Page 1

INSTRUCTION MANUAL

U

®

C

MODELS COVERED:

1151AB2 (115V, 4.2A), 1AB2 (230V, 4.2A),

2AB2 (230V, 6.9A)

IM156R06

L

US

Aquavar ABII Controller

VARIABLE SPEED PUMP CONTROL

INSTALLATION, OPERATION AND TROUBLESHOOTING MANUAL

Page 2

Owner’s Information

Owner’s Information

Table of Contents

Table of Contents

Controller Model Number:

Controller Serial Number:

Pump Model Number:

Pump Serial Number:

Motor Model Number:

Motor SFA:

Tank Serial Number:

Installer:

Installer Telephone Number:

Installation Date:

Wire Lengths (Feet)

Service Entrance to Controller:

Controller to Motor:

Incoming Voltage:

SUBJECT PAGE

1. Safety Instructions ................................................... 3

2. System Components ................................................ 3

3. System Design ......................................................... 4

4. Piping ...................................................................... 5

5. Mounting the Controller ......................................... 5

6. Power Supply and Wiring ........................................ 6

7. Starting the System ............................................... 6-7

8. Diagrams .............................................................. 8-9

9. Troubleshooting ............................................... 10-11

10. Controller Dimensions .......................................... 11

11. Limited Warranty .................................................. 12

NOTICE: RECORD THE MODEL NUMBERS

AND SERIAL NUMBERS FROM THE

PUMP AND CONTROLLER IN THIS

INSTRUCTION MANUAL FOR FUTURE

REFERENCE. GIVE IT TO THE OWNER

OR AFFIX IT TO THE CONTROLLER

WHEN FINISHED WITH THE

INSTALLATION.

NOTE:

• Use Copper wire only.

• Suitable for use on a circuit capable of delivering not more than 5000 RMS

symmetrical amperes. Branch circuit protection provided by fuses.

• Suitable for use in a pollution degree 2 micro-environment.

• Motor overload protection provided at 110% of full load current.

• In order to maintain the environmental rating integrity of the enclosure, all

openings must be closed by equipment rated 3, 3R, 3S, 4, 4X, 6 or 6P.

• Maximum ambient temperature is 50º C.

2

Page 3

Hazardous

voltage

DANGER

Hazardous

Pressure

CAUTION

DANGER

WARNING

CAUTION

CAUTION

1: SAFETY INSTRUCTIONS

WARNING

Hazardous

voltage

Hazardous

Pressure

CAUTION

1: SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE,

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

IN MANUAL AND ON EQUIPMENT.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE UNIT.

electrical or mechanical part of the system. Failure to

disconnect electrical power before attempting any operation or maintenance can result in electrical shock,

burns or death.

6. When in operation, the motor and pump

could start unexpectedly and cause serious injury.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the

pump, the controller or in the manual,

look for one of the following signal

words and be alert to the potential for

personal injury or property damage.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

Used without a safety alert symbol

indicates a potentially hazardous situation which, if not avoided, could result

in property damage.

NOTE: INDICATES SPECIAL

INSTRUCTIONS WHICH ARE

VERY IMPORTANT AND MUST BE

FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS CONTROLLER.

MAINTAIN ALL SAFETY DECALS.

ALL OPERATING INSTRUCTIONS MUST BE

READ, UNDERSTOOD, AND FOLLOWED BY

THE OPERATING PERSONNEL. CENTRIPRO

ACCEPTS NO LIABILITY FOR DAMAGES OR

OPERATING DISORDERS WHICH ARE THE

RESULT OF NON-COMPLIANCE WITH THE

OPERATING INSTRUCTIONS.

2: SYSTEM COMPONENTS

2: SYSTEM COMPONENTS

Please review the Aquavar ABII components and insure

that you have all the parts and are familiar with their

names. Be sure to inspect all components CentriPro

supplies for shipping damage.

Aquavar ABII:

1. Pump with Motor

2. Aquavar ABII Controller with Integral Pressure

Sensor Cable

3. Pressure Tank (supplied on some models)

4. Pressure Sensor

5. Mounting Kit

6. Tank Tee with Pipe Plug

7. Pressure Gauge

WARNING

DO NOT power the unit or run the

pump until all electrical and plumbing connections, especially the pressure

sensor connection, are completed. The

pump should not be run dry. All electrical

work must be performed by a qualied

technician. Always follow the National

Electrical Code (NEC), or the Canadian Electrical

Code (CEC) as well as all local, state and provincial

codes. Code questions should be directed to your local

electrical inspector. Failure to follow electrical codes

and OSHA safety standards may result in personal injury or equipment damage. Failure to follow manufacturer's installation instructions may result in electrical

shock, re hazard, personal injury, death, damage to

equipment, unsatisfactory performance and may void

manufacturer's warranty.

1. This manual is intended to assist in the installation,

operation and repair of the system and must be kept

with the system.

2. Installation and maintenance MUST be performed by

properly trained and qualied personnel.

3. Review all instructions and warnings prior to performing any work on the system.

4. Any safety decals MUST be left on the controller and

pump.

5. The system MUST be disconnected from

the main power supply before attempting any operation or maintenance on the

3

Page 4

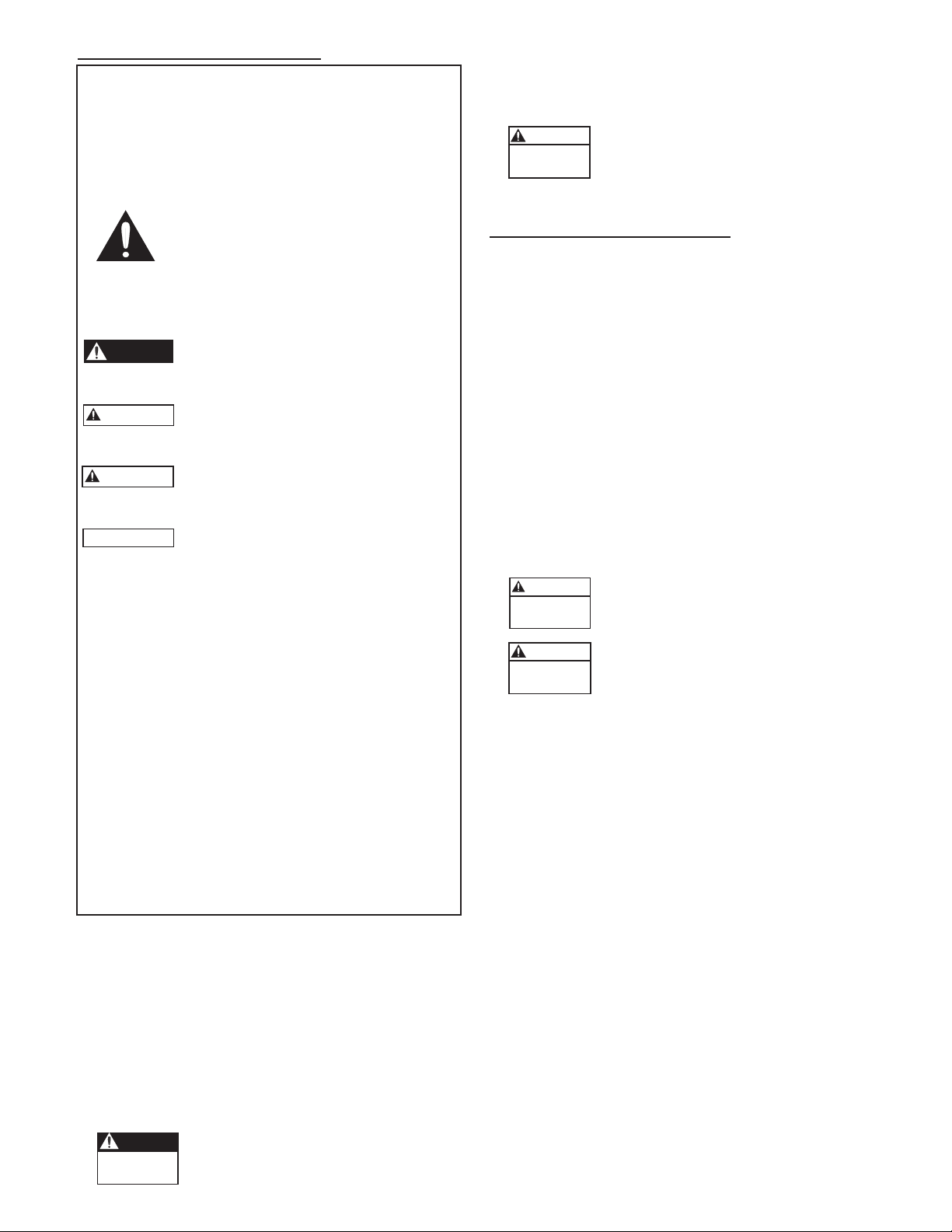

3: SYSTEM DESIGN

3: SYSTEM DESIGN

NOTE: Systems MUST be designed by qualied technicians only and meet all applicable state and local code

requirements.

The following diagrams show a typical system using the Aquavar ABII Constant Pressure System. Connection can be

made directly to a water supply or water can be drawn from a supply tank. Diagram #1 shows a typical set up for a

supply tank.

Home Supply

Aquavar ABII

Controller

Circuit

Breaker

Disconnect

Diagram 1

Aquavar ABII Installation

for Well Pump System

Transducer

Gauge

Tank

Motor/Pump

Relief

Valve

Check Valve

(not included)

To Drain

Check Valve

Isolation Valves

Unions

Isolation

Valve

Well Supply

Atmospheric

Storage Tank

Diagram #2 shows a set-up for municipal water connection. This allows pump maintenance without main line shut-off.

Home Supply Water Main

Check Valve

Aquavar ABII

Isolation Valves

Controller

Circuit

Breaker

Unions

Transducer

Disconnect

Diagram 2

Aquavar ABII

Installation for

Municipal Water System

4

Gauge

Tank

Motor/Pump

Relief

Valve

Check Valve

(not included)

To Drain

Note: A check

valve or double

check valve may

be required on

the suction side

of the pump.

Consult local

codes.

Page 5

Hazardous

Pressure

CAUTION

WARNING

Hazardous

voltage

Hazardous

Pressure

CAUTION

WARNING

Hazardous

Pressure

CAUTION

Hazardous

Pressure

CAUTION

4: PIPING

4: PIPING

General

NOTE: All plumbing work must be performed by a

qualied technician. Always follow all local, state and

provincial codes.

A proper installation requires a pressure relief valve, a ¼"

female N.P.T. threaded tting (found on tank tee) for the

pressure sensor, and properly sized pipe. Piping should

be no smaller than the pump discharge and/or suction

connections. Piping should be kept as short as possible.

Avoid the use of unnecessary ttings to minimize friction

losses.

Some pump and motor combinations

supplied with this system can create over

200 PSI. Select pipe and ttings accordingly

per your pipe suppliers’ recommendation. Consult local

codes for piping requirements in your area.

All joints must be airtight. Use Teon tape or another

type of pipe sealant to seal threaded connections. Please

be careful when using thread sealant as any excess that

gets inside the pipe may plug the pressure sensor.

Galvanized ttings or pipe should never be connected

directly to the stainless steel discharge head or casing

as galvanic corrosion may occur. Barb type connectors

should always be double clamped.

Pressure Tank, Pressure Relief Valve and

Discharge Piping

The standard Hydro-Pro tanks have a pre-charge of 38

PSI. Set the tank pressure, while tank is empty of water,

to 20 psi below the desired system pressure setting.

