Page 1

Variable Speed

Pump Control

New Sizes Addendum*

(August 2004)

Models covered:

04168321 - 2 HP - single phase, 230V

04168331 - 3 HP - single phase, 230V

04169131 - 5 HP - single/three phase, 230V*

04169141 - 7

1

⁄

2 HP - single/three phase, 230V*

04169181 - 10 HP - single phase, 230V*

04169151 - 10 HP - three phase, 230V*

04168371 - 5 HP - three phase, 460V

04168491 - 7

1

⁄2 HP - three phase, 460V

04168501 - 10 HP - three phase, 460V

AQUAVAR

®

G L Pumps

IM154R01

U

®

L

Goulds Pumps

ITT Industries

Page 2

AQUAVAR Controller Technical Data:

AQUAVAR Controller Motor Supply Voltage Recommended

Part Nos. Rated Output Voltage Current 40-60 Hz Circuit Protection

(1)

04168321 2 HP 3 ph 230V 7A

Single Phase

15 Ampere

240 VAC ± 10%

04168331 3 HP 3 ph 230V 10A

Single Phase

15 Ampere

240 VAC ± 10%

04168371 5 HP 3 ph 460V 9A

Three Phase

15 Ampere

380-460 VAC ± 15%

04168491 71⁄2HP 3 ph 460V 131⁄2A

Three Phase

20 Ampere

380-460 VAC ± 15%

04168501 10 HP 3 ph 460V 17A

Three Phase

25 Ampere

380-460 VAC ± 15%

AQUAVARController

(2) Motor Circuit Protection Circuit Protection

Part Rated

Supply V oltage

Input

Input V oltage Current

Single Phase Three Phase

Number Output Frequency INPUT (1) INPUT (1)

(HP) 40-60 Hz (Hz) Phase (V) (A) Fuse Size (A) Fuse Size (A)

04169131 5 220-240 VAC +/- 15% 48....62 1 or 3 ph 3 ph 230V 15 40 20

04169141 71/

2 220-240V AC +/- 15% 48....63 1 or 3 ph 3 ph 230V 22 60 30

04169181 10 220-240VAC +/- 15% 48....64 1ph only 3 ph 230V 28 70 NA

04169151 10 220-240VAC +/- 15% 48....64 3ph only 3 ph 230V 28 NA 40

NOTE: (1) Recommended short circuit protection is UL Type T, very fast acting fuses.

(2) Dimensions are similiar to the 5, 71/

2 and 10 HP, 3 phase, 460 Volt units.

