OPERATOR'S MANUAL

VEHICLE MAINTENANCE

VN,VHD

Volvo d11f and d13f engines

Volvo Trucks. Driving Success.

R

Table of Contents i

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warning Label Information . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Information for the Owner . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Exhaust and Noise Emissions . . . . . . . . . . . . . . . . . . . . . . . . 5

Label Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fuse and Relay Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Proper Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . 24

Injury Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Engine Damage Prevention . . . . . . . . . . . . . . . . . . . . . . . . . 34

Electric System Damage Prevention . . . . . . . . . . . . . . . . . . 36

Reporting Safety Defects . . . . . . . . . . . . . . . . . . . . . . . . . . 38

General Engine Information . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Engine Overview, D11F and D13F Left Side View . . . . . . 39

Engine Overview, D11F and D13F Right Side View . . . . . 40

Engine Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Engine Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Maintenance Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Engine Components, Service Schedules . . . . . . . . . . . . . . . 43

Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

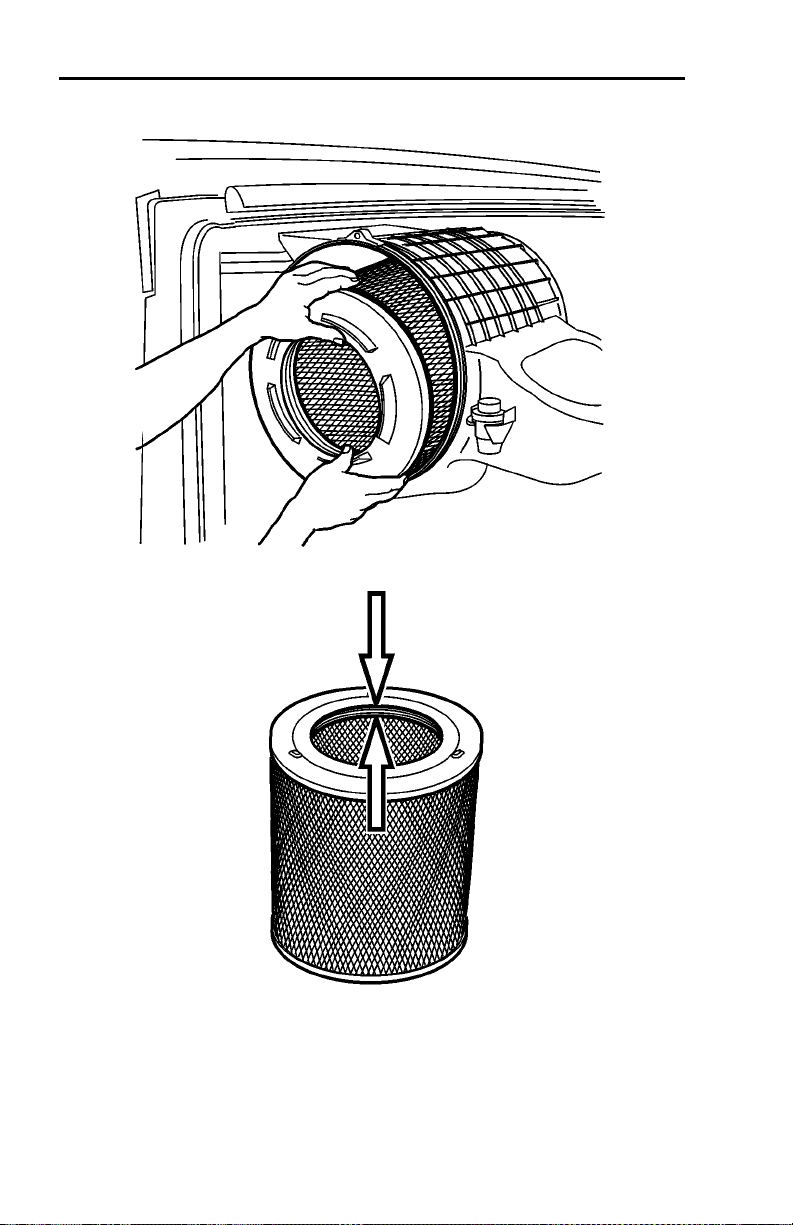

Engine Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Diesel Particulate Filters (If Equipped) . . . . . . . . . . . . . . . 65

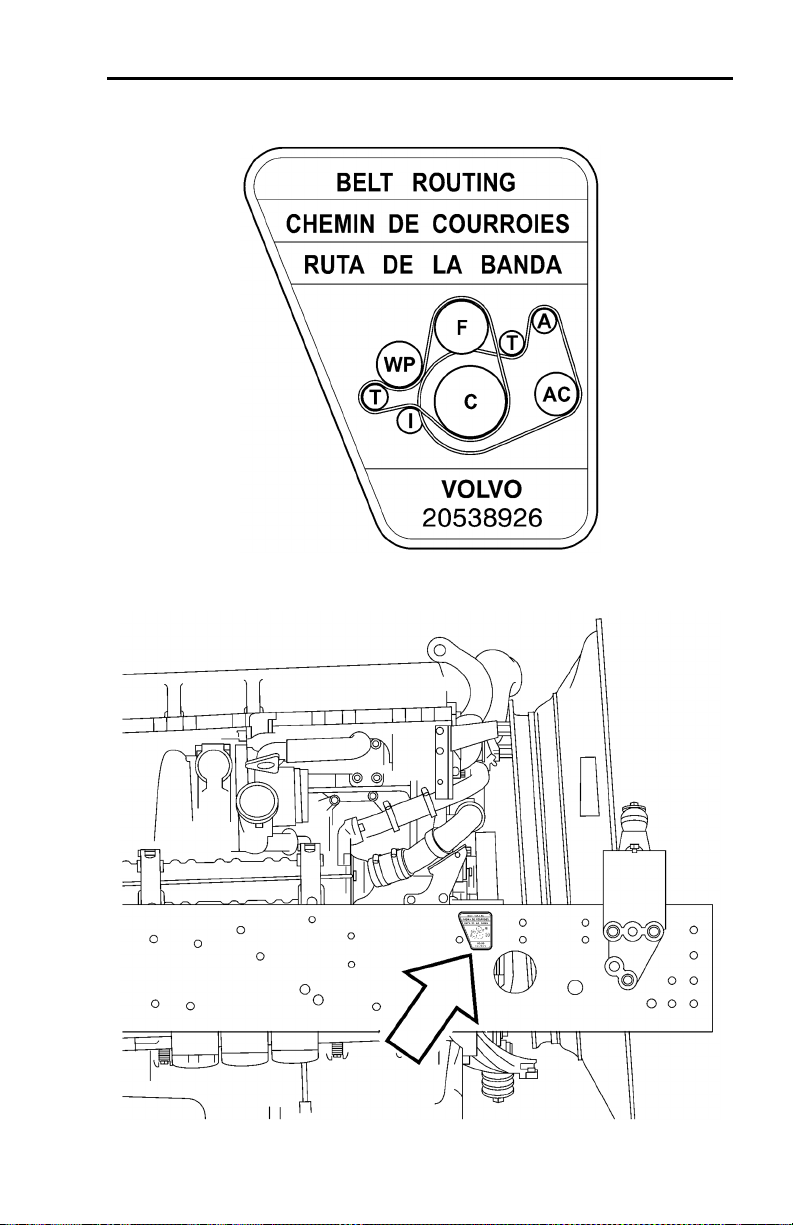

Fan and Auxiliary Drive Belts . . . . . . . . . . . . . . . . . . . . . . 66

Turbocharger and Charge Air Cooler . . . . . . . . . . . . . . . . . 68

Fuel System Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Transmission, Clutch and Rear Axle Maintenance . . . . . . . 73

