VOLVO D4, D6 Service Manual

SERVICE AND MAINTENANCE D4, D6

© 2017 AB VOLVO PENTA

Volvo Penta reserves the right to make changes Printed on environmentally friendly paper

Table of Content |

|

Safety Information ...................................................................................... |

5 |

Spare parts - safety ................................................................................... |

7 |

General Information .................................................................................. |

14 |

Service Protocol ...................................................................................... |

15 |

Preventive repair ..................................................................................... |

16 |

Genuine Volvo Penta Parts ..................................................................... |

23 |

Illustrations .............................................................................................. |

25 |

Chemical products .................................................................................... |

27 |

Chemical products .................................................................................. |

27 |

Special Tools ............................................................................................. |

29 |

Other Special Equipment ........................................................................ |

29 |

Specifications ............................................................................................ |

31 |

Engine Decals ......................................................................................... |

31 |

Transmission Decals ............................................................................... |

32 |

General Tightening Torques .................................................................... |

34 |

Specifications .......................................................................................... |

35 |

Engine ........................................................................................................ |

40 |

Component location ................................................................................ |

41 |

Maintenance Schedule ............................................................................ |

44 |

General inspection .................................................................................. |

45 |

General advice for electronic protection .................................................. |

47 |

Check software status ............................................................................. |

48 |

Air Filter ................................................................................................... |

48 |

Crankcase Ventilation, Filter Change ...................................................... |

49 |

Compressor, oil level ............................................................................... |

50 |

Compressor oil, Replace ......................................................................... |

50 |

Lubrication System ................................................................................... |

52 |

When you work with Chemicals, Fuel and Lubrication Oil, Change ........ |

52 |

Engine Oil, Level Check .......................................................................... |

52 |

Engine oil, Replace ................................................................................. |

54 |

Oil filter, Replace ..................................................................................... |

55 |

Oil topping up and level check ................................................................ |

56 |

Fuel System ............................................................................................... |

64 |

General ................................................................................................... |

64 |

Fuel filter, Change ................................................................................... |

65 |

Fuel pre-filter ........................................................................................... |

66 |

Fuel system, bleeding ............................................................................. |

68 |

Exhaust System ........................................................................................ |

71 |

Exhaust hose .......................................................................................... |

71 |

Turbocharger, Inspection ........................................................................ |

72 |

Cooling System ......................................................................................... |

74 |

Coolant Level, Checking and Topping Up ............................................... |

74 |

Drive Belt, Replace ................................................................................. |

77 |

Seawater Pump, Impeller, Change ......................................................... |

80 |

Seawater Filter, Check and Cleaning ...................................................... |

82 |

Anodes .................................................................................................... |

84 |

Transmission ............................................................................................. |

86 |

IPS ........................................................................................................... |

86 |

IPS ....................................................................................................... |

86 |

Oil drain, IPS ........................................................................................ |

88 |

47707967 09-2022 © AB VOLVO PENTA |

1 |

Oil filter, IPS ......................................................................................... |

88 |

Oil filler, IPS ......................................................................................... |

89 |

IPS, oil level ......................................................................................... |

89 |

Anode, exhaust outlet (IPS) ................................................................. |

90 |

Propeller ............................................................................................... |

91 |

Propeller shaft seals, replacement ....................................................... |

92 |

Transmission: Oil strainer, inner and outer .......................................... |

92 |

Anodes ................................................................................................. |

93 |

Painting IPS Drives .............................................................................. |

94 |

Reversing gear ....................................................................................... |

95 |

Reversing gear, oil and filter change .................................................... |

95 |

Sterndrive ............................................................................................... |

99 |

Valve block, oil filter, change .............................................................. |

101 |

Sterdrive, hydraulic fluids ................................................................... |

103 |

Sterndrive, oil level ............................................................................. |

104 |

Sterndrive, Draining ........................................................................... |

107 |

Sterndrive, Oil Filling .......................................................................... |

109 |

Sterndrive bellows .............................................................................. |

111 |

Propeller ............................................................................................. |

112 |

Checking Protective Anodes .............................................................. |

113 |

Painting the Drive ............................................................................... |

115 |

Long-Term Storage ................................................................................. |

117 |

Storage instruction for long-term storage of new engine ....................... |

119 |

Cleaning engine and transmission ........................................................ |

121 |

Cold Weather Precautions .................................................................... |

123 |

Checklist ................................................................................................ |

125 |

Battery, Maintenance ............................................................................ |

126 |

Index ......................................................................................................... |

129 |

2 |

47707967 09-2022 © AB VOLVO PENTA |

47707967 09-2022 © AB VOLVO PENTA |

3 |

Safety Information

4 |

47707967 09-2022 © AB VOLVO PENTA |

Safety Information

Safety Information

This chapter describes how safety precautions are presented in the manual and on the product. Read the chapter through very carefully before you start the engine or do any maintenance or service. It has to do with your safety; an incorrect operation can lead to personal injury and damage to products or property. It also gives you an introduction to the basic safety rules for using and looking after the engine.

If anything remains unclear or if you are unsure of something, contact your Volvo Penta dealer for assistance.

IMPORTANT:

Always follow local safety instructions and regulations.

