Page 1

INSTRUCTION MANUAL

IM158R04

Model SMVT

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Page 2

2 SMVT Installation, Operation and Maintenance Manual

Page 3

Table of Contents

Table of Contents

Introduction and Safety ........................................................................................................................2

Transportation and Storage ................................................................................................................... 7

Product Description .............................................................................................................................. 8

Installation ..........................................................................................................................................11

Commissioning, Startup, Operation and Shutdown ............................................................................20

Maintenance ....................................................................................................................................... 23

Troubleshooting .................................................................................................................................. 33

Appendix ............................................................................................................................................ 34

Warranty ............................................................................................................................................. 38

Owners Information

Complete this information for your records.

Model number and serial number may be found

on the tag mounted to the motor adapter.

Model Number

Serial Number

___________________________________

Dealer

Dealer phone number

Date of purchase

Date of installation

SMVT Installation, Operation and Maintenance Manual 1

___________________________

____________________________

______________________

__________________________

________________________

Page 4

Introduction and Safety

I. Introduction and Safety

Introduction

Description

This manual provides instructions for the Installation, Operation and Maintenance of the

Goulds Water Technology Model SMVT pumps. This manual covers the standard product

plus common options that are available.

Requirement

This manual must be read and understood before installation and start-up. Goulds Water

Technology shall not be liable for physical injury, damage or delays caused by a failure

to observe the instructions for installation, operation and maintenance contained in this

manual.

Content

This instruction manual covers several different pump models that all have similar power

end configurations. Most assembly, disassembly and inspection procedures are the same for

all the pumps. However, where there are differences, they are called out separately within

the manual. The design, materials and workmanship incorporated in the construction of

Goulds Water Technology pumps makes them capable of giving long, trouble free service.

The life and satisfactory service of any mechanical unit, however, is enhanced and extended

by correct application, proper installation, periodic inspection, condition monitoring

and careful maintenance. This instruction manual was prepared to assist operators in

understanding the construction and the correct methods of installing, operating and

maintaining these pumps.

Key Topics

Transportation and Storage

Product Description

Proper Installation

Start up Procedures

Operation Procedures

Routine Maintenance

Pump Overhaul

Trouble Shooting

Identifying Spare or Repair Parts

2 SMVT Installation, Operation and Maintenance Manual

Page 5

Safety

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling a Goulds Water Technology product. They are published to help prevent

• personal accidents and health problems

• damage to the product

• product malfunction

Observe all safety messages highlighted in other sections of this manual.

A pump is a pressure-containing device with rotating parts that can be dangerous.

Caution: You must observe the instructions for installation, operation, and maintenance contained in this manual. Failure to do so could result in physical injury,

damage, or delays.

Safety message levels

Table 1: Definitions

Safety message level Indication

Introduction and Safety (continued)

Danger: Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Warning: Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Caution: Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

Note: Indicates a potential situation which, if not avoided,

may result in undesirable results or state. Indicates a

practice not related to personal injury.

Electrical Hazard: Indicates the possibility of electrical risks if

direction are not applied in a proper manner.

Environmental safety

Preventive measures for the working area

Always keep the pump station clean to avoid and/or discover emissions.

Recycling guidelines

Always recycle according to the guidelines listed below:

1. Follow local laws and regulations regarding recycling if the unit or parts are accepted by

an authorized recycling company.

2. If the first guideline is not applicable then return the unit or parts to the nearest Goulds

Water Technology representative.

SMVT Installation, Operation and Maintenance Manual 3

Page 6

Introduction and Safety (continued)

Waste and emissions

Observe these safety regulations regarding waste and emissions:

• Properly dispose of all waste.

• Handle and dispose of the pumpage in compliance with applicable environmental

regulations.

• Clean-up all spills in accordance with safety and environmental procedures.

• Report all environmental emissions to the appropriate authorities.

Reference for electrical installation

For electrical installation recycling requirements, consult your local electric utility.

User health and safety

Bulk Material

• Anti-Galling lubricant (such as Dow Corning “MOLYKOTE”)

• Lubrication Oil

• Non-corrosive cleaning agents

• Grease (such as Armored AutoGroup “STP” or Dow Corning “111 Grease”) or a mixture

of equal parts non-petroleum hand soap and water

Rigging Equipment

• Mobile power hoist or traveling crane

• Suitable sling

• Clevises – for use with eyebolts (optional)

Hand Tools

• Impeller Shim (supplied with pump)

• Pipe wrenches

• Feeler gauges

• Set of mechanics tools including: les, wire brush, pliers, wire cutters and pocket knife

• Clean rags

• Dial indicator to assist in motor and pump alignment

• Torque wrench with sockets

• Rubber mallet

• Machinist Level

The working area

Observe these regulations and warnings in the working area:

• Always keep the work area clean.

• Pay attention to the chemical and physical characteristics of the gas and vapors present

in hazardous areas.

• Avoid all electrical dangers. Pay attention to the risks of electric shock or arc ash

hazards.

Product and product positioning requirements

Observe these requirements for the product and the product positioning:

• Never operate a pump unless safety devices are installed.

• Three-phase motors must have a properly sized starter with properly sized heaters

to provide overload and undervoltage protection. Single-phase motors have built-in

overload protectors.

• Never start a pump without the proper priming.

• Never run a pump below the minimum rated ow or with any suction or discharge

valve closed.

4 SMVT Installation, Operation and Maintenance Manual

Page 7

Electrical connections

Electrical connections must be made by authorized electricians in compliance with all

international, national, state and local rules.

Observe the following regulations and warnings for electrical connections.

• Make sure that the product is isolated from the power supply and can not be

energized by mistake. This rule applies to the control circuit as well.

• Make sure that the thermal contacts are connected to a protection circuit according

to the product approvals, and that they are in use.

Observe the following regulations for grounding connections.

Table 2: Grounding

Grounding regulation Comment

All electric equipment must be grounded. This rule applies to pumps as

well as monitoring equipment.

Precautions before work

Observe the following safety precautions before working with or in connection with the

product:

• Make sure that there are no poisonous gases within the work area.

• Provide a suitable barrier around the work area, for example a guard rail.

• Make sure that all safety guards are in place and secure.

• Make sure that the equipment is properly insulated when operating at extreme

temperatures.

• Allow all system and pump components to cool before you handle them.

• Make sure that you have a clear path of retreat.

• Make sure that the product cannot roll or fall over and injure people or damage

property.

• Make sure that the lifting equipment is in good condition.

• Use a lifting harness, a safety line, and a breathing device as required.

• Make sure that the product has been thoroughly cleaned.

• Make sure that a rst-aid kit is close at hand.

• Check the explosion risk before welding or using electric hand tools.

Introduction and Safety (continued)

Precautions during work

Observe the following safety precautions when working with or in connection with the

product:

• Never work alone.

• Stay clear of suspended loads.

• Always lift the product by its lifting device.

• Beware of the risk of a sudden start if the product is used with an automatic level

control.

• Beware of the starting jerk, which can be powerful.

• Rinse the components in water after disassembling the pump.

• Do not exceed the maximum working pressure of the pump.

SMVT Installation, Operation and Maintenance Manual 5

Page 8

Introduction and Safety (continued)

• Do not open any vent or drain valves or remove any plugs while the system is

pressurized. Ensure that the pump is isolated from the system and that pressure is

relieved before you disassemble the pump, remove plugs, or disconnect piping.

• Always bear in mind the risk of:

• electrical accidents

• burn injuries

Clean chemicals from the eyes

1. Forcibly hold the eyelids apart with the fingers.

2. Rinse the eyes for at least 15 minutes. Use an eyewash or running water.

3. Seek medical attention.

Clean chemicals from the body

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. If required, seek medical attention.

Product approval standards

Regular standards

All electrical ratings and performance of the motors comply with UL, CSA and NEMA

standards.

Product warranty

Personnel requirements

All work on the product must be carried out by certified electricians and Goulds Water

Technology authorized mechanics.

Goulds Water Technology disclaims all responsibility for work done by untrained and

unauthorized personnel.

Modification and spare parts

Modifications or changes to the product/installation should only be carried out after

consulting with Goulds Water Technology. Original spare parts and accessories authorized

by Goulds Water Technology are essential for compliance. The use of other parts can

invalidate any claims for warranty or compensation and explosion-proof approvals.