Ex. for a 50 psi system pressure, charge the tank to 30

psi. Use a higher tank pre-charge setting if the system

drifts over 5 PSI at a constant ow rate. Use only “precharged” tanks on this system. Do not use galvanized

tanks. Select an area that is always above 34º F (1.1º

C) in which to install the tank and pressure relief valve.

If this is an area where a water leak or pressure relief

valve blow-off may damage property, connect a drain

line to the pressure relief valve. Run the drain line from

the pressure relief valve to a suitable drain or to an area

where water will not damage property. Use the supplied

tank tee to connect the discharge pipe to the pressure

tank and house plumbing. It is allowable to pump to

multiple locations.

Maximum working pressure of most HydroPro tanks is 125 psi. Check the tank

label or instruction manual to verify data.

Installing the Pump

WARNING: Risk of electric

shock - This pump system has

not been investigated for use

in swimming pool areas.

Plumb suction and discharge of pump into

piping. Locate the pump as near liquid

source as possible. When pumping out of

an atmospheric tank locate the pump below the level

of the liquid in the tank. All piping must be supported

independently of the pump. Be sure that suction

and discharge piping are in line with the suction and

discharge of the pump. Install a check valve between

the discharge of the pump and the pressure sensor and

tank. For additional information refer to Installation,

Operation and Maintenance Instructions supplied with

the pump.

Installing the Pressure Sensor

Install the pressure sensor in the tank tee provided with

the unit. The pressure sensor cable supplied with the

controller is 120 inches long. Locate the controller so

there will be enough cable to properly install the pressure

sensor.

Do not install any shut-off valves, lters or

ow/pressure control devices (except for

a check valve) between the pressure sensor and the discharge of the pump as this could create a

hazardous situation.

Use ONLY the pressure sensor provided with the unit.

Install the pressure sensor into one of the ¼" holes on the

tank tee provided in the kit. Install the pressure sensor

vertically to avoid accumulation of debris in the sensor

port. Do not install the tank tee with the ¼" holes facing

down. Align the connector on the end of the pressure

sensor cable with the mating connector on the pressure

sensor and push it on. The tab will lock it in place.

Prevent water from following the cable and entering

sensor connector by creating a “drip loop” in the cable.

5: MOUNTING THE CONTROLLER

5: MOUNTING THE CONTROLLER

General

Mount the controller in a well ventilated, shaded area

using the supplied mounting kit. The controller must be

mounted vertically. Be sure to leave 8 inches of free air

space on every side of the unit. The controller must be

in an area with an ambient between 34º F (1.1º C) and

104º F (40º C). Model 2AB2 will automatically decrease

(derate) the maximum output current of the drive (6.9A)

if the ambient temperature exceeds 104º F

(40º C). The maximum output current of the drive will

be decreased by 0.069A for every degree Fahrenheit

above 104º F, or -1%/º F. The maximum output current

of the drive will be decreased by 0.12A for every degree

Celsius above 40º C, or -1.75%/º C. Model 1AB2

does not require ambient derating and will maintain

a maximum output current of 4.2A in high ambient

temperatures. If installation is more than 3300 feet above

sea level, drive output should also be derated by 2% per

1000 feet above 3300 feet.

NOTE: Do not block the heat sink (ns) and do not

set anything on the units.

5

Page 6

The controller access cover should always

WARNING

Hazardous

voltage

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

CAUTION

be securely fastened to the control box

due to the dangerous voltage/shock hazard

inside the unit.

6: POWER SUPPLY AND WIRING

6: POWER SUPPLY AND WIRING

Power Supply

The 1151AB2 Controller requires a single

phase power supply of 115 volts +/– 15%.

The 1AB2 and 2AB2 Controllers require

a single phase power supply of 230 volts +/– 15%. All

controllers require a dedicated 20 amp two-pole circuit

breaker. A dedicated circuit means no other appliances

use the same circuit! The output power from the motor

controller is three-phase, variable frequency and variable

voltage. Maximum output voltage and frequency are

line input voltage and 60 Hz, respectively. Low supply

voltage will reduce pump performance.

NOTE: Installation and maintenance MUST be performed by properly trained and qualied personnel.

Always follow the National Electric Code or Canadian

Electric Code, as well as all local, state and provincial

codes when wiring the system.

Wire and Conduit

Do not use wire smaller than 14 AWG. Use of

Metal Conduit with Metal Conduit Connectors is

recommended for all electrical connections.

Output Power Connections

Connect the motor leads for 230 volt or

208 volt operation using the nameplate as a

reference. Connect the output power leads

from the controller to the 3 motor leads in the conduit

box on the motor. Connect the ground (green) output

power lead to the ground screw in the conduit box on

the motor. This step is performed in its entirety at the

factory for complete systems. See diagram 4 for details.

NOTE: If the pump has more than 50 feet of wire

from the controller, consult factory for selection of an

output load lter (load reactor).

to properly ground the controller or motor will create an

electrical shock hazard.

NOTE: Do not use GFCI protection with this controller. Nuisance tripping will result.

7: STARTING THE SYSTEM

7: STARTING THE SYSTEM

Status Code Indicator Light is not a voltage

indicator! Always turn off disconnect switch

and circuit breaker before servicing.

Once the controller is powered it will remain electrically charged for 5 minutes after

power is turned off. Wait 5 minutes after

disconnecting power before opening controller access

cover as there is a severe shock hazard.

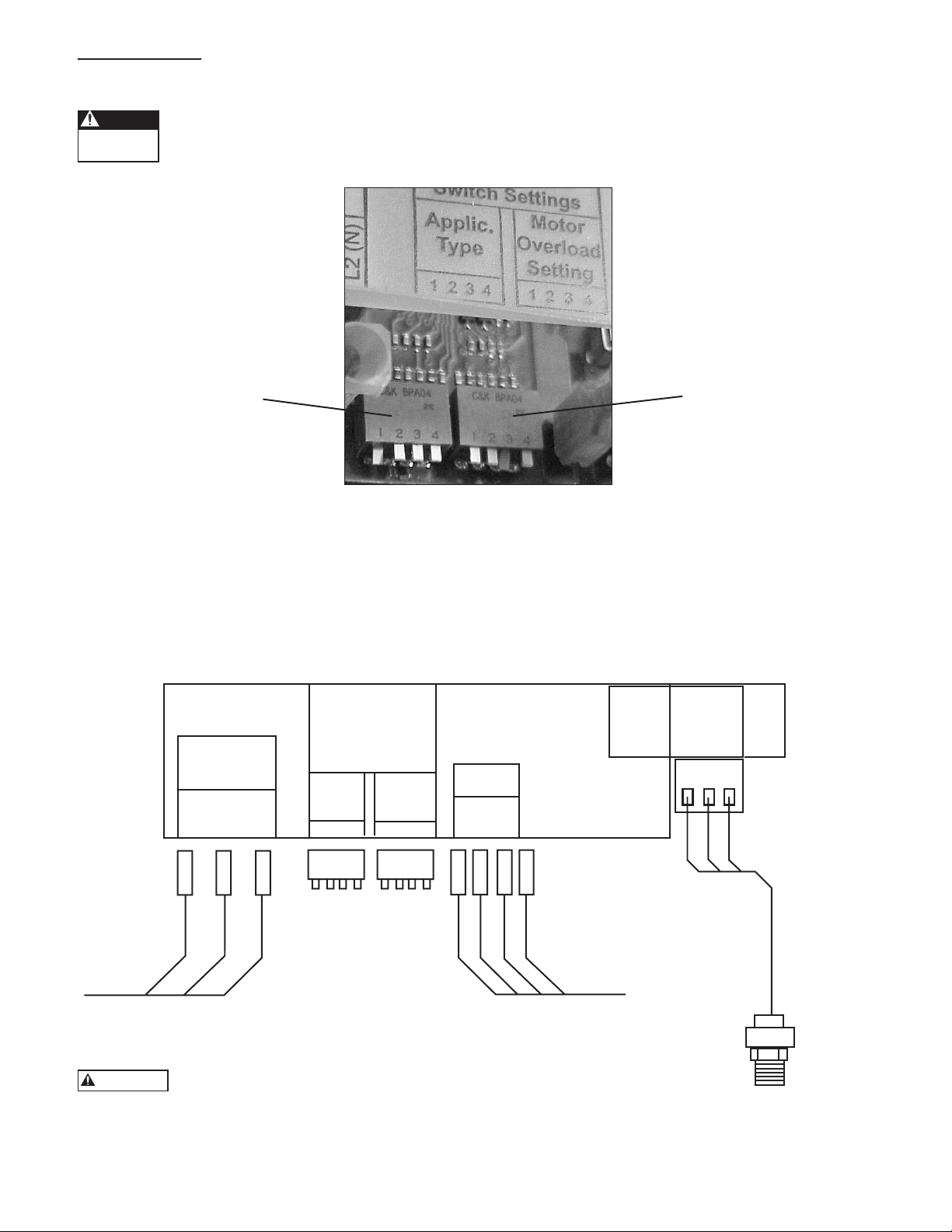

Setting the Motor Overload Switches

When the unit is powered, the Motor Over-

load Setting Switches are at a high voltage

potential. DO NOT touch the Motor Overload Setting Switches while the power is on.

The Motor Overload Setting Switches adjust the level

of motor overload current protection needed to protect

the motor from damage due to overcurrent conditions.

Turn the circuit breaker and disconnect switch to the off

position, and wait 5 minutes. Remove controller access

cover. On the inside of the access cover is the Motor

Overload Setting table.

shows the switch setting for the desired Motor Overload

Setting. Read the Service Factor Amps off the motor

nameplate. Use the Motor Overload Setting table to

match the Service Factor Amps (SF Amps) of the motor

to the correct switch setting.

the Motor Overload Switches according to the correct

combination on the table. If the Service Factor Amps

of the motor do not match any of the Motor Overload

Settings, use the next lowest switch setting.

for details

.

NOTE: The Motor Overload Setting Switches are

preset at the factory for complete systems.

See Diagram 6 for details.

This table

See Diagram 5 for details.

See Diagram 3

Set

Connecting Input Power

Connect the single-phase power supply

leads and Safety Ground wire from a 20

amp two-pole circuit breaker (in the OFF

position) to one side of a 20-amp two-pole disconnect

switch. Connect the input power leads supplied with

the controller to the other side of the disconnect switch.

Be sure to use Metal Conduit with Metal Conduit

Connectors for electrical connections.

The controller has a high leakage current

to ground. The terminals marked "GND"

in the controller must be connected to the

safety ground from the electrical service entrance. Failure

6

Failure to perform this step will result in

loss of Motor Overload Protection and

will void the Motor Warranty. Nuisance Motor Overload Error tripping or motor damage can occur if these

switches are not set properly.

Setting the Pressure

Turn the circuit breaker and disconnect switch to the off

position, and wait 5 minutes. Remove controller access

cover. Open a faucet in the system and turn the breaker/

disconnect switch to the ON position. The pump will

start and pressure will increase to the factory preset 50

PSI. After the pressure has stabilized, use the Increase/

Decrease Pressure Adjust Pushbuttons on the right-hand

side of the controller to adjust the pressure setting.

Page 7

Push and Hold the Increase or Decrease Pressure Adjust

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Pushbutton until the desired pressure setting is reached.

The new pressure setting is automatically saved. Close

the faucet and turn power to controller off. Wait 5

minutes before installing the controller access cover.

NOTE: The maximum allowable pressure setting is

85 psi.

NOTE: It is possible for the pump to maintain

constant pressure with a low ow or a high positive

suction head even if the pump is rotating backwards.

While the pump is running, use an amp probe on one

of the output power leads connected to the motor and

compare the current draw between the two rotation

directions. The lowest current reading indicates the

pump is running in the correct direction.

