Volvo D13F User Manual

Foreword

This booklet is part of a complete service manual. Read the

foreword in the service manual.

WARNING

Always read the booklet Safety before proceeding.

PUB 2012.10

1

Table of contents

03 SPECIFICATIONS

030 General

Tightening torque, cylinder head ................................................................ 6

Engine, specification

General ..................................................................................................... 6

Cylinder block, specifications ...................................................................... 7

Engine transmission, tightening torque ....................................................... 7

Tightening torques .................................................................................... 7

Timing gear casing ................................................................................... 9

Tightening torques, flywheel housing WLO/EXC .................................... 11

Tightening torques, timing gear plate ..................................................... 11

Engine transmission, specification ............................................................ 12

Rocker arm shaft, tightening torques ........................................................ 13

Valve mechanism, specifications .............................................................. 14

Valve mechanism, tightening torques ....................................................... 16

Tightening torques, valve cover ................................................................ 16

Oil sump, tightening torque ....................................................................... 16

Oil cooler, tightening torques .................................................................... 17

Oil cooler ................................................................................................. 17

Oil cooler, cover ...................................................................................... 17

Cylinder block, tightening torques ............................................................. 18

Engine mount incl. bracket ..................................................................... 18

Ladder frame .......................................................................................... 19

Inlet ......................................................................................................... 19

Tightening torque, fuel system .................................................................. 21

Exhaust manifold, tightening torques ........................................................ 21

Turbocharger, tightening torques .............................................................. 21

Crank mechanism, specifications ............................................................. 23

Crankshaft, tightening torques .................................................................. 25

Flywheel, tightening torques ..................................................................... 26

Belt pulley/vibration damper, tightening torques ....................................... 27

................................................................................... 6

21 ENGINE

210 General, common info about 211 - 218

Engine, mounting in work stand ................................................................ 28

Engine, dismantling .................................................................................. 32

Cylinder liners, removing ........................................................................ 39

Engine, assembling .................................................................................. 40

Cylinder liners, installing ......................................................................... 41

Crankshaft, installing .............................................................................. 43

Pistons, installing .................................................................................... 44

Installing timing gear plate ...................................................................... 45

Flywheel housing .................................................................................... 49

Crankshaft seal, rear .............................................................................. 50

Front crankshaft seal .............................................................................. 51

Speed (rpm) sensor, adjusting ................................................................ 54

Engine, removing from work stand ........................................................... 56

211 Cylinder head

Cylinder head, removing ........................................................................... 59

Cylinder head, reconditioning ................................................................... 62

Installing in work stand ........................................................................... 62

Valves, removing .................................................................................... 63

Sleeve for unit injector, removing ........................................................... 64

Tap out with drift ..................................................................................... 65

Pull out with puller ................................................................................... 65

Valve guide, checking ............................................................................. 67

Valve guides, changing ........................................................................... 68

3

Injector sleeve, installing ......................................................................... 69

Cylinder head, checking for leaks

Valve seat, checking ............................................................................... 73

Valve seat, cleaning soot and grinding ................................................... 73

Valve seat, changing .............................................................................. 73

Valves, grinding ...................................................................................... 74

Cylinder head, assembling ..................................................................... 74

Cylinder head, fitting ................................................................................. 76

212 Cylinder block with crankcase ventilation

Cylinder block, liners removed, milling of all liner locations ...................... 82

214 Valve mechanism

Valves, adjusting ....................................................................................... 88

Inlet valves, checking and adjusting ....................................................... 89

Unit injectors, adjusting ........................................................................... 89

Exhaust valves, checking and adjusting ................................................. 90

...........................................................

22 LUBRICATING SYSTEM

223 Oil cooler

Oil cooler, leakage check .......................................................................... 91

71

4

GENERAL

03 SPECIFICATIONS

030 General

5

13

36 35

9

28 27

6

22 21

1

15 16

3

23 24

7

31 32

11

14

38 37

10

30 29

4

18 17

2

19 20

5

25 26

8

33 34

12

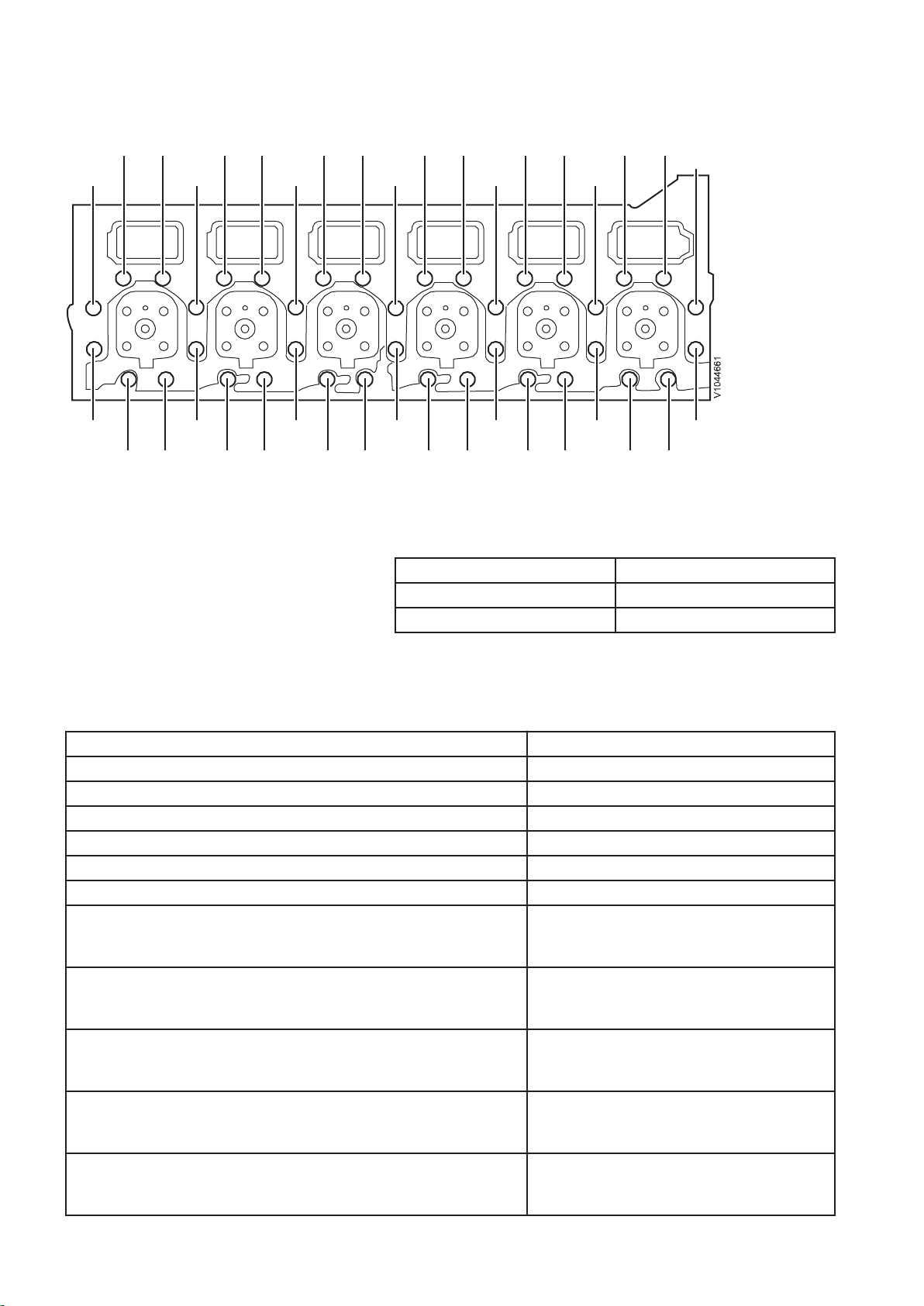

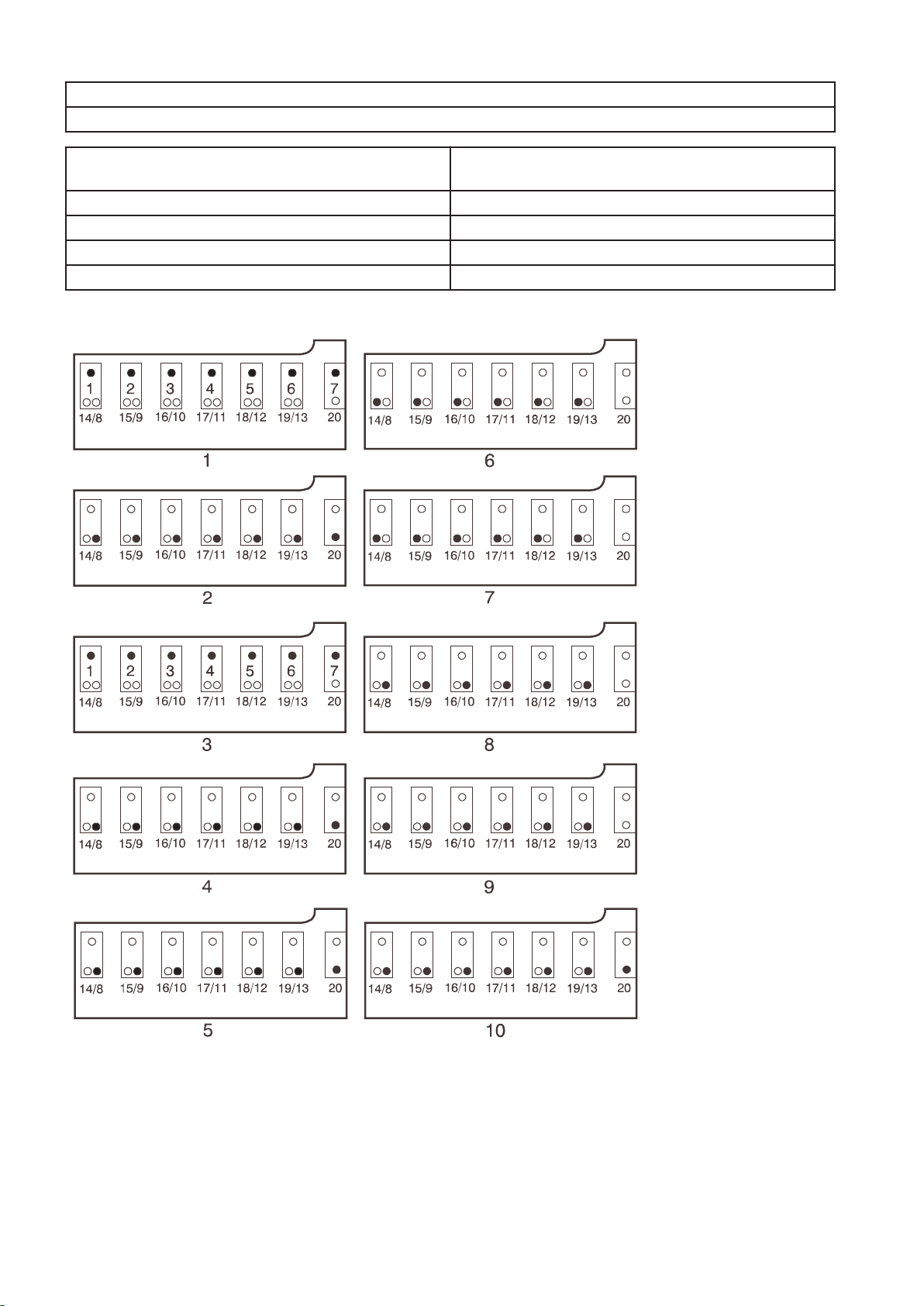

Fig.1 Cylinder head, D13

Tightening torque, cylinder head

NOTE!

Tighten the bolts in the sequence shown in the figure.

Step 1 100±5Nm(74±3.7 lbf ft)

Step 2 120±5° Angle-tightening

Step 3 90±5° Angle-tightening

Engine, specification

General

D13 F

Number of cylinders 6

Cylinder bore 131 mm (5.16 in)

Stroke 158 mm (6.22 in)

Displacement 12.78 litres (3.38 US gal)

Injection order 1–5–3–6–2–4

Compression ratio 18, 5:1

Low idle

EXC

WLO

High idle

EXC

WLO

Max. full load rpm

EXC

WLO

Weight, engine

EXC

WLO

Total length

EXC

WLO

13.33 r/s (800 rpm)

11.67 r/s (700 rpm)

28.33 r/s (1700 rpm)

31.67 r/s (1,900 rpm)

31.67 r/s (1,900 rpm)

35 r/s (2,100 rpm)

1,330 kg (3,042 lbs)

1,330 kg (3,042 lbs)

1 585 mm (62.4 in)

1460 mm (57.5 in)

6

D13 F

Width

EXC

WLO

Height

EXC

WLO

789 mm (31.1 in)

1077 mm (42.4 in)

1 250 mm (49.2 in)

1 215 mm (47.8 in)

Cylinder block, specifications

Length 1 052 mm (41.42 in)

Height, upper block face-crankshaft centre 422 mm (16.6 in)

Height, lower block face-crankshaft centre 120 mm (4.72 in)

Cylinder liners

Type Wet, replaceable

Sealing surface's height over cylinder block's face 0.15 – 0.21 mm (0.0059 — 0.0083 in)