Warranty claim

For warranty claim, contact your Goulds Water Technology representative.

6 SMVT Installation, Operation and Maintenance Manual

Page 9

Transportation and Storage

II. Transportation and Storage

Description

This section describes recommended methods for receiving, storing and handling the pump

prior to physical installation.

Receiving

The pump should be uncrated or unboxed when it is received so that it can be completely

inspected. Carefully check that everything is in good order. Make notes of damaged

or missing items on the receipt and freight bill. File any claims with the transportation

company as soon as possible.

Storage

Short Term: For storage of less than six months, the normal packaging procedures used by

Goulds Water Technology are designed to protect the pump during shipping. After receipt,

store in a covered and dry location.

Long Term: For storage of more than six months, preservative treatment of bearings and

machined surfaces will be required. Rotate the pump and motor shaft several times every

three months. Refer to driver manufacturers for their long term storage procedures. Store in

a covered, dry location.

Handling

Warning: Pump and components are heavy. Failure to properly lift and support

equipment could result in serious physical injury or damage to pumps. Steel toed

shoes must be worn at all times.

Use care when moving pumps. Lifting equipment must be able to adequately support the

pump assembly. Hoist pump using a suitable sling under the motor adapter as shown in

Figure 1. DO NOT lift the pump with the motor installed to the pump assembly.

Consult the motor manufacturer’s Installation, Operation, and

Maintenance manual supplied with your motor for proper handling

procedures for the motor assembly.

Figure 1: Proper Lifting

SMVT Installation, Operation and Maintenance Manual 7

Page 10

Product Description

III. Product Description

Description

This section provides a general description of the Goulds Water Technology Model SMVT

and key engineering specifications.

Overview

The Goulds Water Technology Model SMVT pumps are surface mounted, multi-stage,

vertical turbine pumps.

Pump impellers are closed, shaft driven, and held in position by a positive-locking taper

collet.

Suction and discharge connections are ANSI standard 3 inch 125# or 250# and 4 inch

125# or 250# ange type.

Pumps are available with standard ODP or TEFC motors.

Intended Use

Commercial Applications:

Booster Units

High Rise Building Water Applications

HVAC

Municipal Applications:

Package Pump Stations

Booster Stations

Water Treatment Applications

Irrigation Applications:

Turf Irrigation

Golf Courses

Stadiums

Greenhouses/ Nurseries

Sprinkler Systems

Engineering Data

Torque Values

Table 3: Torque Values

Description Torque (ft.-lbs.)

Motor Bolts – 3, 5, 7.5 HP motors 20

Motor Bolts – 10 to 40 HP motors 45

Motor Bolts – 50, 60, 75 HP motors 70

Casing Bolts 120

Bowl Bolts 45

Coupling Bolts 28

Liquid Temperature:

Liquid temperature from -13ºF (-25ºC) to 150ºF (65ºC)

Note: Pump and piping should be protected from skin contact if temperature is less than

10ºC or higher than 40ºC

8 SMVT Installation, Operation and Maintenance Manual

Page 11

Maximum Working Pressure

Table 4: Maximum Working Pressure

Product Description (continued)

Starts per hour:

Maximum Pressure

Model

175 psi 400 psi

SM1 up to (3) stages more than (3) stages

SM2 up to (3) stages more than (3) stages

SM3 up to (3) stages more than (3) stages

SM4 up to (3) stages more than (3) stages

SM5 up to (4) stages more than (4) stages

SM6 up to (4) stages more than (4) stages

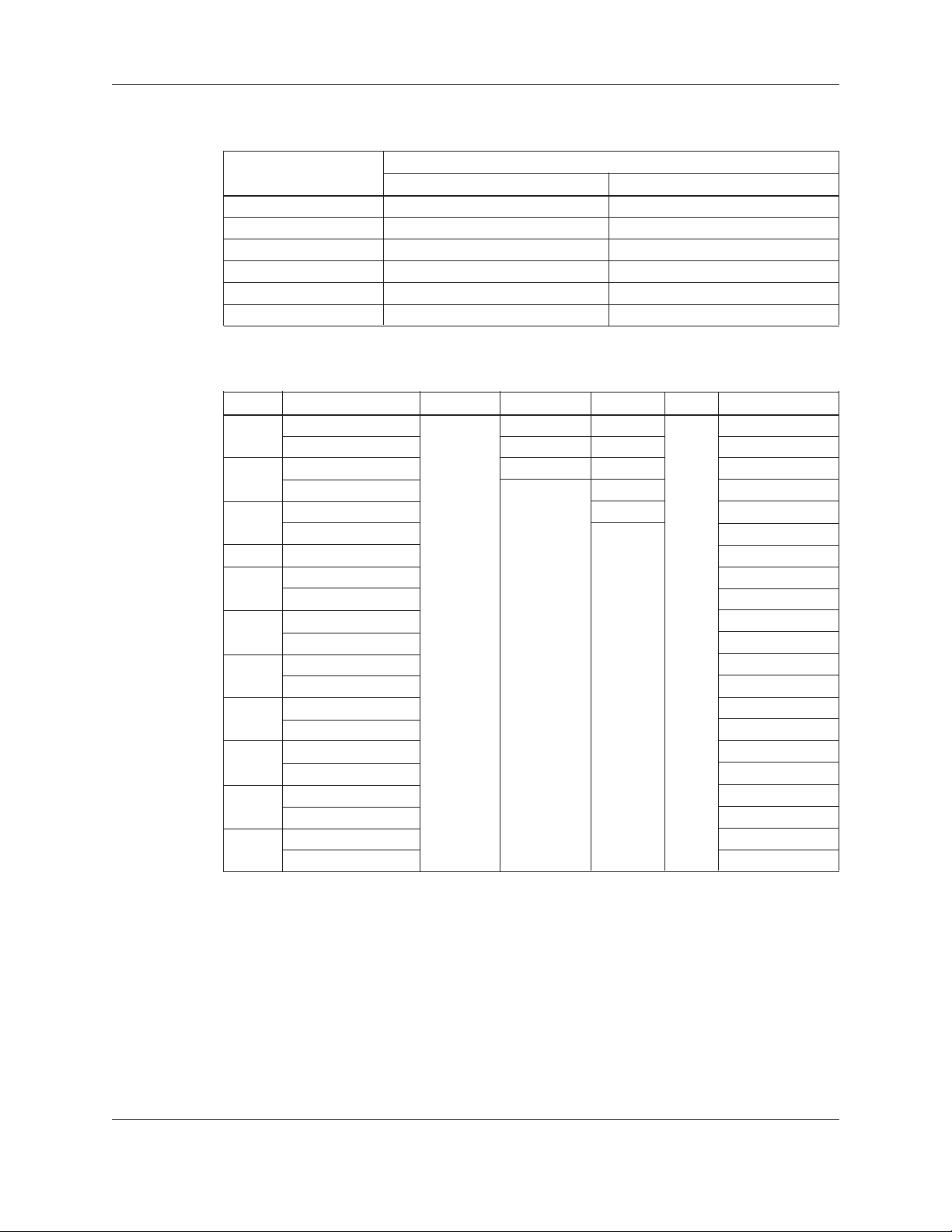

Table 5: Electric Data

2

HP Motor Frame RPM Voltage Phase Hz Start/Hour

5 182TC 230 1 270

184TC 230/460 3 165

182TC 230 1 210

7.5

213TC 3 150

213TC 1 210

10

215TC 135

15 215TC 105

254TC 150

20

256TC 75

256TC 135

25

284TSC 3500 60 30

284TSC

30

286TSC

286TSC 45

40

324TSC 30

324TSC 45

50

326TSC 25

326TSC 30

60

364TSC 25

364TSC 2

75

365TSC 2

2

Electric data is based on Goulds Water Technology choice motors. Other manufacturer’s motors may have

different values.

