VOLVO MOTOR GRADERS

G930

MORE CARE. BUILT IN.

2007.05

SPECIFICATIONS

G930

Base operating weight - approximate

Weights shown include full cab with ROPS, all operating fl uids, operator and standard equipment.

Base - Total lb (kg) 34,830 (15 800)

On front wheels lb (kg) 10,360 (4 700)

On rear wheels lb (kg) 24,470 (11 100)

Maximum combined capacity lb (kg) 42,500 (19 280)

Maximum weight - front lb (kg) 16,700 (7 570)

Maximum weight - rear lb (kg) 31,400 (14 240)

Note that adding weight and attachments to the base grader may necessitate a tire upgrade as maximum weight capacity of tire may

be exceeded.

Productivity (Standard equipment)

Blade pull at base weight (0.9 traction co-effi cient) lb (kg)

Blade pull at maximum base weight (0.9 traction co-effi cient) lb (kg) 28,260 (12 816)

Blade down force capability lb (kg) 18,021 (8 188)

Blade down force is the maximum downward force which may be applied at the cutting edge.

Engine data

Model

Ty p e Turbocharged, Aftercooled

No. of cylinders In Line 6

Bore & stroke in (mm) 4.25 x 5.12 (108 x 130)

Displacement cu in (l) 436 (7,2)

Engine complies to EPA Tier 3, EU Stage IIIA exhaust emission standards.

Electrical system 24 volt - 80 amp

Batteries (two 12 volt) maintenance free 660 CCA 96 AH

Two 12 volt 1300 CCA (231 AH) batteries available optionally

22,023 (9 990)