Number of seal rings per cylinder liner 3

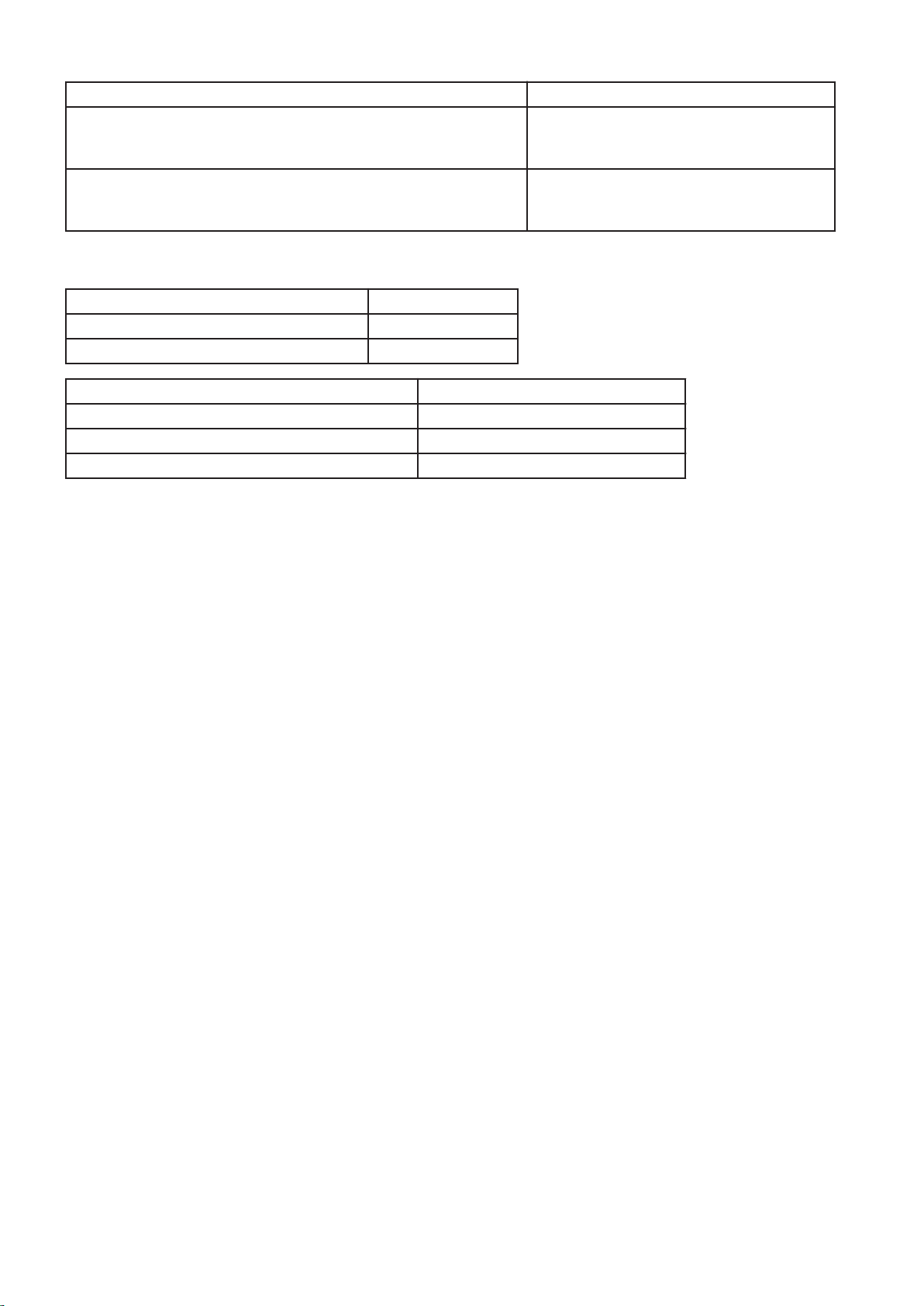

Engine transmission, tightening torque

Tightening torques

NOTE!

Tighten in the order shown in the figure.

7

V1071860

Fig.2

Gears: Tightening torque:

1. Drive gear, crankshaft 24±4 Nm (18±3 lbf ft)

2. Transfer gear, outer gear:

step 1: 25±3 Nm (18.4±2.2 lbf ft)

step 2: angle-tightening 110±5°

3. Transfer gear, adjustable:

step 1: 35±4 Nm (25.8±2.95 lbf ft)

step 2: angle-tightening 120° ±5°

4. Gear, camshaft: Vibration damper's 8.8-bolts may not

be reused.

temporarily: 10 Nm (7.5 lbf ft)

step 1: 45±5 Nm (33±4 lbf ft)

step 2: Angle-tightening 90° ±5°

5. Transfer gear 140±10 Nm (103±7.4 lbf ft)

6. Drive gear, lubrication oil pump for power take-off and

100±10 Nm (74±7.4 lbf ft)

fuel feed pump

8

7. Drive gear, compressor 200+50/-0 Nm (148+37/-0 lbf ft)

V1088409

8. Not used

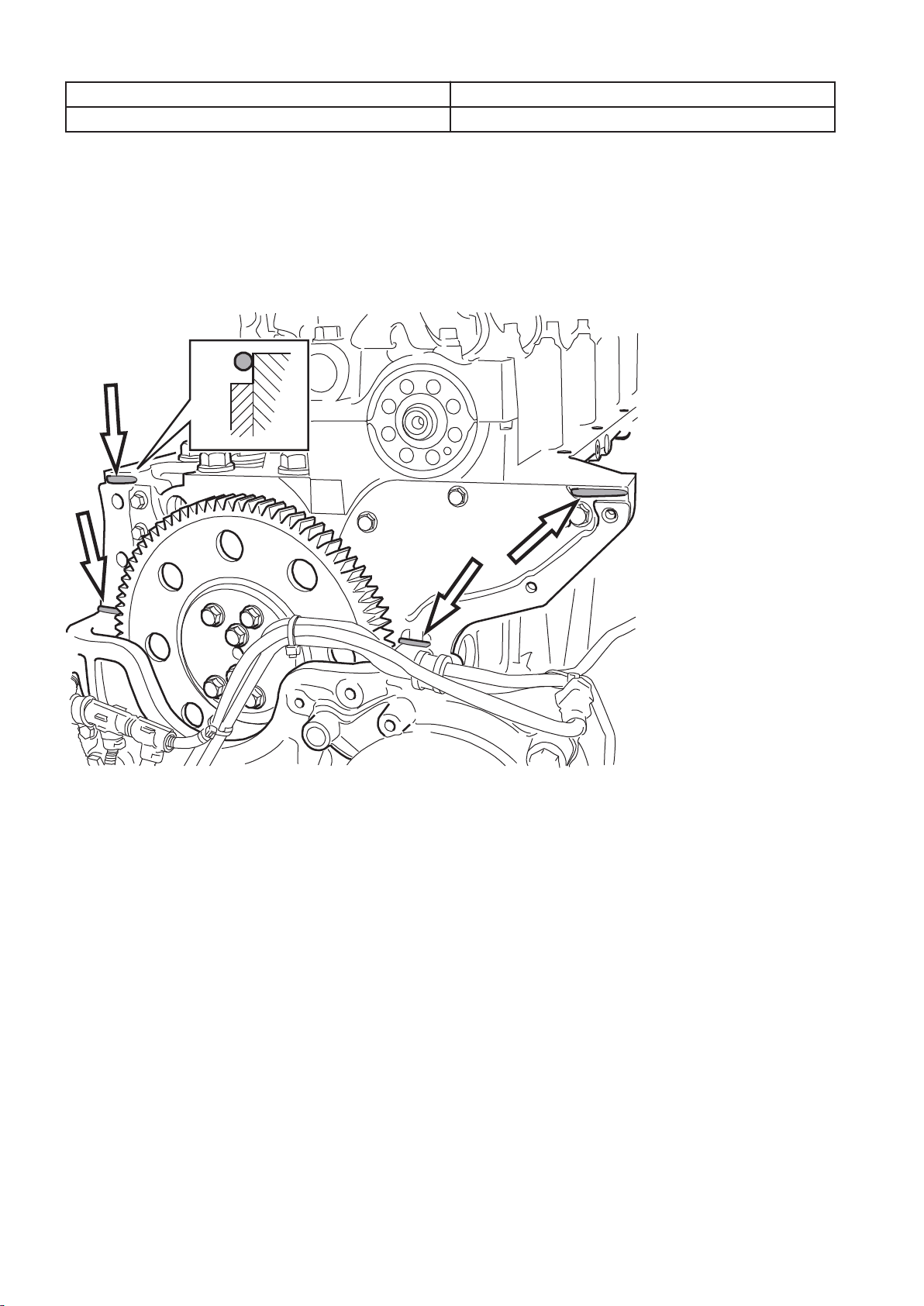

Timing gear casing

Apply a

2 mm (0.08 in) thick bead of sealant (part no. 11713514)

as shown in the figures on the timing gear casing's contact face

against the cylinder head. Install the rubber seals.

NOTE!

The timing gear casing must be installed and torque-tightened

within 20 minutes of applying the sealant.

Fig.3

9

V1088411

Fig.4

V1088408

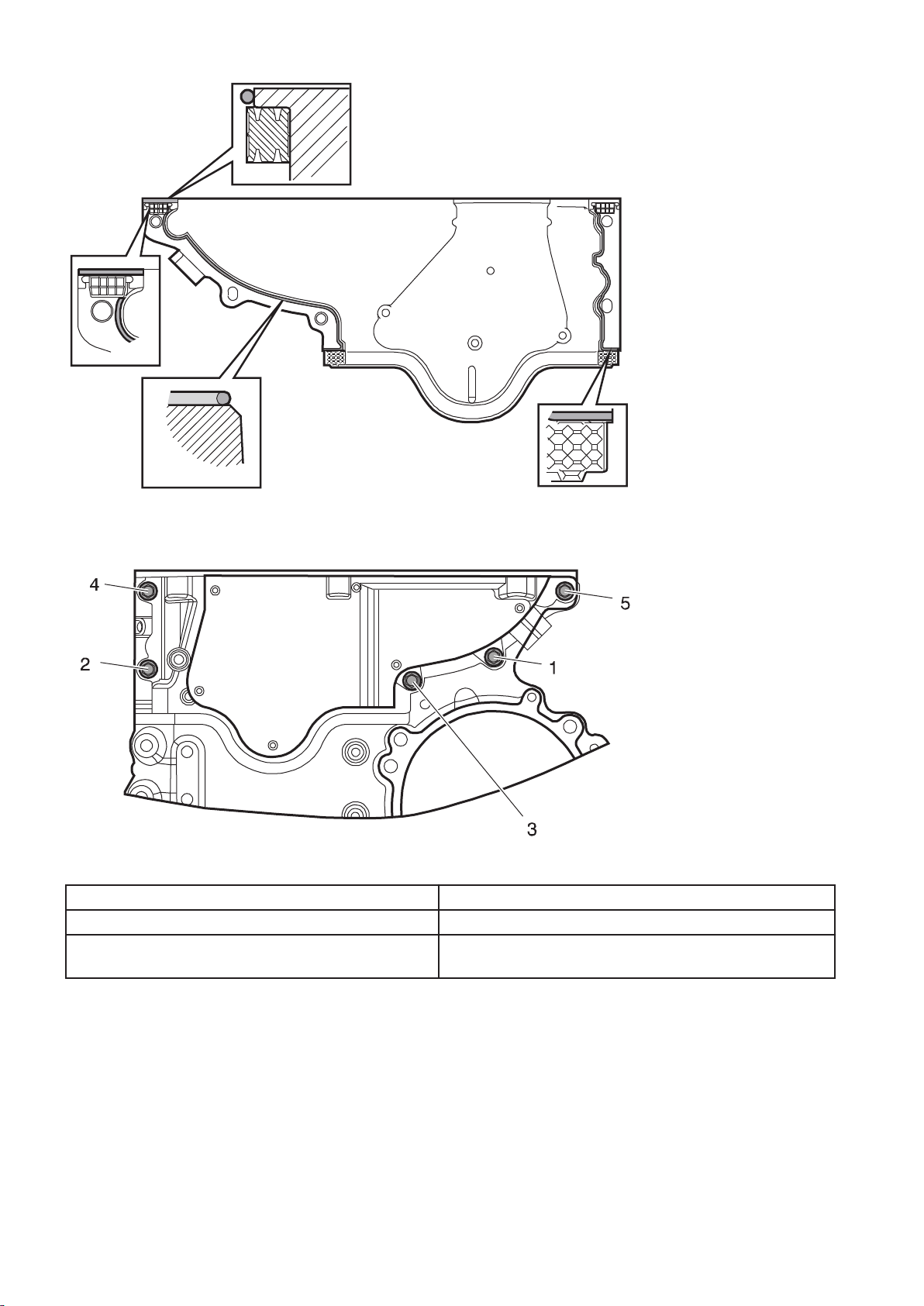

Fig.5 Tightening torques, upper timing gear casing

Timing gear casing (upper)

Step 1: Fasten the casing with the bolts 1 and 2. 4±1 Nm (3±0.74 lbf ft)

Tighten the bolts in the order shown in the above

24±4 Nm (18±3 lbf ft)

figure.