230/460

60

30

3

SMVT Installation, Operation and Maintenance Manual 9

Page 12

Product Description (continued)

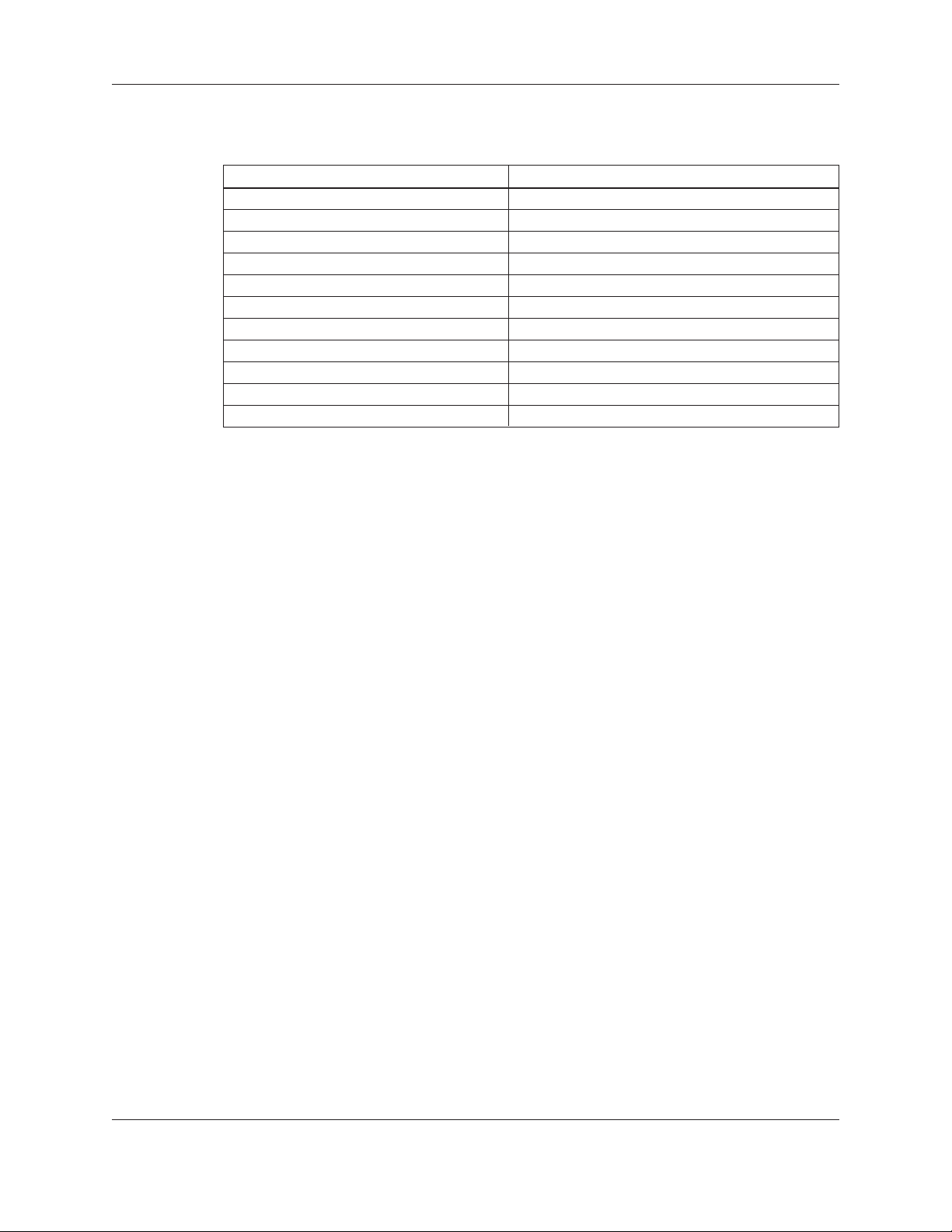

Connections

The following table shows the discharge and suction sizes for each of the SMVT pumps.

Table 6: Pump Connection Sizes

Model and Staging Suction and Discharge Size

SM1 - up to (3) stages Standard 3 inch 125# ANSI Flange

SM1 - more than (3) stages Standard 3 inch 250# ANSI Flange

SM2 - up to (3) stages Standard 3 inch 125# ANSI Flange

SM2 - more than (3) stages Standard 3 inch 250# ANSI Flange

SM3 - up to (3) stages Standard 4 inch 125# ANSI Flange

SM3 - more than (3) stages Standard 4 inch 250# ANSI Flange

SM4 - up to (3) stages Standard 4 inch 125# ANSI Flange

SM4 - (4) stage Standard 4 inch 250# ANSI Flange

SM5 - up to (4) stages Standard 4 inch 125# ANSI Flange

SM5 - (5) and (6) stage Standard 4 inch 250# ANSI Flange

SM6 - up to (4) stages Standard 4 inch 125# ANSI Flange

Noise Level

The noise generated by a pump depends on different factors. Most important are: power,

speed and brand name of the motor, whether there is cavitation or not, operating point of

the pump, and handling of small quantities of air. A guide value for the sound pressure level

measured in dB (A) at a distance of 3 feet from the pump with a 2 pole motor operating

at 60 Hz in ideal circumstances with cold water is 78 dB(A) for pumps up to 5 hp, 83 to

85 dB(A) for pumps with motors ranging from 7.5 to 50 hp. For pumps with 4 or 6 pole

motors, the value can be decreased with +/- 8 dB(A).

Name Plate

Model #

The various versions of the SMVT are identified by a product code number on the pump

label. This number is also the catalog number for the pump. The meaning of each digit in

the product code number is shown in the Appendix. Not all combinations are possible;

consult your Goulds Water Technology distributor for specific requirements.

Performance

Performance curves for your Goulds Water Technology Model SMVT may be found in the

selection program available on www.xyleminc.com/brands/gouldswatertechnology. The

correct performance curve can be determined from the name plate model number as defined

above. You will need to know the pump model number.

10 SMVT Installation, Operation and Maintenance Manual

Page 13

Installation

IV. Installation

Description

This section covers the general information and cautions about installing your pump as well

as specific steps to take during installation.

Location

Locate the pump as near to the liquid source as practical and below the level of the liquid

for automatic self priming. If the pump must be above the liquid source, a foot valve must

be provided on the suction pipe.

Allow adequate space around the pump for servicing and ventilation.

Protect the pump and piping from freezing temperatures.

Provide other weather protection consistent with the motor enclosure rating. The maximum

ambient temperature for the pump is 104°F (40°C).

For installation at altitudes greater than 3,000 feet (1,000 meters), the pump selection

should be de-rated due to the difference in barometric pressure. Contact your Goulds Water

Technology distributor for assistance in selection.

Foundation

The unit must be securely affixed to a leveled concrete or metal base foundation that is

adequate to absorb vibration and to provide permanent, rigid support for the pump and

motor assembly. If the unit is to be installed on a concrete foundation, hold down bolts

should be sunk in concrete and aligned with the holes in the feet. When the concrete has

dried, tighten nuts to keep the pump firmly in position.

Your SMVT pump has been supplied with a rigid base pump body with two feet. The

mounting dimensions are shown in Figure 2.

Figure 2: Base Mounting Dimensions

Installation of Mechanical Seal to Pump Assembly

Your SMVT pump has been shipped with the pump assembly and mechanical seal

disassembled.

1. Remove the (2) coupling guards.

2. Lubricate the inside of the mechanical seal assembly (supplied with pump) with grease

(such as Armored AutoGroup “STP” or Dow Corning “111 Grease”) or a mixture of

equal parts non-petroleum hand soap and water. Be sure that there is an o-ring at the

back of the gland ange.

SMVT Installation, Operation and Maintenance Manual 11

Page 14

Installation (continued)

3. Take care to make sure that the pump shaft is clean; it should be free of all burrs, oil, and

grease. The pump shaft should be completely dry before moving on to the next step.

4. To install the mechanical seal assembly, carefully slide it down the pump shaft until the

gland contacts the mounting surface on the top of the seal housing.

5. Install the (4) hex head bolts on the seal gland to the seal housing. See the “Engineering

Data” section on page 8 of this manual for the proper torque value.

6. Move on to the next section; “Installation of Motor to Pump Assembly”.

Installation of Motor to Pump Assembly

Your SMVT pump has been shipped with the pump assembly and motor disassembled.

1. With an adequately sized crane carefully lower the motor assembly onto the motor

adapter located on the top of the pump.

2. Secure the motor to the motor adapter with the (4) hex head bolts supplied with pump.

See the “Engineering Data” section on page 8 of this manual for the proper torque value.