Volvo D7E

(1920 watt) alternator

2007.05

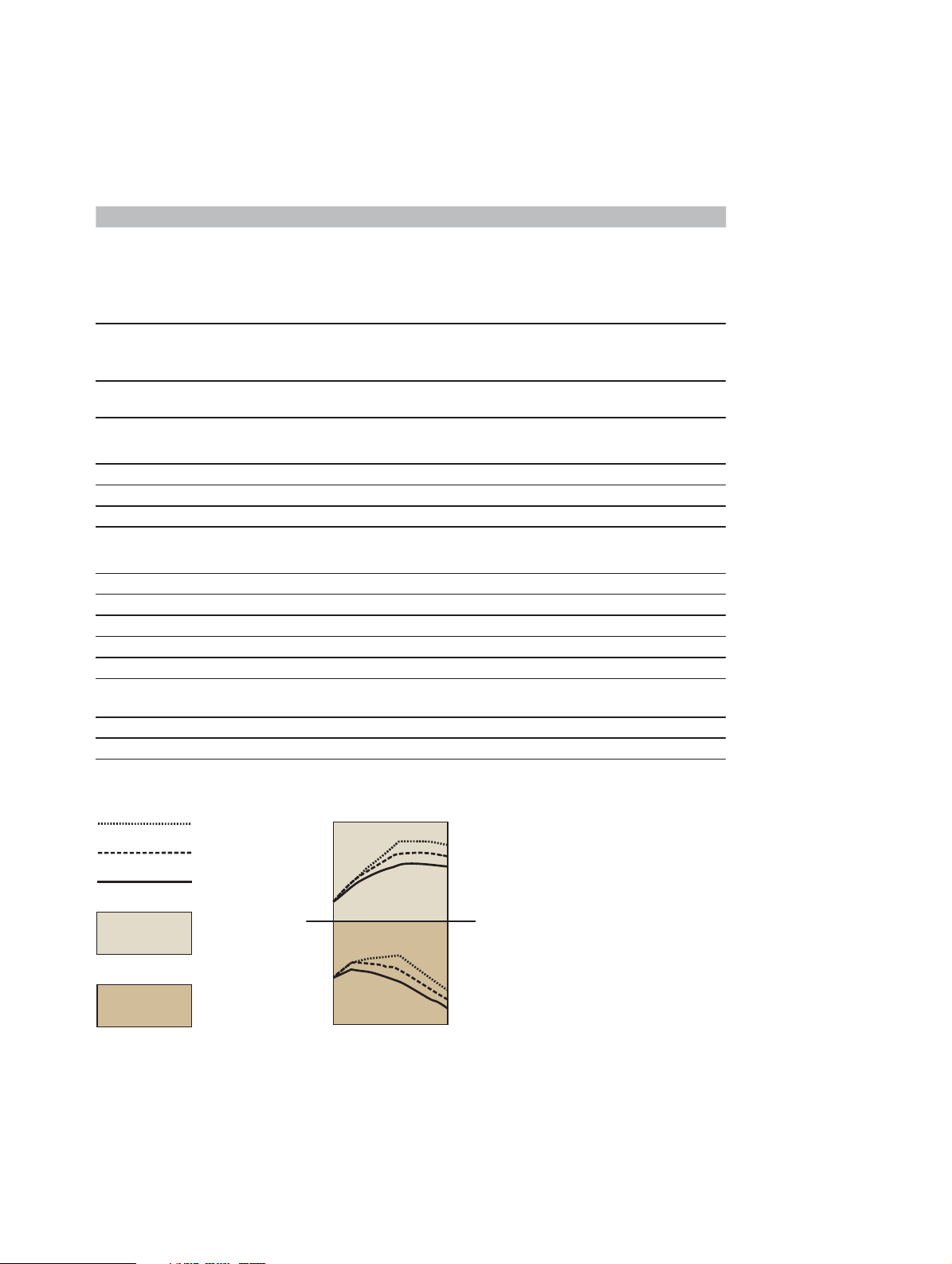

Engine performance curve

Legend

High Range

Mid Range

Low Range

Engine Power

Engine Torque

2

G930

185 245

120 160

55 75

1200 900

800

Net Torque (Nm) Net Power (kW)

400 300

800 1300 1800 2100

Engine Speed (rpm)

Net Power (hp) Net Torque (lb.ft)

700

500

G930

3 Range engine power control

Low range power

Rated net brake horsepower @ 2100 RPM

§

hp (kW) 155 (115)

Torque lb.ft (N.m) 668 (906) @1200

Mid range power

Rated net brake horsepower @ 2100 RPM

§

hp (kW) 175 (130)

Torque lb.ft (N.m) 675 (915) @1400

High range power

Rated net brake horsepower @ 2100 RPM

§

hp (kW) 195 (145)

Maximum net horsepower @ 1800 RPM hp (kW) 204 (154)

Torque lb.ft (N.m) 684 (928) @1550

No engine derating required up to 9,800 ft (3 000 m) altitude. Rated net horsepower SAE J1349/ISO 9249.

§

Rating is @ 2100 RPM except for EU which is rated @ 1900 RPM in low and mid ranges.