Safety texts have the following order of priority:

DANGER!

DANGER!

Indicates a hazardous situation, which, if not avoided, result in death or serious injury.

WARNING!

WARNING!

Indicates a hazardous situation, which, if not avoided, could result in death or serious personal injury.

CAUTION!

CAUTION!

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate personal injury.

IMPORTANT:

Indicates a situation, which, if not avoided, could result in property damage.

NOTICE! Used to draw attention to important information that facilitates work or operations.

!

This symbol is may be used on the product to call your attention to the fact that this is safety information. Always read such information very carefully.

Make sure that warning and information symbols on the engine are clearly visible and legible. Replace symbols that have been damaged or have been painted over.

In some cases, this symbol is used on our products and refers to important information in the Operator’s Manual.

47707967 09-2022 © AB VOLVO PENTA |

5 |

Safety Information

Most chemicals such as engine and transmission oils, glycol, petrol and diesel oil and chemicals used in workshops such as degreasing agents, paint and solvents are harmful to health.

Carefully read the instructions on the product packaging! Always follow the safety regulations, such as the use of protective masks, goggles, gloves, etc. Make sure that other personnel are not exposed to substances that are hazardous to health. Ensure good ventilation.

Manage used and leftover chemicals in the prescribed manner.

Personal safety equipment

CAUTION!

CAUTION!

Always use appropriate safety equipment. Personal protective equipment does not eliminate the risk of injury but it will reduce the degree of injury if an accident does happen.

Some examples are ear protection, eye and face protection, protective footwear, personal protective equipment, head protection, protective clothing, gloves and respirators.

WARNING!

WARNING!

Ensure that all machine guards and safety devices are

in place and are functional.

P0024482

CAUTION!

CAUTION!

Never use tools or products that show signs of damage.

Protect your eyes

CAUTION!

CAUTION!

Wear safety glasses.

Always wear safety glasses if there is a risk of splintering, sparks and spray from the electrolyte (socalled battery acid), or other chemicals. Your eyes are very delicate and damage can result in loss of sight!

Protect your skin

CAUTION!

CAUTION!

Risk of skin damage.

Avoid getting oil on your skin! Prolonged or repeated exposure to oil can dry out the skin. Thereafter, irritation, dryness and eczema and other skin problems may occur.

Use protective gloves and avoid oil-soaked clothes and rags. Wash regularly, especially before eating. Wear suitable protective creams to prevent skin from drying out and to facilitate cleaning.

6 |

47707967 09-2022 © AB VOLVO PENTA |

Safety Information

Fire safety

WARNING!

WARNING!

Fire and Explosion Risk!

Accidental spark could ignite fuel vapors.

All fuels – as well as many lubricants and chemicals – are flammable. Do not allow open flames or sparks near them. Smoking forbidden! Hydrogen from the batteries is also very flammable and explosive in certain mixture with air.

Ensure that the workplace is well ventilated and take the necessary precautions before welding or grinding begins. Always ensure that there is a fire extinguisher

close at hand in the work area.

P0024470

Spare parts - safety

WARNING!

WARNING!

Always use Volvo Penta genuine spare part to minimize the risk of an explosion or fire.

Components in fuel systems and electrical systems on Volvo Penta engines are designed and manufactured to minimize the risk of explosions and fire, in accordance with applicable legal requirements.

Used oils, filters and chemicals etc.

WARNING!

WARNING!

Risk of fire.

Store fuel soaked rags and other flammable material so that there is no danger of them catching fire.

Oil-soaked rags can spontaneously ignite under certain circumstances.

IMPORTANT:

Used fuel and oil filters are environmentally hazardous waste and must be taken to an approved waste management facility for correct handling, as must any used lubricating oil, contaminated fuel, paint residue, solvents, degreasers and wash residue.

Prevent start of the engine

WARNING!

WARNING!

Immobilize the engine by turning off the power supply with the main switch(es) and lock it (them) in the off position before starting work. Place a warning notice at the main switch.

If the engine is equipped with BMS (Battery Management System), always disconnect both battery cables from the battery terminals.

47707967 09-2022 © AB VOLVO PENTA |

7 |

Safety Information

P0024481

P0024808

Ventilation when running the engine

WARNING!

WARNING!

Only start the engine in a well-ventilated area. If operating the engine in a closed area ensure that there is exhaust ventilation leading out of the work area to remove exhaust gases and crankcase ventilation emissions.

The engine must not be operated in areas where there are explosive materials or stored gas.

Rotating parts and hot surfaces

DANGER!

DANGER!

Working with or approaching a running engine is a safety risk. Watch out for rotating components and hot surfaces.

If the engine is in operation and operates another device, you must not, under any circumstances, staying close to the engine.

Work on running engines is strictly prohibited. There are however adjustments that require the engine to be run. Approaching a running engine is a safety risk. Loose clothing and long hair can get caught in the rotating parts; careless movements or a dropped tool can lead to serious personal injury.

Be careful to avoid hot surfaces (exhaust pipes, turbochargers, charge air manifolds, start elements etc.) and hot fluids in pipes and hoses on engines that are running or have just stopped. Re-install all protective covers that were removed during maintenance work before starting the engine.