Setting the Application Switches

When the unit is powered, the Application

Setting Switches are at a high voltage potential. DO NOT touch the Application Setting

Switches while the power is on.

The controller has 6 possible Application Settings.

These settings are used to adjust the Minimum Speed

of the motor and the Ramp Setting, or acceleration and

deceleration ramp. This allows the controller to t a wide

range of applications.

Before adjusting the Application Switches, turn the

circuit breaker and disconnect switch to the off position.

Wait 5 minutes. Remove the controller access cover. On

the inside of the access cover is the Application Switch

Setting Table. See Diagram 6 for details. This table shows

the switch setting needed for the desired system response.

See Diagram 3 for details.

Select a Minimum Speed of 10 Hz if the pressure at the

pump’s suction is within 20 PSI of the desired pressure

setting. Select a Minimum Speed of 30Hz if the pressure

at the pump’s suction is more than 20 PSI below the

desired pressure setting, if pumping from a tank or if

drawing a suction lift.

Changing the Ramp Setting changes how fast the

controller can change the speed of the motor. A Slow

Ramp Setting allows the controller to work better in

applications where the average demand for water is low

(less than 3GPM or about 1 faucet). A Fast Ramp Setting

allows the controller to work better in applications

where the demand for water is high because the motor is

allowed to change speed faster.

System Status

The controller is always powered. A Solid Green Status

Code indicates that the pump is in standby mode (pump

not running) or that the line input voltage is low.

Status Code Indicator Light is not a voltage

indicator! Always turn off disconnect switch

and circuit breaker and wait 5 minutes

before servicing.

A Blinking Green Status Code indicates that the pump

is running. A Blinking or Solid Red Light indicates a

problem with the controller. Refer to the access cover

side panel or Diagram 6 for Status Codes. See Section 9

for more details.

NOTE: The Application Switches are preset at the

factory to “0000” or Minimum Speed = 30 Hz, Ramp

Setting = Fast.

Motor Rotation Direction

If the pressure or ow seems low, check motor rotation

direction. Turn the circuit breaker and disconnect

switch to the off position, and wait 5 minutes. Switch

any two leads on the controller output (T1, T2, or T3).

Turn the circuit breaker and disconnect switch to the on

position. Observe pressure and ow. If pressure or ow

still seems low check plumbing.

7

Page 8

Hazardous

voltage

DANGER

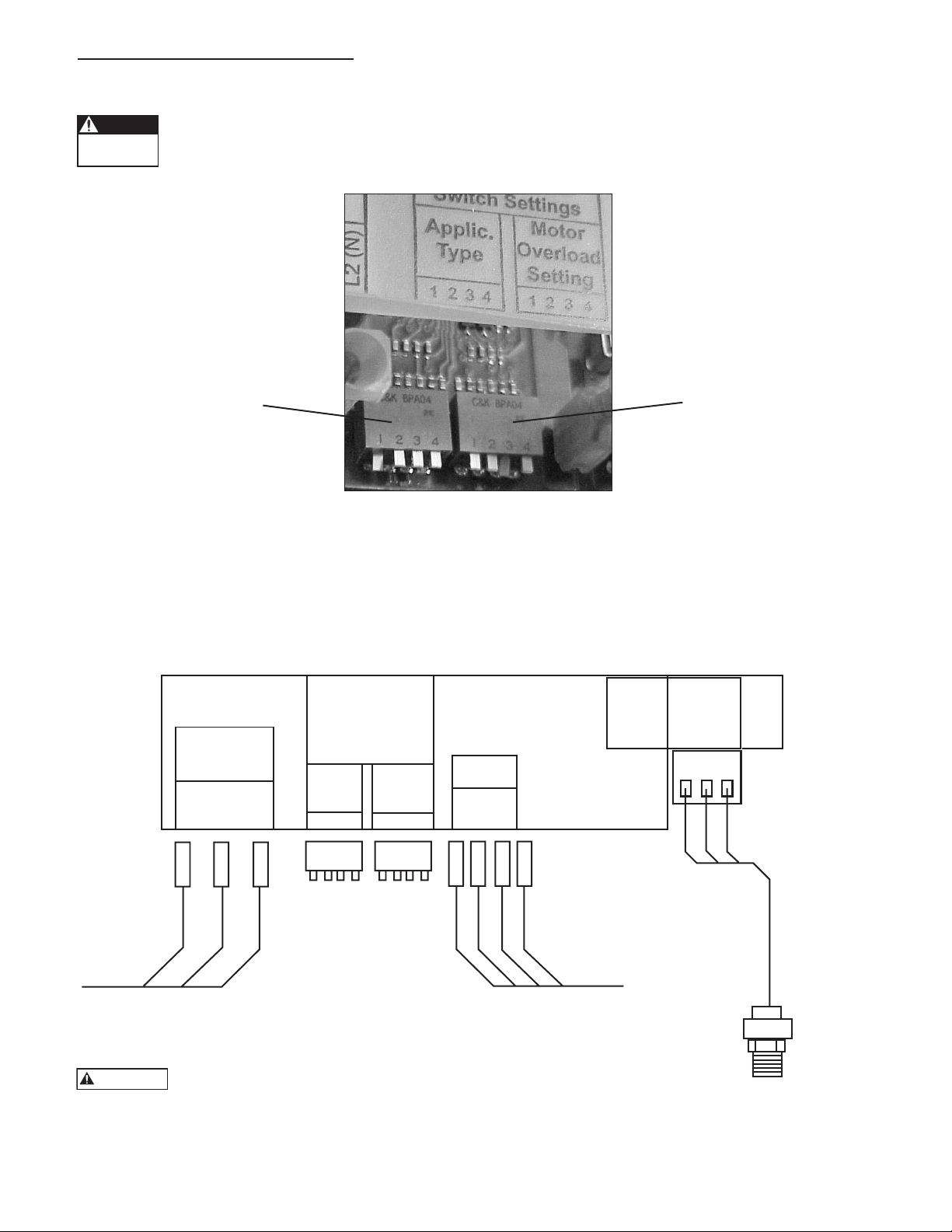

Input

1 Phase

GND

L1

L2 (N)

See Manual For

Switch Settings

Applic.

Type

Output

To Motor

1 2 3 4 1 2 3 4

Pressure

Sensor

Input (Wht)

+5V (Red)

Com. (Blk)

T1T2T3

GND

Motor

Overload

Setting

Line output to motor.

Correct motor rotation

determines order of colors.

Pressure

Sensor

9K518

Line input power from

2-pole disconnect or

circuit breaker.

GREEN

BLACK

BLACK

GREEN

WHITE

RED

BLACK

BLUE

RED

BLACK

8: DIAGRAMS

WARNING

8: DIAGRAMS

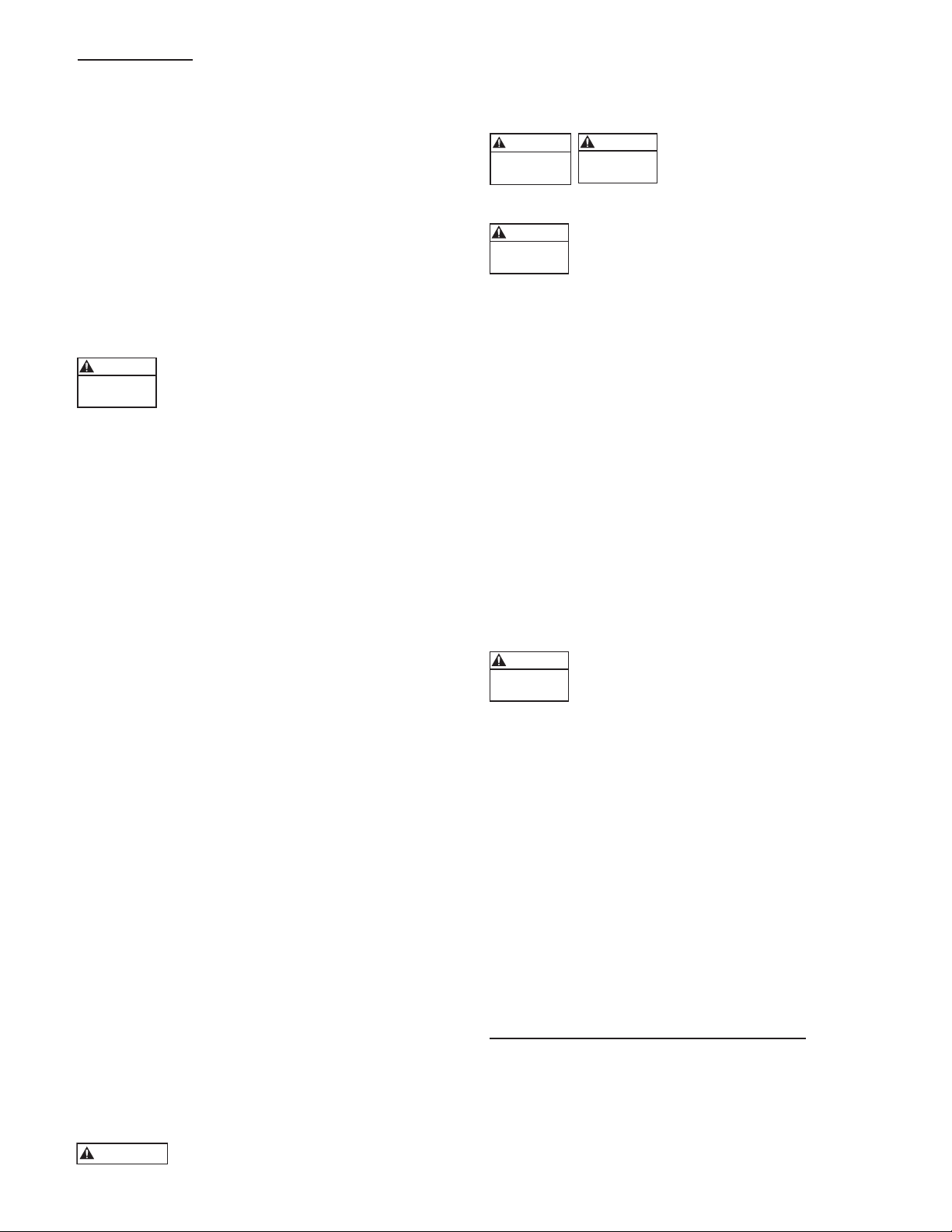

Motor Overload and Application Switch Setting

When the unit is powered, the Motor Overload and Application Setting Switches are at a high voltage

potential. Always turn off the disconnect switch and circuit breaker and wait 5 minutes before touching

the Motor Overload or Application Setting Switches.

Application Switch Setting

See chart that follows for

correct switch settings.

Aquavar ABII Wiring Diagram

Motor Overload Setting

Switches

See chart that follows for

correct switch settings.

Diagram 3

8

Do not connect 230V to a 115V controller. This will

damage the controller and voids the warranty.

