba/interruptor

aproximadamente a nivel de posición.

8. Verifique la distancia de todas las partes efectivas

de los sistemas de bomba principal y de reserva.

9. Quite el montaje de la bomba desde la entrada en T.

Quite la entrada en T de la bomba.

10. Utilice cemento PVC para instalar la entrada en T

de manera permanente en el conducto de descarga,

conforme a las instrucciones del cemento PVC.

ADVERTENCIA

Emanaciones peligrosas. Siga las instrucciones del fabricante deL cemento. Utilice cemento PVC sólo en un área bien

ventilada, lejos del fuego o las llamas.

11. Reinstale el montaje interruptor/soporte.

12. Utilice cemento PVC para instalar de manera

permanente el montaje de la bomba pegando

la válvula de retención en el enchufe lateral de la

entrada en T, con la base de la bomba

aproximadamente nivelada.

13. Ajuste el montaje interruptor/soporte para sostener

la bomba. Ajuste la abrazadera.

14. Asegúrese que la batería esté con carga completa:

luego verifique el funcionamiento desconectando la

energía a la bomba de sumidero principal y cargando

el sumidero hasta que arranque la bomba de funcionamiento a batería. Haga funcionar la bomba hasta

que cumpla un ciclo completo.

15. Puede verificarse el funcionamiento en cualquier

momento girando los pivotes (4) gastados del

interruptor flotante para encender la bomba.

PRECAUCIÓN

El sonido de líquido que se oye en la

parte flotante del interruptor es mercurio, no agua, y debe ser eliminado

correctamente. Si no puede hacerlo así,

podrá devolver el producto para su eliminación al comercio donde lo adquirió.

CONEXIONES ELÉCTRICAS

ADVERTENCIA

Voltaje peligroso. Puede causar descarga

eléctrica importante o fatal. Revise las

instrucciones de seguridad antes de

poner en funcionamiento el cargador.

No modifique el cable ni el enchufe.

INSTALACIÓN DEL CARGADOR/BATERÍA

AVISO: Cuando se conecte por primera vez el carga-

dor a la batería sonará la alarma. Presione el

botón ALARM TEST/RESET en el cargador.

Si la alarma continúa sonando, desconecte un

cable del cargador de la batería y reconéctelo.

Presione ALARM TEST/RESET nuevamente,

la alarma se detendrá.

1. Conecte el cargador como se muestra en la Figura 3.

A. Conecte el cable Positivo (+) desde el cargador a l

a terminal positiva de la batería.

B. Conecte el cable (-) desde el cargador a la terminal

negativa de la batería.

C. Conecte el tercer cable (azul) desde el cargador

a la toma azul sobre el cable marrón de la bomba

justo delante del porta fusible.

D. Coloque el fusible de amperaje 15 dentro de la

½ del porta fusible y conecte la segunda mitad del

porta fusible.

E. Conecte el cable negro de la bomba a la terminal

negativa de la batería.

F. Conecte el cable gris del interruptor marcado

con + a la terminal positiva de la batería.

2. Conecte el cable de energía a una boca de salida

de 115-125 Voltios CA suministrando al menos

2 amperes. No utilice una boca de salida

controlada por interruptor. Marque el circuito en

el panel de potencia principal “Suministro de energía

de la bomba de sumidero de reserva; no lo apague”.

3. Con el cargador correctamente conectado y enchu fado, el panel en el frente del cargador aparecerá

como en uno de los siguientes estados:

A. Si la batería está muerta, el cargador suministrará

una energía de 10 amperes aproximadamente

(ver Figura 3 A).

B. Si la batería está cercana a su carga completa, el

cargador enviará una energía de 5 amperes

aproximadamente (ver Figura 3 B).

C. Si la batería está con carga completa, la corriente

de carga será de 0 amperes y se encenderá la luz

verde del indicador LED (ver Figura 3 C).

4. El cargador está equipado con un disyuntor de

auto-restauración que lo protege de sobrecargas

temporarias. En caso de una sobrecarga, el disyun tor se abrirá. Se restaurará automáticamente luego

de un corto período de enfriamiento. En algunas

condiciones en que la sobrecarga se prolongue, el

disyuntor cumplirá el ciclo, repitiendo el proceso

abrir/reiniciar indefinidamente. Cuando esto ocurre,

el cargador normalmente emitirá un sonido seco a

medida que el disyuntor se abra y se reinicie.

