Page 1

RED JACKET

Water Products

Sump Pump

Sump Pump

Installation and Operation Manual

®

Vertical

Vertical

Model Number:

Serial Number:

Code:

Dealer:

Dealer Phone No.

Purchase Date:

Installation:

IM152R00

Owner’s Information

Owner’s Information

SUBJECT PAGE

General Information ...................................................... 2

Sump Pit........................................................................ 2

Installation .................................................................... 2

Troubleshooting ............................................................. 3

Maintenance .................................................................. 3

Red Jacket Water Products Limited Warranty .................. 4

www.redjacketwaterproducts.com

Table of Contents

Table of Contents

Page 2

General Information

General Information

• Before installation, read the following instructions

carefully. Each pump is individually factory tested to

assure proper performance. By closely following these

instructions, potential operating problems should be

eliminated, providing years of trouble-free service.

WARN ING

Hazardous

voltage

RISK OF ELECTRIC SHOCK. Always

disconnect the pump from the power

source before handling or making adjustments.

• Always wear rubber boots when water is on the floor and

you must unplug the pump. Make sure the pump power

source is a separately fused, grounded 3-wire type

receptacle of 15 amp capacity. DO NOT REMOVE

GROUND PRONG OR PLUG. DO NOT USE AN

EXTENSION CORD. Check to make sure installation is

in accordance with the National Electric code and all

applicable local codes.

• Tools required for installation are a) pipe wrench, b)

regular screw driver, and c) hacksaw (for replacement or

removal of existing rigid piping.)

• DO NOT use pumps in water over 140° F.

• DO NOT drain hot water heaters into the sump pit

when servicing.

• DO NOT use pumps in mud, sand, cement, oil or

chemicals

• DO NOT modify the pumps in any way.

Sump Pit

Sump Pit

2. *SEE NOTE BELOW. Set the new pump in place

making sure the float switch has adequate clearance and

will not hang-up on the pit wall.

1

⁄4" threaded discharge is provided on the pump for

3. A 1

connection to the discharge pipe. Do not reduce the

discharge size to below 1

1

⁄4" as this will affect pump flow

and performance. Schedule 40 PVC pipe is recommended; however, flexible discharge hose kits may be

used for temporary installations.

4. Connect the pipe or the discharge hose to the discharge

of the pump. HAND TIGHTEN ONLY. Overtightening

may cause the pump housing to crack.

5. Install a union or other means of separating the discharge pipe just above the floor to facilitate removal of

the pump if necessary. A check valve is recommended

just above or in place of the union to prevent the

backflow of water after each pump cycle.