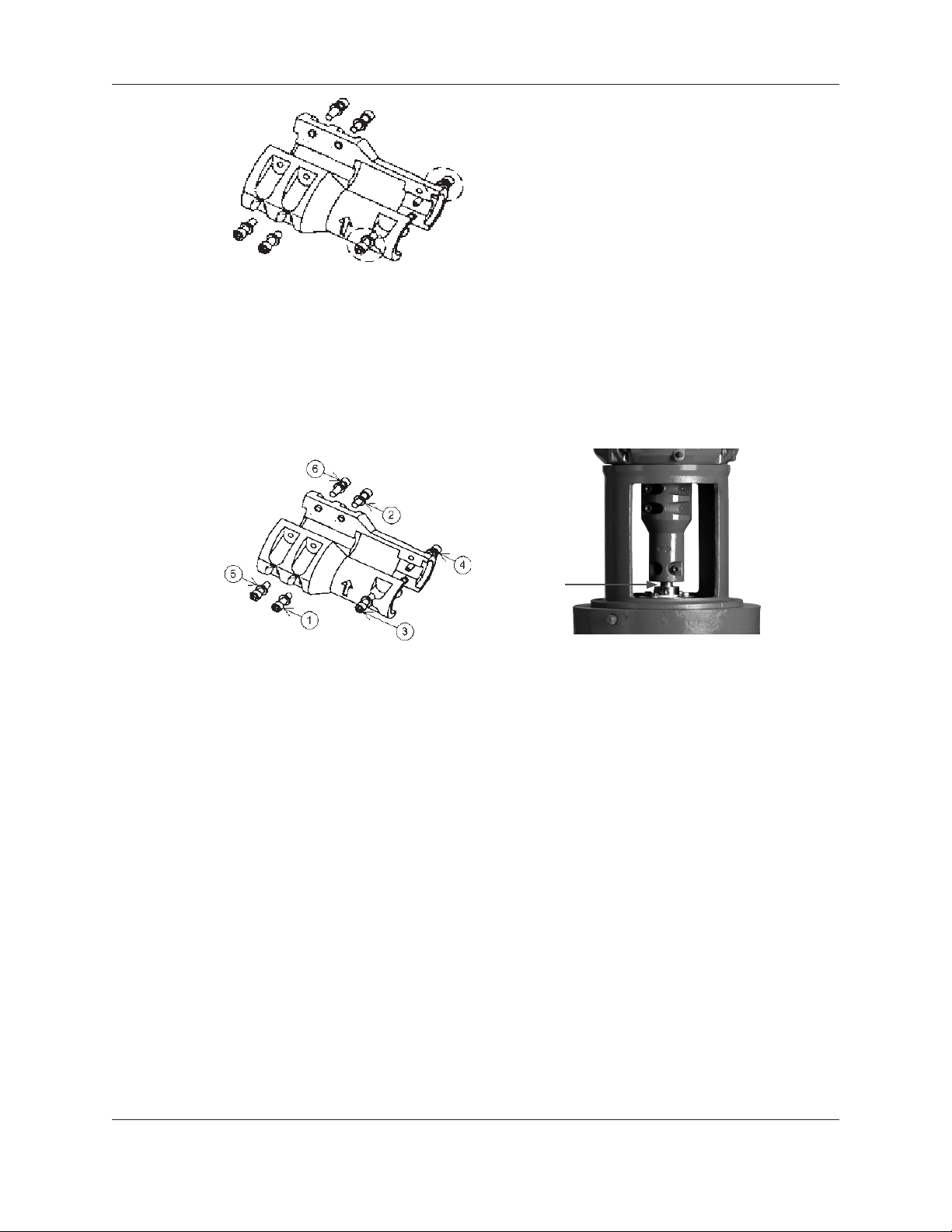

3. Disassemble the coupling (supplied with pump) by removing the (6) socket head screws

and machine washers between the coupling halves (see Figure 3). Retain bolts and dowel

pin for reassembly.

Figure 3: Motor Coupling

Item Quantity Description

A 2 Coupling Half

B 6 Socket Head Cap Screw

C 6 Lock-washer

D 1 Dowel Pin

4. Take care to make sure that the pump and motor shafts are clean; they should be free

of all burrs, oil, and grease. Both the pump and motor shafts should be completely dry

before moving on to the next step.

5. Install the dowel pin on the pump shaft and loosely assemble the shaft coupling. Do not

tighten the coupling at this point; it should be left loose enough to receive the motor

shaft in the following section.

6. Insert the impeller shim (supplied with the pump) between the shaft coupling and seal

gland. This will lift the shaft/impellers to the running position.

7. Very lightly tighten the (2) socket head cap screws on the pump end of the coupling (refer

to Figure 4). Tighten the coupling evenly; ensure that the coupling is symmetrical on both

the pump and motor shafts. Do NOT torque the cap screws in this step.

12 SMVT Installation, Operation and Maintenance Manual

Page 15

Installation (continued)

Figure 4: Coupling Socket Head Screws

8. Very lightly tighten the remaining (4) socket head screws on the coupling. Tighten the

coupling evenly; ensure that the coupling is symmetrical on both the pump and motor

shafts. Do NOT torque the cap screws in this step.

9. Torque the socket head cap screws on the coupling. Refer to Figure 5 for the proper

torque pattern. See the “Engineering Data” section on page 8 of this manual for the

proper torque value.

Figure 5: Coupling Torque Pattern Figure 5a: Run Out Measurement Location

10. Remove the impeller shim and retain for future use.

11. Visually inspect the gaps between the coupling to ensure they are symmetrical on both

sides and consistent throughout the length of the coupling.

12. Inspect run out of the shaft between the bottom of the coupling and the mechanical seal

as shown in Figure 5a. If the run out exceeded 0.005”, the coupling must be adjusted. It

is usually most effective to adjust the four bolt section of the coupling.

13. Tighten the set screws on the seal gland. See the “Engineering Data” section on page 8 of

this manual for the proper torque value.

14. Install the (2) coupling guards.

Piping

General: Guidelines for piping are given in the “Hydraulic Institute Standards” and should

be reviewed prior to installation.

Warning: Never draw piping into place by using force on the suction and

discharge connections of the pump. This may impose dangerous strains on the

unit causing misalignment, poor operation and physical injury and damage to the

equipment.

1. All piping must be supported independently of and line up naturally with the pump suction

and discharge. It MUST NOT place piping loads on the pump.

2. Piping should be no smaller than the pump’s suction and discharge connections and kept as

short as possible, with minimal fittings to minimize friction losses.

SMVT Installation, Operation and Maintenance Manual 13

Page 16

Installation (continued)

3. DO NOT connect piping to pump until pump and/or driver are securely fastened to a

supporting structure.

4. When pumping liquids at elevated temperatures, it is recommended that expansion loops or

joints be used in the suction and discharge piping. Refer to Figure 6 for correct placement

to avoid pump strain or misalignment due to linear expansion of piping.

Figure 6: Correct Placement of Expansion Joint

5. The piping should be arranged to permit pump isolation on both the suction and discharge

sides so that the pump can be drained during maintenance and repair.

6. Carefully clean all pipe parts, valves and ttings and pump branches prior to assembly.

7. All pipe joints MUST be airtight.

8. Proper placement of any temperature probes should be at the top end of the pump

Suction Piping

unit casing in one of the provided ports. Ports will come from factory plugged. Proper

temperature probe location is shown in Figure 7.

Figure 7: Correct Placement of Temperature Probes

Warning: NPSH available must always exceed NPSH required by the pump. For

suction lifts over 10 feet (3 meters) and liquid temperatures over 120°F (49°C),

consult the performance curve for your pump to determine NPSH required.

Properly installed suction piping is a necessity for trouble-free pump operation. Suction

piping should be ushed BEFORE connection to the pump.

1. Use of elbows close to pump suction should be avoided. There should be a minimum of two

pipe diameters of straight pipe between elbow and suction inlet (Reference Figure 8). All

elbows should be long-radius.

14 SMVT Installation, Operation and Maintenance Manual

Page 17

Installation (continued)

Figure 8: Piping Elbows

2. Use suction pipe that is one or two sizes larger than the pump suction with a reducer at the

suction. Suction piping should never be smaller diameter than the pump suction.

3. Reducers should be eccentric at the pump suction with sloping side down and horizontal

side at the top (Reference Figure 9).