13

Page 14

AVISO: Si el ruido seco continúa por más de 30 minutos,

verifique las conexiones inversas del cargador

a la batería y elementos cortocircuitados en la

misma.

MANTENIMIENTO DE LA BATERÍA

AVISO: Para evitar que la cubierta de la batería se pique

o se raspe, no la apoye sobre un piso de cemento

(madera laminada, 2 x 4 , etc.). Instale siempre

la batería un en lugar seco que esté protegido

contra inundación.

1. Desconecte el cargador de la batería.

2. En baterías con tapa superior removible, mida el

peso específico del electrolito. Utilice un hidrómetro

(puede encontrarlo en comercios de auto partes). Si

el peso específico de cualquier elemento es menor a

1,225 o si hay una variación de más de 0,050 entre

elementos, reemplace la batería.

3. Verifique el nivel de electrolito y vuelva a cargarla

según sea necesario.

4. Verifique las terminales y abrazaderas de las baterías

para controlar la firmeza y corrosión. Limpie y ajuste

según sea necesario.

5. Enchufe el cargador de la batería.

FIGURA 3- Panel de

control de la batería

de reserva

3A.

3B.

3C.

A. Batería agotada:

corriente de carga

10 amperes.

B. Batería casi cargada:

corriente de

aproximadamente

5 amperes.

C. Carga completa:

corriente de

0 amperes, luces

del indicador LED

encendidas.

LOCALIZACIÓN DE FALLAS

La bomba no funciona:

1. Verifique todas las conexiones.

2. Verifique que la batería no esté con carga baja o defectuosa.

3. Verifique que el interruptor automático gire hacia arriba y hacia abajo sin dificultad.

4. Fusible fundido en el interruptor. Desconecte la

bomba y quite el filtro. Verifique que el impulsor gire

sin dificultad. Si el impulsor está bloqueado quite la

obstrucción. Reemplace el filtro y el fusible.

El motor zumba pero la bomba no funciona:

1. Verifique que la batería no esté con carga baja o defectuosa.

La bomba funciona pero bombea muy poca agua o nada:

1. Asegúrese que esté instalada una válvula de retención y

que funcione entre la descarga de la bomba principal y

la entrada en T de la bomba de sumidero de reserva.

2. Verifique que no haya una obstrucción en el tubo de

descarga.

3. La longitud y/o altura del tubo de descarga excede la

capacidad de la bomba. Vea la Tabla 1 para conocer la

capacidad de la bomba.

4. Verifique que la batería no esté con carga baja o defectuosa.

5. Perfore un orificio de ventilación de 1/16 a 1/8 de

diámetro entre la descarga de la bomba y la válvula de

retención.

La bomba realiza ciclos demasiado seguidos:

1. La válvula de retención principal ubicada entre la

descarga de la bomba principal y la entrada en T de la

bomba de sumidero de reserva, o la válvula de retención no están instaladas correctamente o no funcionan

de manera apropiada. Instale una nueva o repare según

sea necesario.

NOTA: Las baterías “marinas de ciclo profundo” son

diferentes a las baterías marinas y de automóviles.

14

Page 15

PARTES DE REPARACIÓN

ABRAZADERA DE

1½"

13

MANGUERA

2

12

CODILLO

ENTRADA EN T

11

VÁLVULA DE

RETENCIÓN

1½

1

3

bomba

1¼"