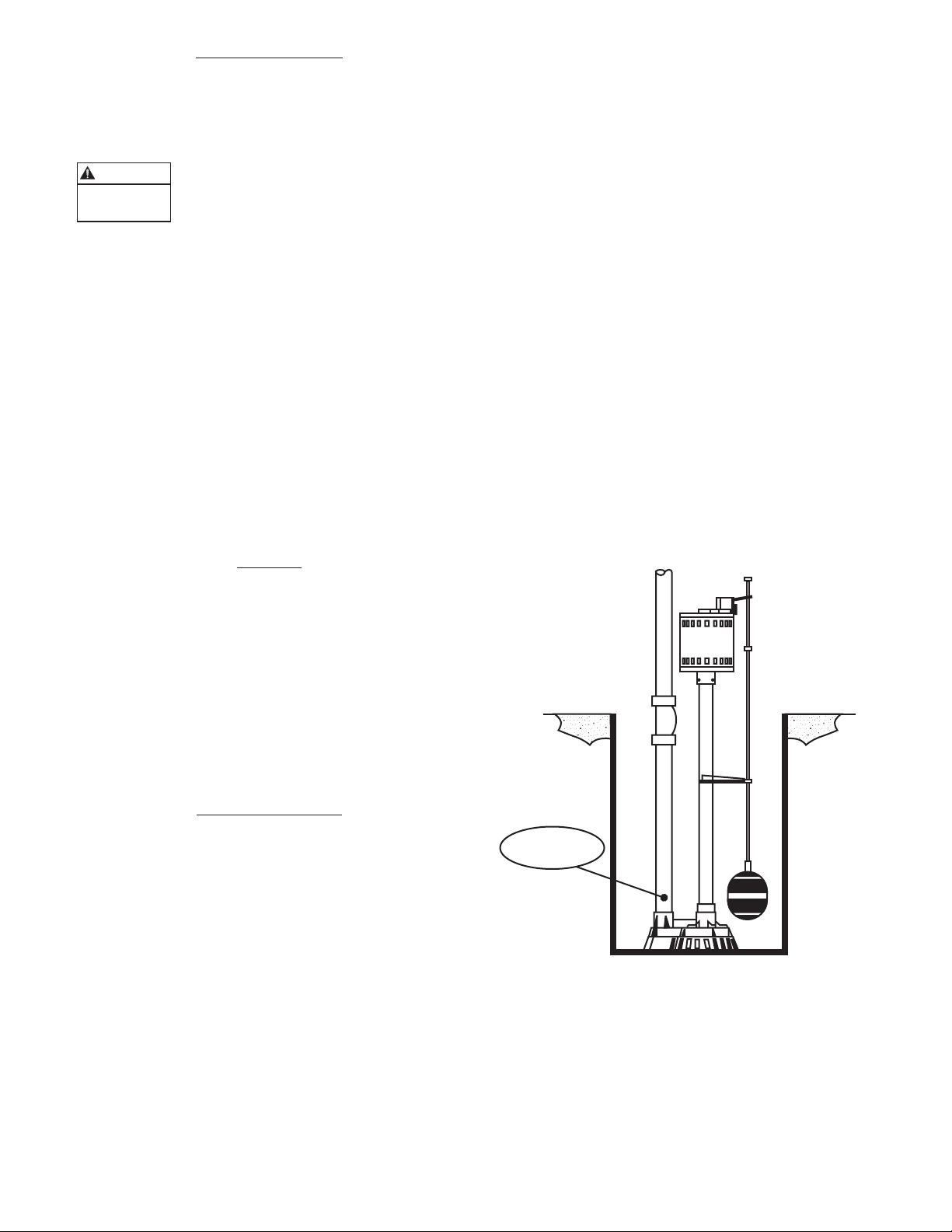

If a check valve is used, a 1⁄8" air bleed hole should be

drilled in the discharge pipe just above the pump’s

discharge outlet to prevent pump “airlock”. See

Figure A. A small spray of water out of this hole is

normal while pump is running.

6. Connect additional pipe as necessary to direct the

discharge to the desired location. Discharge should be

kept as short as possible with a minimum number of

turns. Check all connections for leaks.

11⁄4" DISCHARGE

1. A sump pit not less than 14" in diameter is

recommended. A larger diameter pit is preferred as it

allows for a longer pumping cycle and reduced switch

cycling.

2. If the pit is not already enclosed on the bottom, provide

a hard level bottom of bricks or concrete. DO NOT

place the pump directly on earth, gravel or debris since

this can cause excessive wear of the impeller and possible

jamming. Remove all debris from the bottom of the

sump pit before installation of the pump. A sump pit

cover is suggested for safety and to prevent foreign

objects from entering the pit.

Installation of Pump

Installation of Pump

1. Removal of old pump:

NOTE: DISCONNECT PUMP FROM POWER

SOURCE BEFORE HANDLING.

Separate the discharge pipe at either the check valve or at

the union. If neither a check valve or union is part of the

existing discharge pipe, cut the pipe just above floor level

with a hacksaw and remove the pump. (A union or check

valve will need to be installed at this cut.)

1

⁄8" AIR-BLEED HOLE

Figure A

*NOTE: Pedestal pumps require assembly of the float, rod

and guide. Snap the plastic rod guide into its position with

its pin located in the center hole on the column of the

pump. Insert the threaded end of the float rod down

through the hole in the guide and attach the float ball to

the threaded end. Remove the upper rubber stop and insert

the rod through the hole in the switch arm. Replace the

upper rubber stop at least 1⁄2" from the end of the rod.

2

Page 3

Tr oubleshooting

Troubleshooting

WARN ING

Hazardous

voltage

This guide is designed to help identify reasons for potential

operating problems. It is not a service guide.

DISMANTLING OF PUMP VOIDS WARRANTY.

Servicing of pump other than simple cleaning of pump inlet

or impeller should be referred to the factory or its authorized service centers.

NOTE: The manufacturer assumes no responsibility for

PUMP DOES NOT RUN OR HUM:

1) Line circuit breaker may be off, tripped or loose. Have

a certified electrician check fuse or breaker.

2) Water level in pit may be too low to activate switch.

Add more water to pit.

3) Plug on power cord may not be making contact in

receptacle. Check security and connection.

4) Float may be obstructed. Make sure float is free and not

interfering with the pit wall or other obstruction.

5) If all symptoms check OK, the motor winding may be

open. Consult factory.

PUMP RUNS OR HUMS BUT DOES NOT DELIVER

WATER:

1) Check valve may be installed backwards or is defective.

Check to make sure it is installed properly and flapper

in valve is free to move.

2) Discharge line may be blocked or frozen. Check to see

if line passes through cold areas or is blocked.

3) Pump may be air-locked. Make sure air bleed hole was

drilled in discharge pipe. See Figure A for proper

location of bleed hole.

4) Vertical lift is beyond pump’s capability. Pump’s

maximum lift capability is 17'.

NOTE: At the pump’s maximum lift there will be

5) Inlet screen of pump is plugged or the impeller is

jammed. Remove the pump screen and clean inlet and

impeller.

PUMP RUNS AND REMOVES WATER BUT DOES

NOT SHUT OFF:

1) Float is stuck in the “ON” position. Check to make

sure the float is free to move up and down without

obstruction.

2) Switch is defective. Consult factory.

PUMP RUNS BUT DELIVERS VERY LITTLE WATER.

1) Vertical lift is approaching the pump’s maximum lift

capability. Refer to the above maximum lift chart.

2) Pump’s inlet is partially blocked. Check to make sure

the inlet is clear of debris.

3) Discharge line is partially blocked. Check for blockage.

4) Check valve is not opening all the way. Check for

defective or blocked check valve.

ALWAYS DISCONNECT THE PUMP

FROM POWER SOURCE BEFORE

HANDLING.

damage or injury due to disassembly.

no flow.