Diagram 4

Page 9

8: DIAGRAMS

8: DIAGRAMS (continued)

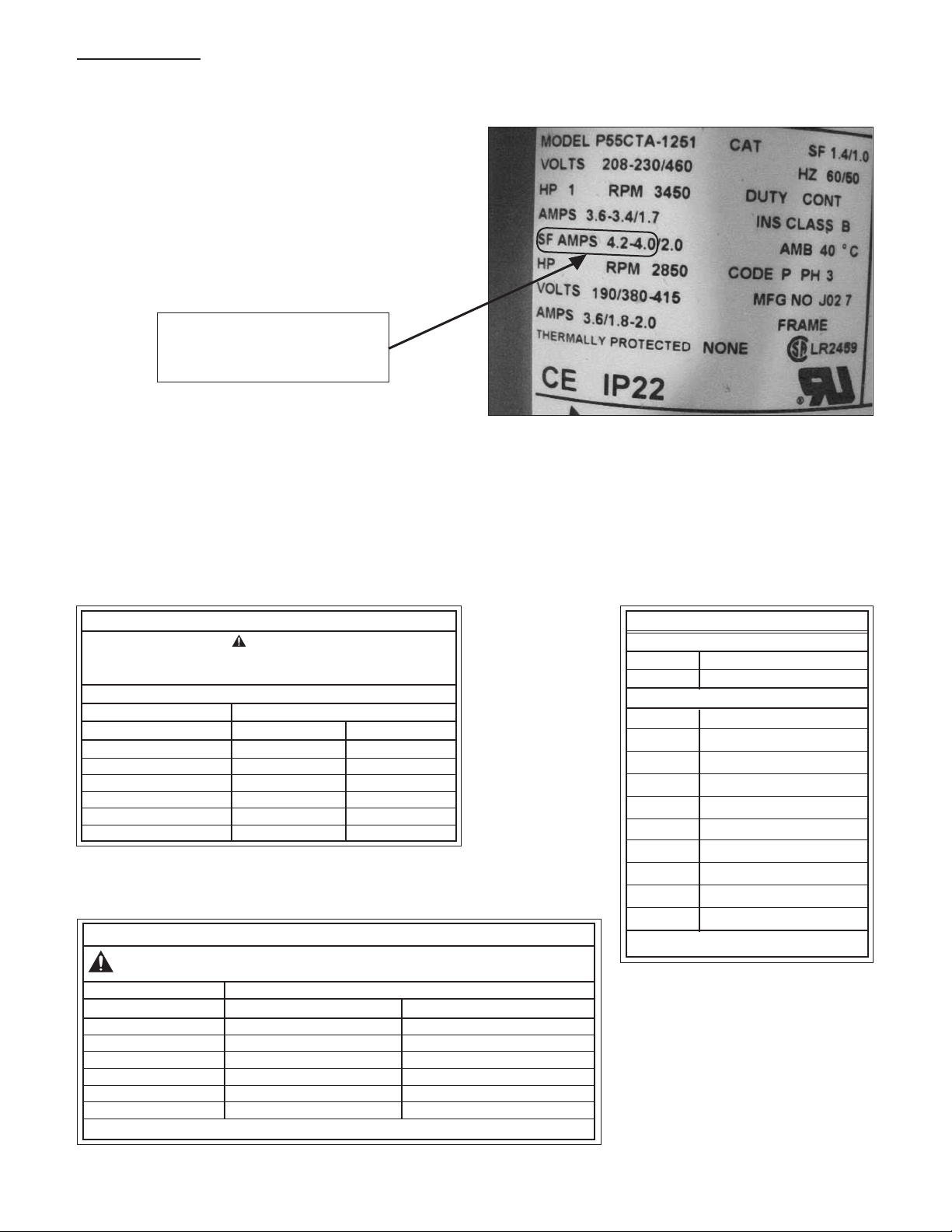

Typical Motor Nameplate Showing Service Factor Amps (SF AMPS)

Service Factor Amps (SF AMPS)

that are used to set the Motor

Overload Setting Switches.

In this example, use the 4.2 Amp setting indicated on the Motor Overload Setting Table. This setting is used to account

for any voltage uctuation.

Diagram 5

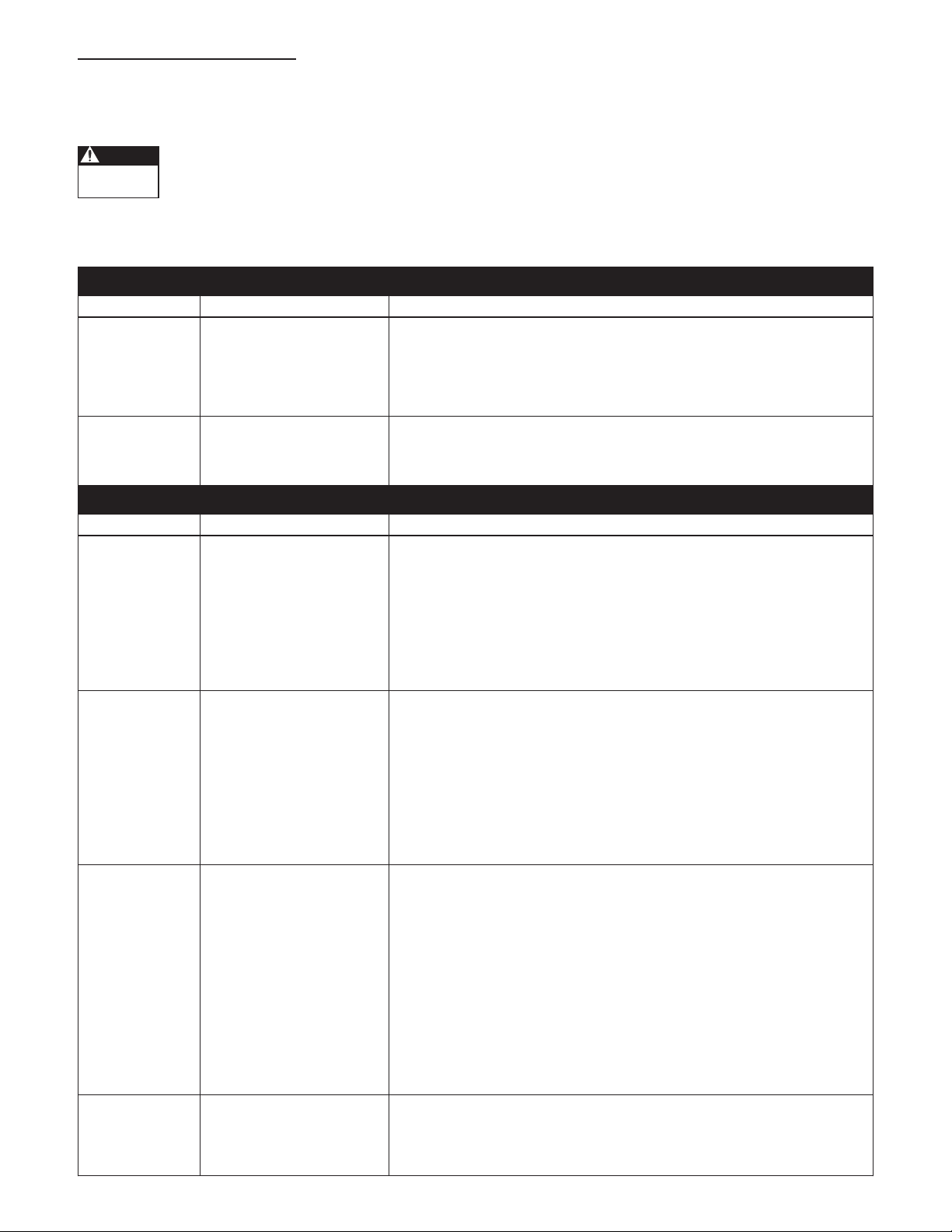

Labels found on the Controller Access Cover:

Motor Overload Setting

WARNING

Disconnect Power And Wait For LED Indicator To Turn

Off Before Touching Motor Overload Setting Switches.

1 = UP 0 = DOWN

DIP Switch Setting Motor Overload Setting (Amps)

1 2 3 4 1AB2 2AB2

1 1 1 1 2.5 4.6

1 1 1 0 2.8 5.2

1 1 0 1 3.3 5.3

1 0 1 1 3.5 5.8

0 1 1 1 3.8 6.5

0 0 0 0 4.2 6.9

Motor Overload Setting Label

Use this label to choose the correct Motor Overload Switch

Setting. This label is found under the controller access cover.

Application Type Switch Setting

WARNING

DIP Switch Setting 1 = UP 0 = DOWN

1 2 3 4 Minimum Speed (Hz) Ramp Setting

1 1 1 1 * 10 Slow

1 1 1 0 * 10 Medium

1 1 0 1 * 10 Fast

1 0 1 1 30 Slow

0 1 1 1 30 Medium

0 0 0 0 30 Fast

*THESE SETTINGS ARE NOT TO BE USED WITH SUBMERSIBLE PUMPS.

Disconnect Power And Wait For LED Indicator To Turn

Off Before Touching Application Setting Switches.

Status Code

to diagnose any

system errors.

Label

Use this label

This label is

found on the

side of the

controller

access cover.

Status Codes*

Green Light Codes

Constant Standby/Low Voltage

Blinking Pump Running

Red Light Codes

Constant Replace Controller

1 Blink No Water/Loss Of Prime

2 Blinks Tank Water-Logged

3 Blinks Pressure Sensor Fault

4 Blinks Pump or Motor Bound

5 Blinks Short Circuit

6 Blinks Ground Fault

7 Blinks High Temperature

8 Blinks Over Voltage (>264V)

9 Blinks Motor Overload

*No Light - No/Very Low Voltage

Application Switch Setting Label

Use this label to choose the correct

Application Switch Setting. This label is

found under the controller access cover.

Diagram 6

9

Page 10

Hazardous

voltage

DANGER

9: TROUBLESHOOTING

9: TROUBLESHOOTING

General

The Aquavar ABII is a self-diagnosing controller. If a problem occurs, observe the Status Code Indicator Light on the

front of the unit. No Status Code Indicator Light means either no or low input voltage (less than 50 V).

Status Code Indicator Light is not a voltage indicator! Always turn off disconnect switch and circuit

breaker and wait 5 minutes before servicing. High voltage may still remain on controller.

Refer to the status code label on the side of the controller access cover to diagnose system errors. See Diagram 6 for details.

USE THE FOLLOWING TABLE TO HELP TROUBLESHOOT PROBLEMS.

GREEN LIGHT CODES

Indicator Code Status Description

Constant Standby/Low Voltage Constant Green Light indicates the pump is off. The system is in

Standby mode when there is no ow in the system and the pressure

setting has been reached. The system is in a Low Voltage condition

when the line input voltage drops below 196VAC for 1AB2 and 2AB2

controllers and 98VAC for 1151AB2 controllers.

Blinking Pump Running Flashing Green Light indicates the pump is running. If pump is not

running, turn off power to controller and wait 5 minutes. Check

output power connections from controller to motor.

RED LIGHT CODES

Constant Controller Error Replace Aquavar ABII Controller

1 Blink No Water/Loss Of Prime This fault is indicated if the system pressure drops 5 PSI or more

below the set pressure and the output current is less than 75% of the

motor overload setting for 10 seconds. The system will automatically

restart in 5 minutes. If 3 faults occur in an hour, the system will not

restart and will need to be manually reset. If the problem reoccurs,

please verify supply capacity, pump capacity, proper setting of the

motor overload switches and that there are no restrictions between

the supply and the pump.

2 Blinks Tank Water-Logged This warning is indicated if there is a drastic drop in system pressure

in a short amount of time. The warning will not impact operation.

The pump will continue to run. This warning can be caused by low air

pressure in the tank or the tank bladder may have failed. This can also

be caused by extreme changes in ow. The error is cleared each time

the pump starts. If the error reoccurs often, check the air pressure in

the tank. Before checking tank air pressure, turn power to control off

to prevent pump from turning on. Relieve system pressure by opening

a faucet.

3 Blinks Pressure Sensor Fault This fault indicates a problem with the pressure sensor feedback.

Verify the connections from the Aquavar ABII Controller to the

pressure sensor. Turn power to controller off and wait 5 minutes.