BOQUILLA DE REDUCCIÓN

(2) si es necesario

Número de orden

Número

de artículo necesaria de reparación

Descripción de la parte Material

Cantidad de la parte

SPBB SPBB2

1 TEntrada T, Enchufe 1½" Termoplástico 1 6K146

2 Boquilla de reducción,1½" x 1¼" Termoplástico 2 4K499

3 Bomba – 2000GPH or 3700GPH Varía 1 9K318 9K499

4 Unidad interruptor flotante — 1 9K319

5 Porta fusible — 1 9K320

6 Fusible-15 amp./25 amp. — 1 9K321 9K565

1 9K322

7 Terminales de cable —

2 9K324

1 9K323

3 9K325

8 Terminales-Batería de pilote superior — 2 9K326

9 Cubierta de batería Termoplástico 1 9K327

10 Montaje del Cargador — 1 9K328

11 Válvula de retención 1" MPT Termoplástico 1 6K147 6K174

12 Codillo-1" FPT Termoplástico 1 6K148 6K175

13 Abrazadera de manguera — 1 4K497

14 Bomba/Disyuntor — 1 9K329

15 Abrazadera de manguera — 1 4K498

INTERRUPTOR

DISYUNTOR

14

12

CODILLO

ABRAZADERA DE

MANGUERA

SI ES NECESARIO

T

(apertura en otro costado)

ABRAZADERA

SI ES NECESARIO

11

VÁLVULA DE RETENCIÓN

1

15

T

1

DISYUNTOR

14

NEGRO

Bomba

MARRÓN

14

PORTA FUSIBLE

5

GRIS

4

INTERRUPTOR

FUSIBLE

FIGURA 4

CONECTORES

AZUL

GRIS

NEGRO/BLANCO

NEGATIVO

POSITIVO

NEGRO

CARGADOR

10

BATERÍA

105 AMP

MÍN.

7

8

7

BOMBA

INTERRUPTOR

4

15

Page 16

GARANTÍA LIMITADA DE RED JACKET WATER PRODUCTS

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Red Jacket Water Products.

Toda parte o partes que resultaren defectuosas dentro del período de garantía serán reemplazadas durante dicho período de garantía sin cargo para el

comerciante. Tal período de garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de

fabricación, la que se cumpla primero.

El comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Red Jacket Water

Products del cual adquiriera la bomba y brindar información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los

reclamos por garantía a través del Departamento de Servicios a Clientes de Red Jacket Water Products.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Red Jacket Water Products y el comer-

ciante para la compra, consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing)

de bombas a los clientes.

(3) “Cliente” es toda entidad que compra o adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente”

puede significar un individuo, sociedad, corporación, sociedad de responsabilidad limitada, asociación o cualquier otra entidad jurídica con actividades en cualquier tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products son una marca registrada de Xylem Inc. o una de sus filiales.

© 2012 Xylem Inc. IM186 Revisión Número 3 Julio 2012

Page 17

MANUEL D'UTILISATION

IM186

Pompe de puisard

de secours à batterie

DIRECTIVES D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

Page 18

Table des matières

SUJET PAGE

Règles de sécurité pour l’installation et l’utilisation .........................................................................................................19

Outillage et matériel de base requis ................................................................................................................................19

Informations générales ..................................................................................................................................................19

Fonctionnement de la pompe et du chargeur ..................................................................................................................19

Exigences relatives à la batterie ......................................................................................................................................20

Installation et utilisation de la pompe .............................................................................................................................20

Raccordement électrique ...............................................................................................................................................21

Branchement de la batterie et du chargeur ......................................................................................................................21

Entretien de la batterie ..................................................................................................................................................22

Diagnostic des anomalies ...............................................................................................................................................22

Pièces de rechange ........................................................................................................................................................23

Garantie limitée ............................................................................................................................................................24

Informations pour le propriétaire

Numéro de modèle de la pompe :

Numéro de série de la pompe :

No de modèle de la commande :

Détaillant :

No de téléphone du détaillant :

Date d’achat : d’installation :

18

Page 19

RÈGLES DE SÉCURITÉ POUR L’INSTALLATION ET L’UTILISATION

DANGER

DANGER

Lire et suivre avec soin toutes les consignes de sécurité

figurant dans le manuel et sur les éléments du système.

Le mot AVIS sert à énoncer des directives spéciales im-

portantes, non liées à des risques.

1. Afin de prévenir les dommages matériels et

les blessures graves, lire les consignes de sécurité

avant d’installer la pompe.

2. Suivre les prescriptions des codes provinciaux ou

nationaux de la plomberie et de l’électricité

pertinents, ainsi que les règlements locaux. L’usage

d’un disjoncteur de fuite à la terre est recommandé

pour tout appareil électrique immergé.

3. Employer la pompe uniquement comme pompe de

puisard domestique de secours, car elle n’est pas

conçue pour servir de pompe de puisard principale.