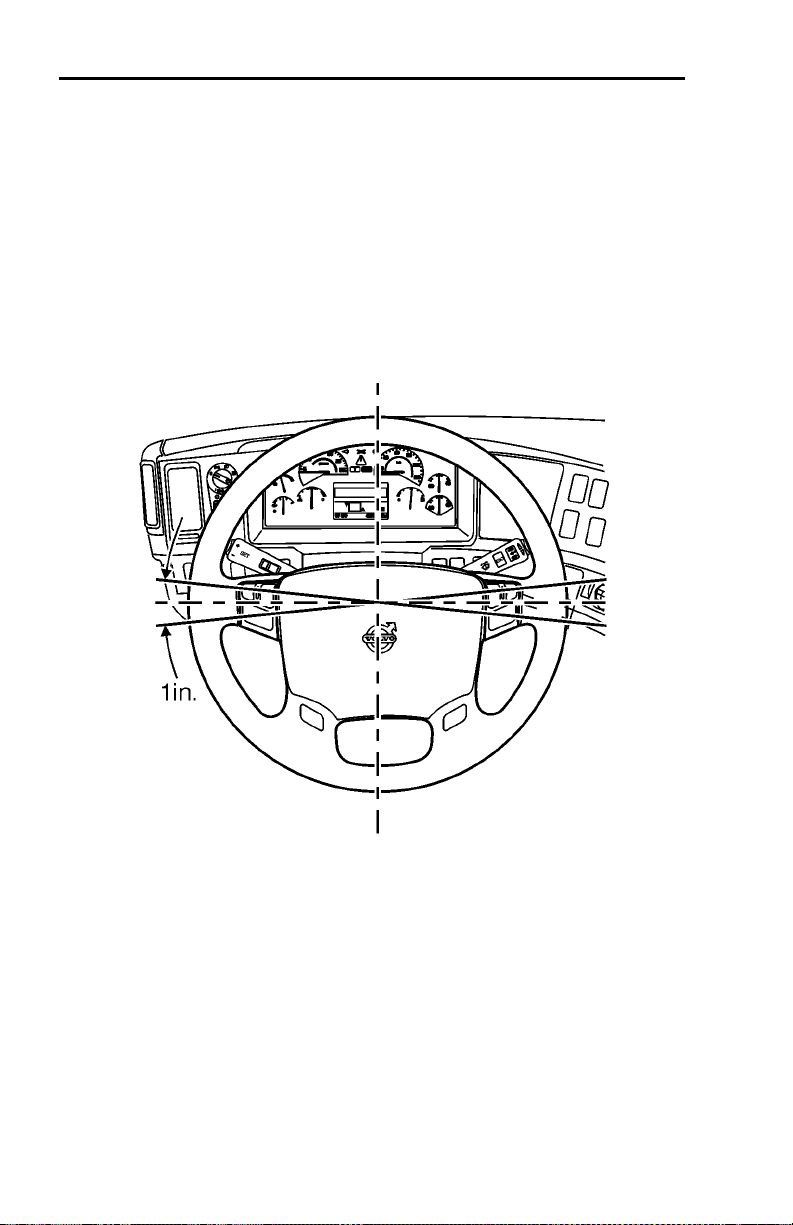

Steering and Brakes Maintenance . . . . . . . . . . . . . . . . . . . . 76

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . . . . 80

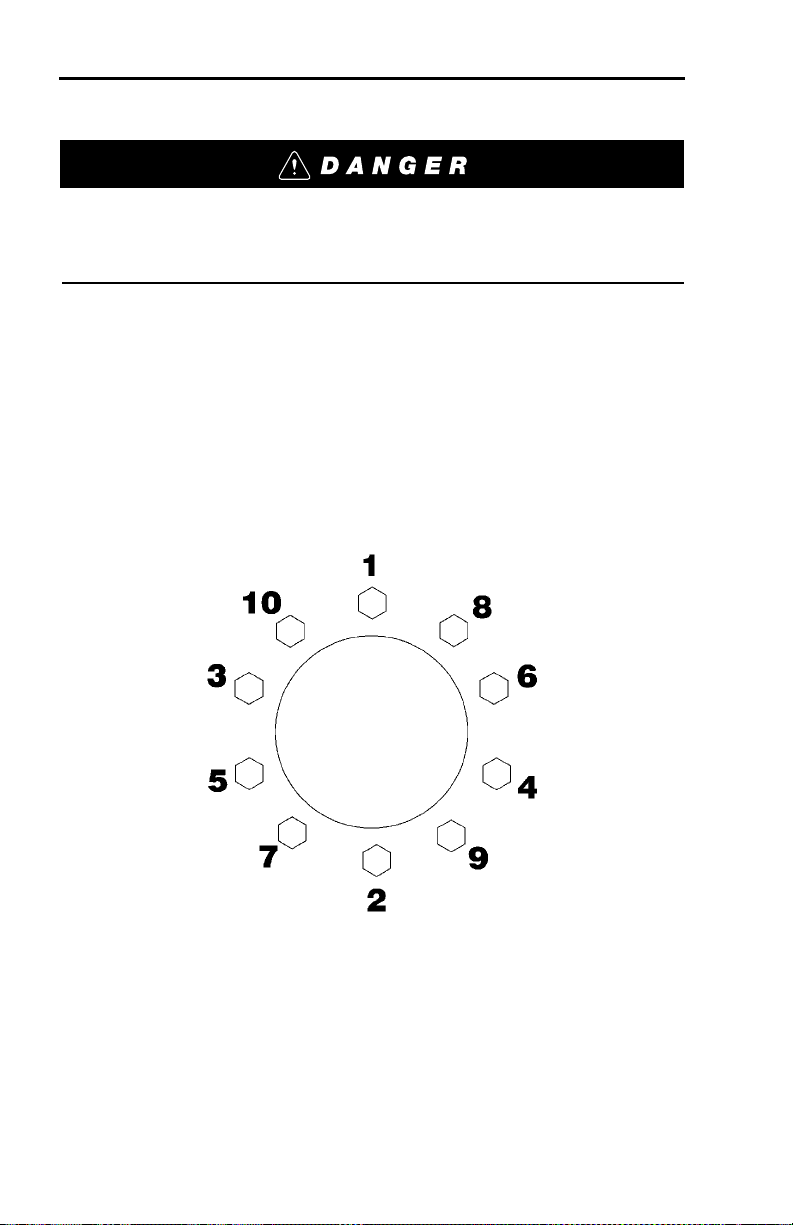

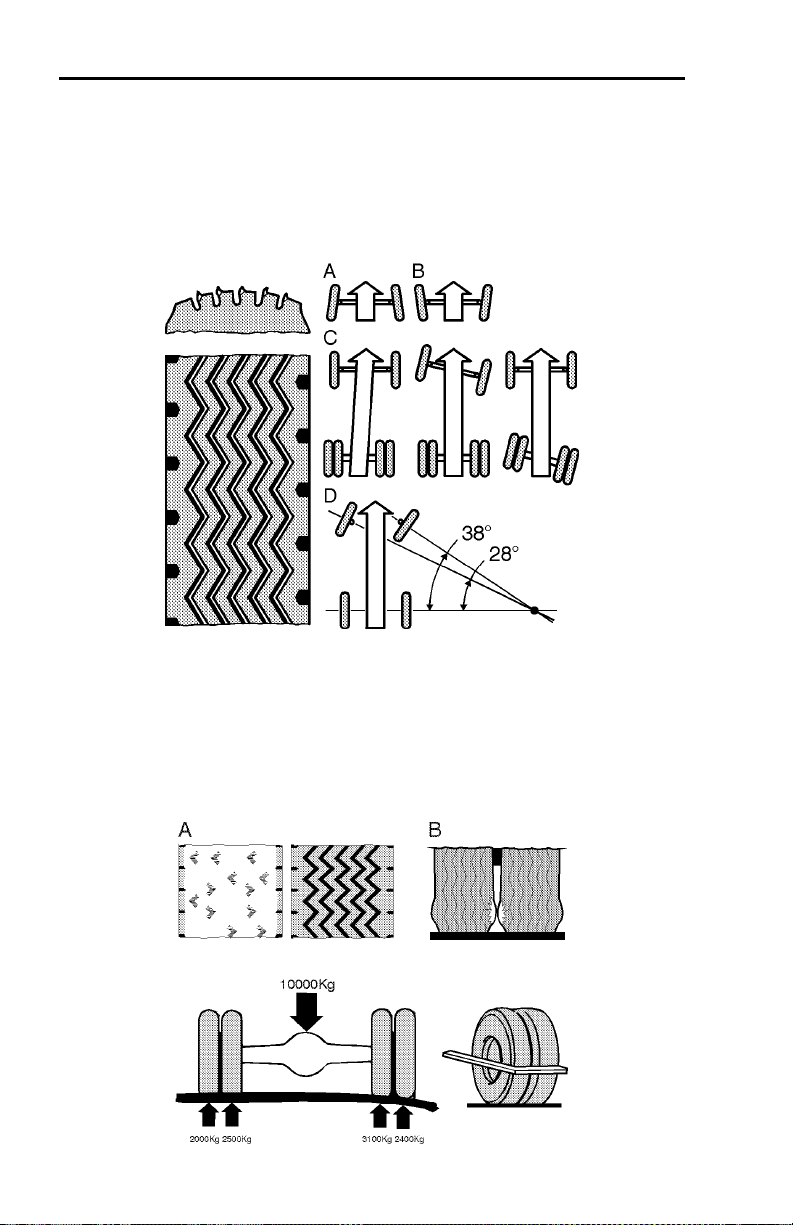

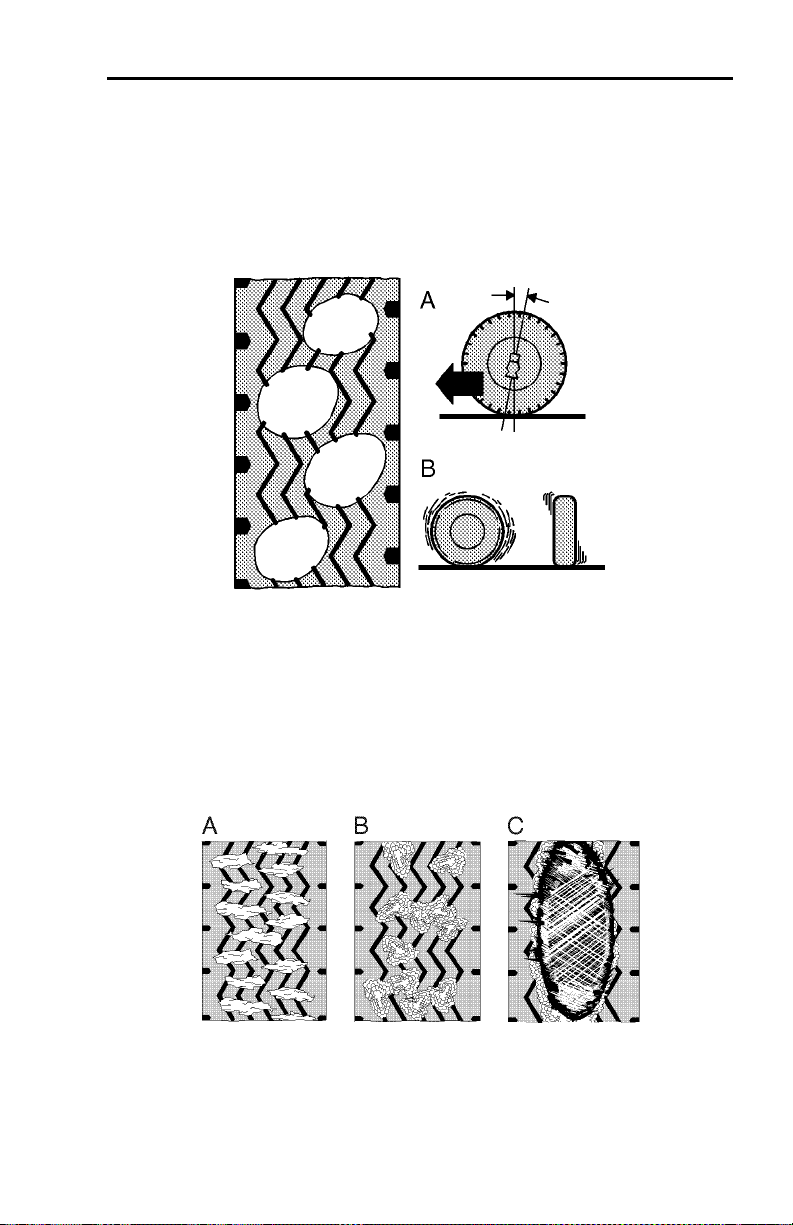

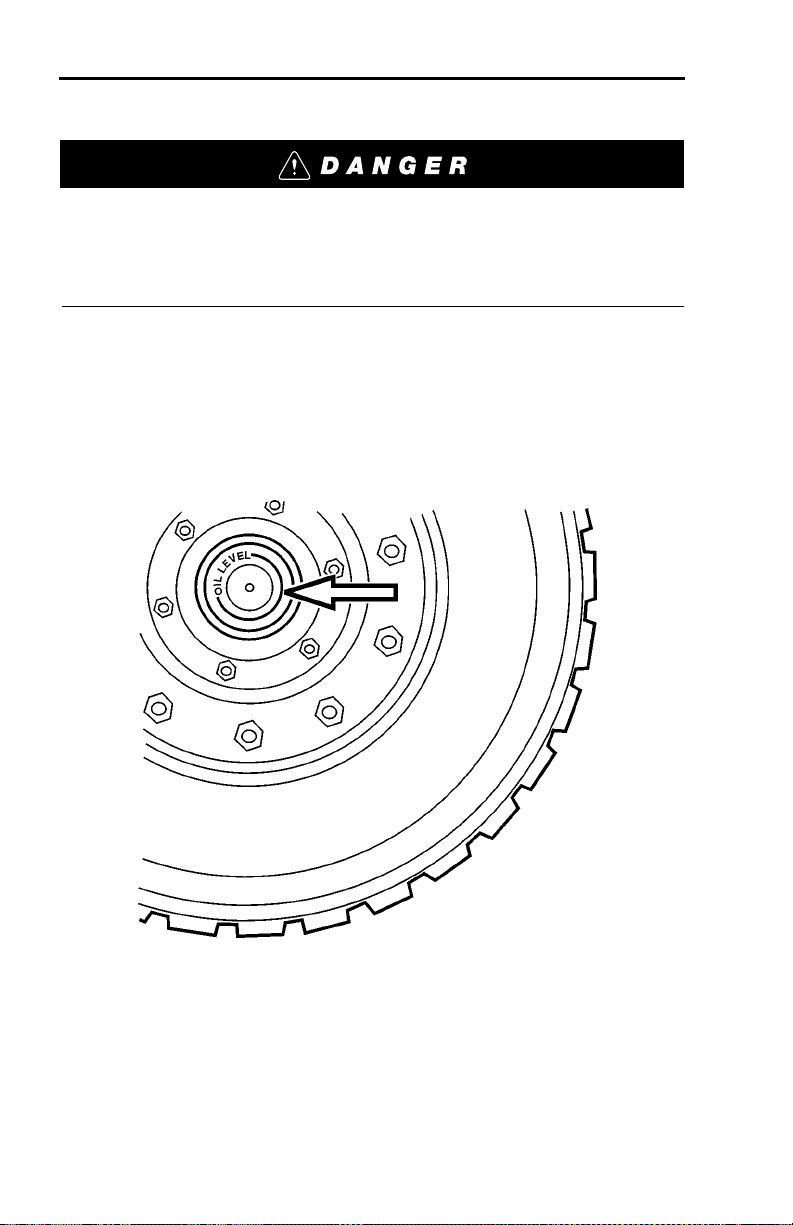

Tires, Wheels and Hub Maintenance . . . . . . . . . . . . . . . . . 82

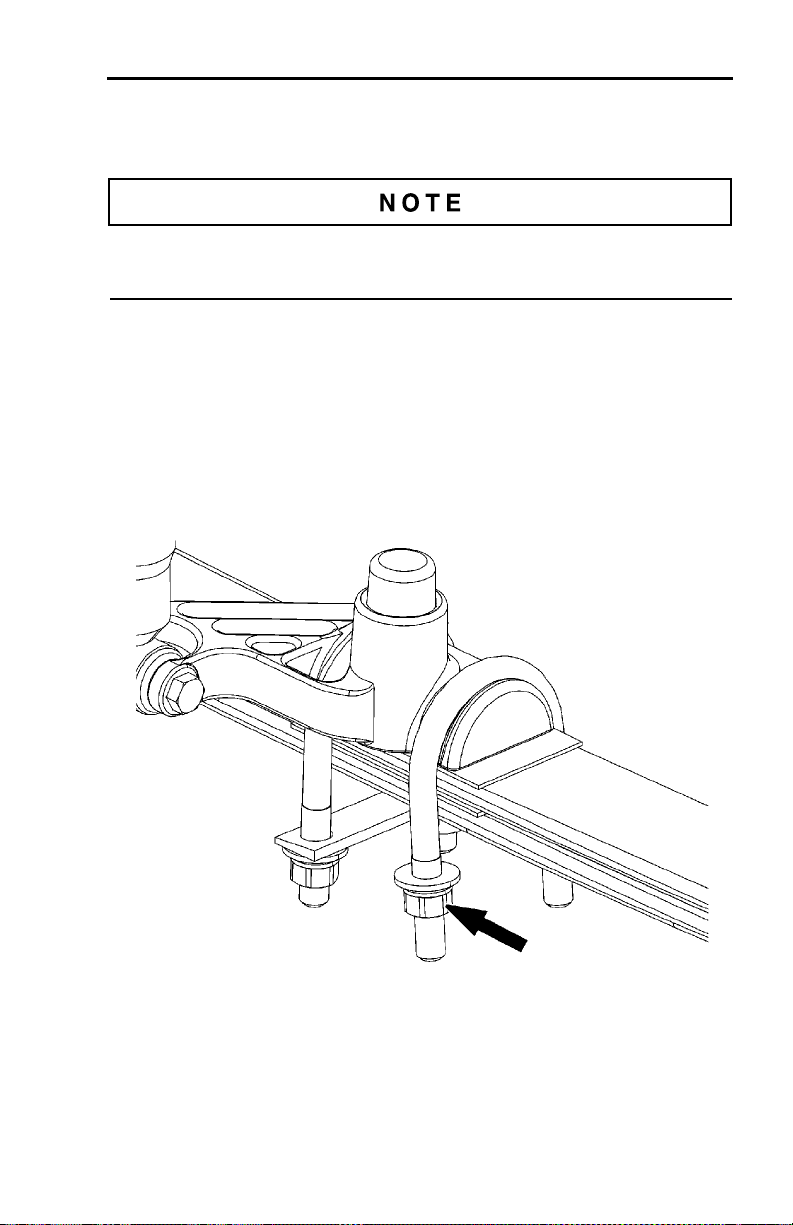

Chassis Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Cab Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Oil Capacity Tables and Viscosity Charts . . . . . . . . . . . . 108

ii Table of Contents

Service Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Service Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Scheduled Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Repair Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Tire Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Fuel and Oil Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Literature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Engine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Service Assistance and Manuals . . . . . . . . . . . . . . . . . . . . 122

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Foreword 1

FOREWORD

DO NOT Remove this manual from the vehicle. It contains important

operational and safety information that is needed by all drivers and owners of

this vehicle.

This manual contains information concerning the safe operation of your

vehicle. It is extremely important that this information is read and understood

before the vehicle is operated. This manual also contains a considerable

amount of information concerning the vehicle, such as vehicle identification,

Preventive Maintenance recommendations and a log for your service records.

Please keep this in the vehicle at all times. Information from other component

manufacturers is supplied in separate manuals in the Owner's Package.

It is important that this manual stay with the vehicle when it is sold. Important

safety information must be passed on to the new customer. The service

information contained in this manual gives the owner important information

about maintaining the vehicle but is not intended as a substitute for the

Preventive Maintenance Service Manual and must not be regarded as such.

The National Highway Traffic Safety Administration (NHTSA) and Volvo

Trucks North America should be informed immediately if you believe that the

vehicle has a defect that could cause a crash, injury or death.

Contact NHTSA by calling the Auto Safety Hotline at 1 (888) 327-4236, by

writing to NHTSA, U.S. Department of Transportation, Washington, DC

20590, by TTY at 1 (800) 424-9153, or visit their website at

www.nhtsa.dot.gov.

Volvo Trucks North America

Greensboro, NC USA

Order number: PV776-21012002

©2008 Volvo Trucks North America, Greensboro, NC USA

All rights reserved. No part of this publication may be reproduced, stored in

retrieval system, or transmitted in any forms by any means, electronic,

mechanical, photocopying, recording or otherwise, without the prior written

permission of Volvo Trucks North America.

2 Foreword

WARNING LABEL INFORMATION

IMPORTANT: Before driving this vehicle, be certain that you have read

and that you fully understand each and every step of the driving and

handling information in this Operator's Manual. Be certain that you fully

understand and follow all safety warnings. It is extremely important that

this information is read and understood before the vehicle is operated.

IT IS IMPORTANT THAT THE FOLLOWING INFORMATION

CONCERNING LABELS BE READ, UNDERSTOOD AND ALWAYS

FOLLOWED.

The following types of labels are used throughout this manual:

A note defines an operating procedure, practice, condition, etc., which is

essential to proper operation of the vehicle.

A danger label directs the operator's attention to unsafe practices which

could result in serious personal injury or death. The danger label is in white

type on a black background with a black border.