Information on the engine

IMPORTANT:

Make sure that all warning and information decals on the product are always visible. Replace decals which have been damaged or painted over.

8 |

47707967 09-2022 © AB VOLVO PENTA |

P0024483

P0024688

Safety Information

Prohibition on use of start spray

WARNING!

WARNING!

Never use start spray or similar agents to start an engine. This may cause an explosion in the inlet manifold. Risk of personal injury.

Before start of engine

WARNING!

WARNING!

Never start the engine if there is reason to suspect fuel and/or gas leaks, or if there is explosive material nearby.

IMPORTANT:

Only start the engine with the air filter and protective caps fitted. Foreign objects in the inlet line could cause machine damage. Also make sure that no tools or other parts have been left next to the engine.

WARNING!

WARNING!

Never start the engine with the valve cover removed. There is a risk of personal injury.

For engines with turbochargers, the rotating compressor turbine can in addition cause serious personal injuries.

Before any work on the electrical system

WARNING!

WARNING!

Always stop the engine first. Then disconnect the current at the main switches and any external power supply before working on the electrical system – to minimize the risk of electrical hazards.

IMPORTANT:

Never disconnect the current using the main switches when the engine is running or by disconnecting the battery cables.

The alternator and electronics could be damaged.

Avoid damage to the engine control module and other electronics

IMPORTANT:

Switch off the main switch before connecting or disconnecting a connector.

Before any work on the cooling system

WARNING!

WARNING!

Stop the engine and let it cool before starting work on the cooling system. Hot fluids and hot surfaces can cause burns.

47707967 09-2022 © AB VOLVO PENTA |

9 |

Safety Information

P0024484

P0024488

Risk of water penetration/sinking

WARNING!

WARNING!

If a launched boat is equipped with sea water tap and safety valve, ensure that these are closed before any work is allowed to begin on the cooling system.

Remember to open the tap and valve before starting the engine!

Hot coolant under pressure

CAUTION!

CAUTION!

Hot coolant can cause burns. Avoid opening the filler cap for the coolant when the engine is still hot. Steam or hot coolant can spray out and system pressure is lost.

Open the filler cap slowly, and release the pressure in the cooling system if the filler cap or valve has to be opened, or if a plug or coolant hose must be removed from a hot engine.

Hot oil under pressure

CAUTION!

CAUTION!

Hot oil can cause burns. Avoid getting hot oil on the skin. Ensure that the lubrication system is not pressurized before starting any work. Never start or operate the engine without the oil filler cap is on. There is a risk that hot oil can spray out.

At any leak detection on the fuel system

WARNING!

WARNING!

Wear safety goggles!

Be extremely careful when searching for leaks in the fuel system high-pressure circuits. There is very high pressure in the jet from pipes and injectors. The fuel may penetrate the tissue and cause serious risk of blood infection (septicemia).

Handling of fuel pipes

IMPORTANT:

High pressure pipes for fuel must not be bent or straightened under any circumstances. Cracks may occur. Damaged pipes must be replaced.

Before any work on the fuel system — Cleanliness

IMPORTANT:

Take great care to keep the fuel system components clean. Even minimal amounts of dirt can cause engine breakdown.

10 |

47707967 09-2022 © AB VOLVO PENTA |

Safety Information

Safe handling of batteries

WARNING!

WARNING!

Risk of fire and explosion. Never allow an open flame or electric sparks near the batteries.

A spark caused by an incorrectly connected battery can be sufficient for the battery to explode resulting in serious injury and damage.

Do not touch the connections during a starting attempt.

Spark hazard! Do not lean over batteries.

Correct polarity of the batteries

IMPORTANT:

Make sure that the positive (+) and negative (–) battery cables are correctly connected to the corresponding battery terminals. Wrong connection may cause severe damage to electrical equipment.

P0024468

Risks of electrolyte in batteries

WARNING!

WARNING!

Always wear protective goggles when charging or handling batteries.

Battery electrolyte is highly corrosive.

Rinse immediately with copious amounts of water if the electrolyte gets in your eyes. Search directly after the rinsing help by medical staff.

If it comes electrolyte to unprotected skin, wash immediately with soap and water.

After finished work with the engine

IMPORTANT:

Always perform a leakage and function check.

Cleaning the engine and components

NOTICE! Follow the instructions Cleaning engine and transmission, page 121.

P0026213

Cleanliness for sensitive components

IMPORTANT:

Observe meticulous cleanliness when handling system components.

Even minimal amounts of dirt could cause a breakdown.