4. Ne pas brancher ni débrancher le chargeur de

batterie si l’on est dans l’eau ou sur un plancher

mouillé. S’assurer qu’une main est libre quand on

branche ou débranche le chargeur. Si le plancher

du sous-sol est mouillé, couper l’alimentation en

courant du sous-sol avant de marcher sur le plancher.

5. Ne pas lever la pompe par son cordon

d’alimentation.

6. Ne pomper que de l’eau avec la pompe de secours.

7. La pompe est lubrifiée à vie. Ne pas essayer de la

lubrifier !

8. Garder le chargeur et le coffre à batterie en un lieu

sec, frais et bien aéré.

9. Pour prévenir les dangers d’incendie ou d’explosion,

maintenir la batterie loin des étincelles

et des flammes.

10. Ne pas renverser d’électrolyte sur la peau, sur les

vêtements ni sur le chargeur. Porter des lunettes de

sécurité pour travailler sur la batterie.

11. La hauteur de refoulement maximale de la pompe

est de 4,6 m (15 pi).

12. S’assurer que les corps étrangers ne peuvent être

aspirés dans la pompe.

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

Le symbole ci-contre est un SYMBOLE

DE SÉCURITÉ employé pour signaler

les mots-indicateurs dont on trouvera

la description ci-dessous. Sa présence

sert à attirer l’attention afin d’éviter les

blessures !

Prévient des risques qui VONT causer

des blessures graves, la mort ou des

dommages matériels importants si l’on

n’en tient pas compte.

Prévient des risques qui, si l’on n’en

tient pas compte, PEUVENT causer

des blessures graves, la mort ou des

dommages matériels importants.

Prévient des risques qui, si l’on n’en

tient pas compte, VONT ou

PEUVENT causer un traumatisme ou

des dommages matériels légers.

Tension dangereuse — peut causer un

choc électrique grave, voire mortel.

L’électrolyte de la batterie est de l’acide

sulfurique, donc corrosif.

OUTILLAGE ET MATÉRIEL DE BASE REQUIS

L’outillage et le matériel suivants sont nécessaires : clés à

tubes, tournevis, scie à métaux, clé à molette, ruban de

Téflon, canif, batterie de 12 V, colle pour polychlorure

de vinyle (PVC), clapet de non-retour (s’il n’y en a pas

d’installé après la pompe principale).

INFORMATIONS GÉNÉRALES

La pompe de puisard de secours à batterie n’est pas conçue pour remplacer la pompe de puisard principale, mais

bien pour servir durant les pannes de courant et autres

défaillances empêchant la pompe principale de fonctionner. Ne pas l’utiliser pour les liquides inflammables ou

chargés chimiquement.

Protéger le chargeur de batterie de l’humidité et des

chocs. Au cours d’une panne de courant ou autre urgence

prolongées épuisant la batterie, on pourra employer temporairement une batterie d’automobile, mais on veillera à

réutiliser la batterie de la pompe dès que possible.

FONCTIONNEMENT DE LA POMPE ET DU

CHARGEUR

La pompe de secours démarrera automatiquement quand

le niveau de l’eau du puisard montera assez pour déclencher le contacteur à flotteur. Après un délai d’environ

quatre (4) secondes, une alarme sonnera. On arrêtera

l’alarme en pressant le bouton ALARME — ESSAI ET

RÉARMEMENT (ALARM TEST/RESET). En fonctionnement normal, l’alarme s’arrêtera environ 4 s après que le

contacteur sera redescendu à sa position d’arrêt (OFF).

Le cycle pourra alors recommencer.

On peut essayer l’alarme en tout temps en pressant

le bouton ALARME — ESSAI ET RÉARMEMENT

(ALARM TEST/RESET).

En cas d’alarme, vérifier le fonctionnement de la pompe

principale, qui pourrait avoir besoin d’entretien, ce qui

est peu probable si l’alarme est due à une panne de courant.

Le chargeur peut faire fonctionner la pompe de secours

et en charger la batterie simultanément tant qu’il est

alimenté en courant. En cas de panne de courant, l’autonomie de la pompe sera proportionnelle à la charge en

ampères-heures (Ah) de la batterie utilisée.