10

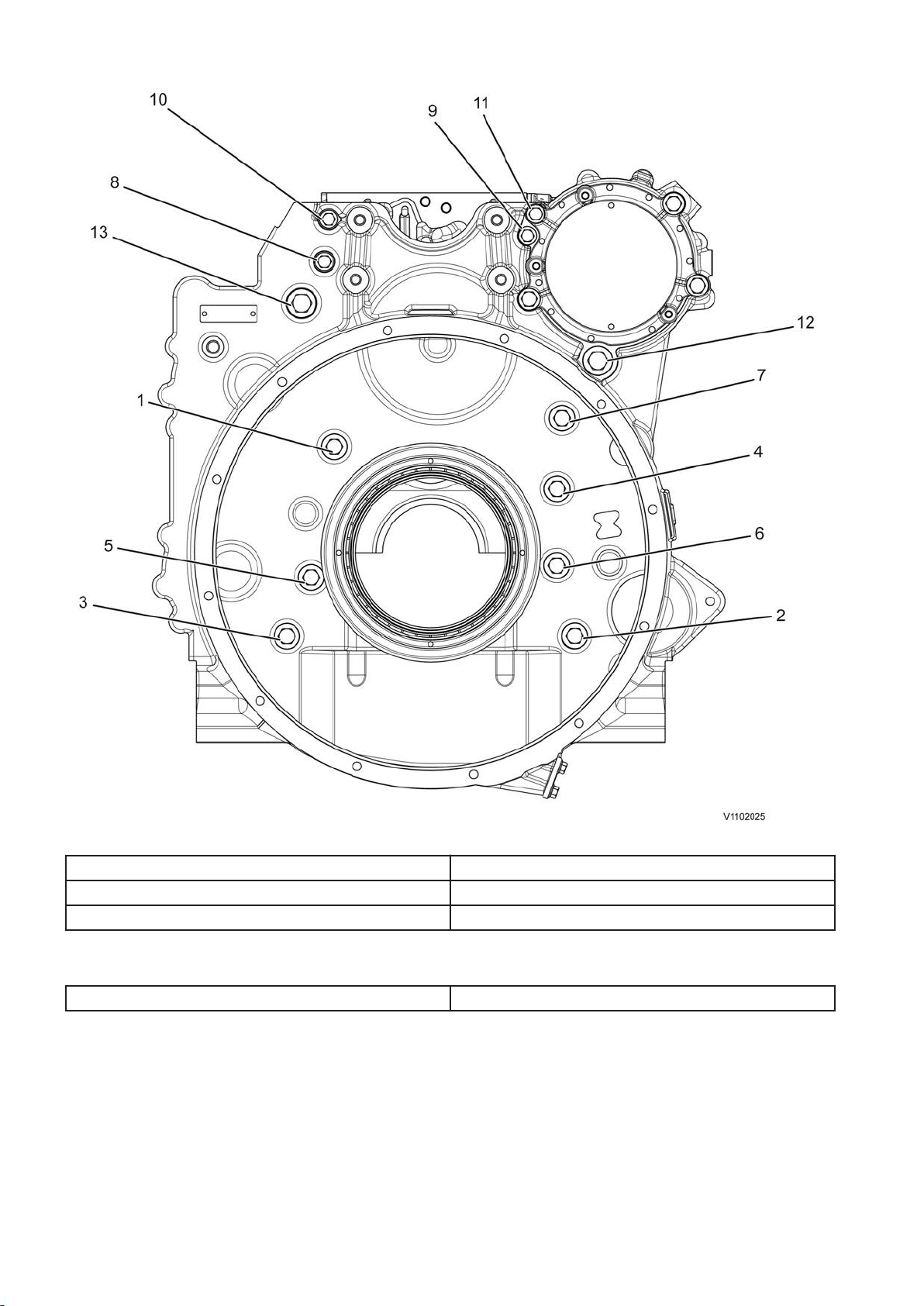

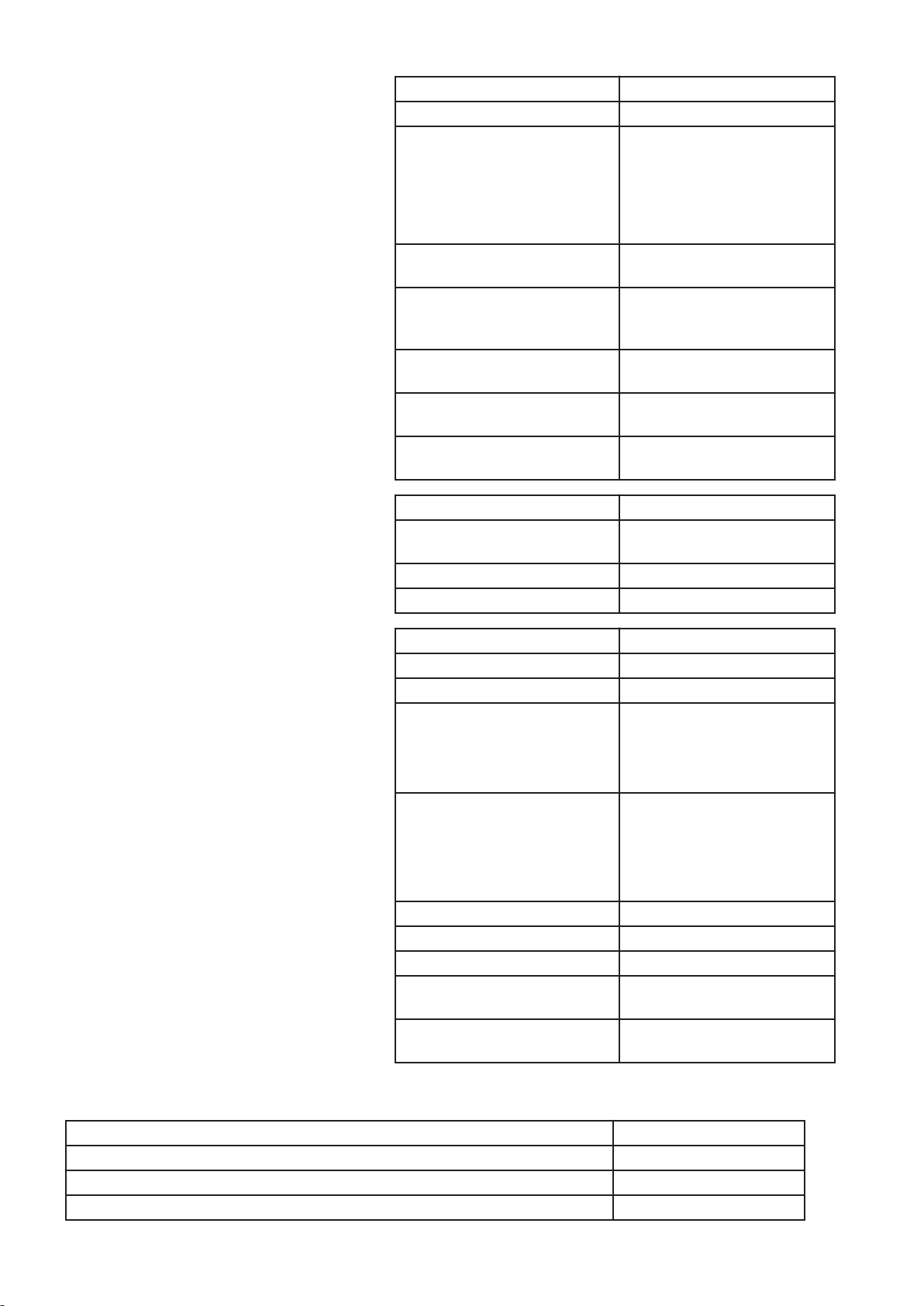

Tightening torques, flywheel housing WLO/EXC

Fig.6 Flywheel housing, WLO/EXC

M14-bolts 160 ± 10 Nm (118 ± 7.4 lbf ft)

M10-bolts 48 ±8 Nm (35.4 ±5.9 lbf ft)

M16-bolts 100±5 Nm (74±3.7 lbf ft)

Tightening torques, timing gear plate

M8-bolts 28±4 Nm (21±3 lbf ft)

11

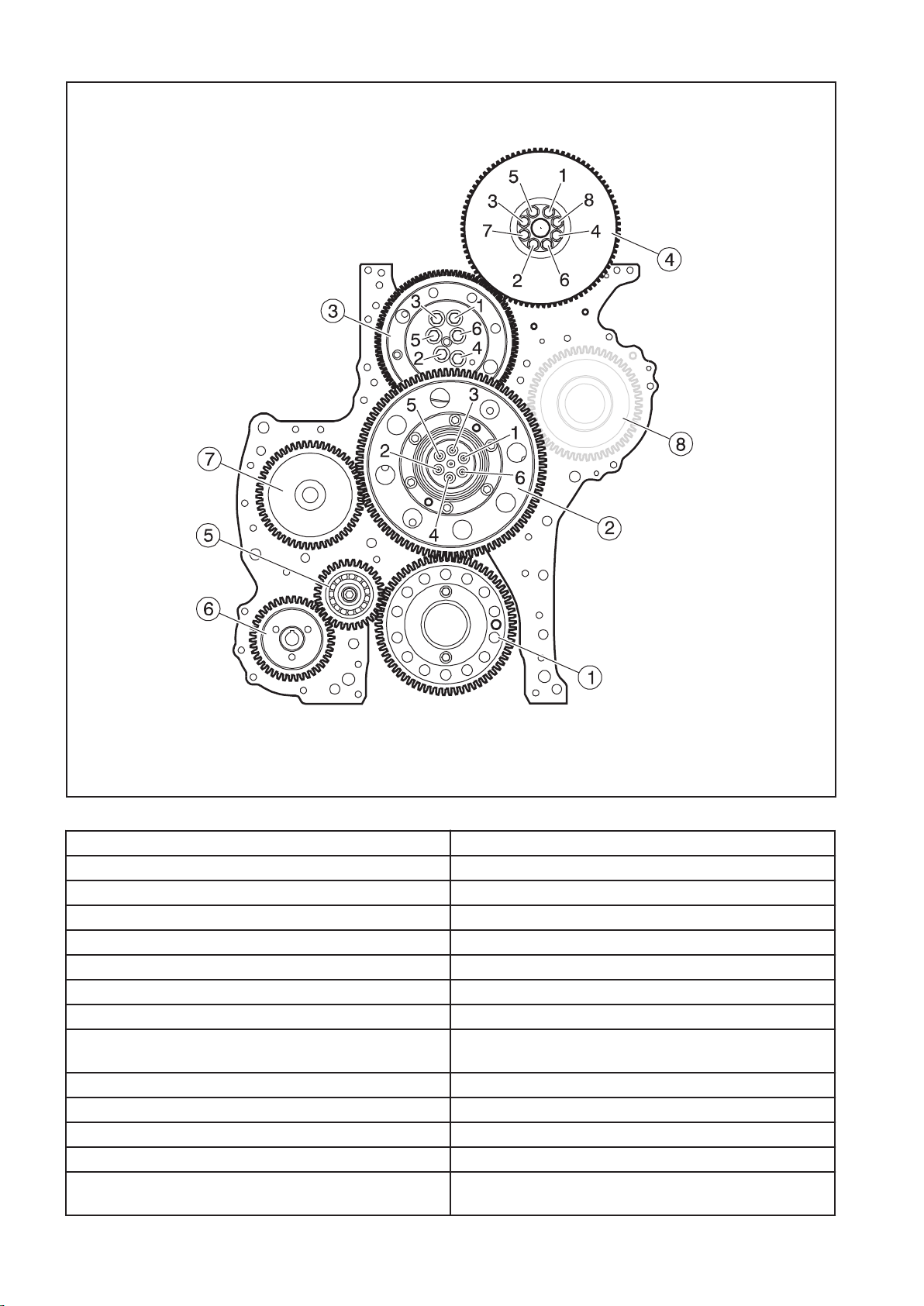

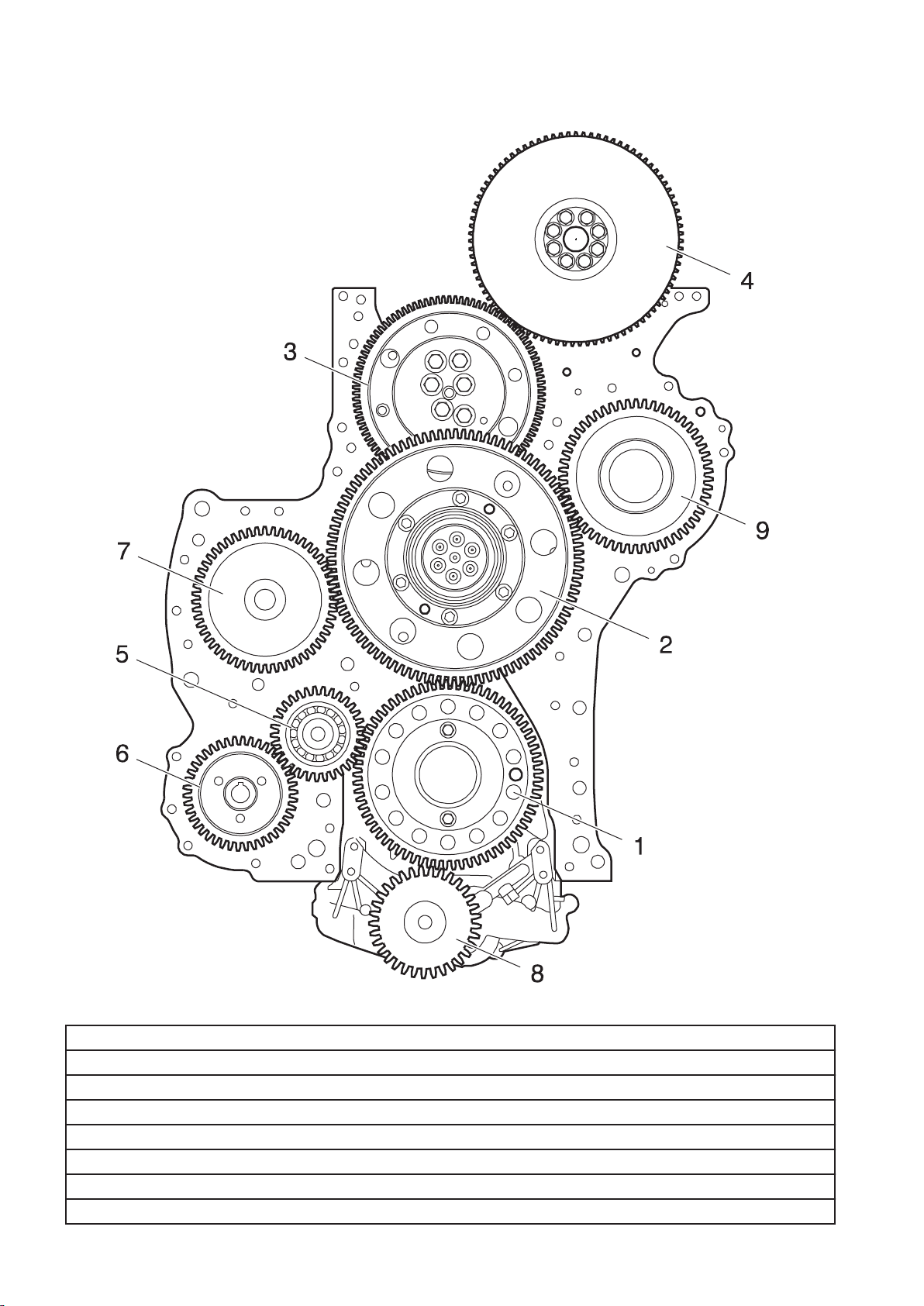

Engine transmission, specification

V1071840

Fig.7

Gears:

1. Drive gear, crankshaft

2. Transfer gears: outer and inner gear

3. Transfer gear (adjustable)

4. Drive gear and vibration damper, camshaft

5. Transfer gear

6. Drive gear, lubrication oil pump for fuel feed pump

7. Drive gear, compressor

12

8. Drive gear, lubrication oil pump

V1082177

9. Not used

Gear flank clearance (backlash), adjustable transfer

0.05–0.15 mm (0.0019–0.0059 in)

gear to camshaft's drive gear

Gear flank clearance (backlash), oil pump's drive gear 0.05–0.41 mm (0.0019–0.016 in)

Gear flank clearance (backlash), other drive gears 0.05–0.20 mm (0.0019–0.0078 in)

For checking camshaft installation:

Valve lift, inlet valve, cylinder 1 at 6° after TDC 1.6 ± 0.3 mm (0.063 ± 0.012 in)

Rocker arm shaft, tightening torques

Fig.8

13

Camshaft: (camshaft and bearing caps in place)

Fit a mandrel to the number 7 bearing bracket to protect the

guide sleeve.