Figure 9: Eccentric Reducer

4. Suction strainers, when used, must have a net “free area” of at least three times the suction

pipe area.

5. Separate suction lines are recommended when more than one pump is operating from the

same source or supply.

Suction Lift Conditions

If pump is to be installed above the liquid source, the following MUST be provided:

1. No part of the suction piping can be above the pump suction (to avoid air pockets).

2. Suction piping must slope upwards to the pump on any horizontal pipe sections.

3. All joints MUST be airtight.

4. A means of maintaining prime during intermittent duty, such as a foot valve, must be

provided.

5. The suction strainer or suction bell MUST be at least three times the diameter of the

suction.

6. Ensure that the size and minimum submergence over the suction inlet is sufcient to prevent

air from entering the pump through a suction vortex. See typical intake piping arrangements

in Figures 10-13.

SMVT Installation, Operation and Maintenance Manual 15

Page 18

Installation (continued)

H min.

D

Figure 10

3.0D

min.

1.5D

min.

H min.

D min.

D D

2

Figure 12

Figures 10-13: Typical Piping Arrangements

Suction Head (Flooded Suction) Conditions

If pump is to be installed below the liquid source, the following MUST be provided:

1. An isolation valve should be installed in the suction line at least two pipe diameters from the

pump suction to permit closing the line for pump maintenance.

H min.

H

16

15

14

13

12

11

10

H = Min. Submergence in feet

Figure 11

9

8

7

6

5

4

3

2

1

1234567891011 121314 1516

V = Velocity in feet per second

= GPM x 0.321

Area

GPM x 0.4085

Figure 13

D

V

2

D

2. Keep suction pipe free from air pockets.

3. Piping should be level or slope gradually downward from the source of supply.

4. No portion of the piping should extend below pump suction.

5. The size of the entrance from the supply should be one or two sizes larger than the suction

pipe.

6. The suction pipe must be adequately submerged below the liquid surface to prevent vortices

and air entrainment at the supply. See above illustrations.

Discharge Piping

1. Isolation and check valves should be installed in the discharge line. Locate the check valve

between the isolation valve and the pump. This will permit inspection of the check valve.

The isolation valve is required for priming, regulation of ow and for inspection and

maintenance of the pump. The check valve prevents pump or seal damage due to reverse

ow through the pump when the driver is off.

2. Increasers, if used, should be placed between the pump and check valves.

3. Cushioning devices should be used to protect the pump from surges and water hammer if

quick closing valves are installed in the system.

WARNING: Do not use the isolation/gate valve to throttle the pump as this

may cause loss of prime, excessive temperatures and damage to pump, voiding

warranty.

16 SMVT Installation, Operation and Maintenance Manual

Page 19

Typical Plumbing and Installation

Installation (continued)

Figure 14: Typical Plumbing and Installation

Final Piping Check

After connecting the piping to the pump, rotate the motor shaft to make sure that there is

no binding.

Wiring

Warning: DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE

WARNING

INSTALLING OR SERVICING PUMP.

Warning: Install ground and wire according to local and National Electrical

Code requirements.

Hazardous voltage

can shock, burn or

cause death.

Warning: Install an all leg electrical power disconnect switch near the pump.

Warning: Electrical supply MUST match motor’s nameplate specications.

Incorrect voltage can cause fire, damage the motor and void the warranty.

SMVT Installation, Operation and Maintenance Manual 17

Page 20

Installation (continued)

WARNING

Hazardous machinery

can cause personal

injury or death.

Warning: Motors without built-in protection MUST be provided with contactors

and thermal overloads for single phase motors, or starters with heaters for three

phase motors. See motor nameplate.

Warning: Motors equipped with automatic thermal protectors open the motor’s

electrical circuit when an overload exists. This can cause the pump to start

unexpectedly and without warning.

• Use only stranded copper wire to motor and ground.

• Wire size MUST limit the maximum voltage drop to 10% of the motor nameplate voltage at

the motor terminals.

• The ground wire MUST be at least as large as the wire to the motor.

• Wires should be color coded for ease of maintenance.

• Follow motor manufacturer’s wiring diagram on the motor nameplate or terminal cover

carefully.

• Three phase motors require all-leg protection with properly sized magnetic starters and

thermal overloads.

Warning: Failure to permanently ground the pump, motor and controls before

connecting to electrical power can cause shock, burns or death.

Connect the electrical leads to the motor as follows:

Single Phase Motors

1. Connect the BLACK wire to the BLACK motor lead.

2. Connect the WHITE wire to the WHITE motor lead.

3. Connect the GREEN wire to the GREEN motor lead.

Three Phase Motors

See Figure 15 for three-phase wiring diagrams.

18 SMVT Installation, Operation and Maintenance Manual

Page 21

208-230V 3/60 460V 3/60

Installation (continued)

Rotation

4

4

5

6

1

L

1

7

7

5

8

6

2

MOTOR LEADS

8

L

2

9

MOTOR LEADS

1

L

1

3

L

3

9

POWER CABLE LEADS

2

3

G

L

2

L

3

G

POWER CABLE LEADS

Figure 15: Three Phase Motor Wiring Diagram

Notice: Incorrect rotation may cause damage to the pump and voids the warranty.

• Correct rotation is left-hand, counter-clockwise when viewed from the motor end.

• Check rotation by observing the motor fan or the coupling THROUGH the coupling guard.

DO NOT confuse the rotation direction with the ow arrows cast into the pump body. The

rotation arrow is cast into the coupling.

• To reverse three phase motor rotation, have a qualied technician interchange any two of

the three power supply leads.

SMVT Installation, Operation and Maintenance Manual 19

Page 22

Commissioning, Startup, Operation and Shutdown

V. Commissioning, Startup, Operation

and Shutdown

Overview

This section covers the basic procedures to use in preparing your pump for startup, starting,

operating and shutting it down. DO NOT CONTINUE UNTIL ALL PARTS OF THE

INSTALLATION PROCESS (SECTION IV) HAVE BEEN COMPLETED.

Priming

Never start the pump until it has been properly primed. Several different methods of

priming can be used, depending upon type of installation and service involved.

Warning: SMVT pumps are not self priming and must be fully primed at all

times during operation. Loss of prime can lead to excessive heat and severe

damage to the pump and seal.

Suction Lift (Liquid below Pump Suction):

1. Install a foot valve at suction end.

2. Remove the vent plug. See Figure 16.

3. With a vented funnel, completely fill the casing with liquid at the vent plug opening.

4. Re-install the vent plug.

5. Open the suction valve.

Flooded suction (Liquid above Pump Suction):

1. Close the discharge valve.

2. Remove the vent plug. See Figure 16.

Figure 16: Vent/Drain Plug Locations

3. Slowly open the suction valve until liquid ows out of the vent plug opening.

4. Re-install the vent plug.

5. Open the discharge valve.

20 SMVT Installation, Operation and Maintenance Manual

Page 23

Precautions

Starting

Commissioning, Startup, Operation and Shutdown (continued)

Warning: Do not operate units without safety guards in place or severe personal

injury may result.

Warning: Splashing or immersing open drip proof motors in uid can cause re,

shock, burns or death. Make sure motor guards are in place.

1. Make sure suction valve and any recirculation or cooling lines are open.

2. Fully close or partially open discharge valve as dictated by system conditions.

3. Start driver.

WARNING

Hazardous machinery

can cause personal

injury or death.

Operation

Warning: DO NOT operate unit without safety guards in place. To do so could

result in severe personal injury or death.

Caution: Immediately observe pressure gauges. If discharge pressure is not

quickly attained, stop driver, re-prime and attempt to restart.

4. Slowly open discharge valve until the desired ow is obtained.

Caution: Observe pump for vibration levels, bearing temperature and excessive

noise. If normal levels are exceeded, shut down and resolve.

5. After stabilizing the system at normal operating conditions, check the piping and adjust

supports if needed.

General considerations:

Caution: Always vary capacity with regulating valve in the discharge line. Never

throttle ow from the suction side.

Caution: Driver may overload if the pumpage specic gravity (density) or

viscosity is greater than originally assumed or the rated ow rate is exceeded.

Caution: Always operate the pump at or near the rated conditions to prevent

damage resulting from cavitation or recirculation.