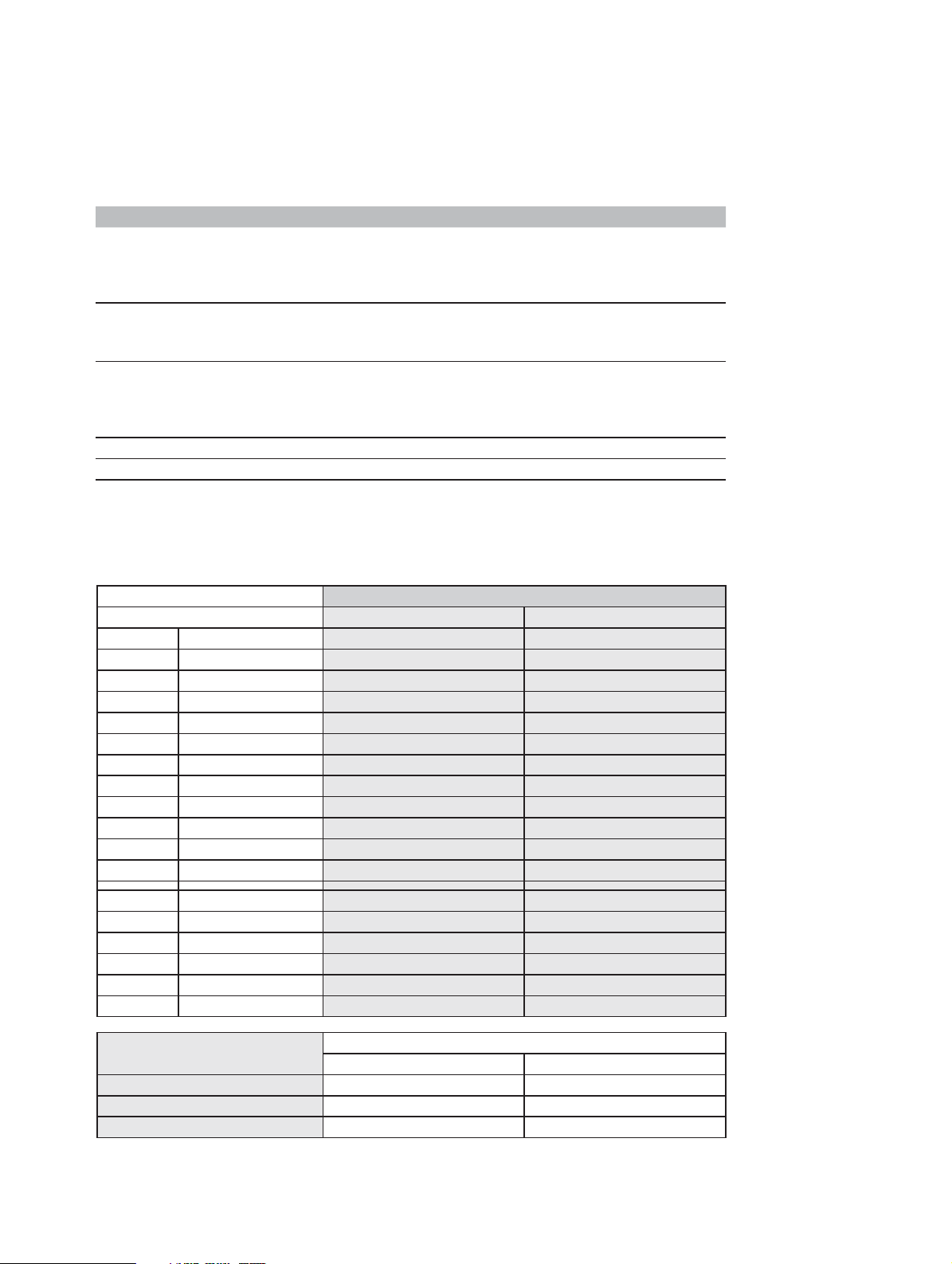

Transmission

Fully sequential, direct drive, Volvo powershift transmission. Engine cannot be started if transmission is in gear. Single lever electronic

transmission controller provides self-diagnostics and overspeed protection. Optional HTE1160 has automatic shifting and travel mode

as standard equipment.

Ground speeds at 2100 RPM with 14:00 tires.

G930

Transmission model HTE840 HTE1160

Gear

F1 mph (km/h) 2.7 (4,3) 2.1 (3,3)

F2 mph (km/h) 3.7 (6,0) 2.7 (4,3)

F3 mph (km/h) 5.2 (8,4) 3.6 (5,8)

F4 mph (km/h) 7.3 (11,7) 4.7 (7,5)

F5 mph (km/h) 10.4 (16,6) 6.1 (9,8)

F6 mph (km/h) 14.5 (23,2) 7.9 (12,7)

F7 mph (km/h) 20.3 (32,5) 10.5 (16,8)

F8 mph (km/h) 28.4 (45,4) 14.0 (22,4)

F9 mph (km/h) 18.2 (29,0)

F10 mph (km/h) 23.8 (38,1)

F11 mph (km/h) 30.8 (49,3)

2007.05

R1 mph (km/h) 2.6 (4,2) 2.1 (3,3)

R2 mph (km/h) 5.1 (8,2) 3.5 (5,7)

R3 mph (km/h) 10.2 (16,3) 6.0 (9,6)