Step 1: Tighten screws 1–7 25±3 Nm (18±2.2 lbf ft)

Step 2: (with shorter additional screws) Tighten screws 8–13 and

60±5 Nm (44±3.7 lbf ft)

20..... 60±5 Nm

Step 3: Angle tighten screws 1-7 90°±5°

Step 4: Remove the extra screws 8–13 and 20

Remove the mandrel from the number 7 bearing bracket.

Rocker arm shaft: (Rocker arm shaft in place)

Step 5: Tighten screws 8 - 13 and 20 in steps in the order 11,

60±5 Nm (44±3.7 lbf ft)

10, 12, 9, 13, 8, 20.

Step 6: Tighten screws 14–19 25±3 Nm (18±2.2 lbf ft)

Step 7: Angle tighten screws 14-19 120°±5°

Step 8: Untighten bolts 8–13

Step 9: Tighten screws 8-13 25±3 Nm (18±2.2 lbf ft)

Step 10: Angle tighten bolts 8 – 13 and 20 120°±5°

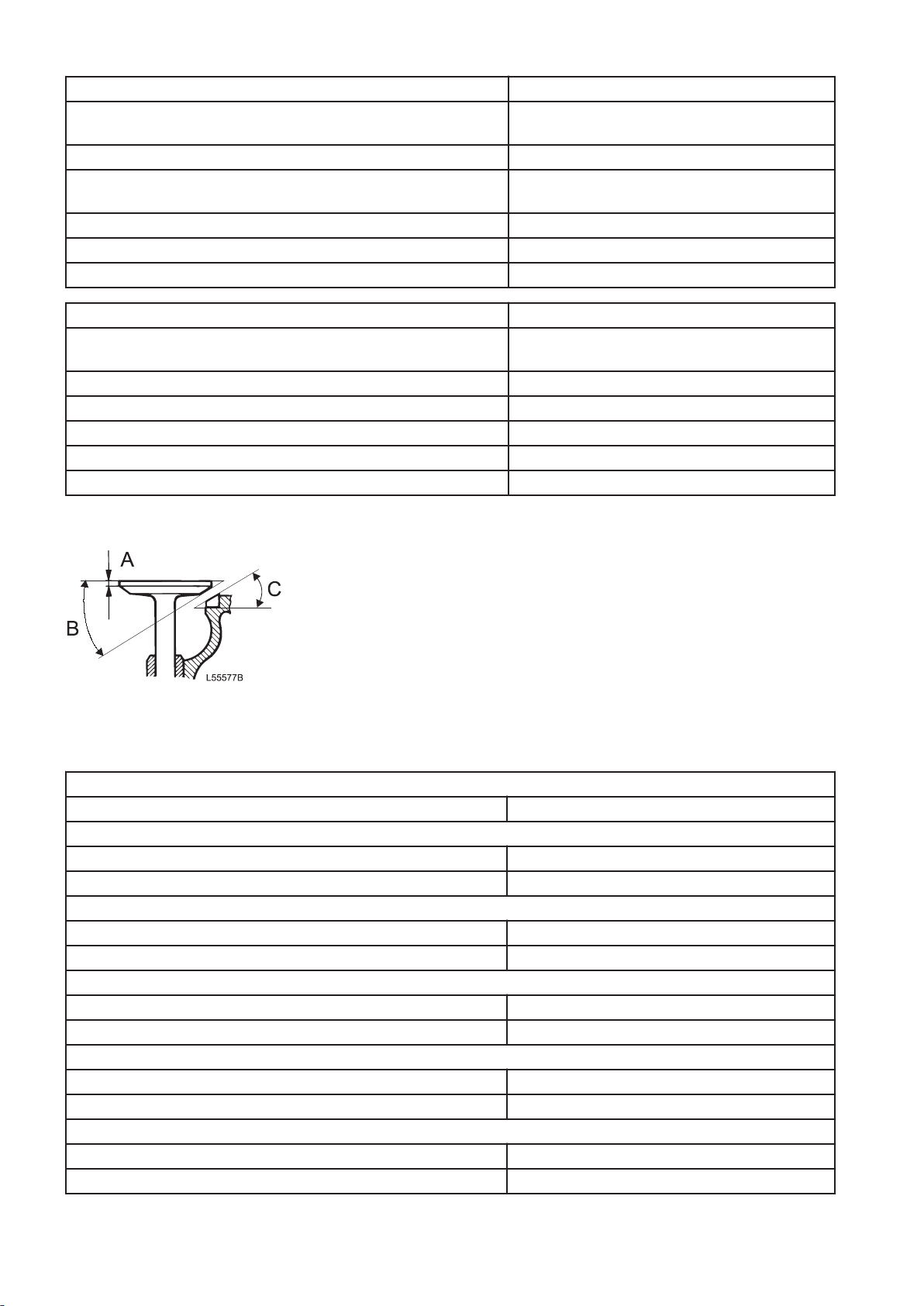

Valve mechanism, specifications

Fig.9

1 Valve disc, thickness (A)

2 Valve's seat angle (B)

3

Valve seat's angle (C)

Valves

Valve arrangement Top valves

Valve disc, diameter

Inlet 42 mm (1.65 in)

Exhaust 40 mm (1.57 in)

Valve stem, diameter

Inlet 7.968 mm (0.3137 in)

Exhaust 7.955 mm (0.3131 in)

Valve's seat angle

Inlet 24.5°

Exhaust 39.5°

Seat's angle in cylinder head

Inlet 25°

Exhaust 40°

Valve disc, thickness

Inlet 2.766 mm (0.108 in)

Exhaust 2.163 mm (0.085 in)

14

Valve clearance, cold engine

Inlet valves, checking value 0.15 — 0.25 mm (0.0059 — 0.0098 in)

Inlet valves, setting value 0.20 mm (0.0079 in)

Exhaust valves, checking value 0.75 — 0.85 mm (0.029 — 0.033 in)

Exhaust valves, setting value 0.8 mm (0.031 in)

Brake rocker arm, checking value 2.78 – 2.92 mm (0.109 – 0.114 in)

Brake rocker arm, setting value 2.85 mm (0.112 in)

Checking value without feeler gauge on valve yoke Min. 3.20 mm (0.126 in)

Distance between valve disc and cylinder head's face:

Inlet

Max. 1.85 mm (0.072 in)

Min. 1.0 mm (0.039 in)

Exhaust

Max. 2.2 mm (0.086 in)

Min. 1.4 mm (0.055 in)

Fig.10 Valve seat and valve seat's position

Valve seats

Outside diameter (A) standard:

Inlet

Exhaust

Ø45 (+0.065+0.081) mm (1.78 in)

Ø43 (+0.07+0.086) mm (1.70 in)

Height (B):

Inlet

Exhaust

7.1 ±0.04 mm (0.279 ±0.0016 in)

7.25 ±0.025 mm (0.285 ±0.001 in)

Valve seat position

Diameter (C) standard:

Inlet

Exhaust

Ø45 H7 (0/+0.025) mm (1.77 in)

Ø43 H7 (0/+0.025) mm (1.69 in)

Depth (D):

Inlet

Exhaust

11.8 ±0.13 mm (0.46 ±0.005 in)

11.2 ±0.13 mm (0.44 ±0.005 in)

Seat's bottom radius (R):

Inlet/exhaust max. 0.8 mm (0.031 in)

Valve guides

Diameter:

Inlet/exhaust Ø8 0/+0.015 mm (0.31 in)

Height above cylinder head's spring face:

Inlet/exhaust 24.5 ±0.2 mm (0.96 ±0.008 in)

Wear value

Clearance, valve stem - guide

Inlet/exhaust max. 0.7 mm (0.028 in)

15

Valve spring

10 1 15 1612 1113

14

6 2 38 79 4

5

19

20

18

17

V1083869

V1063169

16 15 14 13 17 6 71 8

12 11 10 9 18 3 42 5

Inlet

Length, unloaded 73.8 mm (2.90 in)

Exhaust

Outer valve spring:

Length, unloaded 73.8 mm (2.90 in)

Valve mechanism, tightening torques

Tightening torques

Lock nut, inlet valves 38 ± 4 Nm (28 ± 2.9 lbf ft)

Lock nut, floating valve bridge (exhaust) 38 ± 4 Nm (28 ± 2.9 lbf ft)

Lock nut, brake rocker arm 38 ± 4 Nm (28 ± 2.9 lbf ft)

Spring plate (tab) 25±3 Nm (18.5± 2.2 lbf ft)