Remove controller access panel. Be sure sensor cable is wired as

shown in Diagram 4. If cable is wired correctly, check the voltage on

the Input (White) pressure sensor terminal connection in the

Aquavar ABII controller. Using a DC voltmeter, connect the positive

lead to the Input (White) pressure sensor terminal connection, connect

the negative lead to the Com. (Black) pressure sensor terminal

connection. Turn power to controller on. The DC voltage measured

should be in the valid range of 0.5 Vdc to 4.5 Vdc (+/- 0.2 Vdc). If the

voltage is outside this range, replace pressure sensor.

4 Blinks Pump or Motor Bound This fault can be caused by mechanical binding from debris in pump

or from an electrical failure in the motor. Verify the error by turning

power to controller off for 1 minute and then on. Pump must be

checked if error persists.

10

Page 11

9: TROUBLESHOOTING

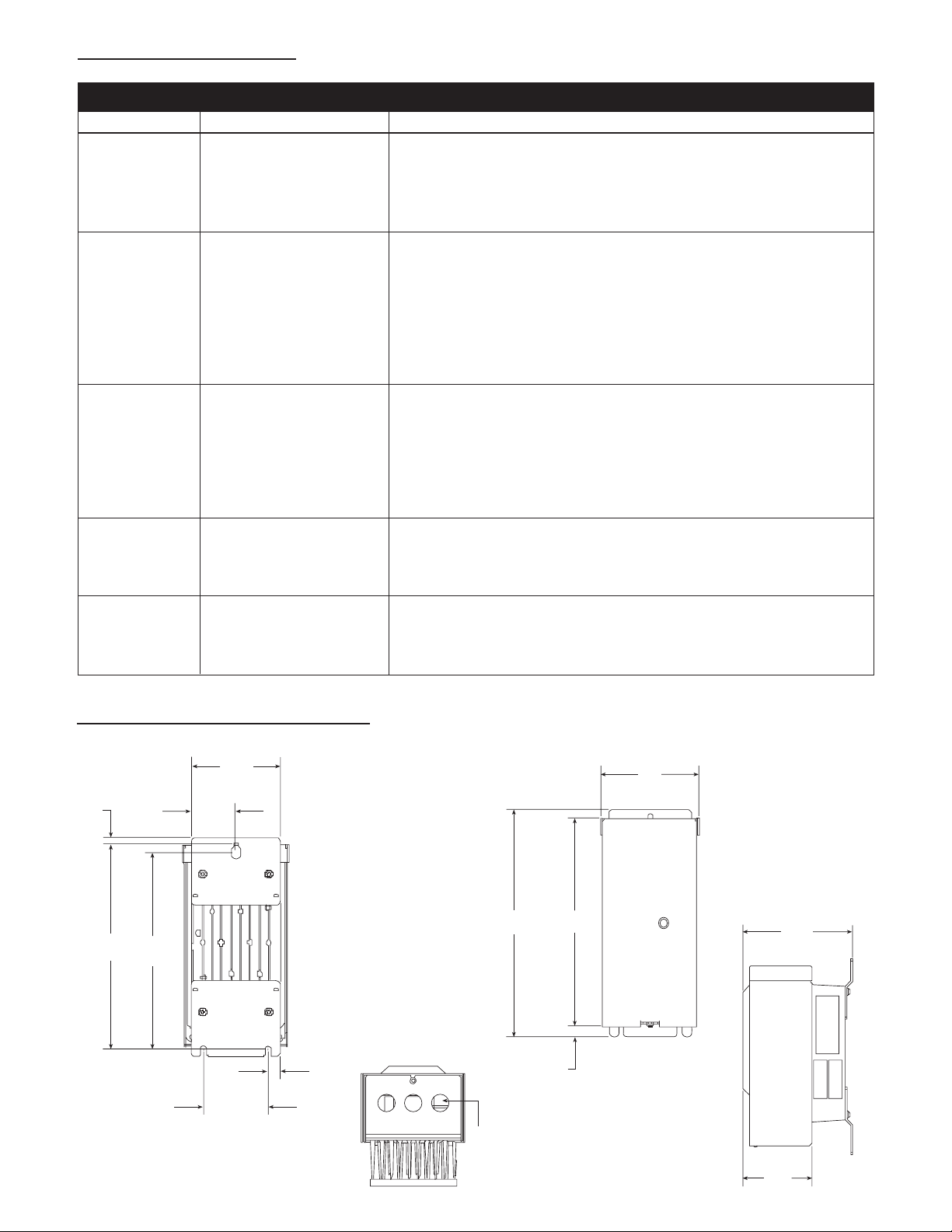

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(135.36)

5.33

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(114.30)

4.50

(57.15)

2.25

(81.28)

3.20

(16.51)

.65

9: TROUBLESHOOTING (continued)

Indicator Code Status Description

5 Blinks Short Circuit Check wiring for shorting phase to phase and phase to ground. Turn

power to controller off and wait 5 minutes. Remove controller

access panel. Disconnect motor leads marked T1, T2, and T3. Measure

resistance between all motor leads using an ohmmeter. NOTE: Motor

winding resistance is typically 2 to 10 OHMS depending on motor.

6 Blinks Ground Fault Check wiring for shorting phase to ground. Turn power to controller

off and wait 5 minutes. Remove controller access panel. Disconnect

motor leads T1, T2, T3, and Ground from controller. Measure

resistance between all motor leads and ground using a Megohmmeter.

Connect one Megohmmeter lead to any one of the motor leads and

the other to ground lead. Set Megohmmeter to 500V DC output.

Resistance readings less than 500,000 ohms or 0.5 Megohms indicate

a damaged motor.

7 Blinks High Temperature This fault is caused by a high temperature inside of the controller. The

controller will shut off when the temperature inside the controller

reaches 158º F (70º C). The controller will turn back on when the

temperature inside the controller reaches 150º F (65.5º C). Avoid

installing the controller where ambient temperatures exceed 104º F

(40º C). Avoid installing the controller where it is exposed to direct

sunlight.

8 Blinks Over Voltage Measure input voltage using an AC voltmeter. Connect the positive

and negative leads to L1 and L2 on the Aquavar ABII controller. Verify

line input voltage is not greater than 264 VAC for 1AB2 and 2AB2

controllers and 132VAC for 1151AB2.

9 Blinks Motor Overload This fault is indicated when the current supplied to the motor exceeds

the Motor Overload Setting on the Aquavar ABII controller. Refer to

Section 7, Setting the Motor Overload DIP Switches for details. If

switches are set according to Section 7, check motor.

10: CONTROLLER DIMENSIONS

10: CONTROLLER DIMENSIONS

RED LIGHT CODES

(8.38)

.33

(242.04)

9.53

(232.56)

9.16

(57.15)

2.25

(114.30)

4.50

(81.28)

3.20

(16.51)

.65

Liquid

Tight

(135.36)

5.33

(12.07)

.48

(237.06)

9.33

(99.06)

3.90

(157.90)

6.22

(259.08)

10.20

1

∨2”

11

Page 12

LIMITED WARRANTY

This warranty applies to this Xylem Inc. product.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twenty-four (24) months from date of installation or thirty (30) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Xylem Inc. distributor from whom the equipment was purchased and furnish complete details

regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Xylem Inc. Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Xylem Inc. and the dealer in purchases, consignments

or contracts for sale of the subject equipment.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing equipment to customers.

(3) “Customer” means any entity who buys or leases the subject equipment from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability

company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.centripro.com

CentriPro and Aquavar ABII are trademarks of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. IM156 Revision Number 6 February 2013

Page 13

MANUAL DE INSTRUCCIÓN

U

®

C

MODELOS CUBIERTOS:

1151AB2 (115V, 4.2A), 1AB2 (230V, 4.2A),

IM156R06

L

US

2AB2 (230V, 6.9A)

Controlador Aquavar ABII

CONTROL DE BOMBA DE VELOCIDAD VARIABLE

MANUAL DE INSTALACIÓN, OPERACIÓN Y RESOLUCIÓN DE PROBLEMAS

Page 14

Información del propietario

Información del propietario

Tabla de contenido

Tabla de contenido

Número de Modelo del Controlador:

Número de serie del Controlador:

Número de modelo de la Bomba:

Número de serie de la Bomba:

Número de modelo del motor de la Bomba:

SFA del motor:

Número de serie del Tanque:

Instalador:

Número de teléfono del instalador:

Fecha de instalación:

Largos de cable (pies)

Entrada de servicio al controlador:

Controlador al motor:

Tensión de entrada:

ASUNTO PÁGINA

1. Instrucciones importantes de seguridad ................. 15

2. Componentes del sistema ...................................... 15

3. Diseño del sistema ................................................. 16

4. Tuberías ................................................................. 17

5. Montaje del controlador ........................................ 17

6. Fuente de alimentación y cableado ........................ 18

7. Arranque del sistema ........................................ 18-19

8. Diagramas ........................................................ 20-21

9. Identicación y resolución de problemas .......... 22-23

10. Dimensiones del controlador ................................. 24

11. Garantía limitada ................................................... 24

AVISO: REGISTRE LOS NÚMEROS DE MODELO

Y DE SERIE DE LA BOMBA Y DEL CONTROLADOR EN ESTE MANUAL DE INSTRUCCIONES PARA CONSULTA FUTURA.

DÉSELO AL PROPIETARIO O SUJÉTELO

AL CONTROLADOR AL FINALIZAR LA

INSTALACIÓN.

NOTA:

• Utilice exclusivamente cables de cobre.

• Adecuado para usarse en un circuito que pueda suministrar 5000 RMS

de amperes simétricos. Los circuitos de derivaciones están protegidos por

medio de fusibles.

• Adecuado para usarse en un microambiente con una contaminación del

grado 2.

• La protección de sobrecarga del motor está establecida a 110% de la

corriente nominal.

14

• Para poder conservar la clasicación ambiental de la cubierta, se deben

cerrar todas las aperturas de los equipos con clasicación 3, 3R, RS, 4,

4X, 6 o 6P.

• La temperatura ambiental que se admite como máximo es de 50°C.

Page 15

Tensión

p

eligrosa

PELIGRO

Presión

Peligrosa

CUIDADO

PELIGRO

ADVERTENCIA

1: INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

Tensión

peligrosa

Presión

Peligrosa

PRECAUCIÓN

1: INSTRUCCIONES DE SEGURIDAD

PARA EVITAR LESIONES PERSONALES GRAVES

O FATALES O DAÑOS SIGNIFICATIVOS A LA

PROPIEDAD, LEA Y RESPETE TODAS LAS INSTRUCCIONES DE SEGURIDAD EN EL MANUAL Y

EN EL EQUIPO.

LA FINALIDAD DE ESTE MANUAL ES AYUDAR EN

LA INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y SE DEBE GUARDAR EL MISMO CON LA

UNIDAD.

Este es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Al ver este símbolo en la

bomba, el controlador o en el manual,

busque una de las siguientes palabras de

señal y esté alerta al potencial de lesión

personal o daños a la propiedad.

Indica una situación posiblemente

peligrosa la cual, si no se evita, podría

producir lesiones graves o aún la

muerte.

Indica una situación inminentemente

peligrosa la cual, si no se evita,

producirá lesiones graves o aún la

muerte.

PRECAUCIÓN

Indica una situación posiblemente

peligrosa la cual, si no se evita,

podría producir lesiones menores o

moderadas.

PRECAUCIÓN

Utilizado sin un símbolo de alerta

de seguridad indica una situación

posiblemente peligrosa la cual, si no se

evita, podría causar daños materiales.

NOTA: INDICA INSTRUCCIONES ESPECIALES

QUE SON MUY IMPORTANTES Y

DEBEN SER SEGUIDAS.

