Volvo 740 1990 User Manual

BRAKE SYSTEM

1990 Volvo 740

1989-90 BRAKES

Volvo - Disc

240 Series, 740 Series, 760 Series

DESCRIPTION

All models use front and rear disc brakes. Three makes of calipers are used: ATE, Bendix (DBA) and Girling. Service brakes are hydraulically-operated by a tandem master cylinder and vacuum power brake unit. Each rear brake line has a pressure valve to prevent rear wheel lock-up. Parking brake is mechanically operated, using rear wheel disc rotor internally-mounted brake shoes.

NOTE: For information on Volvo anti-lock brake system, see appropriate article for 740 and 760 series:

*ANTI-LOCK BRAKE SYSTEM - 1989

*ANTI-LOCK BRAKE SYSTEM - 1990

BRAKE BLEEDING

NOTE: For vehicles with ABS, see

appropriate article for 740 and 760 series:

*ANTI-LOCK BRAKE SYSTEM - 1989

*ANTI-LOCK BRAKE SYSTEM - 1990

BLEEDING PRECAUTIONS

1)On all models equipped with diagonal split hydraulic system, bleed either rear wheel first, then opposite front. Repeat procedure on other side (circuit).

2)On all models equipped with load sensing proportioning valve, bleed valve before bleeding brakes. If master cylinder is equipped with a bleed screw, bleed it first.

MANUAL BLEEDING

1)Exhaust vacuum from power unit by depressing brake pedal several times.

2)Fill master cylinder. Install a clear vinyl bleeder hose onto first bleeder valve to be serviced. See the BLEEDING SEQUENCE table below. Place other end of hose in clean transparent container.

3)Partially fill container with clean brake fluid so end of hose is submerged in fluid. Open bleeder valve 1-2 turns. Slowly depress brake pedal through its full travel.

4)Close bleeder valve and release pedal. Pump pedal several times and push air toward wheel cylinders. Repeat procedure until flow of brake fluid is clear and shows no sign of air bubbles. Proceed to next bleeder valve.

NOTE: Check fluid level in master cylinder frequently during bleeding sequence.

PRESSURE TANK BLEEDING

1) Exhaust vacuum from power unit by depressing brake pedal

several times.

2)Clean the master cylinder cap and surrounding area, then remove cap. With pressure tank at least 1/2 full, connect tank to the master cylinder using proper adapter(s).

3)Attach bleeder hose to first bleeder valve to be serviced. See the BLEEDING SEQUENCE table below. Place other end of hose in clean transparent container. Partially fill container with clean brake fluid, until end of hose is submerged in fluid.

4)Open release valve on pressure bleeder. Open bleeder valve 1-2 turns, noting fluid flow. When fluid flowing in to container is clear and free of air bubbles, close bleeder valve securely.

5)Finish bleeding system in the same manner using correct sequence. Remove pressure tank from master cylinder and check fluid level of master cylinder reservoir.

BLEEDING SEQUENCE TABLE (1)

Application |

Sequence |

|||

240 |

....................................... |

LF, RF, |

LR, |

RR |

740 |

& 760 ................................. |

RR, LR, |

RF, |

LF |

(1) - On calipers with 3 bleeder valves, open all valves simultaneously.

ADJUSTMENTS

BRAKE PEDAL HEIGHT

Brake pedal height should be equal to clutch pedal height. To adjust, loosen lock nut, remove cotter pin and turn push rod until pedal height is equal. Replace cotter pin and tighten lock nut. Pedal travel should be 6-7" (150-170 mm). Pedal travel can ONLY be measured during brake bleeding operation. See BRAKE BLEEDING in this article.

PARKING/EMERGENCY BRAKE

740 Series & 760 Series

Remove cover at rear of center console. Remove adjusting screw by carefully tapping on locking sleeve spring collar with a hammer and screwdriver. Adjust cable so that parking brake is fully applied when lever is pulled 3-5 notches. Install cover.

240Series

1)Remove center console rear ashtray. Working through ashtray hole, loosen parking brake cables adjusting screw until cables are slack. Raise and support rear of vehicle. Remove rear wheels. Align hole in disc/parking brake drum with inside starwheel adjuster.

2)Tighten starwheel until drum can barely be rotated by hand. Back off adjuster until drum just rotates freely (no drag). Install rear wheels. Tighten parking brake cable adjusting screw until parking brake is fully applied when lever is pulled 2-8 notches. Install ashtray and lower vehicle.

STOPLIGHT SWITCH

Adjust switch so brake lights come on when pedal is depressed about 1/2" (13 mm).