CIRCUIT BREAKER TRIPS OR FUSE BLOWS WHEN

PUMP STARTS

1) Fuse or breaker size is too small. A 15 amp breaker

should be used.

2) Other major appliances are on the same circuit. Pump

should be on its own circuit.

3) Pump is connected to an extension cord or wiring is

inadequate. Have an electrician check for proper

wiring.

4) Defective motor or switch. Consult factory.

Maintenance

Maintenance

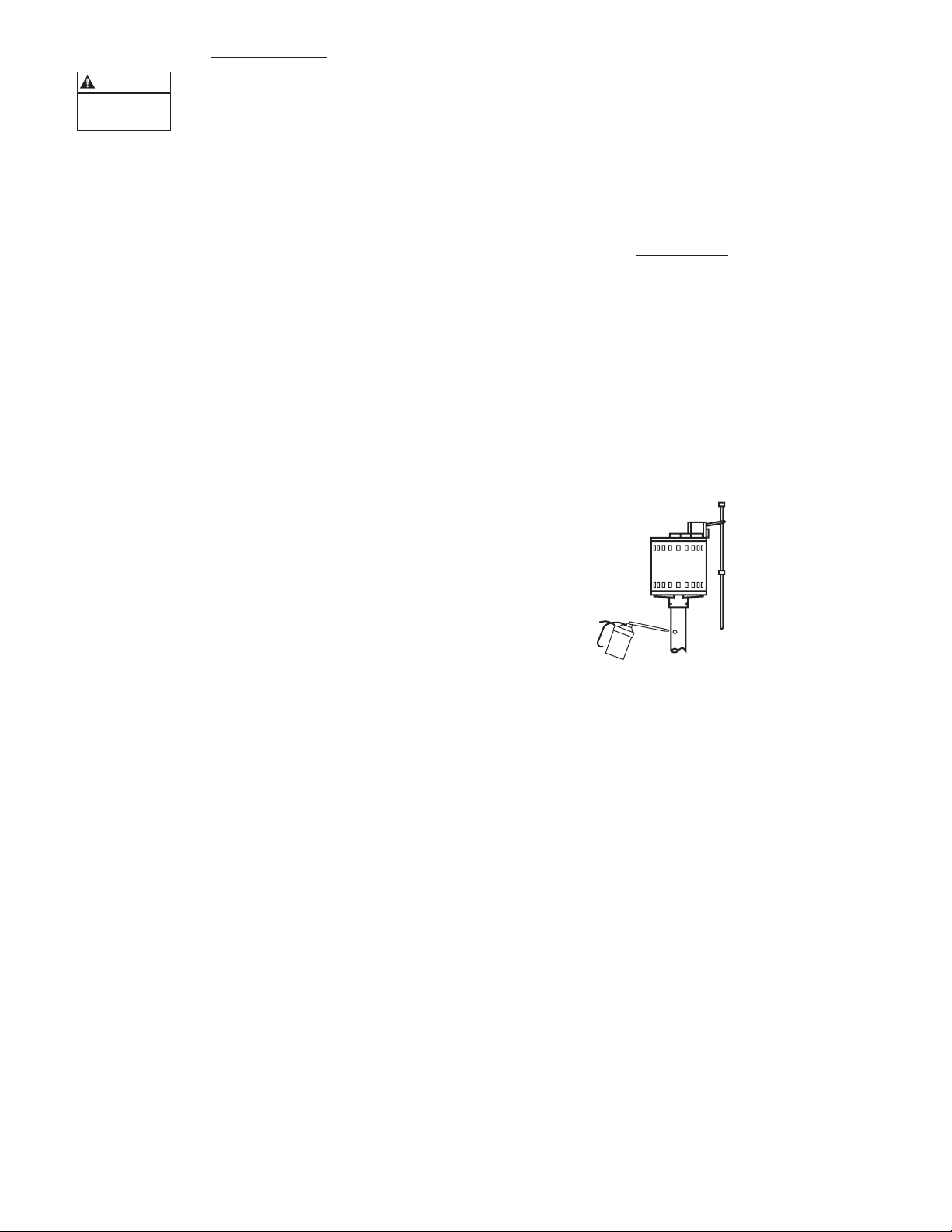

• Pedestal sump pump have open, exposed motors. Take

precautions to make sure the motor does not get wet

from dripping pipes, etc.

• Pour an ounce of 20 or 30 weight oil into the hole near

the top of the pedestal column every 6 months. A label

next to the hole designates where to add the oil. See

Figure B.

• Pour enough water into the sump pit to activate the

pump periodically when not normally in use.

• Check periodically to make sure the pit is free from

accumulated debris, rocks or other objects that may

potentially jam the pump.

Figure B

3

Page 4

RED JACKET

Water Products

®

This warranty applies to all water systems pumps manufactured by Red Jacket Water Products.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall

exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

Red Jacket Water Products (the manufacturer) warrants to the original end-user Purchaser of each of the Manufacturer’s Red Jacket Waterbear, Grizzly and Enduro

submersible pumps that any part thereof which proves to be defective in material or workmanship within 36 months from manufacture date will be replaced at no

charge with a new or re-manufactured part, F.O.B. factory. In the case of the Big-Flo submersible pump and motor unit and all jet and centrifugal pumps, however, the

warranty period shall be the earlier of 24 months from the date of manufacture or 12 months from the date of installation.