47707967 09-2022 © AB VOLVO PENTA |

11 |

General Information

|

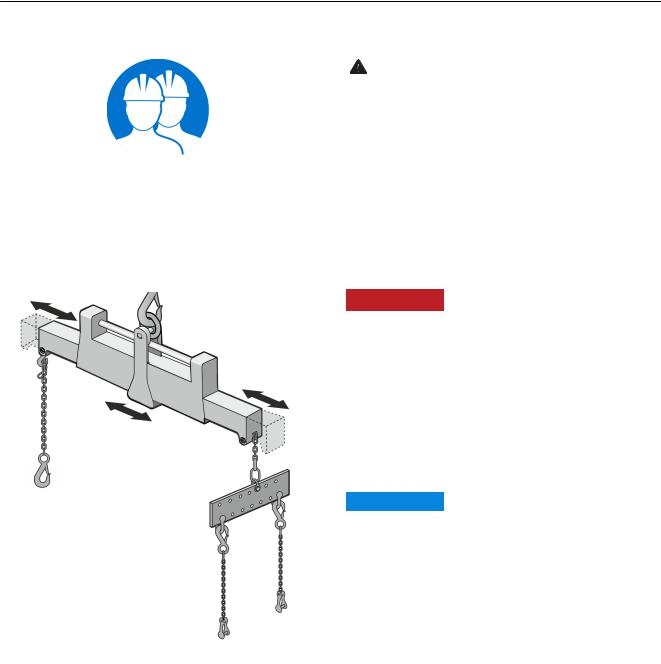

Lifting the engine |

||

|

|

|

|

|

WARNING! |

when removing heavy components, |

|

|

Never work alone |

||

|

even when using lifting devices such as locking tackle |

||

|

lifts. |

||

|

|

|

|

|

IMPORTANT: |

||

P0024485 |

When using a lifting device, two people are usually |

||

|

required to do the work – one to take care of the lifting |

||

|

device – and the other to ensure that components are |

||

|

lifted clear and not damaged during the lifting |

||

|

operations. |

||

Proper lifting equipment

DANGER!

DANGER!

The existing lugs on the engine should be used for lifting. Always check that the lifting equipment used is in good condition and has the load capacity to lift the engine (engine weight including transmission and extra equipment). For safe handling and to avoid damaging components fitted to the top of the engine, the engine must be lifted with a correctly adjusted lifting boom.

Never perform any work on an engine that is only suspended from the lifting equipment.

IMPORTANT:

All chains or wires must run parallel to each other and as perpendicular to the engine as possible. If other equipment attached to the engine has altered its center of gravity, special lifting devices may be needed to obtain the correct balance for safe handling.

P0024689

Example of an adjustable lifting yoke and a lifting tool.

12 |

47707967 09-2022 © AB VOLVO PENTA |

General Information

47707967 09-2022 © AB VOLVO PENTA |

13 |

General Information

General Information

General information

This service and maintenance manual contains descriptions and instructions for the service of the above-mentioned Volvo Penta products in their standard models. The design and servicing items may vary between different products. Applicable service intervals and service procedures are described in the maintenance schedule for the product.

The product designation, serial number and specification are indicated on the engine decals or type plate. This information must always be provided in all correspondence concerning the product.

The manual has been produced primarily for use in Volvo Penta workshops. It is assumed that persons using the manual have fundamental knowledge of the product and are capable of carrying out mechanical and electrical work to industry standards.

Volvo Penta continually develops its products. We therefore reserve the right to make changes.

All of the information in the manual is based on product data available when the manual was published.

NOTICE! The owner is responsible for ensuring that scheduled maintenance is carried out. Warranty claims to Volvo Penta may be declined if neglected maintenance results in faults in the specified product. Refer to the warranty terms supplied with the engine.

Specific terms for the U.S. market

This engine is certified as being in compliance with federal and Californian exhaust restriction regulations. Parts related to exhaust restrictions are covered by the warranty commitment for exhaust restricting systems. Terms and the parts covered are specified under "What is covered by the warranty undertaking for emissions” in “Emission Control System Warranty Statement”. Repairs and service covered by the warranty are carried out by an authorized Volvo Penta distributor or dealer at no charge for diagnostics, labor or parts using genuine Volvo Penta parts in all areas of the exhaust restriction system covered by the warranty and found to be defective.

The use of the service and repair workshop other than a Volvo Penta authorized distributor or dealer or the use of exhaust-related components from other manufacturers than Volvo Penta do not affect the scope of the warranty undertaking for emissionrestricting systems. If emission-related components/ items are included in scheduled service, such parts are marked with a diamond (♦) in the maintenance schedule and service must be carried out at the specified intervals in order to meet the requirements of the warranty undertaking for emission-restricting systems. The full warranty terms can be found in “Emission Control System Warranty Statement”.

14 |

47707967 09-2022 © AB VOLVO PENTA |

General Information

Certified engines

The engine is exhaust-certified, and if it is used in an area where exhaust emissions are regulated by law, this places special demands on the care and maintenance of the engine.

NOTICE! Neglect or failure to follow the items required here may invalidate the engine emissions certificate.

This means that AB Volvo Penta will no longer be able to assume liability for engine specification compliance with the certified model. Volvo Penta is not responsible for damages or costs arising as a result of this.

•Certification means that an engine type has been inspected and approved by the competent authorities. The engine manufacturer guarantees that all engines made of the same type are equivalent to the certified engine.

•It is the responsibility of the user to make sure no intentional misuse of the engine takes place.

•Volvo Penta maintenance and service intervals must be followed.

•All faults must be remedied as soon as possible.

•Only use genuine Volvo Penta replacement parts or parts of the same quality as Volvo Penta replacement parts.

•The engine may not be converted or modified in any way, except with accessories and service kits which Volvo Penta has approved for the engine.

•Volvo Penta recommends that service on injection pumps, pump settings and injectors always be carried out by a qualified workshop.