R4 mph (km/h) 20.0 (32,0) 8.0 (12,8)

R5 mph (km/h) 13.8 (22,0)

R6 mph (km/h) 23.4 (37,5)

Transmission Gear

Engine Power Range Volvo HTE840 Volvo HTE1160

Low F1, F2 R1 F1, F2, F3 R1, R2

Mid F3, F4, F5 R2, R3 F4, F5, F6, F7 R3, R4

High F6, F7, F8 R4 F8, F9, F10, F11 R5, R6

3

G930

Tandems

Depth in (mm) 8.9 (226,5)

Height in (mm) 24.25 (616)

Thickness

inner wall in (mm) 1 (25)

outer wall in (mm) .78 (20)

Center distance in (mm) 61 (1 550)

Drive chain pitch in (mm) 2 (51)

Oscillation degrees ± 15º

Differential / Final drive

Model

Planetary fi nal reduction with an operator controlled wet multiple disc lock/unlock differential.

Wheels & tires (Standard equipment)

Tire size 14:00 x 24, G-2

Ply rating (PR) 12

Rim size in (mm) 9 (223) One piece rim

Bolt-on rims interchangeable between front and rear Yes

Front axle and articulation

Wheel lean degrees R & L 18º

Oscillation degrees up & down 16º

Ground clearance in (mm)

Minimum turning radius using front axle steering, articulation, wheel

lean and unlocked differential

Steering arc degrees 50º

Frame articulation angle degrees 23º

Anti-drift lock valve ensures stable operation. Articulation lock standard.

Hydrostatic power steering of front wheels incorporating two steering cylinders. Meets SAE J1511 FEB. 94, ISO 5010:1992 with

optional secondary steering.

Brakes

Service Brakes: Foot operated

Fade resistant, hydraulically actuated, wet multiple disc service brakes located at the 4 tandem drive wheels are fully sealed and

maintenance free. System features crossover dual braking circuits for uniform braking on both sides of the grader. Includes reserve

power assist and operator warning system (visual and audible).

Parking Brake

Spring applied hydraulically released enclosed wet multiple disc type parking brake in fi nal drive. Effective on all 4 tandem

drive wheels.

Transmission cannot be engaged with park brake on.

Braking systems comply to SAE J/EN ISO 3450:1996.

Volvo uses asbestos free brake components.

Volvo APR70

24 (610)

ft (mm) 23'10" (7 265)

2007.05

4

G930

Frame

Front

Minimum dimensions of box section in (mm) 10.5 x 13.5 (265 x 340)

Plate thickness in (mm) .79 (20)

Vertical section modulus at arch cu in (cm

minimum cu in (cm

maximum cu in (cm

3

) 119 (1 950)

3

) 101 (1 663)

3

) 212 (3 474)

Rear

Minimum dimensions in (mm) 10 x 4 (254 x 100)

Plate thickness in (mm) .38 (9,6)

Optional fi rst user lifetime warranty on frame, includes maintenance free articulation pins and bearings.

Moldboard

Standard moldboard with replaceable end bits in

(mm)

.87 x 25 x 12'

(22 x 635 x 3 658)

Moldboard material SAE 1050 high carbon steel

Edge: through hardened in (mm) 6 x 5/8 (152 x 16) boron steel

Bolt spacing in (mm) 6 (152)

Bolt size in (mm) 5/8 (16)

Slide rails supported by Duramide™ bearings

Moldboard range: Moveable Blade Control System

(Dimensions shown with 14:00 tires and standard moldboard)

Reach outside tires - articulated frame in

(mm)

Reach outside tires - straight frame in

(mm)

Moldboard slide in

(mm)

Circle side shift in

(mm)

Maximum bank sloping angle, left - right degrees

Left/Right

120/119.5

(3 048/3 035)

80/79

(2 020/2 010)

26.5/26.5

(673/673)

30.5/29.5

(775/749)

90º/90º

Moldboard ground clearance in (mm) 17.5 (445)

Moldboard cutting depth in (mm)

Moldboard tilt range degrees forward

degrees back

31 (790)

47º

5º

Superior moldboard mobility permits steep ditch cutting angles and back sloping outside overall machine width.