A warning label directs the operator's attention to unsafe practices which

could result in personal injury or severe damage to the vehicle. The

warning label is in black type on a gray background with a black border.

A caution label directs the operator's attention to unsafe practices where

personal injury is not likely but property damage could occur. The caution

label is in black type on a white background with a black border.

Warning and Advisory Labels

Advisory, Danger, Warning and Caution labels are placed in various locations

of the vehicle to alert drivers and service technicians about situations that may

lead to personal injury or equipment damage. In the event that a label is

damaged or missing the label must be replaced. Contact your authorized

Volvo Truck dealer for assistance regarding Warning and Advisory labels.

General Information 3

GENERAL INFORMATION

INFORMATION FOR THE OWNER

If there are questions on the maintenance and performance of your vehicle,

please discuss them with your Volvo Truck dealer. Your authorized dealer is

required to have trained mechanics, special tools and spare parts to fully

service your vehicle. If necessary, your dealer will contact Volvo Trucks North

America or other manufacturers for any assistance.

In addition to this Maintenance Manual, there may be additional instruction/

operator's manuals supplied by component manufacturers. These manuals are

placed in the Owner's Package and placed in the cab. Be sure to read all the

manuals thoroughly before operating the vehicle.

Also, various safety labels may be placed on components by the component

manufacturer. Be sure to read and follow these labels to prevent damage to the

vehicle, personal injury or even death.

Information in this manual refers to Volvo components and Volvo drivetrain.

There is also certain information regarding the Cummins engine. For detailed

information on the Cummins engine or non-Volvo engines and/or drivetrains

contact your nearest Volvo Truck dealer.

Establish a Preventive Maintenance Program with the help of your local Volvo

Truck dealer. A Preventive Maintenance Program makes it possible to

maximize the amount of time your vehicle is up and running, resulting in

longer component life. This makes for a safer vehicle by reducing any

mechanical failures due to poor maintenance practices.

Federal law requires manufacturers to notify owners of its products in the

event of a Federal Motor Vehicle Safety Standard or if a safety related defect

is discovered. If you are not the original owner of this vehicle, please notify us

about the change in ownership at the address below or through an authorized

Volvo Truck dealer. This is the only way we will be able to contact you if

necessary.

Volvo Trucks North America

P. O. Box 26115

Greensboro, NC 27402-6115

United States of America

4 General Information

This Maintenance Manual covers all Volvo vehicles manufactured by Volvo

Trucks North America, including the whole chassis and all Volvo

manufactured components. For specific maintenance information on vendor

components, manufactured by, for example: Cummins, Fuller, Meritor, etc.,

see the respective manufacturer's service and maintenance literature.

This manual, together with manuals for specific components (for example,

Volvo engine, Cummins engine, Eaton transmission, etc.) contain important

information to be able to operate this vehicle safely. They contain advice and

instructions which will enable you to get the operating economy and

performance that you expect from this quality vehicle.

All information, illustrations and specifications contained in this manual are

based upon the latest product information available at the time of publication.

If any questions arise concerning the current status of Federal or state laws,

the appropriate Federal or state agency should be contacted.

Illustrations are used for reference only and may differ slightly from the actual

vehicle, however, key components addressed in this manual are represented as

accurately as possible.

Volvo Trucks North America reserves the right to make changes at any time or

to change specifications or design without notice and without incurring

obligation.

General Information 5

EXHAUST AND NOISE EMISSIONS

General

USA

The Federal Clean Air Act, Section 203 (a) (3), states the following

concerning the removal of air pollution control devices or modification of a

certified engine to a non-certified configuration:

“The following acts and the causing thereof are prohibited:

(3) For any person to remove or render inoperative any device or element of

design installed on or in a motor vehicle or motor vehicle engine in

compliance with regulations under this part prior to its sale and delivery to the

ultimate purchaser, or for any manufacturer or dealer knowingly to remove or

render inoperative any such design after sale and delivery to the ultimate

purchaser.”

Specifically, please note that no person may make such changes prior to the

sale and delivery of the vehicle to the ultimate purchaser, and, in addition, no

manufacturer or dealer may take such action after sale and delivery of the

vehicle to the ultimate purchaser. The law provides a penalty of up to

$10,000 for each violation.

Canada

The same conditions that apply in the USA apply to Canada, with one

exception. After the vehicle is sold to a retail customer, that is, the end user,

the jurisdiction controlling the emission control devices becomes the province

in which the vehicle is licensed. No changes should be made that render any or

all of the devices inoperative.

Should the owner/operator wish to make any changes to the emission control

devices, check with the provincial authority before making any such changes.

Mexico

The same conditions that apply in the USA apply to Mexico. Refer to the

Mexican Federal Law for Emission Control which adheres to EPA regulations.

No changes should be made that render any or all of the emissions control

devices inoperative.

Should the owner/operator wish to make any changes to the emission control

devices, check with the state authority before making any such changes.

6 General Information

CALIFORNIA EMISSION CONTROL SYSTEMS WARRANTY

Warranty coverage is subject to change without notice. Contact your Volvo

Truck dealer for the current warranty statement.

The California Air Resources Board and Volvo Trucks North America

are pleased to explain the California emission control system warranty on

your new motor vehicle engine. In California, new motor vehicle engines must

be designed, built and equipped to meet the State’s stringent anti-smog

standards. Volvo Trucks North America must warrant the emission control

system on your engine for the period of time listed below provided there has

been no abuse, neglect, or improper maintenance of your engine.

Your emission control system may include parts such as the fuel-injection

system, turbocharger assembly, electronic control module and other

emission-related assemblies.

Where a warrantable condition exists, Volvo Trucks North America will repair

your engine at no cost to you including diagnosis, parts, and labor.

MANUFACTURER’S WARRANTY COVERAGE:

If an emission-related part of your engine is defective, the part will be repaired

or replaced by Volvo Trucks North America. This is your emission control

system DEFECTS WARRANTY.

OWNER’S WARRANTY RESPONSIBILITIES:

As the motor vehicle engine owner, you are responsible for the performance of

the required maintenance listed in this manual. Volvo Trucks North America

recommends that you retain all receipts covering maintenance of your vehicle,

but Volvo Trucks North America. cannot deny warranty solely for the lack of

receipts or for your failure to ensure the performance of all scheduled

maintenance listed in other manuals which were supplied with your vehicle.

You are responsible for presenting your motor vehicle engine to a VOLVO

dealer as soon as a problem exists. The warranty repairs should be completed

in a reasonable amount of time, not to exceed 30 days.

As the motor vehicle engine owner, you should also be aware that Volvo

Trucks North America may deny you warranty coverage if your vehicle or a

part has failed due to abuse, neglect, improper maintenance, or unapproved

modifications.

General Information 7

If you have any questions regarding your warranty rights and responsibilities,

you should contact the Volvo Trucks North America Warranty Department at

P. O. Box 26115, Greensboro, NC 27402-6115, or the California Air

Resources Board at 9480 Telstar Avenue, El Monte, California 91731.

(Applicable only to vehicles and/or engines certified for sale and

registered in the State of California)

Volvo Trucks North America warrants the Emission Control Systems on each

new VOLVO diesel engine in a new VOLVO truck to comply with all State of

California emissions regulations applicable at the time of manufacture of the

engine, and to be free from defects in material and workmanship under normal

use and service up to 60 months, or 100,000 miles, or 3,000 engine operating

hours, whichever occurs first, provided all Volvo Trucks North America

maintenance requirements are followed as described in this manual. All

warranty periods are calculated from the date-in-service of the new vehicle.

The repair or replacement of defective parts will be made without charge for

the cost of parts and, if repairs are made at an authorized Volvo Trucks North

America dealership, there will be no charge for labor.

Volvo Trucks North America’s obligation under this warranty is limited to the

repair or replacement, at Volvo Trucks North America's option, of any part(s)

of the Emission Control Systems of such engine and/or vehicle found to be

defective upon examination by Volvo Trucks North America and provided that

such part(s) were returned to Volvo Trucks North America or its nearest

authorized Dealer within a reasonable period of time.

Qualifications and Limitations:

Not covered by the Emissions Control Systems Warranty:

앫 Malfunctions caused by misuse, improper adjustments, modification,

alteration, tampering, disconnection, improper or inadequate maintenance

and use of improper diesel fuel.

앫 Damage resulting from accident, acts of nature or other events beyond the

control of Volvo Trucks North America.

앫 Inconvenience, loss of use of the vehicle, commercial loss of any kind

including, but not limited to, consequential, incidental damages.

앫 Any vehicle in which the odometer has been altered or damaged so that

mileage cannot be readily determined.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES AND REPRESENTATIONS OR CONDITIONS,

STATUTORY OR OTHERWISE, EXPRESSED OR IMPLIED

INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

8 General Information

PROCEDURES FOR HANDLING EMISSIONS CONTROL

SYSTEM WARRANTY

The following engine components are covered by the supplemental emissions

control system warranty policy as required by the California Code of

Regulations.

a. Turbocharger Assembly

b. VGT Actuator Control Valve

c. Charge Air Cooler

d. Unit Injectors

e. Engine Wiring Harness

f. Electronic Control Module

g. EGR Mixer

h. EGR Cooler

i. EGR Control Valve

j. Crankcase Breather

k. Diesel Particulate Filter (DPF) Assembly

l. DPF Components:

앫 Aftertreatment Fuel Injector (AFI)

앫 AFI Shutoff Valve

앫 Discharge Recirculation Valve

앫 Pre-Catalyst Temp. Sensor

앫 Post-Catalyst Temp. Sensor

앫 Downstream DPF Temp. Sensor

앫 Differential Pressure Sensor

m. Sensors:

앫 Engine Timing/Speed (flywheel)

앫 Engine Position (camshaft)

앫 Temperature — Coolant

앫 Temperature — Inlet Manifold Air

앫 Pressure — Boost Air

앫 Humidity

앫 EGR Temperature

앫 EGR Differential Pressure

General Information 9

The emission warranty for the diesel particulate filter covers defects in

workmanship only. Normal maintenance, such as cleaning ash from the filter

at regular maintenance intervals, is not covered by the emission warranty.

In response to customer requests, Volvo Trucks North America may build

vehicles with engines supplied by other manufacturers, including, but not

limited to, Cummins. In these cases, each engine manufacturer through its

service organization, is responsible for emission control systems warranty on

all parts of the engine assembly, as furnished.

Any unauthorized adjustments to the emission control components can cause

severe damage to the engine.

1. Repairs by VOLVO Dealers, Sub-Dealers and Service Dealers

Repairs covered by the California Emission Control Systems Warranty

will be performed by any authorized VOLVO repair facility at his place

of business with no charge for parts and labor (including diagnosis),

using VOLVO parts for any part of the emission control systems covered

by this warranty and found defective.

2. In an Emergency

In an emergency, where an authorized VOLVO facility is not available,

repairs may be performed at any available service establishment, or by

the owner, using any replacement part, within the limitations of

paragraphs 4 and 5 in this section. An emergency condition exists under

this section if, after 30 days, repairs have not been completed or parts

are not yet available. VOLVO will reimburse the owner for such repairs

that are covered under this warranty, including diagnosis, not to exceed

VOLVO’s suggested retail price for parts replaced and labor charges

based on VOLVO’s recommended time allowance and geographically

appropriate hourly labor rate. Replaced parts and paid invoices must be

presented at a VOLVO facility as a condition of reimbursement for

emergency repairs performed elsewhere.

10 General Information

In the event that damage results from unauthorized adjustments to any

emission control system components, as evidenced by settings other than as

specified, or broken fastener seals, the cost of repairing such damage WILL

NOT BE COVERED under warranty.

3. Repairs by Non-VOLVO Facilities

Owners may elect to have maintenance, replacement, or repair of

emission control systems performed by any repair facility, and may elect

to use parts other than VOLVO parts without invalidating the warranty

on other components, but the cost of such service or parts will not be

covered by VOLVO under its warranty.

4. Use of Non-VOLVO Parts

Use of replacement parts which are not the equivalent of VOLVO parts

may impair the effectiveness of emission control systems. If other than

VOLVO parts are used, the owner should obtain assurances that such

parts are warranted by their manufacturer to be the equivalent of

VOLVO parts in performance and durability. VOLVO assumes no

liability under this warranty with respect to parts other than VOLVO

parts; however, the use of non-VOLVO parts does not invalidate the

warranty on other components unless non-VOLVO parts cause damage

to warranted parts.

5. Maintenance and Maintenance Records

The vehicle owner is responsible for the performance of all required

maintenance specified in this manual.

VOLVO will not deny a warranty claim solely because there is no record

of maintenance; however, VOLVO may deny a warranty claim if failure

to perform required maintenance results in the failure of a warranted

part. Receipts or other records covering the performance of scheduled

maintenance should be retained to answer questions that may arise

concerning maintenance. Maintenance records should be transferred to

subsequent owners if the vehicle is sold.

6. Items Not Covered by the Emission Control Systems Warranty

— Malfunctions caused by misuse, improper adjustments,

modification, alteration, tampering, disconnection, improper or

inadequate maintenance.

— Damage resulting from accident, acts of nature or other events

beyond the control of VOLVO.

— Inconvenience, loss of use of the vehicle, or commercial loss.

— Any vehicle on which the odometer has been changed so that

mileage cannot be readily determined.