Les longues périodes de fonctionnement (panne de

courant prolongée) peuvent épuiser la batterie. Cependant, une fois la pompe mise hors service, la batterie

pourra normalement se recharger d’elle-même assez pour

produire le ½ V nécessaire à la remise en marche du

chargeur.

Dès que le courant sera rétabli, le chargeur rechargera

automatiquement la batterie, en six heures environ.

AVIS : si la batterie ne fournit pas une tension suffisante

après 24 h de charge, l’alarme sonnera. On ne

pourra alors réarmer le dispositif d’alarme (voir

les anomalies et correctifs en page suivante).

19

Page 20

ANOMALIE CORRECTIF

AVERTISSEMENT

Fonctionnement de la Presser RÉARMEMENT (RESET).

pompe de secours Vérifier la pompe principale.

Panne de courant pendant Débrancher le chargeur d’avec

plus de 24 h la batterie. S’adresser à la

société d’électricité.

Charge de batterie durant Déconnecter le chargeur d’avec

plus de 24 h la batterie. Vérifier si la batterie

est défectueuse.

Connexion lâche ou chargeur Débrancher le chargeur d’avec

sans courant la batterie. Vérifier la fiche du

cordon, la prise murale et le

courant au disjoncteur principal.

Une fois le courant rétabli ou la batterie remplacée, on peut réarmer le

dispositif d’alarme.

EXIGENCES RELATIVES À LA BATTERIE

Courant électrique dangereux

Placer la batterie dans son coffre pour prévenir le courtcircuitage des bornes de batterie et, ainsi, les risques de

brûlure graves et d’incendie. Bien assujettir le couvercle

au coffre avec la sangle de ce dernier. Ne pas laisser la

batterie non couverte ni permettre aux enfants de jouer

près du système de pompage.

Le rendement de la pompe de puisard de secours est

fonction de la batterie alimentant la pompe. Meilleure

sera la batterie, meilleur sera le rendement.

L’usage d’une batterie marine à charge poussée de 105 A

est recommandé.

La batterie recommandée fournit un bon rendement pendant de nombreuses heures et garde bien sa charge quand

la pompe est en attente durant de longues périodes.

ATTENTION

L’emploi d’une batterie d’automobile ou

marine standard avec le chargeur prévu

pour la pompe de secours n’est pas

recommandé. Une batterie d’automobile

peut nécessiter une recharge après une à

deux heures d’usage ininterrompu, et les

cycles de charge répétés peuvent causer

la défaillance prématurée des plaques de

batterie.

Employer uniquement une batterie

neuve, chargée à bloc et pouvant aller

dans le coffre à batterie. Les dimensions

maximales sont : 320,7 mm (125⁄8 po) de

longueur, 177,8 mm (7 po) de largeur et

238 mm (93⁄8 po) de hauteur (avec

les bornes).

INSTALLATION ET UTILISATION DE LA POMPE

AVIS : Afin d’éviter tout problème d’assemblage

éventuel, il est recommandé de vérifier la mise

en place et la hauteur des éléments de tuyauterie

et autres composants, dont le contacteur à

flotteur de la pompe de secours, avant de fixer

les tronçons de tuyauterie avec de la colle.

1. Remplir le puisard d’eau jusqu’à ce que la pompe

principale démarre. Marquer le niveau alors atteint

par l’eau comme étant le « haut niveau d’eau

normal ».

2. Pour mettre la pompe de secours à la bonne hauteur,

en placer l’axe horizontal du té de refoulement à au

moins 2 po au-dessus du haut niveau d’eau normal.

3. S’assurer que le té est à au moins 2 po sous le bord

du puisard.

1,6 po (RÉF.)

PUISARD

POMPE DE

SECOURS

CONTACTEURS

À FLOTTEUR

POMPE

PRINCIPALE

Installation type

FIGURE 1

1½ po

(MAX.)

1½ po

(MAX.)

BORD DU PUISARD

2 po (MIN.)

C

AXE DU TÉ

L

2 po (MIN.)