2007.05

5

G930

Circle

Pitch diameter in (mm) 64 (1 626)

Thickness in (mm) 1.25 (32)

Adjustable guide shoes - standard / optional 3 / 5

Adjustable clamp plates - standard / optional 3 / 5

Upper circle wear plates - standard / optional 3 / 5

Circle to drawbar support is provided by Duramide™ wear plates and bearings at the clamp and guide shoes. Duramide™ prevents

metal-to-metal contact and provides maximum service life.

Circle drive

The Volvo dual gear Circle Drive System uses direct acting hydraulic power for exceptional turning and holding capability under

full load. Circle Drive System uses two hardened drive pinions and is protected against impact damage by an overload relief valve as

standard equipment.

Rotation degrees 360º

Drawbar

Dimensions of box section in (mm) 6.5 x 6.5 (165 x 165)

Plate thickness in (mm) 1 & .75 (25 & 19)

Cab & controls

Low profi le cab with ROPS/FOPS

Interior height in (mm)

An optional full height cab is available with an inside height of 72.5" (1 837 mm).

All Volvo Grader cabs and canopies are designed to meet or exceed SAE J/ISO 3471-1:2004 and EN 13510:2000 ROPS

requirements and SAE J/pr EN ISO 3449:2002 Level 2 FOPS requirements.

The retractable seatbelt is 3" (76 mm) wide and meets SAE J386 NOV. 97 and EN ISO 6683:1999. Industry standardized control

lever arrangement.

Interior operator noise levels average

72 dB(A) per ISO 6394:1998 (enclosed cab).

64 (1 620)

2007.05

Implement hydraulics

Circuit type: Closed center, load sense Proportional Demand Flow (PDF) Hydraulic System, with O-ring face seal hose connections.

Main implement pump type Axial piston type

Maximum pressure psi (Bar) 3,000 (207)

Output 2100 RPM gpm (lpm) 55 (208)

Stand by pressure psi (Bar) 350 (24)

Filtration

Large capacity, replaceable in-tank fi lter. Filters both system and re-fi ll oil. With low level and high temperature operator warning.

Hydraulic fan drive pump

Ty p e

Axial piston pump dedicated to the variable speed cooling fan. Reversible cooling fan optionally available.

6

G930

Capacities

Fuel tank U.S. Gal. (l)

Transmission U.S. Gal. (l) 16 (61)

Final drive U.S. Gal. (l) 3.5 (13,2)

Tandems (each) U.S. Gal. (l) 26.4 (100)

Hydraulic oil tank U.S. Gal. (l) 24 (91)

Coolant antifreeze protection to -58º F (-50º C) approx U.S. Gal. (l) 8.2 (31)

Engine oil U.S. Gal. (l) 5.7 (21,5)

Attachments

(Optional unless otherwise stated as standard equipment)

Push Block lb (kg)

Ripper includes rear frame arch support and links lb (kg) 2,600 (1 175)

Mid Mount Scarifi er lb (kg) 1,900 (850)

Front Mount Scarifi er lb (kg) 1,552 (704)

Dozer: 8' (2,4 m) lb (kg) 2,300 (1 045)

9' (2,7 m) lb (kg) 2,360 (1 070)

Dimensions

All dimensions are approximate. A in (mm)

Legend

A = Overall length

B = Bladebase per ISO 7134

C = Wheelbase

D = Width - Front tire center lines

E = Width - Outside tires

F = Overall height with Low Profi le Cab

Add 8.5" (217 mm) for full height cab

Bin (mm) 105 (2 675)

C

D in (mm) 82 (2 076)

E in (mm) 100 (2 537)

F

in (mm)

in (mm)

92 (348)

1,110 (504)

352 (8 930)

247 (6 280)

127 (3 225)

2007.05

F

D

E

B

C

A

7

STANDARD FEATURES / OPTIONAL EQUIPMENT

Model (S - Standard / O - Optional) G930 G940 G946 G960 G970 G976 G990

Powertrain

Volvo engines meets off-road Tier 3 / Stage IIIA emission criteria - 3 power curves S S S S S S S