SMVT Installation, Operation and Maintenance Manual 21

Page 24

Commissioning, Startup, Operation and Shutdown (continued)

Operating at reduced capacity:

WARNING

Warning: DO NOT operate pump below minimum rated ows or with suction

and or discharge valve closed. These conditions may create an explosive hazard

due to vaporization of pumpage and can quickly lead to pump failure, physical

injury or property damage.

Extreme heat can

cause personal injury

or property damage.

Caution: Damage can occur from:

1. Increased vibration levels – affects bearings and mechanical seal.

2. Increased radial loads – Stresses on shaft and bearings.

3. Heat build-up – Vaporization causing rotating parts to score or seize.

4. Cavitation – Damage to internal surfaces of pump.

Operating under Freezing Conditions

Exposure to freezing conditions while pump is idle could cause liquid to freeze and damage

the pump. Liquid inside the pump should be drained.

Shutdown

1. Slowly close the discharge valve.

2. Shut down and lock the driver to prevent accidental rotation.

Warning: When handling hazardous and or toxic uids, proper personal

protective equipment should be worn. If pump is being drained, precautions

must be taken to prevent physical injury. Pumpage must be handled and disposed

of in conformance with applicable environmental regulations.

22 SMVT Installation, Operation and Maintenance Manual

Page 25

VI. Maintenance

Overview

This section covers the procedures, precautions and schedule for maintenance of your

Goulds Water Technology pump. A routine maintenance program can extend the life of

your pump. Well maintained equipment will last longer and require fewer repairs.

Warnings

Failure to disconnect and lockout electrical power before attempting any

maintenance can cause shock, burns or death.

Failure to relieve system pressure and drain system before attempting any

maintenance can cause property damage, personal injury or death.

If piping is hazardous or toxic fluids, system must be flushed prior to performing

service involving liquid end disassembly.

Maintenance Schedule

Inspection intervals should be shortened appropriately if the pumpage is abrasive or

corrosive, or if the environment is classified as potentially explosive.

Maintenance

Routine Maintenance

• Motor Maintenance

• Seal monitoring

• Vibration analysis

• Discharge pressure

• Temperature monitoring

Routine Inspections

• Check for unusual noise, vibration and bearing temperatures

• Inspect pump and piping for leaks

• Check static seal leakage

• Mechanical seal: should be no leakage

3 Month Inspections

• Check the foundation and hold-down bolts for tightness.

• If the pump has been left idle, check the seal and replace if needed.

Annual Inspections

• Check the pump capacity, pressure and power. If pump performance does not satisfy

your process requirements and the process requirements have not changed, the pump

should be disassembled; inspected and worn parts should be replaced. Otherwise, a

system inspection should be done.

Motor Maintenance

Consult the motor manufacturer’s Installation, Operation, and Maintenance manual

supplied with your motor for proper maintenance procedure and schedule.

SMVT Installation, Operation and Maintenance Manual 23

Page 26

Maintenance (continued)

General Disassembly

Required Tools: The following tools should be available for use during pump disassembly

and assembly. Wrenches, lifting sling, rubber mallet, torque wrench with sockets, non-

corrosive cleaning agents, and impeller shim (supplied with pump).

Warning: Lock out power supply to driver motor to prevent accidental startup

and physical injury.

Warning: Pump components can be heavy. Proper methods of lifting must be

employed to avoid physical injury and/or equipment damage. Steel toed shoes

must be worn at all times.

Warning: The pump may handle hazardous and/or toxic uids. Proper personal

protective equipment should be worn. Precautions must be taken to prevent

physical injury. Pumpage must be handled and disposed of in conformance with

applicable environmental regulations.

Warning: Allow all system and pump components to cool before handling them

to prevent physical injury.

Note: Before disassembling the pump for overhaul, ensure all replacement parts

are available.

Mechanical Seal Replacement

Warning: Lock out power supply to driver motor to prevent accidental startup

and physical injury.

Warning: Pump components can be heavy. Proper methods of lifting must be

employed to avoid physical injury and/or equipment damage. Steel toed shoes

must be worn at all times.

Warning: The pump may handle hazardous and/or toxic uids. Proper personal

protective equipment should be worn. Precautions must be taken to prevent

physical injury. Pumpage must be handled and disposed of in conformance with

applicable environmental regulations.

Warning: Allow all system and pump components to cool before handling them

to prevent physical injury.

Note: Before disassembling the pump for overhaul, ensure all replacement parts

are available.

1. Close all necessary suction and discharge valves.

2. Drain the liquid from the pump by removing the lower drain plugs and the upper vent plug.

See Figure 17.

24 SMVT Installation, Operation and Maintenance Manual

Page 27

Maintenance (continued)

Figure 17: Vent/Drain Plug Locations

3. Remove the (2) coupling guards.

4. Disassemble the coupling by removing the (6) socket head screws. Remove the dowel pin

on the pump shaft. See Figure 18. Retain bolts and dowel pin for reassembly.

Figure 18: Motor Coupling

Item Quantity Description

A 2 Coupling Half

B 6 Socket Head Cap Screw

C 6 Lock-washer

D 1 Dowel Pin

5. Loosen the set screws on the seal collar.

6. Remove the (4) hex head cap screws on the seal gland. Retain bolts for reassembly.

7. Carefully lift the entire seal assembly from the seal housing by sliding it up the pump

shaft. Discard the entire seal assembly.

8. Lubricate the inside of the mechanical seal assembly (supplied with pump) with grease

(such as Armored AutoGroup “STP” or Dow Corning “111 Grease”) or a mixture of

equal parts non-petroleum hand soap and water. Be sure that there is an o-ring at the

back of the gland ange.

9. Take care to make sure that the pump shaft is clean; it should be free of all burrs, oil, and

grease. The pump shaft should be completely dry before moving on to the next step.

10. To install the new mechanical seal assembly, carefully slide it down the pump shaft until

the gland contacts the mounting surface on the top of the seal housing.

SMVT Installation, Operation and Maintenance Manual 25

Page 28

Maintenance (continued)

11. Install the (4) hex cap screws on the seal gland to the seal housing. See the “Engineering

Data” section on page 8 of this manual for the proper torque value.

12. Take care to make sure that the pump and motor shafts are clean; they should be free

of all burrs, oil, and grease. Both the pump and motor shafts should be completely dry

before moving on to the next step.

13. Install the dowel pin on the pump shaft and loosely assemble the shaft coupling. Do

not tighten the coupling at this point; it should be left loose enough to set the running

position in the next step.

14. Insert the impeller shim (supplied with the pump) between the shaft coupling and seal

gland. This will lift the shaft/impellers to the running position.

15. Very lightly tighten the (2) socket head cap screws on the pump end of the coupling (refer

to Figure 19). Tighten the coupling evenly; ensure that the coupling is symmetrical on

both the pump and motor shafts. Do NOT torque the cap screws in this step.

Figure 19: Coupling Socket Head Screws

16. Very lightly tighten the remaining (4) socket head screws on the coupling. Tighten the

coupling evenly; ensure that the coupling is symmetrical on both the pump and motor

shafts. Do NOT torque the cap screws in this step.

17. Torque the socket head cap screws on the coupling. Refer to Figure 20 for the proper

torque pattern. See the “Engineering Data” section on page 8 of this manual for the

proper torque value.

Figure 20: Coupling Torque Pattern Figure 20a: Run Out Measurement Location

18. Remove the impeller position shim. Retain for later use.

19. Visually inspect the gaps between the coupling to ensure they are symmetrical on both

sides and consistent throughout the length of the coupling.

20. Inspect run out of the shaft between the bottom of the coupling and the mechanical seal

as shown in Figure 20a. If the run out exceeded 0.005”, the coupling must be adjusted.

It is usually most effective to adjust the four bolt section of the coupling.

26 SMVT Installation, Operation and Maintenance Manual

Page 29

21. Tighten the set screws on the seal gland. See the “Engineering Data” section on page 8 of

this manual for the proper torque value.

22. Install the (2) coupling guards.

23. Follow the instructions in “Section V. Commissioning, Startup, Operation, and

Shutdown” for the proper procedures to restart the pump.

Motor Replacement

1. Remove the (2) coupling guards.

2. Loosen the set screws on the seal gland.

3. Disassemble the coupling by removing the (6) socket head screws. Remove the dowel pin

on the pump shaft. See Figure 21. Retain bolts and dowel pin for reassembly.