A dealer who believes that a warranty claim exists must contact the authorized Red Jacket Water Products distributor from whom the pump was purchased and furnish

complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Red Jacket Water Products Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Red Jacket Water Products and the dealer

in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to

customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited

liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Red Jacket Water Products is a licensed trademark.

The ITT Engineered Blocks symbol is a registered

trademark and tradename of ITT Industries.

Red Jacket Water Products reserves the right to make design improve-

ments and pricing modifications as necessary and without notice.

©2002 Red Jacket Water Products

Printed in U.S.A.

RED JACKET WATER PRODUCTS LIMITED WARRANTY

Page 5

®

RED JACKET

Water Products

Vertical

Vertical

Sump Pump

Sump Pump

Manual de instalación y funcionamiento

Información del propietario

Información del propietario

Número de Modelo:

Número de Serie:

Código:

Agente:

No. telefónico del agente:

Fecha de compra:

Fecha de instalación:

Índice

Índice

TEMA PÁGINA

Información general ....................................................... 6

Fosa del sumidero .......................................................... 6

Instalación ..................................................................... 6

Identificación de fallas .................................................... 7

Maintenimiento ............................................................. 7

Garantía limitada de Red Jacket Water Products .............. 8

Page 6

Información general

Información general

Instalación de la bomba

Instalación de la bomba

• Lea las siguientes instrucciones cuidadosamente antes de

la instalación. Cada bomba es sometida a prueba

individualmente en la fábrica para verificar el

rendimiento apropiado. Siguiendo estas instrucciones en

forma cercana se eliminarán los posibles problemas de

operación, ofreciendo años de servicio sin averías.

ADVERTENCIA

Tensión

peligrosa

RIESGO DE ELECTROCHOQUE.

Siempre desconecte la bomba de la fuente

de energía antes de manejarla o hacer

ajustes.

• Siempre use botas de goma cuando haya agua en el piso y

deba desenchufar la bomba. Asegúrese de que la fuente

de energía de la bomba tenga un tomacorriente trifilar de

15 amperios de capacidad, conectado a tierra y con

fusible separado. NO QUITE EL ENCHUFE O CLAVIJA

DE CONEXIÓN A TIERRA. NO USE UN CABLE DE

EXTENSIÓN. Inspeccione para asegurar que la

instalación sea de acuerdo con el Código Eléctrico de los

Estados Unidos y todos los códigos locales

correspondientes.

• Las herramientas requeridas para instalación son a) llave

para tubos, b)destornillador regular y c) sierra para

metales (para reemplazar o retirar tuberías rígidas

existentes).

• NO use bombas en agua a una temperatura superior a los

140 ºF.

• NO drene los calentadores de agua caliente en la fosa del

sumidero cuando les esté dando servicio.

• NO use las bombas en lodo, arena, cemento, aceite o

productos químicos

• NO modifique las bombas de ninguna manera.

1. Retiro de la bomba vieja.

NOTA: DESCONECTE LA BOMBA DE LA FUENTE

DE ENERGÍA ANTES DE MANEJARLA.

Separe la tubería de descarga ya sea en la válvula de

retención o en la unión. Si la tubería de descarga

existente no incluye ni una válvula de retención ni una

unión, corte la tubería justo arriba del nivel del piso con

una sierra para metales y retire la bomba. (Deberá

instalarse una unión o válvula de retención en este corte.)

2. *VER LA NOTA ABAJO. Coloque la bomba nueva en

posición, asegurándose de que el interruptor de flotador

tenga espacio adecuado y que no cuelgue de la pared de

la fosa.

3. Se incluye una descarga roscada de 11⁄4 pulg. en la bomba

para conectarla a la tubería de descarga. No reduzca el

tamaño de la descarga a menos de 11⁄4 pulg. ya que esto

afectará el flujo y rendimiento de la bomba. Se

recomienda una tubería de PVC (cloruro de polivinilo)

de especificación 40; sin embargo, se pueden usar juegos

de manguera de descarga flexible para instalaciones

temporales.

4. Conecte la tubería o la manguera de descarga a la

descarga de la bomba. APRIETE CON LA MANO

ÚNICAMENTE. El apriete excesivo puede agrietar la

caja de la bomba.

11⁄4" DESCARGA

Fosa de sumidero

Fosa de sumidero

1. Se recomienda una fosa de sumidero de no menos de

14 pulg. de diámetro. Se prefiere una fosa de diámetro

grande ya que permite un ciclo de bombeo más largo y

un ciclo de conmutación reducido.

2. Si la bomba aún no está cubierta sobre el fondo,

proporcione un fondo nivelado duro de ladrillos o

concreto. NO coloque la bomba directamente sobre el

suelo, grava o residuos ya que esto puede producir

desgaste excesivo del impulsor y un posible

atascamiento. Retire todos los residuos del fondo de la

fosa de sumidero antes e instalar la bomba. Se sugiere

instalar una tapa en la fosa de sumidero para mayor

seguridad y para impedir la entrada de objetos extraños a

la fosa.