General Information 11

7. Customer Assistance

Volvo Trucks North America wishes to assure that the California

Emission Control Systems Warranty is properly administered. In the

event that owners do not receive the warranty service to which they

believe they are entitled under the California Emission Control Systems

Warranty, they should contact Volvo Trucks North America Warranty

Administration, (336) 393-2000. The address and telephone number of

each Regional Office is in your vehicle owner's package. Owners in

need of additional assistance or information concerning the California

Emission Control Systems Warranty may also contact:

Volvo Trucks North America

Warranty Administration

(336) 393-2000

12 General Information

CALIFORNIA EMISSION CONTROL SYSTEMS SERVICE

RECORD

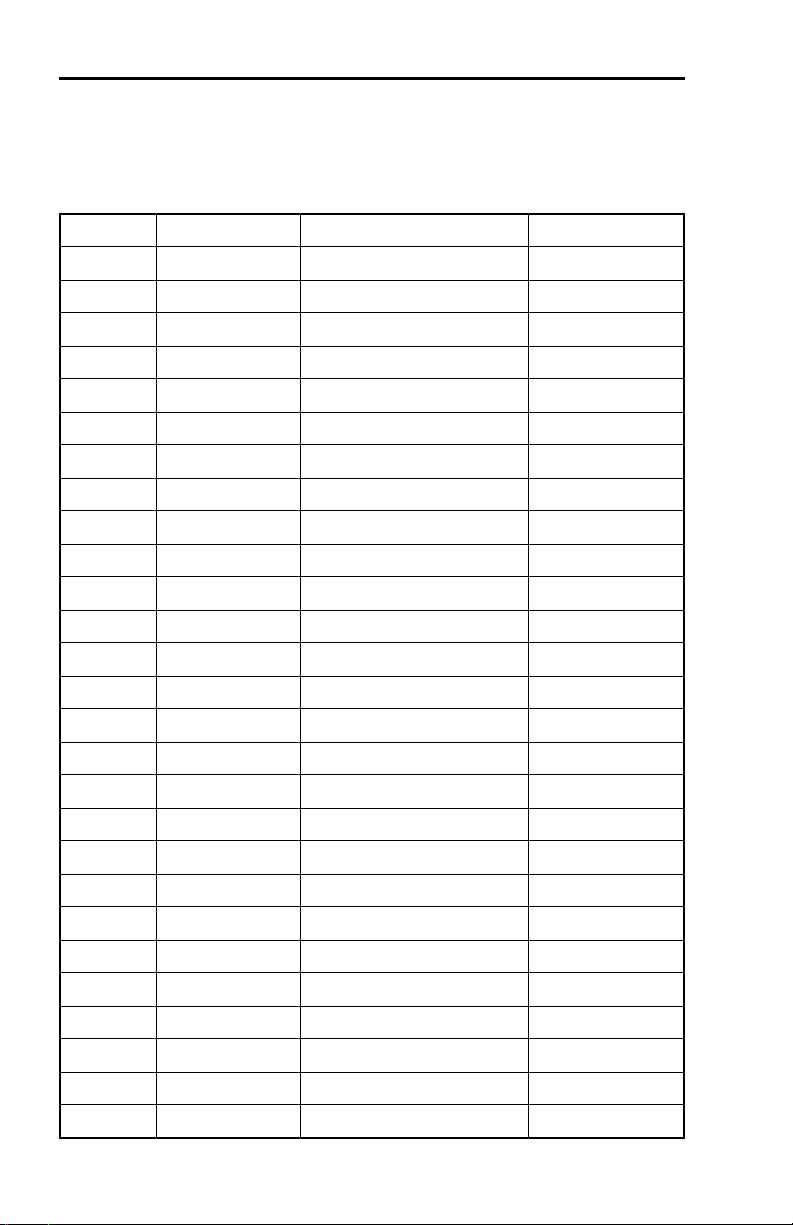

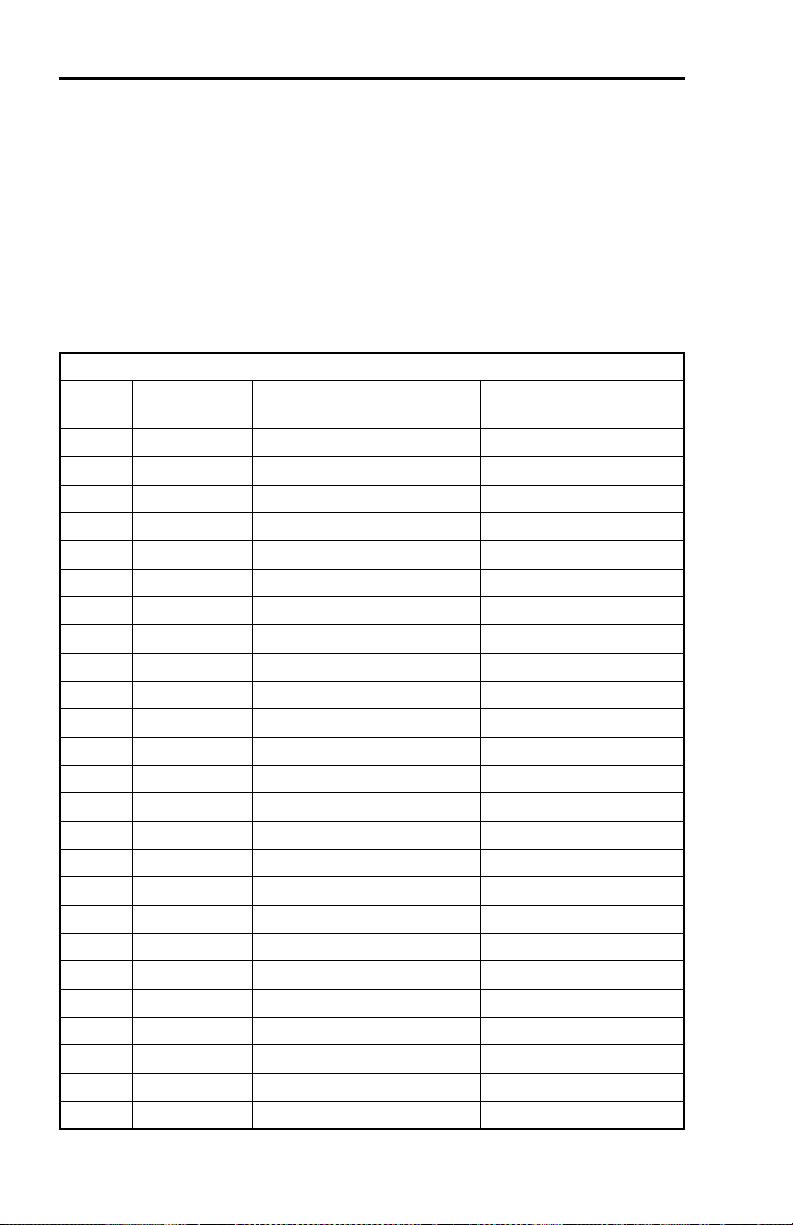

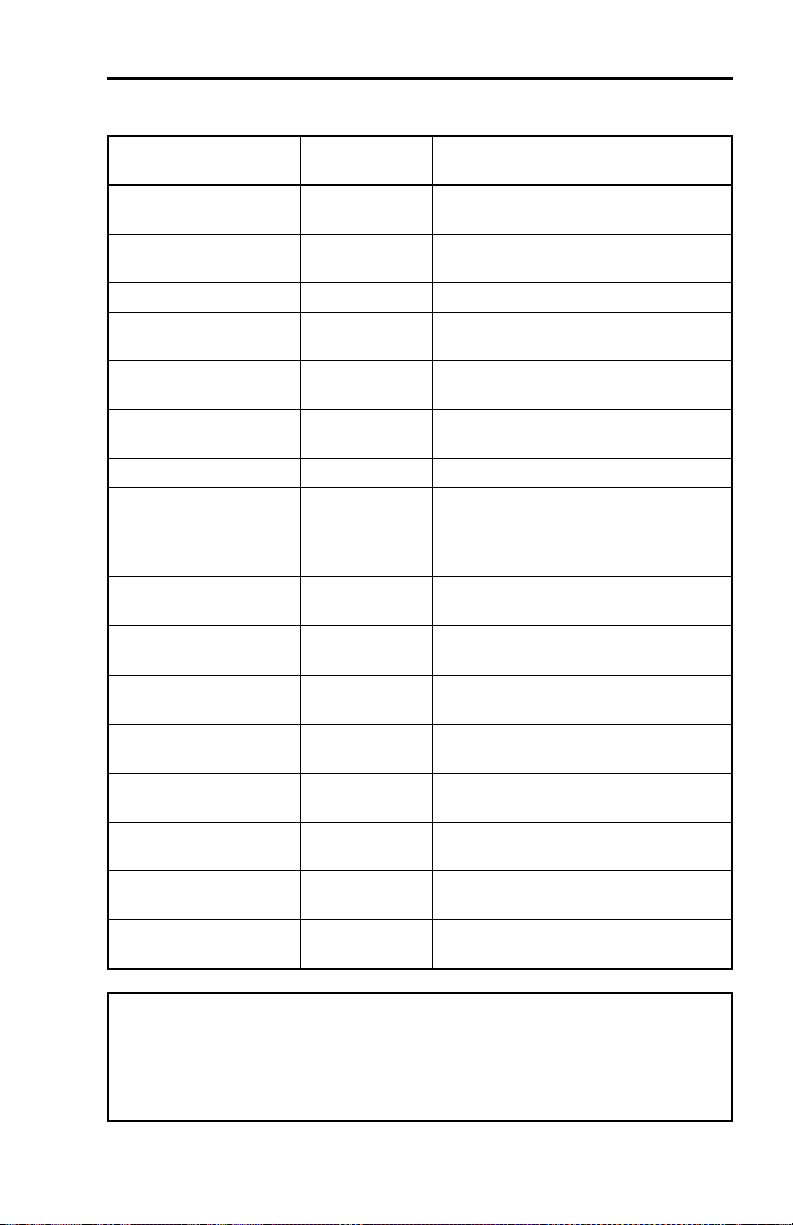

CALIFORNIA EMISSION CONTROL SYSTEMS SERVICE RECORD

DATE KM\MILES SERVICE PERFORMED SERVICED BY

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

__/__/__

General Information 13

GASEOUS EMISSION CONTROL SYSTEMS WARRANTY

For emission control systems information on engines other than VOLVO, refer

to the engine vendor’s publications.

Volvo Trucks North America warrants the Emission Control Systems on each

new VOLVO diesel engine in a new VOLVO truck to comply with all United

States Federal and Canadian emissions regulations applicable at the time of

manufacture of the engine, and to be free from defects in material and

workmanship under normal use and service up to 60 months, or

100,000 miles, whichever occurs first, provided all Volvo Trucks North

America. maintenance requirements are followed as described in this manual.

All warranty periods are calculated from the data-in-service of the new

vehicle. The repair or replacement of defective parts will be made without

charge for the cost of parts and, if repairs are made at an authorized Volvo

Trucks North America. dealership, there will be no charge for labor.

Volvo Trucks North America's obligation under this warranty is limited to the

repair or replacement, at Volvo Trucks North America's option, of any part(s)

of the Emission Control Systems of such engine and/or vehicle found to be

defective upon examination by Volvo Trucks North America and provided that

such part(s) were returned to Volvo Trucks North America or its nearest

authorized Dealer within a reasonable period of time.

Qualifications and Limitations:

Not covered by the Emissions Control Systems Warranty:

앫 Malfunctions caused by misuse, improper adjustments, modification,

alteration, tampering, disconnection, improper or inadequate maintenance

and use of improper diesel fuel.

앫 Damage resulting from accident, acts of nature or other events beyond the

control of Volvo Trucks North America.

앫 Inconvenience, loss of use of the vehicle, commercial loss of any kind

including, but not limited to, consequential, incidental damages.

앫 Any vehicle in which the odometer has been altered or damaged so that

mileage cannot be readily determined.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES AND REPRESENTATIONS OR CONDITIONS,

STATUTORY OR OTHERWISE, EXPRESSED OR IMPLIED

INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

14 General Information

ENGINE GASEOUS EMISSIONS CONTROL SYSTEM

WARRANTY

FEDERAL EMISSION REQUIREMENTS

The following engine components are covered by the supplemental emissions

control system warranty policy as required by the Federal emissions

regulations.

a. Turbocharger Assembly

b. VGT Actuator Control Valve

c. Charge Air Cooler

d. Unit Injectors

e. Engine Wiring Harness

f. Electronic Control Module

g. EGR Mixer

h. EGR Cooler

i. EGR Control Valve

j. Crankcase Breather

k. Diesel Particulate Filter (DPF) Assembly

l. DPF Components:

앫 Aftertreatment Fuel Injector (AFI)

앫 AFI Shutoff Valve

앫 Discharge Recirculation Valve

앫 Pre-Catalyst Temp. Sensor

앫 Post-Catalyst Temp. Sensor

앫 Downstream DPF Temp. Sensor

앫 Differential Pressure Sensor

m. Sensors:

앫 Engine Timing/Speed (flywheel)

앫 Engine Position (camshaft)

앫 Temperature — Coolant

앫 Temperature — Inlet Manifold Air

앫 Pressure — Boost Air

앫 Humidity

앫 EGR Temperature

앫 EGR Differential Pressure

General Information 15

The emission warranty for the diesel particulate filter covers defects in

workmanship only. Normal maintenance, such as cleaning ash from the filter

at regular maintenance intervals, is not covered by the emission warranty.

In response to customer requests, Volvo Trucks North America may build

vehicles with engines supplied by other manufacturers, including, but not

limited to, Cummins. In these cases, each engine manufacturer through its

service organization, is responsible for emission control systems warranty on

all parts of the engine assembly, as furnished.

FEDERAL EMISSION REQUIREMENTS

This section covers the requirement of the United States Clean Air Act which

states:

“The manufacturer shall furnish with each new motor vehicle or motor vehicle

engine such written instructions for the maintenance and use of the vehicle or

engine by the ultimate purchaser as may be reasonable and necessary to assure

the proper functioning of emission control devices and systems.”

This section also covers the requirements of the emissions regulations

promulgated under the Motor Vehicle Safety Act in Canada.

TAMPERING WITH GASEOUS EMISSION CONTROL SYSTEMS

PROHIBITED

The Federal Clean Air Act prohibits the removal or rendering inoperative of

any device or element of design installed on or in a motor vehicle or motor

vehicle engine in compliance with Federal Emission Regulations by:

1. Any person prior to its sale and delivery to the ultimate purchaser, or

2. Any manufacturer or distributor after its sale and delivery to the ultimate

purchaser, or

3. Any person engaged in the business of repairing, servicing, selling,

leasing, or trading motor vehicles or motor vehicle engines following its

sale and delivery to the ultimate purchaser, or

4. Any person who operates a fleet of motor vehicles following its sale and

delivery to the ultimate purchaser.

16 General Information

ENGINES OTHER THAN VOLVO

For specific information on engines other than VOLVO, refer to the

engine vendor’s publications.

Noise Emissions

Volvo Trucks North America warrants to the first person who purchases this

vehicle for purposes other than resale and to each subsequent purchaser, that

this vehicle as manufactured by Volvo Trucks North America was designed,

built and equipped to conform, at the time it left the control of Volvo Trucks

North America, with all applicable U.S. EPA Noise Control Regulations.

This warranty covers this vehicle as designed, built and equipped by Volvo

Trucks North America, and is not limited to any particular part, component or

system of the vehicle manufactured by Volvo Trucks North America Defects

in design, assembly or in any part, component or system of the vehicle as

manufactured by Volvo Trucks North America, which, at the time it left the

control of Volvo Trucks North America caused noise emissions to exceed

Federal standards, are covered by this warranty for the life of the vehicle.