NIVEAU

DÉMARRAGE

(haut niveau d’eau

normal pour la

pompe principale)

CLAPET DE

NON-RETOUR

(requis pour

empêcher le retour

du liquide dans le

puisard)

pump

TÉ

PUMP

TEE

CLAPET DE

NON-RETOUR

TUYAU DE REFOULEMENT

PRIMARY

DE LA POMPE PRINCIPALE

DISCHARGE

PIPE

CLAPET DE

CHECK

NON-RETOUR

VALV E

FIGURE 2

Détails d’assemblage

CHECK

VALV E

POMPE DE SECOURS

PUMP

COUDE

ELBOW

12

11

3

20

Page 21

4. Vérifier les points A et B suivants et exécuter

la tâche C pour s’assurer que la pompe de secours ne

gênera pas le fonctionnement de la pompe

principale :

A. Le contacteur à flotteur sur câble (de la pompe

principale) doit pouvoir bouger librement.

B. Le haut niveau d’eau normal ne doit pas

atteindre le niveau de démarrage de la pompe

de secours.

C. Poser un clapet de non-retour sur le tuyau

de refoulement de la pompe principale,

au-dessous du té de la pompe de secours, mais

suivant le sens d’écoulement du liquide, indiqué

par la flèche du clapet. NE PAS INSTALLER LE

CLAPET EN SENS INVERSE. Le clapet em pêche le liquide de retourner dans le puisard

durant le fonctionnement de la pompe de

secours.

5. Couper un tronçon de tuyau de refoulement à la

longueur appropriée pour la pompe principale.

Employer du tuyau de polychlorure de vinyle (PVC).

Le té fourni permet un raccordement coulissant de

½ po. Au besoin, employer les raccords réducteurs

de 1½ po à 1¼ po inclus. Ne pas coller le té avant

de s’assurer que l’assemblage et l’alignement de

toutes les pièces sont corrects.

6. Visser le clapet de non-retour à fond sur le coude

fourni (v. illustrations en page 22). Enfiler l’autre

bout du coude sur la tubulure de refoulement de la

pompe et l’assujettir avec un collier de serrage.

Insérer l’extrémité libre du clapet dans la branche

médiane du té.

7. Fixer le contacteur à flotteur sur la ferrure en inox

fournie. Attacher la ferrure au té avec un collier de

serrage. Régler la position de la ferrure pour que la

pompe et le contacteur soient à peu près de niveau.

8. Vérifier si les pièces mobiles du système peuvent

bouger librement.

9. Séparer la pompe de secours et l’ensemble ferrure contacteur d’avec le té, puis enlever le té du tuyau

de refoulement de la pompe principale.

10. Fixer le té au tuyau de refoulement avec de la colle

pour PVC, selon les directives d’utilisation de la

colle.

AVERTISSEMENT

Vapeurs dangereuses. Suivre les directives du fabricant de la colle. Utiliser la

colle uniquement en un lieu bien ventilé,

loin de la flamme.

11. Reposer l’ensemble ferrure-contacteur sur le té.

12. Avec de la colle pour PVC, fixer le clapet de la

pompe de secours à la branche médiane du té tout en

s’assurant que le dessous de la pompe sera à peu près

de niveau.

13. Régler la ferrure pour qu’elle supporte la pompe,

puis assujettir la ferrure avec son collier de serrage.

14. S’assurer que la batterie est chargée à bloc. Vérifier

ensuite si la pompe de secours fonctionne correc tement. Pour ce faire, déconnecter la pompe

principale et remplir le puisard d’eau jusqu’à ce que

la pompe de secours démarre. Laisser la pompe

achever son cycle.

15. À l’aide des molettes du contacteur, on peut faire

pivoter celui-ci pour vérifier le fonctionnement de la

pompe de secours.

ATTENTION

Le son que l’on entendra en faisant pivoter le flotteur est celui du mercure qu’il

contient, produit dangereux que l’on

devrait éliminer correctement. Si l’on

ne peut éliminer soi-même le produit de

façon appropriée, on peut le retourner à

cet effet au vendeur du produit.

RACCORDEMENT ÉLECTRIQUE

AVERTISSEMENT

Tension dangereuse — peut causer un

choc électrique grave, voire mortel.

Relire les consignes de sécurité avant

d’employer le chargeur.

Ne pas modifier le cordon d’alimentation ni la fiche.

BRANCHEMENT DE LA BATTERIE ET DU

CHARGEUR

AVIS : l’alarme sonnera lorsque l’on branchera

le chargeur à la batterie la première fois.