Tightening torques, valve cover

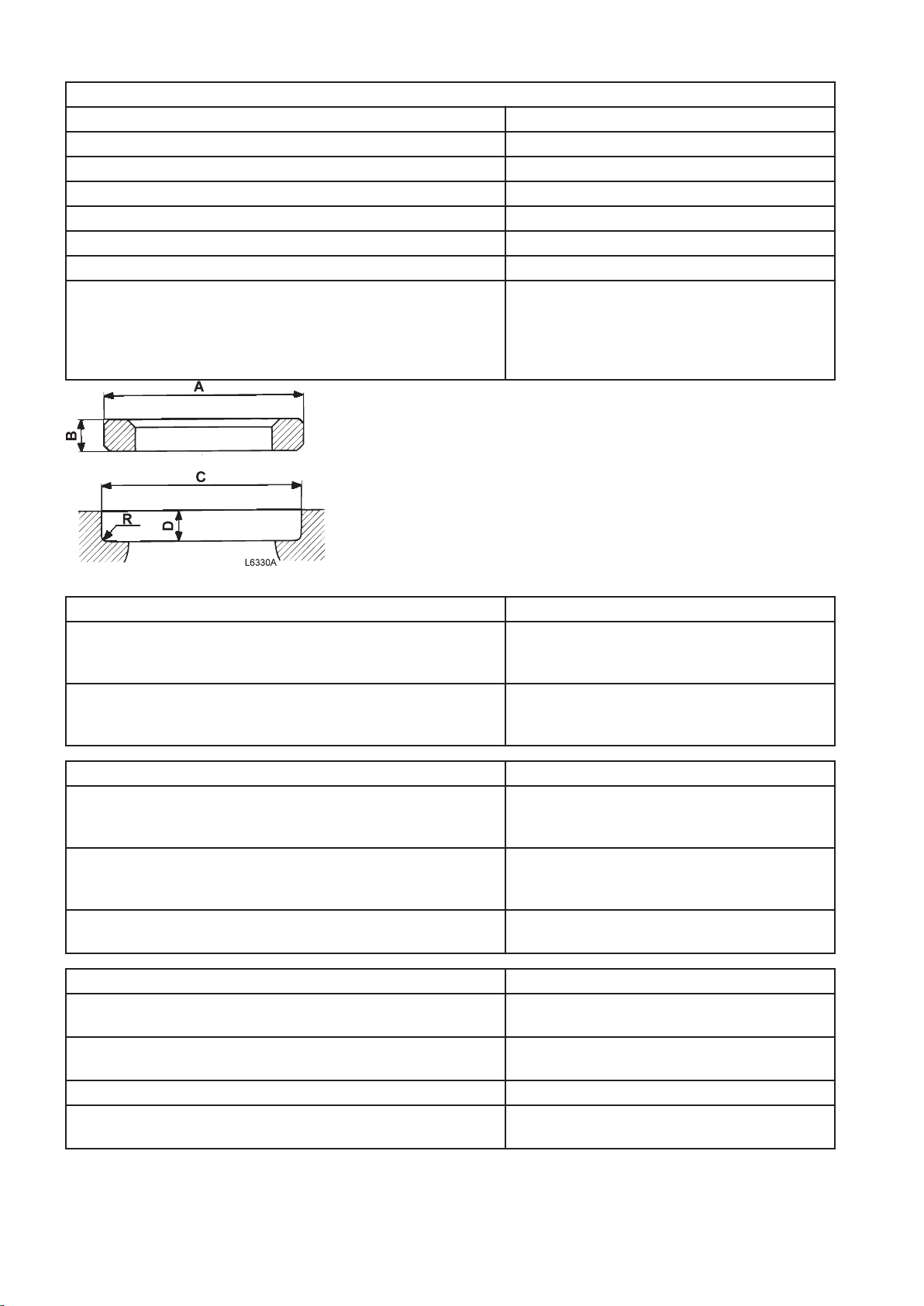

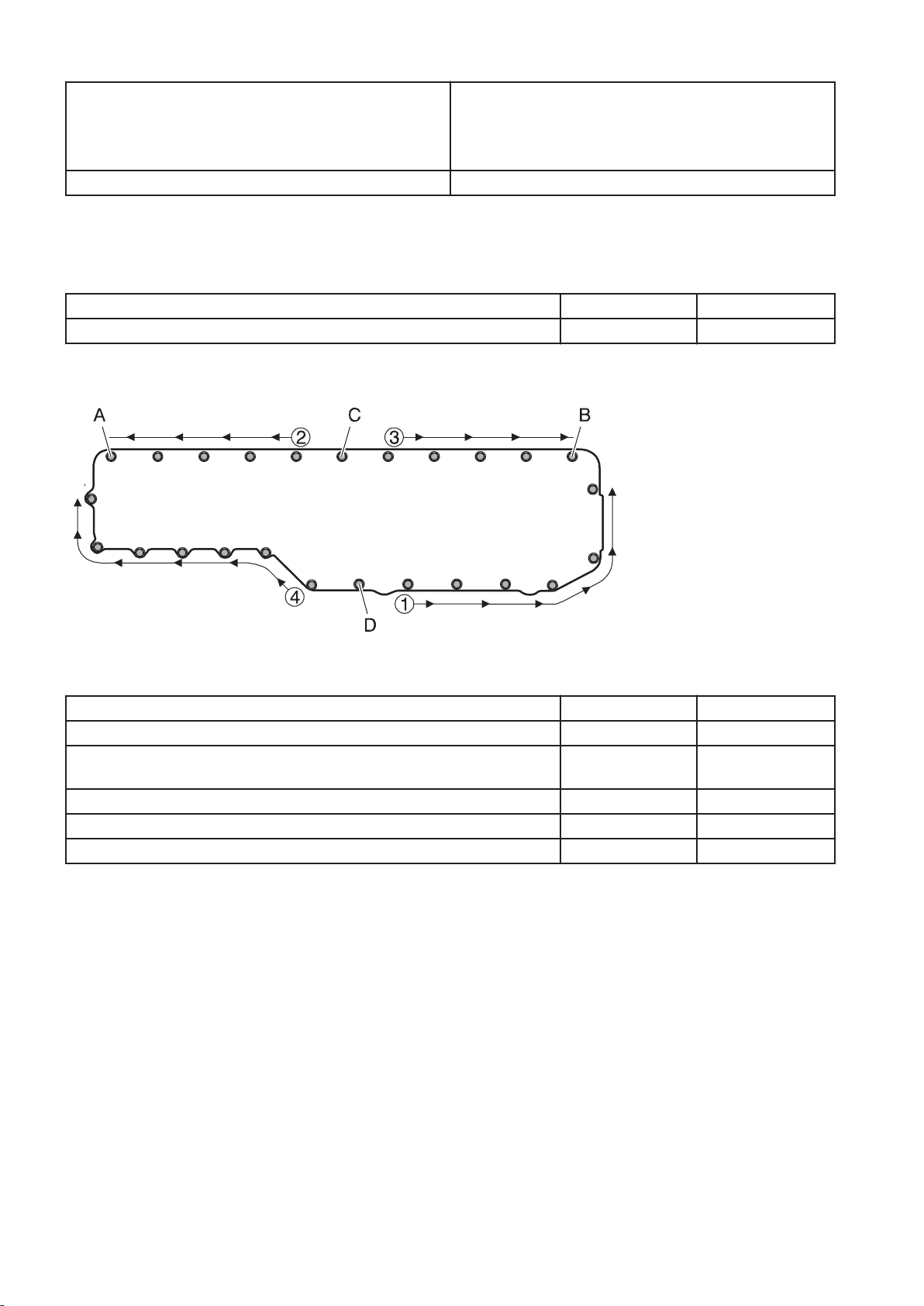

Fig.11 Figure 1 Tightening diagram, valve cover

Valve cover

Valve cover, screws 25 ± 3 Nm (18 ± 2 lbf ft)

Oil sump, tightening torque

Oil sump, tightening diagram

Fig.12 The illustration shows the oil sump for engine D13H, there may be some differences.

16

Oil sump

V1089423

NOTE!

Tighten the bolts in the numerical order shown in the

figure.

Drain plug, oil sump 52±8 Nm (38±6 lbf ft)

24±4 Nm (18±3 lbf ft)