REMOVAL & INSTALLATION

DISC PADS

NOTE: Use Remover (2917) to remove brake pads (if necessary).

ATE Pads

1)Raise and support vehicle. Mark position of wheel in relation to hub for reassembly reference. Remove tire and wheel. Using a drift and hammer, remove the brake pads retaining pins . Remove brake pads retaining spring clips. Compressing caliper pistons, remove brake pads.

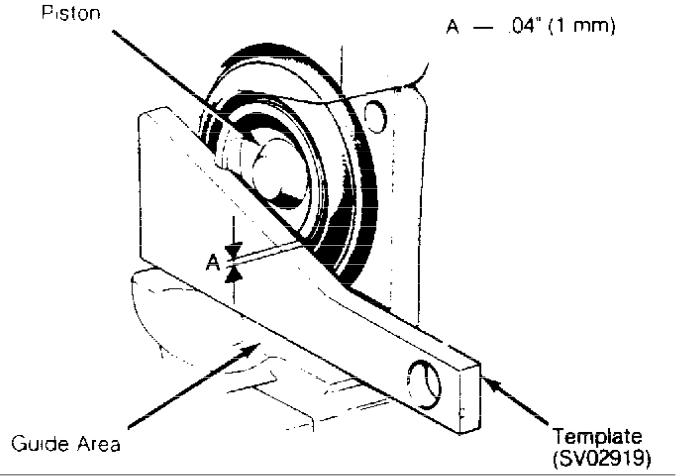

2)Seat pistons in caliper bore with Piston Tool (2809). To avoid brake squealing, check piston position by installing Template (2919). Piston recess should incline 20 degrees in relation to lower guide area on caliper. See Fig. 1.

Fig. 1: Checking ATE Rear Caliper Piston Angle To Avoid Brake Squeal Courtesy of Volvo Cars of North America.

3)If distance from one piston recess to the other recess at measurement "A" exceeds .04" (1 mm), adjust piston position using Adjuster (2918) to rotate piston. See Fig. 1.

4)Install intermediate plates (if equipped) or damper washers (if equipped) in original positions. Install new brake pads and ALWAYS install new brake pad tensioning spring. Install and tap one retaining guide pin into position. Install new tensioning spring. Install other retaining guide pin while holding tensioning spring in

position.

NOTE: Install the damper washers with the small contact face toward pad. DO NOT install intermediate plates in calipers equipped with damper washers.

Bendix & Girling Pads

1)Raise and support vehicle. Mark position of wheel in relation to hub for reassembly reference. Remove tire and wheel. Loosen caliper upper guide pin bolt and remove caliper lower guide pin bolt only from brake pad holder assembly. Swing caliper upward and remove pads.

2)Compress caliper pistons. Inspect rubber guide pin covers and replace if defective. Install brake pads to holder and swing caliper into position. Ensure brake pad tension spring is in proper position. Tighten guide pin bolts to specification. Refer to

TORQUE SPECIFICATIONS table at end of this article.

CALIPER ASSEMBLY

Removal

Raise and support vehicle. Remove wheel. Disconnect brake line connections at caliper. Cap lines to prevent entry of foreign matter. Remove caliper mounting bolts. Lift caliper from mounting bracket.

Installation

1)Position caliper assembly on mounting bracket, and install attaching bolts. After installing bolts, check clearance between disc pads and rotor on both sides of rotor.

2)Maximum deviation between sides should not exceed .004" (. 10 mm) on front calipers or .010" (.25 mm) on rear calipers. To adjust clearance, add shims to caliper. Connect hydraulic lines and bleed hydraulic system.

FRONT DISC BRAKE ROTOR (740 & 760 SERIES)

1)Remove caliper. Remove hub cap. Remove cotter pin and castellated nut. Remove outer wheel bearing. Remove hub and rotor assembly.

2)To install, reverse removal procedure. Tighten castellated nut to 42 ft. lbs. (57 N.m). Back off nut. Tighten nut to 13 INCH lbs. (1.5 N.m). Install cotter pin.

FRONT DISC BRAKE ROTOR (240 SERIES)

With caliper assembly removed, mount a dial indicator and check rotor runout. Runout must not exceed .004" (.10 mm). Measure rotor thickness through one revolution. Thickness variance must not exceed .0008" (.020 mm). Unscrew rotor lock bolts and pull rotor from hub. To install, reverse removal procedure.

REAR DISC BRAKE ROTOR

Remove caliper. Remove screws retaining rotor to hub. Remove rotor. To install, reverse removal procedure.

REAR AXLE SEAL & BEARING

NOTE: For information on models with sealed wheel bearings, see appropriate article:

Loading...

Loading...