Presser alors le bouton ALARME — ESSAI

ET RÉARMEMENT (ALARM TEST/RESET)

du chargeur. Si l’alarme continue à sonner,

débrancher un conducteur de sortie du chargeur

d’avec la batterie, puis le rebrancher. Appuyer de

nouveau sur le bouton, et l’alarme s’arrêtera.

1. Connecter le chargeur et la batterie comme suit

(v. fig. 4) :

A. Brancher le conducteur positif (+) du chargeur

au connecteur + de la batterie.

B. Connecter le conducteur négatif (–) du chargeur

au connecteur – de la batterie.

C. Brancher le fil bleu du chargeur au connecteur

bleu du fil brun de la pompe de secours, près du

porte-fusible.

D. Poser un fusible de 15 A dans le porte-fusible.

E. Connecter le fil noir de la pompe au

connecteur – de la batterie.

F. Brancher le fil gris + (libre) du contacteur à

flotteur au connecteur + de la batterie.

2. Brancher le cordon du chargeur à une prise de

courant de 115 à 125 V c.a., d’au moins 2 A. Ne pas

utiliser une prise reliée à un interrupteur. Inscrire

près du disjoncteur du circuit, sur le tableau de

distribution principal : « Pompe de secours — ne pas

couper le circuit ».

3. Une fois le chargeur connecté correctement, son

indicateur donnera les informations suivantes :

A. Si la batterie est épuisée, le courant de charge

sera environ 10 A (v. fig. 3A).

B. Si la batterie est presque chargée, le courant de

charge sera à peu près 5 A (v. fig. 3B).

C. Si la batterie est chargée à bloc, le courant de

charge sera nul, et le voyant (DEL) vert sera

allumé (v. fig. 3C).

4. Le chargeur est muni d’un disjoncteur à réarmement

automatique le protégeant des surcharges

momentanées. S’il y a surcharge, le disjoncteur se

déclenchera, et se réarmera après une courte période

de refroidissement. Si la surcharge est prolongée,

le disjoncteur se déclenchera et se réarmera durant

un temps indéterminé. En pareil cas, on entendra le

cliquetis répété du disjoncteur.

AVIS : si le cliquetis dure plus de 30 min environ,

vérifier si la position des conducteurs du

chargeur est inversée sur la batterie et si des

cellules de batterie sont court-circuitées.

21

Page 22

ENTRETIEN DE LA BATTERIE

AVIS : afin de prévenir l’endommagement de la surface

du coffre à batterie, ne pas laisser le coffre sur

le sol. On doit toujours le mettre en un lieu sec,

protégé des inondations.

1. Débrancher le chargeur.

2. S’il s’agit d’une batterie à bouchons amovibles,

enlever ceux-ci et vérifier la densité de l’électrolyte

avec un densimètre (vendu dans les magasins de

pièces d’automobiles). Si l’une des cellules présente

une densité inférieure à 1,225 ou que la variation

entre les cellules soit supérieure à 0,050, remplacer

la batterie.

3. Vérifier le niveau d’électrolyte des cellules

et remplir ces dernières au besoin.

4. Inspecter les bornes et les connecteurs de la batterie.

Les débarrasser de toute corrosion et les resserrer

au besoin.

5. Rebrancher le chargeur.

FIGURE 3 —

Indicateur de charge

3A

3B

de la batterie

3A Batterie épuisée —

courant de charge

de 10 A

3B Batterie presque

chargée — courant

de charge de 5 A

3C Batterie chargée

à bloc — courant de

charge nul et voyant

vert allumé

3C

DIAGNOSTIC DES ANOMALIES

La pompe ne fonctionne pas :

1. Vérifier toutes les connexions.

2. Vérifier si la batterie est défectueuse ou si sa

charge est faible.

3. S’assurer que le flotteur du contacteur peut se

déplacer librement.

4. Vérifier si le fusible du circuit du contacteur

à flotteur a sauté. Débrancher la pompe, ôter

la crépine et s’assurer qu’aucun corps étranger ne

bloque la roue. Si la roue est bloquée, la débarrasser

de l’obstacle, puit reposer la crépine et remplacer

le fusible sauté.

Le moteur bourdonne, mais la pompe ne tourne pas :

1. Vérifier si la batterie est défectueuse ou si sa

charge est faible.