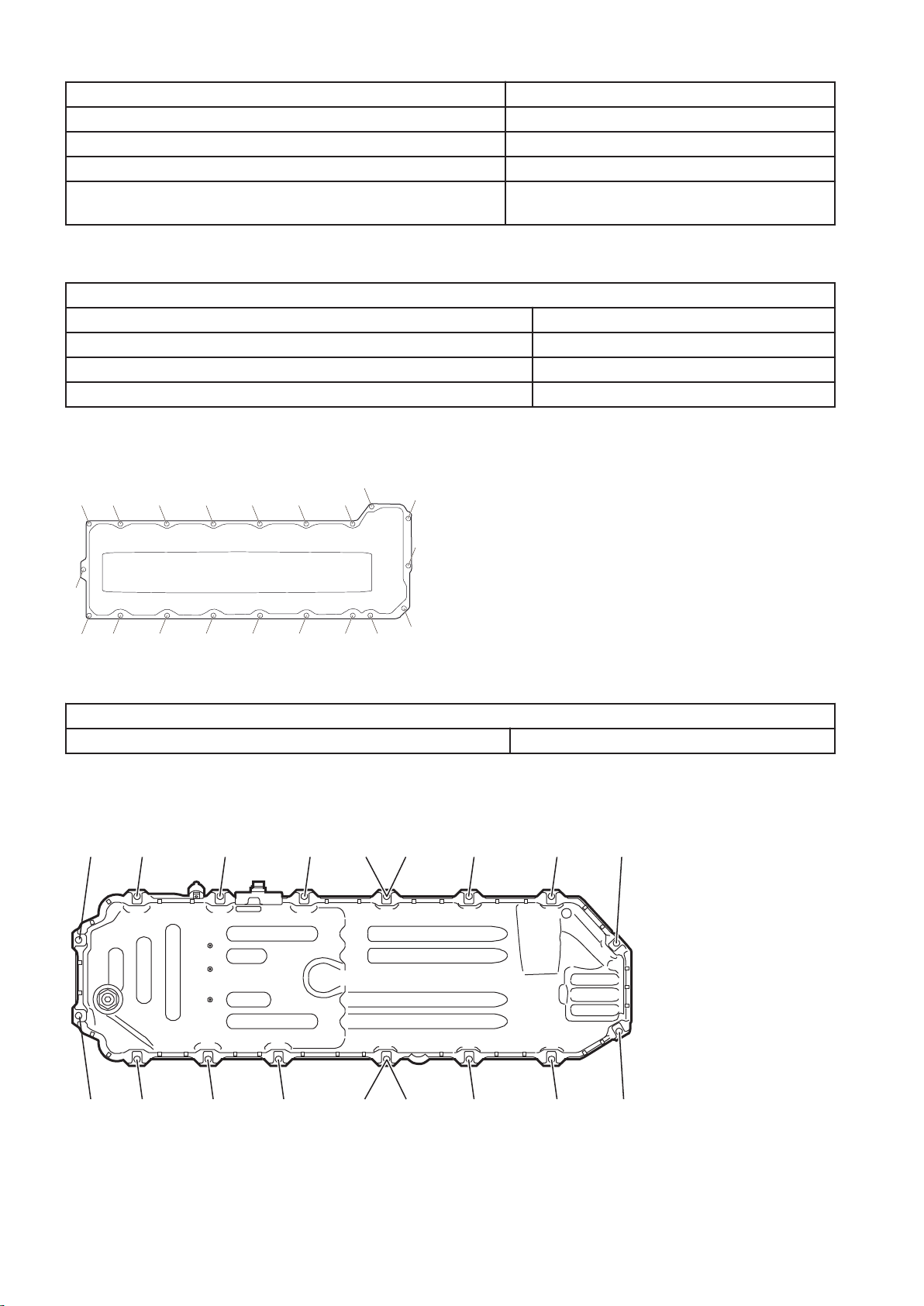

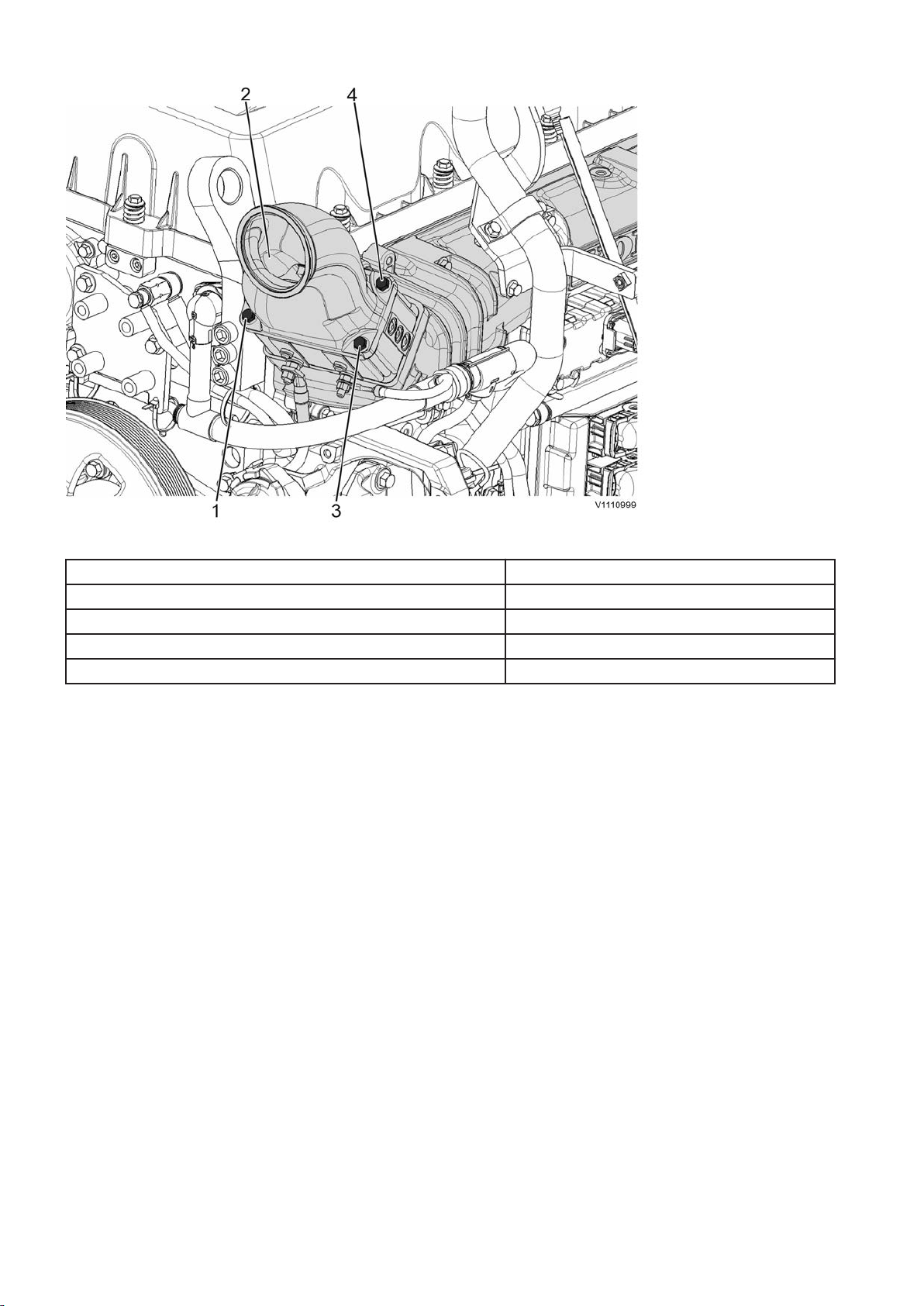

Oil cooler, tightening torques

Oil cooler

Oil cooler, attaching bolts Nm lbf ft

Tighten the bolts crosswise 27 ±4 19,9 ±2,95

Oil cooler, cover

Fig.13

Oil cooler, cover: Nm lbf ft

Install the cover on the engine block and fit bolt A in the oval hole

Press the cover against the coolant pump housing with the special tool

and install bolt B

Install bolts C and D and tighten them 24 ±4 17.7 ±2.95

Tighten the cover's bolts in order, according to diagram 24 ±4 17.7 ±2.95

Finish by tightening bolts C and D again 24 ±4 17.7 ±2.95

17

Cylinder block, tightening torques

Engine mount incl. bracket

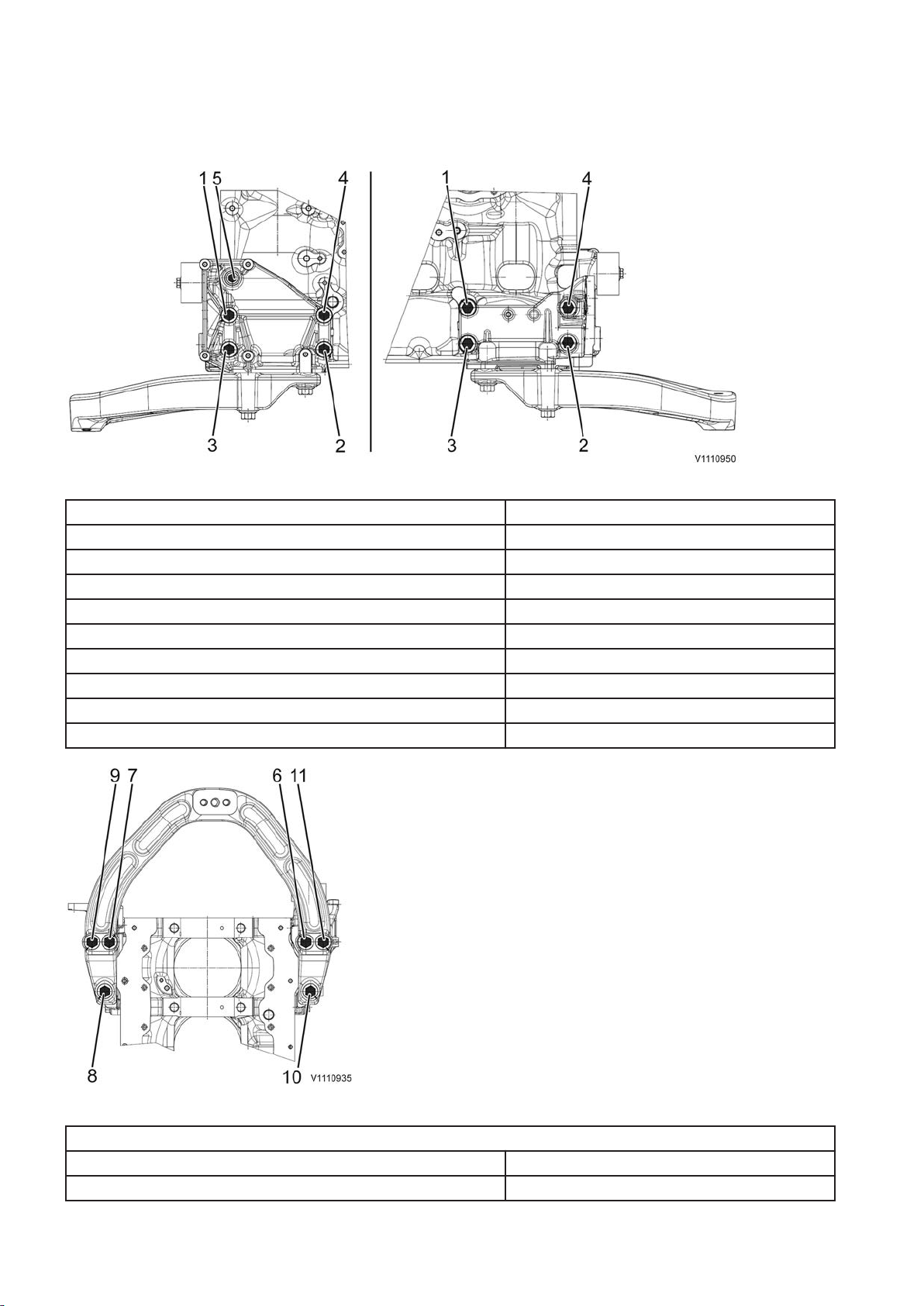

Fig.14 Front engine mount bracket

Front engine mount bracket, cylinder block:

Step 1: Tighten bolt 1. 80 ±15 Nm (59 ±11 lbf ft)

Step 2: Tighten bolts 2 — 4. 105±15 Nm (77.4±11 lbf ft)

Step 3: Angle-tighten bolts 2 — 4 in numerical order 60 ±5°

Step 4: Tighten bolt 1 105±15 Nm (77.4±11 lbf ft)

Step 5: Angle-tighten bolt 1 60 ±5°

Step 6: Tighten bolt 5 Standard bolt tightening torque

Front engine mount to frame 140±25 Nm (103.3±18.4 lbf ft)

Rear engine mount, flywheel housing:

EXC 262±26 Nm (193.2±19 lbf ft)

Fig.15 Front engine mount

Front engine mount to engine mount bracket

Step 1: Tighten bolts 6 – 11 5 ±2 Nm (3.7 ±1.5 lbf ft)

Step 1: Tighten bolts 6 – 11 275 ±45 Nm (203 ±33 lbf ft)

18

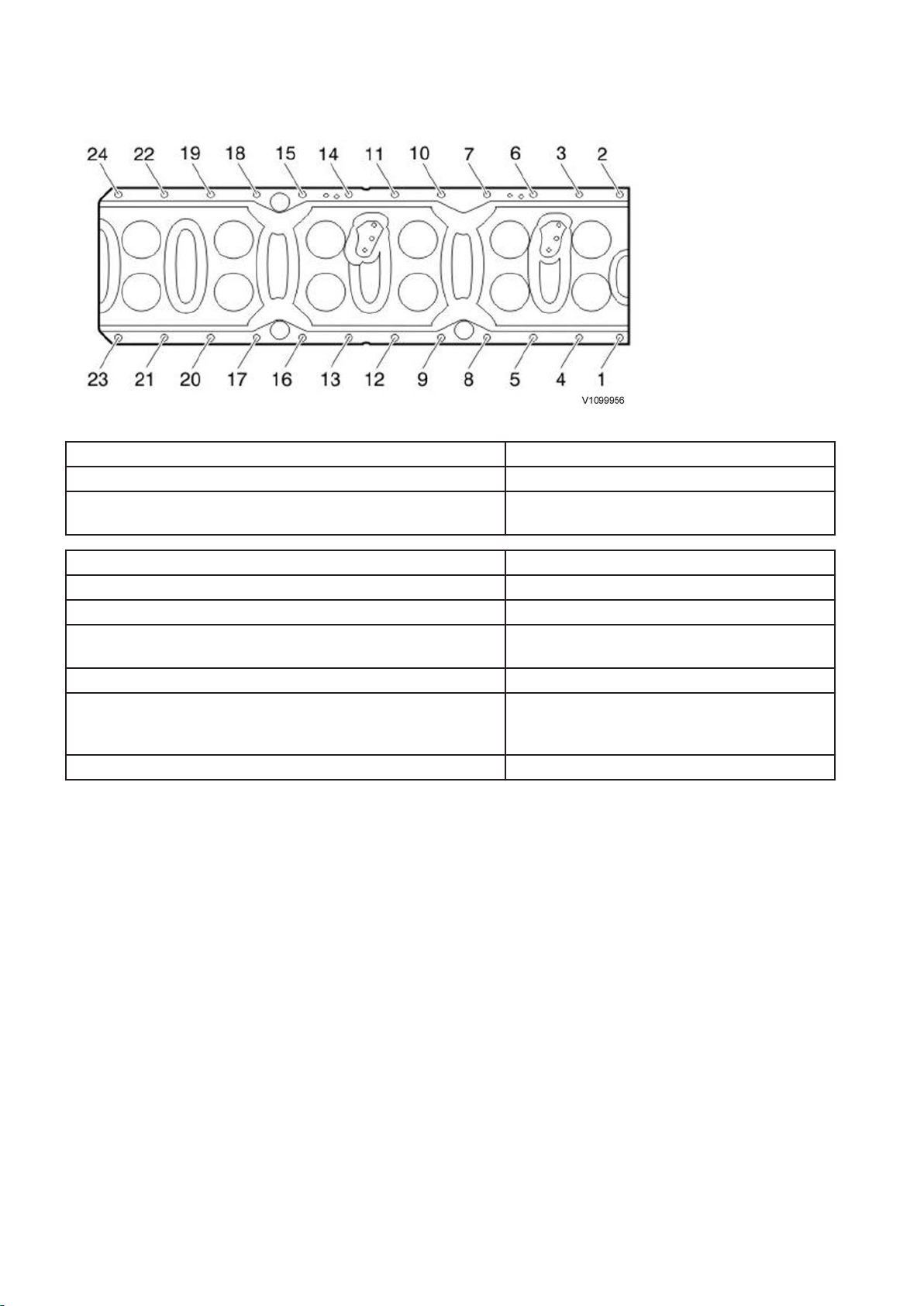

Ladder frame

Fig.16 Ladder frame

Ladder frame

Step 1: Tighten bolts 1 — 24 in numerical order 45±5 Nm (33.19±3.69 lbf ft)

Step 2: Tighten bolts in numerical order 1 — 24 (angletightening)

60 ±5°

Timing gear plate:

M8-bolts 28±4 Nm (20.7±2.95 lbf ft)

Main bearing caps:

Step 1

Step 2 (angle-tightening)

Connecting rod (big-end) caps:

Step 1

Step 2

Step 3 (angle-tightening)

Press tool for measuring liner height 40 Nm (29.5 ft lbf)

150±20 Nm (110.6±14.8 lbf ft)

120 ±5°

20±3 Nm (14.8±2.2 lbf ft)

60±3 Nm (44.3±2.2 lbf ft)

90 ±5°

Inlet

NOTE!

Tighten the bolts according to the numerical order in the figure.

The bolts shall not be reused.

19

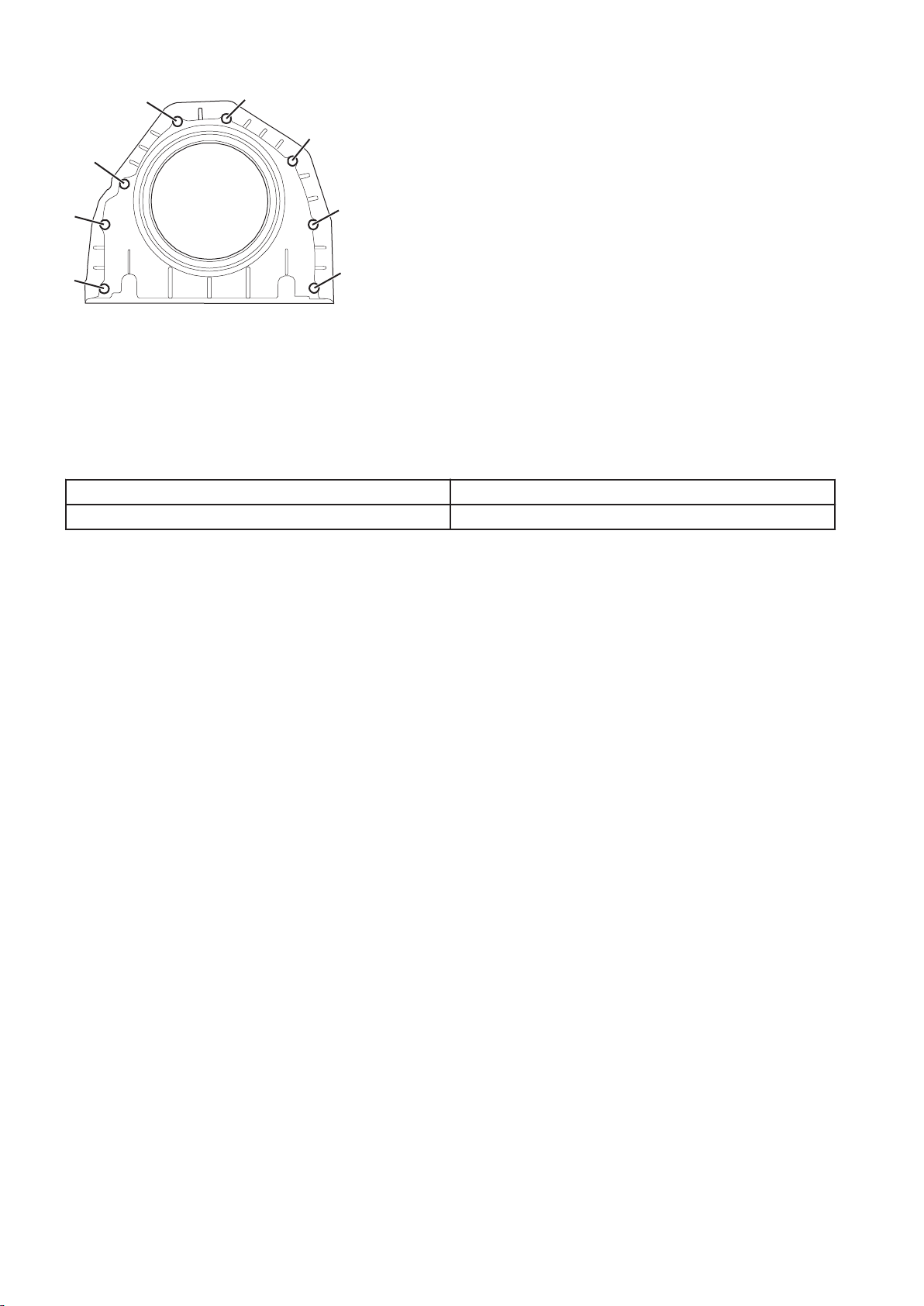

Fig.17 WLO, EXC: Mixing chamber, preheater

Inlet pipe

Mixing chamber, preheater:

Step 1 10±2 Nm (7.38±1.48 lbf ft)

Step 2 24±3 Nm (17.7±2.21 lbf ft)

Plug, M10 (inlet pipe) 20±3 Nm (14.8±2.2 lbf ft)

NOTE!

Torque-tighten the bolts diagonally as shown in the figure.