Noise Control System, Operator Inspection and Maintenance

Requirements

A Noise Control System Maintenance Log is located in this manual. This log

should be used to document all Noise Control System related maintenance,

whether the maintenance results from a specific noise control system

inspection, or a deficiency identified during another general maintenance

event.

If additional log space is needed, further entries may be added on a separate

sheet of paper. Store these additions with the main log to preserve a

comprehensive record. It is recommended that copies of all noise emissions

related maintenance invoices be retained.

The following Noise Control System inspection and maintenance instructions

contain suggested maintenance intervals. These intervals may need adjustment

in order to best accommodate the specific vehicle usage. The following

instructions only concern Noise Emissions related items and do not address or

modify any general vehicle maintenance requirements.

The following elements make up the Noise Control System:

앫 Noise Shielding and Insulation Devices

앫 Cooling System

앫 Exhaust System/DPF System

앫 Air Intake/Air Induction System

앫 Engine Control, EGR and Fuel Systems

General Information 17

Tampering with Noise Control System

Federal law prohibits the following acts or the causing thereof:

(1) The removal or rendering inoperative by any person, other than for

purposes of maintenance, repair, or replacement, of any device or element of

design incorporated into any new vehicle for the purpose of noise control prior

to its sale or delivery to the ultimate purchaser or while it is in use;

or

(2) the use of the vehicle after such device or element of design has been

removed or rendered inoperative by any person.

Among the acts that constitute tampering are the acts listed below:

앫 Removal, or rendering inoperative, of any exhaust components, including

mufflers, heavy or double-wall exhaust tubing, flexible tubing or exhaust

pipe clamping.

앫 Removal, or rendering inoperative, of the temperature-modulated cooling

fan system.

앫 Removal of the cooling fan shroud.

앫 Removal, or rendering inoperative, of the air cleaner or air intake in-line

silencer.

앫 Removal of the sound deadening material from the hood or cab tunnel.

앫 Removal, or rendering inoperative, of the engine speed governor so as to

allow engine speed to exceed the manufacturer's specifications.

앫 Removal of splash shields located inside the wheel housings.

앫 Removal of engine block shields.

앫 Removal of engine crankcase shields or insulation.

앫 Removal of insulated rocker arm covers.

앫 Removal of transmission noise shields.

Noise Shielding and Insulation Devices

Maintenance

Ensure sound shielding and insulating devices are intact. Inspect components

for damage. Primary system components requiring noise related inspection

include the hood, engine compartment insulating materials (including hood

insulation, bulkhead insulation, doghouse insulation, etc.) splash shields, cab

skirts, fender shields, and body panels. Inspect all related fasteners, brackets,

and clamps for damage and tightness.

18 General Information

Regulatory Compliance

Acts that constitute tampering with the Noise Shielding and Insulation

Devices:

Removing or rendering inoperative the engine and/or transmission noise

deadening panels, shields or insulating materials.

Removing or rendering inoperative the cab-tunnel or hood noise insulating

materials.

Removing or rendering inoperative any vehicle body mounted sound

insulation components and/or shields (cab or fender shields, skirts, wheel

housing splash shields, etc.).

Cooling System

DO NOT work near the fan with the engine running or the ignition in the

ON position. The engine fan can engage at any time without warning.

Anyone near the fan when it turns on could be seriously injured.

Maintenance

Visually inspect cooling system components for damage, and/or

misalignment.

Primary system components requiring noise related inspection include fan

blades, fan clutch, fan shroud, fan ring, and recirculation shields. Check fan

blades, fan ring, fan shroud, belt tensioner and recirculation shields for any

damage. Verify that fan blades clear the fan ring. Inspect all related fasteners,

brackets, and clamps for damage and tightness. Confirm operation of

temperature modulated fan clutch.

Regulatory Compliance

Acts that constitute tampering with the Cooling System:

Removing or rendering inoperative cooling system components (such as the

temperature modulated fan clutch, fan shroud, fan ring, recirculation shields,

etc.).

General Information 19

Exhaust System

Hot engine! Avoid all movable parts or hot engine parts, exhaust gases,

and/or fluids. A hot engine, exhaust, and/or fluids can cause burns.

Maintenance

Make sure the exhaust system is intact. Inspect for damage, misalignment and/

or leakage. Primary system components requiring noise related inspection

include exhaust manifold, turbocharger, and all exhaust system (rigid and

flexible) piping. Closely check the system for exhaust leaks. Special attention

should be given to all welds, seams, gaskets, support points, clamps, couplings

and connections.

Inspect all exhaust system fasteners, brackets, and clamps for damage and

tightness.

Regulatory Compliance

Acts that constitute tampering with the Exhaust System:

Removing or rendering inoperative exhaust system components (such as the

pipes, clamps, etc.).

Air Intake/Air Induction System

Maintenance

Make sure the air intake system is intact. Inspect components for damage,

misalignment and/or leakage. Primary system components requiring noise

related inspection include the air cleaner housing, air cleaner element,

turbocharger, charge air cooler and intake manifold.

Also inspect all ducts, pipes, hoses, tubing and elbows used to interconnect the

system. Special attention should be given to all welds, seams, gaskets, support

points, clamps, couplings and connections.

Inspect all intake system fasteners, brackets, and clamps for damage and

tightness.

Regulatory Compliance

Acts that constitute tampering with the Air Intake/Air Induction System:

Removing or rendering inoperative air intake/induction system components

(filter, filter housings, ducts, etc.).

20 General Information

Engine Control, EGR and Fuel Systems

Acts that constitute tampering with Engine Control, EGR and Fuel Systems:

Removing rendering inoperative, or modifying the engine control system such

as the ECU, EGR system components, or fuel system components, in order to

allow the engine to operate outside of the manufacturer's specifications is not

allowed and violates both warranty and legislation.

Noise Control Log

NOISE CONTROL SYSTEM MAINTENANCE LOG

DATE MILEAGE

MAINTENANCE

PERFORMED

MAINTENANCE

FAC ILITY

General Information 21

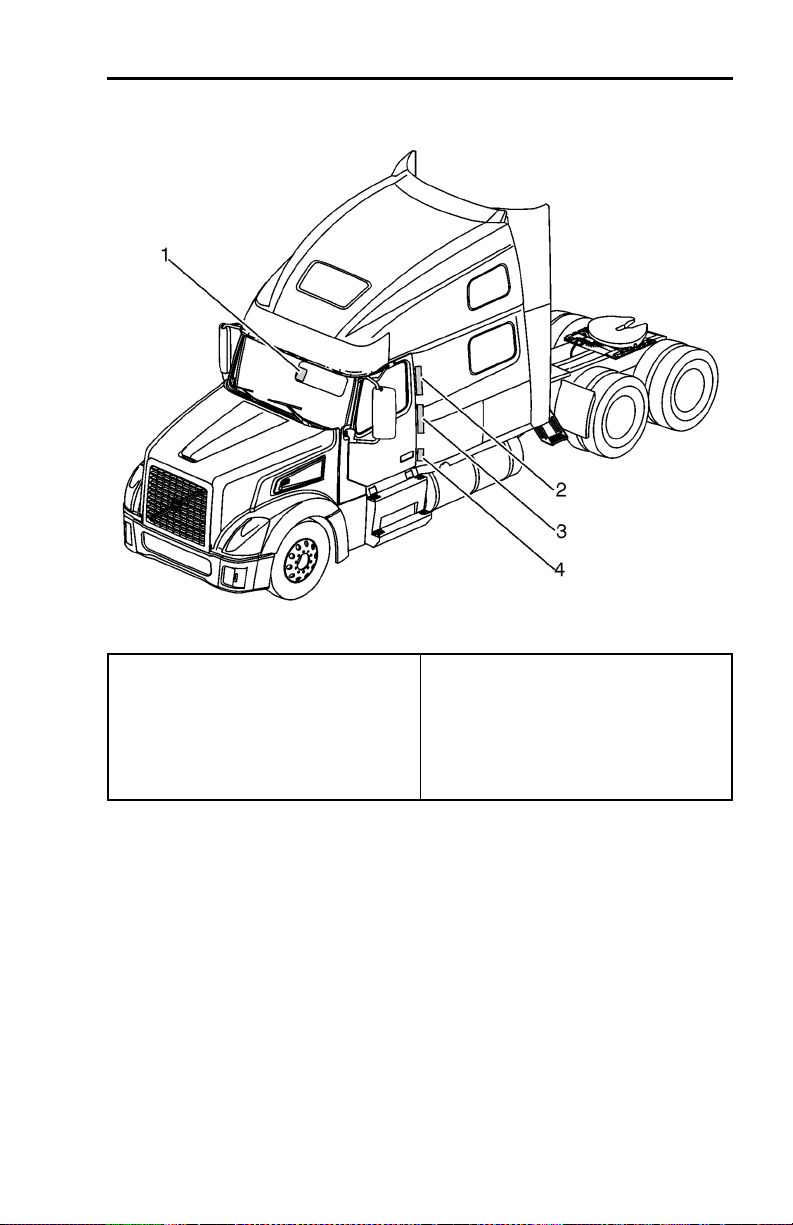

LABEL INFORMATION

VT Shown, VN and VHD Similar

1. Transmission Type and Gear

Pattern This information is

located in the visor.

2. VIN/GAWR Located in the

door frame “B” pillar.

3. VIN/Major Components

Located in the door frame “B”

pillar.

4. Vehicle Noise Emission

Located in the door frame “B”

pillar.

22 General Information

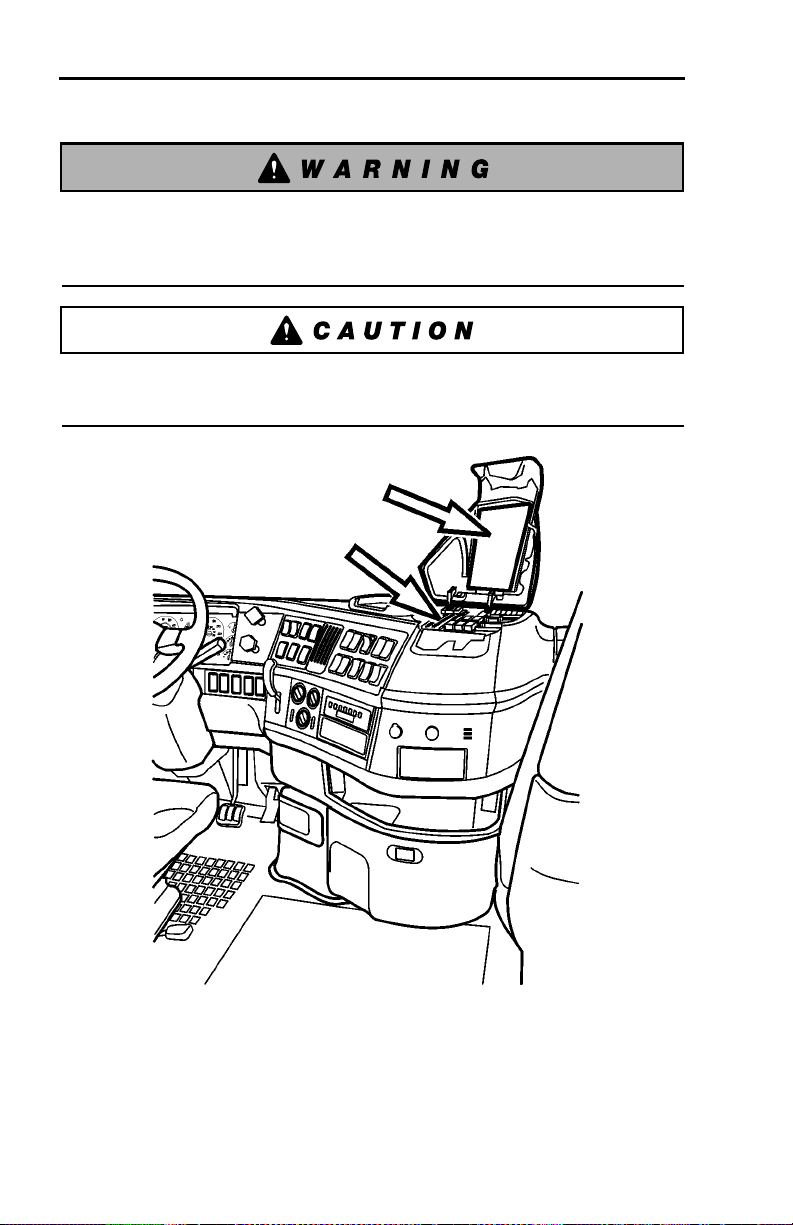

FUSE AND RELAY LOCATION

Always replace fuses and circuit breakers with the same current/

amperage. Increasing fuse or circuit breaker rating may result in

electrical circuit overheating and possible fire.

On sleeper models equipped with fluorescent lighting, there is a 3 AMP

maximum fuse located in the lighting fixture.

General Information 23

The fuse relay panel is located under the top cover of the dash board. The

vehicle has an electrical center located in the middle of the dash under the top

cover. Since the function of some fuses or relays may change for the vehicle

application, refer to the list of functions that is attached beneath each panel.