LEA DETENIDAMENTE TODAS LAS INSTRUCCIONES Y ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN ESTE CONTROLADOR.

MANTENGA TODAS LAS CALCOMANÍAS DE

SEGURIDAD.

EL PERSONAL DE OPERACIONES DEBE

LEER, ENTENDER Y SEGUIR TODAS LAS

INSTRUCCIONES DE OPERACIÓN. CENTRIPRO

NO ACEPTA NINGUNA RESPONSABILIDAD

POR DAÑOS Y PERJUICIOS O PROBLEMAS DE

FUNCIONAMIENTO QUE SEAN EL RESULTADO

DE NO CUMPLIR CON LAS INSTRUCCIONES DE

OPERACIÓN.

1. El objetivo de este manual es ayudar en la instalación,

operación y reparación del sistema y debe ser mantenido con el mismo.

2. La instalación y el mantenimiento DEBEN ser realizados por personal apropiadamente capacitado y competente.

3. Revise todas las instrucciones y advertencias antes de

realizar cualquier trabajo en el sistema.

4. No DEBE quitarse ningún rótulo de seguridad de la

bomba o del controlador.

5. El sistema DEBE desconectarse de la

fuente de alimentación principal antes de

intentar cualquier operación o mantenimiento en la sección eléctrica o mecáni-

ca del sistema. Si no se desconecta la corriente antes

de intentar realizar operaciones o mantenimiento, se

pueden producir quemaduras, electrochoque o aún la

muerte.

6. Cuando están en operación, el motor y

la bomba podrían arrancar inesperadamente y producir lesiones graves.

2: COMPONENTES DEL SISTEMA

2: COMPONENTES DEL SISTEMA

Inspeccione los componentes del sistema Aquavar ABII

y asegúrese de que tenga todas las partes y que esté

familiarizado con sus nombres. Asegúrese de inspeccionar

todos los componentes suministrados por CentriPro para

determinar si resultaron dañados durante el envío.

Aquavar ABII:

1. Bomba con motor

2. Controlador Aquavar ABII con cable de sensor de

presión integral

3. Tanque de presión (provisto en algunos modelos)

4. Sensor de presión

5. Juego de montaje

6. Perl T de tanque con tapón para tubo

7. Indicador de presión

ADVERTENCIA

NO energice la unidad ni haga funcionar

la bomba hasta que se hayan completado todas las conexiones eléctricas y

de tuberías, especialmente la conexión

del sensor de presión. La bomba no

debe hacerse funcionar en seco. Todo el

trabajo eléctrico debe ser realizado por

un técnico calicado. Siempre siga el Código Eléctrico

de EE.UU. (NEC) o el Código Eléctrico Canadiense

(CSA), además de todos los códigos locales, estatales

y provinciales. Las preguntas acerca del código deben

ser dirigidas al inspector eléctrico local. Si se hace caso

omiso a los códigos eléctricos y normas de seguridad

de OSHA, se pueden producir lesiones personales o

daños al equipo. Si se hace caso omiso a las instrucciones de instalación del fabricante, se puede producir

electrochoque, peligro de incendio, lesiones personales o aún la muerte, daños al equipo, rendimiento

insatisfactorio y podría anularse la garantía del fabricante.

15

Page 16

3: DISEÑO DEL SISTEMA

3: DISEÑO DEL SISTEMA

NOTA: Los sistemas DEBEN ser diseñados por técnicos capacitados únicamente y cumplir con todos los re-

querimientos de los códigos estatales y locales correspondientes.

Los siguientes diagramas muestran un sistema típico que utiliza el sistema de presión constante Aquavar ABII. Puede

hacerse la conexión directamente a un suministro de agua o puede extraerse agua de un tanque de suministro. El

diagrama #1 muestra una instalación típica de un tanque de suministro.

Suministro domiciliario

Control

Aquavar ABII

Cortacircuito

Disyuntor

Diagram 1

Instalación Recomendada

de Aquavar ABII para

Sistemas de Bombas

de Pozo

Manómetro

Gauge

Tanque

Motor/Pump

Válvulas de retención

Válvula de aislamiento

Empalmes

Válvula de

desahogo

Válvulas de retención

(no incluida)

Drenaje

Válvula de

aislamiento

Suministro de pozo

Tanque de

almacena-

miento

atmosférico

El diagrama #2 muestra una instalación típica para una conexión de agua municipal. Esto permite mantener la bomba

sin tener que cerrar la línea principal.

Suministro domiciliario

Suministro de pozo

Válvulas de retención

Válvula de

Control

aislamiento

Aquavar ABII

Corta-

circuito

Empalmes

Manómetro

Disyuntor

Diagram 2

Instalación

Recomendada de

Aquavar ABII para Sistemas de Agua Municipal

16

Gauge

Tanque

Motor/Pump

Válvula de

desahogo

Válvulas de retención

(no incluida)

Drenaje

Nota: Puede

ser necesaria

una válvula de

verificación

o válvula de

verificación doble

en el lado de

succión de la

bomba. Consulte

los códigos

locales.

Page 17

ADVERTENCIA

Presión

Peligrosa

PRECAUCIÓN

ADVERTENCIA

Tensión

peligrosa

Presión

Peligrosa

PRECAUCIÓN

Presión

Peligrosa

PRECAUCIÓN

Presión

Peligrosa

PRECAUCIÓN

4: TUBERÍAS

4: TUBERÍAS

Generalidades

NOTA: Todo el trabajo de plomería debe ser realizado

por un técnico calicado. Siempre cumpla con todos

los códigos locales, estatales y provinciales.

Una instalación apropiada requiere una válvula de alivio

de presión, un accesorio roscado N.P.T. hembra de ¼

pulgada (encontrado en el perl T del tanque) para el

sensor de presión y tubería de tamaño apropiado. La

tubería no debe ser más pequeña que las conexiones

de descarga o succión de la bomba. La tubería debe

mantenerse lo más corta posible. Evite utilizar accesorios

innecesarios para reducir al mínimo las pérdidas por

fricción.

Algunas combinaciones de bomba y motor

suministradas con este sistema pueden crear

más de 200 PSI. Seleccione las tuberías

y accesorios de acuerdo con la recomendación de su

proveedor de tuberías. Consulte los códigos locales con

respecto a requisitos de tuberías en su área.

Todas las juntas deben ser herméticas. Utilice cinta de

Teon u otro tipo de sellador de tubos para sellar las

conexiones roscadas. Tenga cuidado cuando utilice

sellador de roscas ya que cualquier exceso que entre a la

tubería podría tapar el sensor de presión.

Los accesorios o tuberías galvanizadas nunca deben

conectarse directamente a la carcasa o al cabezal de

descarga de acero inoxidable ya que podría producirse

corrosión galvánica. Los conectores tipo arpón siempre

deben sujetarse con doble abrazadera.

Tanque de presión, válvula de alivio de presión

y tubería de descarga

Los tanques Hydro-Pro estándar tienen una carga

previa de 38 PSI. Fije la presión del tanque, mientras

que el tanque está vacío del agua, a 20 PSI debajo de

la conguración deseada de la presión de sistema. Por

ejemplo, para una presión de sistema de 50 PSI, cargue el

tanque a 30 PSI. Utilice el valor más alto de precarga del

tanque si la presión del sistema varía más de 5 lbs./pulg.

cuadrada a una velocidad de ujo constante. Utilice sólo

tanques “precargados” en este sistema. No utilice tanques

galvanizados. Seleccione un área que siempre esté a más

de 34º F (1.1º C) en la cual instalar el tanque y la válvula

de alivio de presión. Si éste es un lugar donde una fuga

de agua o purga de la válvula de alivio de presión podría

producir daños materiales, conecte una línea de drenaje

a la válvula de alivio de presión. Conecte una línea de

drenaje desde la válvula de alivio de presión a un drenaje

apropiado o a un lugar donde el agua no produzca daños

materiales. Utilice el perl T del tanque suministrado

para conectar la tubería de descarga al tanque de presión

y la cañerías de la casa. Se puede bombear a lugares

múltiples.

La presión máxima de funcionamiento de

la mayoría de los tanques HydroPro es

125 PSI. Verique los datos en la etiqueta del tanque o su

manual de instrucciones.

Instalación de la bomba

ADVERTENCIA: Riesgo de

electrochoque – Este sistema

de bomba no ha sido evaluado

para usarse en áreas de albercas.

Conecte la succión y descarga de la bomba

a una tubería. Asegúrese de instalar una

válvula de retención en el lado de succión

de la bomba. Deje un mínimo de 6 pulgadas de tubería

recta entre la válvula de retención y la succión de la

bomba. Sitúe la bomba lo más cerca posible a la fuente de

líquido. Cuando bombee desde un tanque atmosférico,

sitúe la bomba por debajo del nivel del líquido en el

tanque. Todas las tuberías deben estar apoyadas en

forma independiente de la bomba. Instale una válvula

de vericación entre la descarga de la bomba y el sensor

de presión y tanque. Para obtener más información,

consulte las instrucciones de instalación, operación y

mantenimiento suministradas con la bomba.

Instalación del sensor de presión

Instale el sensor de presión en el perl T del tanque

suministrado con la unidad. El cable del sensor de

presión suministrado con el controlador es de 120

pulg. de largo. Sitúe el controlador de manera que haya

suciente cable para instalar correctamente el sensor de

presión.

No instale ninguna válvula de cierre, ltros

o dispositivos de control de ujo/presión

(excepto una válvula de vericación) entre

el sensor de presión y la descarga de la bomba ya que

esto podría crear una situación peligrosa.

SÓLO utilice el sensor de presión suministrado

con la unidad. Instale el sensor de presión en uno

de los agujeros de ¼ pulg. en el perl T del tanque

suministrado con el juego. Instale el sensor de presión

verticalmente para evitar la acumulación de detritos en el

oricio del sensor. No instale el perl T del tanque con

los agujeros de ¼ pulg. apuntando hacia abajo. Alinee el

conector en el extremo del cable del sensor de presión

con el conector correspondiente en el sensor de presión

e instálelo empujándolo. La lengüeta quedará trabada en

posición. Evite que el agua avance por el cable y entre

al conector del sensor creando un “lazo de goteo” en el

cable.

5: MONTAJE DEL CONTROLADOR

5: MONTAJE DEL CONTROLADOR

Generalidades

Monte el controlador en un área sombreada y bien

ventilada utilizando el juego de montaje suministrado. El

controlador debe montarse vertical. Asegúrese de dejar

8 pulgadas de espacio libre a cada lado de la unidad. El

controlador debe estar en un lugar con una temperatura

ambiente de 34º F (1.1º C) a 104º F (40º C). Consulte

17

Page 18

con la fábrica acerca de la especicación para reducir la

ADVERTENCIA

Tensión

peligrosa

Tensión

p

eligrosa

PELIGRO

Tensión

p

eligrosa

PELIGRO

Tensión

p

eligrosa

PELIGRO

Tensión

p

eligrosa

PELIGRO

Tensión

p

eligrosa

PELIGRO

Tensión

p

eligrosa

PELIGRO

Tensión

p

eligrosa

PELIGRO

capacidad nominal. Si la instalación es más de 3300 pies

sobre nivel del mar, la salida del mecanismo impulsor se

debe también reducir la capacidad normal por el 2% por

1000 pies sobre 3300 pies.

NOTA: No bloquee los disipadores de calor (aletas) y

no coloque nada sobre las unidades.

La cubierta de acceso del controlador

siempre debe estar rmemente aanzada

a la caja de control debido a la tensión

peligrosa / peligro de electrochoque en el interior de la

unidad.