Rear axle, operator controlled, lock/unlock differential with planetary fi nal reduction S S S S S S S

4 wheel wet disc braking system with crossover dual circuits and reserve power assist S S S S S S S

Spring applied wet multiple disc park brake with operator warning alarm and indicator S S S S S S S

Electronic hand throttle with RPM hold and resume functions S S S S S S S

Operator controlled Power/Speed engine mode S S S S S S S

Direct drive, power shift Volvo HTE840 transmission with 8 forward and 4 reverse gears S S S S S S S

Transmission guard SSSSSSS

Single transmission control lever, with electronic over speed protection, advanced memory

shift and park position lockout

Transmission Autoshift and Travel functions O O O O O O O

Direct Forward to Reverse shuttle shift capability without using the Inching pedal S S S S S S S

Volvo HTE1160 Transmission - 11 speeds forward 6 speeds reverse includes

Autoshift and travel functions

Reversible cooling fan - manual or automatic modes O O O O O O O

Automatic engine protection lowers engine torque and speed if critical conditions occur SSSSSSS

Electrical

Cab mounted headlights with dimmer switch S S S S S S S

Lights; backup, tail, stop and directional S S S S S S S

Backup alarm 112 dB(A) SSSSSSS

Moldboards work lights - 2 or 4 O O O O O O O

Rear work lights - 2 or 4 O O O O O O O

Corner cab work lights - left or right - 2 O O O O O O O

Maintenance free batteries S S S S S S S

110 amp (2460 watt) alternator OOOOOOO

24 volt to 12 volt converter - 30 or 60 amp (600 or 1440 watt) with power point OOOOOOO

Productivity

7 position Blade Control System for optimum blade mobility S S S S S S S

Twin gear direct drive circle turn system with impact protection S S S S S S S

Duramide™ wear strips prevent metal-to-metal contact for maximum service life S S S S S S S

Heavy duty circle support system O O O O O O S

Hinged cooling module fan door for easy trash clean out S S S S S S S

Ground level fueling SSSSSSS

Lockable tool box with storage space for scarifi er shanks S S S S S S S

Moldboards: 12' x 25" x 7/8" (3 658 x 635 x 22 mm) S S S S

13' x 25" x 7/8" (3 962 x 635 x 22 mm) O O O O

14' x 25" x 7/8" (4 267 x 635 x 22 mm) O O O O

12' x 29" x 1" (3 658 x 737 x 25 mm) S S

13' x 29" x 1" (3 962 x 737 x 25 mm) O O

14' x 29" x 1" (4 267 x 737 x 25 mm) OO

14' x 31" x 1" (4 267 x 787 x 25 mm) S

16' x 31" x 1" (4 877 x 787 x 25 mm) O

Moldboard extensions RIGHT or LEFT - 2' (610 mm) O O O O O O O

Moldboard edges - carbide 3/4" x 5" (19 x 127 mm) or 1" x 8" (25 x 203 mm) harden steel O O O O O O O

Brackets for Automatic Blade Control System installation O O O O O O O

Metallic lower moldboard slide bearing OOOOOOS

Tires

Consult your Volvo dealer for full offering

Tires: 14:00 X 24 - G2 S S S S S S

17:5 x 25, 12 PR, G-2 O O O O O O

16:00 X 24 OO S

20:5 X 25 OO

SSSSSSS

OOOOOOO

2007.05

8

Model (S - Standard / O - Optional) G930 G940 G946 G960 G970 G976 G990

Hydraulics

Proportional Demand Flow hydraulic system with short throw, low effort control levers S S SSSSS

10 section hydraulic control valve - includes two spare sections with levers SSSSSSS

Circle turn relief located integral with main manifold SSSSSSS

Hydraulic oil level monitor via Contronics S S SSSSS

Blade Lift Float Control, independent right and left detent style O O O O O O O

Front attachment fl oat control, detent style, independent of other fl oat valves O O O O O O O