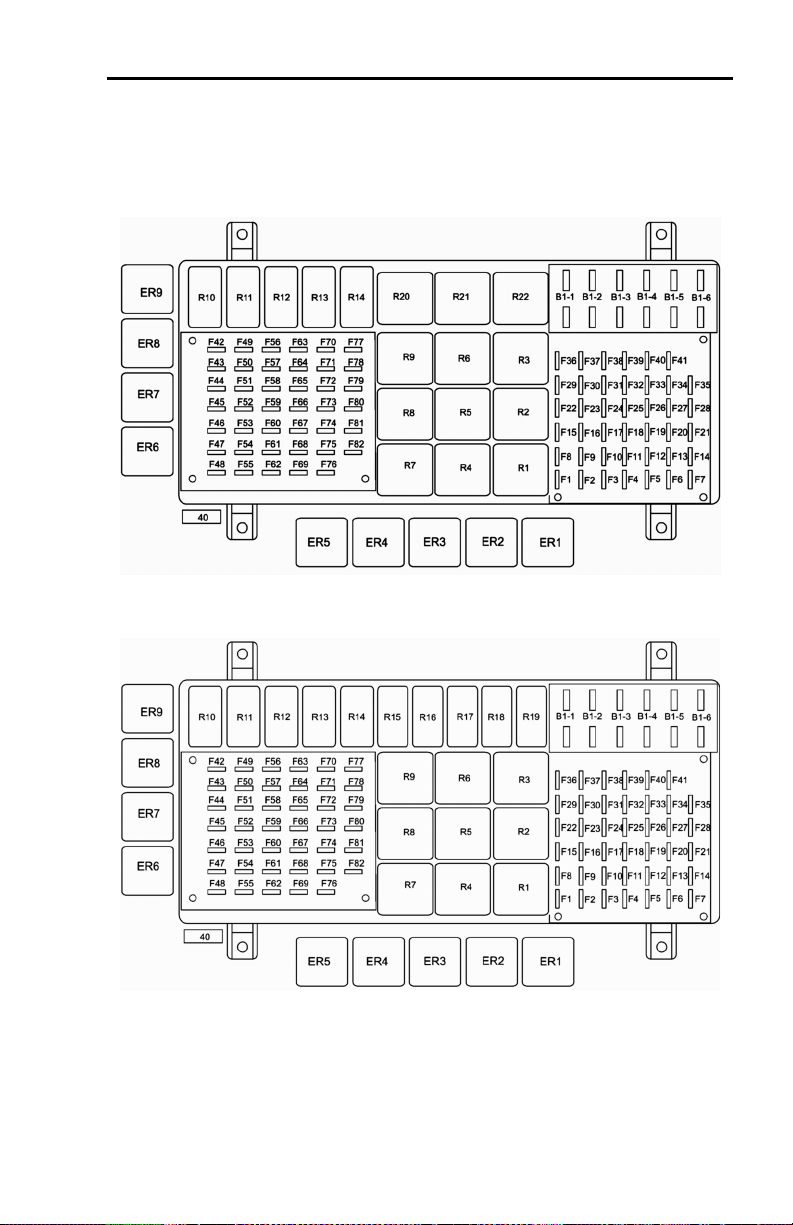

VN Fuse and Relay Center

VHD Fuse and Relay Center

24 Safety Information

SAFETY INFORMATION

PROPER MAINTENANCE PROCEDURE

Before working on a vehicle, set the parking brakes, place the transmission

in neutral, and chock the wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

Exhaust gases contain carbon monoxide. Always run the engine outdoors or

use a properly vented exhaust hose. Prolonged or excessive exposure may

cause serious illness or death.

Never operate the engine in an area where hydrocarbon vapors (gasoline,

for example) are present or are suspected to be present. Hydrocarbon vapors

can enter the air intake and over speed the engine, causing severe engine

damage and/or an explosion and fire. Serious personal injury or death

could occur.

Never try to operate or work on this vehicle while under the influence of

alcohol. Your reflexes can be affected by even a small amount of alcohol.

Drinking and operating this vehicle can lead to an accident, causing serious

personal injury or death.

DO NOT attempt to repair or service this vehicle without having

sufficient training, correct service literature and the proper tools. Failure

to follow this could lead to personal injury or making your vehicle unsafe.

Diesel engine exhaust and some of its constituents are known to the state

of California to cause cancer, birth defects and other reproductive harm.

Safety Information 25

During Maintenance

Remove key from ignition while working on vehicle or engine.

DO NOT allow unauthorized personnel on, around or in the vehicle when

maintenance or repair is being performed.

앫 When operating the engine in an enclosed area, vent the exhaust to the

outside.

앫 Before servicing your vehicle, apply the parking brakes and adequately

chock the wheels in order to prevent unintended vehicle movement. If the

service procedure requires the parking brakes to be released — recheck to

ensure that the wheels are adequately chocked to prevent any forward

and/or rearward movement.

앫 DO NOT use combustible substances in or around the engine either

during repair or maintenance or when running the engine.

앫 DO NOT wear loose clothing or jewelry that can catch or get snagged by

parts or moving components on the engine. Also wear all protective

equipment required by the job conditions, such as protective glasses,

hearing protection, etc.

앫 Make certain that all protective covers and guards are in place and

properly secured.

앫 Never put maintenance fluids into glass containers since glass containers

can break.

앫 Report all problems in a timely manner before they threaten the safety of

operating the vehicle.

앫 DO NOT work on the engine while it is running.

앫 Make sure protective locks and covers are in their proper place.

앫 DO NOT use high amperage electronic starting devices for jump-starting

the engine. Rely on conventional battery charging for charging the

batteries or jump-start with the help of a start battery.

앫 DO NOT attempt repairs you do not understand. If you do not have the

proper tools/knowledge to perform the repairs correctly, Volvo

recommends contacting your nearest Volvo Truck dealer for all necessary

repairs.

앫 When starting an engine after repairs have been made to the fuel or

injection system, prepare equipment for shutting off the engine intake air

and/or fuel supply (to stop the engine), in case there is an over speed on

start-up.

앫 Start the engine only from the driver seat. Never operate the starter motor

across the starter terminals or the batteries as this could bypass the engine

neutral-start system as well as causing damage to the electrical or

electronic systems.

26 Safety Information

Compressed Air and Water

Compressed air can cause serious personal injury. When using compressed

air for cleaning, wear a protective face shield, protective clothing and

protective shoes. Pressurized water could cause particles and/or hot water to

be sprayed in your direction and cause personal injury. The maximum air

pressure must be below 200 kPa (30 psi) for cleaning purposes.

Asbestos Information

The Volvo engine and replacement parts for it shipped from the factory are

asbestos free. Volvo recommends the use of only genuine Volvo spare parts.

Never use any parts that contain or are thought to contain asbestos. Exposure

to asbestos fibers can create serious health risks, including death.

Fluid Penetration

Always use a piece of paper or cardboard when checking for a leak.

Escaping fluid under high pressure, even a pin-hole sized leak, can

penetrate body tissue, causing serious injury or death. If fluid is injected

into your skin, immediate treatment must be administered by a doctor

familiar with this type of injury.

INJURY PREVENTION

Burn Prevention

Engine Parts

Hot engine. Keep yourself clear of all hot engine parts and/or fluids. A hot

engine and/or fluid can cause serious burns.

Safety Information 27

DO NOT raise the engine hood if you see or hear steam or coolant

escaping from the engine compartment. Wait until steam or coolant

cannot be seen or heard any longer before raising the hood.

DO NOT remove the coolant fill cap if the coolant in the surge tank is

boiling. Also, do not remove the cap while the engine and radiator are still

hot. Scalding fluid and steam may be blown out under pressure if the cap

is taken off too soon, which can cause personal injury and damage to

engine components.

DO NOT touch any part of the engine while it is hot. Allow the engine to cool

before any repair or maintenance is performed on the engine.

Relieve all pressure in air, oil, fuel or cooling systems before any lines, fittings

or related items are disconnected or removed.

Coolant

Coolant may be combustible. Coolant leaked or spilled onto hot surfaces

or electrical components can cause a fire. Clean up coolant spills

immediately.

28 Safety Information

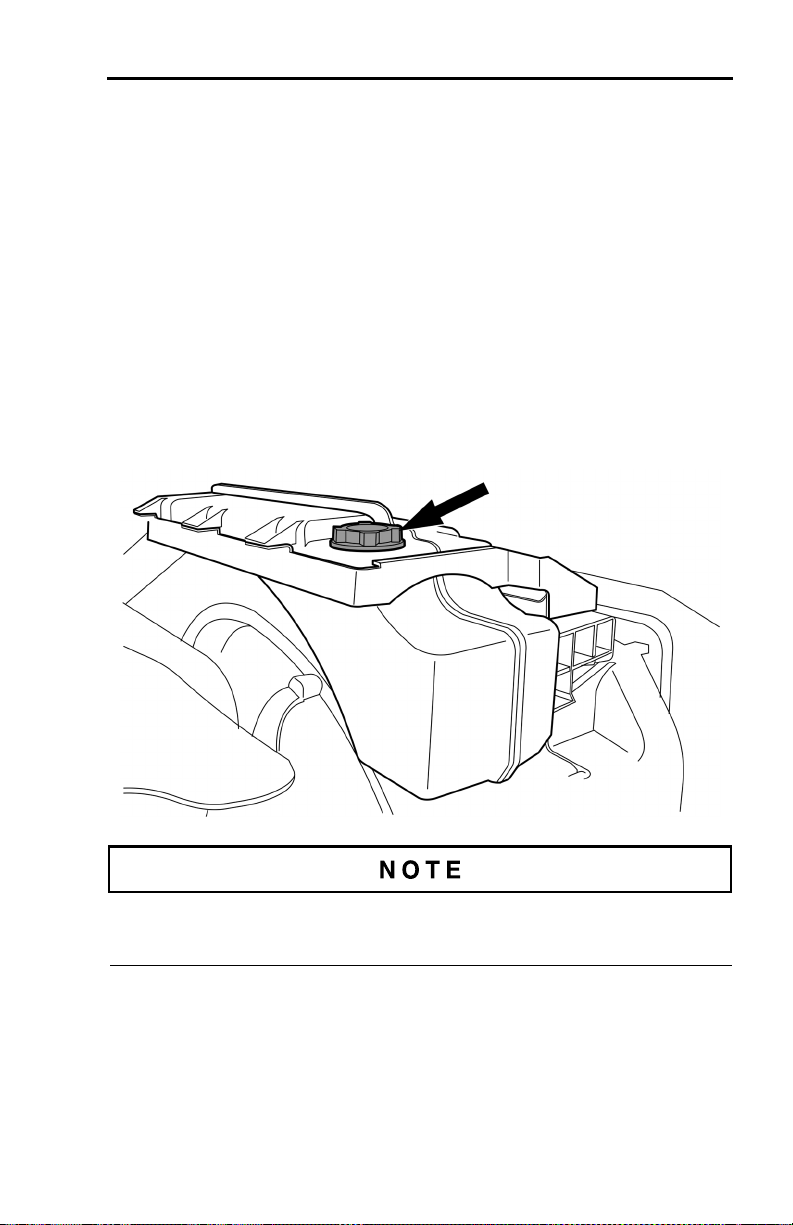

To prevent personal injury, do not climb up on the engine to remove the filler

cap. Use a suitable, properly positioned ladder to reach the cap. At normal

operating temperature, the engine coolant is very hot and under pressure. If

pressure is relieved rapidly in a hot cooling system, the hot coolant can turn

into steam. Any contact with hot coolant or steam can cause severe burns. The

radiator and all heating system and radiator lines and hoses contain hot

coolant.

Verify coolant level only by the markings on the expansion tank. Open the

filler cap only after the engine is stopped and cooled down. Remove the filler

cap slowly to relieve pressure.

Oils

Hot engine. Keep yourself clear of all hot engine parts and/or fluids. A hot

engine and/or fluid can cause serious burns.

Hot oil can cause severe burns. DO NOT allow hot oil to contact the skin.

When changing oil, wear protective gloves.

Batteries

Always wear eye protection when working around batteries to prevent

the risk of injury due to contact with sulfuric acid or an explosion.

Battery posts, terminals and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause cancer

and reproductive harm. Wash hands after handling.

Battery electrolyte contains acid and can cause injury. Avoid contact with the

skin and eyes. Wash hands after touching batteries and connectors. Use of

gloves is recommended. Always wear protective glasses when working with

batteries.

Safety Information 29

Speed Restrictive Tires

Operating a vehicle equipped with speed restrictive tires in excess of their

stated rating may result in tread separation and/or blowout resulting in the

loss of steering control and possible collision. Serious personal injury or

death could occur. Always maintain proper air pressure and never exceed

the tire ratings.

When a vehicle is equipped with speed restrictive tires, DO NOT operate the

vehicle in excess of the indicated speeds. If your vehicle is equipped with such

tires, the speed restrictions will be stated on the sidewall of the tires. The

operator of this vehicle is urged to check the tires of the vehicle to determine if

there are any limitations.

Fire or Explosion Prevention

The diesel engine will operate on any fuel which enters the cylinder,

whether it is from the injectors or from the air intake system. Therefore, if

any solvent is used to flush out the air cleaner element, the engine may over

speed during start-up. Engine damage and severe injury and/or death from

burns or explosion can occur.

Excessive heat may cause the pressurized components of the air conditioned

system to explode. Some mixtures of R134a refrigerant can become

combustible at elevated pressures. Never weld, solder, steam clean or use a

gas torch near any part of the air conditioning system. Severe injury or

death may occur from an explosion.

30 Safety Information

DO NOT service any part of the fuel system while smoking or in the

presence of flames, sparks or hot surfaces. Failure to follow these

precautions can result in fire, which can cause serious injury or death.

DO NOT store fuel containers in the vehicle. They may leak, explode and

cause or feed a fire. Empty or full, they present a hazard that may lead to

burns in the event of a fire.

The engine should not be operated in an area where combustible gases are

suspected to be in the air. These could be drawn into the engine through the

engine air intake system and could cause the engine to over speed with

possible serious damage to the engine and bodily injury or property damage.

Make provisions for shutting off the engine intake air or fuel supply to stop the

engine if there is an over speed on start-up after performing repair or

maintenance on it.

Contact your nearest Volvo Truck dealer for any necessary air conditioning

testing or repairs.

All fuels, most lubricants and some coolant mixtures are flammable. Diesel

fuel is flammable. Gasoline is flammable. The mixture of diesel and gasoline

fumes is extremely explosive. DO NOT smoke while refueling or when in a

refueling area.

Keep all fuels and lubricants stored in properly marked containers and away

from all unauthorized personnel. Store oily rags or other flammable material

in a protective container, in a safe place.

Remove all flammable material such as fuel, oil and other substances before

they accumulate on the engine.

Safety Information 31

DO NOT expose the engine to flames, driving over burning ground.

DO NOT weld or flame cut on or around pipes or tubes that contain

flammable fluids.

Exhaust heat shields may be installed to protect oil or fuel carrying lines and

pipes from hot exhaust parts. To protect from pipe or seal failure, install heat

shields correctly.

Provide adequate and proper waste oil disposal. Always dispose of waste

liquids according to Federal and local regulations. Oil and fuel filters should

be properly installed and housing covers tightened to the proper torque when

being changed.

Starting Aids

DO NOT use ether or other combustible starting aids on any engine

equipped with a preheater. If the engine is equipped with a preheater,

introduction of ether or similar starting aids could cause a fire or explosion

resulting in severe property damage, serious personal injury or death.

DO NOT use ether or other combustible starting aids on engines that

have a heater element or other heating devices installed in the intake

manifold for heating the intake air during cold-starts.

32 Safety Information

Fire Extinguisher

Anytime work is being done to the fuel system or any other area where

flammable substances are being used, have a fire extinguisher available and

know how to use it. Inspect and have it serviced as recommended on its

instruction label.

Respiratory Hazard Prevention

Exhaust gases contain carbon monoxide. Always run the engine outdoors or

use a properly vented exhaust hose. Prolonged or excessive exposure may

cause serious illness or death.