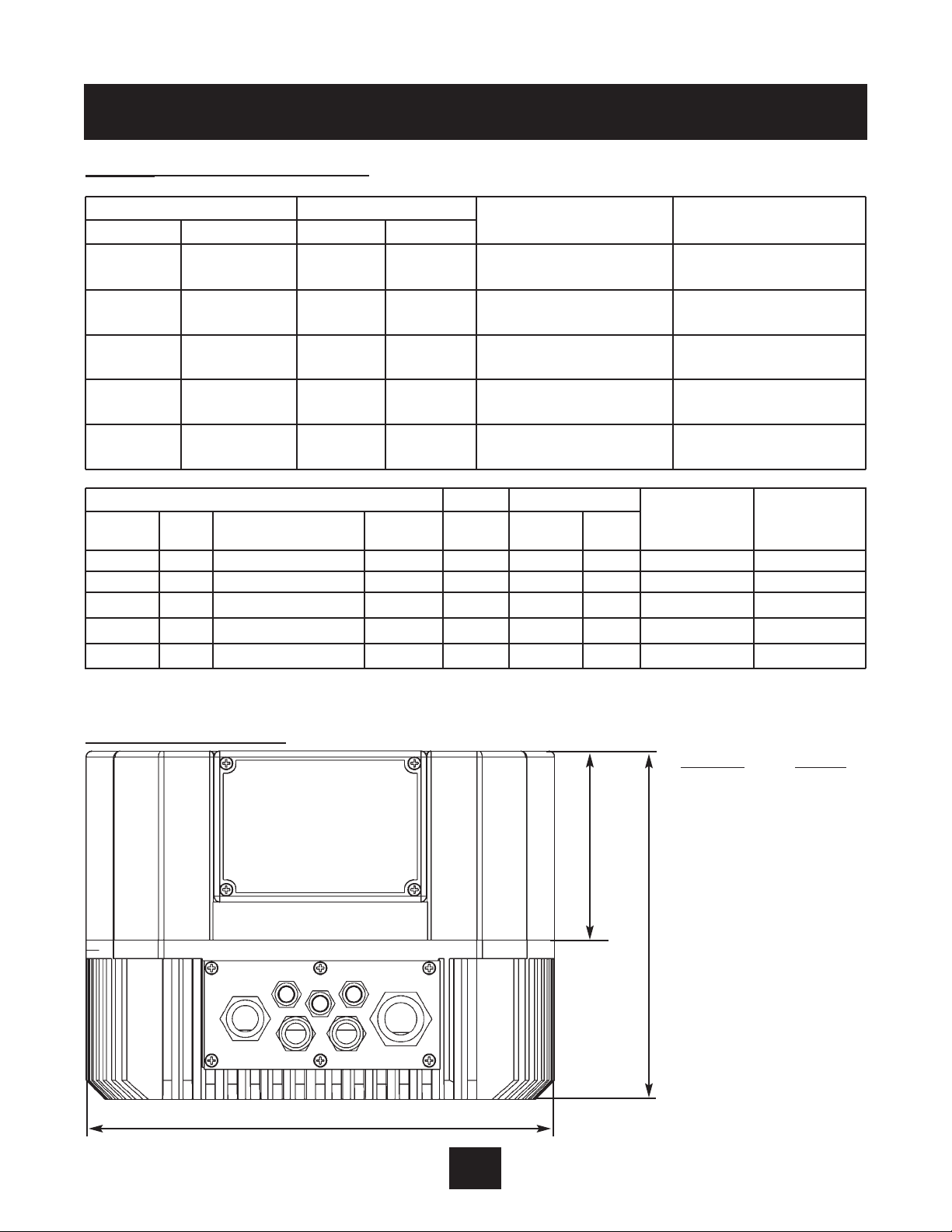

Dimensions and Weights

Part Nos. Weight

04168321 12 lbs.

04168331 12 lbs.

04168371 12 lbs.

04168491 22 lbs.

04168501 22 lbs.

For other technical data,

see Appendix B

of IM043R07.

NOTE: All motors must be

at least 3 phase, TEFC,

Class B design.

AQUAVAR

Ø195 (2–5 HP)

Ø280 (7

1

⁄2–10 HP)

100

185

* Dimensions are in mm.

1 inch = 25.4 mm

1

Page 3

2

AQUAVAR

Electrical Connections (Line Reactors)

Input Line Requirements

Line Voltage

See the Power and Current Ratings table for the allowable fluctuation of AC line voltage for your

particular model. A supply voltage above or below the limits given in the table will cause the

drive to trip with either an overvoltage or under voltage fault.

To verif y power quality, consult your local power utility for a chart recorder.

Exercise caution when applying the AQUAVAR controller on low-line conditions.

For example, and AQUAVAR controller will operate properly on a 208 Vac line – but the maximum

output voltage will be limited to 208 Vac. Now if a motor rated for 230 Vac line voltage is

controlled by this drive, higher motor currents and increased heating will result.

Therefore, ensure that the voltage rating of the motor matches the applied line voltage.

Use of Isolation Transformers and Line Reactors

The AQUAVAR controller is is per fectly suitable in most cases for direct connection to a power source

as specified in this manual and the technical nameplate affixed to the unit. There are however a

few cases where a properly sized isolation transformer

or line reactor should be employed to

minimize the risk of drive malfunction, damage or nuisance tripping:

• As noted in

Table 7

, transformer sizing, when line capacity is greater than 10 times the KVA

rating of the drive. Consult the factory for assistance in sizing the line reactor.

• When power factor correction capacitors are employed on the drive’s power source.

• When the power source is known to be subject to transient power interruptions or

significant voltage spikes.

• When the power source supplying the drive also supplies large devices such as DC drives

that contain controller rectifiers.

• When power quality or known transient voltage spikes is suspected or questioned.