AGUJERO DE PURGA

DE AIRE DE 1⁄8 PULG.

Figura A

*NOTA: En las bombas de pedestal es necesario armar

el flotador, la varilla y la guía. Encaje a presión la guía

de la varilla de plástico a su posición, con su pasador

situado en el agujero central en la columna de la bomba.

Inserte el extremo roscado de la varilla de flotador hacia

abajo por el agujero en la guía y conecte la bola del flotador

al extremo roscado. Retire el tope de goma superior e

inserte la varilla por el agujero en el brazo del interruptor.

Reinstale el tope de goma superior al menos a 1⁄2 pulg. del

extremo de la varilla.

6

Page 7

5. Instale una unión u otro medio para separar la tubería de

descarga justo arriba del piso para facilitar el retiro de

la bomba si es necesario. Se recomienda instalar una

válvula de retención justo arriba o en lugar de la unión

para impedir el contraflujo de agua después de cada ciclo

de la bomba.

Si se usa una válvula de retención, debe taladrase un

agujero de purga de aire de

1

⁄8 pulg. en la tubería de

descarga justo arriba de la salida de descarga de la bomba

para impedir el bloqueo con aire. Ver la Figura B.

Es normal que mientras la bomba esté funcionando salga

un pequeño rociado de agua de este agujero.

6. Conecte tubería adicional, según sea necesario, para

dirigir la descarga al lugar deseado. La descarga debe

mantenerse lo más corta posible, con un número mínimo

de vueltas. Revise todas las conexiones para detectar

fugas.

Mantenimiento e identificación de fallas

Mantenimiento e identificación de fallas

ADVERTENCIA

Tensión

peligrosa

SIEMPRE DESCONECTE LA BOMBA

DE LA FUENTE DE ENERGÍA ANTES

DE MANEJARLA.

Esta guía está diseñada para ayudar a identificar las razones

de posibles problemas de operación. No es una guía de

servicio. SI SE DESMANTELA LA BOMBA, SE ANULA

LA GARANTÍA. Excepto por una simple limpieza de la

entrada o el impulsor de la bomba, el servicio de la bomba

debe ser realizado en la fábrica o centros de servicio

autorizados.

NOTA: El fabricante no asume ninguna responsabilidad

por daños o lesiones debido al desmontaje.

LA BOMBA NO FUNCIONA O TIENE UN

ZUMBIDO:

1) El cortacircuitos de línea puede estar desconectado,

disparado o suelto. Solicite a un electricista certificado

que revise el fusible o el cortacircuitos.

2) El nivel de agua en la fosa podría ser demasiado bajo

para activar el interruptor. Agregue más agua a la fosa.

3) Enchufe del cable de alimentación podría no estar

haciendo contacto en el tomacorriente. Verifique la

seguridad y la conexión.

4) El flotador podría estar obstruido. Asegúrese de que el

flotador esté libre y que no interfiera con la pared de la

fosa u otra obstrucción.

5) Si todo lo demás funciona bien, el devanado del motor

podría estar abierto. Consulte con la fábrica.

LA BOMBA FUNCIONA O HACE UN ZUMBIDO,

PERO NO ENTREGA AGUA:

1) La válvula de retención podría estar instalada al revés o

está defectuosa. Revise para verificar que esté instalada

correctamente y que la chapaleta en la válvula puede

moverse libremente.

2) La línea de descarga podría estar bloqueada o

congelada. Inspeccione para ver si la línea pasa por

áreas frías o si está bloqueada.

3) La bomba podría estar bloqueada con aire. Asegure que

se haya taladrado un agujero de purga de aire en la

tubería de descarga. Consulte La Figura A acerca de

la ubicación apropiada del agujero de purga.

4) La elevación vertical está fuera de la capacidad de la

bomba. La capacidad de elevación máxima de la bomba

está 17 pies.

NOTA: No habrá flujo a la elevación máxima de la bomba.

5) El filtro de entrada de la bomba está tapado o el

impulsor está atascado. Retire el filtro de la bomba y

limpie la entrada y el impulsor.

LA BOMBA FUNCIONA Y EXTRAE AGUA, PERO NO

SE PARA:

1) El flotador está atascado en la posición de

“ENCENDIDO”. Inspeccione para asegurar que el

flotador pueda moverse libremente hacia arriba y abajo

sin obstrucción.

2) El interruptor está defectuoso. Consulte con la fábrica.

LA BOMBA FUNCIONA, PERO ENTREGA MUY

POCA AGUA.

1) La elevación vertical se está aproximando a la capacidad

de elevación máxima de la bomba. Consulte la tabla de

elevación máxima anterior.

2) La entrada de la bomba está parcialmente bloqueada.

Inspeccione para asegurar que la entrada esté libre de

residuos.

3) La línea de descarga está parcialmente bloqueada.

Inspeccione para localizar el bloqueo.

4) Determine si la válvula no se está abriendo por

completo. Revise para determinar si la válvula de

retención está defectuosa o bloqueada.

EL CORTACIRCUITOS SE DISPARA O EL FUSIBLE

SALTA CUANDO ARRANCA LA BOMBA

1) El fusible o el cortacircuitos es demasiado pequeño.