Diesel engine exhaust and some of its constituents are known to the state

of California to cause cancer, birth defects and other reproductive harm.

Always work in a well ventilated space if the engine needs to be running and

use a hose to route the exhaust to the outside.

Poisonous Substances

Coolant is toxic; risk of poisoning.

DO NOT drink coolant. Use proper hand protection when handling. Keep

coolant out of reach of children and animals. Failure to follow these

precautions can cause serious illness or death.

Cooling system supplemental additive contains alkali. To prevent personal

injury, avoid contact with the skin and eyes.

DO NOT drink coolant of any concentration.

Safety Information 33

Crushing or Cutting Prevention

Before working on a vehicle, set the parking brakes, place the transmission

in neutral and chock the wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

DO NOT work near the fan with the engine running or the ignition in the

ON position. The engine fan can engage at any time without warning.

Anyone near the fan when it turns on could be seriously injured.

Never attempt adjustments or repairs while the engine is running, see your

authorized Volvo Truck dealer.

Inspect the fan blade assembly before service for cracks or loose mounting

before starting the engine. Never stand alongside a rotating fan assembly,

particularly at high fan speeds.

Wear protective glasses when striking objects to avoid injury to your eyes.

Chips or other debris can fly off objects that are struck. Make sure no one can

be injured by flying debris before striking any object.

34 Safety Information

Climbing Up and Down

Always have three limbs (one foot and two hands or two feet and one hand)

in contact with the vehicle at all times when entering or exiting the cab or

the area behind the cab. Failure to follow this warning can result in serious

personal injury or death.

DO NOT climb up on or jump off from the engine or stand on components

that cannot support your weight. Use an adequate ladder or scaffolding,

suitably situated.

DO NOT use top of engine or cowling ledge as foothold when reaching on top

of cab. Clean steps, handholds and areas of the vehicle on which you will be

working or are around. Refer to the Operator's Manual for proper entry and

exit procedures.

Always use a three-point stance (two hands and one foot or one hand and

two feet) whenever climbing up or down.

ENGINE DAMAGE PREVENTION

Before Starting the Engine

Before working on a vehicle, set the parking brakes, place the transmission

in neutral and chock the wheels. Failure to do so can result in unexpected

vehicle movement and can cause serious personal injury or death.

Inspect engine for potential hazards. Make sure all protective guards and

covers are properly installed if an engine needs to be started to make

adjustments or checks. To help prevent an accident by moving parts, work

carefully around them.

DO NOT disable or bypass automatic alarm/shutoff circuits. They are

provided to prevent personal injury and engine damage.

Only properly trained and authorized Volvo Service Technicians may attempt

repairs on this vehicle.

Safety Information 35

Engine Starting

DO NOT start the engine or move any of the controls or disengage the parking

brake if the warning tag “DO NOT OPERATE” is attached to the ignition key

or located on the dash. Check with the person who attached the tag before

starting.

Make sure no one is working on or close to the engine or components driven

by the engine before starting it. Always make an inspection of the engine

before and after starting.

Diesel engine exhaust contains products of combustion which may be harmful

to your health. Always start and operate the engine in a well-ventilated area,

and if in an enclosed area, vent the exhaust to the outside.

Start the engine only from the driver seat in the cab. Never start the engine by

shorting across the starter motor terminals or batteries to start the engine as

this could bypass the engine neutral-start system as well as damage the

electrical and electronic system. Always start the engine according to the

required engine starting procedure described in this operator's manual to

prevent major engine component damage and personal injury.

Starting Aids

DO NOT use ether or other combustible starting aids on any engine

equipped with a preheater. If the engine is equipped with a preheater,

introduction of ether or similar starting aids could cause a fire or explosion

resulting in severe property damage, serious personal injury or death.

36 Safety Information

ELECTRIC SYSTEM DAMAGE PREVENTION

Electric and Electronic Systems

Always wear eye protection when working around batteries to prevent

the risk of injury due to contact with sulfuric acid or an explosion.

Never disconnect any charging unit circuit or battery circuit cable from the

battery when the charging unit is operating. A spark can cause the flammable

vapor mixture of hydrogen and oxygen to explode.

To prevent potential sparks from igniting combustible gases produced by some

batteries, attach the negative (—) terminal last when hooking up and remove

the negative terminal first after the engine has started. Check regularly around

the engine and engine compartment for loose or frayed wires. Have all loose

or frayed electrical wires tightened, repaired or replaced before operating the

vehicle.

Grounding Practices

Proper grounding for vehicle and engine electrical and electronic systems is

necessary for proper vehicle and engine performance and reliability. Improper

grounding will result in uncontrolled and unreliable electrical paths.

Uncontrolled engine electrical circuit paths can result in damage to main

bearings, crankshaft journals surfaces and aluminum components.

Uncontrolled electrical circuit paths can also cause electrical noise which may

degrade vehicle and radio performance.

Operating engines without the engine-to-frame ground strap installed can

cause damage to the engine. To prevent electrical discharge damage, check to

make sure the engine's electrical system has an engine-to-frame ground strap.

All ground connections should be tight and free of corrosion.

Safety Information 37

Electronic Engine Control System

The engine uses high voltage to the electronic unit injectors.

DO NOT come in contact with the unit injector terminals while the engine is

running. An electric shock can cause an involuntary muscle spasm and

cause loss of balance and falls leading to severe personal injury or death.

Tampering with the electronic system installation can be dangerous and could

result in personal injury or death and/or engine damage. It is very important to

take the proper precautions with the electrical and electronic system when

charging the batteries, jump-starting or performing electric welding on the

vehicle. See the vehicle Operator's Manual for correct procedures.

This engine is equipped with monitoring features that may cause reduced

power or shutdown under certain conditions. The power output, monitoring

and idling features can only be programmed and/or changed with electronic

service tools and passwords.

Certain features, such as low oil pressure, high coolant temperature or low

coolant level could cause the engine power and/or vehicle speed to be limited

and the engine may also shut down. The shutdown will take approximately

30 seconds from the time the warning feature is activated. See the vehicle

Operator's Manual for more information.

38 Safety Information

REPORTING SAFETY DEFECTS

USA

The National Highway Traffic Safety Administration (NHTSA) and Volvo

Trucks North America should be informed immediately if you believe that the

vehicle has a defect that could cause a vehicle accident, injury or death.

Contact NHTSA by calling the Auto Safety Hotline at 1 (888) 327-4236, by

writing to NHTSA, U.S. Department of Transportation, Washington, DC

20590, by TTY at 1 (800) 424-9153, or visit their website at

www.nhtsa.dot.gov.

Canada

Refer customer complaints to Volvo Trucks Canada, Inc. or to Transport

Canada, Defect Investigations and Recalls.

Canadian customers who wish to report a safety-related defect to Transport

Canada, Defect Investigations and Recalls, may telephone the toll free hotline

1 (800) 333-0510 (within Canada only) or call 1 (613) 993-9851 (from Ottawa

region or outside Canada). Contact Transport Canada by mail at: Transport

Canada, ASFAD, Place de Ville Tower C, 330 Sparks Street, Ottawa

ON K1A 0N5.

For additional road safety information, please visit the Road Safety website at:

http://www.tc.gc.ca/roadsafety/menu.htm

Mexico

Volvo Trucks de Mexico, S.A. de C.V. should be informed immediately if you

believe the vehicle has a defect that could cause a vehicle accident, injury or

death. Contact Volvo Trucks de Mexico by calling: 01 (800) 90 94 900 (within

Mexico only) or 011-52-55-50-81-68-50, or by writing to: Volvo Trucks de

Mexico, S.A. de C.V., Prol. Paseo de la Reforma 600, 1er. Piso — 121, Col.

Santa Fe Peña Blanca, C.P. 01210, México, D.F.

For Roadside assistance information see “Service Assistance and Manuals” on

page 122.

General Engine Information 39

GENERAL ENGINE INFORMATION

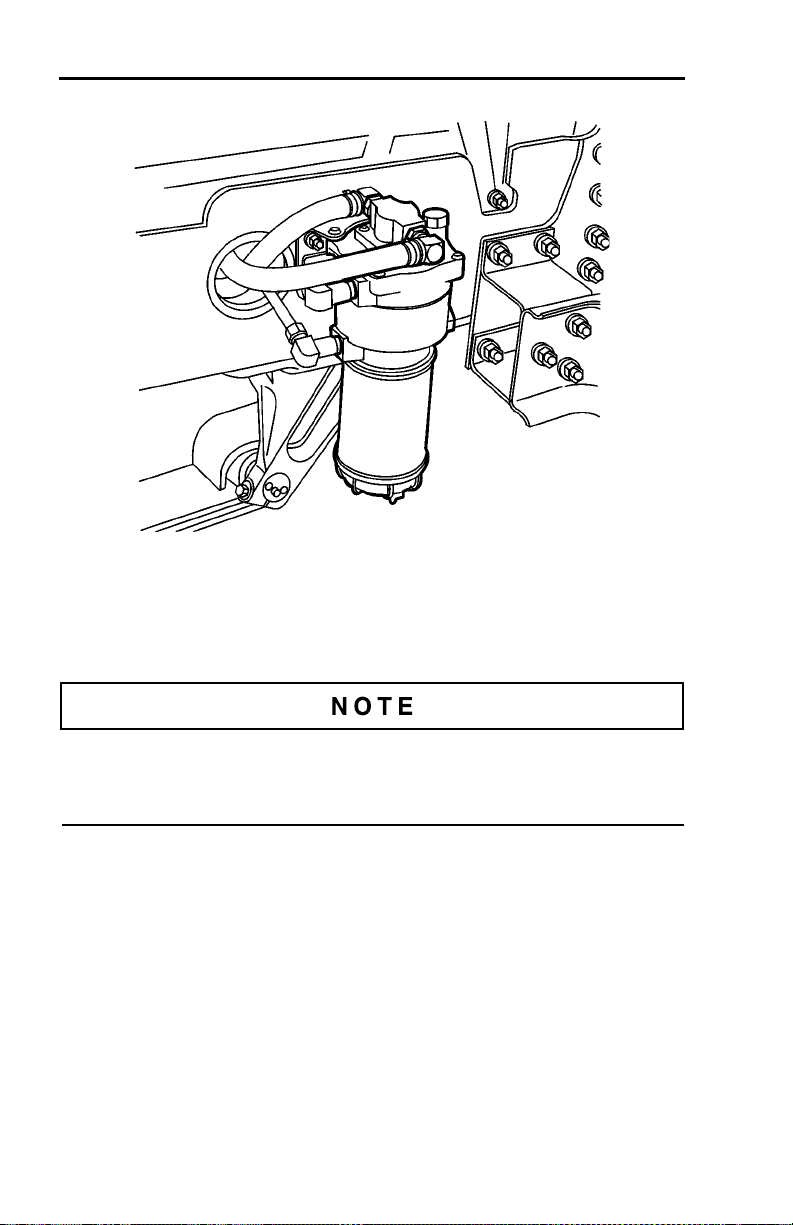

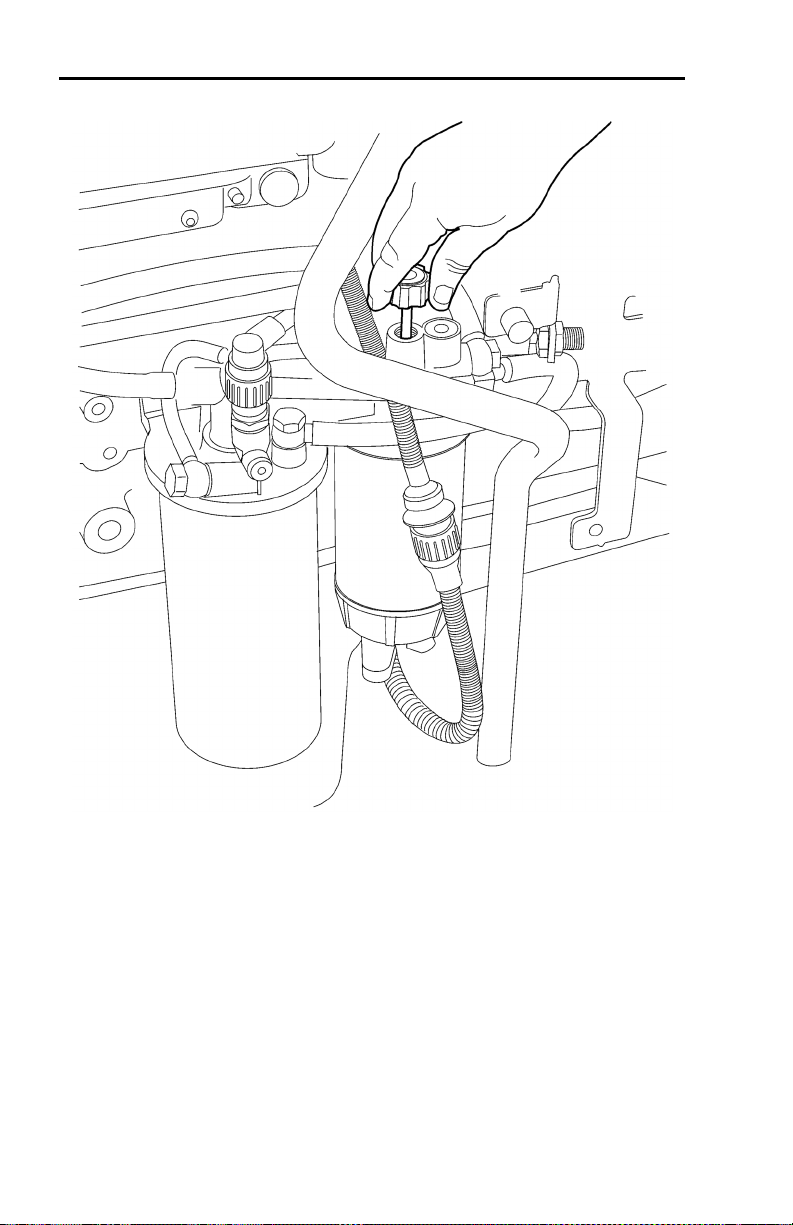

ENGINE OVERVIEW, D11F AND D13F LEFT SIDE VIEW

D13F Engine Shown, D11F Engine Similar

1. Breather Tube

2. Intake Manifold

3. Air Compressor

4. Power Steering Pump

5. Fuel Pump

6. Engine Electronic Control Unit

(EECU)