•No changes may be made to the installation of the exhaust pipe and engine air inlet ducts.

•Any tampering with the engine will hamper EU type-approval of the engine concerned.

•No warranty seals (if present on the product) may be broken by unauthorized persons.

Explanation of the relationship between service intervals and operating conditions

Because operating conditions may vary depending on how the component is used, it is important that the service interval (expressed in hours or months) is not exceeded.

Example: 1000 hours / 24 months. Whichever is the sooner applies. If the component is used for 1000 hours in 18 months, the service must be carried out when the 1000-hour interval is reached.

This is to retain the component’s best quality and service life. The warranty will be void if this is not complied with.

Typical examples are: Propeller shaft seals operating in sandy waters. Air filters exposed to heavily polluted air

Action codes used in the service schedule: C = Cleaning

R = Replacement A = Adjustment L = Lubricate

I = Inspection (includes where necessary also adjustment, cleaning, lubrication and replacement)

Service Protocol

To maintain the functionality of the product Service Protocol shall be followed. The owner or other persons with sufficient technical competence may carry out some measures in accordance with Service Protocol. Contact an authorized Volvo Penta dealer in the case of uncertainty as to how service work must be performed.

Service Protocol contains the necessary maintenance points for your engine in a single document. See more on Volvo Penta‘s website: vppn.volvo.com and Product Center for online service protocol.

47707967 09-2022 © AB VOLVO PENTA |

15 |

General Information

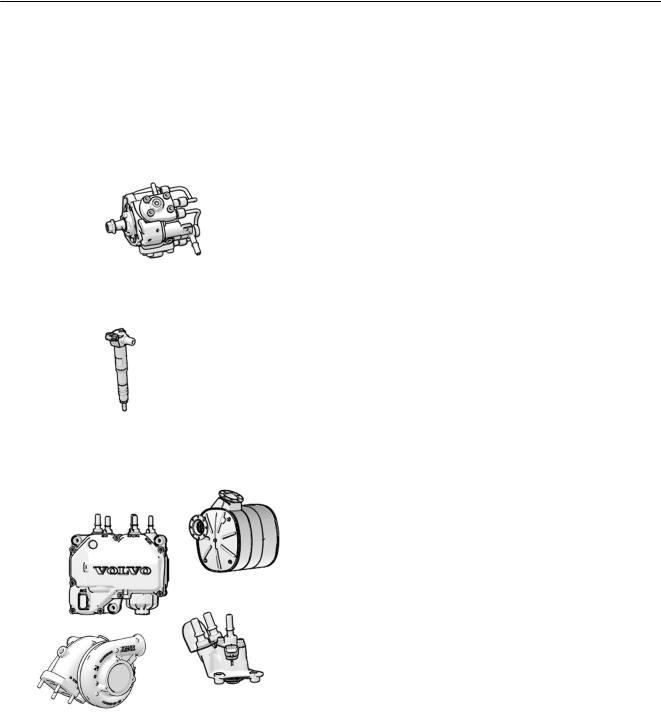

Preventive repair

Here is an overview of the components that may be included in preventive maintenance. May vary depending on the engine's design and construction.

These components form the basis for calculating service contracts and the costs in the service calculator in Product Center.

Fuel system

Fuel pump

Unit injectors

P0026295

Exhaust system

Turbocharger, low-pressure

Turbocharger, high pressure

Overflow valve (Lisk)