Maintenance (continued)

Figure 21: Motor Coupling

Item Quantity Description

A 2 Coupling Half

B 6 Socket Head Cap Screw

C 6 Lock-washer

D 1 Dowel Pin

4. Remove the (4) hex head bolts the join the motor and motor adapter. Retain bolts for

reassembly.

5. With an adequately sized crane carefully remove the motor assembly.

6. With an adequately sized crane carefully lower the new motor assembly onto the motor

adapter located on the top of the pump.

7. Secure the motor with the (4) hex head bolts. See the “Engineering Data” section on page

8 of this manual for the proper torque value.

8. Take care to make sure that the pump and motor shafts are clean; they should be free

of all burrs, oil, and grease. Both the pump and motor shafts should be completely dry

before moving on to the next step.

9. Install the dowel pin on the pump shaft and loosely assemble the shaft coupling. Do not

tighten the coupling at this point; it should be left loose enough to receive the motor

shaft in the following section.

10. Insert the impeller shim (supplied with the pump) between the shaft coupling and seal

gland. This will lift the shaft/impellers to the running position.

11. Very lightly tighten the (2) socket head cap screws on the pump end of the coupling (refer

to Figure 22). Tighten the coupling evenly; ensure that the coupling is symmetrical on

both the pump and motor shafts. Do NOT torque the cap screws in this step.

SMVT Installation, Operation and Maintenance Manual 27

Page 30

Maintenance (continued)

Figure 22: Coupling Socket Head Screws

12. Very lightly tighten the remaining (4) socket head screws on the coupling. Tighten the

coupling evenly; ensure that the coupling is symmetrical on both the pump and motor

shafts. Do NOT torque the cap screws in this step.

13. Torque the socket head cap screws on the coupling. Refer to Figure 23 for the proper

torque pattern. See the “Engineering Data” section on page 8 of this manual for the

proper torque value.

Figure 23: Coupling Torque Pattern Figure 23a: Run Out Measurement Location

14. Remove the impeller shim and retain for future use.

15. Visually inspect the gaps between the coupling to ensure they are symmetrical on both

sides and consistent throughout the length of the coupling.

16. Inspect run out of the shaft between the bottom of the coupling and the mechanical seal

as shown in Figure 23a. If the run out exceeded 0.005”, the coupling must be adjusted.

It is usually most effective to adjust the four bolt section of the coupling.

17. Tighten the set screws on the seal gland. See the “Engineering Data” section on page 8 of

this manual for the proper torque value.

18. Install the (2) coupling guards.

19. Follow the instructions in “Section IV. Installation” to properly wire the motor.

20. Follow the instructions in “Section V. Commissioning, Startup, Operation, and

Shutdown” for the proper procedures to restart the pump.

28 SMVT Installation, Operation and Maintenance Manual

Page 31

Pump Disassembly Instructions and Internal Stack Replacement

Warning: Lock out power supply to driver motor to prevent accidental startup

and physical injury.

Warning: Pump components can be heavy. Proper methods of lifting must be

employed to avoid physical injury and/or equipment damage. Steel toed shoes

must be worn at all times.

Warning: The pump may handle hazardous and/or toxic uids. Proper personal

protective equipment should be worn. Precautions must be taken to prevent

physical injury. Pumpage must be handled and disposed of in conformance with

applicable environmental regulations.

Warning: Allow all system and pump components to cool before handling them

to prevent physical injury.

Note: Before disassembling the pump for overhaul, ensure all replacement parts

are available.

1. Close all necessary suction and discharge valves.

Maintenance (continued)

2. Drain the liquid from the pump by removing the lower drain plugs and the upper vent

plug. See Figure 24.

Figure 24: Vent/Drain Plug Locations

3. Remove the (2) coupling guards.

4. Loosen the set screws on the seal collar.

5. Disassemble the coupling by removing the (6) socket head screws. Remove the dowel pin

on the pump shaft. See Figure 25. Retain bolts and dowel pin for reassembly.

Figure 25: Motor Coupling

SMVT Installation, Operation and Maintenance Manual 29

Page 32

Maintenance (continued)

Item Quantity Description

A 2 Coupling Half

B 6 Socket Head Cap Screw

C 6 Lock-washer

D 1 Dowel Pin

6. Remove the (4) hex head bolts the join the motor and motor adapter. Retain bolts for

reassembly.

7. With an adequately sized crane carefully remove the motor assembly.

8. Remove the (4) hex head bolts on the seal gland. Retain bolts for reassembly.

9. Carefully lift the entire seal assembly from the seal housing by sliding it up the pump

shaft. Retain the seal assembly for pump reassembly.

10. Remove the (12) upper casing bolts. See Figure 26. Retain bolts for reassembly.

UPPER CASING

BOLTS

(TYP 12 PLCS)

Figure 26: Upper Casing Bolts

11. With an adequately sized crane carefully lift the internal stack from the pump casing.

Lift from the motor adapter as shown on page 7 of this manual. The motor adapter, seal

plate, pump shaft, and cartridge stack will lift as a complete unit.

12. Carefully set the cartridge stack removed from the pump so that the stack is supported

and the seal plate is accessible.

13. Remove the (6) bowl bolts that connect the upper bowl of the cartridge stack to the seal

plate. The seal plate and motor adapter can be removed as a single unit. Retain bolts for

reassembly.

14. Assemble the seal plate/motor adapter to the replacement cartridge stack using the (6)

bowl bolts removed in step 13. Torque the bolts in the pattern shown in Figure 27. See

the “Engineering Data” section on page 8 of this manual for the proper torque value.

Figure 27: Bowl Bolts Torque Pattern

30 SMVT Installation, Operation and Maintenance Manual

Page 33

Maintenance (continued)

15. Install a new o-ring on the lower suction cover of the replacement cartridge stack.

16. Remove the old o-ring on the upper ange of the pump casing and discard. Install a new

o-ring on the upper ange of the pump casing.

17. With an adequately sized crane carefully lift the replacement stack. Lift from the motor

adapter as shown on page 7 of this manual. The motor adapter, seal plate, pump shaft,

and cartridge stack will lift as a complete unit.

18. Carefully lower the replacement stack approximately halfway into the pump casing. Align

the motor adapter windows to the desired orientation.

19. VERY slowly and carefully continue to lower the replacement stack into the pump casing.

As the seal plate approaches the upper ange of the pump casing, take care to align the

bolt circles of the pump casing and seal plate.

20. Smoothly guide the replacement stack so that the lower suction cover engages the

pump body. Be careful to avoid damaging the lower o-ring, as this will affect the pump

performance.

21. Install the (12) upper casing bolts ‘nger-tight’.

22. Torque the (12) upper casing bolts in the pattern shown in Figure 28. See the

“Engineering Data” section on page 8 of this manual for the proper torque value.

Figure 28: Upper Casing Bolts Torque Pattern

23. Lubricate the inside of the mechanical seal assembly (supplied with pump) with grease

(such as Armored AutoGroup “STP” or Dow Corning “111 Grease”) or a mixture of

equal parts non-petroleum hand soap and water. Be sure that there is an o-ring at the

back of the gland ange.

24. Take care to make sure that the pump shaft is clean; it should be free of all burrs, oil, and

grease. Pump shaft should be completely dry before moving on to the next step.

25. To install the mechanical seal assembly, carefully slide it down the pump shaft until the

gland contacts the mounting surface on the top of the seal housing.

26. Install the (4) hex cap screws on the seal gland to the seal housing. See the “Engineering

Data” section on page 8 of this manual for the proper torque value.

27. With an adequately sized crane carefully lower the motor assembly onto the motor

adapter located on the top of the pump. Allow the motor shaft to engage into the

coupling. Be careful not to damage the motor shaft.

28. Secure the motor to the motor adapter with the (4) hex head bolts removed in step 6 of

this section. See the “Engineering Data” section on page 8 of this manual for the proper

torque value.

29. Take care to make sure that the pump and motor shafts are clean; they should be free

of all burrs, oil, and grease. Both the pump and motor shafts should be completely dry

before moving on to the next step.

SMVT Installation, Operation and Maintenance Manual 31

Page 34

Maintenance (continued)

30. Install the dowel pin on the pump shaft and loosely assemble the shaft coupling. Do not

tighten the coupling at this point; it should be left loose enough to receive the motor

shaft in the following section.