20

Tightening torque, fuel system

1

3 5 7 9

11

12

108

2

4

6

V1100866

Bolt, fastener yoke, unit injectors. Copper sleeve Steel sleeve

step 1 25 +5/-0 Nm (18.4 +3.7/-0 lbf ft) 20 Nm +5/-0 (14.8 +3.7/-0 lbf ft)

step 2 90° ±5° 90° ±5°

New sleeve or new cylinder head

Bolt, fastener yoke, unit injectors Copper sleeve Steel sleeve

step 1 30 +5/-0 Nm (22 +3.7/-0 lbf ft) 20 +5/-0 Nm (14.8 +3.7/-0 lbf ft)

step 2 150° ±5° 180° ±5°

Step 3: Loose the yoke's bolt until the torqueis10–15 Nm (7.4–11 lbf ft) 10–15 Nm (7.4–11 lbf ft)

step 4 25 +5/-0 Nm (18.4 +3.7/-0 lbf ft) 20 +5/-0 Nm (14.8 +3.7/-0 lbf ft)

step 5 90° ±5° 90° ±5°

Lock nut for adjusting screw, unit injectors 52 ±4 Nm (38.4 ±lbf ft)

Banjo screw, fuel hose

M10 18 ±3 Nm (13.3 ±2.2 lbf ft)

M12 26 ±4 Nm (19.2 ±2.9 lbf ft)

M14 38 ±6 Nm (28 ±4.4 lbf ft)

M16 48 ±8 Nm (35.4 ±6 lbf ft)

Fuel pump (mounted on oil pump) 8 +2/–0 Nm (5.9 +1.5/-0 lbf ft)

Oil pump 24 ±2 Nm (17.7 ±1.5 lbf ft)

Unit injectors, preload Tighten the adjusting screw to zero clearance against the camshaft,

then turn it 240° ±20°

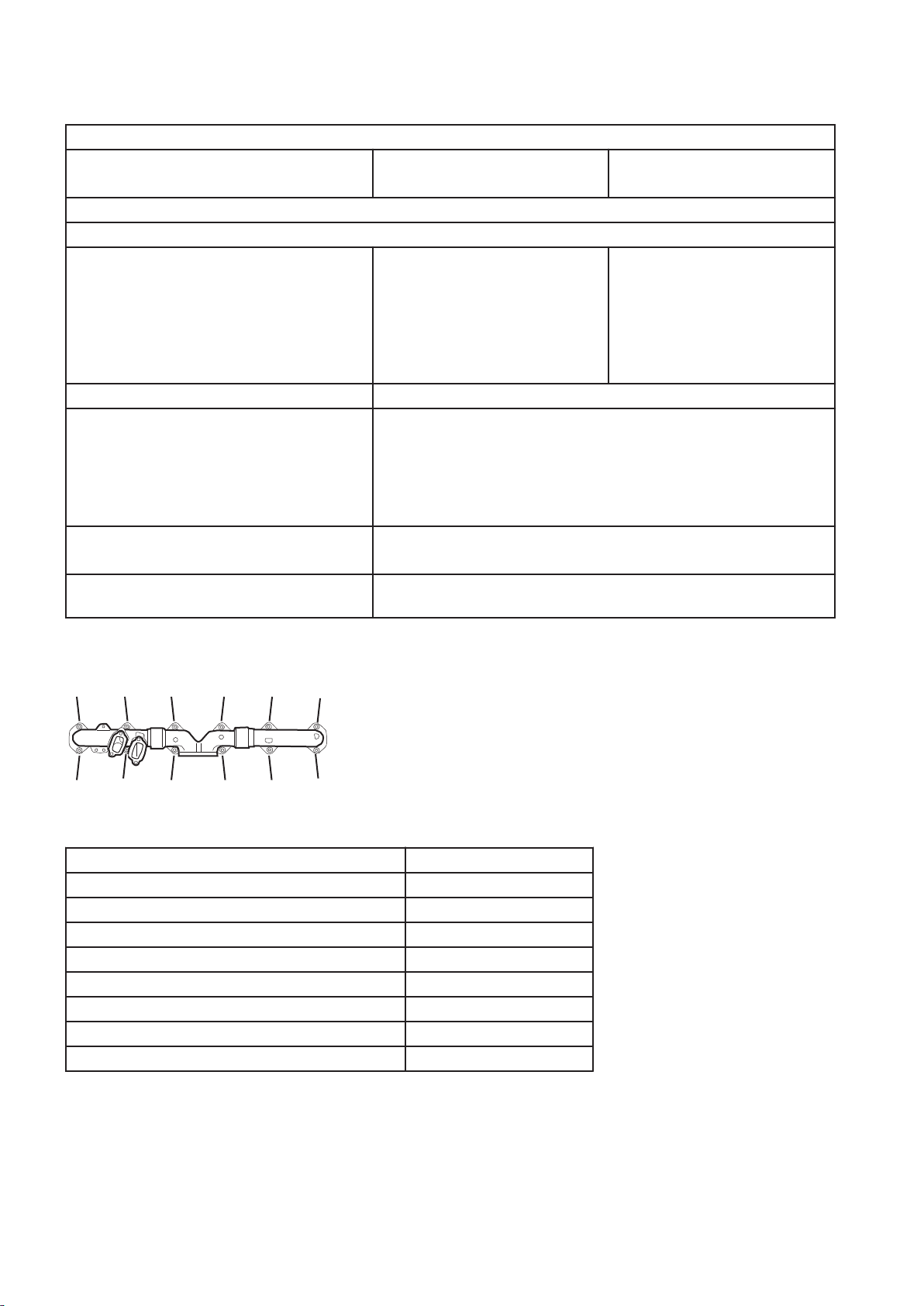

Exhaust manifold, tightening torques

Fig.18

Step 1:

Tighten bolts 1, 4, and 5, 8, and 9, 12 to contact 10±1.5 Nm (7.4±1.1 lbf ft)

Step 2:

Tighten bolts 3 and 2 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 7 and 6 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 11 and 10 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 1 and 4 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 5 and 8 48±8 Nm (35.4±5.9 lbf ft)

Tighten bolts 9 and 12. 48±8 Nm (35.4±5.9 lbf ft)

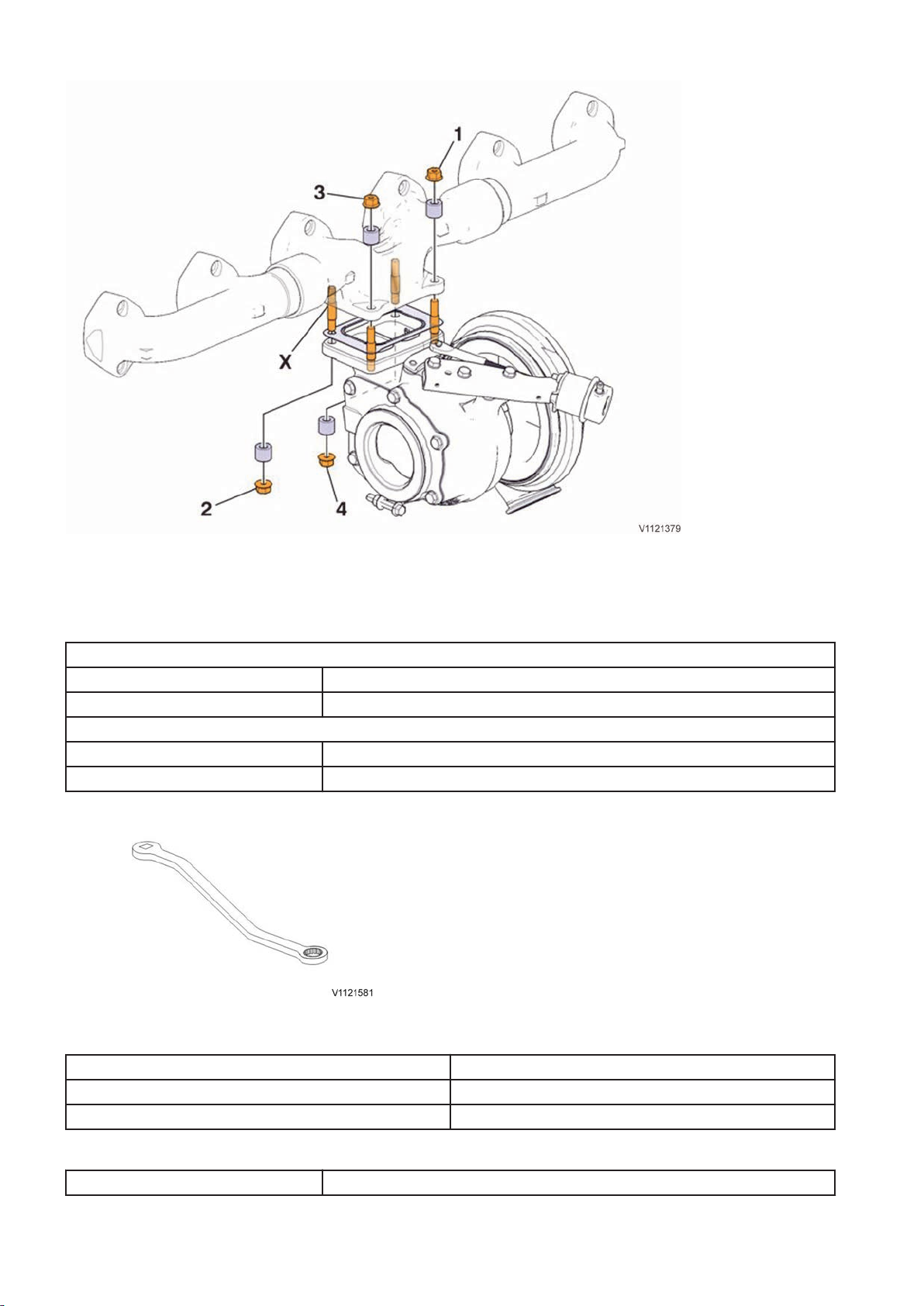

Turbocharger, tightening torques

21

Fig.19 Bolts for installing the turbocharger to the exhaust manifold.

NOTE!

Torque-tighten bolts diagonally as shown in the figure.

Table. Against exhaust manifold

Position 1 and 3

step 1 20 ±4 Nm (14.8 ±3 lbf ft)

step 2 48 ±8 Nm (35.4 ±6 lbf ft)

Position 2 and 4 — using the tool 88830179 Wrench

step 1 16,8 Nm (12.2 lbf ft)

step 2 40,2 Nm (29.6 lbf ft)

Fig.20 88830179 Wrench, for position 2 and 4

Table. Connections for coolant and lubrication oil

Tightening torques, turbo

Coolant lines 38±6 Nm (28±4.4 lbf ft)

Oil lines 48±5 Nm (35.5±3.7 lbf ft)

Table. Charge-air cooler pipe

Clamps 8,5±0,8 Nm (6.3±0.6 lbf ft)

22

Fig.21

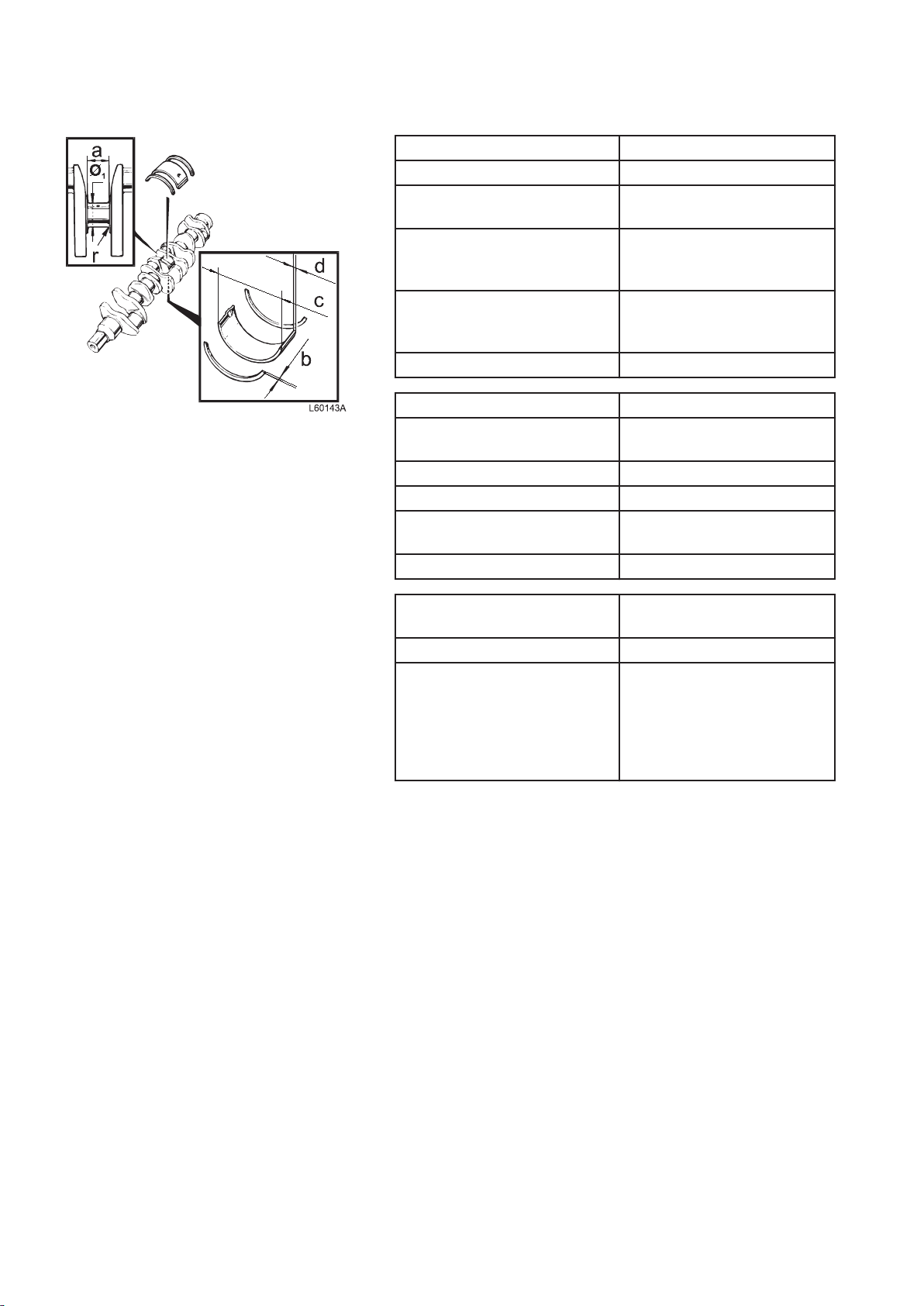

Crank mechanism, specifications

Crankshaft

Length 1 153.8 mm (45.4 in)