Silencer

Diesel particulate filter (DPF), replacement

After-treatment system

Pump unit

Dosage valve

P0026296

16 |

47707967 09-2022 © AB VOLVO PENTA |

General Information

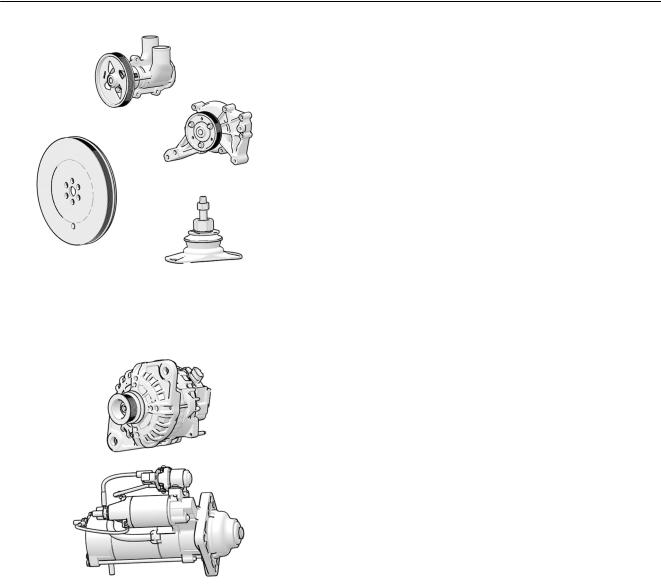

Cooling system

Seawater pump

Coolant pump

Engine

Vibration dampers

Engine pads, kit

P0026297

Electrical system

Alternator

Starter motor

P0026298

47707967 09-2022 © AB VOLVO PENTA |

17 |

General Information

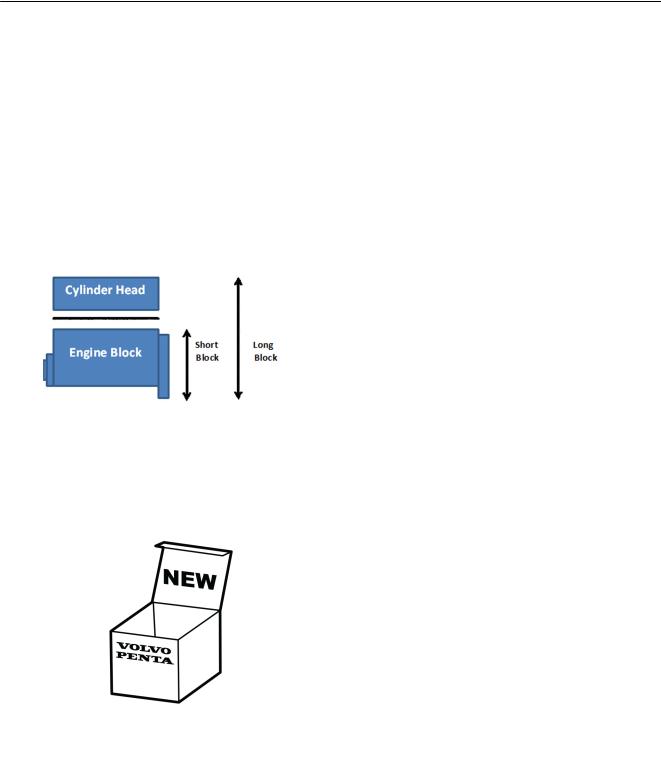

Engine, overhaul

Here is an overview of the components that may be included in a complete overhaul. May vary depending on the engine's design and construction.

E.g. liners may not be replaced on certain engines. In this case, cylinders must be measured to see if new pistons can be installed or if the engine block should be replaced.

The components below provide the basis for calculating service contracts and the costs in the service calculator in Product Center.

Engine: May be overhauled twice, after which the engine is considered spent and is replaced by a long block or new engine.

Overhaul

Long block

Short block

Cylinder head (replacement)