6: FUENTE DE ALIMENTACIÓN Y CABLEADO

6: FUENTE DE ALIMENTACION Y CABLEADO

Fuente de alimentación

The 1151AB2 Controller requires a single

phase power supply of 115 volts +/– 15%.

The 1AB2 and 2AB2 Controllers require

a single phase power supply of 230 volts +/– 15%. All

controllers require a dedicated 20 amp two-pole circuit

breaker. ¡Un circuito dedicado signica que ningún otro

artefacto utiliza el mismo circuito! La potencia de salida

del controlador del motor es trifásica, de frecuencia

variable y de tensión variable. La tensión de salida y la

frecuencia máximas son la tensión de entrada de línea y

60 Hz, respectivamente. La baja tensión de suministro

reducirá el rendimiento de la bomba.

Conexión del suministro eléctrico de entrada

Conecte los conductores de la fuente de

alimentación monofásica y el alambre de

tierra de seguridad desde un cortacircuitos

bipolar de 20 amperios (en posición OFF (apagada) a

un lado de un interruptor de desconexión bipolar de

20 amperios. Conecte los conductores de suministro

eléctrico de entrada con el controlador al otro lado del

interruptor de desconexión. Asegúrese de utilizar tuboconducto metálico con conectores metálicos para las

conexiones eléctricas.

El controlador tiene alta corriente de fuga a

tierra. Los terminales marcados “GND” en

el controlador deben conectarse a la tierra

de seguridad desde la entrada del servicio eléctrico. Si el

controlador o el motor no se conecta correctamente a

tierra, se creará un peligro de electrochoque.

NOTA: No utilice protección de GFCI (interruptores

de circuito accionados por corriente de pérdida a

tierra) con este controlador. Si lo hace, se producirán

disparos falsos.

7: ARRANQUE DEL SISTEMA

7: ARRANQUE DEL SISTEMA

¡La luz indicadora del código de estado

no es un indicador de tensión! Siempre

apague el interruptor de desconexión y el

cortacircuitos antes de dar servicio.

NOTA: La instalación y el mantenimiento DEBEN

ser realizados por personal apropiadamente capacitado y competente. Siempre siga el Código Eléctrico

de EE.UU. o el Código Eléctrico Canadiense, además

de todos los códigos locales, estatales y provinciales

cuando cablee el sistema.

Cable y tubo-conducto

No use cable más pequeño que 14 AWG. Se recomienda

utilizar tubo-conducto metálico con conectores metálicos

para todas las conexiones eléctricas.

Conexiones de suministro de salida

Conecte los conductores del motor para

una operación de 230 voltios o 208 voltios

utilizando la placa de identicación del

mismo como referencia. Conecte los conductores de

suministro eléctrico de salida del controlador a los

tres conductores del motor en la caja de conductos del

motor. Conecte el conductor de suministro eléctrico de

salida (verde) de puesta a tierra al tornillo de puesta a

tierra en la caja de conductos del motor. Esto se realiza

en la fábrica para los sistemas completos. Los cables

del controlador al motor no deben ser más largos que

aquellos suministrados por la fábrica. Ver los detalles en

el diagrama 4.

NOTA: Si la bomba tiene más de 50 pies de alambre

del regulador, consulte la fábrica para la selección de

un ltro de la carga de la salida (reactor de la carga).

18

Una vez que el controlador esté energizado

permanecerá eléctricamente cargado

durante 5 minutos después que el

suministro eléctrico se haya apagado. Espere 5 minutos

después de desconectar el suministro eléctrico antes de

abrir la cubierta de acceso del controlador ya que existe

un peligro serio de electrochoque.

Ajuste de los interruptores de sobrecarga del

motor

Cuando se energiza la unidad, los

interruptores de ajuste de sobrecarga del

motor están a un potencial de alta tensión.

NO toque los interruptores de ajuste de sobrecarga del

motor mientras el suministro eléctrico está activado.

Los interruptores de ajuste de sobrecarga del motor

ajustan el nivel de protección del motor necesario para

que no se ocasionen daños debido a condiciones de

sobrecorriente. Gire el cortacircuitos y el interruptor

de desconexión a la posición de apagado, y espere 5

minutos. Quite la cubierta de acceso del controlador. En

el interior de la cubierta de acceso está la tabla de ajuste

de sobrecarga del motor. Ver los detalles en el diagrama

6. Esta tabla indica las posiciones del interruptor para

obtener la protección contra sobrecargas deseada.

Lea el factor de servicio en amperios de la placa de

identicación del motor. Utilice la tabla de ajuste de

sobrecarga del motor para hacer coincidir los amperios

Page 19

Tensión

p

eligrosa

PELIGRO

Tensión

p

eligrosa

PELIGRO

del factor de servicio del motor con el ajuste correcto

del interruptor. Ajuste los interruptores de sobrecarga

del motor de acuerdo con la combinación correcta

indicada en la tabla. Si los amperios del factor de servicio

del motor no coinciden con ninguno de los ajustes de

sobrecarga del motor, utilice el ajuste del interruptor

inmediatamente más bajo. Ver los detalles en el diagrama

3.

NOTA: Los interruptores de ajuste de sobrecarga

del motor se preajustan en la fábrica para sistemas

completos.

PRECAUCIÓN

Si no se sigue este paso, el motor perderá

su protección contra las sobrecargas y se

anulará la garantía del mismo. Si estos interruptores no

se ajustan correctamente, pueden ocurrir disparos falsos

o erróneos con respecto a sobrecarga del motor.

Ajuste de la presión

Gire el cortacircuitos y el interruptor de desconexión

a la posición de apagado, y espere 5 minutos. Quite la

cubierta de acceso del controlador. Abra una llave en

el sistema y coloque el cortacircuitos/interruptor de

desconexión en la posición ON (encendido). La bomba

arrancará y la presión aumentará al valor prejado de

fábrica de 50 lbs./pulg. cuadrada. Después que la presión

se haya estabilizado, utilice los pulsadores de ajuste de

aumento/disminución en el lado derecho del controlador

para ajustar el valor de presión. Oprima y mantenga

oprimido el pulsador de ajuste de aumento/disminución

de presión hasta alcanzar el valor deseado. El nuevo valor

de presión se retiene automáticamente. Cierre la llave y

apague el controlador. Espere 5 minutos antes de instalar

la cubierta de acceso del controlador.

NOTA: La conguración máxima permitida de la

presión es 85 PSI.

Ajuste de los interruptores de aplicación

Cuando se energiza la unidad, los

interruptores de ajuste de aplicación están

a un potencial de alta tensión. NO toque

los interruptores de ajuste de aplicación mientras el

suministro eléctrico está activado.

El controlador tiene 6 posibles ajustes de aplicación.

Estos ajustes se utilizan para ajustar la velocidad

mínima del motor y el ajuste de incremento, o incremento de aceleración y desaceleración. Esto permite

que el controlador se adapte a una amplia gama de

aplicaciones.

Antes de ajustar los interruptores de aplicación, coloque el cortacircuitos y el interruptor de desconexión

a la posición de apagado. Espere 5 minutos. Quite la

cubierta de acceso del controlador. En el interior de

la cubierta de acceso está la tabla de ajuste del interruptor de aplicación. Esta tabla muestra el ajuste de

los interruptores necesario para obtener la respuesta

deseada del sistema. Ver los detalles en el diagrama 3.

Seleccione una velocidad mínima de 10 Hz si la pre-

sión en la succión de la bomba es de menos de 20 PSI

del valor de presión deseado. Seleccione una velocidad mínima de 30 Hz si la presión en la succión de la

bomba es de más de 20 PSI por debajo de la presión

deseada o si está bombeando desde un tanque.

Al cambiar el ajuste de incremento se cambia la rapidez con que el controlador puede cambiar la velocidad del motor. Un ajuste de incremento lento permite

que el controlador funcione mejor en aplicaciones

donde la demanda promedio de agua es baja (menos

de 3 GPM o aproximadamente una llave). Un ajuste

de incremento rápido permite que el controlador

funcione mejor en aplicaciones donde la demanda de

agua es alta ya que se permite que el motor cambie

de velocidad en forma más rápida.

NOTA: Los interruptores de aplicación vienen

preajustados de fábrica a “0000” o velocidad mínima

= 30 Hz, ajuste de incremento = rápido.

Dirección de rotación del motor

Si la presión o el ujo parece bajo, verique la dirección

de rotación del motor. Gire el cortacircuitos y el

interruptor de desconexión a la posición de apagado, y

espere 5 minutos. Cambie dos conductores cualquiera

en la salida del controlador (T1, T2 o T3). Gire el

cortacircuitos y el interruptor de desconexión a la

posición de encendido. Observe la presión y el ujo.

Si la presión o el ujo aún parece bajo, inspeccione las

tuberías.

NOTA: Es posible que la bomba mantenga presión

constante con un ujo bajo o una carga de succión

positiva alta, aún si la bomba está rotando en dirección inversa. Con la bomba funcionando, utilice una

sonda de corriente en uno de los conductores de suministro eléctrico de salida conectados al motor y compare el consumo de corriente entre las dos direcciones

de rotación. La lectura con el consumo más bajo de

corriente indica que la bomba está funcionando en la

dirección correcta.

Estado del sistema

El controlador está siempre energizado. Un código de

estado verde constante indica que la bomba está en

modo de espera (la bomba no está funcionando) o que la

tensión de entrada de línea es baja.

¡La luz indicadora del código de estado

no es un indicador de tensión! Siempre

apague el interruptor de desconexión y el

cortacircuitos y espere 5 minutos antes de dar servicio.

Un código de estado verde intermitente indica que la

bomba está funcionando. Una luz roja intermitente

o constante indica un problema con el controlador;

consulte los códigos de estado en el panel lateral de la

cubierta de acceso. Consulte la sección 9 para mayores

detalles.

19

Page 20

8: DIAGRAMAS

Tensión

p

eligrosa

PELIGRO

L1

L2 (N)

1 2 3 4 1 2 3 4

T1T2T3

Entrada,

monofásica

TIERRA

Consulte el manual

con respecto a

los ajustes de

los interruptores

Tipo de

aplicación

Salida al

motor

Sensor

de

presión

Entrada (blanco)

+5 V (rojo)

Com. (negro)

TIERRA

Ajuste de

sobre-

carga del

motor

Salida de línea al motor o

reactor de carga. La rotación

correcta del motor determina

el orden de los colores.

Sensor de

presión

9K518

Suministro eléctrico de

entrada de línea de un

cortacircuitos o interruptor

de desconexión bipolar

VERDE

NEGRO

NEGRO

VERDE

BLANC

ROJO

NEGRO

AZUL

ROJO

NEGRO

ADVERTENCIA

8: DIAGRAMAS

Ajuste de los interruptores de sobrecarga del motor y de aplicación

Cuando se energiza la unidad, los interruptores de ajuste de sobrecarga del motor y de aplicación están a

un potencial de alta tensión. Siempre apague el interruptor de desconexión y el cortacircuitos y espere 5

minutos antes de tocar los interruptores de ajuste de sobrecarga del motor o de aplicación.

Configuración del

interruptor de aplicación

Consulte el siguiente cuadro

para información sobre la

configuración correcta del

interruptor.

Diagrama 3

Diagrama de conexiones de la unidad Aquavar ABII

Interruptores de configuración

de sobrecarga del motor

Consulte el siguiente cuadro para

información sobre la configuración

correcta del interruptor.

20

No conecte 230V a un controlador de 115V. Dañará

el controlador y se anulará la garantía.