La pompe tourne, mais son débit est faible ou nul :

1. S’assurer qu’un clapet de non-retour est posé

correctement sur le tuyau de refoulement

de la pompe principale (avant le té de la pompe

de secours) et qu’il fonctionne bien.

2. Vérifier si le tuyau de refoulement est obstrué.

3. Voir si la longueur du tuyau de refoulement ou la

hauteur de refoulement sont excessives (voir

« TABLE 1 — Caractéristiques nominales »).

4. Vérifier si la batterie est défectueuse ou si sa

charge est faible.

5. Percer un trou-purgeur d’air de 1⁄16 à 1⁄8 po de

diamètre dans le tuyau de refoulement de la pompe

principale, avant le clapet de non-retour.

La pompe démarre trop souvent :

1. S’assurer qu’un clapet de non-retour est posé

correctement sur le tuyau de refoulement

de la pompe principale (avant le té de la pompe

de secours) et qu’il fonctionne bien. Au besoin,

apporter les correctifs appropriés.

NOTA :

Les « batteries marines à charge poussée » sont

différentes des batteries d’automobile et des

batteries marines standard !

22

Page 23

PIÈCES DE RECHANGE

3

POMPE

1¼ po

CONTACTEUR

À FLOTTEUR

14

1½ po

RACCORD

RÉDUCTEUR

(2 au besoin)

FERRURE

13

COLLIER DE SERRAGE

2

TÉ

(branche médiane

de l’autre côté)

12

COUDE

NON-RETOUR

TÉ DE

1½ po

1

(AU BESOIN)

1

COLLIER

DE SERRAGE

(AU BESOIN)

11

CLAPET DE

15

SPBB SPBB2

Numéro

Description Matériau

d’article

Quantité

requise

No de pièce

de rechange

1 Té, avec branche médiane de 1½ po Thermoplastique 1 6K146

2 Raccord réducteur de 1½ po à 1¼ po Thermoplastique 2 4K499

3 Pompe de secours – 2000GPH or 3700GPH Varié 1 9K318 9K499

4 Contacteur à flotteur 1 9K319

5 Porte-fusible 1 9K320

6 Fusible de 15 A/25 A 1 9K321 9K565

1 9K322

7 Connecteur de câble

2 9K324

1 9K323

3 9K325

8 Borne de batterie 2 9K326

9 Coffre à batterie Thermoplastique 1 9K327

10 Chargeur 1 9K328

11 Clapet de non-retour de 1 po à filetage extérieur Thermoplastique 1 6K147 6K174

12 Coude de 1 po à filetage intérieur Thermoplastique 1 6K148 6K175

13 Collier de serrage 1 4K497

14 Ferrure 1 9K329

15 Collier de serrage 1 4K498

NOIR

POMPE

BRUN

GRIS

PORTE-FUSIBLE

5

FUSIBLE

BLEU

CONNECTEUR

NÉGATIF

BATTERIE DE

105 A (MIN.)

POSITIF

7

8

12

COUDE

COLLIER

DE SERRAGE

NON-RETOUR

POMPE

CLAPET DE

11

TÉ

FERRURE

CONTACTEUR

À FLOTTEUR

CONT. À

FLOTTEUR

4

GRIS

NOIR ET BLANC

NOIR

7

14

CHARGEUR

10

1

14

FIGURE 4

4

23

Page 24

GARANTIE LIMITÉE DE RED JACKET WATER PRODUCTS

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Red Jacket Water Products.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant la première : douze (12)

mois à compter de la date d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Red Jacket Water Products agréé

chez lequel la pompe a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du

service à la clientèle de Red Jacket Water Products.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ni de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) « Distributeur » signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant

d’intermédiaire entre Red Jacket Water Products et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) « Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités

commerciales sont la vente ou la location de pompes à des clients.

3) « Client » signifie une entité qui achète ou loue les pompes en question chez un détaillant. Le « client » peut être une personne, une société de personnes, une société de capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (866) 325-4210

Télécopie: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products est une marque déposée de Xylem Inc. ou d'une de ses filiales.

© 2012, Xylem Inc. IM186 Révision numéro 3 Juillet 2012

Loading...

Loading...