Debe usarse un cortacircuitos de 15 amperios.

2) Hay otros artefactos mayores conectados al mismo

circuito. La bomba debe tener su propio circuito.

3) La bomba está conectada a un cable de extensión o

el cableado es inadecuado. Solicite que un electricista

verifique el cableado apropiado.

4) Motor defectuoso en el interruptor. Consulte con

la fábrica.

Mantenimiento

Mantenimiento

• Las bombas tipo pedestal para sumidero tienen motores

abiertos y expuestos. Tome precauciones para asegurar

que los goteos de las tuberías no mojen el motor, etc.

• Vierta una onza de aceite de 20 ó 30 de peso en el

agujero cerca del extremo superior de la columna del

pedestal cada 6 meses. Una etiqueta adyacente al agujero

indica dónde agregar el aceite. Ver la figura B.

• Vierta suficiente agua en la fosa de sumidero para activar

la bomba periódicamente cuando no esté normalmente

en uso.

• Inspeccione periódicamente para asegurar que la fosa esté

libre de residuos acumulados, rocas u otros objetos que

pudiesen atascar la bomba.

Figura B

7

Page 8

RED JACKET

Water Products

®

GARANTÍA LIMITADA DE RED JACKET WATER PRODUCTS

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Red Jacket Water Products.

Toda parte o partes que resulten defectuosas dentro del período de garantía serán reemplazadas sin cargo para el comerciante durante dicho período de garantía. Tal

período de garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de fabricación, cualquiera se cumpla

primero.

Red Jacket Water Products (el fabricante) garantiza al comprador – usuario final original de cada una de las bombas sumergibles Red Jacket Waterbear, Grizzly y Enduro

del fabricante que cualquier pieza de las mismas que resulte defectuosa en cuanto a material o mano de obra durante el período de 36 meses a partir de la fecha de

fabricación será reemplazada sin cargo con una pieza nueva o reacondicionada, L.A.B. fábrica. Sin embargo, en el caso de la bomba sumergible y motor Big-Flo y todas

las bombas de inyección y centrífugas, el período de garantía será de 24 meses a partir de la fecha de fabricación o 12 meses a partir de la fecha de instalación, según lo

que ocurra primero.

Todo comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Red Jacket Water Products del

cual adquiriera la bomba, y ofrecer información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los reclamos por garantía a través del

Departamento de Servicios a Clientes de Red Jacket Water Products.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Red Jacket Water Products y el comerciante para la

compra, consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación, asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing)

de bombas a clientes.

(3) “Cliente” es toda entidad que compra o que adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente” puede significar

un individuo, una sociedad, una corporación, una sociedad de responsabilidad limitada, una asociación o cualquier otra entidad jurídica con actividades en cualquier

tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE

Red Jacket Water Products es una marca licenciada.

El símbolo ITT Engineered Blocks es una marca registrada

y una marca comercial de ITT Industries.

Red Jacket Water Products se reserva el derecho de hacer mejoras de

diseño y modificaciones de precios según sea necesario y sin previo

aviso.

©2002 Red Jacket Water Products

Impreso en EE.UU

Page 9

RED JACKET

Water Products

Sump Pump

Sump Pump

Manuel d’installation et d’utilisation

MD

®

Vertical

Vertical

Informations pour le propriétaire

Informations pour le propriétaire

Numéro de modèle :

Numéro de série :

Code :

Détaillant :

No de téléphone du détaillant :

Date d’achat :

Date d’installation :

Table des matières

Table des matières

SUJET PAGE

Informations générales ................................................. 10

Puisard ........................................................................ 10

Installation .................................................................. 10

Diagnostic des anomalies .............................................. 11

Entretien ..................................................................... 11

Garantie limitée de Red Jacket Water Products .............. 12

Page 10

Informations générales

Informations générales

• Avant d’installer la pompe, lire les directives suivantes

avec soin. Le personnel de l’usine essaie chaque pompe

pour s’assurer que ses performances sont appropriées. Si

l’on suit de près les directives ci-jointes, on devrait

éliminer tout incident de fonctionnement possible et

obtenir de la pompe des années de service sans incident.

AVERTISSEMENT

Tension

dangereuse

RISQUE DE CHOC ÉLECTRIQUE –

Avant d’effectuer quelque travail que ce soit

sur la pompe, on doit toujours la

débrancher.

• Il faut toujours porter des bottes de caoutchouc pour

débrancher la pompe quand le sol est mouillé. S’assurer

que la prise de courant de la pompe est montée sur un

circuit trifilaire distinct de 15 A à fusible, mis à la terre.

N’ENLEVER NI LA FICHE, NI LA BROCHE DE

TERRE, NI N’UTILISER DE RALLONGE. S’assurer que

l’installation est conforme aux prescriptions du code

provincial ou national de l’électricité.

• Les outils requis pour l’installation sont les suivants : a)

clé à tubes ; b) tournevis ordinaire ; et c) scie à métaux

(pour remplacer ou enlever les tuyaux rigides en place).

• NE PAS employer l’appareil pour pomper de l’eau dont

la température dépasse 140 °F.

• NE PAS vidanger dans le puisard l’eau chaude du

chauffe-eau pour faire l’entretien de celui-ci.