31. Insert the impeller shim (supplied with the pump) between the shaft coupling and seal

gland. This will lift the shaft/impellers to the running position.

32. Very lightly tighten the (2) socket head cap screws on the pump end of the coupling (refer

to Figure 29). Tighten the coupling evenly; ensure that the coupling is symmetrical on

both the pump and motor shafts. Do NOT torque the cap screws in this step.

Figure 29: Coupling Socket Head Screws

33. Very lightly tighten the remaining (4) socket head screws on the coupling. Tighten the

coupling evenly; ensure that the coupling is symmetrical on both the pump and motor

shafts. Do NOT torque the cap screws in this step.

34. Torque the socket head cap screws on the coupling. Refer to Figure 30 for the proper

torque pattern. See the “Engineering Data” section on page 8 of this manual for the

proper torque value.

Figure 30: Coupling Torque Pattern Figure 30a: Run Out Measurement Location

35. Remove the impeller shim and retain for future use.

36. Visually inspect the gaps between the coupling to ensure they are symmetrical on both

sides and consistent throughout the length of the coupling.

37. Inspect run out of the shaft between the bottom of the coupling and the mechanical seal

as shown in Figure 30a. If the run out exceeded 0.005”, the coupling must be adjusted. It

is usually most effective to adjust the four bolt section of the coupling.

38. Tighten the set screws on the seal gland. See the “Engineering Data” section on page 8 of

this manual for the proper torque value.

39. Install the (2) coupling guards.

32 SMVT Installation, Operation and Maintenance Manual

Page 35

40. Follow the instructions in “Section IV. Installation” to properly wire the motor.

41. Follow the instructions in “Section V. Commissioning, Startup, Operation, and

Shutdown” for the proper procedures to restart the pump.

VII. Troubleshooting

Failure to disconnect and lockout electrical power before attempting any maintenance

can cause shock, burns or death.

Symptoms

MOTOR NOT RUNNING

(See Probable Causes 1 through 5)

LITTLE OR NO LIQUID BEING DELIVERED BY PUMP

(See Probable Causes 6 through 12)

POWER CONSUMPTION TOO HIGH

(See Probable Causes 3, 12, 13, 15)

EXCESSIVE NOISE AND VIBRATION

(See Probable Causes 3, 6-8, 10, 12, 13, 16 )

Troubleshooting

PROBABLE CAUSE

1. Motor thermal protector tripped.

2. Open circuit breaker or blown fuse.

3. Impellers binding.

4. Motor improperly wired.

5. Defective Motor.

6. Pump is not primed, air or gas in liquid.

7. Discharge or suction plugged, or valve closed.

8. Incorrect rotation (three-phase only)

9. Low voltage or phase loss.

10. Impellers worn or plugged.

11. System head too high.

12. NPSHa too low-excessive suction lift or losses.

13. Discharge head too low-excessive ow rate.

14. Fluid viscosity, specific gravity too high.

15. Worn bearing.

16. Pump, motor or piping loose.

SMVT Installation, Operation and Maintenance Manual 33

Page 36

Appendix

VIII. Appendix

SMVT Product Line Numbering System

The various versions of the SMVT line are identified by a product code number on the pump label.

This number is also the catalog number for the pump. The meaning of each digit in the product

code number is shown below. Note: Not all combinations are possible. Consult your Goulds Water

Technology distributor.

Example Product Code: SM3A1J2C1VA

BEP

Flow

Product 60 Hz

Line (50 Hz) Material Hz/RPM HP Driver Stages Seal Options Trim

A Trim B Trim C Trim

D Trim E Special Trim

V = Vertical Mount

H = Horizontal Mount

1 = Standard 2B Crane Seal

A = 1, B = 2, C = 3, D = 4,

E = 5, F = 6, G = 7, H = 8,

J = 9, K = 10, L = 11, M = 12

1 = 1 PH ODP,

2 = 3 PH ODP,

3 = 3 PH 575 V ODP,

4 = 1 PH TEFC,

5 = 3 PH TEFC,

6 = 3 PH 575 V TEFC,

7 = 3 PH 415 V ODP,

8 = 3 PH 415 V TEFC

A = 3 HP, B = 5 HP, C = 7.5 HP,

D = 10 HP, E = 15 HP, F = 20 HP,

G = 25 HP, H = 30 HP, J = 40 HP,

K = 50 HP, L = 60 HP, M = 75 HP

1 = 60 Hz, 3600 RPM;

2 = 50 Hz, 3000 RPM

A = Standard construction

with carbon steel casing

D = Standard construction

with stainless steel casing

1 = 175 GPM (33 m3/hr),

2 = 230 GPM (45 m3/hr),

3 = 380 GPM (72 m3/hr),

4 = 480 GPM (91 m3/hr),

5 = 600 GPM (114 m3/hr),

6 = 700 GPM (133 m3/hr)

SM = SMVT

34 SMVT Installation, Operation and Maintenance Manual

Page 37

Sectional Pump Assembly

Appendix (continued)

Item No. Description

1 Pump Body

1B Pipe Plug – Drain

2 Suction Cover

2A O-Ring – Suction Cover

3 Intermediate Bowl

3A Hex Screws – Bowl

4 Bearing

5 Impeller

6 Taperlock

7 Shaft

8 Casing

8A O-Ring – Casing

8B Hex Screws – Casing

9 Motor Support

9A Guard – Motor Support

9B Pipe Plug

Motor Support

Hex Screws –

9C

10 Mechanical Seal

10A Hex Screws – Seal

11 Coupling

11A Cap Screws – Coupling

11B Lock Washers – Coupling

11C Dowel Pin – Coupling

12 Motor

12A Hex Screws – Motor

13 Seal Plate

SMVT Installation, Operation and Maintenance Manual 35

Page 38

Notes

Notes

36 SMVT Installation, Operation and Maintenance Manual

Page 39

Notes

Notes

SMVT Installation, Operation and Maintenance Manual 37

Page 40

WARRANTY

WARRANTY – Company warrants title to the product(s) and, except as noted with respect to items not of Company’s manufacturer,

also warrants the product(s) on date of shipment to Purchaser, to be of the kind and quality described herein, and free of defects

in workmanship and material. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, INCLUDING

BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANT-ABILITY AND FITNESS, AND CONSTITUTES THE

ONLY WARRANTY OF COMPANY WITH RESPECT TO THE PRODUCT(S).

If within one year from date of initial operation, but not more than 18 months from date of shipment by Company of any

item of product(s), Purchaser discovers that such item was not as warranted above and promptly noties Company in writing

thereof, Company shall remedy such nonconformance by, at Company’s option, adjustment or repair or replacement of the

item and any affected part of the product(s). Purchaser shall assume all responsibility and expense for removal, reinstallation,

and freight in connection with the foregoing remedies. The same obligations and conditions shall extend to replacement parts

furnished by Company hereunder. Company shall have the right of disposal of parts replaced by it. Purchaser agrees to notify

Company, in writing, of any apparent defects in design, material or workmanship, prior to performing any corrective action

back-chargeable to the Company. Purchaser shall provide a detailed estimate for approval by the Company.

ANY SEPARATE LISTED ITEM OF THE PRODUCT(S) WHICH IS NOT MANUFACTURED BY THE COMPANY IS NOT

WARRANTED BY COMPANY and shall be covered only by the express warranty, if any, of the manufacturer thereof.

THIS STATES THE PURCHASER’S EXCLUSIVE REMEDY AGAINST THE COMPANY AND ITS SUPPLIERS RELATING

TO THE PRODUCT(S), WHETHER IN CONTRACT OR IN TORT OR UNDER ANY OTHER LEGAL THEORY, AND

WHETHER ARISING OUT OF WARRANTIES, REPRESENTATIONS, INSTRUCTIONS, INSTALLATIONS OR DEFECTS

FROM ANY CAUSE.

Company and its suppliers shall have no obligation as to any products which has been improperly stored or handled, or which

has not been operated or maintained according to instructions in Company or supplier furnished manuals.

Xylem, Inc.

P.O. Box 5487

Lubbock, TX 79408

Phone: (806) 763-7867

Fax: (800) 453-4749

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem, Inc. IM158 Revision Number 4 October 2012

Loading...

Loading...