7. Fuel Filter

8. Fuel/Water Separator

9. Fuel Filter

10. Hand-Priming Pump

11. Crankcase Ventilator

12. Alternator

13. AC Compressor

14. Alternator/AC Compressor Belt

15. Fan/Coolant Pump Belt

16. EGR Mixing Chamber

40 General Engine Information

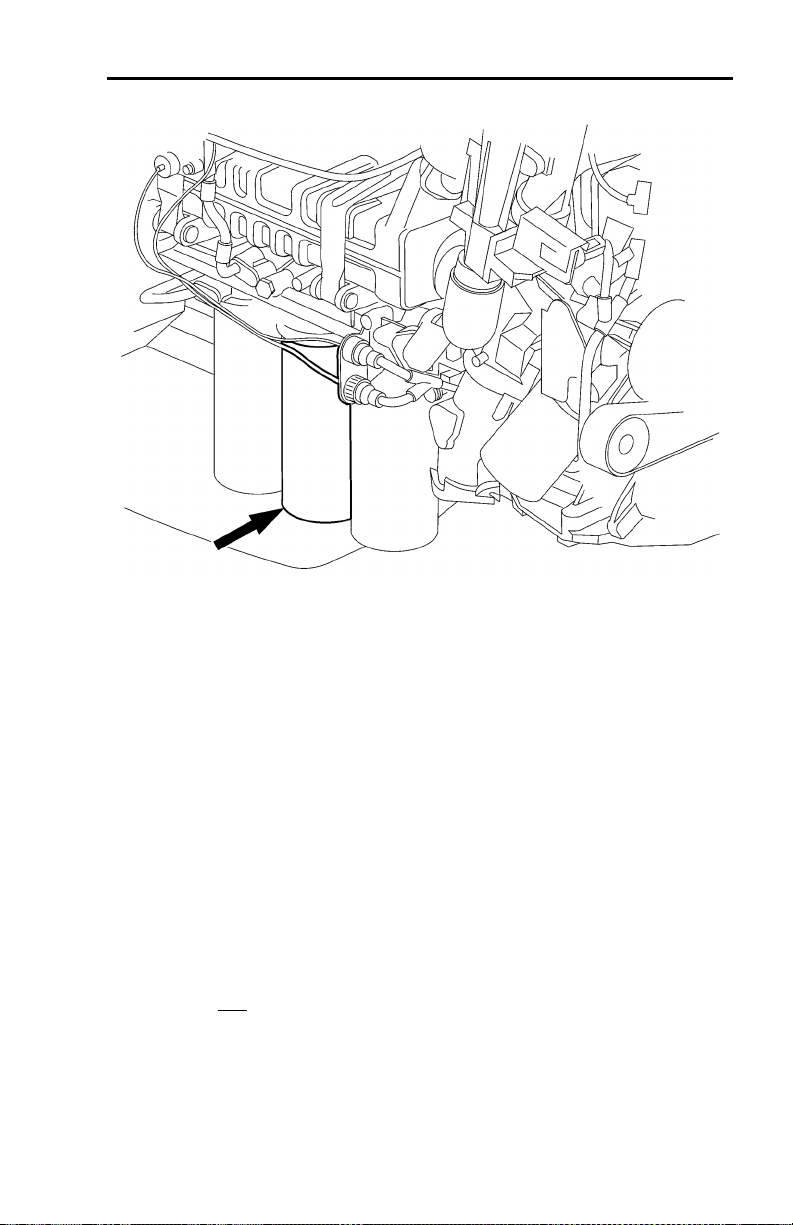

ENGINE OVERVIEW, D11F AND D13F RIGHT SIDE

VIEW

D13F Engine Shown, D11F Engine Similar

17. Exhaust Manifold

18. Valve Cover

19. Engine Pre-Heater Element

(Optional)

20. Thermostat Housing

21. Belt Tensioner

22. Coolant Pump

23. Coolant Filter

ENGINE STORAGE

24. Venturi Pipe

25. Oil Filters

26. Oil Pan

27. EGR Cooler

28. Turbocharger

29. Starter Motor

30. EGR Valve

Engine Storage 41

ENGINE STORAGE

If the vehicle must be parked for a period (more than 30 days), protect it as

follows:

1. Drain the engine oil.

2. Fill up to the proper level with oil of the recommended quality and

viscosity.

3. Fill up the fuel tanks with the recommended grade of fuel.

4. Run the engine for two minutes around 1000 rpm. Shut the engine down.

DO NOT drain the oil after this run.

5. Check the coolant for proper levels of antifreeze and inhibitor (SCA)

protection. Service as necessary.

6. Seal all engine openings using protective covers.

To return to service an engine preserved in this manner, remove previously

installed protective covers. Check all fluid levels and if necessary replace

engine oil contaminated by condensation.

MAINTENANCE AND SERVICE

42 Maintenance and Service

MAINTENANCE HAZARDS

Before working on or inspecting a vehicle, set the parking brakes, place the

transmission in neutral and chock the wheels. Failure to do so can result in

unexpected vehicle movement and can cause serious personal injury or

death.

DO NOT attempt to repair or service this vehicle without having sufficient

training, correct service literature and the proper tools. Failure to follow this

could lead to personal injury or death, or making your vehicle unsafe.

Read all safety information before working on the vehicle. Refer to “Proper

Maintenance Procedure” on page 24.

Maintenance and Service 43

ENGINE COMPONENTS, SERVICE SCHEDULES

Component Operation

Fuel Filter — All

Engine Models

Water Separator — All

Engine Models

Air Filter — US07 Change Control lamp indication/24 months

Air Filter — Euro 4 Change

Coolant (Standard —

All Engine Models

Coolant (ELC) — All

Engine Models

Coolant Filter — US07 Change 80 000(50,000) or 6 months

Coolant Conditioner —

Euro 4

Coolant Filter (ELC) —

US07

Coolant Filter (ELC) —

Euro 4

Valves/Injectors — All

Engine Models**

Valves/Injectors — All

Engine Models**

Drive Belts VN —

Euro 4 (Highway)

Drive Belts VHD —

Euro 4 (Vocational)

DPF Filter — (If

equipped)

AF Injector — (If

equipped)

Change Each oil change*

Filter change Each oil change*

Change 400 000(250,000)/24/4,000

Change 1 000 000(600,000)/48/12,000

Change

Change 240 000(150,000)15/2,500

Change

Initial Adjust 200 000(125,000)/12/2,500

Adjust 400 000(250,000)/24/5,000

Change 500 000(300,000) or 36 months

Change 240 000(150,000) or 12 months

Change 240 000(150,000) or 4,500 hours

Clean 240 000(150,000) or 4,500 hours

Km (Miles)/Maximum Months/

Hours

At maximum restriction as indicated

on gauge, or 12 months

Traditional coolants requiring

Supplemental Coolant Additive

(SCA)

80 000(50,000) or 6 months

No SCA requirement

240 000(150,000) or 12 months

* Under certain conditions (for example, irregular fuel quality), the fuel/

water separator filters may require more frequent replacement.

** Valves must be adjusted whenever the rocker shaft has been removed

and reinstalled for any reason.

44 Maintenance and Service

COOLING SYSTEM

General Coolant Information

Coolant is toxic; risk of poisoning. DO NOT drink coolant. Use proper hand

protection when handling. Keep coolant out of reach of children and

animals. Failure to follow these precautions can cause serious illness or

death.

DO NOT raise the engine hood if you see or hear steam or coolant

escaping from the engine compartment. Wait until steam or coolant

cannot be seen or heard before raising the hood.

DO NOT remove the coolant fill cap if the coolant in the surge tank is

boiling. Also, DO NOT remove the cap while the engine and radiator are

still hot. Scalding fluid and steam may be blown out under pressure if the

cap is taken off too soon and can cause personal injury.

Coolant may be combustible. Coolant leaked or spilled onto hot surfaces

or electrical components can cause a fire. Clean up coolant spills

immediately.

Volvo Trucks North America does not recommend using plain water in the

cooling system. Water alone is corrosive at engine operating temperatures and

does not provide adequate boiling protection. The engine may develop

corrosion and cavitation problems in the engine and radiator, and the boiling

point of the coolant is lowered compared to a proper antifreeze and water

mixture. Failure to follow Volvo Truck North America's cooling system care/

maintenance recommendations can render the warranty invalid.

The main purpose of coolant is to transport heat from the hot parts of the

engine to the radiator and to protect the cooling system from corrosion.

Maintenance and Service 45

In addition to this, the coolant must:

앫 Protect against pitting and cavitation erosion damage of the water pump

and cylinder liners.

앫 Protect against freezing and boiling.

앫 Prevent formation of scale, sludge deposits and clogging.

앫 Be harmless to polymer materials and seals in the cooling system.

앫 Maintain its liquid properties in cold climates.

Many engine failures can be traced back to a problem in the cooling system. If

the coolant level is allowed to go below the bottom of the tank, there is the risk

of the engine shutting down. See the operator's manual for more information

on the warning functions.

Always dispose of coolant according to Federal or local regulations. Take all

used coolant to a recycling or waste collection center.

Coolant mixture consisting of an antifreeze solution in water should be used

year-round to provide freeze and boil-over protection as well as providing a

stable environment for seals and hoses.

46 Maintenance and Service

DO NOT use antifreeze formulated for automobile gasoline engines. These

have a very high silicate content that will clog the radiator and leave unwanted

deposits in the engine.

Freeze Protection Down To: Percentage of Antifreeze in Mixture

-25° C (-13° F) 40%

-30° C (-22° F) 46%

-38° C (-36° F) 54%

-46° C (-51° F) 60%

A well functioning and maintained cooling system is as important to the

engine as performing regular oil changes or using good fuel. To get the best

result use quality products and service the system at the correct intervals.

Please read this section carefully.

Keep the radiator (including charge air cooler) and the frontal area free from

bugs, dirt, leaves, etc. (see “Cleaning Charge Air Cooler and Radiator

Package” on page 68 for cleaning information).

Check the coolant level in the tank regularly. Fill the tank as necessary with

the correct coolant.

Inspection of the whole cooling system is important. Check for swollen or

deteriorated heater and radiator hoses, loose hose clamps and connections, and

radiator leaks.

DO NOT work near the fan with the engine running. The engine fan can

engage at any time without warning. Anyone near the fan when it turns on

could be seriously injured. Before turning on the ignition, be sure that no

one is near the fan.

Maintenance and Service 47

Never add coolant to a hot or overheated engine. Engine damage can result.

Allow the engine to cool first.

Additives

Additives help prevent rust, scale and mineral deposits from forming.

Additives also protect metals from corrosion, prevent water pump and

cylinder liner cavitation and contain anti-foaming agents. Additives are

depleted during normal engine operation and need to be replaced. For

non-extended life coolant mixture, this means the addition of Supplemental

Coolant Additives (SCA) at any time the additive goes below the

recommended level. For extended life coolant mixture, this means an extender

package added halfway through the coolant lifetime.

Regular Coolant Change Interval

Replace the coolant every 400 000 km (250,000 miles), 4,000 hours or every

two years, whichever comes first.

Coolant SCA level must be tested at least twice per year or whenever coolant

loss occurs. For maximum coolant system efficiency, test the system at every

engine oil change interval, every 1,000 hours or every 6 months (whichever

comes first). For proper SCA levels, consult Service Manual.

Regular Coolant Filter Change Intervals

Hot engine. Keep clear of all hot engine parts and fluids. A hot engine and

fluids can cause serious burns.

The charged coolant filter contains 8 units of SCA that are released slowly

over time to maintain the recommended level during operation. Consult

engine service manual for proper SCA level and change intervals.

Change the regular coolant filter every 80 500 km (50,000 miles).

48 Maintenance and Service

Extended Life Coolant Change Interval

Extended life coolant will test as out of additives (SCA), but SCA should not be

added. Shortened engine life may be the result of adding SCA.

Replace coolant every 960 000 km (600,000 miles), 12,000 hours or every

four years, whichever comes first.

An extender package must be added to the cooling system after 480 000 km

(300,000 miles), 6,000 hours or two years, whichever comes first.

DO NOT add supplement coolant additives (SCA) to extended life

coolant.

Should the extended life coolant system become contaminated with regular

coolant exceeding 10% of the system's total capacity or if SCA is added to

extended life coolant, drain the system and refill with new extended life

coolant or regular coolant.

Extended Lift Coolant Filter Change Interval

Hot engine. Keep clear of all hot engine parts and fluids. A hot engine and

fluids can cause serious burns.

DO NOT use a filter that contains SCA. Damage to components can result.

Replace the extended life coolant filter every 240 000 km (150,000 miles),

2,500 hours or 15 months, whichever comes first, to prevent external rust

damage to the filter walls.

Maintenance and Service 49

FUEL SYSTEM

Fuel Safety Reminders

A diesel engine will operate on any fuel which enters the cylinder, whether it

is from the injectors or from the air intake system. Therefore, if any solvent

is used to flush out the air cleaner element, the engine may over speed

during start-up. Engine damage, severe personal injury or death from burns

or explosion may occur.

DO NOT mix gasoline or alcohol with diesel oil fuel. This mixture can

cause an explosion and result in severe personal injury or death.

DO NOT remove the fuel tank cap near an open flame. Diesel fumes are

combustible and can cause an explosion or fire resulting in severe personal

injury or death.

If a fuel leak is detected, stop the engine immediately. The vapors from

hot fuel are highly flammable which may result in a fire.

DO NOT store fuel containers in the vehicle. They may leak, explode and

cause or feed a fire. Empty or full, they present a hazard that may lead to

burns in the event of a fire.

50 Maintenance and Service

Diesel Fuel Specification

Quality

Diesel engines for 2007 and later model year vehicles are designed to operate

only with Ultra Low Sulfur Diesel (ULSD) fuel. Use of fuel other than ULSD

will reduce the efficiency and durability of the engine, permanently damage

the advanced emission control systems, reduce fuel economy and possibly

prevent the engine from running at all. Manufacturer's warranties are likely to

be rendered void by usage of improper or incorrect fuel, and usage of fuels

other than ULSD fuel in diesel-powered vehicles is illegal and punishable

with civil penalties. Use of fuel additives to compensate for the lower sulfur

content is NOT recommended by Volvo Trucks North America.

The proper selection of fuel is essential for good economy, performance and

engine life. No. 2D ULSD should be used when climatic conditions permit.

No. 1D ULSD can be used during cold weather conditions. Blends of No. 1D

and No. 2D ULSD fuels can be used to suit various climatic conditions.

The use of lighter fuels (grade No. 1-D) can reduce fuel economy.

Euro 4 Engines

Ultra Low Sulfur Diesel (ULSD) fuel with a maximum sulfur content of

15 ppm is required to meet emission certification for Euro 4 emission engines.

Using approved diesel fuel with a maximum sulfur content of 500 ppm in

Euro 4 emission engines will meet all reliability standards.