• NE PAS utiliser la pompe dans la vase, le sable, le ciment,

l’huile et les produits chimiques.

• NE PAS modifier la pompe de quelque façon que ce soit.

2. VOIR *NOTA CI-DESSOUS. Placer la pompe neuve de

manière à laisser au flotteur assez d’espace pour qu’il ne

puisse rester bloqué contre les parois du puisard.

3. La pompe possède un orifice de refoulement taraudé de

11⁄4 po de diamètre. Ne pas réduire ce diamètre pour ne

pas altérer le débit ni les performances de la pompe. Un

tuyau en PVC de nomenclature (« schedule ») 40 est

recommandé. On peut cependant utiliser du tuyau

souple pour les installations temporaires.

4. Visser le tuyau à l’orifice de refoulement de la pompe,

MAIS À LA MAIN SEULEMENT : un serrage excessif

pourrait faire fendre le corps de pompe.

5. Poser un raccord du type union ou autre juste au-dessus

du niveau du plancher pour faciliter l’enlèvement de la

pompe au besoin. Il est recommandé de poser un clapet

de non-retour au-dessus ou à la place du raccord pour

empêcher le refoulement du liquide à chaque arrêt

de la pompe.

Si l’on emploie un clapet de non-retour, on devrait

percer un trou-purgeur d’air de 1⁄8 po dans le tuyau, près

de l’orifice de refoulement de la pompe, pour éliminer

les « poches d’air » (fig. A). Il est normal qu’un peu d’eau

sorte du trou pendant le fonctionnement de la pompe.

6. Poser le reste de la tuyauterie de refoulement, qui devrait

être aussi courte et aussi droite que possible. S’assurer

qu’aucun joint ne fuit.

11⁄4" ORIFICE DE REFOULEMENT

Puisard

Puisard

1. Un puisard d’au moins 14 po de diamètre est

recommandé, bien qu’un diamètre plus grand soit

préférable pour permettre un cycle de pompage plus

long et réduire ainsi la fréquence de fonctionnement du

contacteur.

2. Si le puisard n’a pas de fond fermé solide, en faire un de

niveau avec des briques ou du béton. NE PAS poser la

pompe directement sur la terre, le gravier ou une surface

jonchée de débris, qui pourraient causer l’usure

prématurée et le blocage de la roue. Enlever les débris du

fond du puisard avant d’y installer la pompe. Il est

suggéré de munir le puisard d’un couvercle pour la

sécurité et pour empêcher les objets d’y tomber.

Installation

Installation

1. Enlèvement de la vieille pompe :

NOTA : DÉBRANCHER LA POMPE AVANT DE

TRAVAILLER DESSUS.

Séparer la pompe du tuyau de refoulement au clapet de

non-retour ou au raccord union. S’il n’y a ni clapet ni

raccord, couper le tuyau juste au-dessus du niveau du

plancher avec une scie à métaux, puis enlever la pompe.

(On devra poser un clapet de non-retour ou un raccord

union pour raccorder le tuyau à la pompe neuve.)

TROU-PURGEUR

D’AIR DE 1⁄8 po

Figure A

*NOT A : les pompes sur jambe nécessitent le montage du

flotteur, de sa tige et de son guide. Insérer avec pression

l’ergot du guide en plastique dans le trou situé près du

centre de la jambe. Enfiler le bout fileté de la tige dans le

trou du guide, vers le bas, puis y visser le flotteur. Ôter la

butée de caoutchouc de l’autre bout de la tige, insérer la

tige dans l’orifice du bras du contacteur, reposer la butée de

caoutchouc et la placer à au moins 1⁄2 po du bout de la tige.

10

Page 11

Diagnostic des anomalies

Diagnostic des anomalies

AVERTISSEMENT

Tension

dangereuse

AVANT DE TRAVAILLER SUR LA

POMPE, ON DOIT TOUJOURS LA

DÉBRANCHER.

Le guide de dépannage suivant aide à diagnostiquer les

causes d’anomalies possibles. Il n’est donc pas un guide

d’entretien. LE DÉMONTAGE DE LA POMPE EN

ANNULE LA GARANTIE. S’il s’agit d’un entretien autre

que le simple nettoyage de l’entrée ou de la roue de la

pompe, il devrait être effectué à l’usine ou à un centre de

services agréé.

NOTA : le fabricant ne sera nullement tenu responsable

des dommages et blessures dus au démontage.

LA POMPE NE FONCTIONNE PAS NI NE PRODUIT

DE RONFLEMENT :

1. Le disjoncteur du circuit d’alimentation est ouvert,

déclenché ou mal connecté. Le faire vérifier par un

électricien.

2. Le niveau de l’eau dans le puisard est trop bas pour

actionner le contacteur. Ajouter de l’eau dans le

puisard.

3. Le courant ne circule pas entre la prise et la fiche du

cordon d’alimentation. Vérifier si la fiche est bien

branchée et si les connexions sont correctes.

4. Le flotteur est bloqué. S’assurer que le mouvement de

ce dernier n’est pas gêné par les parois du puisard ou un

objet quelconque.

5. Si aucune des anomalies ci-dessus n’est en cause, il se

peut que l’enroulement du moteur soit ouvert.