Diagrama 4

Page 21

8: DIAGRAMAS

8: DIAGRAMAS (continuación)

Placa de identificación de motor típica mostrando los amperios de factor de servicio (SF AMPS)

Los amperios de factor de servicio

(SF AMPS) que se utilizan para

ajustar los interruptores de ajuste

de sobrecarga del motor.

En este ejemplo, utilice el ajuste de 4.2 amperios indicados en la tabla de ajuste de sobrecarga del motor. Este ajuste se

utiliza para tomar en cuenta cualquier uctuación de tensión.

Diagrama 5

Rótulos en la cubierta de acceso del controlador :

Configuración de sobrecarga del motor

ADVERTENCIA

Desconecte el suministro eléctrico y espere a que el

indicador de diodo luminiscente se apague antes de tocar

los interruptores de ajuste de sobrecarga del motor.

1 = ARRIBA 0 = ABAJO

Ajuste del interruptor DIP Ajuste de sobrecarga del motor (amperios)

1 2 3 4 1AB2 2AB2

1 1 1 1 2.5 4.6

1 1 1 0 2.8 5.2

1 1 0 1 3.3 5.3

1 0 1 1 3.5 5.8

0 1 1 1 3.8 6.5

0 0 0 0 4.2 6.9

Rótulo de ajuste de sobrecarga del motor

Utilice este rótulo para seleccionar el ajuste correcto del interruptor de sobrecarga

del motor. Este rótulo está situado debajo de la cubierta de acceso del controlador.

Configuración del interruptor de tipo de aplicación

ADVERTENCIA

Ajuste del interruptor DIP

1 2 3 4 Veloc. mínima (Hz) Ajuste de incremento

1 1 1 1 * 10 Lento

1 1 1 0 * 10 Mediano

1 1 0 1 * 10 Rápido

1 0 1 1 30 Lento

0 1 1 1 30 Mediano

0 0 0 0 30 Rápido

*ESTOS AJUSTES NO DEBEN UTILIZARSE CON LAS BOMBAS SUMERGIBLES.

Desconecte el suministro eléctrico y espere a que el indicador de diodo luminiscente se apague antes de tocar los

interruptores de ajuste de sobrecarga del motor.

1 = ARRIBA 0 = ABAJO

Diagrama 6

Rótulo de ajuste

de los interrup-

tores de apli-

Utilice este rótulo

para seleccionar el

ajuste correcto del

interruptor de apli-

cación. Este rótulo

está situado debajo

de la cubierta de

acceso del contro-

cación

lador.

Códigos de estado*

Códigos de luz verde

Constante En espera/baja tensión

Intermitente

Constante Reemplace el controlador

1 parpadeo No hay agua/pérdida de cebado

2 parpadeos

3 parpadeos

4 parpadeos

5 parpadeos

6 parpadeos

7 parpadeos

8 parpadeos

9 parpadeos

*No hay luz – no hay tensión/tensión

Rótulo de código de estado

Utilice este rótulo para diagnosticar cualquier error del sistema. Este rótulo está

situado al costado de la cubierta de acceso

del controlador.

La bomba está funcionando

Códigos de luz roja

Tanque inundado con agua

Falla del sensor de presión

Bomba o motor atascado

Cortocircuito

Falla a tierra

Alta temperatura

Tensión excesiva (>264 V)

Sobrecarga del motor

muy baja

21

Page 22

9: IDENTIFICACIÓN Y RESOLUCIÓN DE PROBLEMAS

Tensión

p

eligrosa

PELIGRO

9: IDENTIFICACIÓN Y RESOLUCIÓN DE PROBLEMAS

Generalidades

La unidad Aquavar ABII es un controlador de autodiagnóstico. Si ocurre un problema, observe la luz indicadora de

código de estado en la sección delantera de la unidad. Si no hay luz indicadora de código de estado signica que no hay

tensión de entrada o que ésta es baja (menos de 50 V).

¡La luz indicadora del código de estado no es un indicador de tensión! Siempre apague el interruptor de

desconexión y el cortacircuitos y espere 5 minutos antes de dar servicio.

Consulte el rótulo de códigos de estado al costado de la cubierta de acceso del controlador para diagnosticar los errores

del sistema. Ver los detalles en el diagrama 6.

UTILICE LA TABLA SIGUIENTE COMO AYUDA PARA IDENTIFICAR Y SOLUCIONAR PROBLEMAS.

CÓDIGOS DE LUZ VERDE

Código

del indicador

Constante En espera/baja tensión La luz verde constante indica que la bomba está apagada. El sistema

está en modo de espera cuando no hay ujo en el mismo y no se ha

alcanzado el valor de presión. El sistema está en una condición de

la baja tensión cuando la línea caídas de voltaje de entrada de

información debajo de 196VAC para los reguladores 1AB2 y 2AB2 y

de 98VAC para los reguladores

Intermitente La bomba está La luz verde intermitente indica que la bomba está funcionando.

funcionando Si a bomba no está funcionando, apague el suministro eléctrico

al controlador y espere 5 minutos. Revise las conexiones de

suministro eléctrico de salida del controlador al motor.

Estado Descripción

CÓDIGOS DE LUZ ROJA

Constante Error del controlador Reemplace el controlador Aquavar ABII

1 parpadeo No hay agua/pérdida Se indica esta falla si la presión del sistema cae 5 PSI o más por debajo

de la presión congurada y la corriente de salida es inferior al 75% del

ajuste de sobrecarga del motor durante 10 segundos. El sistema se

reiniciará automáticamente en 5 minutos. Si se producen 3 fallas en

una hora, el sistema no se reiniciará y deberá ser reiniciado

manualmente. Si el problema vuelve a ocurrir, verique la capacidad

de suministro, la capacidad de bombeo, la correcta conguración de

los interruptores de sobrecarga del motor y que no haya restricciones

entre el suministro y la bomba.

2 parpadeos Tanque inundado Esta advertencia se indica si existe una caída drástica en la presión del

con agua sistema en un corto período de tiempo. La advertencia no afectará la

operación. La bomba seguirá funcionando. Esta advertencia puede ser

provocada por baja presión de aire en el tanque o una falla en la

cámara del tanque. Esto también puede ser provocado por cambios

extremos en el ujo. El error se borra cada vez que la bomba arranca.

Si el error vuelve a ocurrir con frecuencia, controle la presión de aire

en el tanque. Antes de controlar la presión de aire en el tanque,

apague la energía al control para evitar que la bomba se encienda.

Alivie la presión del sistema abriendo un grifo.

3 parpadeos Falla del sensor Esta falla indica un problema con la retroalimentación del sensor de

de presión presión. Verique las conexiones del controlador Aquavar ABII al

sensor de presión. Apague el suministro eléctrico al controlador y

espere 5 minutos. Quite el panel de acceso del controlador. Verique

que el cable del sensor está conectado en la forma mostrada en el

Diagrama 6. Si el cable está conectado correctamente, mida la tensión

en la conexión de entrada (blanca) del terminal del sensor de presión

en el controlador Aquavar ABII. Con un voltímetro de CC, conecte el

conductor positivo a la conexión de entrada (blanca) del terminal del

sensor de presión; conecte el conductor negativo a la conexión Com.

22

Page 23

9: IDENTIFICACIÓN Y RESOLUCIÓN DE PROBLEMAS

9: IDENTIFICACIÓN Y RESOLUCIÓN DE PROBLEMAS (continuación)

CÓDIGOS DE LUZ ROJA

Código

del indicador

3 parpadeos Falla del sensor (negra) del terminal del sensor de presión. Encienda el controlador.

de presión La tensión de CC medida debe estar en el intervalo válido de 0.5 Vcc

(continuación) a 4.5 Vcc (+/- 0.2 Vcc). Si la tensión está fuera de este intervalo,

reemplace el sensor de presión.

4 parpadeos Bomba o motor Esta falla puede deberse al atascamiento mecánico causado por

atascado residuos en la bomba o debido a una falla eléctrica en el motor.

Verique el error apagando el suministro eléctrico al controlador

durante 1 minuto y luego enciéndalo. Debe inspeccionarse la bomba

si el error persiste.

5 parpadeos Cortocircuito Revise el cableado para detectar un cortocircuito de fase a fase o de

fase a tierra. Apague el suministro eléctrico al controlador y espere

5 minutos. Quite el panel de acceso del controlador. Desconecte

los conductores del motor marcados T1, T2 y T3. Mida la resistencia

entre todos los conductores del motor con un ohmiómetro.

Nota: Típicamente, la resistencia del devanado del motor es de 2 a 10

ohmios, dependiendo del motor.

6 parpadeos Falla a tierra Inspeccione el cableado para detectar cortocircuitos de fase a tierra.

Apague el suministro eléctrico al controlador y espere 5 minutos.

Quite el panel de acceso del controlador. Desconecte los conductores

del motor T1, T2, T3 y la conexión a tierra del controlador. Mida la

resistencia entre todos los conductores del motor y tierra con un

megaohmiómetro. Conecte un conductor del megaohmiómetro a

cualquiera de los conductores del motor y el otro al conductor de

conexión a tierra. Ajuste el megaohmiómetro a una salida de 500 VCC.

Los valores de resistencia inferiores a 500,000 ohmios o 0.5

megaohmio indican que el motor está dañado.

7 parpadeos Alta temperatura Esta falla es causada por una temperatura alta dentro del controlador.

El controlador se apagará cuando la temperatura en su interior alcanza

158º F (70º C). El controlador se encenderá nuevamente cuando la

temperatura en su interior alcanza 150º F (65.5º C). Evite instalar el

controlador en lugares donde la temperatura ambiente excede 104º F

(40º C). Evite instalar el controlador en lugares expuestos a la luz

directa del sol.

8 parpadeos Tensión excesiva Mida la tensión de entrada con un voltímetro de CA. Conecte los

conductores positivo y negativo a L1 y L2 en el controlador

Aquavar ABII. Verique que la línea voltaje de entrada de información

no sea mayor de 264 VAC para los reguladores 1AB2 y 2AB2 y

132VAC para 1151AB2.

9 parpadeos Sobrecarga del motor Esta falla se indica cuando la corriente suministrada al motor excede el

ajuste de sobrecarga del motor en el controlador Aquavar ABII.

obtener más detalles.

la Sección 7, inspeccione el motor.

Estado Descripción

Consulte la Sección 7: Ajuste de los interruptores DIP de sobrecarga del motor para

Si los interruptores están ajustados de acuerdo con

23

Page 24

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(114.30)

4.50

(57.15)

2.25

(81.28)

3.20

(16.51)

.65

10: DIMENSIONES DEL CONTROLADOR

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(135.36)

5.33

10: DIMENSIONES DEL CONTROLADOR

(114.30)

4.50

(8.38)

.33

(242.04)

9.53

(232.56)

9.16

(57.15)

2.25

(81.28)

3.20

(16.51)

.65

dispositivo

impermeable

de

1

⁄2 pulgada

(259.08)

10.20

(12.07)

.48

(237.06)

9.33

(135.36)

5.33

(99.06)

3.90

(157.90)

6.22

GARANTÍA LIMITADA

Esta garantía es aplicable a este Xylem Inc. el producto.

Toda parte o partes que resultaren defectuosas dentro del período de garantía serán reemplazadas durante dicho período de garantía sin cargo para el comerciante. Tal período de

garantía se extiende por veinticuatro (24) meses a partir de la fecha de instalación, o treinta (30) meses a partir de la fecha de fabricación, la que se cumpla primero.

El comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Xylem Inc. del cual adquiriera la equipo y

brindar información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los reclamos por garantía a través del Departamento de Servicios a Clientes de

Xylem Inc.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Xylem Inc. y el comerciante para la compra, consignación o

contratos de venta de las equipo en cuestión.