Cylinder head, gasket

P0026299

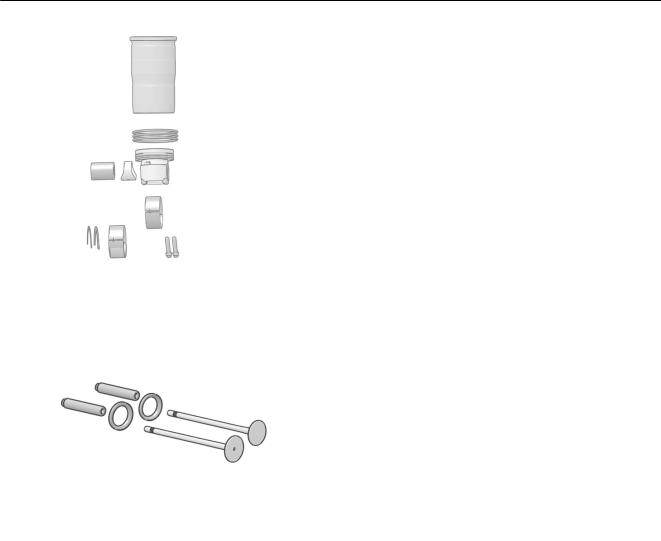

Engine, overhaul kit

Cylinder head, overhaul kit

Gaskets, kit

Flat gaskets

Valve cover, gasket

P0026300

18 |

47707967 09-2022 © AB VOLVO PENTA |

General Information

Cylinder liners, kit

Main bearings, kit

Big end bearings, kit

Thrust washers, kit

Camshaft bearings, kit

P0026301

Exhaust valve

Valve seat

P0026302

47707967 09-2022 © AB VOLVO PENTA |

19 |

General Information

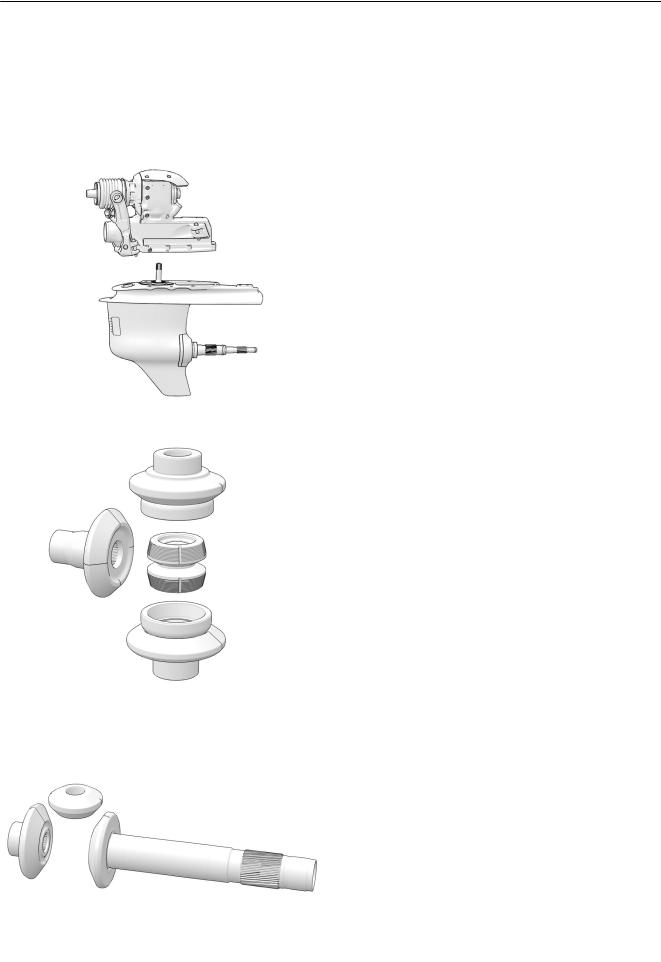

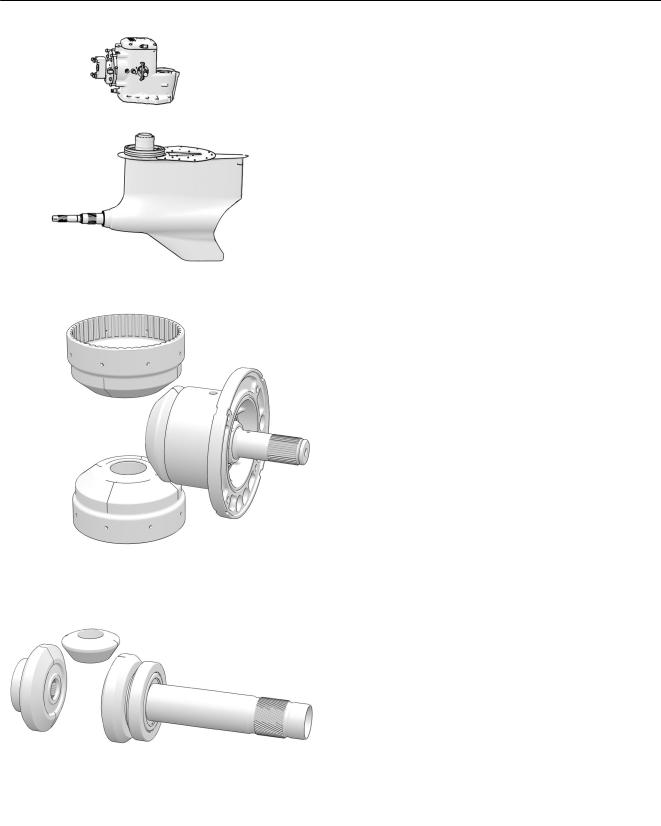

Transmission, overhaul

Here is an overview of the components that may be included in a complete overhaul/replacement. May vary depending on the transmission's design and construction.

The components below provide the basis for calculating service contracts and the costs in the service calculator in Product Center.

The transmission is overhauled once, then the complete unit is replaced

Overhaul, Aquamatic

Aquamatic sterndrive, replacement

Upper gear

Lower gear

P0026303

Repair, Aquamatic

Upper gear, kit

Sliding sleeve

P0026304

Lower gear, kit

P0026305

20 |

47707967 09-2022 © AB VOLVO PENTA |

General Information

Overhaul, IPS

IPS Drive, replacement

Upper gear

Lower gear

P0026306

Repair, IPS

Upper gear, kit

P0026307

Lower gear, kit

P0026308

47707967 09-2022 © AB VOLVO PENTA |

21 |

General Information

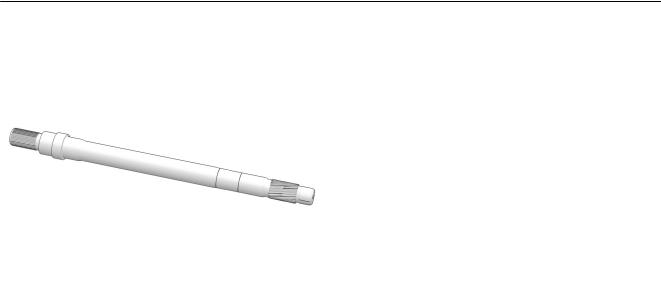

Propeller shaft

P0026309

22 |

47707967 09-2022 © AB VOLVO PENTA |

General Information

Genuine Volvo Penta Parts

Volvo Penta products are designed and manufactured to achieve the highest quality. All parts are manufactured so that together they provide the best possible reliability. For this reason, we always recommending the use of Genuine Volvo Penta Partsas they are manufactured based on the same stringent specifications as the factory-installed parts in Volvo Penta powertrains.

Lube oils

Volvo Penta supplies a wide range of lubricants developed especially for Volvo Penta engines. VDS (Volvo Drain Specification) is a Volvo standard that specifies Volvo’s oil grade requirements. We recommend the use of the specified oil to ensure engine function and a long service life.

Transmission oil

In a marine environment it is vitally important that the correct gear lubricant is used for the product concerned.

In Volvo Penta's extensive testing we pick out those oils that meet our requirements for functionality and that within the oil change intervals ensure the product’s service life.