Several remote valve locations for attachments O O O O O O O

Secondary steering (power assisted) O O O O O O O

Operator Cab

Illuminated entry when cab doors are opened - enclosed cab only S S SSSSS

Adjustable steering control pedestal with tilt head for maximum operator comfort S S SSSSS

Gauges include: coolant temperature, engine oil pressure, fuel level, hourmeter,

articulation angle indicator

Multi-function Volvo Contronic Monitoring System with visual and audible warnings S S SSSSS

Deluxe, cloth covered, fully adjustable suspension seat when grader is equipped with

an enclosed cab - 3" (75 mm) retractable seatbelt

Deluxe air suspension, cloth covered, fully adjustable suspension seat -

3" (75 mm) retractable seatbelt

Left and right outside dual rear view mirrors S S SSSSS

Fold-away left and right outside dual rear view mirrors O O O O O O O

Dual interior rear view mirrors S S SSSSS

Enclosed Low Profi le Cab with ROPS and FOPS – left and right cab door with steps S S SSSSS

Enclosed High Profi le Cab with ROPS and FOPS – left and right cab door with steps O O O O O O O

Low Profi le canopy shell (SPLIT) with ROPS – left and right entry with steps O O O O

Cab heater - 50,000 BTU with cab pressurizer and replaceable fi lters, 10 outlets S S SSSSS

Air conditioner - 35,000 BTU • HFC-134a (non-CFC refrigerant) with cab heater O O O O O O O

Defroster fan with multiple outlets O O O O O O O

Radio/CD player with 4 speakers O O O O O O O

Single arm front cab wiper and washer, enclosed cab S S SSSSS

Single arm wiper and washer - rear window O O O O O O O

Single arm wiper and washer - lower windows front left & right O O O O O O O

Dual arm front windshield, increased coverage, Low Profi le Cab only O O O O O O O

Intermittent wipers on all wipers ordered O O O O O O O

Window - lower front - opening O O O O O O O

Window - left/right side - opening sliders with multiple position openings O O O O O O O

Lower cab shield, encloses bottom of cab to frame O O O O O O O

Attachments

Fenders front or rear OOOOOO

Dozer Blade: 8' (2.5 m) O O O O

9' (2.7 m) O O O O O O O

10' (3.0 m) OOO

Front Mounted Scarifi er with 5 scarifi er teeth O O O O O O

Mid Mount Scarifi er with 5 scarifi er teeth O O O O

Push Block OOOOOOO

Ripper/Scarifi er, rear with 3 ripper shanks O O O O O O O

Other

Painted high gloss Volvo yellow and grey SSSSSSS

First user lifetime frame warranty – includes articulation pins and bearings O O O O O O O

Paint - custom colors OOOOOOO

Low ambient fl uids for extreme cold conditions below -14º F (-10º C) O O O O O O O

Tool kit OOOOOOO

Sound reduction packages (Standard in EU markets) O O O O O O O

Rear licence plate bracket O O O O O O O

Air compressor - engine driven with tank O O O O O O O

Volvo CareTrack – remote monitoring system O O O O O O O

Partial listing of available options. Certain features may be standard or not available within specifi c market.

Consult your Volvo Motor Grader distributor for more information.

SSSSSSS

SSSSSSS

OOOOOOO

2007.05

9

Volvo Construction Equipment is different. It’s designed, built

and supported in a different way. That difference comes from

an engineering heritage of over 170 years. A heritage of

thinking first about the people who actually use the machines.

About how to help them be safer, more comfortable, more

productive. About the environment we all share. The result

of that thinking is a growing range of machines and a global

support network dedicated to helping you do more. People

around the world are proud to use Volvo. And we’re proud

of what makes Volvo different – More care. Built in.

All products are not available in all markets. Under our policy of continuous improvement, we reserve the right to change

specifications and design without prior notice. The illustrations do not necessarily show the standard version of the machine.

Ref. No. VOE22B1002263 US/English

Printed in pdf 2007.05 GRD

Volvo, Goderich

Loading...

Loading...