Communiquer avec l’usine.

LA POMPE FONCTIONNE OU PRODUIT UN

RONFLEMENT, MAIS N’A AUCUN DÉBIT :

1. Le clapet de non-retour est défectueux ou posé à

l’envers. S’assurer qu’il est bien posé et que son

obturateur n’est pas bloqué.

2. La conduite de refoulement est obstruée ou gelée.

Vérifier s’il y a obstruction ou si la conduite est exposée

au froid.

3. De l’air est emprisonné dans la pompe. S’assurer que le

tuyau de refoulement est muni d’un trou-purgeur d’air

à l’endroit suggéré dans la figure A.

4. La hauteur de refoulement est excessive. La hauteur de

refoulement maximale de la pompe est 17 pi.

NOTA : la pompe ne fournira aucun débit à la hauteur

de refoulement maximale indiquée.

5. La crépine de la pompe est obstruée, ou la roue est

bloquée. Déposer la crépine. Nettoyer cette dernière

ainsi que l’entrée et la roue de la pompe.

LA POMPE FONCTIONNE ET POMPE L’EAU, MAIS

NE S’ARRÊTE PAS :

1. Le flotteur est bloqué en position de « MISE EN

MARCHE ». S’assurer qu’il peut se déplacer librement

vers le haut et le bas.

2. Le contacteur est défectueux. Communiquer avec

l’usine.

LA POMPE FONCTIONNE, MAIS SON DÉBIT EST

TRÈS FAIBLE :

1. La hauteur de refoulement est proche de la hauteur de

refoulement maximale de la pompe. Voir la table B

ci-dessus.

2. L’entrée de la pompe est partiellement obstruée.

S’assurer qu’elle est dégagée.

3. La conduite de refoulement est partiellement obstruée.

Vérifier s’il y a obstruction.

4. Le clapet de non-retour ne s’ouvre pas complètement.

Vérifier s’il est défectueux ou bloqué.

QUAND LA POMPE DÉMARRE, LE DISJONCTEUR SE

DÉCLENCHE, OU LE FUSIBLE SAUTE :

1. Le fusible ou le disjoncteur ne peut supporter l’intensité

de courant. On devrait utiliser un fusible ou un

disjoncteur de 15 A.

2. Un appareil important est branché sur le même circuit

que la pompe. La pompe doit avoir un circuit

d’alimentation distinct.

3. La pompe est branchée à une rallonge, ou le câblage est

inapproprié. Faire vérifier le câblage par un électricien.

4. Le moteur ou le contacteur est défectueux.

Communiquer avec l’usine.

Entretien

Entretien

• Les pompes de puisard sur jambe possèdent un moteur

ouvert, donc non protégé contre les liquides. S’assurer

qu’aucune fuite d’eau des tuyaux ni aucun autre liquide

n’atteindra le moteur.

• Tous les six (6) mois, verser une once d’huile du type 20

ou 30 dans le trou situé près du haut de la jambe de la

pompe (fig. B). Une étiquette est apposée à cette fin près

du trou.

• Verser régulièrement de l’eau dans le puisard pour mettre

la pompe en marche quand il n’y en a pas assez pour

faire fonctionner la pompe à une fréquence normale.

• Vérifier régulièrement le puisard pour s’assurer qu’il n’y a

pas d’accumulation de débris, de roches ni d’objets

pouvant bloquer la pompe.

Figure B

11

Page 12

RED JACKET

Water Products

MD

®

GARANTIE LIMITÉE DE RED JACKET WATER PRODUCTS

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Red Jacket Water Products.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant la première : douze (12) mois à compter de

la date d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Red Jacket Water Products (le fabricant) garantit à l’acheteur utilisateur initial de chacune des pompes submersibles Red Jacket Waterbear, Grizzly et Enduro du

fabricant que toute pièce présentant un défaut de fabrication ou de matériaux dans les 36 mois suivant la date de fabrication sera remplacée sans frais par une pièce neuve

ou réusinée, franco usine. Cependant, pour les moteurs et pompes submersibles Big-Flo et toutes les pompes centrifuges et à jet, la période de garantie suivante expirant

la première s’appliquera : 24 mois à compter de la date de fabrication ou 12 mois à partir de la date d’installation.

Le détaillant qui, aux termes de la présente garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Red Jacket Water Products agréé chez

lequel la pompe a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du service à la clientèle de

Red Jacket Water Products.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ou de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) « Distributeur » signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant

d’intermédiaire entre Red Jacket Water Products et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en

question.

2) « Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les

activités commerciales sont la vente ou la location de pompes à des clients.

3) « Client » signifie une entité qui achète ou loue les pompes en question chez un détaillant. Le « client » peut être une personne, une

société de personnes, une société de capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à

quelque activité que ce soit.

LA PRÉSENTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Red Jacket Water Products est une marque de commerce autorisée.

Le logo à blocs siglés d’ITT est une marque déposée

et de commerce d’ITT Industries.

Red Jacket Water Products se réserve le droit d'améliorer ses

produits et de modifier ses prix au besoin et sans préavis.

© 2002, Red Jacket Water Products

Imprimé aux É.-U.

Loading...

Loading...