While oils from various suppliers meets both SAE class (viscosity) and API class (quality), their additives often differ. Additives can be up to 35% of the total volume, and are crucial to how oil can handle a given water content while still maintaining the necessary lubricating properties. The additives also affect the friction in, for example, the IPS unit clutch assembly. The correct oil is crucial for the proper functioning of the transmission.

IMPORTANT:

It is extremely important not to use other oil than specified for the IPS unit.

NOTICE! Volvo Penta will deny all warranty claims if it emerges that the wrong oil has been used in the IPS unit.

NOTICE! For reverse gears, the oil change intervals and maintenance instructions recommended by the manufacturer must be adhered to.

Coolant

The main function of a coolant is to absorb heat from the engine. The coolant also protects against freezing, lime deposits and corrosion. Volvo Penta Coolant VCS (yellow) and Volvo Penta Coolant (green) are two completely different types of coolants, which contain different types of inhibitors. Different types of coolants (colors) must not be mixed.

47707967 09-2022 © AB VOLVO PENTA |

23 |

General Information

If the concentrated coolant must be diluted with water, the water's chemical composition may impair the corrosion protection. In areas with high levels of sodium and calcium in tap water, the coolant must be diluted with distilled water. Alternatively, Volvo Penta coolant is available for purchase ready diluted.

|

Protection against |

Mixing the |

freeze bursting down |

concentrated coolant |

to: |

40 % |

-25 °C |

46 % |

-30 °C |

54 % |

-38 °C |

60 % |

-46 °C |

NOTICE! It is important to use coolant with a concentration of 40-60 % in the cooling system even where there is no risk of freezing. The coolant also prevents corrosion and deposits. A mixture with a concentration above 60 % will impair antifreeze protection.

24 |

47707967 09-2022 © AB VOLVO PENTA |

Chemical products

Colors used in illustrations

Most illustrations include a highlighted component which is secured by a bolt or similar as part of a (light gray) engine or transmission.

P0022106

Illustrations

•Highlighted components (blue)

•Fastener (red)

•Assembly (light gray)

•Background (white)

•Special tools (yellow)

•Seals (green)

(as of 06/2018)

Other types of symbols used in the images are divided into the following categories:

•Safety

•Important

•Cleanliness

•Position

•Movement

•Measured value

•Tools

•Chemicals

•Sealant

•Units

47707967 09-2022 © AB VOLVO PENTA |

25 |

Chemical products

26 |

47707967 09-2022 © AB VOLVO PENTA |

Special Tools

Chemical products

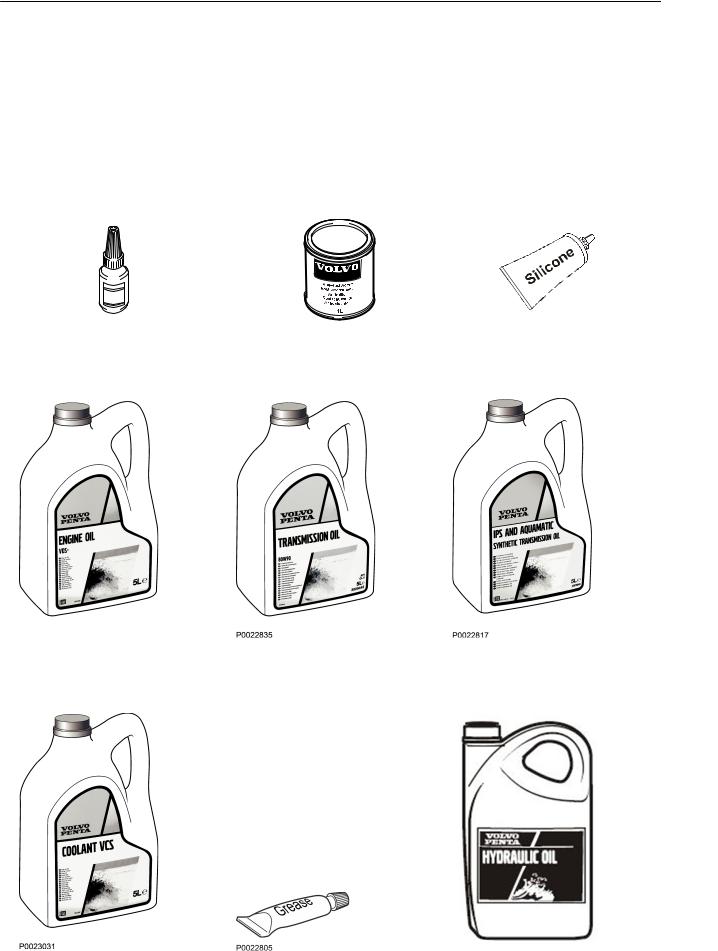

Chemical products

The following is a selection of Volvo Penta recommended chemical products. The products are available for purchase at regional Volvo Penta dealerships. Deviations may occur in the range, see Specifications.

For correct part numbers, refer to the Parts catalogue.

P0001869

Thread locking fluid Corrosion protection Sealant

Engine oil |

Transmission oil |

IPS synthetic gear lubricant |

VCS Coolant |

Grease |

ATF oil |

47707967 09-2022 © AB VOLVO PENTA |

27 |

Special Tools

28 |

47707967 09-2022 © AB VOLVO PENTA |

Loading...

Loading...