Table 7: Transformer Sizing for the AQUAVAR Controller

Controller HP 1 2 3 5 7.5 10 15 20 25 30 40 50 60 75

Transformer kVA 2 4 5 9 13 18 23 28 36 42 56 70 90 112

* Consult factory for more information, if needed.

Page 4

3

AQUAVAR

Mounting P

rocedure

Components Included

(4) Screw M 5 x 60 (1) Thermal Resistor Cable Gland (4) Motor Mounting Clamp

Mounting

Gasket

4 screws

M5x50

Center bit

Transducer

Display

changeable

to 180º

Connection

motor

conduit box

Thermistor

4 mounting

clamps

Mounting:

• Remove the 3 screws from the

AQUAVAR cover.

• Place the center bit in the

AQUAVAR heat sink.

• Place the AQUAVAR on the motor.

• Hang the 4 clamps by the heat

sink and mount with the 4 screws.

• Mount the cover with the

3 screws (remember to use the

gaskets).

• Depending on pump orientation,

the display can be rotated 180º.

Page 5

4

AQUAVAR

Wiring P

rocedure

– Single Phase Connections (2, 3, 5, 71⁄2 and 10 HP)

– Three Phase Connections (5, 7

1

⁄2,10 and 15 HP)

AQUAVAR

®

AQUAVAR

®

RS485 Interface

Control Terminals

RS485 Interface

Control Terminals

Power Supply Motor Connection

1x230 VAC 3 Phase Out

L=L

1

, N=L

2

U V W

Power Supply Motor Connection

3x400 VAC 3 Phase Out

L

1

, L2,L

3

U V W

Page 6

5

AQUAVAR

Pin Connection

(to display)

40 Pin Connection

(to power board)

DIP - Switch

SW 4

24VDC Output

(max. 800mA)

for External Fan

RS485

Terminals

Motor ConnectionControl Terminal BlockMain Supply

Main P

arts of the Control Board (PN# 2509641)

Dip-Switch on the Controller Board

SW4: DIP-Switch to Select the Switching Frequency

Before switching, disconnect the power supply, otherwise

the AQUAVAR could be destroyed.

SW 4 Switching Frequency

12

OFF OFF 8 kHz (Standard)

ON OFF 5 kHz

OFF ON 4 kHz

ON ON 2.5 kHz* *Recommended for submersible motors.

NOTE

Lower switching frequencies reduce heat in motor,

but increase audible noise.

For complete wiring procedures, refer to page 18 of IM043R07.

For complete programming procedures, refer to page 26 of IM043R07.

SW 4

2

1

8

ATTENTION

Page 7

6

AQUAVAR

F

ront Plate

The diagram below shows the location of the programming keys and displays on the new

AQUAVAR models. Use this illustration with the programming steps in IM043R07.

nd

2

I

+

ON

RUNPOWER

AQUAVAR

Power

Run

FAULT

®

0

Sch 60.25

OFF

Select

*

Fault

Page 8

G L Pumps

©2004 ITT Water Technology, Inc.

September, 2004 1 Goulds Drive

Printed in U.S.A. Auburn, NY 13021

AQUAVAR LIMITED WARRANTY

This warranty applies to all new style AQUAVAR controllers referenced on the front of this booklet.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the distributor during the warranty period. The warranty period shall exist for a period of twenty four (24) months from

date of installation or thirty (30) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Pumps distributor from

whom the AQUAVAR was purchased and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Pumps Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) "Distributor" means any individual, partnership, corporation, association, or other legal relationship that

stands between Goulds Pumps and the dealer in purchases, consignments or contracts for sale of the

subject pumps.

(2) "Dealer" means any individual, partnership, corporation, association or other legal relationship which

engages in the business of selling or leasing pumps to customers.

(3) "Customer" means any entity who buys or leases the subject AQUAVAR from a dealer. The "customer" may

mean an individual, partnership, corporation, limited liability company, association or other legal entity

which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Goulds Pumps is a brand of ITT Water Technology, Inc. a subsidiary of ITT Industries, Inc.

AQUAVAR, G&L Pumps and Goulds Pumps and

the ITT Engineered Blocks Symbol are registered

trademarks and tradenames of ITT Industries.

www.goulds.com

Goulds Pumps

ITT Industries

Loading...

Loading...