Crankshaft, max. axial

clearance

Max. permitted ovality of main

bearing and big-end bearing

pins

Max. permitted conicity of main

bearing and big-end bearing

pins

Max. run-out of middle bearing 0.15 mm (0.0059 in)

Main bearing pin

Diameter (Ø) for reworking,

standard

surface finish, main bearing pin Ra 0.25 mm (0.00098 in)

surface finish, radius Ra 0.4 mm (0.00044 in)

Width, thrust bearing pin (a),

standard

Fillet radius (r) 4.0 mm (0.157 in)

0.4 mm (0.016 in)

0.006 mm (0.00024 in)

< 0.02 mm (< 0.0008 in)

108.0 mm (4.25 in)

47.0 mm (1.85 in)

Thrust washers (thrust

bearings)

Width (b), standard 3.18 mm (0.125 in)

Oversize:

0.1 mm (0.0039 in) 3.28 mm (0.129 in)

0.2 mm (0.0079 in) 3.38 mm (0.133 in)

0.3 mm (0.0118 in) 3.48 mm (0.137 in)

0.4 mm (0.0157 in) 3.58 mm (0.141 in)

23

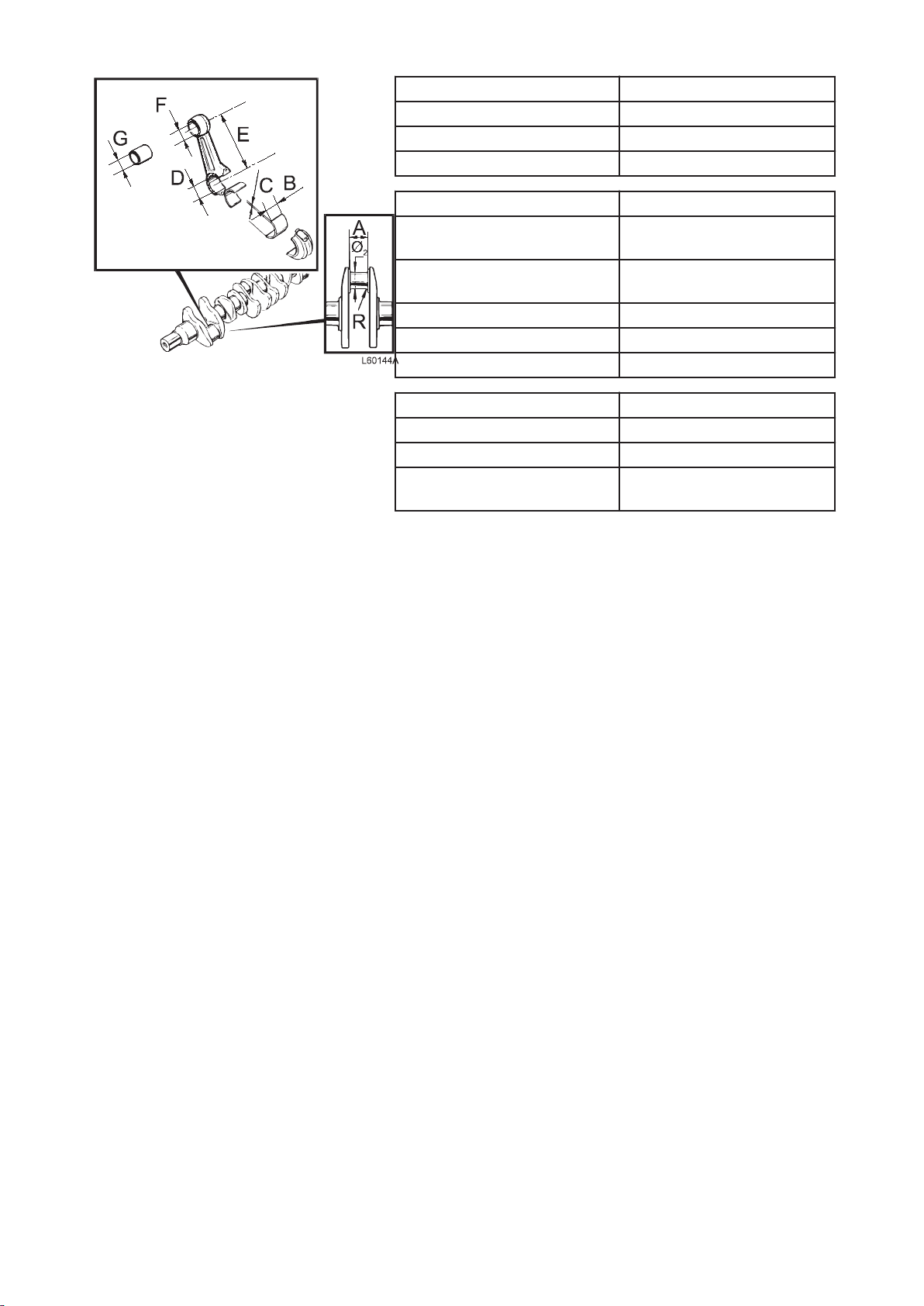

Fig.22

Main bearing shells

Type Replaceable

Outer diameter (c) 113.065 mm (4.451 in)

Thickness (d), standard 2.485 mm (0.098 in)

Crankshaft bearing pins

Diameter (Ø) for reworking,

99 mm (3.897 in)

standard

Surface finish, crankshaft

Ra 0.25

bearing pin

Surface finish, radius Ra 0.4

Width (A) 57 mm (2.244 in)

Fillet radius (r) 4.0 mm (0.157 in)

Connecting rods' bearing shells

Outer diameter (B) 103.85 mm (4.088 in)

Thickness (C), standard 2.389 mm (0.094 in)

Diameter, bearing shell's

103.835 mm (4.088 in)

bearing seat (D)

24

Connecting rod

Length, centre – centre (E) 267.5 mm (10.53 in)

Marking:

"FRONT" on

to face the front.

Connecting rods and caps are

pair-marked with a three-digit

running number.

Connecting rod bushing's

internal diameter (G)

Axial clearance, connecting rod

– crankshaft, with marking

directly opposite each other

Big-end bearing, radial

clearance, oiled part

Straightness (max.) deviation

per 100 mm measured length

Twisting (max.) deviation per

100 mm measured length

Piston

Height above cylinder block

face

Number of ring grooves 3

Front marking Arrow facing forward

rod shall be turned

58 mm (2.283 in)

< 0.35 mm (<0.014 in)

< 0.10 mm (0.0039 in)

0.06 mm (0.0024 in)

0.15 mm (0.0059 in)

0.15–0.21 mm (0.006– 0.008

in)

Piston rings

Compression rings

Quantity 2

Piston ring clearance in groove:

upper compression ring Trapezius-shaped profile

lower compression ring 0.09–0.14 mm (0.003– 0.005

in)

Piston ring gap in ring opening:

upper compression ring 0.40–0.55 mm (0.0157–

0.0216 in)

lower compression ring 1.30–1.50 mm (0.051– 0.059

in)

Oil scraper ring

Quantity 1

Width incl. spring 3.41 mm (0.134 in)

Piston ring clearance in groove 0.05–0.10 mm (0.019– 0.039

in)

Piston ring gap in ring opening 0.30–0.55 mm (0.011– 0.021

in)

Crankshaft, tightening torques

Cover, crankshaft seal

Step 1: Fasten the cover with the bolts 2 and 7 and tighten to contact.

Step 2: Tighten bolts 2 and 7 24±4 Nm (17.7±2.95 lbf ft)

Step 3: Tighten the bolts in numerical order 1, 3 — 6, 8 as shown in the figure. 24±4 Nm (17.7±2.95 lbf ft)

25

V1048013

1

2

3

4

5

6

7

8

Fig.23

Flywheel, tightening torques

NOTE!

The bolts

Tighten the bolts in the order shown in the following figure. All

bolts are tightened in two steps:

Step 1 60±5 Nm (44±3.7 lbf ft)

Step 2, angle-tightening 120°±10°

may only be reused twice, then new bolts shall be used.

26

Fig.24 Flywheel

Belt pulley/vibration damper, tightening torques

Fig.25 Belt pullet/vibration damper

Vibration damper and belt pulley

Step 1, according to numerical order in figure: 35±5 Nm (25.8±3.7 lbf ft)

Step 2, according to numerical order in figure: 90±10 Nm (66.4±7.4 lbf ft)

27

ENGINE WITH MOUNTING AND EQUIPMENT

21 ENGINE

210 General, common info about 211 218

Engine, mounting in work stand

Op. no. 210-081

Tools:

9986485 Support

88800345 Fixture

88800123 Fixture

Lifting eye, 2 pcs.

Sling 3 m (118 in)

Ratchet block 1,500 kg (3307 lbs)

NOTE!

Since the engine illustrations in the service publications are

reused for different engine versions, some parts may vary from

the version

illustrations is always correct.

in question. However, the essential information in the

Engine D13F, weight:

WLO approx. 1,330 kg (3,932 lbs)

EXC approx. 1,330 kg (3,932 lbs)

1 Unplug the sensors and the cable harness. Unplug the

connectors from the E-ECU. Remove the cable channel.

28

V1044013

1

2

3

4

5

6

7

8

10

11

9

Fig.26 Sensor, control system

1 Sensor for coolant level, SE2603

Sensor for coolant temperature, SE2606

2

3 E-ECU

4 Cable channel

5 Camshaft sensor, engine position, SE2703

6 Sensor for boost pressure/charge-air temperature, SE2507/SE2508

7 Sensor for air pressure/air temperature, SE2501/SE2502

8 Speed (rpm) sensor, flywheel, SE2701

9 Sensor for oil pressure, SE2203

10 Sensor for oil level/oil temperature, SE2205/SE2202

11 Sensor for crankcase pressure, SE2509

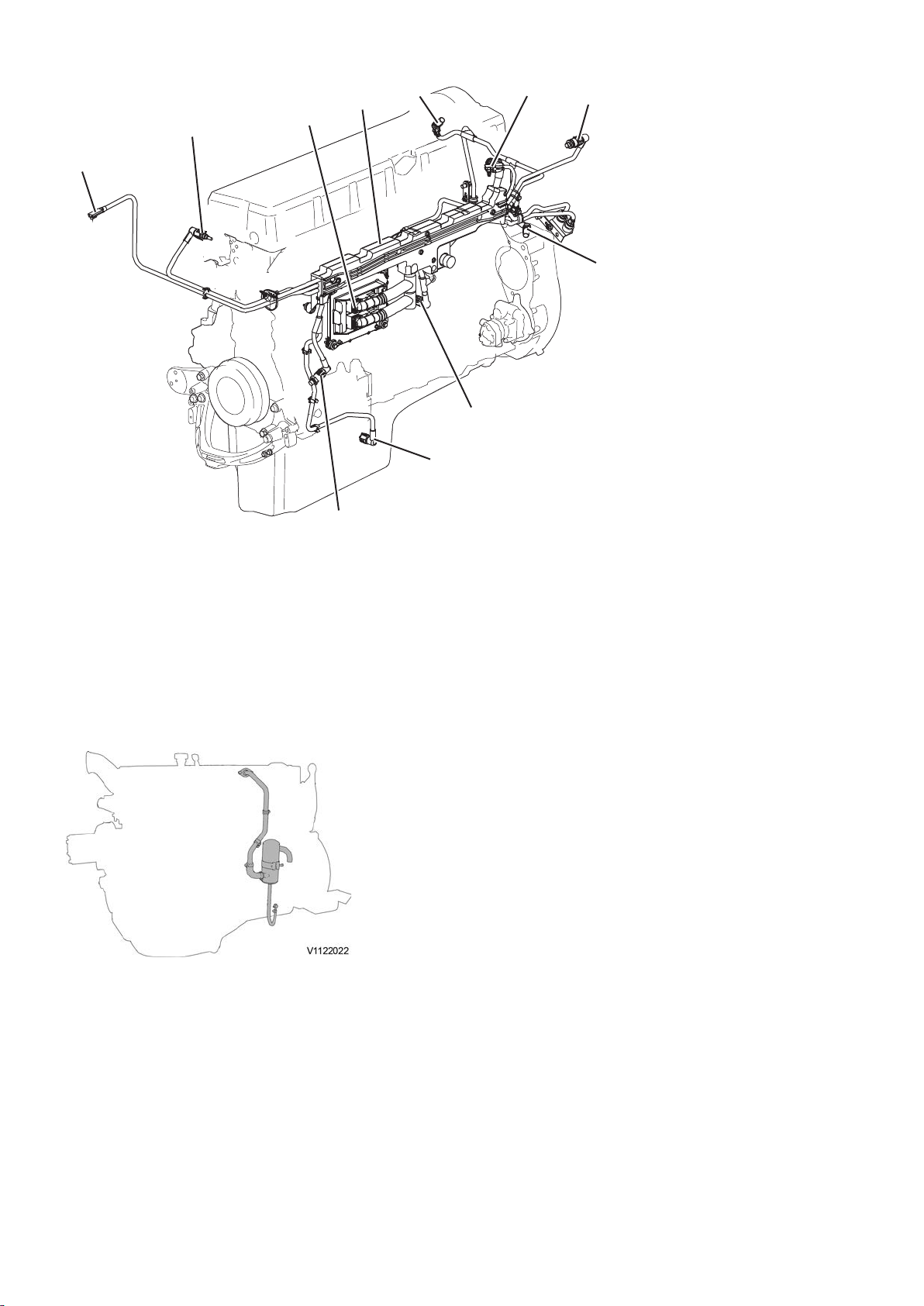

2 Disconnect the oil trap hose from the oil sump. Disconnect

the oil trap pipe from the valve cover. Remove the oil trap,

pipe and hose.

Fig.27 Oil trap with hose and pipe

NOTE!

Collet the waste oil in a suitable container.

29

Loading...

Loading...